Examining the Influence of Sustainable Construction Supply Chain Drivers on Sustainable Building Projects Using Mathematical Structural Equation Modeling Approach

Abstract

1. Introduction

2. Literature Review

2.1. Sustainable Supply Chain Implementation

2.2. Sustainable Supply Chain Management (SSCM)

2.3. Overall Sustainable Success

2.3.1. Economic

2.3.2. Environmental

2.3.3. Social

2.4. Key Drivers of SCSC Implementation and OSS

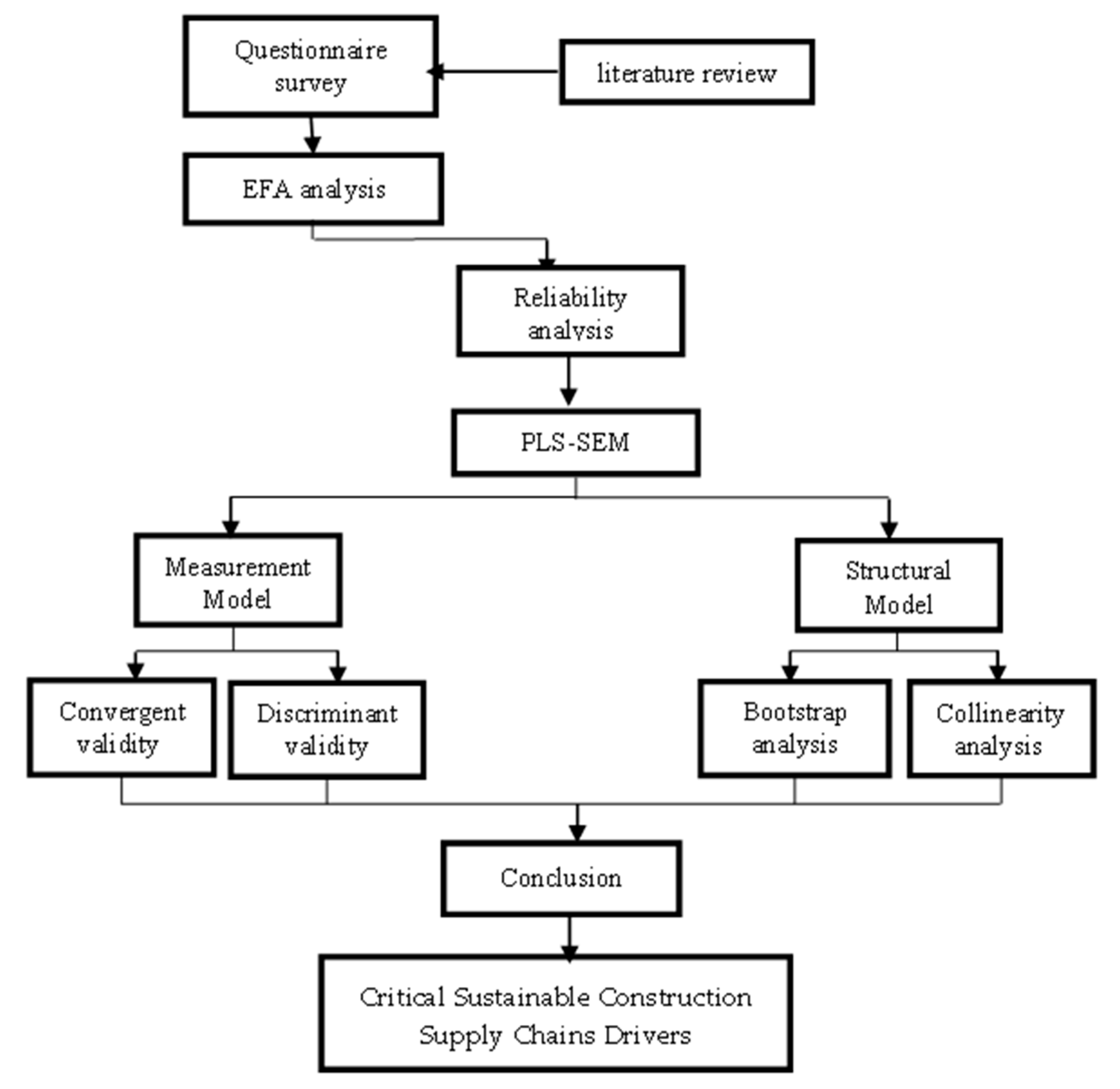

3. The Study Design and Methods

3.1. Analysis Construct Validity: EFA Assessment

3.2. Methodical Approach (Structured Equation Modelling)

3.2.1. Common Method Bias (CMB)

3.2.2. Convergent Validity (CV)

3.2.3. Discriminant Validity (DV)

3.2.4. Path Model

4. Results

4.1. Common Method Bias (CMB)

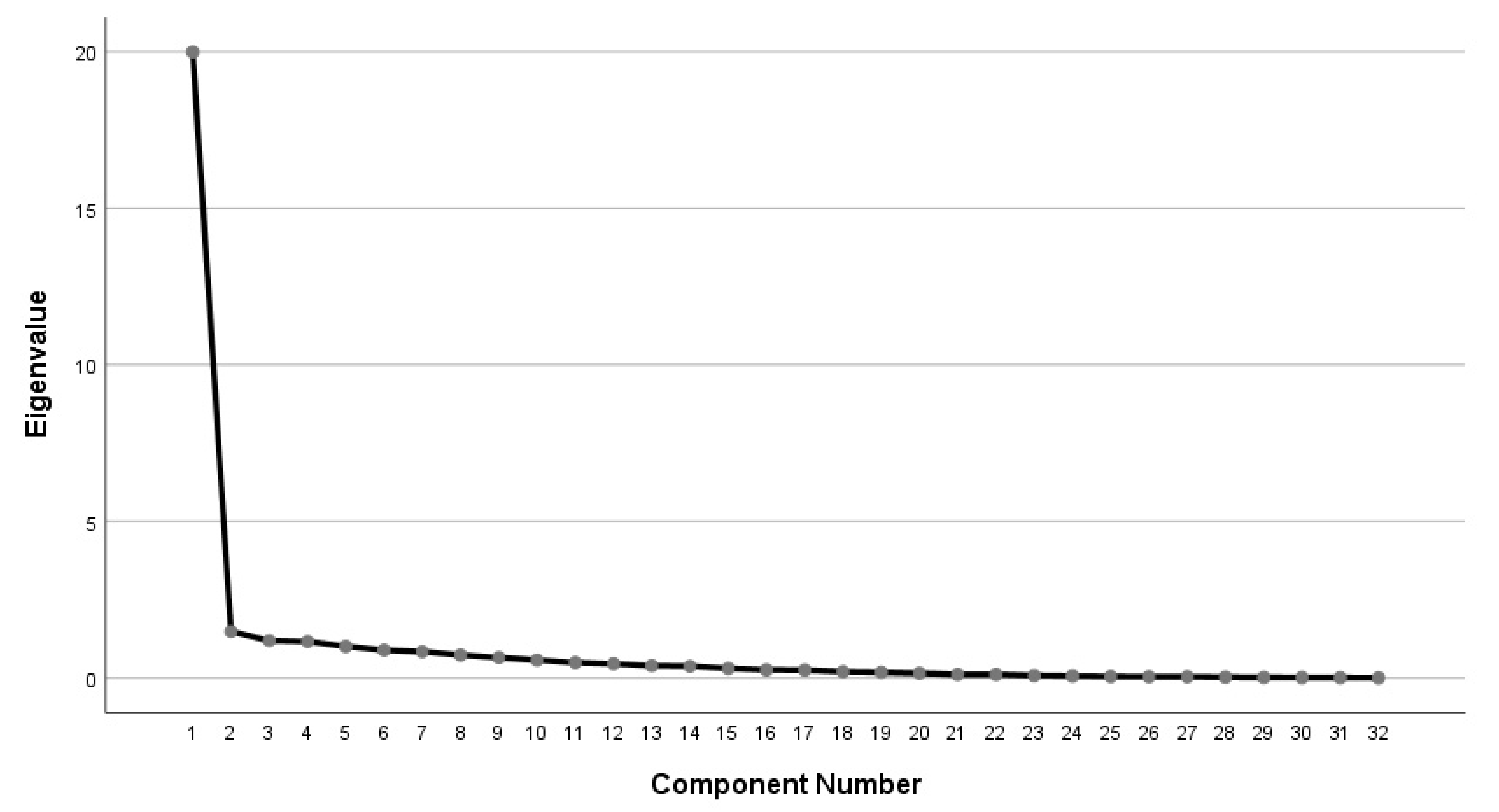

4.2. EFA for SCSC Implementation Drivers

4.3. Common Method Bias (CMB)

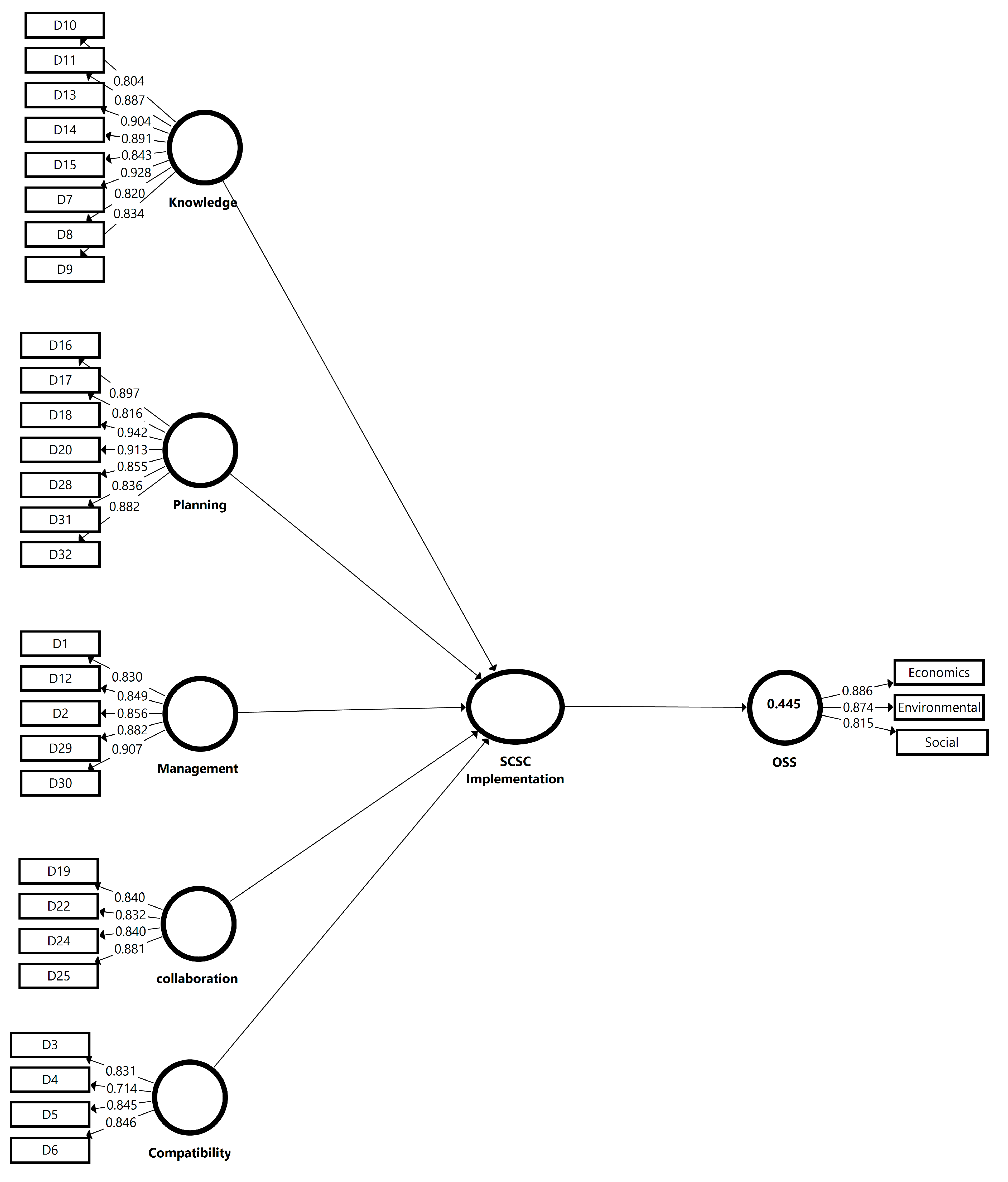

4.4. Analytical Model

- i.

- Fornell–Larcker Criterion,

- ii.

- Cross Loading, and

- iii.

- Hetrotrait–Monotrait Criterion Ratio (HTMT)

4.5. Second-Order Analysis

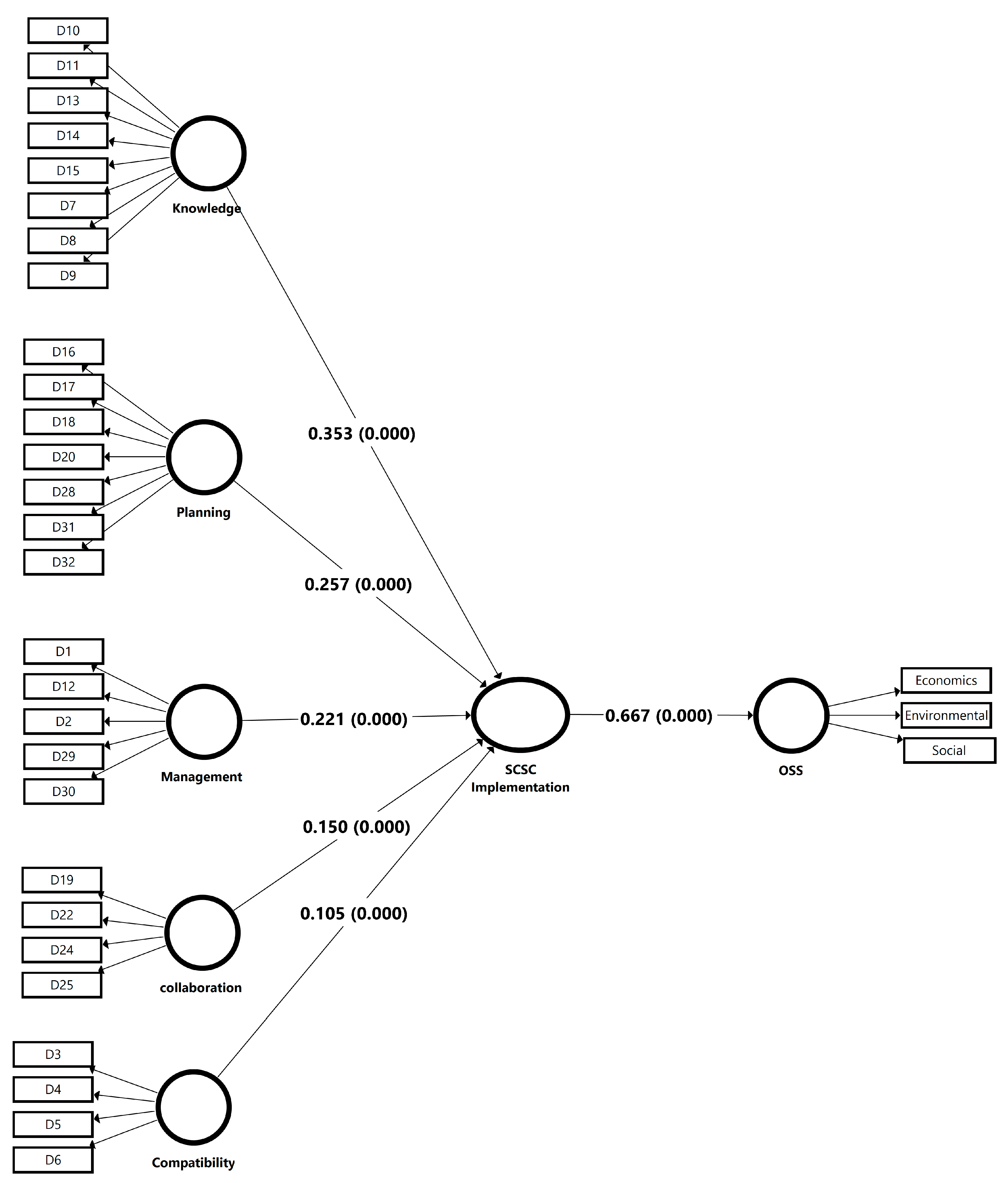

4.6. Structural Model Analysis

4.7. Explanatory Operational Model’s Power

4.8. Analytical Significance of the Operational Model

4.9. The IPMA (Importance Performance Matrix Analysis)

5. Discussion

5.1. Impact of SCSC Implementation Drivers on OSS

5.2. Framework for Implementing Sustainable Construction Supply Chains

5.2.1. Knowledge

5.2.2. Planning

5.2.3. Management

5.2.4. Collaboration

5.2.5. Compatibility

5.3. Theoretical and Empirical Contributions

- This research provides a theoretical role by identifying and conceptualising additional ideas that could be incorporated into the theoretical outline including the effect of SCSC driver adoption concerning OSS during project lifecycles.

- The lack of research on SCSC driver implementation in developing nations like Egypt is critical, as adopting sustainable practices is vital for economic development and environmental sustainability. Developing countries face unique challenges that require a different approach than advanced countries, and, therefore, it is essential to examine the elements that initiate the SCSC implementation in such nations. By thoroughly assessing the significant SCSC drivers for implementation with OSS, this research has delivered a valuable understanding of the elements critical for promoting sustainable practices in the AECO sector. Policymakers and relevant authorities can use these findings to develop effective action plans to overcome the acknowledged SCSC driver implementation barriers in developing countries. Furthermore, the study’s findings are significant because they demonstrate that the adoption of SCSC is not limited to advanced countries. Developing nations like Egypt can also take steps to implement sustainable practices by identifying and addressing the unique challenges they face. In this way, the research has been underwritten to develop a more wide-ranging understanding of SCSC driver implementation in the global context.

- The proposed model is anticipated to drive the implementation of SCSC drivers in developing countries. This practical contribution examines the theoretical connections between the binary concepts of SCSC adoption drivers and OSS throughout the building project lifecycle, which has not been fully explored in the current literature.

5.4. Managerial Implications

- The study provides AECO companies with a list of significant drivers of SCSC that can be addressed to overcome the challenges and hurdles associated with implementing SCSCs, ultimately enhancing client satisfaction through improved quality assurance.

- The proposed model can potentially be a valuable tool for policymakers, construction professionals, and relevant authorities, striving to improve sustainable implementation practices in the AECO industry. By providing a predictive framework for understanding the relationship between SCSC driver implementation and OSS, this model can help identify key drivers that should be prioritised to promote the sustainable application in building schemes. Furthermore, this research can lay a foundation for further studies and analysis in the field of SCSC driver implementation and its impact on OSS, particularly in developing countries like Egypt. Overall, this study offers a priceless understanding of the constraints and opportunities related to implementing SCSC in the construction industry and offers a novel approach to understanding the complex relationship between SCSC driver implementation and OSS.

- The study’s contribution is particularly relevant for decision-makers in the AECO industry who seek to improve the adoption of SCSCs. By clearly understanding the significant SCSC drivers that need to be addressed, this study can aid decision-making in addressing the problems and hurdles of implementing sustainable constructions. It can lead to higher client satisfaction through improved quality visualisation.

- Moreover, the analytical approach proposed in this study offers a framework for decision-making concerning SCSC driver implementation on OSS throughout the building project lifecycle. This framework can support policymakers in recognising and prioritising the most critical drivers that need to be addressed, thereby enabling a more effective and efficient deployment of SCSCs in building projects.

5.5. Limitation of Study and Direction of Future Research

- This study has certain geographical limitations that need to be considered when interpreting the findings. The survey tool used in this research was administered solely to building experts located in southwestern Egypt, thus making it difficult to generalise the results to other regions. Therefore, future studies are recommended to extend the geographical scope beyond this study by including more regions in Egypt as well as similar developing nations to enhance the validity and generalisability of research findings.

- One limitation of this cross-sectional study is the lack of consideration for historical and organisational perspectives on SCSC adoption. To gain a more comprehensive understanding of the interface between SCSC adoption challenges and OSS in the building project lifecycle, future research should be longitudinal in nature. This will enable researchers to track changes over time and provide a deeper insight into the complexities associated with SCSC adoption.

- Third, this study focused on the SEM-PLS applications to evaluate the links between OSS and SCSC drivers in construction projects—lifecycle through theoretic conceptualisation. Hence, future studies might focus on the documentation of the level of viable adoption through the adoption of theory, comprising the Technology Acceptance Model (TAM), Innovative Diffusion Theory (IDT), and Technology organisation and environment model (TOEM).

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mousa, A. A Business approach for transformation to sustainable construction: An implementation on a developing country. Resour. Conserv. Recycl. 2015, 101, 9–19. [Google Scholar] [CrossRef]

- Kissi, E.; Boateng, E.; Adjei-Kumi, T. Strategies for implementing value management in the construction industry of Ghana. In Proceedings of the DII-2015 Conference on Infrastructure Development and Investment Strategies for Africa, Livingstone, Zambia, 16–18 September 2015; pp. 255–267. [Google Scholar]

- Adeyemi, L.A.; Idoko, M. Developing Local Capacity for Project Management—Key To Social And Business Transformation In Developing Countries. In Proceedings of the PMI Global Congress 2008—Asia Pacific, Sydney, Australia, 3–5 March 2008. [Google Scholar]

- Kim, S.-Y.; Lee, Y.-S.; Nguyen, V.T. Barriers to applying value management in the Vietnamese construction industry. J. Constr. Dev. Ctries. 2016, 21, 55. [Google Scholar] [CrossRef]

- Jekale, W. Performance for Public Construction Projects in Developing Countries: Federal Road and Educational Building Projects in Ethiopia. Ph.D. Thesis, Norwegian University of Science Technology, Trondheim, Norway, 2004. [Google Scholar]

- Barakat, M.S.; Naayem, J.H.; Baba, S.S.; Kanso, F.A.; Borgi, S.F.; Arabian, G.H.; Nahlawi, F.N. Egypt Economic Report: Between the Recovery of the Domestic Economy and the Burden of External Sector Challenges. 2016. Available online: http://www.bankaudigroup.com (accessed on 31 March 2023).

- Soliman, M.M.A.I. Risk Management in International Construction Joint Ventures in Egypt. Ph.D. Thesis, University of Leeds, Leeds, UK, 2014. [Google Scholar]

- Abd El-Razek, M.; Bassioni, H.; Mobarak, A. Causes of delay in building construction projects in Egypt. J. Constr. Eng. Manag. 2008, 134, 831–841. [Google Scholar] [CrossRef]

- Mukhamedjanova, K.A. Concept of supply chain management. J. Crit. Rev. 2020, 7, 759–766. [Google Scholar]

- Moysiadis, T.; Spanaki, K.; Kassahun, A.; Kläser, S.; Becker, N.; Alexiou, G.; Zotos, N.; Karali, I. AgriFood supply chain traceability: Data sharing in a farm-to-fork case. Benchmarking Int. J. 2022. ahead-of-print. [Google Scholar] [CrossRef]

- Christopher, M.; Peck, H. Building the resilient supply chain. Int. J. Logist. Manag. 2004, 15, 1–14. [Google Scholar] [CrossRef]

- Caniato, F.F.A.; Rice, J. Building a secure and resilient supply chain. Supply Chain Manag. Rev. 2003, 7, 22–30. [Google Scholar]

- Ponomarov, S.Y.; Holcomb, M.C. Understanding the concept of supply chain resilience. Int. J. Logist. Manag. 2009, 20, 124–143. [Google Scholar] [CrossRef]

- Raut, R.D.; Narkhede, B.; Gardas, B.B. To identify the critical success factors of sustainable supply chain management practices in the context of oil and gas industries: ISM approach. Renew. Sustain. Energy Rev. 2017, 68, 33–47. [Google Scholar] [CrossRef]

- Naz, F.; Kumar, A.; Majumdar, A.; Agrawal, R. Is artificial intelligence an enabler of supply chain resiliency post COVID-19? An exploratory state-of-the-art review for future research. Oper. Manag. Res. 2022, 15, 378–398. [Google Scholar] [CrossRef]

- Petit-Boix, A.; Leipold, S. Circular economy in cities: Reviewing how environmental research aligns with local practices. J. Clean. Prod. 2018, 195, 1270–1281. [Google Scholar] [CrossRef]

- Pettit, T.J.; Croxton, K.L.; Fiksel, J. The Evolution of Resilience in Supply Chain Management: A Retrospective on Ensuring Supply Chain Resilience. J. Bus. Logist. 2019, 40, 56–65. [Google Scholar] [CrossRef]

- Chowdhury, M.M.H.; Quaddus, M.; Agarwal, R. Supply chain resilience for performance: Role of relational practices and network complexities. Supply Chain Manag. Int. J. 2019, 24, 659–676. [Google Scholar] [CrossRef]

- Nguyen, N.C.; Bosch, O.J. A systems thinking approach to identify leverage points for sustainability: A case study in the Cat Ba Biosphere Reserve, Vietnam. Syst. Res. Behav. Sci. 2013, 30, 104–115. [Google Scholar] [CrossRef]

- Sapiri, H.; Zulkepli, J.; Ahmad, N.; Abidin, N.Z.; Hawari, N.N. Introduction to System Dynamic Modelling and Vensim Software: UUM Press; UUM Press: Kedah, Malaysia, 2017. [Google Scholar]

- Ullah, F.; Sepasgozar, S.M. A study of information technology adoption for real-estate management: A system dynamic model. In Innovative Production and Construction: Transforming Construction Through Emerging Technologies; World Scientific: Singapore, 2019; pp. 469–486. [Google Scholar]

- Naslund, D.; Williamson, S. What is management in supply chain management?—A critical review of definitions, frameworks and terminology. J. Manag. Policy Pract. 2010, 11, 11–28. [Google Scholar]

- Touboulic, A.; Walker, H. Theories in sustainable supply chain management: A structured literature review. Int. J. Phys. Distrib. Logist. Manag. 2015, 45, 16–42. [Google Scholar] [CrossRef]

- Reefke, H.; Sundaram, D. Key themes and research opportunities in sustainable supply chain management–identification and evaluation. Omega 2017, 66, 195–211. [Google Scholar] [CrossRef]

- Cavone, G.; Dotoli, M.; Epicoco, N.; Morelli, D.; Seatzu, C. Design of modern supply chain networks using fuzzy bargaining game and data envelopment analysis. IEEE Trans. Autom. Sci. Eng. 2020, 17, 1221–1236. [Google Scholar] [CrossRef]

- Cavone, G.; Dotoli, M.; Epicoco, N.; Morelli, D.; Seatzu, C. A game-theoretical design technique for multi-stage supply chains under uncertainty. In Proceedings of the 2018 IEEE 14th International Conference on Automation Science and Engineering (CASE), Munich, Germany, 20–24 August 2018; pp. 528–533. [Google Scholar]

- Ghufran, M.; Khan, K.I.A.; Thaheem, M.J.; Nasir, A.R.; Ullah, F. Adoption of Sustainable Supply Chain Management for Performance Improvement in the Construction Industry: A System Dynamics Approach. Architecture 2021, 1, 161–182. [Google Scholar] [CrossRef]

- Seuring, S.; Müller, M. From a literature review to a conceptual framework for sustainable supply chain management. J. Clean. Prod. 2008, 16, 1699–1710. [Google Scholar] [CrossRef]

- Stindt, D. A generic planning approach for sustainable supply chain management-How to integrate concepts and methods to address the issues of sustainability? J. Clean. Prod. 2017, 153, 146–163. [Google Scholar] [CrossRef]

- Parsa, S.; Roper, I.; Muller-Camen, M.; Szigetvari, E. Have labour practices and human rights disclosures enhanced corporate accountability? The case of the GRI framework. Account. Forum 2018, 42, 47–64. [Google Scholar] [CrossRef]

- Sabri, Y.; Micheli, G.J.; Cagno, E. Supplier selection and supply chain configuration in the projects environment. Prod. Plan. Control 2020, 33, 1155–1172. [Google Scholar] [CrossRef]

- Rajeev, A.; Pati, R.K.; Padhi, S.S.; Govindan, K. Evolution of sustainability in supply chain management: A literature review. J. Clean. Prod. 2017, 162, 299–314. [Google Scholar] [CrossRef]

- Daraei, A.; Sherwani, A.F.H.; Faraj, R.H.; Kalhor, Q.; Zare, S.; Mahmoodzadeh, A. Optimization of the outlet portal of Heybat Sultan twin tunnels based on the value engineering methodology. SN Appl. Sci. 2019, 1, 270. [Google Scholar] [CrossRef]

- Fahimnia, B.; Jabbarzadeh, A. Marrying supply chain sustainability and resilience: A match made in heaven. Transp. Res. Part E Logist. Transp. Rev. 2016, 91, 306–324. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A.; Sokolov, B.; Ivanova, M. Literature review on disruption recovery in the supply chain. Int. J. Prod. Res. 2017, 55, 6158–6174. [Google Scholar] [CrossRef]

- Rachwan, R.; Abotaleb, I.; Elgazouli, M. The influence of value engineering and sustainability considerations on the project value. Procedia Environ. Sci. 2016, 34, 431–438. [Google Scholar] [CrossRef]

- Seuring, S. Supply chain management for sustainable products–insights from research applying mixed methodologies. Bus. Strategy Environ. 2011, 20, 471–484. [Google Scholar] [CrossRef]

- Ashby, A.; Leat, M.; Hudson-Smith, M. Making connections: A review of supply chain management and sustainability literature. Supply Chain Manag. Int. J. 2012, 17, 497–516. [Google Scholar] [CrossRef]

- Kshetri, N. 1 Blockchain’s roles in meeting key supply chain management objectives. Int. J. Inf. Manag. 2018, 39, 80–89. [Google Scholar] [CrossRef]

- Parmigiani, A.; Klassen, R.D.; Russo, M.V. Efficiency meets accountability: Performance implications of supply chain configuration, control, and capabilities. J. Oper. Manag. 2011, 29, 212–223. [Google Scholar] [CrossRef]

- Jabbarzadeh, A.; Fahimnia, B.; Sabouhi, F. Resilient and sustainable supply chain design: Sustainability analysis under disruption risks. Int. J. Prod. Res. 2018, 56, 5945–5968. [Google Scholar] [CrossRef]

- Mukherjee, K.; Mondal, S.J.T.A.; Management, S. Analysis of issues relating to remanufacturing technology—A case of an Indian company. Technol. Anal. Strat. Manag. 2009, 21, 639–652. [Google Scholar] [CrossRef]

- Faisal, M.N. Sustainable supply chains: A study of interaction among the enablers. Bus. Process. Manag. J. 2010, 16, 508–529. [Google Scholar] [CrossRef]

- Hussain, M. Modelling the Enablers and Alternatives for Sustainable Supply Chain Management. Master’s Thesis, Concordia University, Montreal, QC, Canada, 2011. [Google Scholar]

- Diabat, A.; Govindan, K. An analysis of the drivers affecting the implementation of green supply chain management. Resour. Conserv. Recycl. 2011, 55, 659–667. [Google Scholar] [CrossRef]

- Mathiyazhagan, K.; Govindan, K.; NoorulHaq, A.; Geng, Y. An ISM approach for the barrier analysis in implementing green supply chain management. J. Clean. Prod. 2013, 47, 283–297. [Google Scholar] [CrossRef]

- Dashore, K.; Sohani, N. Green supply chain management: A hierarchical framework for barriers. J. Sustain. 2008, 5, 2011. [Google Scholar]

- Muduli, K.; Govindan, K.; Barve, A.; Kannan, D.; Geng, Y. Role of behavioural factors in green supply chain management implementation in Indian mining industries. Resour. Conserv. Recycl. 2013, 76, 50–60. [Google Scholar] [CrossRef]

- Luthra, S.; Garg, D.; Kumar, S.; Haleem, A. Implementation of the green supply chain management in manufacturing industry in India using interpretive structural modeling technique. BPR Technol. A J. Sci. Technol. Manag. 2012, 1, 1–17. [Google Scholar]

- Kumar, S.; Luthra, S.; Haleem, A. Customer involvement in greening the supply chain: An interpretive structural modeling methodology. J. Ind. Eng. Int. 2013, 9, 6. [Google Scholar] [CrossRef]

- Sharma, S.; Panda, B.; Mahapatra, S.; Sahu, S. Analysis of barriers for reverse logistics: An Indian perspective. Int. J. Model. Optim. 2011, 1, 101. [Google Scholar] [CrossRef]

- Kannan, G.; Pokharel, S.; Kumar, P.S. A hybrid approach using ISM and fuzzy TOPSIS for the selection of reverse logistics provider. Resour. Conserv. Recycl. 2009, 54, 28–36. [Google Scholar] [CrossRef]

- Sarkis, J.; Hasan, M.A.; Shankar, R. Evaluating environmentally conscious manufacturing barriers with interpretive structural modeling. In Proceedings of the Environmentally Conscious Manufacturing VI, Boston, MA, USA, 1–4 October 2006; Volume 6385, pp. 68–76. [Google Scholar]

- Manikanda Prasath, K. Barriers in green supply chain management: An Indian foundry perspective. In Proceedings of the Second International Conference on Advances in Industrial Engineering Applications (ICAIEA 2014), Chennai, India, 6–8 January 2014. [Google Scholar]

- Wang, G.; Wang, Y.; Zhao, T. Analysis of interactions among the barriers to energy saving in China. Energy Policy 2008, 36, 1879–1889. [Google Scholar] [CrossRef]

- dos Muchangos, L.S.; Tokai, A.; Hanashima, A. Analyzing the structure of barriers to municipal solid waste management policy planning in Maputo city, Mozambique. Environ. Dev. 2015, 16, 76–89. [Google Scholar] [CrossRef]

- Mangla, S.; Kumar, P.; Barua, M.K. An evaluation of attribute for improving the green supply chain performance via DEMATEL method. Int. J. Mech. Eng. Robot. Res. 2014, 1, 30–35. [Google Scholar]

- Al Zaabi, S.; Al Dhaheri, N.; Diabat, A. Analysis of interaction between the barriers for the implementation of sustainable supply chain management. Int. J. Adv. Manuf. Technol. 2013, 68, 895–905. [Google Scholar] [CrossRef]

- Oke, A.; Aghimien, D.; Olatunji, S. Implementation of value management as an economic sustainability tool for building construction in Nigeria. Int. J. Manag. Value Supply Chain. 2015, 6, 55–64. [Google Scholar]

- Kineber, A.F.; Othman, I.; Oke, A.E.; Chileshe, N.; Zayed, T. Exploring the value management critical success factors for sustainable residential building—A structural equation modelling approach. J. Clean. Prod. 2021, 293, 126115. [Google Scholar] [CrossRef]

- Aarseth, W.; Ahola, T.; Aaltonen, K.; Økland, A.; Andersen, B. Project sustainability strategies: A systematic literature review. Int. J. Proj. Manag. 2017, 35, 1071–1083. [Google Scholar] [CrossRef]

- Martens, M.L.; Carvalho, M.M. Key factors of sustainability in project management context: A survey exploring the project managers’ perspective. Int. J. Proj. Manag. 2017, 35, 1084–1102. [Google Scholar] [CrossRef]

- Abidin, N.Z.; Pasquire, C.L. Revolutionize value management: A mode towards sustainability. Int. J. Proj. Manag. 2007, 25, 275–282. [Google Scholar] [CrossRef]

- Fewings, P.; Henjewele, C. Construction Project Management: An Integrated Approach; Routledge: Oxfordshire, UK, 2019. [Google Scholar]

- Hartmann, T.; Van Meerveld, H.; Vossebeld, N.; Adriaanse, A. Aligning building information model tools and construction management methods. Autom. Constr. 2012, 22, 605–613. [Google Scholar] [CrossRef]

- Halpin, D.; Woodhead, R. Construction Management; Wiley: New York, NY, USA, 1998. [Google Scholar]

- Eastman, C.M.; Eastman, C.; Teicholz, P.; Sacks, R.; Liston, K. BIM Handbook: A Guide to Building Information Modeling for Owners, Managers, Designers, Engineers and Contractors; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Azhar, S.; Carlton, W.A.; Olsen, D.; Ahmad, I. Building information modeling for sustainable design and LEED® rating analysis. Autom. Constr. 2011, 20, 217–224. [Google Scholar] [CrossRef]

- Wong, K.-d.; Fan, Q. Building information modelling (BIM) for sustainable building design. Facilities 2013, 31, 138–157. [Google Scholar] [CrossRef]

- Soltani, S. The contributions of building information modelling to sustainable construction. World J. Eng. Technol. Soc. 2016, 4, 193. [Google Scholar] [CrossRef]

- Sassi, P. Strategies for Sustainable Architecture; Taylor & Francis: Abingdon, UK, 2006. [Google Scholar]

- Golan, M.S.; Jernegan, L.H.; Linkov, I. Trends and applications of resilience analytics in supply chain modeling: Systematic literature review in the context of the COVID-19 pandemic. Environ. Syst. Decis. 2020, 40, 222–243. [Google Scholar] [CrossRef]

- Quinlan, A.E.; Berbés-Blázquez, M.; Haider, L.J.; Peterson, G.D. Measuring and assessing resilience: Broadening understanding through multiple disciplinary perspectives. J. Appl. Ecol. 2016, 53, 677–687. [Google Scholar] [CrossRef]

- Altay, N.; Gunasekaran, A.; Dubey, R.; Childe, S.J. Agility and resilience as antecedents of supply chain performance under moderating effects of organizational culture within the humanitarian setting: A dynamic capability view. Prod. Plan. Control 2018, 29, 1158–1174. [Google Scholar] [CrossRef]

- Scholten, K.; Scott, P.S.; Fynes, B. Building routines for non-routine events: Supply chain resilience learning mechanisms and their antecedents. Supply Chain Manag. Int. J. 2019, 24, 430–442. [Google Scholar] [CrossRef]

- Ghufran, M.; Khan, K.I.A.; Ullah, F.; Alaloul, W.S.; Musarat, M.A. Key Enablers of Resilient and Sustainable Construction Supply Chains: A Systems Thinking Approach. Sustainability 2022, 14, 11815. [Google Scholar] [CrossRef]

- Brady, M. Realising supply chain resilience: An exploratory study of Irish firms’ priorities in the wake of Brexit. Contin. Resil. Rev. 2020, 3, 22–36. [Google Scholar] [CrossRef]

- Papadopoulos, T.; Gunasekaran, A.; Dubey, R.; Altay, N.; Childe, S.J.; Fosso-Wamba, S. The role of Big Data in explaining disaster resilience in supply chains for sustainability. J. Clean. Prod. 2017, 142, 1108–1118. [Google Scholar] [CrossRef]

- Ruiz-Benítez, R.; López, C.; Real, J.C. The lean and resilient management of the supply chain and its impact on performance. Int. J. Prod. Econ. 2018, 203, 190–202. [Google Scholar] [CrossRef]

- Ralston, P.; Blackhurst, J. Industry 4.0 and resilience in the supply chain: A driver of capability enhancement or capability loss? Int. J. Prod. Res. 2020, 58, 5006–5019. [Google Scholar] [CrossRef]

- Christopher, M.; Rutherford, C.J. Creating supply chain resilience through agile six sigma. Crit. Eye 2004, 7, 24–28. [Google Scholar]

- Ivanov, D.; Sokolov, B.; Dolgui, A. The Ripple effect in supply chains: Trade-off ‘efficiency-flexibility-resilience’ in disruption management. Int. J. Prod. Res. 2013, 52, 2154–2172. [Google Scholar] [CrossRef]

- Ivanov, D. New drivers for supply chain structural dynamics and resilience: Sustainability, industry 4.0, self-adaptation. In Structural Dynamics and Resilience in Supply Chain Risk Management; Springer: Berlin/Heidelberg, Germany, 2018; pp. 293–313. [Google Scholar]

- Soni, U.; Jain, V.; Kumar, S. Measuring supply chain resilience using a deterministic modeling approach. Comput. Ind. Eng. 2014, 74, 11–25. [Google Scholar] [CrossRef]

- Jain, V.; Kumar, S.; Soni, U.; Chandra, C. Supply chain resilience: Model development and empirical analysis. Int. J. Prod. Res. 2017, 55, 6779–6800. [Google Scholar] [CrossRef]

- Rosič, H.; Bauer, G.; Jammernegg, W. A framework for economic and environmental sustainability and resilience of supply chains. In Rapid Modelling for Increasing Competitiveness; Springer: Berlin/Heidelberg, Germany, 2009; pp. 91–104. [Google Scholar]

- Badurdeen, F.; Wijekoon, K.; Shuaib, M.; Goldsby, T.J.; Iyengar, D.; Jawahir, I.S. Integrated modeling to enhance resilience in sustainable supply chains. In Proceedings of the 2010 IEEE International Conference on Automation Science and Engineering, Toronto, ON, Canada, 21–24 August 2010; pp. 130–135. [Google Scholar]

- Govindan, K.; Azevedo, S.G.; Carvalho, H.; Cruz-Machado, V. Lean, green and resilient practices influence on supply chain performance: Interpretive structural modeling approach. Int. J. Environ. Sci. Technol. 2015, 12, 15–34. [Google Scholar] [CrossRef]

- Mari, S.I.; Lee, Y.H.; Memon, M.S. Sustainable and Resilient Supply Chain Network Design under Disruption Risks. Sustainability 2014, 6, 6666–6686. [Google Scholar] [CrossRef]

- Kun, A. Social Dialogue and Corporate Social Responsibility (CSR) in the EU. In EU Collective Labour Law; Edward Elgar Publishing: Cheltenham, UK, 2021. [Google Scholar]

- Rojon, C.; McDowall, A.; Saunders, M.N.K. On the Experience of Conducting a Systematic Review in Industrial, Work, and Organizational Psychology. J. Pers. Psychol. 2011, 10, 133–138. [Google Scholar] [CrossRef]

- Mangla, S.K.; Kumar, P.; Barua, M.K. Flexible Decision Approach for Analysing Performance of Sustainable Supply Chains Under Risks/Uncertainty. Glob. J. Flex. Syst. Manag. 2014, 15, 113–130. [Google Scholar] [CrossRef]

- Shields, P.M.; Tajalli, H. Intermediate theory: The missing link in successful student scholarship. J. Public Aff. Educ. 2006, 12, 313–334. [Google Scholar] [CrossRef]

- Christensen, C.M. The ongoing process of building a theory of disruption. J. Prod. Innov. Manag. 2006, 23, 39–55. [Google Scholar] [CrossRef]

- Kineber, A.F.; Othman, I.; Oke, A.E.; Chileshe, N.; Buniya, M.K. Impact of Value Management on Building Projects Success: Structural Equation Modeling Approach. J. Constr. Eng. Manag. 2021, 147, 04021011. [Google Scholar] [CrossRef]

- Buniya, M.K.; Othman, I.; Durdyev, S.; Sunindijo, R.Y.; Ismail, S.; Kineber, A.F. Safety Program Elements in the Construction Industry: The Case of Iraq. Int. J. Environ. Res. Public Health 2021, 18, 411. [Google Scholar] [CrossRef]

- Singh, P.S.; Oke, A.E.; Kineber, A.F.; Olanrewaju, O.I.; Omole, O.; Samsurijan, M.S.; Ramli, R.A. A mathematical analysis of 4IR innovation barriers in developmental social work—A structural equation modeling approach. Mathematics 2023, 11, 1003. [Google Scholar] [CrossRef]

- Williams, B.; Onsman, A.; Brown, T. Exploratory factor analysis: A five-step guide for novices. Australas. J. Paramed. 2010, 8, 1–13. [Google Scholar] [CrossRef]

- Thompson, B. Exploratory and Confirmatory Factor Analysis: Understanding Concepts and Applications; American Psychological Association: Washington, DC, USA, 2004; pp. 10000–10694. [Google Scholar]

- Oke, A.E.; Kineber, A.F.; Albukhari, I.; Othman, I.; Kingsley, C. Assessment of Cloud Computing Success Factors for Sustainable Construction Industry: The Case of Nigeria. Buildings 2021, 11, 36. [Google Scholar] [CrossRef]

- Costello, A.B.; Osborne, J. Best practices in exploratory factor analysis: Four recommendations for getting the most from your analysis. Pract. Assess. Res. Eval. 2005, 10, 7. [Google Scholar]

- Oke, A.E.; Kineber, A.F.; Al-Bukhari, I.; Famakin, I.; Kingsley, C. Exploring the benefits of cloud computing for sustainable construction in Nigeria. J. Eng. Des. Technol. Soc. 2021. ahead-of-print. [Google Scholar] [CrossRef]

- Tabachnick, B.G.; Fidell, L.S.; Ullman, J.B. Using Multivariate Statistics; Pearson: Boston, MA, USA, 2007; Volume 5. [Google Scholar]

- Robert, O.K.; Dansoh, A.; Ofori-Kuragu, J.K. Reasons for adopting public–private partnership (PPP) for construction projects in Ghana. Int. J. Constr. Manag. 2014, 14, 227–238. [Google Scholar] [CrossRef]

- Oke, A.E. Evaluation of the Administration of Construction Bonds in Lagos and Ondo States, Nigeria. Ph.D. Thesis, Federal University of Technology, Akure, Nigeria, 2015. [Google Scholar]

- Amaratunga, D.; Kulatunga, U.; Liyanage, C.; Hui, E.C.; Zheng, X. Measuring customer satisfaction of FM service in housing sector. Facilities 2010, 28, 306–320. [Google Scholar] [CrossRef]

- Byrne, B.M. Structural Equation Modeling with AMOS: Basic Concepts, Applications, and Programming; Multivariate Applications Series; Routledge/Taylor & Francis Group: New York, NY, USA, 2010. [Google Scholar]

- Ringle, C.M.; Sarstedt, M.; Straub, D.W. Editor’s Comments: A Critical Look at the Use of PLS-SEM in “MIS Quarterly”. MIS Q. 2012, 36, iii–xiv. [Google Scholar] [CrossRef]

- Yuan, K.H.; Wu, R.; Bentler, P.M. Ridge structural equation modelling with correlation matrices for ordinal and continuous data. Br. J. Math. Stat. Psychol. 2011, 64, 107–133. [Google Scholar] [CrossRef]

- Sarstedt, M.; Ringle, C.M.; Smith, D.; Reams, R.; Hair, J.F., Jr. Partial least squares structural equation modeling (PLS-SEM): A useful tool for family business researchers. J. Fam. Bus. Strategy 2014, 5, 105–115. [Google Scholar] [CrossRef]

- Podsakoff, P.M.; MacKenzie, S.B.; Lee, J.-Y.; Podsakoff, N.P. Common method biases in behavioral research: A critical review of the literature and recommended remedies. J. Appl. Psychol. 2003, 88, 879. [Google Scholar] [CrossRef] [PubMed]

- Williams, L.J.; Cote, J.A.; Buckley, M.R. Lack of method variance in self-reported affect and perceptions at work: Reality or artifact? J. Appl. Psychol. 1989, 74, 462. [Google Scholar] [CrossRef]

- Strandholm, K.; Kumar, K.; Subramanian, R. Examining the interrelationships among perceived environmental change, strategic response, managerial characteristics, and organizational performance. J. Bus. Res. 2004, 57, 58–68. [Google Scholar] [CrossRef]

- Harman, H.H. Modern Factor Analysis; University of Chicago Press: Chicago, IL, USA, 1976. [Google Scholar]

- Podsakoff, P.M.; Organ, D.W. Self-reports in organizational research: Problems and prospects. J. Manag. 1986, 12, 531–544. [Google Scholar] [CrossRef]

- Hulland, J. Use of partial least squares (PLS) in strategic management research: A review of four recent studies. Strateg. Manag. J. 1999, 20, 195–204. [Google Scholar] [CrossRef]

- Fornell, C.; Larcker, D.F. Evaluating structural equation models with unobservable variables and measurement error. J. Mark. Res. 1981, 18, 39–50. [Google Scholar] [CrossRef]

- Nunnally, J.C.; Bernstein, I. The Role of University in the Development of Entrepreneurial Vocations: A Spanish Study. In Psychometric Theory; McGraw-Hill: New York, NY, USA, 1978. [Google Scholar]

- Wong, K.K.-K. Partial least squares structural equation modeling (PLS-SEM) techniques using SmartPLS. Mark. Bull. 2013, 24, 1–32. [Google Scholar]

- Hair, J.F.; Anderson, R.E.; Babin, B.J.; Black, W.C. Multivariate Data Analysis: A Global Perspective, 7th ed.; Pearson Education: Upper Saddle River, NJ, USA, 2010. [Google Scholar]

- Campbell, D.T.; Fiske, D.W. Convergent and discriminant validation by the multitrait-multimethod matrix. Psychol. Bull. 1959, 56, 81. [Google Scholar] [CrossRef]

- Alkilani, S.G.R.Z. Performance Measurement and Improvement Model for Small and Medium Contractors in Developing Countries. Ph.D. Thesis, The University of New South Wales, Sydney, Australia, 2018. [Google Scholar]

- Henseler, J.; Hubona, G.; Ray, P.A. Using PLS path modeling in new technology research: Updated guidelines. Ind. Manag. Data Syst. 2016, 116, 2–20. [Google Scholar] [CrossRef]

- MacKenzie, S.B.; Podsakoff, P.M. Common method bias in marketing: Causes, mechanisms, and procedural remedies. J. Retail. 2012, 88, 542–555. [Google Scholar] [CrossRef]

- Kineber, A.F.; Othman, I.; Oke, A.E.; Chileshe, N.; Alsolami, B. Critical Value Management Activities in Building Projects: A Case of Egypt. Buildings 2020, 10, 239. [Google Scholar] [CrossRef]

- Al-Mekhlafi, A.-B.A.; Isha, A.S.N.; Chileshe, N.; Abdulrab, M.; Kineber, A.F.; Ajmal, M. Impact of Safety Culture Implementation on Driving Performance among Oil and Gas Tanker Drivers: A Partial Least Squares Structural Equation Modelling (PLS-SEM) Approach. Sustainability 2021, 13, 8886. [Google Scholar] [CrossRef]

- Kineber, A.F.; Siddharth, S.; Chileshe, N.; Alsolami, B.; Hamed, M.M.J.S. Addressing of Value Management Implementation Barriers within the Indian Construction Industry: A PLS-SEM Approach. Sustainability 2022, 14, 16602. [Google Scholar] [CrossRef]

- Sharma, S. Applied Multivariate Techniques; John Wiley and Sons: Hoboken, NJ, USA, 1996. [Google Scholar]

- Tavakol, M.; Dennick, R. Making sense of Cronbach’s alpha. Int. J. Med. Educ. 2011, 2, 53. [Google Scholar] [CrossRef]

- Al-Ashmori, Y.Y.; Othman, I.; Rahmawati, Y.; Amran, Y.H.M.; Sabah, S.H.A.; Rafindadi, A.D.; Mikić, M. BIM benefits and its influence on the BIM implementation in Malaysia. Ain Shams Eng. J. 2020, 11, 1013–1019. [Google Scholar] [CrossRef]

- Hair, J.F., Jr.; Hult, G.T.M.; Ringle, C.; Sarstedt, M. A Primer on Partial Least Squares Structural Equation Modeling (PLS-SEM); Sage Publications: Thousand Oaks, CA, USA, 2016. [Google Scholar]

- Bagozzi, R.P.; Yi, Y. On the evaluation of structural equation models. J. Acad. Mark. Sci. 1988, 16, 74–94. [Google Scholar] [CrossRef]

- Perry, R.H.; Charlotte, B.; Isabella, M.; Bob, C. SPSS Explained; Routledge: London, UK, 2004. [Google Scholar]

- Amos, D.; Au-Yong, C.P.; Musa, Z.N. The mediating effects of finance on the performance of hospital facilities management services. J. Build. Eng. 2021, 34, 101899. [Google Scholar] [CrossRef]

- Shah, R.; Goldstein, S.M. Use of structural equation modeling in operations management research: Looking back and forward. J. Oper. Manag. 2006, 24, 148–169. [Google Scholar] [CrossRef]

- Shook, C.L.; Ketchen, D.J., Jr.; Hult, G.T.M.; Kacmar, K.M. An assessment of the use of structural equation modeling in strategic management research. Strateg. Manag. J. 2004, 25, 397–404. [Google Scholar] [CrossRef]

- Chin, W.W.; Newsted, P.R. Structural equation modeling analysis with small samples using partial least squares. Stat. Strateg. Small Sample Res. 1999, 1, 307–341. [Google Scholar]

- Hair, J.F.; Risher, J.J.; Sarstedt, M.; Ringle, C.M. When to use and how to report the results of PLS-SEM. Eur. Bus. Rev. 2019, 31, 2–24. [Google Scholar] [CrossRef]

- Hair, J.F., Jr.; Hult, G.T.M.; Ringle, C.M.; Sarstedt, M.; Danks, N.P.; Ray, S.; Hair, J.F.; Hult, G.T.M.; Ringle, C.M.; Sarstedt, M. Evaluation of reflective measurement models. In Partial Least Squares Structural Equation Modeling (PLS-SEM) Using R: A Workbook; Springer Nature: Berlin/Heidelberg, Germany, 2021; pp. 75–90. [Google Scholar]

- Hair, J.F.; Ringle, C.M.; Sarstedt, M. Partial least squares structural equation modeling: Rigorous applications, better results and higher acceptance. Long Range Plan. 2013, 46, 1–12. [Google Scholar] [CrossRef]

- Hair, J.F., Jr.; Matthews, L.M.; Matthews, R.L.; Sarstedt, M. PLS-SEM or CB-SEM: Updated guidelines on which method to use. Int. J. Multivar. Data Anal. 2017, 1, 107–123. [Google Scholar] [CrossRef]

- Chin, W.W. Commentary: Issues and opinion on structural equation modeling. MIS Q. 1998, 22, vii–xvi. [Google Scholar]

- Adabre, M.A.; Chan, A.P.; Edwards, D.J.; Adinyira, E. Assessing Critical Risk Factors (CRFs) to Sustainable Housing: The Perspective of a sub-Saharan African Country. J. Build. Eng. 2021, 41, 102385. [Google Scholar] [CrossRef]

- Chin, W.W. The partial least squares approach to structural equation modeling. Mod. Methods Bus. Res. 1998, 295, 295–336. [Google Scholar]

- Cohen, J. Statistical Power for the Behavioural Sciences; Lawrence Erlbaum Associates Inc.: Mahwah, NJ, USA, 1988. [Google Scholar]

- Hair, J.F.; Ringle, C.M.; Sarstedt, M. PLS-SEM: Indeed a silver bullet. J. Mark. Theory Pract. 2011, 19, 139–152. [Google Scholar] [CrossRef]

- Lam, J.S.L.; Bai, X. A quality function deployment approach to improve maritime supply chain resilience. Transp. Res. Part E Logist. Transp. Rev. 2016, 92, 16–27. [Google Scholar] [CrossRef]

- Bhushan, U.; Aserkar, R.; Kumar, K.N.; Seetharaman, A. Effectiveness of Just In Time Manufacturing Practices. Int. J. Bus. Manag. Econ. Res. 2017, 8, 1109–1114. [Google Scholar]

- Katsaliaki, K.; Galetsi, P.; Kumar, S. Supply chain disruptions and resilience: A major review and future research agenda. Ann. Oper. Res. 2021, 319, 965–1002. [Google Scholar] [CrossRef]

- Choirun, A.; Santoso, I.; Astuti, R. Sustainability risk management in the agri-food supply chain: Literature review. IOP Conf. Ser. Earth Environ. Sci. 2020, 475, 012050. [Google Scholar] [CrossRef]

- Chowdhury, M.M.H.; Quaddus, M.A. Supply chain sustainability practices and governance for mitigating sustainability risk and improving market performance: A dynamic capability perspective. J. Clean. Prod. 2021, 278, 123521. [Google Scholar] [CrossRef]

- Rudestam, K.E.; Newton, R.R. Surviving Your Dissertation: A Comprehensive Guide to Content and Process; Sage Publications: Thousand Oaks, CA, USA, 2014. [Google Scholar]

- Tanko, B.L. Roadmap for Implementing Value Management in the Nigerian Construction Industry. Ph.D. Thesis, Faculty of Built Environment and Surveying, Universiti Technologi Malaysia, Johor Bahru, Malaysia, 2018. [Google Scholar]

- Bohari, A.A.M.; Skitmore, M.; Xia, B.; Teo, M.; Khalil, N. Key stakeholder values in encouraging green orientation of construction procurement. J. Clean. Prod. 2020, 270, 122246. [Google Scholar] [CrossRef]

- Chen, Q.; Feng, H.; de Soto, B.G. Revamping construction supply chain processes with circular economy strategies: A systematic literature review. J. Clean. Prod. 2021, 335, 130240. [Google Scholar] [CrossRef]

- Balasubramanian, S.; Shukla, V. Green supply chain management: An empirical investigation on the construction sector. Supply Chain Manag. Int. J. 2017, 22, 58–81. [Google Scholar] [CrossRef]

- Widding, L.O. Entrepreneurial knowledge management and sustainable opportunity creations: A conceptual framework. Int. J. Learn. Intellect. Cap. 2007, 4, 187–202. [Google Scholar]

- Ngah, R.; Abd Wahab, I.; Salleh, Z. The Sustainable Competitive Advantage of Small and Medium Entreprises (SMEs) with Intellectual Capital, Knowledge Management and Innovative Intelligence: Building a Conceptual Framework. Adv. Sci. Lett. 2015, 21, 1325–1328. [Google Scholar] [CrossRef]

- Ojo, E.; Mbowa, C.; Akinlabi, E.T. Barriers in implementing green supply chain management in construction industry. In Proceedings of the International Conference on Industrial Engineering and Operations Management, Bali, Indonesia, 7–9 January 2014. [Google Scholar]

- Mojumder, A.; Singh, A. An exploratory study of the adaptation of green supply chain management in construction industry: The case of Indian Construction Companies. J. Clean. Prod. 2021, 295, 126400. [Google Scholar] [CrossRef]

- Balasubramanian, S. A hierarchiacal framework of barriers to green supply chain management in the construction sector. J. Sustain. Dev. 2012, 5, 15–27. [Google Scholar] [CrossRef]

- Elbarkouky, M.; Abdelazeem, G. A green supply chain assessment for construction projects in developing countries. WIT Trans. Ecol. Environ. 2013, 179, 1331–1341. [Google Scholar]

- Alhamali, R.M. Critical success factors for green supply chain management practices: An empirical study on data collected from food processing companies in Saudi Arabia. Afr. J. Bus. Manag. 2019, 13, 160–167. [Google Scholar]

- Bhardwaj, B.R. Role of green policy on sustainable supply chain management. Benchmarking Int. J. 2016, 23, 456–468. [Google Scholar] [CrossRef]

- Paulraj, A.; Chen, I.J. Environmental uncertainty and strategic supply management: A resource dependence perspective and performance implications. J. Supply Chain Manag. 2007, 43, 29–42. [Google Scholar] [CrossRef]

- Lee, D. Implementation of collaborative activities for sustainable supply chain innovation: An analysis of the firm size effect. Sustainability 2019, 11, 3026. [Google Scholar] [CrossRef]

- Zhang, H.; Guo, F. Research on Partner Selection Issue of Manufacturing Enterprise under Supply Chain Environment. In Proceedings of the Emerging Research in Artificial Intelligence and Computational Intelligence, Taiyuan, China, 23–25 September 2011; pp. 230–238. [Google Scholar]

- Qader, G.; Shahid, Z.A.; Junaid, M.; Shaikh, I.M.; Qureshi, M.A. The role of diffusion of innovation theory towards the adoption of halal meat supply chain. J. Islam. Mark. 2022. ahead-of-print. [Google Scholar] [CrossRef]

- Vachon:, S.; Klassen, R.D. Extending green practices across the supply chain. Int. J. Oper. Prod. Manag. 2006, 26, 795–821. [Google Scholar] [CrossRef]

| Code | Enablers | Studies |

|---|---|---|

| En1 | Highest Organizational Support | [76,77] |

| En2 | Flexibility | [17,78] |

| En3 | Discernibility | [17,76,78,79] |

| En4 | Fitness | [77,80] |

| En5 | Affinity | [76,77] |

| En6 | Quality assurance | [81] |

| En7 | Receptiveness | [81,82] |

| En8 | High-tech Ability | [81,82,83] |

| En9 | Swiftness | [77,80] |

| En10 | Safe Keeping The Supply Chain | [80] |

| En11 | Partnership | [17,79] |

| En1 | Instant Faith | [77,78] |

| En13 | Revenue and Risk Sharing | [84,85] |

| En14 | Data Distribution | [86,87] |

| En15 | Elastic System | [82,88] |

| En16 | Philosophy of risk management | [81,82] |

| En17 | Data Safety | [89] |

| En18 | Tactical Risk Design | [75,90] |

| En19 | Commercial Communal | [91] |

| En20 | Accountability | [88,92] |

| En21 | Eventuality Design | [81] |

| En22 | Security Standard | [82] |

| En23 | Elastic Shipping | [81] |

| En24 | Supply Efficacy | [77,80] |

| En25 | Clearness | [81,82,83] |

| En26 | Self-Rule | [81] |

| En27 | Market Understanding | [86,87] |

| En28 | Firmness | [17,78] |

| En29 | Control | [17,76,78,79] |

| En30 | Reliability | [75,90] |

| En31 | Suitable Arrangement | [17,79] |

| En32 | Equanimity | [82] |

| Drivers | Initial | Extraction |

|---|---|---|

| DR1 | 1.000 | 0.723 |

| DR2 | 1.000 | 0.770 |

| DR3 | 1.000 | 0.804 |

| DR4 | 1.000 | 0.812 |

| DR5 | 1.000 | 0.651 |

| DR6 | 1.000 | 0.808 |

| DR7 | 1.000 | 0.891 |

| DR8 | 1.000 | 0.711 |

| DR9 | 1.000 | 0.812 |

| DR10 | 1.000 | 0.670 |

| DR11 | 1.000 | 0.793 |

| DR12 | 1.000 | 0.780 |

| DR13 | 1.000 | 0.770 |

| DR14 | 1.000 | 0.786 |

| DR15 | 1.000 | 0.784 |

| DR16 | 1.000 | 0.840 |

| DR17 | 1.000 | 0.818 |

| DR18 | 1.000 | 0.874 |

| DR19 | 1.000 | 0.814 |

| DR20 | 1.000 | 0.841 |

| DR21 | 1.000 | 0.706 |

| DR22 | 1.000 | 0.742 |

| DR23 | 1.000 | 0.805 |

| DR24 | 1.000 | 0.645 |

| DR25 | 1.000 | 0.707 |

| DR26 | 1.000 | 0.820 |

| DR27 | 1.000 | 0.713 |

| DR28 | 1.000 | 0.798 |

| DR29 | 1.000 | 0.774 |

| DR30 | 1.000 | 0.844 |

| DR31 | 1.000 | 0.704 |

| DR32 | 1.000 | 0.795 |

| Drivers | Components | ||||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | |

| D1 | 0.516 | ||||

| D2 | 0.743 | ||||

| D3 | 0.529 | ||||

| D4 | 0.788 | ||||

| D5 | 0.514 | ||||

| D6 | 0.549 | ||||

| D7 | 0.783 | ||||

| D8 | 0.507 | ||||

| D9 | 0.712 | ||||

| D10 | 0.694 | ||||

| D11 | 0.555 | ||||

| D12 | 0.653 | ||||

| D13 | 0.660 | ||||

| D14 | 0.666 | ||||

| D15 | 0.563 | ||||

| D16 | 0.765 | ||||

| D17 | 0.769 | ||||

| D18 | 0.783 | ||||

| D19 | 0.778 | ||||

| D20 | 0.706 | ||||

| D21 | 0.563 | ||||

| D22 | 0.614 | ||||

| D23 | 0.577 | ||||

| D24 | 0.540 | ||||

| D25 | 0.583 | ||||

| D26 | 0.685 | ||||

| D27 | 0.602 | ||||

| D28 | 0.576 | ||||

| D29 | 0.583 | ||||

| D30 | 0.514 | ||||

| D31 | 0.555 | ||||

| D32 | 0.612 | ||||

| Model Constructs | Cronbachs Alpha | Composite Reliability | Average Variance Extracted (AVE) |

|---|---|---|---|

| Compatibility | 0.826 | 0.884 | 0.658 |

| Knowledge | 0.951 | 0.959 | 0.748 |

| Management | 0.916 | 0.937 | 0.749 |

| OSS | 0.824 | 0.894 | 0.738 |

| Planning | 0.95 | 0.959 | 0.772 |

| collaboration | 0.87 | 0.911 | 0.72 |

| Constructs | Compatibility | Knowledge | Management | OSS | Planning | Collaboration |

|---|---|---|---|---|---|---|

| Compatibility | 0.811 | |||||

| Knowledge | 0.77 | 0.865 | ||||

| Management | 0.722 | 0.856 | 0.865 | |||

| OSS | 0.556 | 0.664 | 0.626 | 0.859 | ||

| Planning | 0.741 | 0.809 | 0.845 | 0.624 | 0.878 | |

| collaboration | 0.706 | 0.792 | 0.795 | 0.511 | 0.787 | 0.849 |

| Constructs | Compatibility | Knowledge | Management | OSS | Planning | Collaboration |

|---|---|---|---|---|---|---|

| Compatibility | ||||||

| Knowledge | 0.858 | |||||

| Management | 0.821 | 0.812 | ||||

| OSS | 0.642 | 0.739 | 0.706 | |||

| Planning | 0.817 | 0.847 | 0.8 | 0.697 | ||

| collaboration | 0.832 | 0.808 | 0.803 | 0.598 | 0.862 |

| Drivers | Compatibility | Knowledge | Management | Planning | Collaboration | OSS |

|---|---|---|---|---|---|---|

| D3 | 0.831 | 0.6 | 0.687 | 0.672 | 0.541 | 0.485 |

| D4 | 0.714 | 0.472 | 0.454 | 0.388 | 0.547 | 0.299 |

| D5 | 0.845 | 0.689 | 0.619 | 0.68 | 0.622 | 0.461 |

| D6 | 0.846 | 0.708 | 0.56 | 0.617 | 0.585 | 0.527 |

| D10 | 0.59 | 0.804 | 0.627 | 0.612 | 0.593 | 0.523 |

| D11 | 0.779 | 0.887 | 0.797 | 0.76 | 0.686 | 0.683 |

| D13 | 0.66 | 0.904 | 0.775 | 0.727 | 0.693 | 0.556 |

| D14 | 0.652 | 0.891 | 0.82 | 0.747 | 0.699 | 0.558 |

| D15 | 0.609 | 0.843 | 0.77 | 0.742 | 0.756 | 0.521 |

| D7 | 0.733 | 0.928 | 0.765 | 0.719 | 0.702 | 0.599 |

| D8 | 0.607 | 0.82 | 0.616 | 0.66 | 0.686 | 0.584 |

| D9 | 0.685 | 0.834 | 0.729 | 0.614 | 0.657 | 0.566 |

| D2 | 0.548 | 0.653 | 0.856 | 0.657 | 0.591 | 0.484 |

| D29 | 0.629 | 0.733 | 0.882 | 0.78 | 0.736 | 0.422 |

| D30 | 0.655 | 0.813 | 0.907 | 0.81 | 0.813 | 0.563 |

| D12 | 0.593 | 0.744 | 0.849 | 0.702 | 0.687 | 0.566 |

| D1 | 0.69 | 0.751 | 0.83 | 0.69 | 0.592 | 0.672 |

| D16 | 0.691 | 0.693 | 0.706 | 0.897 | 0.648 | 0.585 |

| D17 | 0.554 | 0.639 | 0.612 | 0.816 | 0.64 | 0.49 |

| D18 | 0.632 | 0.687 | 0.749 | 0.942 | 0.69 | 0.59 |

| D20 | 0.641 | 0.69 | 0.793 | 0.913 | 0.702 | 0.514 |

| D28 | 0.789 | 0.829 | 0.804 | 0.855 | 0.742 | 0.575 |

| D31 | 0.566 | 0.683 | 0.715 | 0.836 | 0.695 | 0.557 |

| D32 | 0.657 | 0.736 | 0.793 | 0.882 | 0.71 | 0.524 |

| D19 | 0.5 | 0.609 | 0.6 | 0.635 | 0.84 | 0.361 |

| D22 | 0.613 | 0.684 | 0.645 | 0.666 | 0.832 | 0.428 |

| D24 | 0.621 | 0.669 | 0.731 | 0.62 | 0.84 | 0.433 |

| D25 | 0.652 | 0.719 | 0.716 | 0.744 | 0.881 | 0.502 |

| Economics | 0.642 | 0.659 | 0.639 | 0.597 | 0.473 | 0.886 |

| Environmental | 0.387 | 0.545 | 0.523 | 0.539 | 0.402 | 0.874 |

| Social | 0.357 | 0.482 | 0.42 | 0.457 | 0.437 | 0.815 |

| Paths | B | Standard Deviation (STDEV) | T Statistics | p Values |

|---|---|---|---|---|

| Compatibility -> SCSC Implementation | 0.105 | 0.016 | 6.723 | 0 |

| Knowledge -> SCSC Implementation | 0.353 | 0.025 | 13.893 | 0 |

| Management -> SCSC Implementation | 0.221 | 0.017 | 12.755 | 0 |

| Planning -> SCSC Implementation | 0.257 | 0.024 | 10.812 | 0 |

| collaboration -> SCSC Implementation | 0.15 | 0.018 | 8.214 | 0 |

| Exogenous Latent Variable | R2 | Adj R2 | Explained Size |

|---|---|---|---|

| OSS | 0.445 | 0.445 | Moderate-High |

| Endogenous Latent Variable | SSO | SSE | Q2 (=1 − SSE/SSO) |

| Indicators of Project Success | 177.000 | 121.996 | 0.311 |

| Predictor | Significance | Performance |

|---|---|---|

| SCSC drivers execution | 1.2 | 67.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Attia, E.-A.; Alarjani, A.; Uddin, M.S.; Kineber, A.F. Examining the Influence of Sustainable Construction Supply Chain Drivers on Sustainable Building Projects Using Mathematical Structural Equation Modeling Approach. Sustainability 2023, 15, 10671. https://doi.org/10.3390/su151310671

Attia E-A, Alarjani A, Uddin MS, Kineber AF. Examining the Influence of Sustainable Construction Supply Chain Drivers on Sustainable Building Projects Using Mathematical Structural Equation Modeling Approach. Sustainability. 2023; 15(13):10671. https://doi.org/10.3390/su151310671

Chicago/Turabian StyleAttia, El-Awady, Ali Alarjani, Md. Sharif Uddin, and Ahmed Farouk Kineber. 2023. "Examining the Influence of Sustainable Construction Supply Chain Drivers on Sustainable Building Projects Using Mathematical Structural Equation Modeling Approach" Sustainability 15, no. 13: 10671. https://doi.org/10.3390/su151310671

APA StyleAttia, E.-A., Alarjani, A., Uddin, M. S., & Kineber, A. F. (2023). Examining the Influence of Sustainable Construction Supply Chain Drivers on Sustainable Building Projects Using Mathematical Structural Equation Modeling Approach. Sustainability, 15(13), 10671. https://doi.org/10.3390/su151310671