Abstract

Polyvinyl alcohol fiber engineered cementitious composites (PVA-ECC) have attracted wide attention due to their high toughness and narrow cracks. This review evaluated research results on PVA-ECC to further promote its research and application. The suitable length, diameter, and content of PVA fiber for ECC were recommended. The surface modification method of PVA fiber was determined and the dispersion evaluation method of PVA fiber was explored. An investigation into the mechanical properties of PVA-ECC was conducted, and the influence of PVA fiber content and fly ash content was evaluated. The improvement degree of PVA fiber on the durability of ECC and the strengthening mechanism was clarified. Results indicate that the recommended PVA fiber length for ECC was 12 mm, the diameter was 39 μm or 40 μm, and the content was 0.60–2.00%. The surface physical modification method was recommended for PVA fiber surface modification, and the mass equalization method was recommended for the evaluation of PVA fiber dispersion. With ordinary concrete, the tensile strain of PVA-ECC can be increased by 200–320 times, and the average improvement degree of flexural strength was 43%. Tensile strength and flexural strength of PVA-ECC increase first and then decrease with the increase in fiber content. With the increase in fly ash content, the tensile strength, compressive strength, and flexural strength of PVA-ECC decreased. PVA fiber content, fly ash content, and freeze–thaw medium are the main factors affecting the frost resistance of PVA-ECC. Compared with ordinary concrete, the average decreased degree of electric flux of PVA-ECC at 28 d was 21%, and the average decreased degree of carbonation depth of PVA-ECC at 3–28 d was 9–20%.

1. Introduction

Engineered cementitious composites (ECC) have excellent mechanical properties and durability. However, it is brittle and easy to crack, which seriously affects the safety and durability of the structure and reduces the service life of the structure. Engineering experts have explored a variety of solutions to improve its crack resistance and toughening ability, and more and more new materials are being used in ECC [1,2,3]. Among them, polyvinyl alcohol fiber engineered cementitious composites (PVA-ECC) have attracted wide attention because of their high toughness and narrow cracks.

Current research on PVA-ECC mainly focuses on exploring the influence of PVA fiber length, diameter, and other factors on the performance of PVA-ECC, and the surface modification methods and dispersion evaluation methods of PVA fiber. Moreover, good mechanical properties and durability are also the focus of research on PVA-ECC. Regarding the influence of PVA fiber length on the performance of PVA-ECC, Said et al. have shown that when the length of PVA used for ECC is 8 mm, the compressive strength is 62.98 MPa [4]. The PVA fiber diameter has a significant effect on the performance of the PVA-ECC. Zhang et al. pointed out that when the PVA fiber diameter was 39 μm, the ultimate tensile strain of PVA-ECC was the largest, reaching 2.6%, which showed significant strain hardening and multi-point cracking characteristics [5]. To clarify the best surface modification method for PVA fiber, Arain et al. treated the PVA fiber surface with oil and found that compared with unmodified PVA fiber, the chemical debonding between the modified PVA fiber and the matrix could be reduced to a certain extent after the oil treatment, with a decrease of up to 2.8 J/m2 [6]. Drechsler et al. selected n-butyl aldehyde and other aldehydes to modify the surface of PVA fiber to control the interaction between fiber and matrix in the PVA-ECC [7]. The dispersion evaluation method of PVA fiber in ECC is not uniform. Zhang et al. established a fluorescence microscopic analysis technique to quantitatively evaluate the dispersion property of PVA fibers in a matrix [8]. Liu et al. assessed the dispersion of PVA fibers in the matrix based on fluorescence image analysis, using two indexes of PVA fiber dispersion coefficient and effective utilization rate [9]. In terms of the variation law of the mechanical properties of PVA-ECC, Li et al. studied the stress–strain relationship of PVA-ECC under different fly ash content conditions and found that when the fly ash content was 75%, the maximum tensile strain reached 6.23%, and the average crack width was 1.14 mm [10]. Ling et al. found that 1.5% PVA fiber increased the flexural strength of specimens by 114.4% and the fracture toughness index by 197.5% through flexural tests [11]. To explore the durability of PVA-ECC, Şahmaran et al. found that when the fly ash content was 55%, PVA-ECC showed excellent frost resistance after 300 freeze–thaw cycles [12]. Haque et al. pointed out that the incorporation of PVA fiber could reduce the internal defects of ECC, hinder the penetration and diffusion of CO2, and effectively improve the carbonization resistance of the ECC [13]. Zhang et al. found that the chloride ion erosion depth of the PVA-ECC specimen was reduced compared with the reference specimen, and the maximum was 33.8% [14]. In summary, the current scholars have studied the factors affecting the performance of PVA-ECC, the surface modification and dispersion evaluation of PVA fiber, and the mechanics and durability of PVA-ECC, and have achieved some results. However, the influence of characteristic parameters such as length, diameter, and content of PVA fiber on the performance of the substrate needs to be further discussed to provide a reference for clarifying the technical indicators of PVA fiber for ECC. Moreover, the research on the surface modification method of PVA fiber is not deep enough, which is limited to indoor experimental research. And the evaluation method of PVA fiber dispersion is not yet mature, which can not effectively improve the mixing quality of the PVA-ECC mixture. In addition, there are many studies on the mechanical and durability properties of PVA-ECC, but its performance evolution needs to be further explored. Moreover, the strengthening mechanism of PVA fiber on ECC mechanics and durability has not yet formed a system, which needs to be summarized.

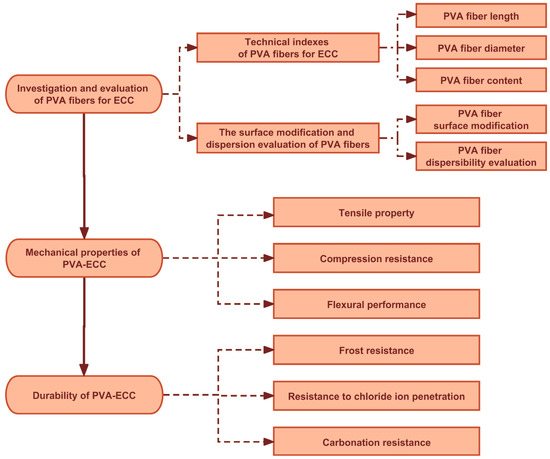

This review comprehensively evaluates current research results and applications of PVA-ECC. Technical indexes of PVA fibers for ECC are recommended. The surface modification method of PVA fiber is determined, and the dispersion evaluation method of PVA fiber is explored. Moreover, the variation of mechanical properties and durability of PVA-ECC is revealed. To sum up, this review provides a valuable reference for further research and application of PVA-ECC. The structure of the paper is shown in Figure 1.

Figure 1.

Structure of the paper.

2. Investigation and Evaluation of PVA Fibers for ECC

2.1. Technical Indexes of PVA Fibers for ECC

2.1.1. PVA Fiber Length

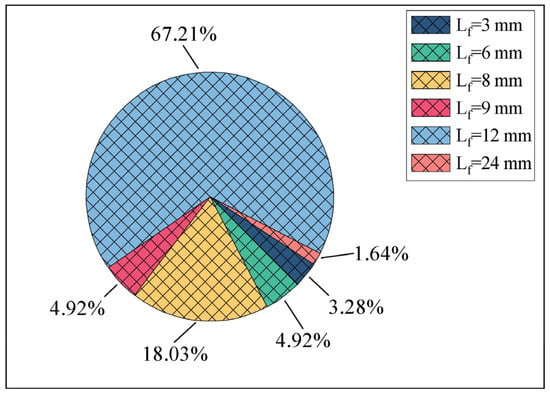

The effect of PVA fiber length on ECC is reflected in the performance. Researchers pointed out that when the PVA fiber content is the same and the length of PVA fiber is longer, the compressive strength and flexural strength of ECC will be greater [15,16]. However, Said et al. found that shorter PVA fibers could improve the compressive strength more [4]. However, Sasmal et al. considered that the influence of PVA fiber length on flexural strength was not significant [17]. It can be concluded that different experts and scholars have different research results on the mechanical properties of ECC with PVA fiber length, but most believe that longer PVA fiber is more conducive to the improvement of mechanical properties. This section discusses the PVA fiber length commonly used in studies on PVA-ECC to determine the appropriate PVA fiber length, as shown in Figure 2 [3,4,5,6,7,9,10,11,12,13,14,15,16,17,18,19,20,21,22,23,24,25,26,27,28,29,30,31,32,33,34,35,36,37,38,39,40,41,42,43,44,45,46,47,48,49,50,51,52,53,54,55,56].

Figure 2.

PVA fiber length for ECC.

Figure 2 shows that the PVA fiber lengths commonly used for studies on PVA-ECC mostly were 8 mm and 12 mm, accounting for 18.03% and 67.21%, respectively; by contrast, 24 mm PVA fibers accounted for only 1.64%. As can be seen, ECC in the selection of PVA fiber length, the use of 12 mm fibers is more extensive. However, the PVA fiber length should be considered and selected carefully to realize the toughening and anti-cracking effects of PVA fibers on ECC. The analysis indicates that the long length of PVA fibers incorporated into ECC is not conducive to their uniform dispersion in the ECC matrix, but rather to agglomeration, which will have a negative effect on the performance of ECC. Moreover, the more difficult and costly the process to obtain longer PVA fibers. However, when the PVA fiber is short, its bridging effect in the ECC matrix is limited, resulting in poor strengthening and toughening effect of PVA fiber on ECC. Therefore, the recommended PVA fiber length for ECC is 12 mm.

2.1.2. PVA Fiber Diameter

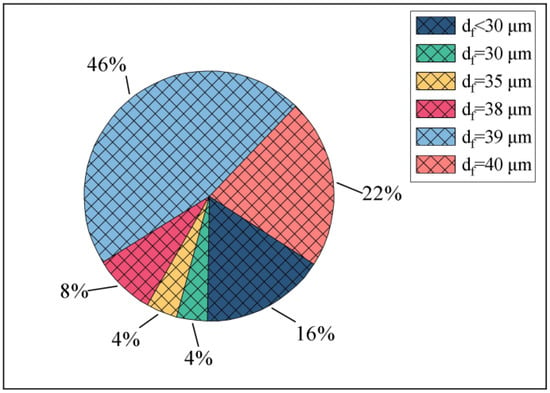

The diameter of PVA fiber affects the bridging stress of the fibers in the ECC. It was shown that when the fiber diameter is large, PVA-ECC exhibits a significant strain hardening and multi-point cracking mode, while when the fiber diameter is small, PVA-ECC exhibits a significant strain softening and single-point cracking mode [5]. This section discusses the PVA fiber diameter commonly used in studies on PVA-ECC to determine the appropriate PVA fiber diameter, as shown in Figure 3 [3,4,5,6,7,8,9,10,11,12,13,14,15,16,17,18,19,20,21,22,23,24,26,27,29,30,31,32,33,34,35,36,37,38,39,40,42,43,45,49,50,53,54,55,56,57].

Figure 3.

PVA fiber diameter for ECC.

Figure 3 shows that the diameters of PVA fibers for ECC are mostly 39 μm and 40 μm, of which 39 μm and 40 μm fibers have the highest proportion, accounting for 46% and 22%, respectively, while 35 μm and 38 μm diameter fibers account for only 4%. It can be concluded that when the diameter of PVA fiber is selected for ECC, more consideration is given to PVA fiber with a larger diameter. This is because, when the PVA fiber diameter is small, there is no guarantee that the PVA fiber is pulling out of the ECC matrix rather than breaking. However, when the diameter of PVA fiber is large, it can be achieved that most PVA fibers are pulled out rather than broken, achieving a strengthening, toughening, and crack resistance effect of PVA fibers on the ECC matrix [5]. In addition, the smaller diameter PVA fiber processing difficulties, easy to improve production costs. Therefore, it is recommended that the diameter of PVA fiber for ECC should be 39 μm or 40 μm.

2.1.3. PVA Fiber Content

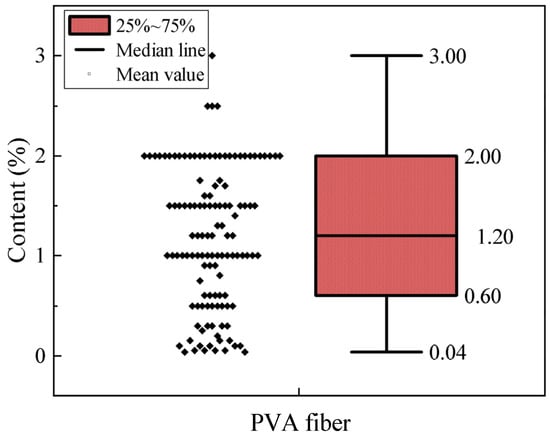

Different PVA fiber contents have different effects on the performance of PVA-ECC. A critical PVA fiber content has been established. PVA fiber contents below this critical limit could not achieve the toughening and anti-cracking effect on ECC. However, when the fiber content is higher than the critical value, the PVA fibers agglomerate easily owing to the difficulty in dispersion, reducing the performance of ECC and increasing the material cost. Therefore, the PVA fiber content for ECC should be controlled within an ideal range. This section discusses the PVA fiber content commonly used in studies on ECC to determine the appropriate PVA fiber content, as shown in Figure 4 [3,4,5,6,8,9,10,11,12,13,14,15,16,17,20,21,24,25,26,27,28,29,30,31,32,33,34,35,36,37,38,39,40,41,42,43,44,45,49,50,51,52,53,54,55,56,58,59,60,61].

Figure 4.

PVA fiber content for ECC.

Figure 4 shows a wide range of fluctuations in the PVA fiber contents used in ECC, with the highest and lowest contents at 3.00% and 0.04%, respectively. In addition, the quartile range of PVA fiber content for ECC was 0.60–2.00%, with the mean and median values at 1.20% and 2.00%, respectively. The test frequency with 1.00% content is second only to 1.20%. Accordingly, the PVA fiber content of ECC can be adopted by 2.00% for performance consideration, and 0.60% for economy consideration. Thus, the ideal PVA fiber content should be between the upper and lower quartiles of the box plot; that is, 0.60–2.00%. In addition, the above PVA fiber content is determined according to the performance requirements and economic costs of ECC. However, considering that the larger PVA fiber content is not conducive to its dispersion in the matrix. Therefore, it is suggested that the performance, cost, and dispersion of PVA fiber should be collaboratively considered in the subsequent experimental study when designing the optimum content of PVA fiber.

2.2. The Surface Modification and Dispersion Evaluation of PVA Fibers

2.2.1. PVA Fiber Surface Modification

Since the surface of PVA fiber has high hydrophilicity, a strong chemical bonding force is generated during the binding process with ECC. This results in an excessive bonding force between PVA fiber and matrix, which limits the bridging effect of PVA fiber. Furthermore, the surface modification of PVA fiber is beneficial to improve the dispersion of PVA fiber in the matrix. It is therefore important to surface modify PVA fiber to adjust and control the bonding force between PVA fiber and matrix, to improve the performance of ECC. At present, PVA fiber surface modification methods mainly focus on surface physical modification, while surface grafting modification and surface chemical modification have also made some progress, usually using environmental scanning electron microscopy (SEM), atomic force microscopy (AFM), contact angle measurement, and X-ray photoelectron spectroscopy (XPS) to evaluate the effect of PVA fiber modification.

- (1)

- Surface physical modification

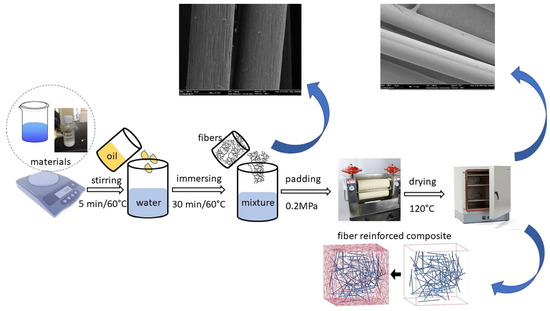

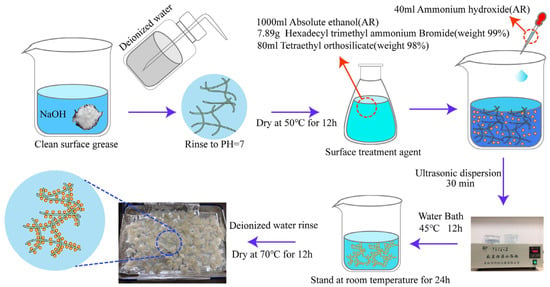

Reducing the contact between the PVA fiber and the matrix is the key to surface physical modification. Oil or emulsion forms a coating layer on the surface of PVA fiber, and changes the hydrophilic state to the hydrophobic state on the surface of PVA fiber, to adjust the adhesion between PVA fiber and matrix. This is a practical modification method. Among them, oil treatment is the most commonly used surface physical modification method at present. The oiling scheme is illustrated graphically in Figure 5. Oil treatment can reduce PVA fiber/matrix adhesion force and control fiber/matrix friction force within a certain range. However, the oil treatment has a certain limit on reducing the chemical bonding force between the PVA fiber and the matrix. In addition, research into the effects of different oil coating amounts on ECC performance is a pressing issue.

Figure 5.

Fiber surface treatment illustration [19].

Silicone softener [20], styrene–butadiene emulsion [21], vinyl acetate emulsion (VAE) [58], and boric anhydride [58] are commonly used emulsions. Among them, silicone softener has good film-forming properties, which can make the original gully structure on the surface of PVA fiber evenly covered and filled under the action of silicone softener, to improve the bonding effect between PVA fiber and matrix [20]. The addition of styrene-butadiene emulsion fills the pores in the matrix and forms a thick latex film to reduce water permeability. This improves the tensile strength of PVA-ECC, up to 4.5 MPa [21]. The VAE emulsion can inhibit the hydration of the adjacent gel materials and reduce the binding force between the PVA fiber and the matrix, thus optimizing the performance of the ECC [58].

In addition to the above oil and emulsion modification, the PVA fiber can be soaked in an epoxy resin–alcohol solution first, and then the PVA fiber coated with epoxy resin is fully mixed with the nano graphite. At this time, the epoxy resin coating and the nano graphite coating on the surface of the PVA fiber can isolate the PVA fiber from the matrix, thus reducing the binding force between the PVA fiber and the matrix [22].

- (2)

- Surface graft modification

Surface graft modification refers to connecting polymer or inorganic materials on the surface of PVA fiber by various methods so that the graft monomer can enhance the interfacial bonding effect between PVA fiber and matrix to improve the overall performance of ECC. Surface graft modification can be divided into conventional grafts and other grafts.

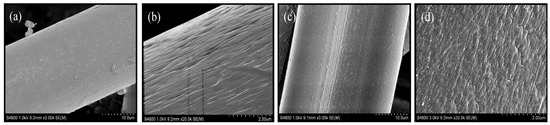

Conventional grafting refers to grafting polymer monomer onto the surface of PVA fiber employing the initiator. Ceric ammonium nitrate can be used as an initiator for graft modification of PVA fiber surface using glycidyl methacrylate (GMA), and the morphology of PVA fiber before and after modification is shown in Figure 6. Compared with the raw PVA fiber, it can be seen that the surface of the modified PVA fiber has a uniform scale-like structure, and the surface of the modified PVA fiber is rougher [62].

Figure 6.

Morphology of PVA fiber before and after modification [62]: (a) raw fiber 3000 times; (b) raw fiber 20,000 times; (c) modified fiber 3000 times; (d) modified fiber 2000 times.

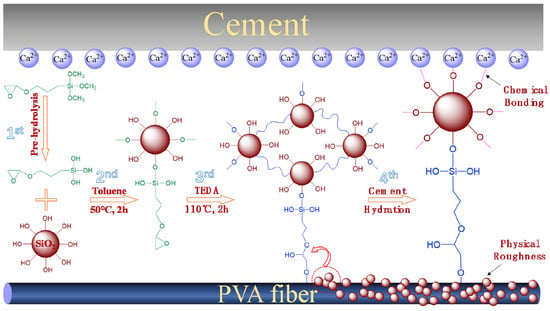

Other grafts are the grafting of inorganic substances onto the surface of the PVA fiber using a surface treatment agent or coupling agent. Polydopamine (PDA) and polyethyleneimine (PEI) can be used as surface pretreatments for PVA fibers, and finally, graphene oxide is grafted onto the surface of PVA fibers [18]. In addition, γ-(2, 3-epoxypropoxy) propytrimethox-ysilane (KH560) can also be used as a coupling agent to graft nano-silica (SiO2 NPs) onto the surface of PVA fibers. Figure 7 is the reaction mechanism schematically.

Figure 7.

Schematic of the grafting procedure of SiO2 NPs on PVA fibers and interfacial strengthening with cement upon hydration [57].

- (3)

- Surface chemical modification

It is possible to use the hydroxyl energy on the surface of PVA fiber for acetylation reaction or by other methods and achieve the purpose of improving the bonding property of PVA fiber and matrix. Surface chemical modification mainly includes the acetalization modification method and sol–gel method.

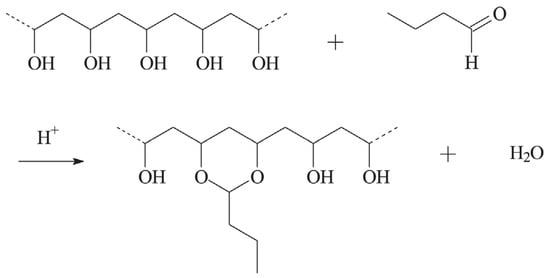

Acetalizing modification method refers to the acetylation reaction between PVA fiber and aldehydes so that the number of the hydroxyl groups on the surface of PVA fiber is greatly reduced to achieve the purpose of regulating and controlling the bonding performance between PVA fiber and the matrix. Drechsler et al. used butanal, iso-butanal, or pentanal to modify the surface of PVA fiber [7]. Moreover, Curosu et al. found alkyl chains can be covalently bonded to the fiber surface by an acid-catalyzed acetal reaction of butyraldehyde diluted with sulfuric acid (H2SO4) and hydrochloric acid (HCl), as shown in Figure 8 [23].

Figure 8.

Reaction of butyraldehyde with PVA fiber [23].

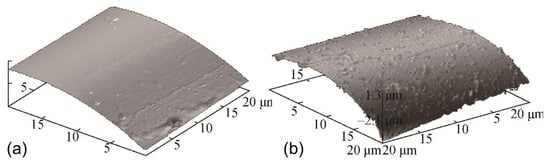

Sol–gel method is the chemical compounds containing highly active components through solution, sol, gel, and solidification, and then after heat treatment to form oxides or other compounds solid methods. Figure 9 shows the specific steps of PVA fiber modification by sol–gel method. For example, the sol–gel method can be used to coat the surface of PVA fibers with nano-silica particles, so that the grooves on the surface of PVA fibers are fully filled with nano-silica particles, thus changing the hydrophilic state of the PVA fiber surface to a hydrophobic state and increasing the surface roughness of PVA fibers, as shown in Figure 10.

Figure 9.

The schematic diagram of PVA fiber modified by the sol–gel method [24].

Figure 10.

Surface morphology of PVA fiber [24,63]: (a) raw fiber; (b) modified fiber.

Comparing the above three PVA fiber surface modification methods, the advantages and disadvantages and improvement directions are summarized, as shown in Table 1. The three methods can be used to achieve the surface modification of PVA fiber, according to the overall analysis. However, at this time, surface modification of PVA fiber is only possible in laboratory settings, and there is a gap between low-cost and large-scale production applications. Surface physical modification is advised as a PVA fiber surface modification method after a thorough comparison of surface grafting modification, surface chemical modification, and surface modification methods.

Table 1.

Comparative analysis of three surface modification methods of PVA fiber.

The urgent area that needs to be addressed is how to further optimize the PVA fiber surface modification process under the presumption of ensuring the stability of PVA fiber performance and significant modification effect, comprehensive selection of effective and environmentally friendly modification materials, as well as clarify the influence of PVA fiber surface modification on the performance of PVA-ECC. The cooperative treatment of PVA fiber by multiple modification methods will be the future research trend because it is challenging to obtain acceptable modification effects by a single modification method.

2.2.2. PVA Fiber Dispersibility Evaluation

To prevent PVA fibers from aggregating and creating a weak interface inside the matrix, which would affect the overall performance of ECC, PVA fibers should be uniformly dispersed in the matrix. Therefore, how to qualitatively and quantitatively evaluate the dispersion of PVA fibers in ECC is an urgent problem to be solved. For the study on the dispersive evaluation method of PVA fibers, Yuan et al. used the mass equalization weighing method and gray co-incidence matrix image processing method [25]. Cao et al. used statistical methods and image processing methods [26,64]. Zhang and Liu et al. analyzed the dispersion of PVA fibers in ECC with fluorescence microscopy [6,7]. To explore the dispersion evaluation methods of PVA fiber, this section comprehensively investigated different dispersion evaluation methods and their relative applicability, as shown in Table 2 [6,7,25,26,64].

Table 2.

PVA fiber dispersibility evaluation method.

In conclusion, at present, the dispersion evaluation methods of PVA fiber mainly include digital image processing technology, scanning electron microscopy, CT image gray recognition technology, optical microscopy, and mass equalization method. Among them, digital image processing technology has high requirements for equipment and a complex calculation process. The effectiveness of recognition is directly related to the accuracy of evaluation results. Scanning electron microscopy (SEM) is too complicated to treat the specimen, and if the specimen is not treated properly, the imaging effect will be poor and the accuracy will be reduced. CT image gray recognition technology to identify fiber dispersion maturity is low, cannot accurately identify the identification of feature points, and the price is expensive. An optical microscope artificially observes fiber dispersion, which is more suitable for preliminary judgment. With the help of coefficient of variation calculation in mathematical statistics, the mass equalization method quantifies the dispersion effect. It has the advantages of simple equipment requirements, manual operation costs, and simple recorded data, which can reduce human errors through refined tests. The dispersion evaluation method is scientific and has a reliable inspection principle. In summary, considering the operability, accuracy, and economic cost, the mass equalization method is recommended to evaluate the dispersibility of PVA fiber in ECC.

3. Mechanical Properties of PVA-ECC

3.1. Tensile Property

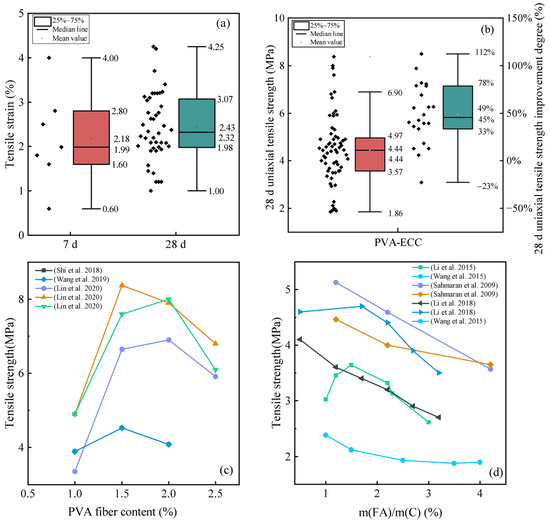

Due to the incorporation of PVA fiber, ECC has superior tensile ductility than ordinary concrete material under tensile stress, showing strain-hardening and multi-crack characteristics. At present, the tests for studying the tensile properties of materials mainly include direct tensile and splitting tensile tests, and the most direct and effective test is a direct tensile test. Figure 11 summarizes the tensile strain and tensile strength from various studies to further clarify the characteristics of the tensile property of PVA-ECC and statistically regularize the results [10,27,28,30,31,59,60,61].

Figure 11.

PVA-ECC tensile properties and influencing factors: (a) tensile strain; (b) uniaxial tensile strength; (c) effect of PVA fiber content on tensile strength [28,30,31]; (d) effect of fly ash content on tensile strength [10,59,60,61].

As shown in Figure 11a, the 7 d tensile strain of PVA-ECC were 1.60%, 1.99%, and 2.80% for the smaller quartile Q1, median Q2, and larger quartile Q3, respectively. The interquartile range Iqr = Q3 − Q1 was 1.2%. The Iqr data indicate a low concentration degree. In addition, at 28 d, 50% of the tensile strain data of PVA-ECC ranged from 1.98–3.07%; the corresponding Iqr values were 1.09%. The data below the median of 2.32% were more concentrated and exhibited an overall tendency toward the Q1 values. Referring to the ultimate tensile strain of ordinary concrete at cracking 0.01–0.02% [32,33]. It can be concluded that the 28 d tensile strain of PVA-ECC is about 200–320 times that of ordinary concrete.

Figure 11b shows that the quartile range of PVA-ECC uniaxial tensile strength at 28 d was 3.57–4.97 MPa. The Iqr was 1.4 MPa. The data in the 4.44–4.97 MPa range were more concentrated. Moreover, the data dispersion was large. In addition, Figure 10b also shows the quartile range of uniaxial tensile strength improvement degree of PVA-ECC at 28 d by 33–78% compared with that of ordinary concrete. The Iqr was 45%. The data in the 33–45% range were more concentrated. The average degree of improvement was 49%. In summary, compared with ordinary concrete, PVA-ECC has excellent tensile toughness. The analysis results suggest that the uniformly distributed PVA fiber forms a three-dimensional mesh structure in the ECC structure, which has a supporting effect on the matrix. When the ECC carries the splitting effect, the PVA fiber bears part of the tensile stress by virtue of its high strong and high modulus characteristics, which effectively alleviates the tensile stress and plays a reinforcing role. At the same time, PVA fiber gives full play to the bridging effect, prevents further cracking and damage to the ECC structure, improves the integrity and integrity of the matrix, and thus improves the ability of the ECC to resist tensile damage. In addition, cement and fly ash in the material composition of ECC improves the tensile strain capacity of the ECC structure. This is because cement and fly ash optimize the bonding performance between PVA fiber and matrix, and cement, fly ash, and PVA fiber play a synergistic role in strengthening and toughening.

Figure 11c shows that when the content of PVA fiber is 0–2.5%, the tensile strength of PVA-ECC increases first and then decreases with the increase in PVA fiber content, and the optimal content of PVA fiber content is 1.5–2%. The analysis results suggest that when the content of PVA fiber is insufficient, the bridging effect of PVA fiber cannot be fully utilized, and its toughening and crack resistance effect is general, which cannot achieve the purpose of improving the tensile strength of ECC. However, when the PVA fiber content is too high, it is easy to cause the PVA fiber not to be uniformly dispersed in the matrix, resulting in more undesirable defects in the matrix, which makes the overall performance of ECC uneven, resulting in a decrease in the tensile strength of PVA-ECC. Therefore, further research should be carried out on the material composition of PVA-ECC. Moreover, the appropriate fiber content and how the mixing quality of the mixture can be improved should be clarified to ensure that PVA fibers positively affect the tensile strength of ECC.

Figure 11d shows that the tensile strength of PVA-ECC decreased with the increase in fly ash content. The reason is that with the increase in FA content, the cement content gradually decreases, resulting in insufficient hydration products, which weakens the strength of ECC. However, Sahmaran et al. pointed out that although the increase in FA content leads to a decrease in tensile strength, it is beneficial to obtain high tensile strain capacity, because the increase in FA content will reduce the chemical bond and matrix toughness at the fiber/matrix interface and increase the interface friction bond, thus obtaining high tensile strain capacity. In addition, the increase in fly ash content is beneficial to reduce costs. Therefore, the optimum content of fly ash should be determined according to the performance requirements of PVA-ECC and the economic cost.

3.2. Compression Resistance

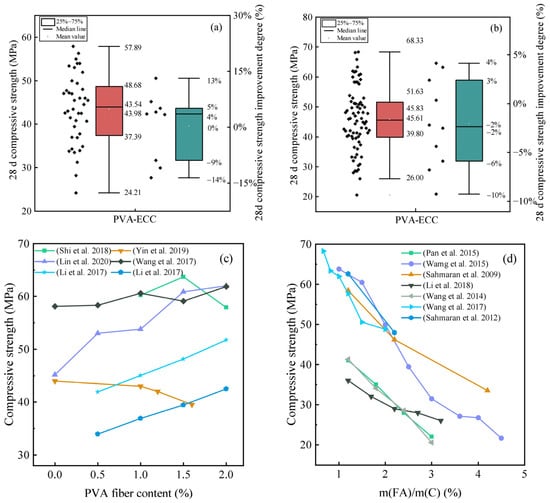

Due to the absence of coarse aggregate, PVA-ECC is less stiff than ordinary concrete materials. However, the PVA fiber added plays a bridging role, which can prevent cracks from expanding inside the matrix so that extreme brittle failure will not occur, and improved the compression deformation ability of ECC. At present, PVA-ECC compressive strength is usually characterized by cylinder or cube compressive strength. Figure 12 summarizes the compressive strength from various studies to further clarify the characteristics of the compression resistance of PVA-ECC and statistically regularize the results [20,27,28,29,30,31,35,36,37,38,39,40,59,60,61,65,66].

Figure 12.

PVA-ECC compression properties and influencing factors: (a) cylinder compressive strength; (b) cubic compressive strength; (c) effect of PVA fiber content on compressive strength [28,29,31,36,39]; (d) effect of fly ash content on compressive strength [27,35,36,37,59,60,61].

Figure 12a shows that 50% of the data of PVA-ECC cylinder compressive strength at 28 d ranged from 37.39–48.68 MPa. The Iqr was 11.29 MPa. The data below the median was highly dispersed. The average value was 43.98 MPa. Figure 11b shows that the quartile range of PVA-ECC cubic compressive strength at 28 d was 39.80–51.63 MPa. The Iqr was 11.83 MPa. The data was symmetrical. Moreover, the dataset had a large dispersion. It can be concluded that cube specimens exhibit higher compressive strength than cylindrical specimens, which is supported by the research results of Chung et al. [40].

Figure 12a shows that 50% of the cylinder compressive strength data of PVA-ECC at 28 d improved by −9–5% compared with that of ordinary concrete. The Iqr was 14%. The data above the median of 4% was more concentrated and exhibited an overall tendency toward the Q3 values. Moreover, the dataset had a large dispersion. The average degree of improvement was 0%. Figure 12b shows that the quartile range of cubic compressive strength improvement degree of PVA-ECC at 28 d by −6–3% compared with that of ordinary concrete. The Iqr was 9%. Moreover, the dataset had a large dispersion. The average degree of improvement was −2%. It can be concluded that compared with ordinary concrete, PVA-ECC has no obvious advantage in compressive strength, and the compressive strength of the two is close. The analysis results suggest that the PVA fibers have high hydrophilicity owing to the large number of hydroxyl groups on the surface. Therefore, in the process of bonding with ECC, PVA fiber and cement hydration products (e.g., C-S-H) are effectively bonded. This ensures the significant bridging effect of the PVA fibers. Therefore, when ECC bears compressive stress, PVA fiber gives full play to the bridging effect, and the supporting system formed by it can bear part of the load. PVA fiber plays a role in synergistic force, stress transfer, and deformation mitigation in the process of bearing deformation, thus improving the compressive strength of ECC. In addition, PVA fiber acts like an air entraining agent, introducing microbubbles into the matrix, regulating the bonding force between PVA fiber and matrix, and making PVA fiber play an active role in resisting compressive strength. However, when the content of PVA fiber is large, it is difficult to disperse the PVA fiber uniformly when the mixture is mixed, which makes the PVA fiber agglomerate in the matrix, and the coating of the cementing material gradually weakens, resulting in poor defects in the matrix, which leads to the little effect of PVA fiber on the compressive strength, and even has a negative impact on the compressive strength.

As shown in Figure 12c, at present, the research rules of PVA-ECC compressive strength with PVA fiber content are not uniform. Some studies believe that the compressive strength increases with the increase in PVA fiber content, while some studies point out that the compressive strength decreases with the increase in PVA fiber content. In fact, the two are not contradictory. This is because there are differences in the material composition design of PVA-ECC in different experimental studies. The effect of PVA fiber content on compressive strength has two opposite aspects. The positive effect is that PVA fiber plays a bridging role to inhibit the speed and width of crack expansion, so as to improve the compressive strength of ECC. The negative effect is that with the increase in PVA fiber content, PVA fiber is difficult to disperse uniformly, the pores in the matrix increase, and the density of the ECC structure deteriorates, thus reducing the compressive strength of ECC.

Figure 12d shows that the compressive strength of PVA-ECC decreases with the increase in fly ash content. The reason is that after FA replaces part of the cement, the proportion of cement decreases, resulting in fewer hydration products, and the amount of unhydrated FA increases, resulting in lower compactness of the overall structure and lower compressive strength. Therefore, in the design of fly ash content, a higher fly ash content can be selected for economic considerations, while a lower fly ash content should be considered for performance effects.

3.3. Flexural Performance

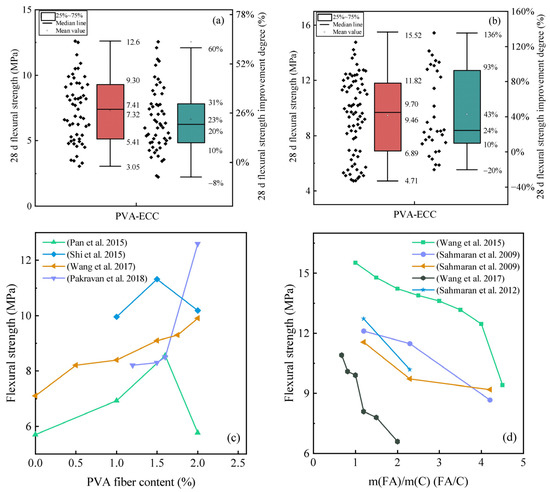

Under the action of PVA fiber bridging, the crack propagation and crack width of ECC are limited, which makes the tensile part exhibit the strain hardening characteristic of multi-crack cracking; thus, the deformation ability and bending toughness of ECC are improved [42,67]. Figure 13 summarizes the flexural strength from various studies to further clarify the characteristics of the flexural performance of PVA-ECC and statistically regularize the results [17,27,28,29,35,36,37,38,59,60,67,68].

Figure 13.

PVA-ECC flexural performance and influencing factors: (a) three-point flexural test; (b) four-point flexural test; (c) effect of PVA fiber content on flexural strength [27,28,36,67]; (d) effect of fly ash content on flexural strength [36,37,59,60].

Figure 13a shows that the flexural strength Q1–Q3 of PVA-ECC at 28 d within the three-point flexural test were 5.41 MPa, 7.41 MPa, and 9.30 MPa, respectively. The Iqr was 3.89 MPa. The data below the median was highly dispersed. The average value was 7.32 MPa. Figure 13b shows that the quartile range of PVA-ECC flexural strength at 28 d within the four-point flexural test was 6.89–11.82 MPa. The Iqr was 4.93 MPa. The data above the median 9.70 MPa was more concentrated and exhibited an overall tendency toward the Q3 values.

Figure 13a shows the quartile range of flexural strength improvement degree of PVA-ECC at 28 d within the three-point flexural test by 10–31% compared with that of ordinary concrete. The Iqr was 21%. The data below the median of 20% were more concentrated. The average degree of improvement was 23%. Figure 13b shows that the flexural strength of PVA-ECC at 28 d within the four-point flexural test improved by 10–93% compared with that of ordinary concrete. The Iqr was 83%. The data above the median were highly dispersed. The average degree of improvement was 43%.

In conclusion, compared with ordinary concrete, PVA-ECC has higher flexural strength. This is because the PVA fiber uniformly distributed in the ECC plays a bridging role and uses its own high strength and high modulus characteristics, which has a positive impact on the flexural strength of the ECC. Under the action of bending load, the random distribution of PVA fiber effectively weakens the stress inside the matrix, and the PVA fiber across the crack gives full play to the bridging effect, inhibits the development of cracks inside the matrix, and limits the width of cracks, so that the ECC shows the strain-hardening characteristics of multi-crack cracking, and even the ECC is destroyed, though it still has good integrity, which is not similar to the brittle failure of concrete materials. Therefore, PVA-ECC has strong deformation ability and bending toughness under bending load.

Figure 13c shows that when the content of PVA fiber is 0–2.5%, the flexural strength of PVA-ECC increases first and then decreases with the increase in PVA fiber content, and the optimal content of PVA fiber content is 1.5–2%. It is concluded that when the content of PVA fiber is between 1.5–2.0%, the PVA fibers are uniformly distributed in the matrix, which not only ensures its isotropic mechanical properties, but also enables it to give full play to the bridging effect, thus playing a positive role in the flexural performance of ECC. However, when the PVA fiber content is greater than 2.0%, and the mixing quality of the mixture is poor, the PVA fiber is agglomerated, so that the PVA fiber cannot be uniformly dispersed in the matrix, and the stress concentration problem occurs inside the matrix, which has a negative effect on the flexural performance of ECC, resulting in a decrease in the ductility of ECC. Therefore, further research should be carried out on the material composition of PVA-ECC to clarify the optimum content of PVA fibers to reduce the weakening of the flexural strength due to the admixture of PVA fiber.

Figure 13d shows that the flexural strength of PVA-ECC decreased with the increase in fly ash content. The analysis shows that when the fly ash is too high, the bonding force between the PVA fiber and the matrix is too low, which limits the bridging effect of PVA fiber and leads to the decrease in flexural strength of PVA-ECC. However, the high content of fly ash increases the interfacial friction bond and improves the deformation ability of PVA-ECC, which is manifested in that the cracking of PVA-ECC under load results in its larger deformation ability and higher toughness.

4. Durability of PVA-ECC

4.1. Frost Resistance

The incorporation of PVA fibers can enhance the freeze-resistance of ECC because PVA fibers uniformly dispersed in the matrix can withstand the tensile stress caused by freezing expansion, inhibit crack propagation, and effectively resist the expansion pressure generated in the freeze–thaw cycle. In addition, PVA fiber has a similar effect to air entraining agent, and PVA fiber can introduce microbubbles into the matrix, increase the air content of the matrix, and effectively alleviate the hydrostatic pressure and osmotic pressure during the low-temperature cycle, to improve the frost resistance of ECC. At present, the frost resistance of PVA-ECC is mainly evaluated by relative dynamic elastic modulus loss rate, dynamic elastic modulus loss rate, mechanical property loss rate, and maximum freeze–thaw cycles. The frost resistance of PVA-ECC is affected by many factors.

- (1)

- PVA fiber content

The content of PVA fiber is an important factor affecting the freezing resistance of PVA-ECC. The increase in PVA fiber content is beneficial to give full play to the fiber bridging effect to limit the crack propagation, and to improve the frost resistance of ECC. However, when the fiber content is too high, the fiber is difficult to disperse uniformly, and fiber agglomeration is easy to occur, which reduces the frost resistance of ECC. Zhao et al. considered that the optimum content was 0.15%, the mechanical properties of PVA-ECC after freeze–thaw cycles were the best, and the compressive strength loss rate was only 35% [46]. Ge et al. pointed out that the optimal content was 2% when the mass loss rate and relative longitudinal dynamic elastic modulus loss rate of PVA-ECC were the minima [47]. In view of this, it is suggested that the cost, performance, and dispersion of the fiber in the matrix should be considered comprehensively when designing the content of PVA fiber.

- (2)

- Fly ash content

Whether the content of fly ash is moderate determines whether the addition of fly ash can improve ECC frost resistance. After the fly ash is mixed into the ECC, the fly ash particles can fill the gap between the cement particles, and the hydrated calcium silicate gel formed by the hydration of the fly ash fills the pore gap of the matrix, which improves the compactness of the ECC. At the same time, part of the hollow glass sphere of fly ash is introduced into the matrix, which will cut off the channel of capillary water seepage, thereby improving the frost resistance of ECC. However, when the content of fly ash is too high, the reaction time of volcanic ash is prolonged, and a large amount of fly ash is not hydrated, which leads to the decrease in air content in the matrix and the decrease in frost resistance of ECC. Therefore, further research should be carried out on the composition of PVA-ECC materials to determine the optimal fly ash content, and to ensure that fly ash has a positive effect on the frost resistance of ECC.

- (3)

- Freeze–thaw medium

In addition, Du et al. pointed out that compared with water freeze–thaw, PVA-ECC had worse freeze resistance in a chlorine environment [48]. However, the effect of freeze–thaw medium on the frost resistance of PVA-ECC has not been studied in depth, and there are only experimental conclusions on macroscopic mechanical properties. It is an urgent problem to further explore the influence mechanism of different freeze–thaw media on the performance of PVA-ECC based on microscopic means.

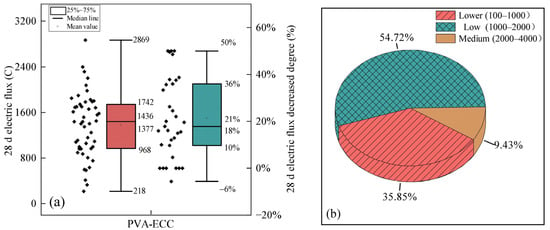

4.2. Resistance to Chloride Ion Penetration

At present, the indicators for evaluating chloride ion penetration are not uniform, mainly including electric flux, chloride ion diffusion coefficient, water penetration height, etc. In this paper, the investigation is conducted by referring to the Standard for Test Methods of Long-term Performance and Durability of Ordinary Concrete (GB/T 50082-2009) [69] and the evaluation indexes of electric flux suggested by ASTM C1202 [70]. The evaluation standards of chlorine ion permeability of ASTM C1202 are shown in Table 3. In this section, to clarify the resistance of PVA-ECC to chloride ion penetration, the electric flux test results of PVA-ECC are summarized in Figure 14 [14,49,50,51,52,53,68].

Table 3.

Evaluation standard of chloride ion permeability based on electric flux.

Figure 14.

PVA-ECC resistance to chloride ion penetration: (a) PVA-ECC electric flux; (b) evaluation distribution of chloride ion permeability of PVA-ECC.

Figure 14a shows that the electric fluxes Q1–Q3 of PVA-ECC at 28 d were 968 C, 1436 C, and 1742 C, respectively. The Iqr was 774 C. The data in the 1436–1742 C range were more concentrated. The data dispersion was large. The average value was 1377 C. Moreover, the quartile range of electric flux decreased and the degree of PVA-ECC at 28 d is 10–36% compared with that of ordinary concrete. The Iqr values were 26%. The data dispersion was large. The average degree of decrease in the electric flux at 28 d was 21%. Figure 14b shows that in the evaluation distribution of chlorine ion permeability of PVA-ECC, 54.72% belonged to low grade, and only 9.43% belonged to medium grade.

In summary, compared with ordinary concrete, PVA-ECC exhibits excellent resistance to chloride ion penetration. The analysis results suggest that the uniform distribution of PVA fibers stably plays a bridging role and forms a supporting system inside the matrix. PVA fibers play a role of “reinforcement stabilization” and “anchoring and interlocking”, effectively bridging micro-cracks and controlling crack width, improving the integrity and consistency of the matrix, reducing the chloride ion penetration and migration channels inside the ECC structure, resulting in a decrease in the amount of chloride ion penetration and migration, thereby improving the impermeability of ECC. In addition, fly ash can also improve the resistance to chloride ion erosion of PVA-ECC. Because of the filling effect of fly ash, fly ash particles fully fill the matrix voids and the internal pore size of the matrix is refined, which increases the compactness of ECC. On the other hand, the volcanic ash reaction of fly ash can produce reaction products such as hydrated calcium silicate and hydrated calcium aluminate. These products can improve the internal structure of the matrix and reduce the porosity of the matrix, thus hindering the penetration and migration of chloride ions.

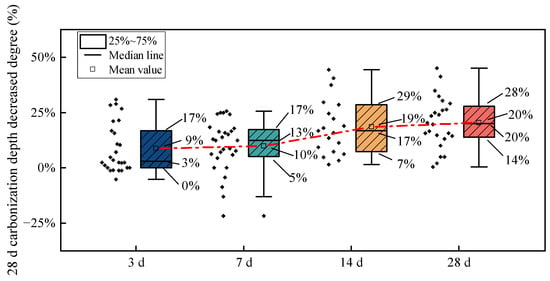

4.3. Carbonation Resistance

The working environment of ECC is complex. During the service period, they are usually exposed to air. The CO2 in the air will cause the carbonization of the material, which will reduce the durability of the structure [54]. In this section, to clarify the carbonization resistance of PVA-ECC, the carbonization test results of PVA-ECC are summarized in Figure 15 [54,55,56,71,72,73].

Figure 15.

Carbonation resistance of PVA-ECC.

Figure 15 shows that the quartile range of carbonation depth decreased degree of PVA-ECC at 3 d, 7 d, 14 d, and 28 d is 0–17%, 5–17%, 7–29%, and 14–28% compared with that of ordinary concrete, respectively. The Iqr values were 17%, 12%, 22%, and 14%, respectively. The data dispersion was large. It can be concluded that compared with ordinary concrete, PVA fiber has a significant positive effect on the carbonation resistance of ECC. The analysis results suggest that the uniformly dispersed PVA fibers form a dense mesh structure in the matrix, which reduces the micropores inside the matrix to a certain extent, improves the compactness of the matrix, optimizes the internal structure of the matrix, and then reduces the diffusion channel of CO2. On the other hand, PVA fibers efficiently play a bridging role, which inhibits the speed and width of crack expansion inside the matrix, improves the ECC structure, hinders the diffusion of CO2, and improves the carbonation resistance of ECC. However, there is a critical value for PVA fiber to improve the carbonation resistance of ECC, which is the optimal content of PVA fiber. Below the optimum content, the bridging effect of PVA fiber is general, resulting in the strengthening, toughening, and crack resistance effect of PVA fibers on ECC not being achieved. However, higher than the optimal content, PVA fibers are difficult to disperse uniformly, resulting in more fine pores in the matrix, providing channels for the diffusion of CO2, which has a negative effect on the carbonation resistance of ECC.

In addition, Figure 15 shows that the average degrees of decrease in the carbonation depth at 3 d, 7 d, 14 d, and 28 d were 9%, 13%, 19%, and 20%, respectively. It can be concluded that with the extension of carbonization time, the decreased degree of PVA-ECC carbonization depth increases gradually. When the carbonization time is longer (14 d, 28 d), the carbonization resistance of PVA fiber to ECC is more significant. The reason is the positive effect of the incorporation of fly ash into ECC. In the middle and late carbonization periods, the secondary reaction of fly ash gradually plays a role. The hydration products of fly ash, calcium silicate hydrate, and calcium aluminate hydrate can improve the internal structure of the matrix and make the matrix denser, thus hindering the diffusion of CO2 and reducing the carbonization rate of ECC.

5. Conclusions

This review comprehensively discussed the application of PVA fibers in ECC. The literature review is summarized as follows:

- (1)

- The suitable length, diameter, and content of PVA fiber for ECC were specified. It is recommended that the length of PVA fiber is 12 mm, the diameter is 39 μm or 40 μm, and the content is 0.60–2.00%.

- (2)

- Comprehensive comparison of surface physical modification, surface grafting modification, and surface chemical modification methods, surface physical modification is recommended as a PVA fiber surface modification method. Compared with digital image processing technology, scanning electron microscopy, CT image gray recognition technology, and optical microscopy, the mass equipartition method is recommended as the dispersibility evaluation method of PVA fiber.

- (3)

- Compared with ordinary concrete, the tensile strain of PVA-ECC can be increased by 200–320 times, the compressive strength has no obvious advantage, and the average improvement degree of flexural strength (four-point flexural) was 43%. The tensile strength and flexural strength of PVA-ECC increase first and then decrease with the increase in fiber content, the compressive strength has no obvious rule, and the optimum fiber content was recommended to be 1.5–2%. The tensile strength, compressive strength, and flexural strength of PVA-ECC decrease with the increase in fly ash content. When designing fly ash content, the performance and economy of PVA-ECC should be considered comprehensively.

- (4)

- Compared with ordinary concrete material, PVA-ECC has excellent durability performance. PVA fiber content, fly ash content, and freeze–thaw medium were the main factors affecting the frost resistance of PVA-ECC. Compared with ordinary concrete, the average decreased degree of electric flux of PVA-ECC was 21% (28 d), and the average decreased degree of carbonation depth of PVA-ECC was 9–20% (3–28 d).

- (5)

- The current research on the durability of PVA-ECC is weak, and the durability issues of PVA-ECC should be studied in depth, especially the anti-alkali–silica reaction. And the research on the performance of PVA-ECC mainly focuses on the macro level; the micro research on the influence of PVA fiber on the performance of ECC should be carried out in the future. Moreover, the strengthening mechanism of PVA fiber on ECC was explored using macro and micro means. In addition, the current PVA fiber has limitations in surface modification, dispersion evaluation, and performance improvement, which is not conducive to the performance improvement of PVA-ECC and the large-scale application of physical engineering. Therefore, the follow-up research on hybrid fiber engineered cementitious composites should be carried out to explore new combinations (such as PVA fiber + steel fiber, PVA fiber + PP fiber, etc.), and to clarify the performance evolution of hybrid fibers on ECC.

Author Contributions

Conceptualization, L.C., C.W. and Q.C.; methodology, L.C., C.W. and S.C.; investigation, S.C., F.C. and Q.C.; data analysis, L.C., S.C. and F.C.; visualization, S.C., F.C. and Q.C.; writing—original draft, L.C. and S.C.; review, L.C., C.W. and Q.C.; editing, L.C., S.C., C.W., F.C. and Q.C.; supervision, L.C. and C.W.; funding acquisition, L.C. and C.W. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Science and Technology Project of Shaanxi Transportation Technology Consulting Co., Ltd., Innovation Capability Support Program of Shaanxi (No. 2022TD-07), China Postdoctoral Science Foundation (2023M730356).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data used to support the findings of this study are available from the corresponding author upon request.

Acknowledgments

This research work is supported by the Science and Technology Project of Shaanxi Transportation Technology Consulting Co., Ltd., Innovation Capability Support Program of Shaanxi (No. 2022TD-07), China Postdoctoral Science Foundation (2023M730356). That sponsorship and interest are gratefully acknowledged.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Editorial Department of China Journal of Highway and Transport. Review on China’s pavement engineering research·2020. China J. Highw. Transp. 2020, 33, 1–66. [Google Scholar]

- Wang, C.; Li, Y.; Wen, P.; Zeng, W.; Wang, X. A comprehensive review on mechanical properties of green controlled low strength materials. Constr. Build. Mater. 2022, 363, 129611. [Google Scholar] [CrossRef]

- Liu, L.; Wang, C.; Liang, Q.; Chen, F.; Zhou, X. A state-of-the-art review of rubber modified cement-based materials: Cement stabilized base. J. Clean. Prod. 2023, 392, 136270. [Google Scholar] [CrossRef]

- Said, S.H.; Razak, H.A.; Othman, I. Flexural behavior of engineered cementitious composite (ECC) slabs with polyvinyl alcohol fibers. Constr. Build. Mater. 2015, 75, 176–188. [Google Scholar] [CrossRef]

- Zhang, J.; Ju, X.; Guo, Z. Tensile Properties of Fiber Reinforced Cement Composite with Different PVA Fibers. J. Build. Mater. 2009, 12, 706–710. [Google Scholar]

- Arain, M.F.; Wang, M.; Chen, J.; Zhang, H. Study on PVA fiber surface modification for strain-hardening cementitious composites (PVA-SHCC). Constr. Build. Mater. 2019, 197, 107–116. [Google Scholar] [CrossRef]

- Drechsler, A.; Frenzel, R.; Caspari, A.; Michel, S.; Holzschuh, M.; Synytska, A.; Curosu, I.; Liebscher, M.; Mechtcherine, V. Surface modification of poly (vinyl alcohol) fibers to control the fiber-matrix interaction in composites. Colloid Polym. Sci. 2019, 297, 1079–1093. [Google Scholar] [CrossRef]

- Zhang, L.; Guo, L.; Sun, W.; Zhang, W.; Chen, Z. Rheological property and fiber dispersion of high ductility cementitious composites. J. Southeast Univ. (Nat. Sci. Ed.) 2014, 44, 1037–1040. [Google Scholar]

- Liu, J.; Zhang, L.; Li, C.; Liu, J. Dispersive Characterization and Control of Fiber in Polyvinyl Alcohol Fiber Cement Composites. J. Chin. Ceram. Soc. 2015, 43, 1061–1066. [Google Scholar]

- Li, W.; Zhou, X.; Li, N. Research on the effect of fly ash content on the tensile properties of pva-ecc. In Proceedings of the 2015 Asia-Pacific Energy Equipment Engineering Research Conference, Zhuhai, China, 13–14 June 2015. [Google Scholar]

- Ling, Y.; Zhang, P.; Wang, J.; Chen, Y. Effect of PVA fiber on mechanical properties of cementitious composite with and without nano-SiO2. Constr. Build. Mater. 2019, 229, 117068. [Google Scholar] [CrossRef]

- Şahmaran, M.; Özbay, E.; Yücel, H.E.; Lachemi, M.; Li, V.C. Frost resistance and microstructure of Engineered Cementitious Composites: Influence of fly ash and micro poly-vinyl-alcohol fiber. Cem. Concr. Compos. 2012, 34, 156–165. [Google Scholar] [CrossRef]

- Haque, A.M.; Chen, B.; Ahmad, M.R. Evaluating the physical and strength properties of fiber reinforced magnesium phosphate cement mortar considering mass loss. Constr. Build. Mater. 2019, 217, 427–440. [Google Scholar] [CrossRef]

- Zhang, Q.; Xie, Y.; Gu, R.; Liang, X.; Zhang, Z. Chloride ion resistance of multi-scale fiber reinforced cementitious composites. J. Civ. Environ. Eng. 2023, 1–10. [Google Scholar]

- Tan, M.; Sun, R.; Zhou, Z.; Zhu, X.; Zhao, Z. Experimental study on the influence of PVA fiber length and content on the properties of engineering cement-based composites. Railw. Eng. 2014, 3, 115–117. [Google Scholar]

- Yu, B.; Zhou, J.; Kong, Y.; Yang, W.; Cheng, B. Effect of PVA Fiber Length on Mechanical Properties of Ultra-High Toughness Cementitious Composites. Bull. Chin. Ceram. Soc. 2020, 39, 3425–3431. [Google Scholar]

- Sasmal, S.; Avinash, G. Investigations on mechanical performance of cementitious composites micro-engineered with poly vinyl alcohol fibers. Constr. Build. Mater. 2016, 128, 136–147. [Google Scholar] [CrossRef]

- Yao, X.; Shamsaei, E.; Chen, S.; Zhang, Q.; de Souza, F.B.; Sagoe-Crentsil, K.; Duan, W. Graphene oxide-coated Poly (vinyl alcohol) fibers for enhanced fiber-reinforced cementitious composites. Compos. Part B Eng. 2019, 174, 107010. [Google Scholar] [CrossRef]

- Arain, M.F.; Wang, M.; Chen, J.; Zhang, H. Experimental and numerical study on tensile behavior of surface modified PVA fiber reinforced strain-hardening cementitious composites (PVA-SHCC). Constr. Build. Mater. 2019, 217, 403–415. [Google Scholar] [CrossRef]

- Wang, M.; Muhammad, F.A.; Zhang, H.; Guo, Y. Effect of Srftace Mdifcation of Domestic Polyvinyl Alcohol Fiber on Fexural Propeties of Engineered Cementtious Compoites. Synth. Fiber China 2019, 48, 37–41+45. [Google Scholar]

- Kim, K.-W.; Yu, C.; Han, J.-W.; Park, C.-G. Strength and durability of rapid set PVA fiber reinforced LMC for pavement repair. Polym. Polym. Compos. 2019, 27, 179–188. [Google Scholar] [CrossRef]

- Ding, C.; Guo, L.; Chen, B.; Xu, Y.; Cao, Y.; Fei, C. Micromechanics theory guidelines and method exploration for surface treatment of PVA fibers used in high-ductility cementitious composites. Constr. Build. Mater. 2019, 196, 154–165. [Google Scholar] [CrossRef]

- Curosu, I.; Liebscher, M.; Alsous, G.; Muja, E.; Li, H.; Drechsler, A.; Frenzel, R.; Synytska, A.; Mechtcherine, V. Tailoring the crack-bridging behavior of strain-hardening cement-based composites (SHCC) by chemical surface modification of poly(vinyl alcohol) (PVA) fibers. Cem. Concr. Compos. 2020, 114, 103722. [Google Scholar] [CrossRef]

- Zhou, Y.; Huang, J.; Yang, X.; Dong, Y.; Feng, T.; Liu, J. Enhancing the PVA fiber-matrix interface properties in ultra high performance concrete: An experimental and molecular dynamics study. Constr. Build. Mater. 2021, 285, 122862. [Google Scholar] [CrossRef]

- Yuan, Q.; Liang, N.; Zhao, C.; Yang, Z.; Zeng, S. Effect of PVA Fibers Dispersion on Mechanical Properties of Cement Mortar and Cement Stabilized Macadam. J. Build. Mater. 2021, 24, 921–929. [Google Scholar]

- Cao, Y.; Li, Y.; Zheng, N.; Wang, Q.; Zhou, Y. Research on Evaluation Method of Fiber Mixing Uniformity of PVA Fiber Cement Stabilized Macadam. Highway 2018, 63, 32–35. [Google Scholar]

- Pan, Z.; Wu, C.; Liu, J.; Wang, W.; Liu, J. Study on mechanical properties of cost-effective polyvinyl alcohol engineered cementitious composites (PVA-ECC). Constr. Build. Mater. 2015, 78, 397–404. [Google Scholar] [CrossRef]

- Shi, L.; Lin, S.T.K.; Lu, Y.; Ye, L.; Zhang, Y. Artificial neural network based mechanical and electrical property prediction of engineered cementitious composites. Constr. Build. Mater. 2018, 174, 667–674. [Google Scholar] [CrossRef]

- Yin, Y.; Qiu, B. Experimental Study on Mechanical Properties and Early Cracking of Polyvinyl Alcohol Fiber Concrete. Bull. Chin. Ceram. Soc. 2019, 38, 454–458. [Google Scholar]

- Wang, Y.; Sun, L.; Gao, Y.; Liu, S. Experimental Study on Shear Performance of Oblique Section Of PVA-ECC Beams. Ind. Constr. 2019, 49, 184–188+42. [Google Scholar]

- Lin, J.-X.; Song, Y.; Xie, Z.-H.; Guo, Y.-C.; Yuan, B.; Zeng, J.-J.; Wei, X. Static and dynamic mechanical behavior of engineered cementitious composites with PP and PVA fibers. J. Build. Eng. 2020, 29, 101097. [Google Scholar] [CrossRef]

- Ma, H.; Cai, J.; Lin, Z.; Qian, S.; Li, V.C. CaCO3 whisker modified Engineered Cementitious Composite with local ingredients. Constr. Build. Mater. 2017, 151, 1–8. [Google Scholar] [CrossRef]

- Lin, J.; Yu, J.; Li, V.C. Mechanical properties of PVA filber reinforced engineered cementitious composites after thermal treatment. Acta Mater. Compos. Sin. 2016, 1, 116–122. [Google Scholar]

- Gao, S.; Wang, Z.; Wang, W.; Qiu, H. Effect of shrinkage-reducing admixture and expansive agent on mechanical properties and drying shrinkage of Engineered Cementitious Composite (ECC). Constr. Build. Mater. 2018, 179, 172–185. [Google Scholar] [CrossRef]

- Wang, W.; Pan, Z.; Meng, S.; Qiao, Z. Study on Mechanical Properties of Domestic PVA Fiber Reinforced Cementitious Composite. Ind. Constr. 2014, 44, 958–964. [Google Scholar]

- Wang, H.; Tian, W. Experimental Study of Mechanical Properties and Frost Resistance Of PVA-ECC. Ind. Constr. 2017, 47, 123–125+130. [Google Scholar]

- Sahmaran, M.; Yücel, H.E.; Demirhan, S.; Li, V.C. Combined effect of aggregate and mineral admixtures on tensile ductility of engineered cementitious composites. ACI Mater. J. 2012, 109, 627. [Google Scholar]

- Huang, J.; Yang, D.; Zhu, Z.; Wang, T.; Wang, T. Reseach of the long-term mechanical properties of polyiny lalcohol fber cncrete. Concrete 2019, 354, 76–80. [Google Scholar]

- Li, Y.; Cheng, G.; Liu, Z. Analysis of Strength And Deformation Prpperties On PVA-ECC under Uniaxial Compression. Ind. Constr. 2017, 47, 122–126+158. [Google Scholar]

- Chung, K.L.; Ghannam, M.; Zhang, C. Effect of specimen shapes on compressive strength of engineered cementitious composites (ECCs) with different values of water-to-binder ratio and PVA fiber. Arab. J. Sci. Eng. 2018, 43, 1825–1837. [Google Scholar] [CrossRef]

- Dias, F.G.; Segadaes, A.M.; Perottoni, C.A.; Cruz, R.C.D. Assessment of the fluxing potential of igneous rocks in the traditional ceramics industry. Ceram. Int. 2017, 43, 16149–16158. [Google Scholar] [CrossRef]

- Li, V.C. On engineered cementitious composites (ECC) a review of the material and its applications. J. Adv. Concr. Technol. 2003, 1, 215–230. [Google Scholar] [CrossRef]

- Huang, J.; Yang, D.; Zhu, Z.; Wang, T.; Du, B.; Wang, T. Experimental study on durblity of polyvinyl alcohol fiber concrete. Concrete 2019, 356, 61–65. [Google Scholar]

- Al Rikabi, F.T.; Sargand, S.M.; Khoury, I.; Hussein, H.H. Material Properties of Synthetic Fiber–Reinforced Concrete under Freeze-Thaw Conditions. J. Mater. Civ. Eng. 2018, 30, 04018090. [Google Scholar] [CrossRef]

- Deng, Z.; Xuan, H.; Xu, H. Experimental Study of Durability Properties of High Toughness Fiber Reinforced Cementiitous Composites under Freezing and Thawing Cycles. J. North China Univ. Water Resour. Electr. Power (Nat. Sci. Ed.) 2013, 34, 16–19. [Google Scholar]

- Zhao, X.; Wang, X.; Qiao, H.; Huang, R. Study on Freeze-thaw Cycle Damage Law and Model of PVA Fiber Reinforced Concrete. China Concr. Cem. Prod. 2022, 53–57. [Google Scholar] [CrossRef]

- Ge, W.; Cai, C.; Ji, X.; Ashour, A.F.; Cao, D. Experimental study of mechanical properties of PVA-ECC under freeze-thaw cycles. J. Test. Eval. 2018, 46, 2330–2338. [Google Scholar] [CrossRef]

- Du, X.; Li, J.; Zhang, X.; Zhao, X.; Zhou, Z. Durability of Concrete with Low Content Polyvinyl Alcohol Fibers. J. Univ. Jinan (Sci. Technol.) 2017, 31, 371–376. [Google Scholar]

- Zhong, J.; Wang, Z.; Gao, Q. Chloride ion resistance of cementitious composites with PVA fiber reinforcement. Concrete 2019, 356, 105–108. [Google Scholar]

- Ding, X.; Zhang, J.; Wang, Q. Chloride Ion Permeability of Low Shrinkage Engineered Cementitious Composite. J. Build. Mater. 2017, 20, 827–834. [Google Scholar]

- Yan, C.; Cao, Y.; Liu, S.; Wang, X.; Pang, P. Experimental study on salt erosion resistance of PVA fiber concrete. Concrete 2020, 374, 56–60. [Google Scholar]

- Li, L.; Tan, Y.; Li, K.; Yang, L.; Du, X. Comparative Study on Effect of Basalt Fiber, Polyacrylonitrlie Fiber, and Polyvinyl Alcohol Fiber on Concrete Performance. Railw. Eng. 2019, 59, 130–134. [Google Scholar]

- Si, W.; Feng, X. Experimental Study on Flexural Strength and Chloride Ion Permeability of PVA-ECC. Bull. Chin. Ceram. Soc. 2018, 37, 2214–2217. [Google Scholar]

- Cai, X. Experimental Research on the Durable Properties of Ultra High Toughness Cementitious Composites (UHTCC). Master’s Thesis, Dalian University of Technology, Dalian, China, 2010. [Google Scholar]

- Bao, W.; Li, L.; Yuan, L. Experiment on carbonation properties of green ductile cementitious composite. J. Shenyang Univ. Technol. 2018, 40, 104–108. [Google Scholar]

- Luo, Z. Study on Effect of PVA Fiber Modification on Carbonation Resistance of Concrete. Master’s Thesis, Huazhong University of Science and Technology, Wuhan, China, 2021. [Google Scholar]

- Zhang, W.; Zou, X.; Wei, F.; Wang, H.; Zhang, G.; Huang, Y.; Zhang, Y. Grafting SiO2 nanoparticles on polyvinyl alcohol fibers to enhance the interfacial bonding strength with cement. Compos. Part B Eng. 2019, 162, 500–507. [Google Scholar] [CrossRef]

- Sun, M.; Chen, Y.; Zhu, J.; Sun, T.; Shui, Z.; Ling, G.; Zhong, H.; Zheng, Y. Effect of modified polyvinyl alcohol fibers on the mechanical behavior of engineered cementitious composites. Materials 2018, 12, 37. [Google Scholar] [CrossRef]

- Wang, H.; Tian, W.; Qing, L.; Xu, L. Dosage of Fly Ash on the Mechanical Properties of PVA Cementitious Composites. Bull. Chin. Ceram. Soc. 2015, 34, 2997–3003. [Google Scholar]

- Sahmaran, M.; Lachemi, M.; Hossain, K.M.A.; Ranade, R. Influence of aggregate type and size on ductility and mechanical properties of engineered cementitious composites. ACI Mater. J. 2009, 106, 308. [Google Scholar]

- Li, Y.; Zhu, J.; Wu, Y.; Yu, P. Research of Mechanics Properties of PVA Fiber Cementitions Composites. J. Beijing Univ. Technol. 2018, 44, 553–560. [Google Scholar]

- Ke, Y.; Shen, Y.; Fei, G.; Wang, H. Surface Modification of Water Soluble Polyvinyl Alcohol Fiber with Glycidyl Methacrylate and Its Strengthening Mechanism. Polym. Mater. Sci. Eng. 2013, 29, 103–106+111. [Google Scholar]

- Ding, C.; Guo, L.; Chen, B.; Deng, Z.; Huang, G. Alkali Resistance and Surface Modification of High Strength and High Modulus PVA Fibers. J. Chin. Ceram. Soc. 2019, 47, 228–235. [Google Scholar]

- Cao, Y.; Zhao, Y.; Wang, Q.; Xia, Z.; Zheng, N. Mixng Uifomiy of Cement Stililed Macadam with PVA Fiber. J. Chongqing Jiaotong Univ. (Nat. Sci.) 2018, 37, 29–33. [Google Scholar]

- Zhou, J.; Pan, J.; Leung, C.K.Y. Mechanical behavior of fiber-reinforced engineered cementitious composites in uniaxial compression. J. Mater. Civ. Eng. 2015, 27, 04014111. [Google Scholar] [CrossRef]

- Zhang, W.; Yin, C.; Ma, F.; Huang, Z. Mechanical properties and carbonation durability of engineered cementitious composites reinforced by polypropylene and hydrophilic polyvinyl alcohol fibers. Materials 2018, 11, 1147. [Google Scholar] [CrossRef]

- Pakravan, H.R.; Jamshidi, M.; Latifi, M. The effect of hydrophilic (polyvinyl alcohol) fiber content on the flexural behavior of engineered cementitious composites (ECC). J. Text. Inst. 2018, 109, 79–84. [Google Scholar] [CrossRef]

- Zhong, J.F. Multi-Objective Optlmization and Working State Analysis of Cement-Based Composite with PVA Fiber. Ph.D. Thesis, Harbin Institute of Technology, Harbin, China, 2020. [Google Scholar]

- GB/T 50082-2009; Standard for Test Methods of Long-Term Performance and Durability of Ordinary Concrete. China Architecture and Building Press: Beijing, China, 2010.

- ASTM C1202-2010; Standard Test Method for Electrical Indication of Concrete’s Ability to Resist Chloride Ion Penetration. American Society for Testing Material (ASTM): West Conshohocken, PA, USA, 2010.

- Zhang, P.; Wan, J.; Su, H.; Dai, X. Carbonation Resistance of Nano-particles and PVA Fiber Reinforced Cement Based Composites. Water Resour. Power 2017, 35, 108–111. [Google Scholar]

- Zhang, P.; Li, Q.; Wang, J.; Shi, Y.; Ling, Y. Effect of PVA fiber on durability of cementitious composite containing nano-SiO2. Nanotechnol. Rev. 2019, 8, 116–127. [Google Scholar] [CrossRef]

- Luo, Z.; Yang, X.; Ji, H.; Zhang, C. Carbonation Model and Prediction of Polyvinyl Alcohol Fiber Concrete with Fiber Length and Content Effects. Int. J. Concr. Struct. Mater. 2022, 16, 9. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).