Belt Rotation in Pipe Conveyors: Failure Mode Analysis and Overlap Stability Assessment

Abstract

1. Introduction

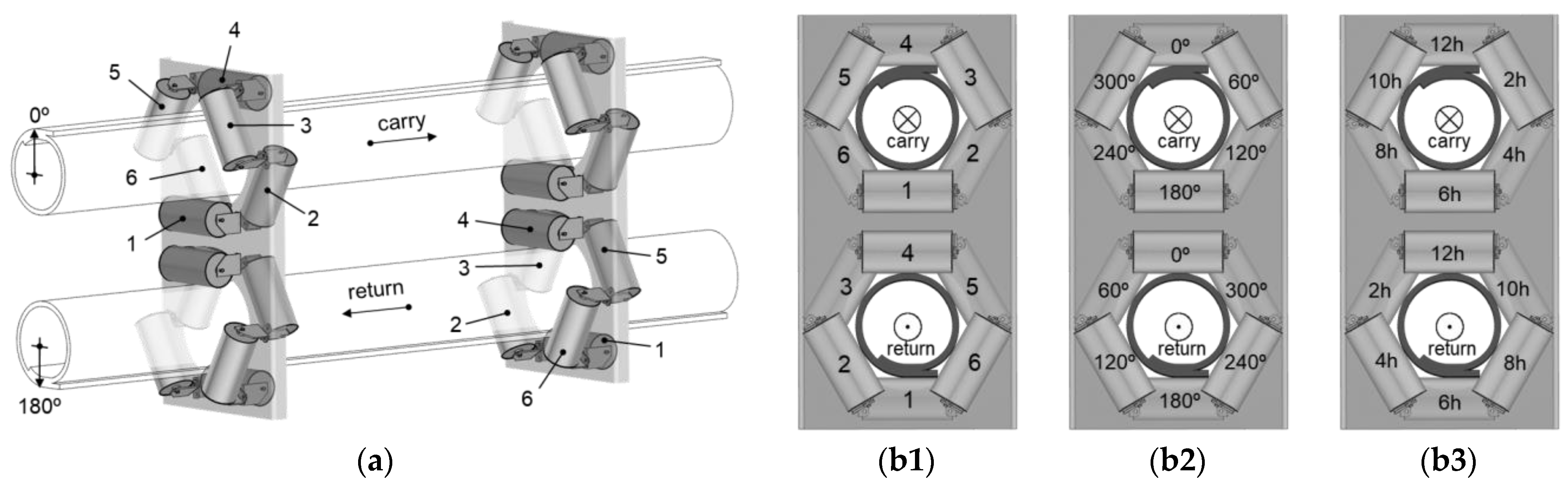

2. Failure Mode Analysis

- Bulk spillage or powder emission: Belt rotation may affect the overlap sealing efficiency, causing spillage of the material [3] or dust emissions in the twisted regions.

- Damage to the belt edges: Belt rotation may damage the external side of the overlap edge because of the pinching of the belt between the idler rolls (in the case of the in-line panel arrangement) or the friction of the belt with the housing of the idler rolls (in the case of the offset arrangement).

- Fire on the pipe belt: Premature failures in idler rolls caused by pinching or friction between the belt and the idler housing may trigger conveyor fires that easily propagate within the facility owing to the belt’s movement [31].

- Wear on the belt edges: Belt rotation may increase the stress concentration of the powder or bulk material and the friction rubber between the overlapping edges, leading to premature wear and affecting its sealing capability.

- Rainwater ingress: Carry flights are susceptible to the contamination of powder or bulk material by rainwater in the case of belt rotation, which is particularly relevant for equipment that is exposed to long shutdowns with the belt under rotated conditions.

- Propagation of cracks in the belt surface: Dynamic strain in the radial direction resulting from belt rotation favors crack propagation on the back cover surface of the belt, leading to accelerated aging owing to oxidative attack [32].

2.1. Causes and Contributing Factors

2.2. Strong Winds

2.3. Heavy Rain

2.4. Sub-Zero Temperatures

2.5. Sunlight, Ozone, Oxygen, and Heat

2.6. Prolonged Shutdown

2.7. Hard-Flowing Powdered or Bulk Materials

2.8. Dewatered Materials

2.9. Deteriorating Powder or Bulk Materials

2.10. Unstable Filling Degrees

2.11. Improper Routing

2.12. High Belt Speeds

2.13. Belt Sag

2.14. Excessive Belt Cycling

2.15. Improper Belt Reinforcement

2.16. Low Belt Length/Pipe Diameter Ratio

2.17. Improper Transverse Bending Stiffness

2.18. Poor Structural Alignment

2.19. Heterogeneous Hardness along the Belt Length

2.20. Vulcanizing and Splicing Issues

2.21. Excessive Tension during Installation

2.22. Improper Tension Force

2.23. Improper Belt Training

2.24. Low Tension in Molding Rolls

2.25. Missing or Seized Idler Rolls

3. Methods

3.1. Rotational Holding Torque

- Material lift between the inlet and outlet;

- Longitudinal belt tension;

- Filling degree variation and bulk solids properties;

- Belt properties, environmental, and operational conditions.

3.2. Overlap Stability Index

3.3. Experimental Method

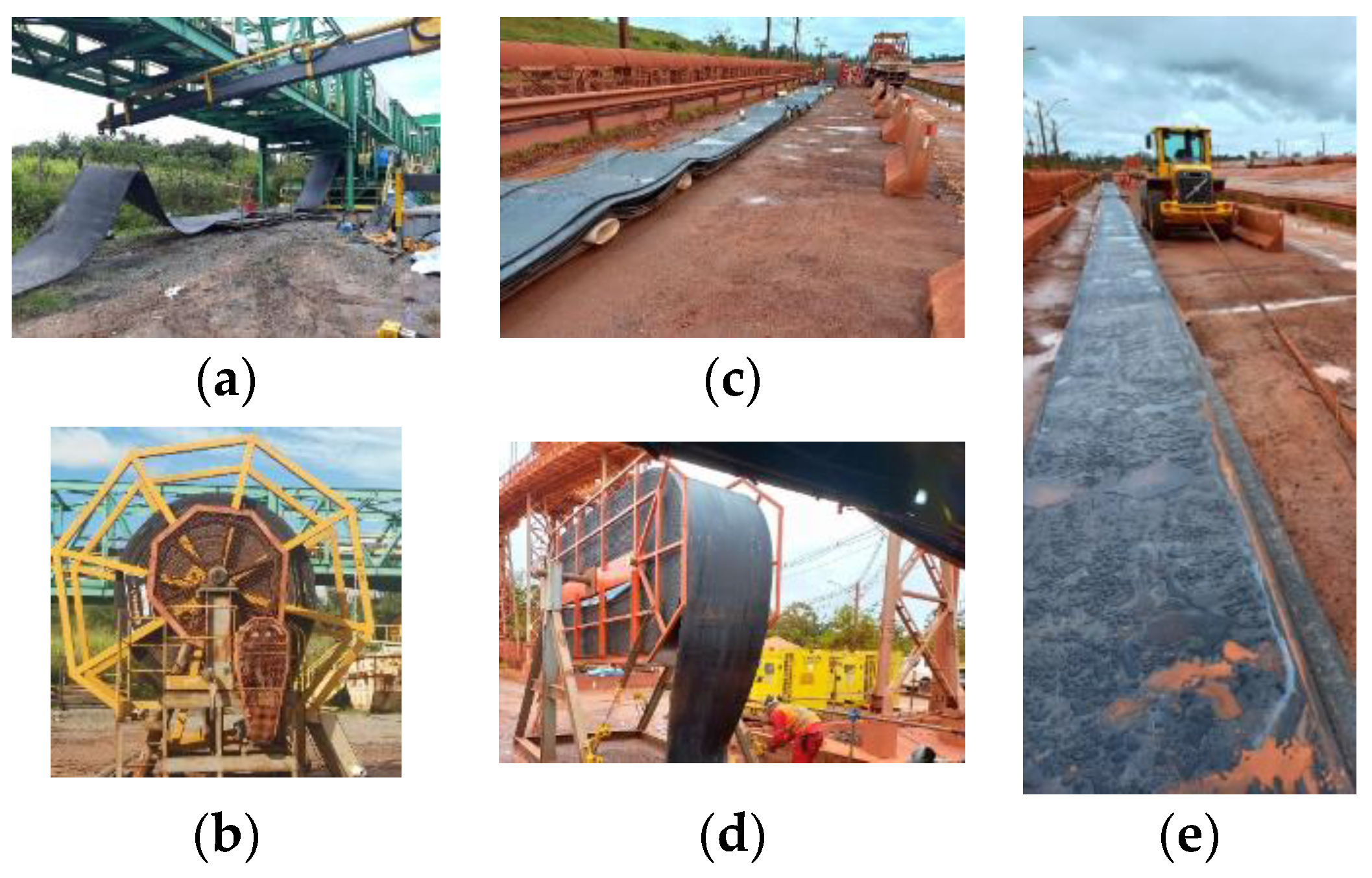

- Acquisition of operation data. This step involved acquiring data related to the degree of belt filling during the unloading operations of a regular shipment. Mass flow data were collected, historicized, and processed using the OSIsoft PI System application for later retrieval at 5-min intervals during a 5-day unloading operation. The calibrated belt scale was located upstream of the pipe conveyor, and the data were logged in tons/h.

- Collection of design parameters. This step comprised the gathering of technical data, including the curves and elevation of the conveyor routing, as well as the equipment specifications available in drawings, schematics, and structural and mechanical calculations.

- Harmonization of the filling degree percentage. This step comprised the calculation of the filling degree percentage and then processing the data in 10% steps to correspond with those utilized in the software for the belt simulation. We programmed Python code and applied the conversion presented in Equation (24):

- 4.

- Simulation of contact forces in curved flights. This step comprised the calculation of the contact forces of the belt in curved flights using the Belt Analyst software, from no-load operations to 80% in increments of 10%. The data were exported in an electronic spreadsheet format for later processing.

- 5.

- Assessment of contact losses in curved flights. This step involved assessing the contact losses in the idler rolls, which may have contributed to the rotation. Warning labels were provided in the radar charts using Python coding for each idler roll position on the curved flights.

- 6.

- Calculation of contact forces in a straight flight. This step comprised the calculation of the contact forces of the belt in its theoretical equivalent straight flight using our proposed methodology, from no-load operations to 80% in increments of 10%. Python coding was used to process and store the data frames.

- 7.

- Calculation of the holding torque and rotary moment. This step involved calculating the rotational holding torque and rotary moment of the belt based on the calculated and simulated contact forces and considering the friction coefficient as proposed in our methodology. Python coding was used to generate the time series for each idler roll and the total values.

- 8.

- Estimation of normal kernel density functions. This step comprised the numerical calculation of the minimum functions and stress–strength models for the smoothed normal kernel density estimation of the rotational holding torque and rotary moment of the belt. A graphical view was provided in the probability density charts using Python coding for each curved section during the carry flight.

- 9.

- Calculation of the OSI. The index was calculated using the Python integration library, as per the proposed methodology. Python coding was used to calculate the index for each curved section during the carry flight.

- 10.

- Assessment of field installation. This step involved inspecting the critical flights detected in the assessment of contact losses, as well as those for which the OSI presented higher differences. We visually inspected the equipment during the flights of interest and discussed the findings and outlook.

4. Results and Discussions

- Belt length

- Panel spacing

- Belt thickness

- Belt linear mass

- Powder or bulk density

- Nominal pipe diameter

- Overlap outer edge direction

- Elastic modulus of the belt

- Poisson’s ratio of the belt in the longitudinal direction

- Poisson’s ratio of the belt in the transversal direction

- Belt speed

- Belt’s remaining life

- ISO 703:2017 Conveyor belts—Transverse flexibility (troughability) [45];

- ISO 188:2023 Rubber, vulcanized or thermoplastic—Accelerated aging and heat resistance tests [46];

- ISO 1431-1:2022 Rubber, vulcanized or thermoplastic—Resistance to ozone cracking—Part 1: Static and dynamic strain testing [32];

- ISO 1817:2022 Rubber, vulcanized or thermoplastic—Determination of the effect of liquids [35];

- ISO 6943:2017 Rubber, vulcanized—Determination of tension fatigue [47];

- ISO 27727:2008 Rubber, vulcanized—Measurement of fatigue crack growth rate [48];

- ISO/TR 7620:2005 Rubber materials—Chemical resistance [119].

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- CEMA7. Conveyor Equipment Manufacturers Association Belt Conveyors for Bulk Materials, 7th ed.; Conveyor Equipment Manufacturers Association: Naples, FL, USA, 2014; 978-1891171-44-4. [Google Scholar]

- Zamiralova, M.E.; Lodewijks, G. Measurement of a pipe belt conveyor contact forces and cross section deformation by means of the six-point pipe belt stiffness testing device. Measurement 2015, 70, 232–246. [Google Scholar] [CrossRef]

- Zamiralova, M.E.; Lodewijks, G. Shape stability of pipe belt conveyors: From throughability to pipe-ability. FME Trans. 2016, 44, 263–271. [Google Scholar]

- Zheng, Q.J.; Xu, M.H.; Chu, K.W.; Pan, R.H.; Yu, A.B. A coupled FEM/DEM model for pipe conveyor systems: Analysis of the contact forces on belt. Powder Technol. 2017, 314, 480–489. [Google Scholar] [CrossRef]

- Molnár, V.; Fedorko, G.; Stehlíková, B.; Michalik, P.; Kopas, M. Mathematical models for indirect measurement of contact forces in hexagonal idler housing of pipe conveyor. Measurement 2014, 47, 794–803. [Google Scholar] [CrossRef]

- Molnár, V.; Fedorko, G.; Andrejiová, M.; Grinčová, A.; Tomašková, M. Analysis of influence of conveyor belt overhang and cranking on pipe conveyor operational characteristics. Measurement 2015, 63, 168–175. [Google Scholar] [CrossRef]

- Zamiralova, M.E. Design Aspects of Pipe Belt Conveyors. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2017. [Google Scholar] [CrossRef]

- Hötte, S. Experimentelle Untersuchungen zu den Normalkräften bei Schlauchgurten; TEWISS-Technik-und-Wissen-GmbH: Garbsen, Germany, 2014. [Google Scholar]

- Sun, X.; Meng, W.; Zhao, H.; Yuan, Y.; Yang, Z. Analysis on the bending stiffness and the form force of the pipe conveyor belt. Sens. Transducers 2013, 161, 655. [Google Scholar]

- Zhang, Y.; Steven, R. Pipe conveyor and belt: Belt construction, low rolling resistance and dynamic analysis. In Proceedings of the SME Annual Meeting, Seattle, WA, USA, 19–22 February 2012. [Google Scholar]

- Molnar, V.; Fedorko, G.; Honus, S.; Andrejiova, M.; Grincova, A.; Michalik, P.; Palencar, J. Research in placement of measuring sensors on hexagonal idler housing with regard to requirements of pipe conveyor failure analysis. Eng. Fail. Anal. 2020, 116, 104703. [Google Scholar] [CrossRef]

- Wang, S.; Li, D.; Hu, K. Analysis and experimental study on pressure characteristics of supporting roller group of pipe belt conveyor. Shock Vib. 2019, 2019, 7061847. [Google Scholar] [CrossRef]

- Guo, S.; Huang, W.; Li, X. Normal force and sag resistance of pipe conveyor. Chin. J. Mech. Eng. 2020, 33, 48. [Google Scholar] [CrossRef]

- Molnár, V.; Fedorko, G.; Andrejiová, M.; Grinčová, A.; Kopas, M. Monitoring of dependences and ratios of normal contact forces on hexagonal idler housings of the pipe conveyor. Measurement 2015, 64, 168–176. [Google Scholar] [CrossRef]

- Molnár, V.; Fedorko, G.; Andrejiová, M.; Grinčová, A.; Michalik, P. Online monitoring of a pipe conveyor. Part I: Measurement and analysis of selected operational parameters. Measurement 2016, 94, 364–371. [Google Scholar] [CrossRef]

- Molnár, V.; Fedorko, G.; Andrejiová, M.; Grinčová, A.; Michalik, P. Online monitoring of pipe conveyors part II: Evaluation of selected operational parameters for the design of expert system. Measurement 2017, 104, 1–11. [Google Scholar] [CrossRef]

- VMolnár; Sabovčík, M. Static testing evaluation of pipe conveyor belt for different tensioning forces. Open Eng. 2019, 9, 580–585. [Google Scholar] [CrossRef]

- Molnar, V.; Fedorko, G.; Stehlikova, B.; Paulikova, A. Influence of tension force asymmetry on distribution of contact forces among the conveyor belt and idler rolls in pipe conveyor during transport of particulate solids. Measurement 2015, 63, 120–127. [Google Scholar] [CrossRef]

- VMolnár; Fedorko, G.; Stehlíková, B.; Kudelás, L.; Husáková, N. Statistical approach for evaluation of pipe conveyor’s belt contact forces on guide idlers. Measurement 2013, 46, 3127–3135. [Google Scholar] [CrossRef]

- Stehlikova, B.; Molnar, V.; Fedorko, G.; Michalik, P.; Paulikova, A. Research about influence of the tension forces, asymmetrical tensioning and filling rate of pipe conveyor belt filled with the material on the contact forces of idler rolls in hexagonal idler housing. Measurement 2020, 156, 107598. [Google Scholar] [CrossRef]

- Molnár, V.; Fedorko, G.; Honus, S.; Andrejiová, M.; Grinčová, A.; Michalik, P. Prediction of contact forces on idler rolls of a pipe conveyor idler housing for the needs of its online monitoring. Measurement 2019, 139, 177–184. [Google Scholar] [CrossRef]

- Molnar, V.; Fedorko, G.; Stehlikova, B.; Michalik, P.; Kopas, M. Influence of tension and release in piped conveyor belt on change of normal contact forces in hexagonal idler housing for pipe conveyor loaded with material. Measurement 2016, 84, 21–31. [Google Scholar] [CrossRef]

- Hötte, S.; Overmeyer, L.; Wennekamp, T. Form force behaviour of pipe conveyors in different curve radii. Bulk Solids Handl. 2011, 31, 164–169. [Google Scholar]

- Molnár, V.; Fedorko, G.; Stehlíková, B.; Tomašková, M.; Hulínová, Z. Analysis of asymmetrical effect of tension forces in conveyor belt on the idler roll contact forces in the idler housing. Measurement 2014, 52, 22–32. [Google Scholar] [CrossRef]

- Bombasaro, E.; Oddera, R. Field measurement of contact forces on rollers for a large diameter pipe conveyor. Open Eng. 2020, 11, 130–141. [Google Scholar] [CrossRef]

- Santos, L.D.S.E.; Filho, P.R.C.F.R.; Macêdo, E.N. 2020Development of idler for measuring indentation rolling resistance in pipe conveyor belts. Measurement 2020, 153, 107413. [Google Scholar] [CrossRef]

- de Graaff, R.M.T. Troughability Testing on Troughed and Pipe Conveyor Belts-Trogbaarheid Testen Met Trog-en Pijp-Transportbanden; Delft University of Technology: Delft, The Netherlands, 2012. [Google Scholar]

- Maksarov, V.; Zlotnikov, E.; Olt, J. Determining the load on support rollers the pipe conveyor belt. In Proceedings of the 28th DAAAM International Symposium, Zadar, Croatia, 8–11 November 2017; DAAAM International: Maria Lankowitz, Austria, 2017. [Google Scholar]

- Batwe, S.; Jaju, S.; Vaidya, S. Pipe Conveyor. Int. Res. J. Eng. Technol. 2017, 4, 978–983. [Google Scholar]

- Dmitriev, V.G.; Efimov, M.S. Evaluation and method for reducing the angular deviations of the tubular conveyor belt during rotational motion, Mining Information and Analytical. Bull. Sci. Tech. J. 2009, 16, 31–53. [Google Scholar]

- Santos, L.D.S.E.; Soares, W.K.D.S.; Filho, P.R.C.F.R. A method for investigating the influence of rainwater on the useful life of idlers in pipe belt conveyors during seasonal operations. Eng. Fail. Anal. 2022, 141, 106702. [Google Scholar] [CrossRef]

- ISO 1431-1:2022; Rubber, Vulcanized or Thermoplastic—Resistance to Ozone Cracking—Part 1: Static and Dynamic Strain Testing. ISO: Geneva, Switzerland, 2022.

- Santos, L.D.S.E.; Filho, P.R.C.F.R.; Macêdo, E.N. Indentation rolling resistance in pipe conveyor belts: A review. J. Braz. Soc. Mech. Sci. Eng. 2021, 43, 230. [Google Scholar] [CrossRef]

- Imai, A. Pipe conveyor Development, benchmark and future trend. In Proceedings of the BulkSolids India 2011, the International Conference & Exhibition on Storing, Handling and Transporting Bulk Solids and Powders, Mumbai, India; 2011. [Google Scholar]

- ISO 1817:2022; Rubber, Vulcanized, or Thermoplastic—Determination of the Effect of Liquids. ISO: Geneva, Switzerland, 2022.

- Lodewijks, G. Determination of rolling resistance of belt conveyors using rubber data: Fact or fiction? Bulk Solids Handl. 2003, 23, 384–391. [Google Scholar]

- Loeffler, F.J.; Gulledge, J.D., Jr. Pipe/Tube Conveyors A Modern Method of Coal and Ash Transportation; Pennwell Conferences & Exhibitions: Houston, TX, USA, 1995. [Google Scholar]

- ISO 18766:2014; Rubber, Vulcanized or Thermoplastic—Low-Temperature Testing—General Introduction and Guide. ISO: Geneva, Switzerland, 2014.

- Andrejiova, M.; Grincova, A.; Marasova, D. Measurement and simulation of impact wear damage to industrial conveyor belts. Wear 2016, 368–369, 400–407. [Google Scholar] [CrossRef]

- Hakami, F.; Pramanik, A.; Basak, A.K. Wear of rubber material in conveyor belt system. In Tribology of Elastomers; Springer Nature Singapore: Singapore, 2022; pp. 23–51. [Google Scholar] [CrossRef]

- Mars, W.V.; Fatemi, A. Factors that affect the fatigue life of rubber: A literature survey. Rubber Chem. Technol. 2004, 77, 391–412. [Google Scholar] [CrossRef]

- Kang, W.; Liu, J.; Xiong, W.; You, T.; Wang, X.; Zeng, K.; Deng, Y.; Guo, Z.; Yuan, K. Basic mechanical and fatigue properties of rubber materials and components for railway vehicles: A literature survey. Rev. Adv. Mater. Sci. 2022, 61, 587–610. [Google Scholar] [CrossRef]

- Woo, C.S.; Park, H.S. Useful lifetime prediction of rubber component. Eng. Fail. Anal. 2011, 18, 1645–1651. [Google Scholar] [CrossRef]

- Brown, R.P.; Forrest, M.J.; Soulagnet, G. Long-Term and Accelerated Ageing Tests on Rubbers; Rapra Technology Limited: Shrewsbury, UK, 2000. [Google Scholar]

- ISO 703:2017; Conveyor Belts—Transverse Flexibility (Troughability). ISO: Geneva, Switzerland, 2017.

- ISO 188:2023; Rubber, Vulcanized, or Thermoplastic—Accelerated Aging and Heat Resistance Tests. ISO: Geneva, Switzerland, 2023.

- ISO 6943:2017; Rubber, Vulcanized—Determination of Tension Fatigue. ISO: Geneva, Switzerland, 2017.

- ISO 27727:2008; Rubber, Vulcanized—Measurement of Fatigue Crack Growth Rate. ISO: Geneva, Switzerland, 2008.

- Carr, M.J.; Roberts, A.W.; Wheeler, C.A. A revised methodology for the determination of bulk material cohesion and adhesion. Adv. Powder Technol. 2019, 30, 2110–2116. [Google Scholar] [CrossRef]

- Ganesan, V.; Rosentrater, K.A.; Muthukumarappan, K. Flowability and handling characteristics of bulk solids and powders–A review with implications for DDGS. Biosyst. Eng. 2008, 101, 425–435. [Google Scholar] [CrossRef]

- Johanson, J.R. Know Your Material-How to Predict and Use the Properties of Bulk Solids. Chem. Eng. 1978, 85, 9–17. [Google Scholar]

- Craik, D.J.; Miller, B.F. The flow properties of powders under humid conditions. J. Pharm. Pharmacol. 1958, 10 (Suppl. 1), 136T–144T. [Google Scholar] [CrossRef] [PubMed]

- Moreyra, R.; Peleg, M. Effect of equilibrium water activity on the bulk properties of selected food powders. J. Food Sci. 1981, 46, 1918–1922. [Google Scholar] [CrossRef]

- Schulze, D. Powders and Bulk Solids; Springer International Publishing: Cham, Switzerland, 2021. [Google Scholar] [CrossRef]

- Frew, I.; Wypych, P.W.; Mar, L. Different Modes of Dust Testing for Bulk Solids; University of Newcastle: Callaghan, NSW, Australia, 2013. [Google Scholar]

- Chen, X.L.; Wheeler, C.A.; Donohue, T.J.; McLean, R.; Roberts, A.W. Evaluation of dust emissions from conveyor transfer chutes using experimental and CFD simulation. Int. J. Miner. Process. 2012, 110–111, 101–108. [Google Scholar] [CrossRef]

- Kesler, F.; Prener, M. DEM: Simulation of conveyor transfer chutes. FME Trans. 2009, 37, 185–192. [Google Scholar]

- Ambrisko, L.; Marasova, D. Investigation of the ageing influence on the hardness of essential belt component. In Proceedings of the 18th International Multidisciplinary Scientific GeoConferences SGEM 2018, Albena, Bulgaria, 2–8 July 2018. [Google Scholar]

- Harrison, A.; Roberts, A.W.; Eng, O.M. Trends in the Application of Troughed Conveyor Belts. In Proceedings of the International Materials Handling Conference, Johannesburg, South Africa; 1983. [Google Scholar]

- Harrison, A. Propagation of longitudinal and transverse cracks on the covers of steel-cord belts. Min. Technol. 1982, 64, 738. [Google Scholar]

- VDI 4438:2019; VDI, Entwurf Pipe Conveyor—Design Criteria, Calculation and Safety Instructions. Verein Deutscher Ingenieure: Düsseldorf, Germany, 2019; p. 4438.

- JB/T10380; Pipe Belt Conveyor, 2nd ed. China Machinery Industry Federation (CMIF): Beijing, China, 2013.

- Zhang, Y. Extended reach: Overland pipe conveyor with low rolling resistance belt. Bulk Solids Handl. 2013, 33, 16–21. [Google Scholar]

- Minikin, A.; Dilffeld, M.; Fischer, W. Residuals removal at Maritza E1—Design, installation and commissioning of a tube belt conveyor. Bulk Solids Handl. 2014, 34. [Google Scholar]

- Kulagin, D.S. Establishment of bending radius of the tubular conveyor in the horizontal plane by modelling on the computer, Mining Informational and Analytical Bulletin. Sci. Tech. J. 2009, 16, 114–129. [Google Scholar]

- Andrianov, I.V.; Van Horssen, W.T. On the transversal vibrations of a conveyor belt: Applicability of simplified models. J. Sound Vib. 2008, 313, 822–829. [Google Scholar] [CrossRef]

- Suweken, G.; Van Horssen, W.T. On the transversal vibrations of a conveyor belt with a low and time-varying velocity. Part II: The beam-like case. J. Sound Vib. 2003, 267, 1007–1027. [Google Scholar] [CrossRef]

- Suweken, G.; Van Horssen, W.T. On the transversal vibrations of a conveyor belt with a low and time-varying velocity. Part I: The string-like case. J. Sound Vib. 2003, 264, 117–133. [Google Scholar] [CrossRef]

- Efimov, M.S. Determination of the restoring moments from the action of the load during the rotational movement of the tubular conveyor belt. Min. Inf. Anal. Bull. Sci. Tech. J. 2007, 11, 307–309. [Google Scholar]

- DIN 22112–1; Belt Conveyors for Underground Coal Mining—Idlers—Part 1: Dimensions. DIN: Berlin Germany, 2010.

- Zamiralova, M.E.; Lodewijks, G. Energy consumption of pipe belt conveyors: Indentation rolling resistance. FME Trans. 2012, 40, 171–176. [Google Scholar]

- Wheeler, C.; Munzenberger, P.; Ausling, D.; Beh, B. “Energy Efficient Belt Conveyor Design” Tunra Bulk Solids Research Associates; The University of Newcastle: Callaghan, NSW, Australia, 2018; p. 27. [Google Scholar]

- Neubecker, I. An overland pipe conveyor with 22 horizontal and 45 vertical curves connecting coal mine with rail load out. Bulk Solids Handling 1998, 18, 457–462. [Google Scholar]

- Ilanković, N.; Živanić, D.; Zuber, N. The influence of fatigue loading on the durability of the conveyor belt. Appl. Sci. 2023, 13, 3277. [Google Scholar] [CrossRef]

- Barburski, M. Analysis of the pipe conveyor belt pressure on the rollers on its circuit. J. Ind. Text. 2016, 45, 1619–1634. [Google Scholar] [CrossRef]

- Weigang, S.; Hongbo, J. Research Progress and Design Calculation Method of Tubular Belt Conveyor. Chin. J. Eng. Des. 2018, 25, 1–11. [Google Scholar]

- Guo, Y.-C.; Wang, S.; Hu, K.; Li, D. Optimization and experimental study of transport section lateral pressure of pipe belt conveyor. Adv. Powder Technol. 2016, 27, 1318–1324. [Google Scholar] [CrossRef]

- Haak, D. Overview and Characteristics of Pipe Conveyor Systems and Applications-Een Overzicht En de Karakteristieken van Buisvormige Transportbanden En de Toepassing Daarvan; Delft University of Technology: Delft, The Netherlands, 2017. [Google Scholar]

- Zamiralova, M.E.; Lodewijks, G. Review of the troughability test ISO 703 for quantifying a uniform transverse bending stiffness for conveyor belts. Arch. Civ. Mech. Eng. 2017, 17, 249–270. [Google Scholar] [CrossRef]

- Fedorko, G.; Molnár, V.; Živčák, J.; Dovica, M.; Husáková, N. Failure analysis of textile rubber conveyor belt damaged by dynamic wear. Eng. Fail. Anal. 2013, 28, 103–114. [Google Scholar] [CrossRef]

- Kozhushko, G.G.; Kopnov, V.A. Fatigue strength functions in shear loading of fabric conveyor belts. Int. J. Fatigue 1995, 17, 539–544. [Google Scholar] [CrossRef]

- E.N. Din 16974:2016; Conveyor Belts: IRR Related to Belt Width—Requirements, Testing. DIN: Berlin, Germany, 2016.

- AS 1334.13:2017; Methods of Testing Conveyor and Elevator Belting Determination of Indentation Rolling Resistance of Conveyor Belting. Standards Australia: Sydney, NSW, Australia, 2017.

- Indrajati, I.N.; Setyorini, I. Service life prediction of rubber belt conveyor using kinetics approach. AIP Conf. Proc. 2020, 2197, 090002. [Google Scholar] [CrossRef]

- ISO 5285:2012; Conveyor Belts—Guidelines for Storage and Handling. ISO: Geneva, Switzerland, 2012.

- Lemmi, T.S.; Barburski, M.; Kabzinski, A.; Frukacz, K. Effect of vulcanization process parameters on the tensile strength of carcass of textile-rubber reinforced conveyor belts. Materials 2021, 14, 7552. [Google Scholar] [CrossRef]

- Dobrotă, D. Vulcanization of rubber conveyor belts with metallic insertion using ultrasounds. Procedia Eng. 2015, 100, 1160–1166. [Google Scholar] [CrossRef]

- Minkin, A.; Jungk, A.; Hontscha, T. Design, replacement, and power measurements for the Long Distance pipe conveyor belt at western arch coal skyline Mine, USA. AMS-Online 2013, 2, 16–25. [Google Scholar]

- AMinkin; Jungk, A.; Hontscha, T. Belt replacement at a long distance pipe conveyor: Belt design, installation and power measurements. Bulk Solids Handl. 2012, 32, 16–21. [Google Scholar]

- Cherednik, P.N. Setting the critical value of the belt tension when braking a tubular conveyor. Min. Inf. Anal. Bull. Sci. Tech. J. 2016, 12, 213–219. [Google Scholar]

- Dmitriev, V.G.; Sergeeva, N.V. Traction calculation of tubular belt conveyors. Min. Inf. Anal. Bull. Sci. Tech. J. 2009, 16, 144–169. [Google Scholar]

- Michalik, P.; Zajac, J. Using of computer integrated system for static tests of pipe conveyer belts. In Proceedings of the 13th International Carpathian Control Conference (ICCC), High Tatras, Slovakia, 28–31 May 2012; IEEE Publications: Piscataway, NJ, USA, 2012; pp. 480–485. [Google Scholar] [CrossRef]

- Jennings, A.; Perrone, P.; Cornet, J. Case study: Correcting control problems on Essroc’s multidrive station, horizontally curved conveyor. Trans. Soc. Min. Metall. Explor. 2013, 334, 472–476. [Google Scholar]

- Lodewijks, G. Two decades dynamics of belt conveyor systems. Bulk Solids Handl. 2002, 22, 124–132. [Google Scholar]

- Kruse, D.J. Optimizing conveyor take-up systems using dynamic analysis and the implementation of capstans. In Bulk Material Handling by Conveyor SME Conference; Society for Mining, Metallurgy and Exploration: Littleton, Colorado, USA, 2002. [Google Scholar]

- Staples, P. The history of pipe conveyors. Bulk Solids Handl. 2002, 22, 210–213. [Google Scholar]

- Drenth, K.F. The rotation of pipe conveyors Bulk Solids India Conference paper, Nehru Centre, Mumbai, 2010, pp. 1–6. Advisor: Lodewijks, G. Report no. 50303. Maritime Archive, Mechanical, Maritime and Materials Engineering, Marine and Transport Technology, Transport Engineering and Logistics. In Proceedings of the BulkSolids India 2011, the International Conference & Exhibition on Storing, Handling and Transporting Bulk Solids and Powders, Mumbai, India, 2011. [Google Scholar]

- Fedorko, G.; Ivančo, V.; Molnár, V.; Husáková, N. Simulation of interaction of a pipe conveyor belt with moulding rolls. Procedia Eng. 2012, 48, 129–134. [Google Scholar] [CrossRef]

- Molnár, V.; Fedorko, G.; Stehlíková, B.; Michalik, P. Analysis of a pipe conveyor’s idler housing failure due to a missing roller in terms of contact forces. Eng. Fail. Anal. 2021, 127, 105527. [Google Scholar] [CrossRef]

- (PN-M) 46606; Przenośniki Taśmowe—Krążnikit, 2nd ed. Polski Komitet Normalizacyjny: Warsaw, Poland, 2010.

- (SANS) 1313–3; Conveyor Belt Idlers—Part 3: Performance Specifications for Troughed Belt Conveyor Idlers—Metallic and Non-metallic—For Idler Roller Rotational Speeds of up to 750 Revolutions per Minute, 1st ed. South African National Standards: Cape Town, South Africa, 2012.

- DIN 22112-3:2022-12; Belt Conveyors for Underground Coal Mining—Idlers—Part 3: Testing. DIN: Berlin Germany, 2022.

- Fedorko, G.; Molnár, V.; Vasiľ, M.; Salai, R. Proposal of digital twin for testing and measuring of transport belts for pipe conveyors within the concept Industry 4.0. Measurement 2021, 174, 108978. [Google Scholar] [CrossRef]

- Carter, R.A. New conveyor tech: Designing for productivity. Eng. Min. J. 2021, 222, 44–47. [Google Scholar]

- Nuttall, A.J.G. Design Aspects of Multiple Driven Belt Conveyors; TRAIL Research School: Delft, The Netherlands, 2007. [Google Scholar]

- Budynas, R.G.; Nisbett, J.K. Shigley’s Mechanical Engineering Design, 10th ed.; McGraw-Hill Education: New York, NY, USA, 2015; p. 1082. [Google Scholar]

- Gabriel, P. Investigation and Modelling of Rubber Friction. Ph.D. Thesis, Queen Mary University of London, London, UK, 2010. [Google Scholar]

- Maegawa, S.; Itoigawa, F.; Nakamura, T. Effect of normal load on friction coefficient for sliding contact between rough rubber surface and rigid smooth plane. Tribol. Int. 2015, 92, 335–343. [Google Scholar] [CrossRef]

- Persson, B.N.J. Theory of rubber friction and contact mechanics. J. Chem. Phys. 2001, 115, 3840–3861. [Google Scholar] [CrossRef]

- Yang, C.; Persson, B.N.J. Contact mechanics: Contact area and interfacial separation from small contact to full contact. J. Phys. Condens. Matter 2008, 20, 215214. [Google Scholar] [CrossRef]

- Klüppel, M.; Heinrich, G. Rubber friction on self-affine road tracks. Rubber Chem. Technol. 2000, 73, 578–606. [Google Scholar] [CrossRef]

- Wesemeier, M. Theoretical investigations of the forming force on pipe belt conveyor. Bulk Mater. 1997, 3, 29. [Google Scholar]

- Chernenko, V.D. Calculation of Continuous Transport Systems. Politekhnika; Politekhnika: Saint Petersburg, Russia, 2008. [Google Scholar]

- Bhushan, B. Introduction to Tribology; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar] [CrossRef]

- Ciavarella, M. A simplified version of Persson’s multiscale theory for rubber friction due to viscoelastic losses. J. Tribol. 2018, 140, 011403. [Google Scholar] [CrossRef]

- Sundararajan, C.R. Probabilistic Structural Mechanics Handbook: Theory and Industrial Applications; Springer Science+Business Media: Berlin/Heidelberg, Germany, 1995. [Google Scholar]

- Wand, M.P.; Jones, M.C. Smoothing, 1st ed.; Chapman & Hall: New York, NY, USA; CRC Press: Boca Raton, FL, USA, 1994. [Google Scholar] [CrossRef]

- Chacón, J.E.; Duong, T. Multivariate Kernel Smoothing and Its Applications; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- ISO/TR 7620:2005; Rubber materials—Chemical resistance. ISO: Geneva, Switzerland, 2005.

- Klippel, E.; Oliveira, R.A.R.; Maslov, D.; Bianchi, A.G.C.; Delabrida, S.E.; Garrocho, C.T.B. Embedded edge artificial intelligence for longitudinal rip detection in conveyor belt applied at the industrial mining environment. SN Comput. Sci. 2022, 3, 280. [Google Scholar] [CrossRef]

| Recommendation | Criteria | Filling Degree |

|---|---|---|

| CEMA 7th [1] | No lumps and good feed control | 80–85% |

| Typical value | 75% | |

| Very lumpy or feed control is poor | 60% or less | |

| JB/T 10380:2013 [61] | Lump size is less than 1/3 of nominal diameter | 75% |

| Lump size is less than 1/2 of nominal diameter | 50–60% | |

| Lump size is less than 2/3 of nominal diameter | 40–50% | |

| VDI 4438:2019 [62] | Lump size is less than 1/3 of nominal diameterNo lumps and good feed control | 80% |

| Lump size is less than 1/3 of nominal diameterTypical value | 60–80% | |

| Lump size is less than 1/3 of nominal diameterVery lumpy or feed control is poor | 30% |

| Variable | Criteria | Coefficient | Value |

|---|---|---|---|

| Belt reinforcement | Nylon | p | 0 |

| Polyester nylon | 1 | ||

| Aramid | 2 | ||

| Steel cord | 4 | ||

| Nominal pipe diameter (mm) | From 150 to 300 | f | 0 |

| From 300 to 500 | 1 | ||

| Curve’s central angle | <25 degrees | c | 0 |

| Between 25 and 50 degrees | 1 | ||

| Between 50 and 75 degrees | 2 | ||

| Between 75 and 100 degrees | 3 | ||

| Minimum curve radii (mm) | |||

| Parameter | Unit | Value |

|---|---|---|

| Belt length | m | 1.45 |

| Panel spacing | m | 2 |

| Belt thickness | mm | 19 |

| Belt linear mass | kg/m | 30.7 |

| Powder or bulk density | kg/m³ | 881 |

| Nominal pipe diameter | mm | 375 |

| Overlap outer edge | Left or left | Left |

| Elastic modulus of the belt | MPa | 10 |

| Poisson’s ratio of the belt in the longitudinal direction | - | 0.45 |

| Poisson’s ratio of the belt in the transversal direction | - | 0.45 |

| Belt speed | m/s | 4.9 |

| Point | Type | Vertical Radius (m) | Horizontal Radius (m) | Direction | Flight Length (m) | Lift (m) | Grouped Flights |

|---|---|---|---|---|---|---|---|

| 1 | Carry | Straight | 171.88 | 16.77 | 1 | ||

| 2 | Carry | 270 | Right | 7.35 | 0.72 | 2–9 | |

| 3 | Carry | 270 | Right | 5.77 | 0.60 | ||

| 4 | Carry | 150 | 270 | Right | 1.40 | 0.15 | |

| 5 | Carry | 150 | 270 | Right | 1.40 | 0.12 | |

| 6 | Carry | 150 | 270 | Right | 0.50 | 0.04 | |

| 7 | Carry | 170 | 270 | Right | 7.14 | 0.61 | |

| 8 | Carry | 170 | 270 | Right | 7.17 | 0.01 | |

| 9 | Carry | 170 | 270 | Right | 16.40 | 0.01 | |

| 10 | Carry | 270 | Right | 46.45 | 0.04 | 10 | |

| 11 | Carry | 270 | Right | 23.56 | 0.02 | 11–12 | |

| 12 | Carry | 270 | Right | 23.56 | 0 | ||

| 13 | Carry | 270 | Right | 73.44 | 0 | 13 | |

| 14 | Carry | Straight | 42.44 | 0 | 14 | ||

| 15 | Carry | 270 | Left | 23.56 | 0 | 15–16 | |

| 16 | Carry | 270 | Left | 23.56 | 0 | ||

| 17 | Carry | 270 | Left | 21.44 | 0 | 17 | |

| 18 | Carry | Straight | 45.00 | 0 | 18 | ||

| 19 | Carry | Straight | 72.00 | 0.15 | 19 |

| Contact Forces (N) | F1 | 742.59 | 791.36 | 832.79 | 870.84 | 911.16 | 964.75 | 994.26 | 1035.66 | 1091.19 |

| F2 | 408.15 | 413.51 | 436.21 | 473.66 | 524.66 | 592.94 | 676.60 | 791.55 | 955.03 | |

| F3 | 230.14 | 229.60 | 229.03 | 228.42 | 227.95 | 227.25 | 226.69 | 230.79 | 253.53 | |

| F4 | 189.32 | 189.26 | 189.32 | 189.34 | 189.31 | 189.28 | 189.29 | 189.34 | 189.30 | |

| F5 | 284.75 | 284.09 | 283.38 | 282.62 | 282.04 | 281.17 | 280.48 | 285.55 | 313.69 | |

| F6 | 450.32 | 452.23 | 473.82 | 511.72 | 564.33 | 637.39 | 700.60 | 764.60 | 815.84 | |

| Rotational Holding Torque (Nm) | T1 | 216.28 | 230.11 | 241.84 | 252.61 | 264.01 | 279.15 | 287.48 | 299.16 | 314.82 |

| T2 | 120.93 | 122.47 | 128.98 | 139.70 | 154.28 | 173.75 | 197.55 | 230.16 | 276.40 | |

| T3 | 69.54 | 69.38 | 69.21 | 69.04 | 68.90 | 68.69 | 68.53 | 69.72 | 76.33 | |

| T4 | 57.63 | 57.61 | 57.63 | 57.64 | 57.63 | 57.62 | 57.62 | 57.64 | 57.63 | |

| T5 | 85.38 | 85.19 | 84.98 | 84.76 | 84.59 | 84.34 | 84.14 | 85.61 | 93.74 | |

| T6 | 133.02 | 133.57 | 139.75 | 150.58 | 165.60 | 186.40 | 204.37 | 222.52 | 237.04 | |

| Total | 682.78 | 698.32 | 722.39 | 754.33 | 795.00 | 849.96 | 899.70 | 964.82 | 1055.97 | |

| Curved Flight | Overlap Position (°) | Clearance to the Belt Back Cover (mm) | |||||

|---|---|---|---|---|---|---|---|

| Idler 1 | Idler 2 | Idler 3 | Idler 4 | Idler 5 | Idler 6 | ||

| 10 | 10 | 0 | 0 | 0 | 30 | 42 | 0 |

| 13 | 10 | 0 | 0 | 0 | 40 | 35 | 0 |

| 15–16 | 0 | 0 | 0 | 5 | 30 | 24 | 0 |

| 17 | 0 | 0 | 0 | 23 | 35 | 25 | 0 |

| Variable | Value |

|---|---|

| Average (%) per shipment | 0.4 |

| Contact force in the bottom roll F1 (N) | 824.3543 |

| Contact force in the upper roll F4 (N) | 41.2177 |

| Solved (%) | 62.8751 |

| Estimated lifespan of the belt (months) | 72 |

| Proposed lifespan for replacement (months) | 26.7299 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Santos, L.S.; Macêdo, E.N.; Ribeiro Filho, P.R.C.F.; Cunha, A.P.A.; Cheung, N. Belt Rotation in Pipe Conveyors: Failure Mode Analysis and Overlap Stability Assessment. Sustainability 2023, 15, 11312. https://doi.org/10.3390/su151411312

Santos LS, Macêdo EN, Ribeiro Filho PRCF, Cunha APA, Cheung N. Belt Rotation in Pipe Conveyors: Failure Mode Analysis and Overlap Stability Assessment. Sustainability. 2023; 15(14):11312. https://doi.org/10.3390/su151411312

Chicago/Turabian StyleSantos, Leonardo S., Emanuel N. Macêdo, Paulo R. C. F. Ribeiro Filho, Adilto P. A. Cunha, and Noé Cheung. 2023. "Belt Rotation in Pipe Conveyors: Failure Mode Analysis and Overlap Stability Assessment" Sustainability 15, no. 14: 11312. https://doi.org/10.3390/su151411312

APA StyleSantos, L. S., Macêdo, E. N., Ribeiro Filho, P. R. C. F., Cunha, A. P. A., & Cheung, N. (2023). Belt Rotation in Pipe Conveyors: Failure Mode Analysis and Overlap Stability Assessment. Sustainability, 15(14), 11312. https://doi.org/10.3390/su151411312