Experimental Investigation on Thermal Conductivity of Straw Boards Based on the Temperature Control Box—Heat Flux Meter Method

Abstract

1. Introduction

2. Experimental Program

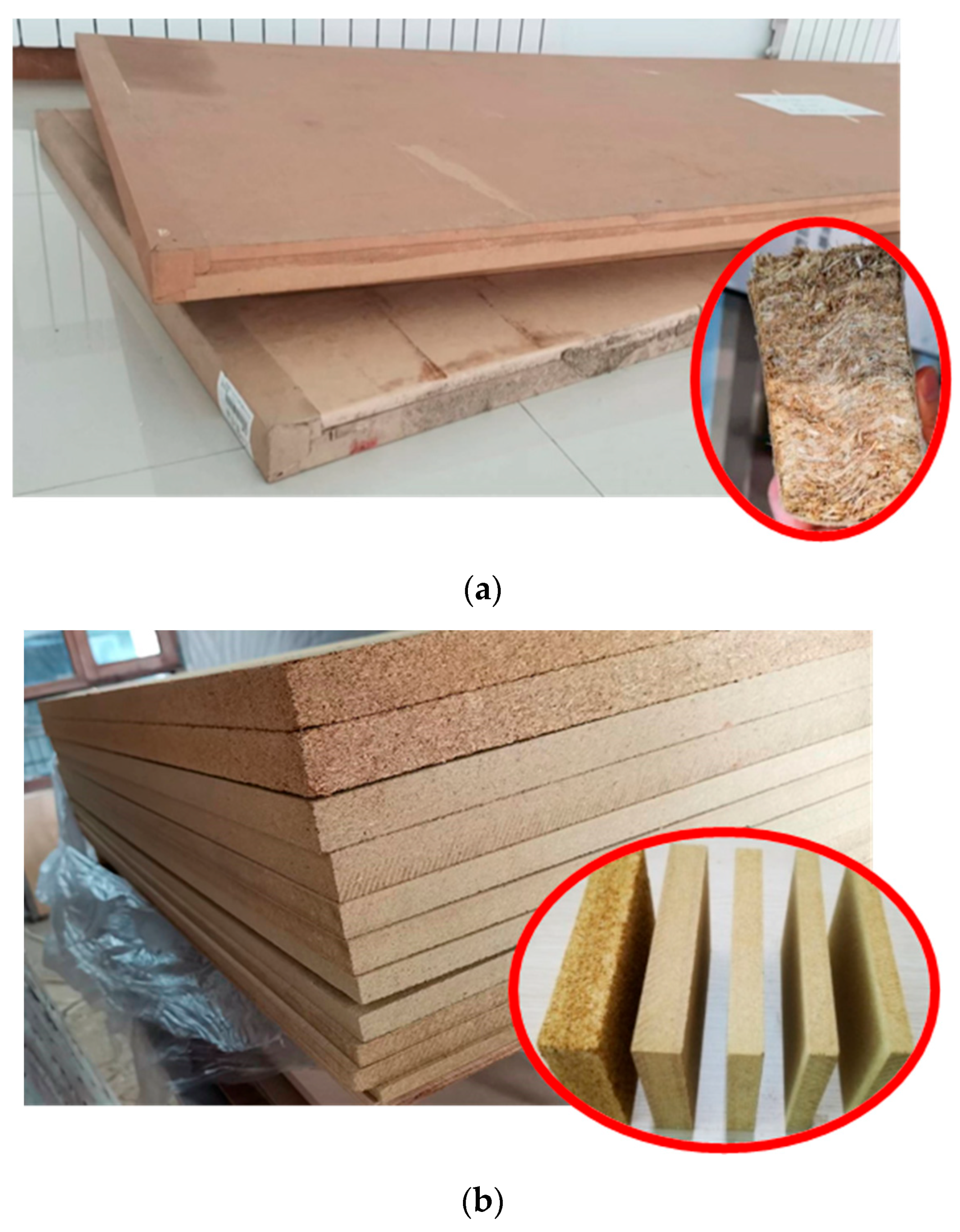

2.1. Test Specimens

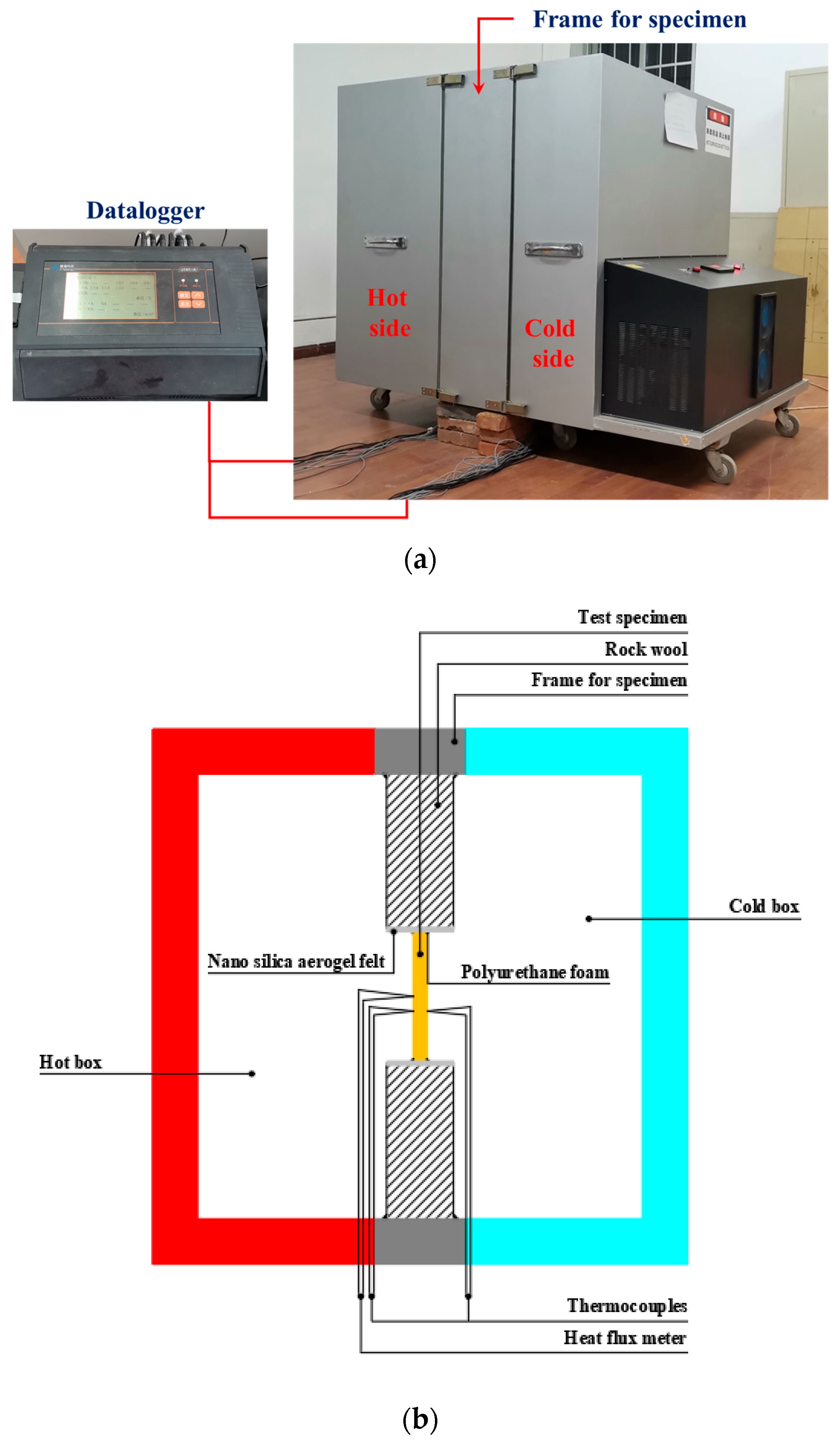

2.2. Test Method and Apparatus

3. Experimental Results

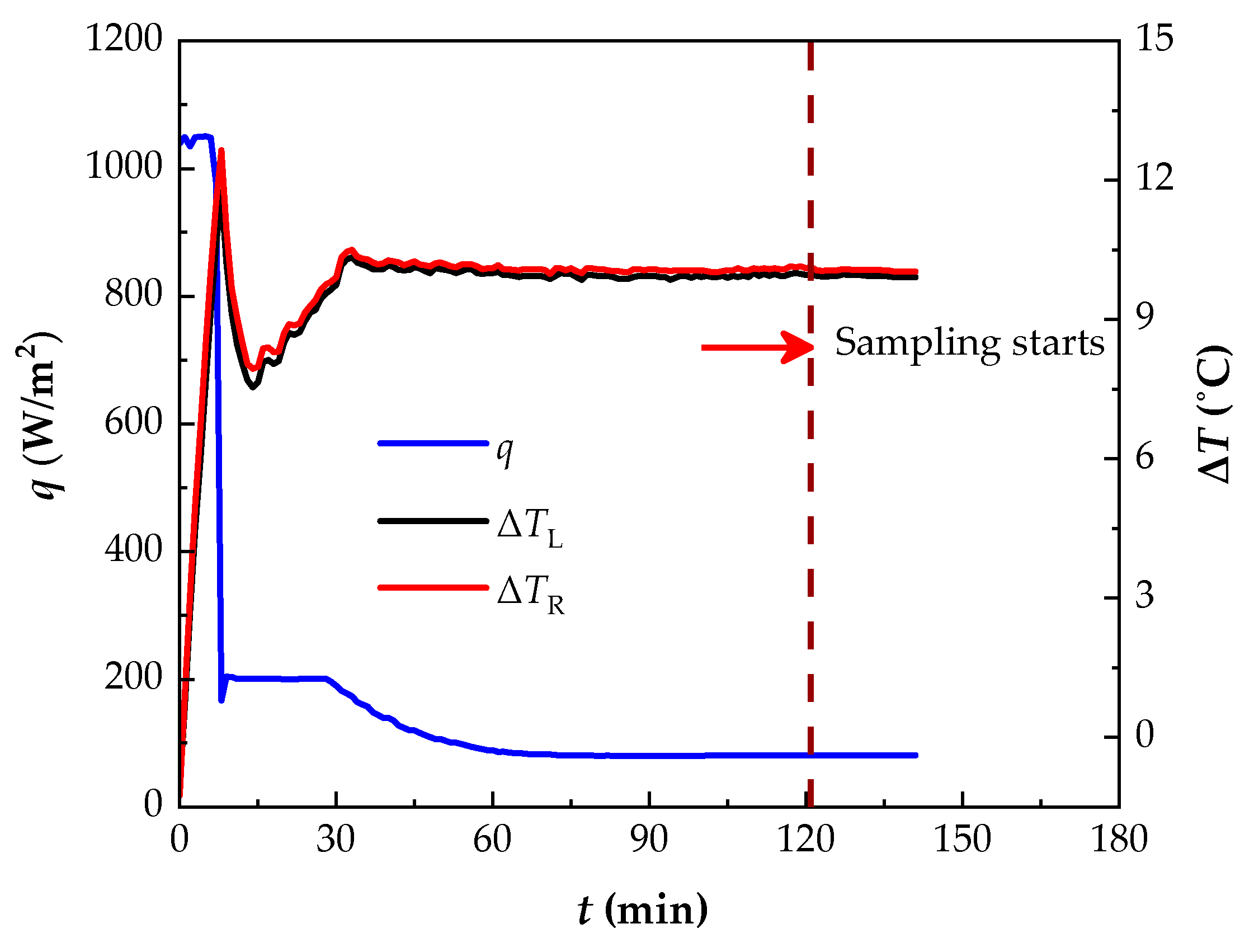

3.1. Validation of the Temperature Control Box—Heat Flux Meter Method

3.1.1. Experimental Results for the Guarded Hot Plate Method

3.1.2. Experimental Results for the Temperature Control Box—Heat Flux Meter Method and Method Validation

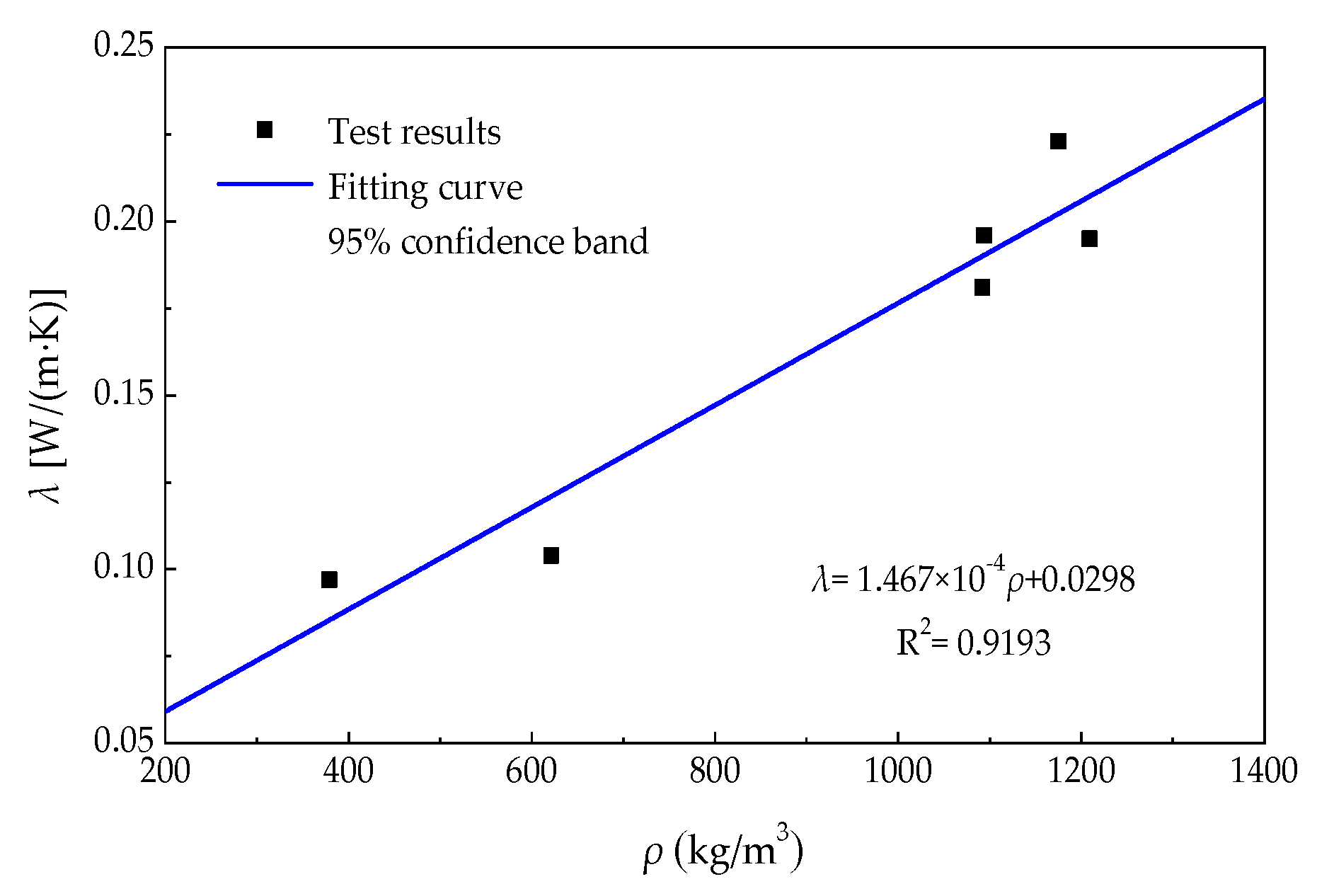

3.2. Thermal Property of Straw Boards

4. Discussion

5. Conclusions

- The fluctuation amplitudes of the monitored parameters, including q and ΔT, for the TCB-HFM tests during the steady state are much smaller than a generally acceptable limit of 5%, although slightly bigger than those for the GHP test. Moreover, the 5.9% deviation of the λ between the two test methods is within a reasonable range. The TCB-HFM is verified as an alternative test method to conduct investigations on the thermal properties of materials.

- The λ of two types of straw boards that include six specifications in total is obtained via the TCB-HFM tests, in which the maximum fluctuation amplitudes for ΔT and q are 1.95% and 2.77% for all specimens during the steady state. Based on the experimental results, the correlation between the ρ and λ for such material is found and expressed by a linear fitting formula with the determination coefficient R2 of 0.9193.

- The test results for λ of other straw bio-based materials in previous studies are compared with the fitting curve. It is found that the fitting formula has the feasibility to predict the λ of more types of straw bio-based materials, and the density is dominant among several factors that have effects on the thermal conductivity of straw bio-based materials.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tlaiji, G.; Ouldboukhitine, S.; Pennec, F.; Biwole, P. Thermal and mechanical behavior of straw-based construction: A review. Constr. Build. Mater. 2022, 316, 125915. [Google Scholar] [CrossRef]

- Shi, L.Y.; Zhang, H.B.; Li, Z.X.; Man, X.; Wu, Y.; Zheng, C.; Liu, J. Analysis of moisture buffering effect of straw-based board in civil defence shelters by field measurements and numerical simulations. Build. Environ. 2018, 143, 366–377. [Google Scholar] [CrossRef]

- Liu, L.; Li, H.; Lazzaretto, A.; Manente, G.; Tong, C.; Liu, Q.; Li, N. The development history and prospects of biomass-based insulation materials for buildings. Renew. Sustain. Energy Rev. 2017, 69, 912–932. [Google Scholar] [CrossRef]

- Cascone, S.; Evola, G.; Gagliano, A.; Sciuto, G.; Baroetto Parisi, C. Laboratory and in-situ measurements for thermal and acoustic performance of straw bales. Sustainability 2019, 11, 5592. [Google Scholar] [CrossRef]

- Ashour, T. The Use of Renewable Agricultural By-Products as Building Materials. Ph.D. Thesis, Benha University, Moshtohor, Egypt, 2003. [Google Scholar] [CrossRef]

- Beck, A.; Heinemann, U.; Reidinger, M.; Fricke, J. Thermal Transport in Straw Insulation. J. Build. Phys. 2004, 27, 227–234. [Google Scholar] [CrossRef]

- Vejeliene, J. Processed straw as effective thermal insulation for building envelope constructions. Eng. Struct. Technol. 2012, 4, 96–103. [Google Scholar] [CrossRef]

- Shea, A.; Wall, K.; Walker, P. Evaluation of the thermal performance of an innovative prefabricated natural plant fibre building system. Build. Serv. Eng. Res. Technol. 2013, 34, 369–380. [Google Scholar] [CrossRef]

- Wei, K.; Lv, C.L.; Chen, M.Z.; Zhou, X.; Dai, Z.; Shen, D. Development and performance evaluation of a new thermal insulation material from rice straw using high frequency hot-pressing. Energy Build. 2015, 87, 116–122. [Google Scholar] [CrossRef]

- Conti, L.; Barbari, M.; Monti, M. Steady-State thermal properties of rectangular straw-bales (RSB) for building. Buildings 2016, 6, 44. [Google Scholar] [CrossRef]

- D’Alessandro, F.; Bianchi, F.; Baldinelli, G.; Rotili, A.; Schiavoni, S. Straw bale constructions: Laboratory, in field and numerical assessment of energy and environmental performance. J. Build. Eng. 2017, 11, 56–68. [Google Scholar] [CrossRef]

- Gallegos-Ortega, R.; Magaña-Guzmán, T.; Reyes-López, J.A.; Romero-Hernández, M.S. Thermal behavior of a straw bale building from data obtained in situ. A case in Northwestern México. Build. Environ. 2017, 124, 116–122. [Google Scholar] [CrossRef]

- Sabapathy, K.A.; Gedupudi, S. Straw bale based constructions: Measurement of effective thermal transport properties. Constr. Build. Mater. 2019, 198, 182–194. [Google Scholar] [CrossRef]

- Dušek, J.; Jerman, M.; Podlena, M.; Böhm, M.; Černý, R. Sustainable composite material based on surface-modified rape straw and environment-friendly adhesive. Constr. Build. Mater. 2021, 300, 124036. [Google Scholar] [CrossRef]

- Ratiarisoa, R.V.; Magniont, C.; Ginestet, S.; Oms, C.; Escadeillas, G. Assessment of distilled lavender stalks as bioaggregate for building materials: Hygrothermal properties, mechanical performance and chemical interactions with mineral pozzolanic binder. Constr. Build. Mater. 2016, 124, 801–815. [Google Scholar] [CrossRef]

- Zhou, Y.P.; Trabelsi, A.; Mankibi, M.E. A review on the properties of straw insulation for buildings. Constr. Build. Mater. 2022, 330, 127215. [Google Scholar] [CrossRef]

- ISO 8301:1991; Thermal Insulation—Determination of Steady-State Thermal Resistance and Related Properties—Heat Flow Meter Apparatus. International Organization for Standardization: Geneva, Switzerland, 1991. Available online: https://www.iso.org/standard/15421.html (accessed on 10 July 2023).

- GB/T 10295-2008; Thermal Insulation—Determination of Steady-State Thermal Resistance and Related Properties—Heat Flow Meter Apparatus. Chinese Standard: Beijing, China, 2008. Available online: https://www.codeofchina.com/standard/GBT10295-2008.html (accessed on 10 July 2023).

- ISO 8302:1991; Thermal Insulation—Determination of Steady-State Thermal Resistance and Related Properties—Guarded Hot Plate Apparatus. International Organization for Standardization: Geneva, Switzerland, 1991. Available online: https://www.iso.org/standard/15422.html (accessed on 10 July 2023).

- GB/T 10294-2008; Thermal Insulation—Determination of Steady-State Thermal Resistance and Related Properties—Guarded Hot Plate Apparatus. Chinese Standard: Beijing, China, 2008. Available online: https://www.codeofchina.com/search/default.html?page=1&keyword=GB/T%2010294-2008 (accessed on 10 July 2023).

- ISO 8990:1994; Thermal Insulation—Determination of Steady-State Thermal Transmission Properties—Calibrated and Guarded Hot Box. International Organization for Standardization: Geneva, Switzerland, 1994. Available online: https://www.iso.org/standard/16519.html (accessed on 10 July 2023).

- GB/T 13475-2008; Thermal Insulation—Determination of Steady-State Thermal Transmission Properties—Calibrated and Guarded Hot Box. Chinese Standard: Beijing, China, 2008. Available online: https://www.codeofchina.com/search/default.html?page=1&keyword=GB/T%2013475-2008 (accessed on 10 July 2023).

- Costes, J.-P.; Evrard, A.; Biot, B.; Keutgen, G.; Daras, A.; Dubois, S.; Lebeau, F.; Courard, L. Thermal Conductivity of Straw Bales: Full Size Measurements Considering the Direction of the Heat Flow. Buildings 2017, 7, 11. [Google Scholar] [CrossRef]

- Douzane, O.; Promis, G.; Roucoult, J.; Le, A.D.T.; Langlet, T. Hygrothermal performance of a straw bale building: In situ and laboratory investigations. J. Build. Eng. 2016, 8, 91–98. [Google Scholar] [CrossRef]

- Bakatovich, A.; Davydenko, N.; Gaspar, F. Thermal insulating plates produced on the basis of vegetable agricultural waste. Energy Build. 2018, 180, 72–82. [Google Scholar] [CrossRef]

- Sun, K.; Zheng, C.R.; Wang, X.D. Thermal performance and thermal transmittance prediction of novel light-gauge steel-framed straw walls. J. Build. Eng. 2023, 67, 2352–7102. [Google Scholar] [CrossRef]

- GB/T 21723-2008; Wheat/Rice-Straw Particleboard. Chinese Standard: Beijing, China, 2008.

- Liuzzi, S.; Rigante, S.; Ruggiero, F.; Stefanizzi, P. Straw based materials for building retrofitting and energy efficiency. Key Eng. Mater. 2016, 678, 50–63. [Google Scholar] [CrossRef]

| Label | Dimensions: Length l × Width w × Thickness d (mm × mm × mm) | Nominal Density ρn (kg/m3) | Actual Density ρ (kg/m3) |

|---|---|---|---|

| PSB58 | 3000 × 1200 × 58 | 400 | 379 |

| WSSB12 | 2440 × 1220 × 12 | 1200 | 1209 |

| WSSB15 | 2440 × 1220 × 15 | 1100 | 1092 |

| WSSB18 | 2440 × 1220 × 18 | 1100 | 1175 |

| WSSB25 | 2440 × 1190 × 25 | 1100 | 1094 |

| WSSB30 | 2440 × 1220 × 30 | 620 | 621 |

| Sample Number | Temperature or Temperature Difference for the Left Specimen (°C) | Temperature or Temperature Difference for the Right Specimen (°C) | Φ (W) | ||||

|---|---|---|---|---|---|---|---|

| Metering Section Surface Plate TL1 | Cooling Unit Surface Plate TL2 | ΔTL | Metering Section Surface Plate TR1 | Cooling Unit Surface Plate TR2 | ΔTR | ||

| 1 | 39.938 | 29.979 | 9.959 | 40.104 | 29.979 | 10.125 | 3.641 |

| 2 | 39.947 | 30.009 | 9.938 | 40.060 | 30.002 | 10.058 | 3.642 |

| 3 | 39.949 | 30.000 | 9.949 | 40.063 | 29.996 | 10.067 | 3.642 |

| 4 | 39.949 | 30.019 | 9.930 | 40.064 | 30.011 | 10.053 | 3.642 |

| 5 | 39.950 | 30.040 | 9.910 | 40.067 | 30.035 | 10.032 | 3.642 |

| Average | 39.947 | 30.009 | 9.938 | 40.072 | 30.005 | 10.067 | 3.642 |

| Thermal Parameter | Average | Coefficient of Variation (COV) | Maximum Deviation from the Average (MDA) |

|---|---|---|---|

| q | 80.932 W/m2 | 0.01% | 0.03% |

| ΔTL | 9.935 °C | 0.21% | 0.33% |

| ΔTR | 10.059 °C | 0.19% | 0.66% |

| Specimen | Thermal Parameter | Average | Coefficient of Variation (COV) | Maximum Deviation from the Average (MDA) |

|---|---|---|---|---|

| WT−t25−1 | q | 105.729 W/m2 | 0.68% | 1.39% |

| ΔT1 | 11.943 °C | 0.50% | 1.20% | |

| ΔT2 | 13.167 °C | 0.50% | 1.27% | |

| ΔT3 | 13.795 °C | 0.67% | 0.76% | |

| WT−t25−2 | q | 108.733 W/m2 | 0.69% | 1.26% |

| ΔT1 | 13.971 °C | 0.40% | 0.92% | |

| ΔT2 | 15.214 °C | 0.70% | 1.41% | |

| ΔT3 | 14.019 °C | 0.48% | 0.85% |

| Specimen | MDA for ΔT | MDA for q | λ [W/(m·K)] | λavg [W/(m·K)] |

|---|---|---|---|---|

| WT−t12−1 | 1.92% | 0.99% | 0.177 | 0.195 |

| WT−t12−2 | 1.79% | 1.40% | 0.198 | |

| WT−t12−3 | 1.94% | 1.49% | 0.193 | |

| WT−t15−1 | 1.67% | 1.18% | 0.180 | 0.181 |

| WT−t15−2 | 1.38% | 1.11% | 0.182 | |

| WT−t18−1 | 1.18% | 0.77% | 0.199 | 0.223 |

| WT−t18−2 | 1.95% | 1.12% | 0.231 | |

| WT−t18−3 | 1.60% | 0.90% | 0.215 | |

| WT−t25−1 | 1.27% | 1.39% | 0.204 | 0.196 |

| WT−t25−2 | 1.41% | 1.26% | 0.189 | |

| WT−t30−1 | 1.35% | 0.97% | 0.101 | 0.104 |

| WT−t30−2 | 1.02% | 0.62% | 0.107 | |

| ST−t58−1 | 1.22% | 2.15% | 0.095 | 0.097 |

| ST−t58−2 | 1.36% | 2.77% | 0.100 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, K.; Zheng, C.; Wu, Y.; Zhang, W. Experimental Investigation on Thermal Conductivity of Straw Boards Based on the Temperature Control Box—Heat Flux Meter Method. Sustainability 2023, 15, 10960. https://doi.org/10.3390/su151410960

Sun K, Zheng C, Wu Y, Zhang W. Experimental Investigation on Thermal Conductivity of Straw Boards Based on the Temperature Control Box—Heat Flux Meter Method. Sustainability. 2023; 15(14):10960. https://doi.org/10.3390/su151410960

Chicago/Turabian StyleSun, Kuo, Chaorong Zheng, Yue Wu, and Wenyuan Zhang. 2023. "Experimental Investigation on Thermal Conductivity of Straw Boards Based on the Temperature Control Box—Heat Flux Meter Method" Sustainability 15, no. 14: 10960. https://doi.org/10.3390/su151410960

APA StyleSun, K., Zheng, C., Wu, Y., & Zhang, W. (2023). Experimental Investigation on Thermal Conductivity of Straw Boards Based on the Temperature Control Box—Heat Flux Meter Method. Sustainability, 15(14), 10960. https://doi.org/10.3390/su151410960