Factorial Mixture Design for Properties Optimization and Modeling of Concrete Composites Incorporated with Acetates as Admixtures

Abstract

:1. Introduction

2. The Experimental Part

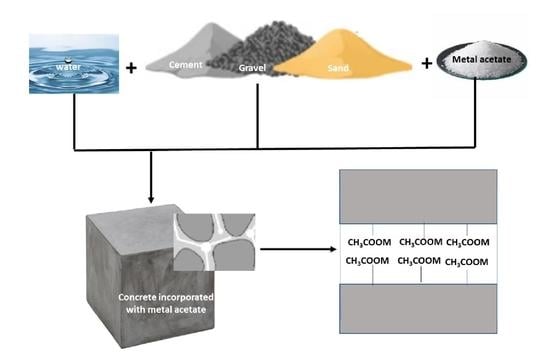

2.1. Materials

2.2. Methodology

2.3. The Properties Investigated

3. Results and Discussion

3.1. The Experimental Results

3.2. ANOVA Results

3.3. Microstructure Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ibrahim, H.D.; Xue, P.; Eltahir, E.A.B. Multiple Salinity Equilibria and Resilience of Persian/Arabian Gulf Basin Salinity to Brine Discharge. Front. Mar. Sci. 2020, 7, 573. [Google Scholar] [CrossRef]

- Dodds, W.; Goodier, C.; Christodoulou, C.; Austin, S.; Dunne, D. Corrosion risk assessment of structural concrete with coarse crushed concrete aggregate. Proc. Inst. Civ. Eng.—Constr. Mater. 2020, 173, 57–69. [Google Scholar] [CrossRef]

- del Campo, J.M.; Negro, V. Nanomaterials in Protection of Buildings and Infrastructure Elements in Highly Aggressive Marine Environments. Energies 2021, 14, 2588. [Google Scholar] [CrossRef]

- Bautista-Gutierrez, K.P.; Herrera-May, A.L.; Santamaría-López, J.M.; Honorato-Moreno, A.; Zamora-Castro, S.A. Recent Progress in Nanomaterials for Modern Concrete Infrastructure: Advantages and Challenges. Materials 2019, 12, 3548. [Google Scholar] [CrossRef]

- Khudhair, N.A.; Al-Sammarraie, A.M.A. Enhancing of Corrosion Protection of Steel Rebar in Concrete Using TiO2 Nanoparticles as Additive. Iraqi J. Sci. 2019, 60, 1898–1903. [Google Scholar] [CrossRef]

- Amran, A.; Onaiz, A.M.; Fediuk, R.; Vatin, N.I.; Rashid, R.S.M.; Abdelgader, H.; Ozbakkaloglu, T. Self-Healing Concrete as a Prospective Construction Material: A Review. Materials 2022, 15, 3214. [Google Scholar] [CrossRef]

- Koleva, D.A. An Innovative Approach to Control Steel Reinforcement Corrosion by Self-Healing. Materials 2018, 11, 309. [Google Scholar] [CrossRef]

- Hossain, N.; Chowdhury, M.A.; Kchaou, M. An overview of green corrosion inhibitors for sustainable and environment friendly industrial development. J. Adhes. Sci. Technol. 2020, 35, 673–690. [Google Scholar] [CrossRef]

- Topçu, I.B.; Eskişehir Osmangazi University; Uzunömeroğlu, A. Properties of corrosion inhibitors on reinforced concrete. J. Struct. Eng. Appl. Mech. 2020, 3, 93–109. [Google Scholar] [CrossRef]

- Inamuddin, M.I.A.; Ahamed, M.I.; Luqman, M.; Altalhi, T. Sustainable Corrosion Inhibitors, Ch.6; Materials Research Forum LLC.: Millersville, PA, USA, 2019. [Google Scholar]

- Lee, H.-S.; Saraswathy, V.; Kwon, S.-J.; Karthick, S. Corrosion Inhibitors for Reinforced Concrete: A Review. In Corrosion Inhibitors, Principles and Recent Applications, Mahmood Aliofkhazraei; IntechOpen: London, UK, 2017. [Google Scholar] [CrossRef]

- Paulson, B.M.; Thomas, K.J.; Raphael, V.P.; Shaju, K.S.; Ragi, K. Mitigation of concrete reinforced steel corrosion by penta sodium triphosphate: Physicochemical and electrochemical investigations. SN Appl. Sci. 2020, 2, 1813. [Google Scholar] [CrossRef]

- Reddy, V.S.; Prashanth, T.; Raju, S.P.; Prashanth, P. Effect of Organic and Inorganic Corrosion Inhibitors on Strength Properties of Concrete. E3S Web Conf. 2020, 184, 01112. [Google Scholar] [CrossRef]

- Awolusi, T.; Oke, O.; Akinkurolere, O.; Sojobi, A. Application of response surface methodology: Predicting and optimizing the properties of concrete containing steel fibre extracted from waste tires with limestone powder as filler. Case Stud. Constr. Mater. 2018, 10, e00212. [Google Scholar] [CrossRef]

- Castaneda, H.; Hassan, M.; Radovic, M.; Milla, J.; Karayan, A. Self-Healing Microcapsules as Concrete Aggregates for Corrosion Inhibition in Reinforced Concrete; Project No. 17CLSU08; Tran-SET Publication: Baton Rouge, LA, USA, 2018. [Google Scholar]

- Karavokyros, L.; Katsiotis, N.; Tzanis, E.; Batis, G.; Sapalidis, A.; Chatzopoulos, A.; Sideris, K.; Beazi-Katsioti, M. The Effect of Mix-Design and Corrosion Inhibitors on the Durability of Concrete. J. Mater. Sci. Chem. Eng. 2020, 8, 64–77. [Google Scholar] [CrossRef]

- Mohammed, T.U.; Ahmed, T.; Apurbo, S.M.; Mallick, T.A.; Shahriar, F.; Munim, A.; Awal, M.A. Influence of Chemical Admixtures on Fresh and Hardened Properties of Prolonged Mixed Concrete. Adv. Mater. Sci. Eng. 2017, 2017, 9187627. [Google Scholar] [CrossRef]

- Li, D.-L.; Zheng, D.-P.; Wang, D.-M.; Zhao, J.-H.; Du, C.; Ren, C.-F. Influence of Organic Esters on Portland Cement Hydration and Hardening. Adv. Mater. Sci. Eng. 2018, 2018, 3203952. [Google Scholar] [CrossRef]

- Mao, Q.; Zhang, J.; Ma, J.; Liu, H.; Wang, Z.; Cui, S. Improvement of Shrinkage Reduction and Superplasticity of Polycarboxylate Admixture by Ester and Silane Groups. J. Mater. Civ. Eng. 2022, 34, 10. [Google Scholar] [CrossRef]

- Hassouna, F.M.A.; Abu-Zant, H. Effects of Superplasticizers on Fresh and Hardened Portland Cement Concrete Characteristics. Int. J. Appl. Sci. Technol. 2016, 5, 32–36. Available online: https://staff.najah.edu/media/published_research/2020/06/20/final.pdf (accessed on 9 February 2020).

- Lai, G.; Liu, X.; Li, S.; Xu, Y.; Zheng, Y.; Guan, J.; Gao, R.; Wei, Z.; Wang, Z.; Cui, S. Development of chemical admixtures for green and environmentally friendly concrete: A review. J. Clean. Prod. 2023, 389, 136116. [Google Scholar] [CrossRef]

- Fang, Y.; Wang, J.; Qian, X.; Wang, L.; Chen, P.; Qiao, P. A renewable admixture to enhance the performance of cement mortars through a pre-hydration method. J. Clean. Prod. 2022, 332, 130095. [Google Scholar] [CrossRef]

- Kılınççeker, G.; Menekşe, C. The effect of acetate ions on the corrosion of reinforcing steel in chloride environments. Prot. Met. Phys. Chem. Surfaces 2015, 51, 659–666. Available online: https://link.springer.com/article/10.1134/S2070205115040176 (accessed on 9 February 2020). [CrossRef]

- Ryu, H.-S.; Kim, D.-M.; Shin, S.-H.; Park, W.-J.; Kwon, S.-J. Steel-Corrosion Characteristics of an Environmental Inhibitor using Limestone Sludge and Acetic Acid. Int. J. Concr. Struct. Mater. 2018, 12, 13. Available online: https://ijcsm.springeropen.com/articles/10.1186/s40069-018-0243-x (accessed on 9 February 2020). [CrossRef]

- Al-Kheetan, M.J.; Rahman, M.M. Integration of Anhydrous Sodium Acetate (ASAc) into Concrete Pavement for Protection against Harmful Impact of Deicing Salt. Prop. Interfaced Mater. Film. JOM 2019, 71, 4899–4909. Available online: https://link.springer.com/article/10.1007/s11837-019-03624-3 (accessed on 9 February 2020). [CrossRef]

- Al-Kheetan, M.J.; Ghaffar, S.H.; Awad, S.; Chougan, M.; Byzyka, J.; Rahman, M.M. Microstructural, Mechanical and Physical Assessment of Portland Cement Concrete Pavement Modified by Sodium Acetate under Various Curing Conditions. Infrastructures 2021, 6, 113. [Google Scholar] [CrossRef]

- Al-Kheetan, M.J.; Ghaffar, S.H.; Madyan, O.A.; Rahman, M.M. Development of low absorption and high-resistant sodium acetate concrete for severe environmental conditions. Constr. Build. Mater. 2020, 230, 117057. [Google Scholar] [CrossRef]

- Iraqi Standard (IQ. S 5:2019) for CEM I (42.5 R). Available online: https://uowa.edu.iq/filestorage/file_1542638623.pdf (accessed on 9 February 2020).

- Ahmed, S.M.; Kamal, I. Electrical resistivity and compressive strength of cement mortar based on green magnetite nanoparticles and wastes from steel industry. Case Stud. Constr. Mater. 2022, 17, e01712. [Google Scholar] [CrossRef]

- Hameed, M.M.; AlOmar, M.K.; Baniya, W.J.; AlSaadi, M.A. Prediction of high-strength concrete: High-order response surface methodology modeling approach. Eng. Comput. 2021, 38, 1655–1668. [Google Scholar] [CrossRef]

- Öztaş, A.; Pala, M.; Özbay, E.; Kanca, E.; Çağlar, N.; Bhatti, M.A. Predicting the compressive strength and slump of high strength concrete using neural network. Constr. Build. Mater. 2006, 20, 769–775. [Google Scholar] [CrossRef]

- Silva, D.; Monteiro, P. Analysis of C3A hydration using soft X-rays transmission microscopy: Effect of EVA copolymer. Cem. Concr. Res. 2005, 35, 2026–2032. [Google Scholar] [CrossRef]

- Silva, D.; Roman, H.; Gleize, P. Evidences of chemical interaction between EVA and hydrating Portland cement. Cem. Concr. Res. 2002, 32, 1383–1390. [Google Scholar] [CrossRef]

- Peter, L.F.; Smith, B.C. Ionic radii for Group 1 and Group 2 halide, hydride, fluoride, oxide, sulfide, selenide and telluride crystals. Dalton Trans. 2010, 39, 7786–7791. Available online: https://pubs.rsc.org/en/content/articlelanding/2010/dt/c0dt00401d (accessed on 9 February 2020).

- Cao, K.; Wang, L.; Xu, Y.; Shen, W.; Wang, H. The Hydration and Compressive Strength of Cement Mortar Prepared by Calcium Acetate Solution. J. Adv. Civ. Eng. 2021, 2021, 8817725. [Google Scholar] [CrossRef]

- Abed, A.A.; Kamal, I.M. Factorial Design for Studying the Properties of Recycled Aggregate Concrete Exposed to Aggressive Media. J. Eng. Res. 2021, 9, 1–24. [Google Scholar] [CrossRef]

- Abed, A.A.; Bas, Y.J.; Al-Hasani, A.; Kamal, I. Investigation on some properties of hardened cement-Biogenic ash composites. AIP Conf. Proc. 2022, 2660, 020054. [Google Scholar] [CrossRef]

- Ma, H.; Sun, Z.; Ma, G. Research on Compressive Strength of Manufactured Sand Concrete Based on Response Surface Methodology (RSM). Appl. Sci. 2022, 12, 3506. [Google Scholar] [CrossRef]

- Vishnupriyan, M.; Annadurai, R. A study on the macro-properties of PCB fiber-reinforced concrete from recycled electronic waste and validation of results using RSM and ANN. Asian J. Civ. Eng. 2023, 24, 1667–1680. [Google Scholar] [CrossRef]

- Scrivener, K.L. Backscattered electron imaging of cementitious microstructures: Understanding and quantification. Cement Concrete Compos. 2004, 26, 935–945. [Google Scholar] [CrossRef]

- Hassan, M.S. SEM-Backscattered Imaging Analysis of Cementitious Composite Matrix Incorporating Mineral Admixture. Eng. Technol. J. 2014, 32, 696–703. [Google Scholar]

- Ozturk, A.U.; Baradan, B. Effects of admixture type and dosage on microstructural and mechanical properties of cement mortars. KSCE J. Civ. Eng. 2011, 15, 1237–1243. [Google Scholar] [CrossRef]

| The Operating variables | Exp. No. | |||||||||

| 1 | 2 * | 3 | 4 | 5 | 6 | 7 | 8 | 9 | ||

| (Acetate/cement) % wt. | 3.50 | 3.50 | 2.00 | 5.00 | 2.00 | 5.60 | 5.00 | 1.38 | 3.50 | |

| W/C | 0.48 | 0.51 | 0.49 | 0.49 | 0.53 | 0.51 | 0.53 | 0.51 | 0.54 | |

| Type of acetate | Concrete Property | Exp. No. | ||||||||

| 1 | 2 * | 3 | 4 | 5 | 6 | 7 | 8 | 9 | ||

| K acetate | Compressive strength (MPa) | 38.90 | 32.45 | 35.80 | 37.00 | 25.29 | 33.61 | 29.12 | 29.80 | 25.02 |

| Density (g/cm3) | 2.39 | 2.37 | 2.37 | 2.41 | 2.38 | 2.408 | 2.376 | 2.393 | 2.365 | |

| Slump (cm) | 2.00 | 4.00 | 3.50 | 4.50 | 2.00 | 3.00 | 4.50 | 2.00 | 5.00 | |

| Ca acetate | Compressive strength (MPa) | 42.88 | 40.50 | 39.98 | 41.97 | 35.82 | 40.89 | 37.22 | 38.31 | 33.60 |

| Density (g/cm3) | 2.39 | 2.37 | 2.37 | 2.40 | 2.37 | 2.385 | 2.38 | 2.36 | 2.37 | |

| Slump (cm) | 3.0 | 3.5 | 7.0 | 10.0 | 15.0 | 18.0 | 8.0 | 4.0 | 6.0 | |

| Ethyl acetate | Compressive strength (MPa) | 35.20 | 33.9 | 32.10 | 29.70 | 27.29 | 26.10 | 32.90 | 28.99 | 27.30 |

| Density (g/cm3) | 2.43 | 2.37 | 2.42 | 2.43 | 2.39 | 2.397 | 2.405 | 2.393 | 2.399 | |

| Slump (cm) | 2.50 | 3.00 | 5.00 | 3.00 | 5.00 | 3.50 | 5.00 | 4.00 | 4.50 | |

| (Without acetate) | Compressive strength (MPa) | 29.36 | 29.36 | 28.31 | 25.96 | 24.88 | ||||

| Acetate Type | The Generated Empirical Regression Model Equation | Regression Coefficient R2 (%) | Optimized Compressive Strength Value (MPa) | Optimized Operating Variables |

|---|---|---|---|---|

| Ca | Compressive strength = −665.62 + 2871.01 W + 4.63 A − 2932.86 W2 − 4.92 W A − 0.22A2 | 96.97 | 42.68 | w/c = 0.48 and CaA content = 5.1% |

| K | Compressive strength = 20.70 + 339.75 W − 8.99 A − 640.64 W2 + 21.67 W K − 0.17 A 2 | 99.89 | 38.76 | w/c = 0.48 and KA content = 4.24% |

| Ethyl | Compressive strength = −898.76 + 3728.86 W − 7.52 A − 3828.22 W2 + 50.0 W A − 2.62 A2 | 91.41 | 38.31 | w/c = 0.51 and EA content = 3.45% |

| Where W = W/C, A = acetate content (wt.%) | ||||

| Acetate Type | The Generated Empirical Regression Model Equation | Regression Coefficient R2 (%) | Optimized Density g/cm3 | Optimized Operating Variables |

|---|---|---|---|---|

| Ca | Density = 5.93225 − 14.18 W + 0.064 CaA + 14.06 W2 − 0.13 W CaA + 0.0008 CaA2 | 96.83 | 2.42 | w/c = 0.48 and CaA content = 5.6 % |

| K | Density = 3.70748 − 5.94 W + 0.15 KA + 6.72 W2 − 0.37 W KA + 0.006 KA2 | 97.17 | 2.45 | w/c = 0.48 and KA content = 5.6% |

| Ethyl | Density = 17.8716 − 59.82 W − 0.048 EA + 57.97 W2 + 0.017 W EA + 0.006 EA2 | 94.33 | 2.47 | w/c = 0.48 and EA content = 5.6% |

| Where W = W/C, CaA = Calcium acetate content (wt.%), KA = Potassium acetate content (wt.%), EA = Ethyl acetate content (wt.%) | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abed, A.A.; Mojtahedi, A.; Lotfollahi Yaghin, M.A. Factorial Mixture Design for Properties Optimization and Modeling of Concrete Composites Incorporated with Acetates as Admixtures. Sustainability 2023, 15, 10608. https://doi.org/10.3390/su151310608

Abed AA, Mojtahedi A, Lotfollahi Yaghin MA. Factorial Mixture Design for Properties Optimization and Modeling of Concrete Composites Incorporated with Acetates as Admixtures. Sustainability. 2023; 15(13):10608. https://doi.org/10.3390/su151310608

Chicago/Turabian StyleAbed, Ammar Ali, Alireza Mojtahedi, and Mohammad Ali Lotfollahi Yaghin. 2023. "Factorial Mixture Design for Properties Optimization and Modeling of Concrete Composites Incorporated with Acetates as Admixtures" Sustainability 15, no. 13: 10608. https://doi.org/10.3390/su151310608

APA StyleAbed, A. A., Mojtahedi, A., & Lotfollahi Yaghin, M. A. (2023). Factorial Mixture Design for Properties Optimization and Modeling of Concrete Composites Incorporated with Acetates as Admixtures. Sustainability, 15(13), 10608. https://doi.org/10.3390/su151310608