Sustainability Assessment of Steel Industry in the Belt and Road Area Based on DPSIR Model

Abstract

:1. Introduction

1.1. Research Background

1.2. Literature Review

1.3. Research Innovation and Content

2. Model Construction and Research Methods

2.1. Model Construction

2.1.1. SCSI Logic Based on DPSIR Model

2.1.2. Evaluation Index Selection

2.2. Research Methods

2.2.1. Comprehensive Weighting

2.2.2. Spatial Autocorrelation Analysis

2.2.3. Geodetector

2.3. Data Sources

3. Spatial-Temporal Changes of Inter-Provincial SCSI in the Belt and Road

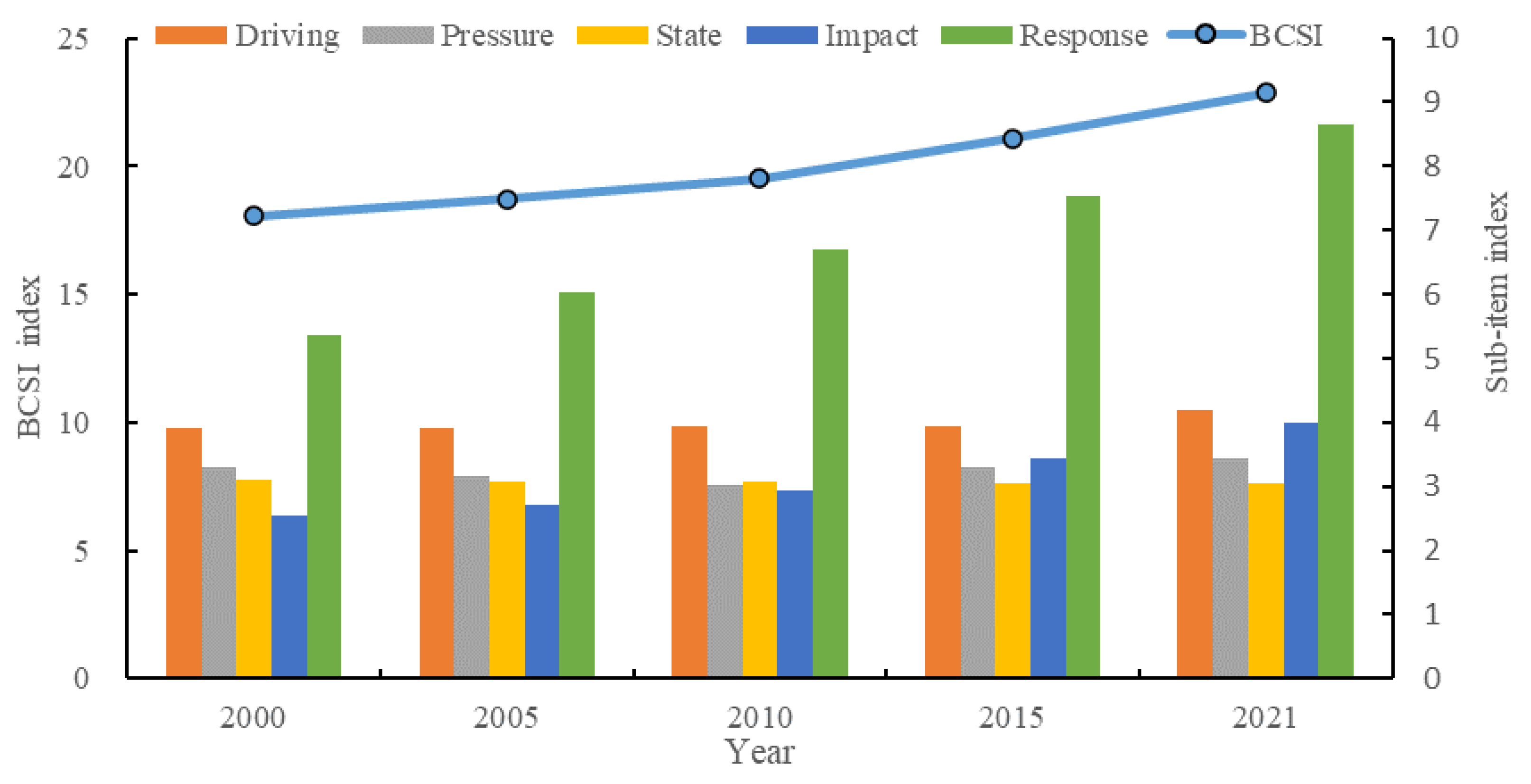

3.1. Time Change Analysis of SCSI in the Belt and Road

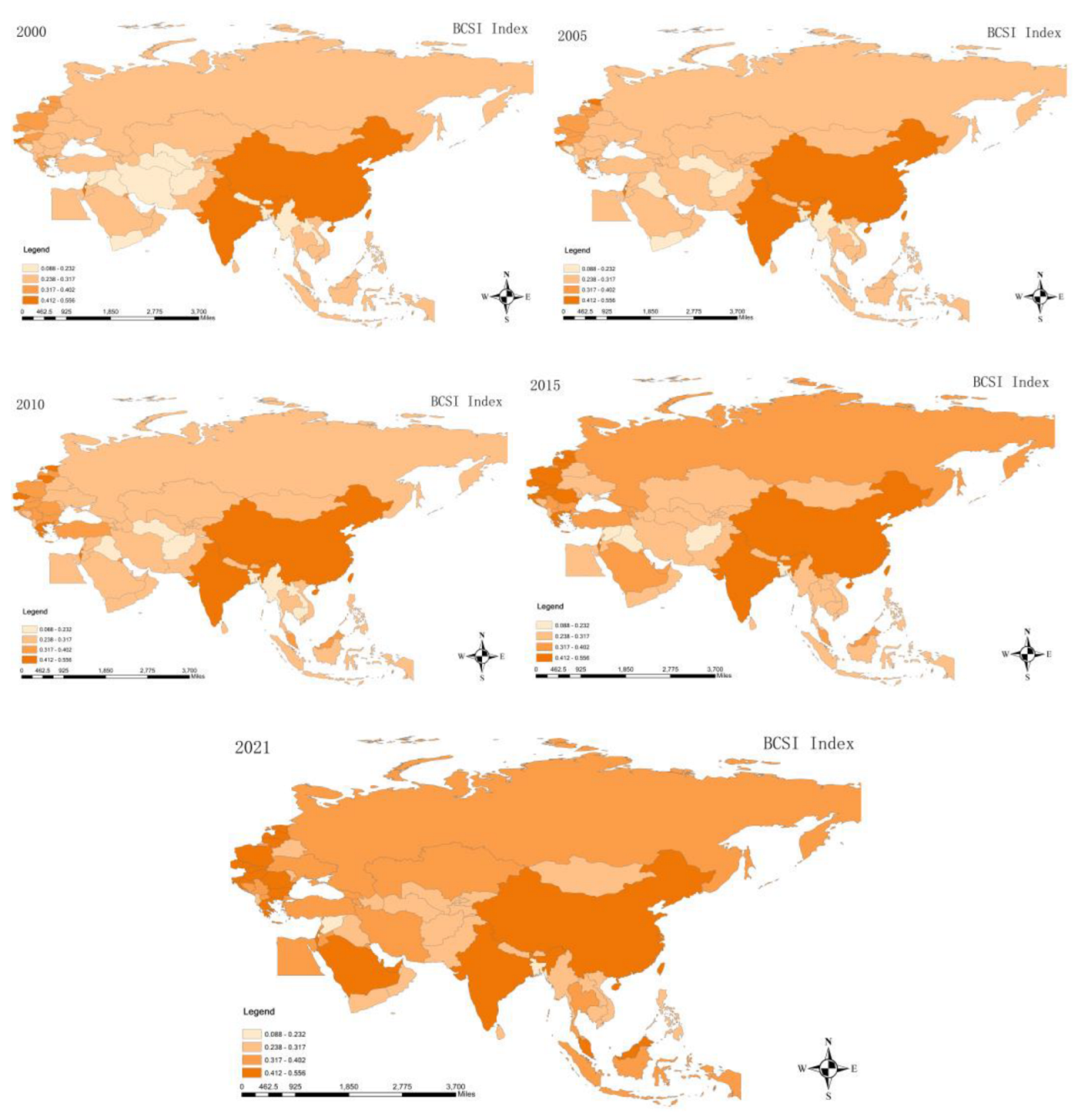

3.2. Spatial Change Analysis of SCSI in Belt and Road

3.3. Spatial Correlation Analysis of SCSI in Belt and Road

4. Analysis of Influencing Factors of Spatial Differences of SCSI

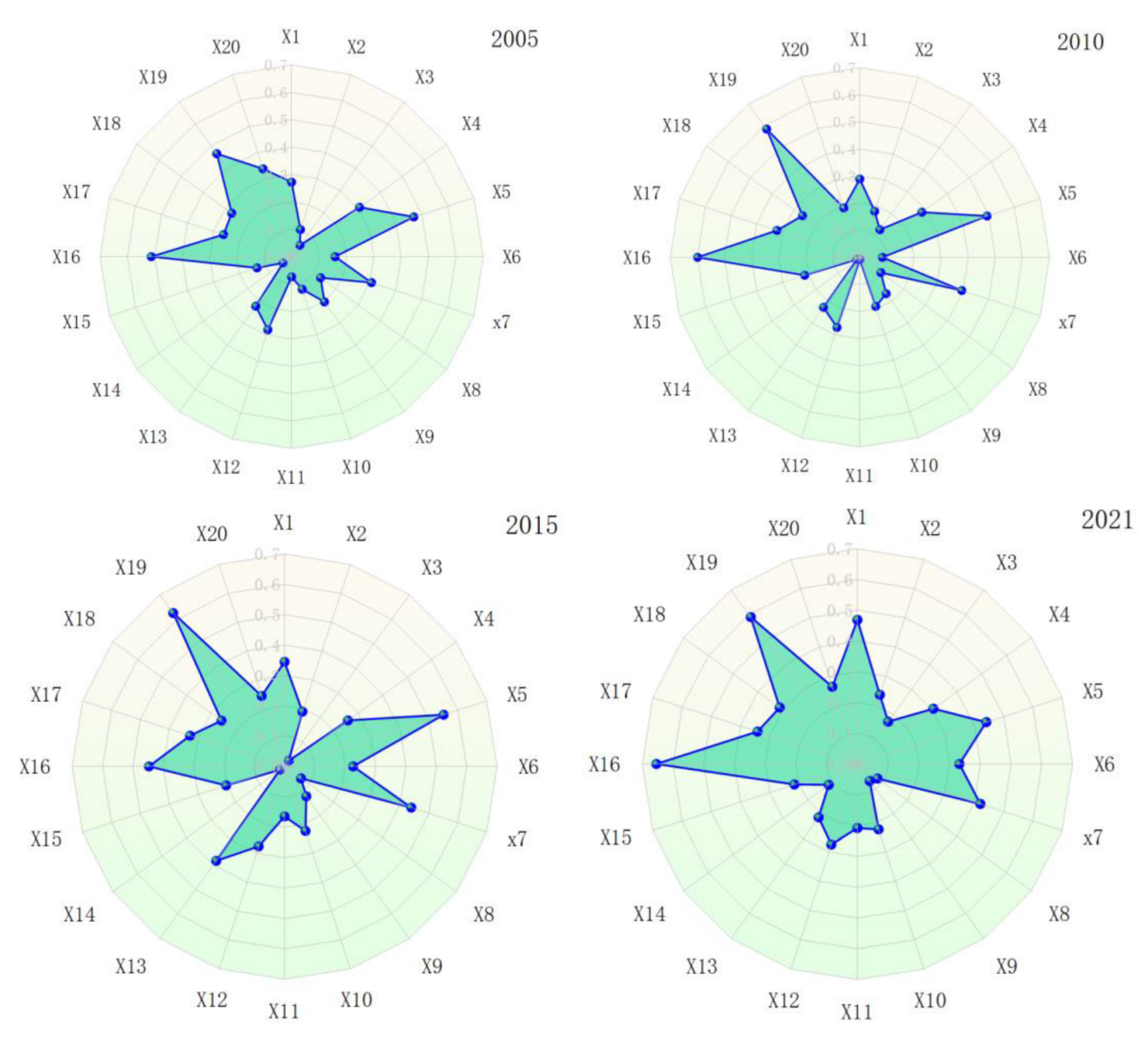

4.1. Intensity of Influencing Factors of SCSI

4.2. Analysis of Multi-Factor Interactions

5. Conclusions, Recommendations, and Discussion

5.1. Conclusions

5.2. Recommendations

5.3. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tolettini, L.; Di Maria, E. Structuring and Measuring Environmental Sustainability in the Steel Sector: A Single Case Study. Sustainability 2023, 15, 6272. [Google Scholar] [CrossRef]

- Andreotti, M.; Brondi, C.; Micillo, D.; Zevenhoven, R.; Rieger, J.; Jo, A.; Ballarino, A. SDGs in the EU Steel Sector: A Critical Review of Sustainability Initiatives and Approaches. Sustainability 2023, 15, 7521. [Google Scholar] [CrossRef]

- Xu, D.; Liu, E.; Duan, W.; Yang, K. Consumption-Driven Carbon Emission Reduction Path and Simulation Research in Steel Industry: A Case Study of China. Sustainability 2022, 14, 13693. [Google Scholar] [CrossRef]

- Lin, Y.; Yang, H.; Ma, L.; Li, Z.; Ni, W. Low-carbon development for the iron and steel industry in China and the world: Status quo, future vision, and key actions. Sustainability 2021, 13, 12548. [Google Scholar] [CrossRef]

- Wu, R.; Lin, B. Environmental regulation and its influence on energy-environmental performance: Evidence on the Porter Hypothesis from China’s iron and steel industry. Resour. Conserv. Recycl. 2022, 176, 105954. [Google Scholar] [CrossRef]

- Xin, H.; Wang, S.; Chun, T.; Xue, X.; Long, W.; Xue, R.; Zhang, R. Effective pathways for energy conservation and emission reduction in iron and steel industry towards peaking carbon emissions in China: Case study of Henan. J. Clean. Prod. 2023, 399, 136637. [Google Scholar] [CrossRef]

- Fang, C.; Liu, X. Comprehensive measurement for carrying capacity of resources and environment of city clusters in central China. Chin. Geogr. Sci. 2010, 20, 281–288. [Google Scholar] [CrossRef]

- Tian, Y.; Sun, C. Comprehensive carrying capacity, economic growth and the sustainable development of urban areas: A case study of the Yangtze River Economic Belt. J. Clean. Prod. 2018, 195, 486–496. [Google Scholar] [CrossRef]

- Daily, G.C.; Ehrlich, P.R. Population, sustainability, and Earth’s carrying capacity. BioScience 1992, 42, 761–771. [Google Scholar] [CrossRef]

- Arcos, J.C. Population growth, economic necessity and industrial growth versus environmental impact and carrying capacity. J. Environ. Sci. Health Part C 1990, 8, 421–438. [Google Scholar] [CrossRef]

- Rees, W.E. Ecological footprints and appropriated carrying capacity: What urban economics leaves out. Environ. Urban. 1992, 4, 121–130. [Google Scholar] [CrossRef]

- Rees, W.E. Revisiting carrying capacity: Area-based indicators of sustainability. Popul. Environ. 1996, 17, 195–215. [Google Scholar] [CrossRef]

- Matooane, L.; Diab, R.D. Air pollution carrying capacity in the South Durban Industrial Basin: Research in action. S. Afr. J. Sci. 2001, 97, 450–453. [Google Scholar]

- Wang, W.; Zeng, W. Optimizing the regional industrial structure based on the environmental carrying capacity: An inexact fuzzy multi-objective programming model. Sustainability 2013, 5, 5391–5415. [Google Scholar] [CrossRef] [Green Version]

- Gao, T.; Liu, Q.; Wang, J. A comparative study of carbon footprint and assessment standards. Int. J. Low-Carbon Technol. 2014, 9, 237–243. [Google Scholar] [CrossRef] [Green Version]

- Zhou, X.Y.; Lei, K.; Meng, W.; Khu, S.T. Industrial structural upgrading and spatial optimization based on water environment carrying capacity. J. Clean. Prod. 2017, 165, 1462–1472. [Google Scholar] [CrossRef]

- Niu, F.; Yang, X.; Zhang, X. Application of an evaluation method of resource and environment carrying capacity in the adjustment of industrial structure in Tibet. J. Geogr. Sci. 2020, 30, 319–332. [Google Scholar] [CrossRef]

- Gao, Q.; Fang, C.; Liu, H.; Zhang, L. Conjugate evaluation of sustainable carrying capacity of urban agglomeration and multi-scenario policy regulation. Sci. Total Environ. 2021, 785, 147373. [Google Scholar] [CrossRef]

- Lu, W.; Yin, C.; Zhang, Y.; Fu, Z.; Guo, H.; Yu, L.; Liu, Y. Consistency Evaluation of Ecological Carrying Capacity and Industrial Layout Based on” Three Lines One Permit” Index System. Beijing Da Xue Xue Bao 2021, 57, 749–755. [Google Scholar]

- Liu, Y.; Shi, F.; He, H.; Shen, L.; Luo, W.; Sun, L. Study on the Matching Degree between Land Resources Carrying Capacity and Industrial Development in Main Cities of Xinjiang, China. Sustainability 2021, 13, 10568. [Google Scholar] [CrossRef]

- Paiva, T.; Ribeiro, M.P.; Coutinho, P. Capacity-Building Model to Promote Innovation and Sustainability in the Portuguese Agro-Industrial Sector. Sustainability 2022, 14, 15873. [Google Scholar] [CrossRef]

- Chai, N.; Zhou, W. The DPSIRM-Grey cloud clustering method for evaluating the water environment carrying capacity of Yangtze River economic Belt. Ecol. Indic. 2022, 136, 108722. [Google Scholar] [CrossRef]

- Sun, J.; Miao, J.; Mu, H.; Xu, J.; Zhai, N. Sustainable development in marine economy: Assessing carrying capacity of Shandong province in China. Ocean Coast. Manag. 2022, 216, 105981. [Google Scholar] [CrossRef]

- Yu, W.; Tao, T. Scenario Simulation for the Urban Carrying Capacity Based on System Dynamics Model in Shanghai, China. Sustainability 2022, 14, 12910. [Google Scholar] [CrossRef]

- Luo, H.; Lin, X. Dynamic Analysis of Industrial Carbon Footprint and Carbon-Carrying Capacity of Zhejiang Province in China. Sustainability 2022, 14, 16824. [Google Scholar] [CrossRef]

- Wang, R.; Cheng, J.; Zhu, Y.; Lu, P. Evaluation on the coupling coordination of resources and environment carrying capacity in Chinese mining economic zones. Resour. Policy 2017, 53, 20–25. [Google Scholar] [CrossRef]

- Zhao, L.; Li, J.; Shao, Q. Evaluation of urban comprehensive carrying capacity: Case study of the Beijing–Tianjin–Hebei urban agglomeration, China. Environ. Sci. Pollut. Res. 2020, 27, 19774–19782. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, Y.; Wang, Y. Comprehensive evaluation and influencing factors of urban agglomeration water resources carrying capacity. J. Clean. Prod. 2021, 288, 125097. [Google Scholar] [CrossRef]

- Zhang, M.; Liu, Y.; Wu, J.; Wang, T. Index system of urban resource and environment carrying capacity based on ecological civilization. Environ. Impact Assess. Rev. 2018, 68, 90–97. [Google Scholar] [CrossRef]

- Yang, J.; Ding, H. A quantitative assessment of sustainable development based on relative resource carrying capacity in Jiangsu Province of China. Int. J. Environ. Res. Public Health 2018, 15, 2786. [Google Scholar] [CrossRef] [Green Version]

- Tong, S.; Ji, X.; Chu, Y.; Liu, T.; Wang, F. Spatio-Temporal Analysis about Resource and Environmental Carrying Capacity (RECC) of Mining Cities in Coal-Concentrated Areas: A Case Study of Huaihai Economic Zone in China. Sustainability 2023, 15, 1367. [Google Scholar] [CrossRef]

- Jiming, H.; Jinnan, W.; Hongqiang, J.; Nianlei, L. Strategies for Industrial Development Layout in China within the Constraints of Environmental Carrying Capacity. Strateg. Study Chin. Acad. Eng. 2017, 19, 20–26. [Google Scholar]

- Chen, Y.; Tian, W.; Zhou, Q.; Shi, T. Spatiotemporal and driving forces of Ecological Carrying Capacity for high-quality development of 286 cities in China. J. Clean. Prod. 2021, 293, 126186. [Google Scholar] [CrossRef]

- Tan, F.; Wang, F.; Niu, Z. Multiscale disparity and spatial pattern of comprehensive carrying capacity in the Yangtze River Economic Belt, China. Ecol. Indic. 2023, 148, 110119. [Google Scholar] [CrossRef]

- Gari, S.R.; Newton, A.; Icely, J.D. A review of the application and evolution of the DPSIR framework with an emphasis on coastal social-ecological systems. Ocean Coast. Manag. 2015, 103, 63–77. [Google Scholar] [CrossRef] [Green Version]

- Elliott, M.; Burdon, D.; Atkins, J.P.; Borja, A.; Cormier, R.; De Jonge, V.N.; Turner, R.K. “And DPSIR begat DAPSI (W) R (M)!”-a unifying framework for marine environmental management. Mar. Pollut. Bull. 2017, 118, 27–40. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kristiadi, Y.; Sari, R.F.; Herdiansyah, H.; Hasibuan, H.S.; Lim, T.H. Developing DPSIR Framework for Managing Climate Change in Urban Areas: A Case Study in Jakarta, Indonesia. Sustainability 2022, 14, 15773. [Google Scholar] [CrossRef]

- Mirchi, A.; Madani, K.; Watkins, D.; Ahmad, S. Synthesis of system dynamics tools for holistic conceptualization of water resources problems. Water Resour. Manag. 2012, 26, 2421–2442. [Google Scholar] [CrossRef]

- Wang, Y.; Cheng, H.; Huang, L. Water resources carrying capacity evaluation of a dense city group: A comprehensive water resources carrying capacity evaluation model of Wuhan urban agglomeration. Urban Water J. 2018, 15, 615–625. [Google Scholar] [CrossRef]

- Xing, K.; Zhu, Q.; Zou, X.H. Analysis on the Supply Situation of Ferrite Resources in China. Nat. Resour. Econ. China 2022, 35, 27–37. [Google Scholar]

- Rousset, F.; Ferdy, J.B. Testing environmental and genetic effects in the presence of spatial autocorrelation. Ecography 2014, 37, 781–790. [Google Scholar] [CrossRef]

- Lv, A.; Han, Y.; Zhu, W.; Zhang, S.; Zhao, W. Risk assessment of water resources carrying capacity in China. JAWRA J. Am. Water Resour. Assoc. 2021, 57, 539–551. [Google Scholar] [CrossRef]

- Peng, T.; Deng, H.; Lin, Y.; Jin, Z. Assessment on water resources carrying capacity in karst areas by using an innovative DPESBRM concept model and cloud model. Sci. Total Environ. 2021, 767, 144353. [Google Scholar] [CrossRef] [PubMed]

| Target Layer | Standard Layer | Index Layer | Unit | Indicator Property |

|---|---|---|---|---|

| SCSI Evaluation Index System | Driving (D) | X1: GDP per capita | Dollar | − |

| X2: Urbanization rate | % | − | ||

| X3: GDP growth rate | % | + | ||

| X4: Total population | people | + | ||

| X5: Domestic macro environment | - | + | ||

| Pressure (P) | X6: Greenhouse gas emissions | - | + | |

| X7: Water source pressure | - | + | ||

| X8: Air pollution | - | + | ||

| X9: Degree of water scarcity | - | + | ||

| State (S) | X10: Steel production per capita | kg/person | − | |

| X11: Level of primary steel shortage | Dollar | + | ||

| X12: The degree of shortage of iron and steel products | Dollar | + | ||

| X13: Advantages of steel import volume | % | + | ||

| Influence (I) | X14: Industrial emphasis | % | + | |

| X15: Electrification rate | % | + | ||

| X16: Industrial infrastructure | - | + | ||

| X17: Proportion of medium and high-tech industries | % | − | ||

| Response (R) | X18: Sewage treatment level | - | + | |

| X19: Research and innovation environment | - | + | ||

| X20: Economic freedom | - | + |

| Index Layer | Entropy Weight | Coefficient of Variation Weight | Comprehensive Weight |

|---|---|---|---|

| X1: GDP per capita | 0.005 | 0.017 | 0.011 |

| X2: Urbanization rate | 0.031 | 0.042 | 0.037 |

| X3: GDP growth rate | 0.002 | 0.011 | 0.007 |

| X4: Total population | 0.378 | 0.281 | 0.329 |

| X5: Domestic macro environment | 0.021 | 0.036 | 0.028 |

| X6: Greenhouse gas emissions | 0.068 | 0.062 | 0.065 |

| X7: Water source pressure | 0.022 | 0.036 | 0.029 |

| X8: Air pollution | 0.050 | 0.055 | 0.053 |

| X9: Degree of water scarcity | 0.028 | 0.056 | 0.042 |

| X10: Steel production per capita | 0.004 | 0.015 | 0.010 |

| X11: Level of primary steel shortage | 0.002 | 0.009 | 0.006 |

| X12: The degree of shortage of iron and steel products | 0.001 | 0.005 | 0.003 |

| X13: Advantages of steel import volume | 0.004 | 0.016 | 0.010 |

| X14: Industrial emphasis | 0.019 | 0.037 | 0.028 |

| X15: Electrification rate | 0.004 | 0.015 | 0.009 |

| X16: Industrial infrastructure | 0.064 | 0.065 | 0.064 |

| X17: Proportion of medium and high-tech industries | 0.009 | 0.023 | 0.016 |

| X18: Sewage treatment level | 0.147 | 0.099 | 0.123 |

| X19: Research and innovation environment | 0.133 | 0.097 | 0.115 |

| X20: Economic freedom | 0.007 | 0.021 | 0.014 |

| Serial Number | Nation | SCSI Indices of Belt and Road Countries. | ||||

|---|---|---|---|---|---|---|

| 2000 | 2005 | 2010 | 2015 | 2021 | ||

| 1 | China | 0.556 | 0.555 | 0.561 | 0.592 | 0.648 |

| 2 | Mongolia | 0.289 | 0.258 | 0.238 | 0.248 | 0.272 |

| 3 | Russia | 0.306 | 0.304 | 0.307 | 0.338 | 0.399 |

| 4 | Malaysia | 0.265 | 0.270 | 0.327 | 0.393 | 0.436 |

| 5 | Singapore | 0.504 | 0.525 | 0.482 | 0.483 | 0.499 |

| 6 | Indonesia | 0.280 | 0.279 | 0.286 | 0.311 | 0.353 |

| 7 | Brunei | 0.347 | 0.344 | 0.323 | 0.421 | 0.450 |

| 8 | the Philippines | 0.251 | 0.261 | 0.268 | 0.271 | 0.278 |

| 9 | Thailand | 0.273 | 0.280 | 0.289 | 0.303 | 0.347 |

| 10 | Cambodia | 0.238 | 0.237 | 0.230 | 0.248 | 0.258 |

| 11 | Laos | 0.194 | 0.202 | 0.216 | 0.242 | 0.240 |

| 12 | Vietnam | 0.242 | 0.251 | 0.255 | 0.269 | 0.300 |

| 13 | Myanmar | 0.206 | 0.212 | 0.214 | 0.235 | 0.246 |

| 14 | Maldives | 0.264 | 0.249 | 0.241 | 0.267 | 0.290 |

| 15 | Sri Lanka | 0.250 | 0.254 | 0.265 | 0.268 | 0.278 |

| 16 | Bangladesh | 0.088 | 0.086 | 0.089 | 0.089 | 0.090 |

| 17 | Pakistan | 0.251 | 0.258 | 0.264 | 0.292 | 0.286 |

| 18 | India | 0.461 | 0.505 | 0.516 | 0.541 | 0.590 |

| 19 | Bhutan | 0.223 | 0.268 | 0.254 | 0.271 | 0.293 |

| 20 | Afghanistan | 0.188 | 0.216 | 0.214 | 0.220 | 0.283 |

| 21 | Nepal | 0.223 | 0.248 | 0.243 | 0.237 | 0.250 |

| 22 | Uzbekistan | 0.226 | 0.234 | 0.258 | 0.265 | 0.300 |

| 23 | Tajikistan | 0.259 | 0.250 | 0.243 | 0.248 | 0.242 |

| 24 | Kazakhstan | 0.269 | 0.248 | 0.253 | 0.302 | 0.337 |

| 25 | Kyrgyzstan | 0.278 | 0.265 | 0.252 | 0.255 | 0.287 |

| 26 | Turkmenistan | 0.227 | 0.224 | 0.230 | 0.234 | 0.242 |

| 27 | United Arab Emirates | 0.304 | 0.298 | 0.299 | 0.329 | 0.434 |

| 28 | Oman | 0.274 | 0.272 | 0.290 | 0.291 | 0.314 |

| 29 | Azerbaijan | 0.270 | 0.268 | 0.290 | 0.296 | 0.315 |

| 30 | Egypt | 0.250 | 0.268 | 0.280 | 0.308 | 0.329 |

| 31 | Greece | 0.349 | 0.396 | 0.431 | 0.425 | 0.455 |

| 32 | Bahrain | 0.287 | 0.313 | 0.296 | 0.301 | 0.346 |

| 33 | Georgia | 0.300 | 0.285 | 0.283 | 0.322 | 0.365 |

| 34 | Kuwait | 0.328 | 0.322 | 0.325 | 0.328 | 0.355 |

| 35 | Lebanon | 0.229 | 0.254 | 0.278 | 0.292 | 0.322 |

| 36 | Qatar | 0.227 | 0.251 | 0.282 | 0.379 | 0.419 |

| 37 | Saudi Arabia | 0.293 | 0.249 | 0.283 | 0.333 | 0.424 |

| 38 | Türkiye | 0.282 | 0.292 | 0.320 | 0.345 | 0.355 |

| 39 | Syria | 0.218 | 0.245 | 0.236 | 0.227 | 0.232 |

| 40 | Armenia | 0.293 | 0.295 | 0.298 | 0.322 | 0.335 |

| 41 | Yemen | 0.211 | 0.224 | 0.233 | 0.247 | 0.261 |

| 42 | Iraq | 0.184 | 0.183 | 0.204 | 0.174 | 0.235 |

| 43 | Iran | 0.201 | 0.234 | 0.256 | 0.282 | 0.336 |

| 44 | Israel | 0.429 | 0.427 | 0.439 | 0.456 | 0.471 |

| 45 | Jordan | 0.259 | 0.264 | 0.280 | 0.293 | 0.349 |

| 46 | Albania | 0.266 | 0.226 | 0.278 | 0.291 | 0.309 |

| 47 | Estonia | 0.366 | 0.412 | 0.453 | 0.469 | 0.484 |

| 48 | Belarus | 0.271 | 0.267 | 0.258 | 0.278 | 0.313 |

| 49 | Bulgaria | 0.270 | 0.314 | 0.335 | 0.365 | 0.408 |

| 50 | Bosnia and Herzegovina | 0.204 | 0.221 | 0.257 | 0.295 | 0.333 |

| 51 | Poland | 0.349 | 0.380 | 0.395 | 0.453 | 0.472 |

| 52 | Montenegro | 0.234 | 0.267 | 0.310 | 0.349 | 0.409 |

| 53 | Czech Republic | 0.370 | 0.399 | 0.418 | 0.464 | 0.471 |

| 54 | Croatia | 0.317 | 0.363 | 0.372 | 0.441 | 0.453 |

| 55 | Latvia | 0.327 | 0.339 | 0.349 | 0.414 | 0.481 |

| 56 | Lithuania | 0.337 | 0.388 | 0.409 | 0.462 | 0.468 |

| 57 | Romania | 0.288 | 0.286 | 0.366 | 0.412 | 0.411 |

| 58 | North Macedonia | 0.256 | 0.269 | 0.327 | 0.360 | 0.356 |

| 59 | Moldova | 0.296 | 0.291 | 0.260 | 0.291 | 0.285 |

| 60 | Serbia | 0.238 | 0.273 | 0.322 | 0.385 | 0.397 |

| 61 | Slovak Republic | 0.304 | 0.339 | 0.393 | 0.436 | 0.429 |

| 62 | Slovenia | 0.412 | 0.425 | 0.438 | 0.452 | 0.477 |

| 63 | Ukraine | 0.250 | 0.257 | 0.259 | 0.267 | 0.326 |

| 64 | Hungary | 0.350 | 0.370 | 0.392 | 0.427 | 0.445 |

| Grading Standards | Level I | Level II | Level III | Level IV |

|---|---|---|---|---|

| Division basis | (0, V − B] | (V − B, V] | (V, V + B] | (V + B, 1] |

| (0, 0.231] | (0.203, 0.317] | (0.317, 0.401] | (0.401, 1] |

| Year | Moran’s I | p Value | Z Value |

|---|---|---|---|

| 2000 | 0.006 | 0.367 | 0.339 |

| 2001 | −0.048 | 0.311 | −0.493 |

| 2002 | −0.007 | 0.447 | 0.133 |

| 2003 | −0.063 | 0.235 | −0.722 |

| 2004 | −0.063 | 0.235 | −0.722 |

| 2005 | −0.055 | 0.279 | −0.586 |

| 2006 | −0.055 | 0.279 | −0.586 |

| 2007 | −0.055 | 0.279 | −0.586 |

| 2008 | −0.055 | 0.279 | −0.586 |

| 2009 | −0.055 | 0.279 | −0.586 |

| 2010 | −0.069 | 0.215 | −0.788 |

| 2011 | −0.049 | 0.315 | −0.483 |

| 2012 | −0.039 | 0.365 | −0.345 |

| 2013 | −0.035 | 0.387 | −0.286 |

| 2014 | −0.012 | 0.479 | 0.052 |

| 2015 | −0.052 | 0.298 | −0.531 |

| 2016 | −0.059 | 0.265 | −0.629 |

| 2017 | −0.116 | 0.073 | −1.454 |

| 2018 | −0.150 | 0.026 | −1.963 |

| 2019 | −0.178 | 0.009 | −2.352 |

| 2020 | −0.197 | 0.004 | −2.628 |

| 2021 | −0.184 | 0.007 | −2.447 |

| Years | Driving (D) | Pressure (P) | State (S) | Influence (I) | Response (R) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Moran’s I | Z | p | Moran’s I | Z | p | Moran’s I | Z | p | Moran’s I | Z | p | Moran’s I | Z | p | |

| 2000 | 0.289 | 5.082 | 0.000 | 0.348 | 4.777 | 0.000 | 0.274 | 4.143 | 0.000 | 0.078 | 1.255 | 0.105 | 0.162 | 2.415 | 0.008 |

| 2001 | 0.276 | 4.855 | 0.000 | 0.378 | 5.172 | 0.000 | 0.253 | 3.881 | 0.000 | 0.072 | 1.182 | 0.119 | 0.175 | 2.562 | 0.005 |

| 2002 | 0.281 | 4.948 | 0.000 | 0.370 | 5.073 | 0.000 | 0.225 | 3.519 | 0.000 | 0.059 | 0.999 | 0.159 | 0.181 | 2.664 | 0.004 |

| 2003 | 0.282 | 4.960 | 0.000 | 0.366 | 5.045 | 0.000 | 0.247 | 3.791 | 0.000 | 0.068 | 1.119 | 0.132 | 0.196 | 2.856 | 0.002 |

| 2004 | 0.268 | 4.735 | 0.000 | 0.394 | 5.420 | 0.000 | 0.262 | 3.957 | 0.000 | 0.080 | 1.278 | 0.101 | 0.214 | 3.086 | 0.001 |

| 2005 | 0.277 | 4.865 | 0.000 | 0.349 | 4.856 | 0.000 | 0.270 | 4.021 | 0.000 | 0.077 | 1.233 | 0.109 | 0.231 | 3.306 | 0.000 |

| 2006 | 0.277 | 4.867 | 0.000 | 0.303 | 4.277 | 0.000 | 0.304 | 4.492 | 0.000 | 0.066 | 1.080 | 0.140 | 0.234 | 3.343 | 0.000 |

| 2007 | 0.274 | 4.814 | 0.000 | 0.329 | 4.584 | 0.000 | 0.298 | 4.384 | 0.000 | 0.063 | 1.045 | 0.148 | 0.248 | 3.516 | 0.000 |

| 2008 | 0.272 | 4.785 | 0.000 | 0.338 | 4.689 | 0.000 | 0.256 | 3.771 | 0.000 | 0.066 | 1.079 | 0.140 | 0.261 | 3.686 | 0.000 |

| 2009 | 0.278 | 4.880 | 0.000 | 0.442 | 6.019 | 0.000 | 0.208 | 3.103 | 0.001 | 0.051 | 0.881 | 0.189 | 0.265 | 3.728 | 0.000 |

| 2010 | 0.276 | 4.855 | 0.000 | 0.513 | 6.937 | 0.000 | 0.178 | 2.698 | 0.003 | 0.084 | 1.317 | 0.094 | 0.266 | 3.737 | 0.000 |

| 2011 | 0.280 | 4.908 | 0.000 | 0.518 | 7.000 | 0.000 | 0.197 | 2.958 | 0.002 | 0.106 | 1.605 | 0.054 | 0.290 | 4.046 | 0.000 |

| 2012 | 0.283 | 4.952 | 0.000 | 0.560 | 7.559 | 0.000 | 0.165 | 2.506 | 0.006 | 0.096 | 1.472 | 0.071 | 0.305 | 4.232 | 0.000 |

| 2013 | 0.285 | 4.990 | 0.000 | 0.572 | 7.715 | 0.000 | 0.136 | 2.104 | 0.018 | 0.123 | 1.826 | 0.034 | 0.301 | 4.172 | 0.000 |

| 2014 | 0.290 | 5.069 | 0.000 | 0.601 | 8.098 | 0.000 | 0.142 | 2.202 | 0.014 | 0.118 | 1.761 | 0.039 | 0.291 | 4.038 | 0.000 |

| 2015 | 0.292 | 5.095 | 0.000 | 0.583 | 7.867 | 0.000 | 0.165 | 2.471 | 0.007 | 0.102 | 1.548 | 0.061 | 0.295 | 4.087 | 0.000 |

| 2016 | 0.294 | 5.129 | 0.000 | 0.523 | 7.068 | 0.000 | 0.163 | 2.427 | 0.008 | 0.073 | 1.173 | 0.120 | 0.292 | 4.055 | 0.000 |

| 2017 | 0.295 | 5.136 | 0.000 | 0.444 | 6.024 | 0.000 | 0.155 | 2.318 | 0.010 | 0.116 | 1.736 | 0.041 | 0.295 | 4.078 | 0.000 |

| 2018 | 0.297 | 5.179 | 0.000 | 0.346 | 4.757 | 0.000 | 0.138 | 2.084 | 0.019 | 0.147 | 2.151 | 0.016 | 0.304 | 4.200 | 0.000 |

| 2019 | 0.310 | 4.960 | 0.000 | 0.347 | 4.760 | 0.000 | 0.119 | 1.823 | 0.034 | 0.139 | 2.035 | 0.021 | 0.310 | 4.275 | 0.000 |

| 2020 | 0.310 | 4.959 | 0.000 | 0.338 | 4.656 | 0.000 | 0.100 | 1.555 | 0.060 | 0.130 | 1.919 | 0.027 | 0.309 | 4.256 | 0.000 |

| 2021 | 0.303 | 4.849 | 0.000 | 0.330 | 4.547 | 0.000 | 0.081 | 1.309 | 0.095 | 0.132 | 1.954 | 0.025 | 0.317 | 4.369 | 0.000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, J.; Yu, Q.; Hou, X. Sustainability Assessment of Steel Industry in the Belt and Road Area Based on DPSIR Model. Sustainability 2023, 15, 11320. https://doi.org/10.3390/su151411320

Xu J, Yu Q, Hou X. Sustainability Assessment of Steel Industry in the Belt and Road Area Based on DPSIR Model. Sustainability. 2023; 15(14):11320. https://doi.org/10.3390/su151411320

Chicago/Turabian StyleXu, Jianming, Qinfei Yu, and Xiaoyang Hou. 2023. "Sustainability Assessment of Steel Industry in the Belt and Road Area Based on DPSIR Model" Sustainability 15, no. 14: 11320. https://doi.org/10.3390/su151411320