Optimizing Perishable Product Supply Chain Network Using Hybrid Metaheuristic Algorithms

Abstract

1. Introduction

- Formulating a novel LIRP model that addresses the design of a multi-period, multi-product PPSCN while simultaneously considering damage in the inventory and transportation processes, as well as specific shelf life;

- Developing two hybrid metaheuristic algorithms: hybrid GA and VNS (HGA-VNS) and hybrid MPGA and VNS (HMP-GA-VNS) to search for optimal solutions;

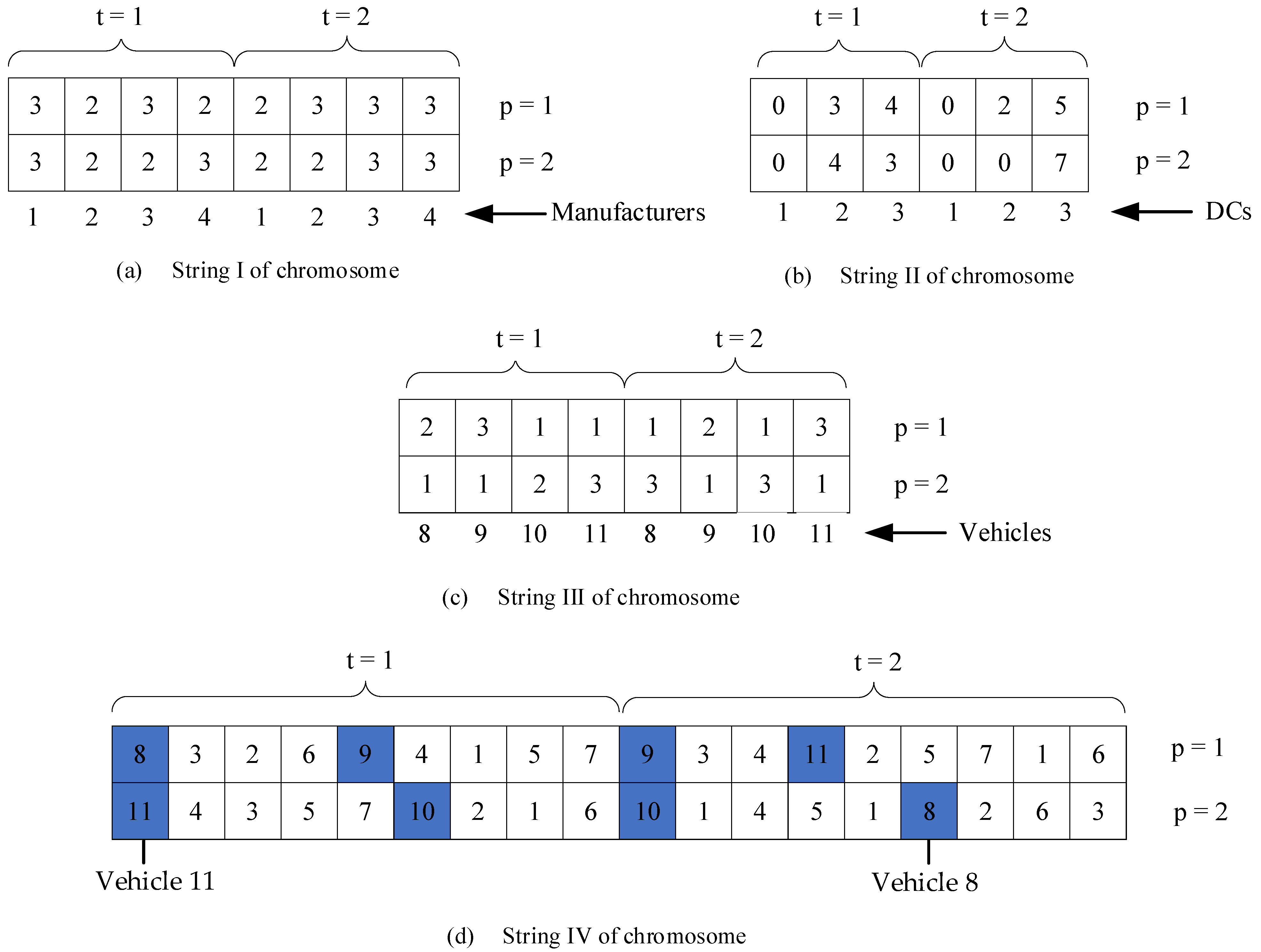

- Designing a new chromosome representation for the unique structure of the problem;

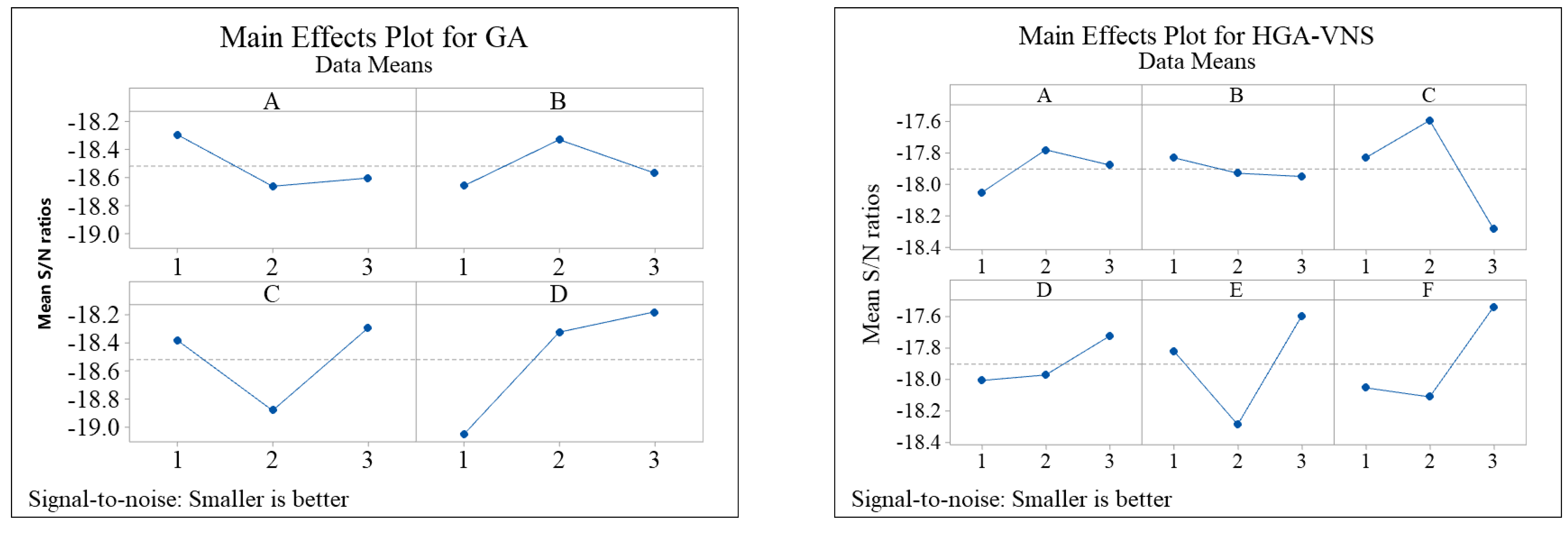

- Employing the Taguchi experimental design method and conducting means and analysis of variance to assess the effectiveness of the developed hybrid metaheuristic algorithms;

- Conducting sensitivity analysis to validate the proposed model.

2. Problem Description

2.1. Assumptions

- Each retailer is served by one vehicle for one perishable product at any period.

- The demands of retailers are independent and follow specific probability distributions.

- Each product in the system has a predetermined shelf life.

- The number of DCs and their capacities are limited.

- The vehicle routing problem is specifically defined between the DCs and retailers.

- The number and capacity of vehicles are predetermined.

- Shortage considerations are not included.

2.2. Notation

| at manufacturer | |

| The waste rate during the transportation process in all systems | |

| M | A sufficiently large number |

| is operated; 0, otherwise | |

| ; 0, otherwise | |

| ; 0, otherwise | |

| ; 0, otherwise | |

| ; 0, otherwise | |

| 1, if perishable product p is procured during period m and delivered out from DC j during period t; 0, otherwise | |

| Auxiliary non-negative variable used for subtour elimination |

2.3. Mathematical Model

3. Solution Algorithms

3.1. Key Element Design of Hybrid Metaheuristic Algorithms

3.1.1. Chromosome Representation

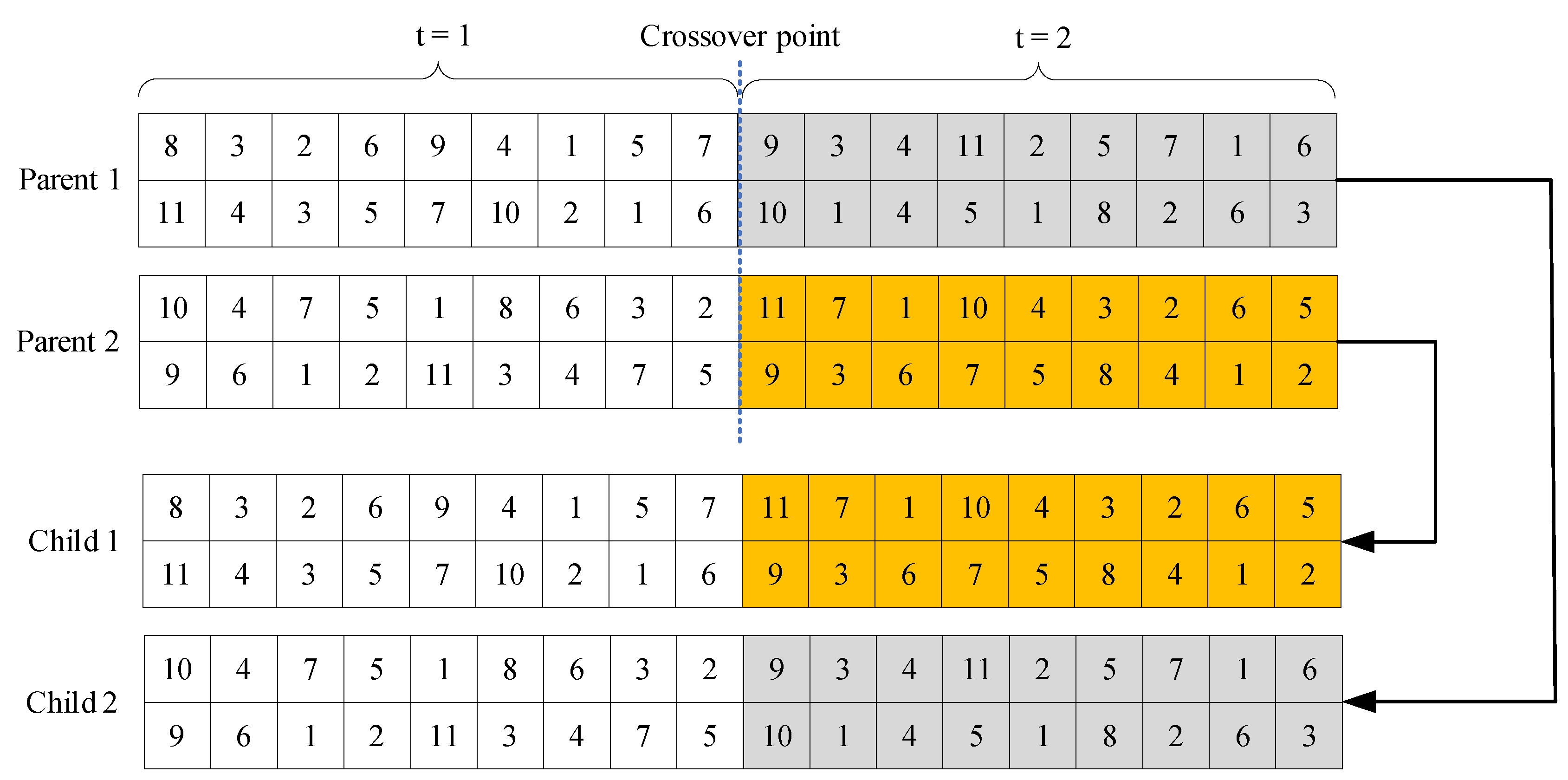

3.1.2. Crossover

- (1)

- Single-point crossover is employed in this study. Specifically, crossovers are applied to String II of the chromosome. Following the approach proposed by Hiassat et al. [28], the crossover points are selected from a valid crossover set, which consists of boundary points between each period.

- (2)

- A pair of chromosomes is randomly chosen from the set.

- (3)

- Segmentation is performed, and the right-hand side of the chromosomes is exchanged at the randomly selected location point.

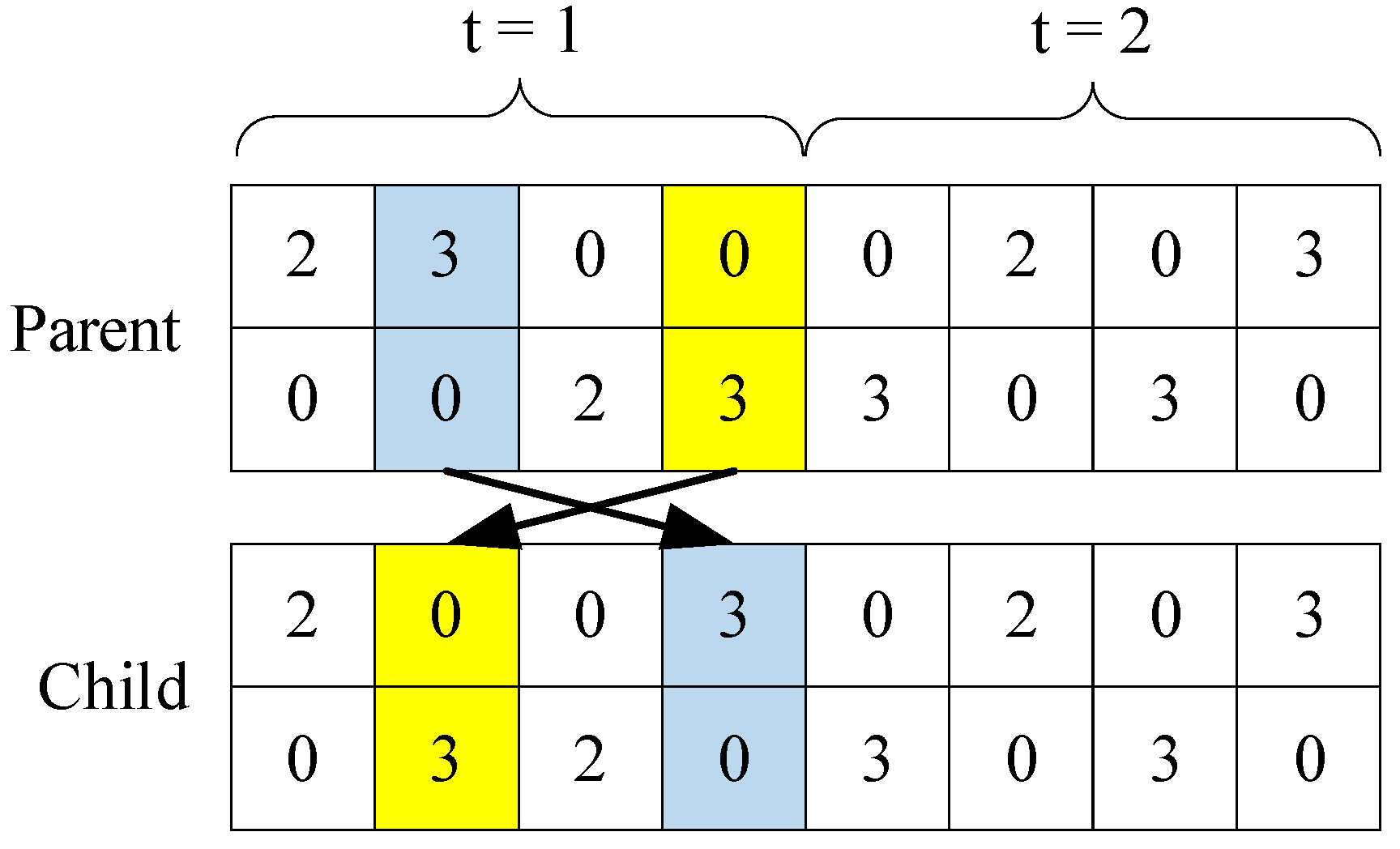

3.1.3. Mutation

3.1.4. Infeasible Solution Repair Mechanisms

3.2. Variable Neighborhood Search Algorithm

| Algorithm 1: Pseudocode of VNS | |

| 1 | Initialization |

| Parameters: maximum iterations of VNS (Maxiter), neighbourhood structures size | |

| Receive/generate population with size P and assess them | |

| Pick up the best solution as initial solution | |

| 2 | For iterMaxiter do |

| 3 | For do |

| 4 | = shaking ( |

| 5 | X″ = local search ( |

| 6 | If |

| 7 | |

| 8 | l = 1; |

| 9 | Else |

| 10 | l = l + 1; |

| 11 | End if |

| 12 | End for |

| 13 | End for |

| 14 | Report the best solution; |

| 15 | End |

3.3. HGA-VNS Algorithm

| Algorithm 2: Pseudocode of HGA-VNS | |

| Step 1: | Initialization |

| Step 1.1: Set parameters: population size (), maximum iterations (), crossover rate (), mutation rate () | |

| Step 1.2: Generate individuals using the coding mechanism to form the initial population | |

| Step 2: | Calculation of individual fitness values () |

| Step 3: | Select operation () |

| Step 4: | Crossover operation () |

| Step 5: | Mutation operation () |

| Step 6: | Repairing operation () |

| Step 7: | VNS local search () |

| Step 8: | Repeat steps 2 to 7 until the maximum iterations of the GA are reached |

| Step 9: | Final solution () |

3.4. HMPGA-VNS Algorithm

| Algorithm 3: Pseudocode of HMPGA-VNS | |

| Step 1: | Initialization |

| Step 1.1: Set parameters: population size (), subpopulation size (), maximum iterations (), crossover rate (), mutation rate (), migration period (), migration size (). | |

| Step 1.2: Generate individuals according to the coding mechanism to form the initial population, which is then divided into P/SP subpopulations. | |

| Step 2: | Evolutionary operations for each subpopulation (same as GA, but operated independently): |

| Step 2.1: Perform selection operation within each subpopulation (). | |

| Step 2.2: Conduct crossover operation within each subpopulation (). | |

| Step 2.3: Perform mutation operation within each subpopulation (). | |

| Step 3: | Perform repairing operation within each subpopulation (). |

| Step 4: | Calculate individual fitness values within each subpopulation (). |

| Select individuals with better fitness values as representatives of each subpopulation (). | |

| Step 5: | Perform migration operation for representatives among subpopulations (). |

| Step 6: | Merge the subpopulations (). |

| Step 7: | Apply VNS local search (). |

| Step 8: | Repeat steps 2 to 7 until the maximum iterations of MPGA are reached. |

| Step 9: | Obtain the final solution (). |

4. Computation Results

4.1. Instances

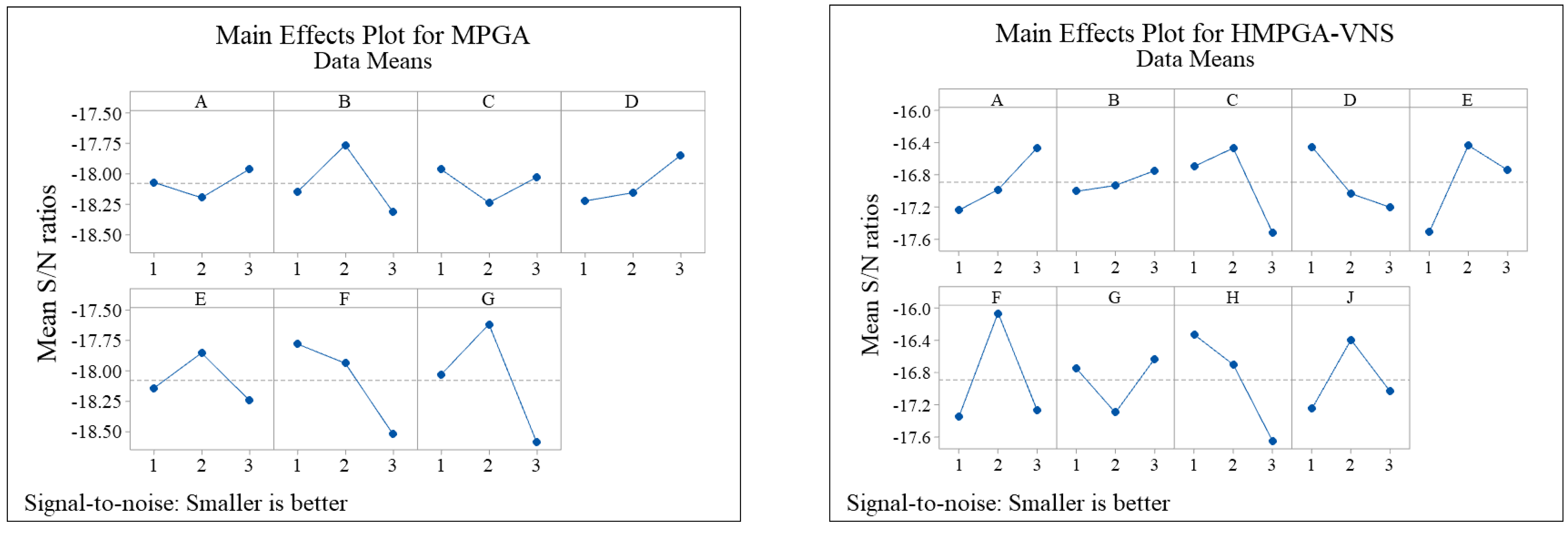

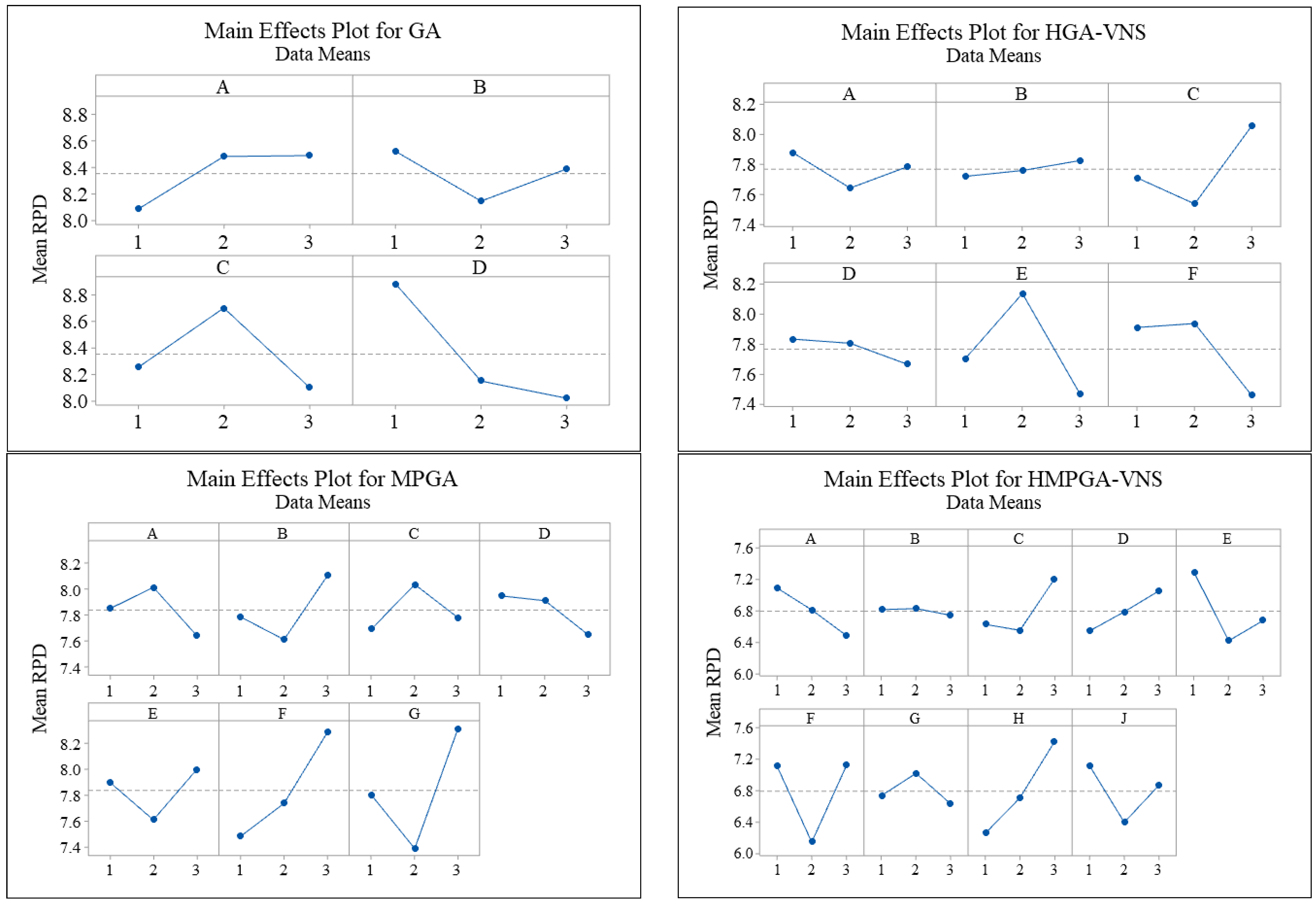

4.2. Parameters Setting

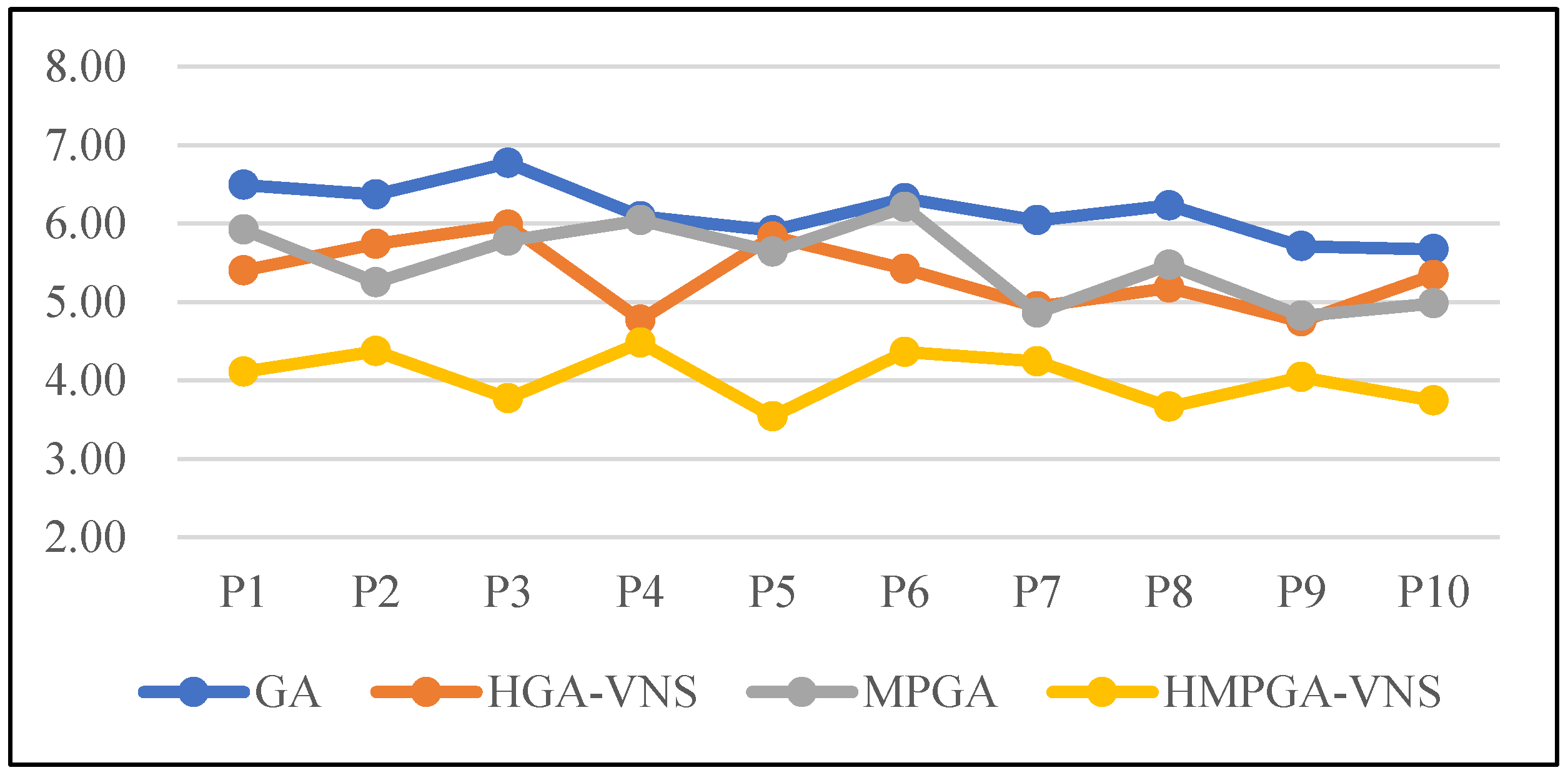

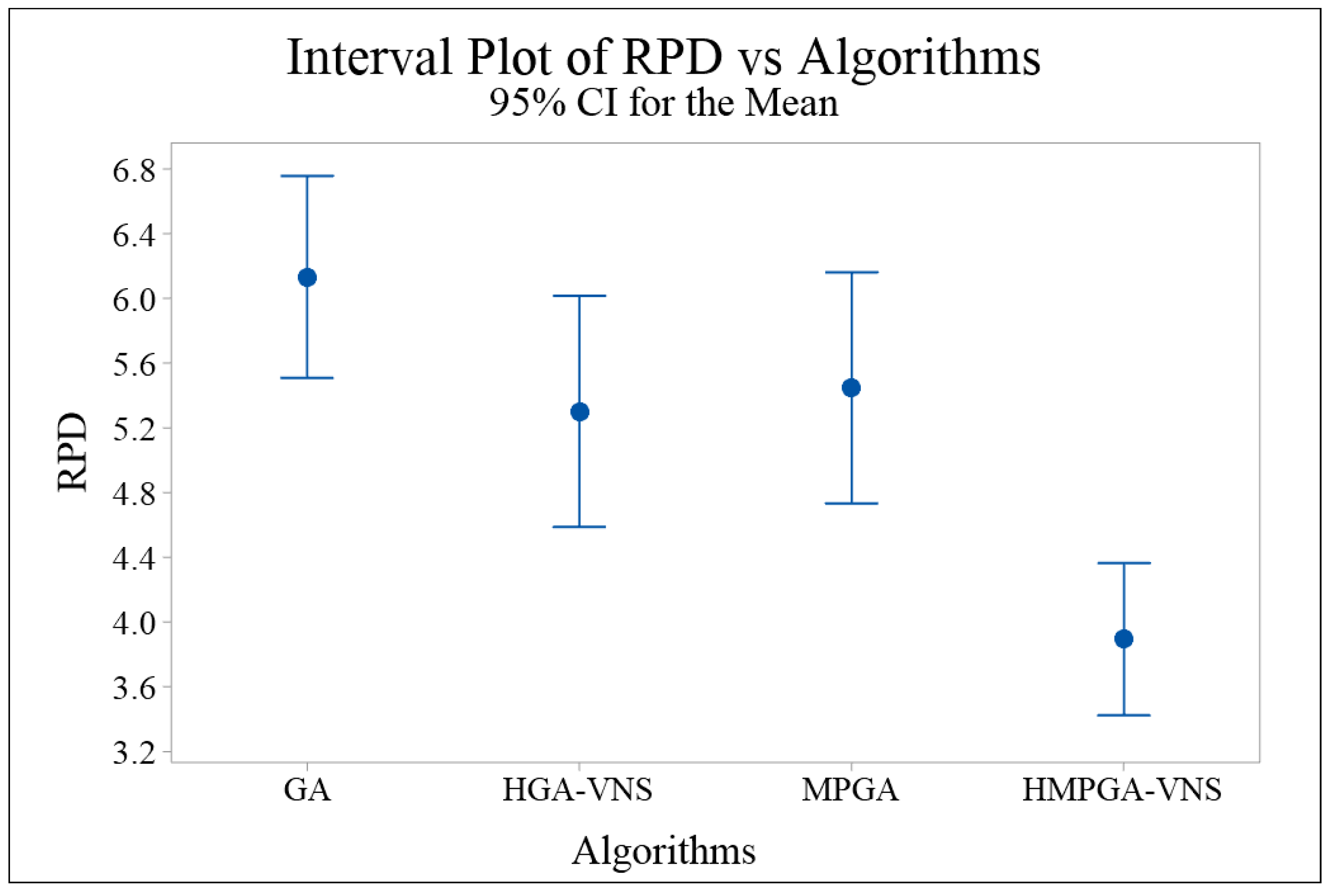

4.3. Experimental Results

4.4. Sensitivity Analysis

4.5. Managerial Implications

5. Conclusions, Limitations, and Future Works

- In terms of the absence of an official dataset, randomly generated data were employed to conduct an experimental analysis. This approach may not fully represent real-world scenarios.

- Like many other metaheuristic algorithms, the proposed algorithms in this study often lack theoretical guarantees or bounds on their performance. It can be challenging to evaluate the quality of solutions obtained or predict the behavior of the algorithms across different problem instances.

- The effectiveness of the hybrid metaheuristic approaches presented in this paper relies on the coder’s proficiency in finding the initial solution.

- Enhancing the reliability and validity of the findings by incorporating realistic scenario datasets that are relevant to the PPSCN.

- Exploring the exact methods such as the Lagrangian relaxation methods or Benders decomposition to achieve more precise results.

- Investigating the application of new metaheuristic algorithms or developing novel heuristics to further optimize the results.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ferguson, M.; Ketzenberg, M.E. Information sharing to improve retail product freshness of perishables. Prod. Oper. Manag. 2006, 15, 57–73. [Google Scholar] [CrossRef]

- Roberti, M.; Scheer, F.P. RFID will help keep perishables fresh. RFID J. 2005. Available online: http://www.rfidjournal.com/article/articleview/1775/1/1/ (accessed on 12 June 2023).

- Dai, Z.; Aqlan, F.; Zheng, X.T.; Gao, K. A location-inventory supply chain network model using two heuristic algorithms for perishable products with fuzzy constraints. Comput. Ind. Eng. 2018, 119, 338–352. [Google Scholar] [CrossRef]

- Jia, P.; Dong, Z. Analyses on the Way of Changing the Growth Mode of Circulation Economy. Asian Soc. Sci. 2009, 5, 53. [Google Scholar] [CrossRef]

- Liu, A.J.; Zhu, Q.Y.; Xu, L.; Lu, Q.; Fan, Y.Q. Sustainable supply chain management for perishable products in emerging markets: An integrated location-inventory-routing model. Transp. Res. Part E Logist. Transp. Rev. 2021, 150, 19. [Google Scholar] [CrossRef]

- Meidute-Kavaliauskiene, I.; Yildirim, F.; Ghorbani, S.; Cincikaite, R. The Design of a Multi-Period and Multi-Echelon Perishable Goods Supply Network under Uncertainty. Sustainability 2022, 14, 2472. [Google Scholar] [CrossRef]

- Akram, H.W.; Akhtar, S.; Ahmad, A.; Anwar, I.; Sulaiman, M. Developing a Conceptual Framework Model for Effective Perishable Food Cold-Supply-Chain Management Based on Structured Literature Review. Sustainability 2023, 15, 4907. [Google Scholar] [CrossRef]

- Liu, L.H.; Lee, L.S.; Seow, H.V.; Chen, C.Y. Logistics Center Location-Inventory-Routing Problem Optimization: A Systematic Review Using PRISMA Method. Sustainability 2022, 14, 15853. [Google Scholar] [CrossRef]

- Ali, S.; Bhargava, A.; Saxena, A.; Kumar, P. A Hybrid Marine Predator Sine Cosine Algorithm for Parameter Selection of Hybrid Active Power Filter. Mathematics 2023, 11, 598. [Google Scholar] [CrossRef]

- Govindan, K.; Jafarian, A.; Nourbakhsh, V. Designing a sustainable supply chain network integrated with vehicle routing: A comparison of hybrid swarm intelligence metaheuristics. Comput. Oper. Res. 2019, 110, 220–235. [Google Scholar] [CrossRef]

- Goodarzian, F.; Taleizadeh, A.A.; Ghasemi, P.; Abraham, A. An integrated sustainable medical supply chain network during COVID-19. Eng. Appl. Artif. Intell. 2021, 100, 104188. [Google Scholar] [CrossRef]

- Wu, T.; Shen, H.C.; Zhu, C. A multi-period location model with transportation economies-of-scale and perishable inventory. Int. J. Prod. Econ. 2015, 169, 343–349. [Google Scholar] [CrossRef]

- Gholami-Zanjani, S.M.; Jabalameli, M.S.; Klibi, W.; Pishvaee, M.S. A robust location-inventory model for food supply chains operating under disruptions with ripple effects. Int. J. Prod. Res. 2021, 59, 301–324. [Google Scholar] [CrossRef]

- Savadkoohi, E.; Mousazadeh, M.; Torabi, S.A. A possibilistic location-inventory model for multi-period perishable pharmaceutical supply chain network design. Chem. Eng. Res. Des. 2018, 138, 490–505. [Google Scholar] [CrossRef]

- Hamdan, B.; Diabat, A. A two-stage multi-echelon stochastic blood supply chain problem. Comput. Oper. Res. 2019, 101, 130–143. [Google Scholar] [CrossRef]

- Liu, M.; Tang, H.; Wang, Y.F.; Li, R.X.; Liu, Y.; Liu, X.; Wang, Y.Q.; Wu, Y.Y.; Wu, Y.; Sun, Z.J. Enhancing Food Supply Chain in Green Logistics with Multi-Level Processing Strategy under Disruptions. Sustainability 2023, 15, 917. [Google Scholar] [CrossRef]

- Coelho, L.C.; Laporte, G. Optimal joint replenishment, delivery and inventory management policies for perishable products. Comput. Oper. Res. 2014, 47, 42–52. [Google Scholar] [CrossRef]

- Diabat, A.; Abdallah, T.; Le, T. A hybrid tabu search based heuristic for the periodic distribution inventory problem with perishable goods. Ann. Oper. Res. 2016, 242, 373–398. [Google Scholar] [CrossRef]

- Le, T.; Diabat, A.; Richard, J.P.; Yih, Y. A column generation-based heuristic algorithm for an inventory routing problem with perishable goods. Optim. Lett. 2013, 7, 1481–1502. [Google Scholar] [CrossRef]

- Dai, Z.; Gao, K.; Giri, B.C. A hybrid heuristic algorithm for cyclic inventory-routing problem with perishable products in VMI supply chain. Expert Syst. Appl. 2020, 153, 113322. [Google Scholar] [CrossRef]

- Azadeh, A.; Elahi, S.; Farahani, M.H.; Nasirian, B. A genetic algorithm-Taguchi based approach to inventory routing problem of a single perishable product with transshipment. Comput. Ind. Eng. 2017, 104, 124–133. [Google Scholar] [CrossRef]

- Rohmer, S.U.K.; Claassen, G.D.H.; Laporte, G. A two-echelon inventory routing problem for perishable products. Comput. Oper. Res. 2019, 107, 156–172. [Google Scholar] [CrossRef]

- Wu, X.; Nie, L.; Xu, M. Designing an integrated distribution system for catering services for high-speed railways: A three-echelon location routing model with tight time windows and time deadlines. Transp. Res. Part C Emerg. Technol. 2017, 74, 212–244. [Google Scholar] [CrossRef]

- Zhu, S.X.; Ursavas, E. Design and analysis of a satellite network with direct delivery in the pharmaceutical industry. Transp. Res. Part E Logist. Transp. Rev. 2018, 116, 190–207. [Google Scholar] [CrossRef]

- Chen, C.; Tian, Z.; Yao, B. Optimization of two-stage location–routing–inventory problem with time-windows in food distribution network. Ann. Oper. Res. 2019, 273, 111–134. [Google Scholar] [CrossRef]

- Zandkarimkhani, S.; Mina, H.; Biuki, M.; Govindan, K. A chance constrained fuzzy goal programming approach for perishable pharmaceutical supply chain network design. Ann. Oper. Res. 2020, 295, 425–452. [Google Scholar] [CrossRef]

- Rafie-Majd, Z.; Pasandideh, S.H.R.; Naderi, B. Modelling and solving the integrated inventory-location-routing problem in a multi-period and multi-perishable product supply chain with uncertainty: Lagrangian relaxation algorithm. Comput. Chem. Eng. 2018, 109, 9–22. [Google Scholar] [CrossRef]

- Hiassat, A.; Diabat, A.; Rahwan, I. A genetic algorithm approach for location-inventory-routing problem with perishable products. J. Manuf. Syst. 2017, 42, 93–103. [Google Scholar] [CrossRef]

- Partovi, F.; Seifbarghy, M.; Esmaeili, M. Revised solution technique for a bi-level location-inventory-routing problem under uncertainty of demand and perishability of products. Appl. Soft. Comput. 2023, 133, 109899. [Google Scholar] [CrossRef]

- Aghighi, A.; Goli, A.; Malmir, B.; Tirkolaee, E.B. The stochastic location-routing-inventory problem of perishable products with reneging and balking. J. Ambient. Intell. Humaniz. Comput. 2021, 14, 6497–6516. [Google Scholar] [CrossRef]

- Biuki, M.; Kazemi, A.; Alinezhad, A. An integrated location-routing-inventory model for sustainable design of a perishable products supply chain network. J. Clean. Prod. 2020, 260, 120842. [Google Scholar] [CrossRef]

- Mladenovi, N.; Hansen, P.J.C.; Research, O. Variable Neighborhood Search. Comput. Oper. Res 1997, 24, 1097–1100. [Google Scholar] [CrossRef]

- Rath, S.; Gutjahr, W.J. A math-heuristic for the warehouse location-routing problem in disaster relief. Comput. Oper. Res. 2014, 42, 25–39. [Google Scholar] [CrossRef]

- Almouhanna, A.; Quintero-Araujo, C.L.; Panadero, J.; Juan, A.A.; Khosravi, B.; Ouelhadj, D. The location routing problem using electric vehicles with constrained distance. Comput. Oper. Res. 2020, 115, 104864. [Google Scholar] [CrossRef]

- Zhao, C.X.; Chen, J.H.; Zhang, X.C.; Cui, Z.Y. Solution of Multi-Crew Depots Railway Crew Scheduling Problems: The Chinese High-Speed Railway Case. Sustainability 2022, 14, 491. [Google Scholar] [CrossRef]

- Zegordi, S.H.; Nia, M.A.B. A multi-population genetic algorithm for transportation scheduling. Transp. Res. Part E Logist. Transp. Rev. 2009, 45, 946–959. [Google Scholar] [CrossRef]

- Cochran, J.K.; Horng, S.M.; Fowler, J.W. A multi-population genetic algorithm to solve multi-objective scheduling problems for parallel machines. Comput. Oper. Res. 2003, 30, 1087–1102. [Google Scholar] [CrossRef]

- Pourvaziri, H.; Naderi, B. A hybrid multi-population genetic algorithm for the dynamic facility layout problem. Appl. Soft. Comput. 2014, 24, 457–469. [Google Scholar] [CrossRef]

- Wang, T.; Wang, Q.Y.; Zhang, C.Q. Research on the Optimal Operation of a Novel Renewable Multi-Energy Complementary System in Rural Areas. Sustainability 2021, 13, 2196. [Google Scholar] [CrossRef]

- Hajiaghaei-Keshteli, M.; Molla-Alizadeh-Zavardehi, S.; Tavakkoli-Moghaddam, R. Addressing a nonlinear fixed-charge transportation problem using a spanning tree-based genetic algorithm. Comput. Ind. Eng. 2010, 59, 259–271. [Google Scholar] [CrossRef]

- Tavana, M.; Santos-Arteaga, F.J.; Mahmoodirad, A.; Niroomand, S.; Sanei, M. Multi-stage supply chain network solution methods: Hybrid metaheuristics and performance measurement. Int. J. Syst. Sci. Oper. Logist. 2018, 5, 356–373. [Google Scholar] [CrossRef]

| Reference | Problem | Assumptions | Solution Methods | ||||

|---|---|---|---|---|---|---|---|

| LIRP | Multi-Product | Multi-Period | Damage in Inventory Process | Damage in Transportation Process | Specific Shelf Life | ||

| Chen et al. (2019) [25] | √ | - | - | - | √ | - | Hybrid heuristic |

| Zandkarimkhani et al. (2020) [26] | √ | √ | √ | - | - | - | Hybrid approach |

| Rafie-Majd et al. (2018) [27] | √ | √ | √ | √ | - | √ | Lagrangian relaxation algorithm |

| Hiassat et al. (2017) [28] | √ | - | √ | - | - | - | GA |

| Partovi et al. (2023) [29] | √ | - | √ | - | - | - | Revised solution technique |

| Aghighi et al. (2021) [30] | √ | - | - | - | - | - | Improved GA |

| Biuki et al. (2020) [31] | √ | √ | √ | - | - | √ | Hybrid GA-PSO |

| Liu et al. (2021) [5] | √ | √ | √ | - | - | - | YALMIP toolbox |

| This study | √ | √ | √ | √ | √ | √ | Hybrid GA-VNS, hybrid MPGA-VNS |

| Parameter | Range | Parameter | Range | Parameter | Range |

|---|---|---|---|---|---|

| 105 U (3.0, 4.0) | 105 U (1.5, 2.0) | U (30, 50) | |||

| U (80, 100) | U (0.4, 0.5) | U (30, 60) | |||

| U (0.2, 0.3) | U (30, 40) | U (200, 300) | |||

| U (1000, 1500) | % U (10, 30) | U (3, 5) |

| Instance No. | |I| – |J| – |K| – |P| – |V| – |T| | Instance No. | |I| – |J| – |K| – |P| – |V| – |T| |

|---|---|---|---|

| P1 | 2 – 2 – 5 – 2 – 2 – 2 | P6 | 3 – 4 – 18 – 4 – 4 – 4 |

| P2 | 2 – 2 – 8 – 2 – 2 – 2 | P7 | 3 – 5 – 20 – 5 – 5 – 5 |

| P3 | 2 – 3 – 10 – 3 – 3 – 3 | P8 | 3 – 5 – 25 – 5 – 5 – 5 |

| P4 | 2 – 3 – 12 – 3 – 3 – 3 | P9 | 3 – 6 – 30 – 6 – 6 – 6 |

| P5 | 2 – 4 – 15 – 4 – 4 – 4 | P10 | 3 – 6 – 37 – 6 – 6 – 6 |

| GA Factors | GA Levels | HGA-VNS Factors | HGA-VNS Levels |

| A1: 120 A2: 240 A3: 360 | A1: 120 A2: 240 A3: 360 | ||

| B1: 400 B2: 600 B3: 800 | B1: 400 B2: 600 B3: 800 | ||

| C1: 0.70 C2: 0.75 C3: 0.80 | C1: 0.70 C2: 0.75 C3: 0.80 | ||

| D1: 0.10 D2: 0.15 D3: 0.20 | D1: 0.10 D2: 0.15 D3: 0.20 | ||

| Maxiter | E1: 100 E2: 200 E3: 300 | ||

| F1: 3 F2: 4 F3: 5 | |||

| MPGA Factors | MPGA Levels | HMPGA-VNS Factors | HMPGA-VNS Levels |

| A1: 120 A2: 240 A3: 360 | A1: 120 A2: 240 A3: 360 | ||

| B1: 400 B2: 600 B3: 800 | B1: 400 B2: 600 B3: 800 | ||

| C1: 0.70 C2: 0.75 C3: 0.80 | C1: 0.70 C2: 0.75 C3: 0.80 | ||

| D1: 0.10 D2: 0.15 D3: 0.20 | D1: 0.10 D2: 0.15 D3: 0.20 | ||

| E1: 20 E2: 30 E3: 40 | E1: 20 E2: 30 E3: 40 | ||

| F1: 10 F2: 20 F3: 40 | F1: 10 F2: 20 F3: 40 | ||

| G1: 4 G2: 6 G3: 8 | G1: 4 G2: 6 G3: 8 | ||

| Maxiter | H1: 100 H2: 200 H: 300 | ||

| I1: 3 I2: 4 I3: 5 |

| L9 | A | B | C | D |

|---|---|---|---|---|

| 1 | 1 | 1 | 1 | 1 |

| 2 | 1 | 2 | 2 | 2 |

| 3 | 1 | 3 | 3 | 3 |

| 4 | 2 | 1 | 2 | 3 |

| 5 | 2 | 2 | 3 | 1 |

| 6 | 2 | 3 | 1 | 2 |

| 7 | 3 | 1 | 3 | 2 |

| 8 | 3 | 2 | 1 | 3 |

| 9 | 3 | 3 | 2 | 1 |

| Change of Demand | −40% | −20% | Base Case | 20% | 40% |

|---|---|---|---|---|---|

| Objective value | 12,354,318.19 | 15,789,639.54 | 19,452,555.80 | 23,154,377.17 | 27,177,165.7 |

| Sensitivity (%) | −36.49 | −18.83 | 0 | 19.03 | 39.71 |

| Product Shelf Life | 2 | 3 | Base Case | 5 | 6 |

|---|---|---|---|---|---|

| Objective value | 19,966,103.27 | 19,645,136.10 | 19,452,555.80 | 19,263,866.00 | 19,176,329.51 |

| Sensitivity (%) | 2.64 | 0.99 | 0 | −0.97 | −1.42 |

| Change of Waste Rate | −40% | −20% | Base Case | 20% | 40% |

|---|---|---|---|---|---|

| Objective value | 18,318,471.79 | 18,865,088.61 | 19,452,555.80 | 20,242,329.57 | 21,255,807.72 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pan, L.; Shan, M.; Li, L. Optimizing Perishable Product Supply Chain Network Using Hybrid Metaheuristic Algorithms. Sustainability 2023, 15, 10711. https://doi.org/10.3390/su151310711

Pan L, Shan M, Li L. Optimizing Perishable Product Supply Chain Network Using Hybrid Metaheuristic Algorithms. Sustainability. 2023; 15(13):10711. https://doi.org/10.3390/su151310711

Chicago/Turabian StylePan, Lihong, Miyuan Shan, and Linfeng Li. 2023. "Optimizing Perishable Product Supply Chain Network Using Hybrid Metaheuristic Algorithms" Sustainability 15, no. 13: 10711. https://doi.org/10.3390/su151310711

APA StylePan, L., Shan, M., & Li, L. (2023). Optimizing Perishable Product Supply Chain Network Using Hybrid Metaheuristic Algorithms. Sustainability, 15(13), 10711. https://doi.org/10.3390/su151310711