1. Introduction

Although coal resource consumption in China has gradually decreased in recent years, a one-time consumption of coal resources still accounted for over 50% of the total energy supply by the end of 2021 [

1]. During mine production, the mines often face hazards, including water inrush; high temperature; stress, gas, and coal dust explosion; etc. Water inrush is one of the most common types of disasters that is prone to occur. According to the comprehensive statistics from 2001 to 2021, there were 1105 damage accidents in domestic mines, and the number of deaths reached 4476 [

2]. For example, a water inrush accident occurred during the mining of 3301 working face in Xinhe mine, with a water volume of 1316 m

3/h, seriously threatening the personnel safety and mine operation [

3]. As the extraction of coal seam continues to advance downwards, the threat of water damage from the roof and floor aquifers gradually becomes apparent. Meanwhile, the tectonics of the minefield have become more complex, promoting the occurrence of water inrush events. The cracks in the coal seam roof are fully developed during the excavation process, and there is a possibility of water inrush from the roof aquifer [

4]. If not prevented and controlled, it will cause incredible adverse consequences for enterprises and society. Predicting the risk distribution of coal seam water inrush can provide a more scientific and effective reference for mine water hazard prevention and control measures mainly focused on mine grouting treatment [

5,

6].

Numerous scholars have obtained abundant achievements related to water inrush from coal seam roofs through extensive practical summary and theoretical analysis [

7,

8,

9]. In terms of theory, the “upper three zones” served as the fundamental basis for the study of water inrush mechanisms in coal seam roofs [

10]. With the deepening of research on the separation layer water and key stratum, the research on the mechanism of roof water inrush has been expanded [

11,

12]. In terms of the risk of water inrush, the traditional methods include the water inrush coefficient method [

13], the hydrogeological analysis method [

14], and the geophysical exploration method [

15]. However, the above methods have certain limitations, high cost, large workload, and a single factor. Compared to them, multi-factor comprehensive analysis is widely used in many fields, such as mine water inrush and aquifer water abundance, and has been extensively verified to be highly feasible. For example, Wu [

16] proposed the “three maps-double predictions” model, which scientifically and reasonably applies multiple factors to predict the water inrush risk. Zhou [

17] used the AHP method to analyze the characteristics, hydrogeology, and structural control factors of the roof aquifer and superimposed them to obtain water-rich zoning. Gao et al. [

18] analyzed the water inflow under the influence of multiple factors and used nonlinear regression to construct the water inflow evaluation model. In addition, scholars have used more diverse information fusion evaluation methods to promote the prediction and evaluation of water inrush hazards, and have achieved better results, such as the entropy method (EM), BP neural network, Fuzzy analytic hierarchy process, and so on [

19,

20,

21].

In further research, experts and scholars combined and analyzed different evaluation methods to optimize the prediction model. For example, Liu and Li [

22] extracted nine water inrush factors from three aspects: water source, water inrush channel, and mining space, and adopted the expert scoring method and trapezoidal fuzzy distribution method to comprehensively evaluate the fuzzy membership degree of each factor, establishing a classification and evaluation analysis of water inrush risk. Zhang and Yang [

23] used AHP and grey relational analysis to combine the weights of five main control factors and the correlation degree between water inrush accidents, and obtained a shallow roof water inrush risk analysis model that was consistent with the actual water inflow. Xie et al. [

24] used AHP and EM to comprehensively establish a combination set pair analysis model for the four main control factors and built a prediction model. With the new attempts of machine learning in the field of mine disasters, good results have been achieved in predicting the risk of water inrush. For example, Zhao et al. [

25] used water inrush points to extract eight main control factors and substituted them into the random forest and PNN model for training verification. It was found that the prediction effect of the random forest was in line with the actual situation. Yang et al. [

26] mainly used the DIFF-TCN model and DIFF-LSTM model to predict the average daily water inflow of the Tingnan mine in Shanxi, demonstrating the good predictive potential of deep learning in hydrological forecasting. However, machine learning generally requires a large number of training and validation samples, and statistical samples and geological data are limited. Thus, these problems greatly affect the prediction effect of water inrush risk, and the prediction effect is not accurate enough. Currently, the purpose of multi-factor comprehensive analysis in predicting water inrush is to establish an indicator system for the influencing factors of water inrush, comprehensively assign weights to two or more evaluation methods, and superimpose them to obtain the zonation and evaluation of water inrush risk [

27]. Nevertheless, it is a fact that distinct differences in hydrogeological and geological conditions, incomplete data, and different evaluation methods still exist among mines; there is no clear method regulation widely applicable.

Based on previous research results, this paper selects two methods: AHP and PCA. The AHP method mainly relies on the subjective judgment of experts on the risk factors of water inrush, and human errors may exist; PCA determines principal component indicators through dimensionality reduction, which have certain correlation and are in line with the main control factors selected in this study, providing more scientific objective weights for this research area. We use improved Game Theory (IGT) to give weight to subjective and objective weights and obtain scientific and reasonable comprehensive weights. In this study, six evaluation indexes are selected from three aspects: lithologic structure characteristics, hydraulic characteristics, and tectonics conditions. Based on AHP and PCA, combined with IGT, the prediction and evaluation model of water inrush from the aquifer above the 11-2 coal seam is established in the Kouzidong mine.

2. Study Area and Evaluation Indices

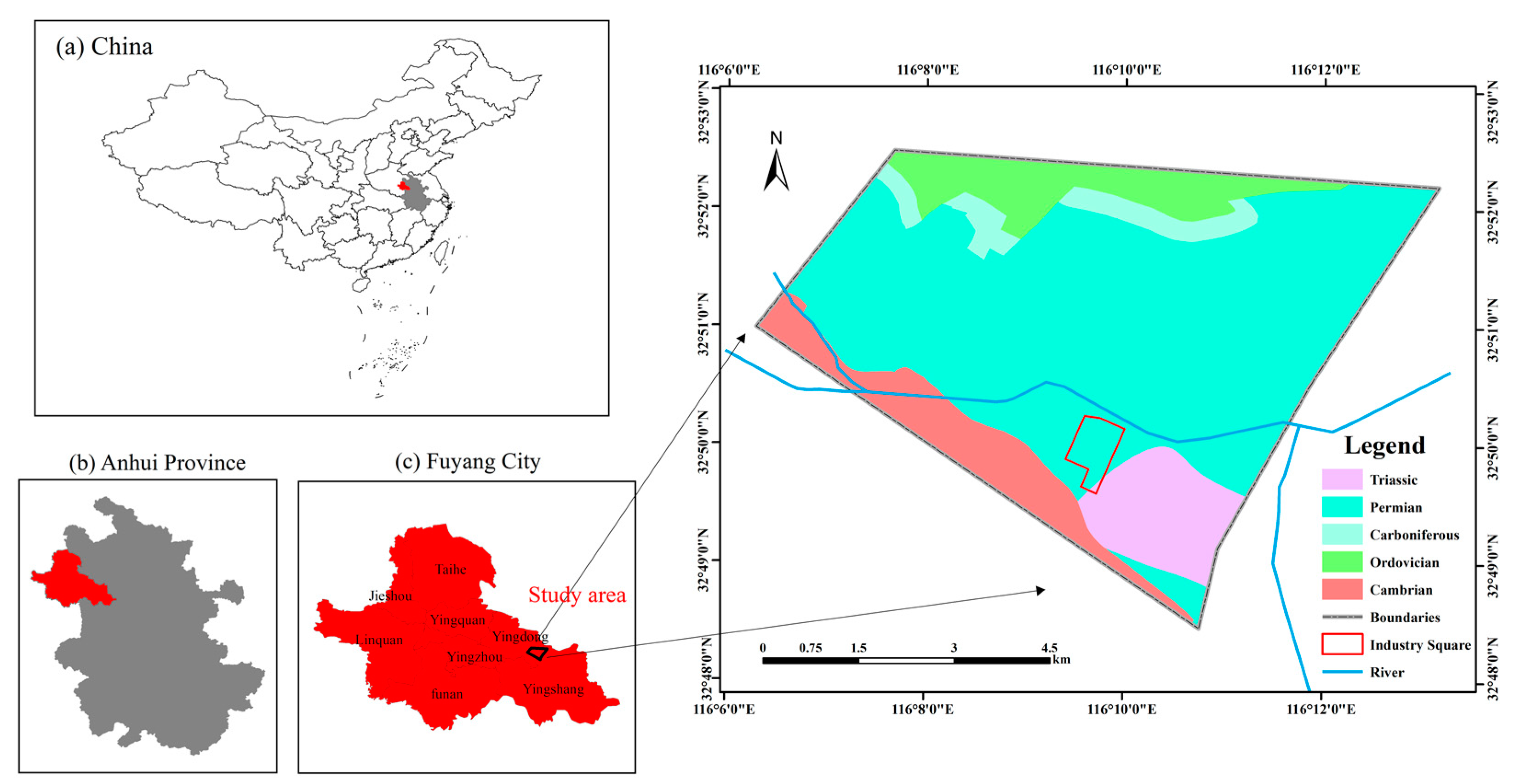

The Kouzidong mine is sited at the junction of Yingdong District and Yingshang County in Fuyang City, with most of its area located within Yingdong District and a small portion within Yingshang County. It is adjoined by the Liuzhuang mine to the east, the unexploited Kouzi minefield to the west, and faces the Banji mine to the north. Geographic coordinates are 116°07′40″ E~116°13′08″ E in longitude and 32°48′30″ N~32°52′32″ N in latitude. The area is adjacent to F12 and F12-1 faults to the east, and DF3 faults and DF3-1 faults to the west, starting from the Fufeng fault to the south and reaching the outcrop of Taiyuan Formation strata to the north. The mining elevation range within the area is −554~−1200 m. The strike length is 7.4 km, the dip width is 3.51~7.86 km, and the area is approximately 43.4773 km

2. The geomorphology of the study area is the alluvial plain along the Huai River, with small topographic relief, as shown in

Figure 1.

The region is a warm temperate semi-humid monsoon climate, with an annual average temperature of +15.1 °C, a daily maximum temperature of +41.4 °C, and a daily low temperature of +21.7 °C according to historical statistical data from the local monitored station. The precipitation in the study area is moderate, and the four seasons are distinct. The average annual rainfall is 893.74 mm and is more concentrated in the summer.

Fault zones, fractures, and pore channels have changed during mining, which may cause a large amount of water to enter the working faces or roadways [

28]. The 11-2 coal seam is the stable and minable coal seam in the east, mainly composed of a single coal seam, and some of the 1~3 layers are drilled. The roof stratum is dominated by sand shale interbeds, the soft and hard parts complement each other, and the water abundant of the roof aquifer is strong. The 11-2 coal seam is a preparatory mining coal seam, and the risk assessment of the water inrush from the roof and floor is necessary for safe operation.

2.1. Geological Conditions

The sedimentary strata in the study area are Upper Archaean (Ar

3), Qingbaikou (Zq), Cambrian (Є), Ordovician (O), Carboniferous (C), Permian (P), Triassic (T), Neoproterozoic (E) and Quaternary (Q) from bottom to top. The coal-bearing strata are composed of three groups of strata at the bottom of the Shanxi Formation, as well as in the Shihezi Formation. The total thickness of mineable coal-bearing strata is 763.90 m, where an average coal thickness is 33.39 m, with a coal-bearing coefficient of 4.37%. The main minable coal seams are numbered from top to bottom as follows: 13-1, 11-2, 8, 5, and 1 coal seam, and the average cumulative thickness is 21.99 m, accounting for 79.02% of the mining section total thickness in

Figure 2.

Chenqiao anticline develops in the northwest of mine, roughly incomplete, with a slow rise and fall in monoclinic structure. For the axis of the syncline northwest, the dip angle of the layer is slower. The development of mine faults has certain regularity; that is, the main NE faults are developed, followed by NW and EW faults.

2.2. Hydrogeologic Conditions

The underground aquifers in the study area are mainly divided into three sections: the Cenozoic loose layer aquifer, the Permian coal-bearing sandstone aquifer, and the limestone aquifer. The limestone aquifer is divided into four groups: the Cambrian limestone karst fissure aquifer, the Ordovician karst fissure aquifer, the Taiyuan Formation karst fissure aquifer, and the Benxi Formation aquifer. Due to the replenishment and drainage relationship between the study area and the surrounding areas, which is approximately closed loop by the F1 reverse fault, and Shangtangji reverse fault. Some faults are mainly in the NE direction, resulting in smaller enclosed areas, so the hydrogeological unit in this area is not relatively open. The water yield of aquifers mainly manifests static characteristics. Except for a small portion of aquifers that are directly in contact with the overlying thick loose layer aquifer, most of the groundwater is stagnant on the whole. The sandstone aquifer of 11-2 coal roof serves as a direct water supply source and is unevenly distributed.

2.3. Evaluation Indicators

On the basis of the existing hydrogeological and geological conditions in the study area, six dominant factors are determined through comprehensive analysis from three aspects: lithologic structure characteristics, tectonics characteristics, and hydraulic characteristics. The following is a brief analysis of the six factors, namely, aquitard effective thickness (AET), aquiclude thickness (AT), the ratio of sandstone to mudstone (RSM), rock quality designation (RQD), wash water quantity of geological log (WWQ), and fault fractal dimension (FFD).

AET is one of the most basic indicators determining the water abundance of the aquifer. Due to the relatively large sandstone particles in the roof aquifer, it is conducive to water storage. Thus, the thicker the aquifer, the stronger its water richness. According to previous research experience, the total thickness of fine sandstone, medium sandstone, and coarse sandstone layers in the coal seam roof aquifer is mostly obtained by stacking them together. However, the permeability of different sandstones is different due to their varying porosity, and this statistical method has some interference with the prediction of water yield. We introduce the equivalent thickness of the aquifer based on its occurrence characteristics [

29]; that is, the sum of the equivalent thicknesses of three types of sandstone with reference to coarse sandstone as the standard (1.0). The calculation formula for the equivalent thickness (

H) of the aquifer is:

where

H is the equivalent sandstone thickness (m); α represents coarse sandstone (m); β is medium sandstone (m); and γ is fine sandstone (m).

The AET value ranges from 6.03 m to 39.95 m, and the thickness gradually increases outward from the central and western regions in this study (

Figure 3a).

AT mainly plays a role in blocking the sandstone fissure water above the coal seam [

30]. However, due to the disturbance of mining, the roof will continuously collapse and generate induced fractures resulting in a decrease in the water resistance of the waterproof layer. Therefore, it is crucial to calculate the thickness of the waterproof layer in the water-conducting fracture zone for analyzing roof water inrush. In the same situation, the thickness of the waterproof layer is inversely proportional to the degree of danger of roof water inrush; that is, the thicker the roof waterproof layer, the lower the risk of water inrush. The AT value is 14.55~55.05 m. The thickness of mudstone gradually increases from northwest to southeast regions (

Figure 3b).

RSM is the ratio of sandstone with strong water-bearing capacity to mudstone with strong water resistance [

31]. The particle size of sandstone is usually bigger than that of mudstone and sandy mudstone. The higher the percentage of sandstone to mudstone (mudstone, sandy mudstone) in the target formation, the stronger the water richness of the roof sandstone. The ratio ranges from 0.156 to 3.053, with a relatively higher ratio in some parts of the central and western regions (

Figure 3c).

RQD is the most direct quality indicator for predicting the water abundance of sandstone aquifers. The drilled samples directly reflect the specific situation of rock fragmentation in the strata and the degree of crack development in the rock mass [

32]. The smaller the degree of fragmentation of rock samples, the higher the integrity of the rock mass, and the weaker the water richness of the aquifer. On the contrary, the greater the degree of rock fragmentation, the less complete it is, and the more favorable it is for water storage, resulting in stronger water abundance. The RQD is 34.78~93.84%, and the core recovery rate in the study area increases from west to east, indicating that the roof strata of the 11-2 coal seam in the central and eastern regions are relatively complete. The stratigraphic integrity of scattered areas in the east and some areas along the western boundary is poor (

Figure 3d).

During the drilling, the variation in WWQ directly reflects the permeability of the aquifer or the connectivity of the water channel. If there is a significant increase in wash water quantity, it indicates that the aquifer has good permeability or good connectivity of water channels, such as cracks and pores, which directly indicates changes in the strength of water abundance in each layer. WWQ in the research area is 0.05~0.56 m

3/h. The value in the western region is higher than that in the eastern research area, indicating that the western roof strata have strong water abundance (

Figure 3e).

FFD damages the original stratigraphic sequence. This study aims to determine the extent of structural changes, which is beneficial for further studying the water abundance of aquifers [

33]. On the basis of traditional distribution characteristics of fault structures, further quantitative analysis of fault structures is carried out. The structure is an important factor controlling the development of aquifer space in rock formations, which determines the size of groundwater storage and transportation space, the boundaries of hydrogeological units, the exposure conditions, and the distribution characteristics of aquifers. We select indicators that are favorable for the analysis of water abundance in the sandstone aquifer and display the geometric distribution characteristics of fault structures through mathematical methods and geographic information systems. The similarity dimension of faults is selected for quantitative analysis of the development of fault structures. The formula for calculating the fractal dimension of faults is as follows:

where

Ds is the fractal dimension value;

r is the side length of the grid unit: 800 m, 400 m, 200 m, and 100 m;

N(r) is the number of faults within each level of the unit.

This section first extracts the fault trace map after a comprehensive analysis of the comprehensive hydrogeological map, mining engineering plan, and other data. We directly loaded the above fault trace CAD drawings using ArcGIS 10.5 and extracted the fault trace. Secondly, we created an initial mesh unit of 800 m × 800 m fishing net that should cover all fault traces within the study area as much as possible. In addition, annotation points were generated at the center of each grid, and the fishing net units were numbered according to their attributes, numbered as 1,2,3 … 69, and the number of grids through which the fault trajectory passes was calculated. Based on the initial side length of the grid unit of 800 m, we continued to create three types of square grid units with dimensions of 400 m, 200 m, and 100 m for fishing nets according to the above process. According to the calculation formula (2), we obtained the similarity dimension

Ds and finally generated a thematic map of FFD. The fractal dimension value ranges from 0.3000 to 1.697. The fractal dimension value of faults directly reflects the high level of development of the fault structure, mainly distributed in the central and western regions (

Figure 3f).

4. Results and Discussion

4.1. Evaluation and Results of AHP and PCA

Using Yaahp 2020 to calculate the objective weights of each indicator (

Table 1), the consistency test of the AHP method first obtained CI = 7.0, which met the model requirements.

Six evaluation indicators were obtained using drilling results and structural outline maps, and all data were normalized using GIS before being extracted into an Excel table in GIS. We use SPSS 25.0 to conduct PCA on six indicators to obtain the total variance explanation and principal component coefficient matrix (

Table 2 and

Table 3). After verification, the KMO value is 0.692 and

p = 0.000, which were in accord with the conditions for using the PCA method. Eventually, the objective contribution rates of each indicator were obtained after calculation, as depicted in

Table 4.

4.2. Comprehensive Weights of Evaluation Indicators

According to the AHP–PCA–IGT model, the comprehensive weights of various water inrush indicators were ultimately obtained. The comprehensive weights of the evaluation indicators for roof water inrush are shown in

Table 5.

4.3. Risk Assessment Map of Model

According to Equation (19), we established a risk index model for water inrush. After normalizing the six indicators, GIS was used to overlay various factors to obtain a vulnerability map of the water inrush risk of the 11-2 coal seam roof.

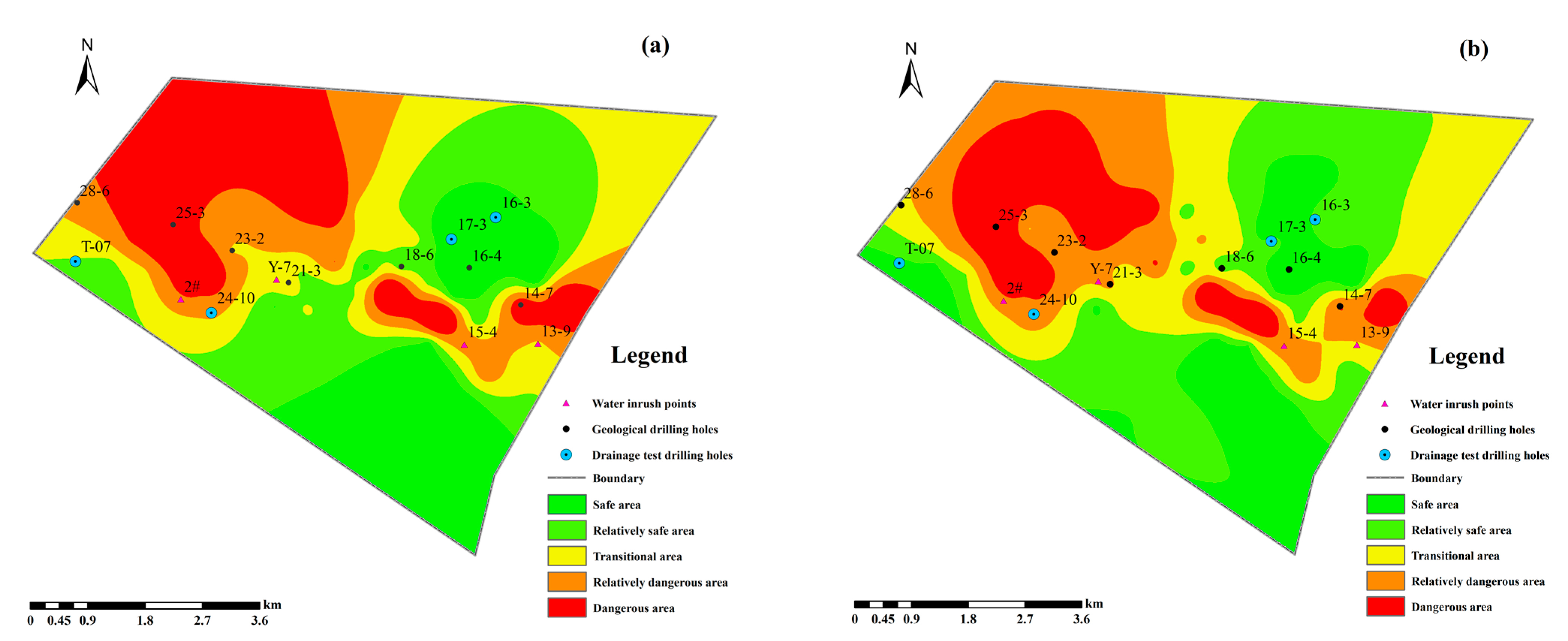

In order to visualize the risk map of roof water inrush, we used the Janks natural breakpoint method to divide the grid data output into five categories: safe area, relatively safe area, transitional area, relatively dangerous area, and dangerous area, as shown in

Figure 4. The AHP model was classified as follows: safe area, vulnerability range of 0.2098–0.3423; relatively safe area, vulnerability range of 0.3424–0.4233; transitional area, vulnerability range of 0.4234–0.5043; relatively dangerous area, vulnerability range of 0.5044–0.5951; dangerous area, vulnerability range of 0.5952–0.8357. The AHP–PCA–IGT model was classified as follows: safe area, vulnerability range of 0.1978–0.2827; relatively safe area, vulnerability range of 0.2828–0.3497; transitional area, vulnerability range of 0.3498–0.4302; relatively dangerous area, vulnerability range of 0.4303–0.5173; dangerous area, vulnerability range of 0.5174–0.7675.

As seen in

Figure 5, the AHP model and AHP–PCA–IGT model shows that the risk of roof water inrush is relatively higher, and the overall risk level gradually decreases from central to north–south. The main areas with relatively high risks and high risks are located in the western and a small part of the eastern regions. The vast majority of areas with the highest risk of water inrush are distributed in the central and western regions, and it is important to focus on developing water prevention and control strategies in this area to ensure normal coal mining operations. In addition to the fully developed tectonics of faults and small faults, the distribution of aquifers and aquifers provides the material basis for the water inrush risk, and the degree of lithologic fragmentation provides important support for water abundance.

According to the AHP–PCA–IGT risk assessment map of water inrush (

Figure 5 and

Table 6), it can be seen that the red zone represents the danger area, orange stands for the relatively danger area, yellow serves as the transition area, light green is the relatively safe area, and the green zone is the safe area. The areas with the danger area are mainly distributed in the central and western regions of the study area, as well as sporadic eastern regions. The scope includes 14 boreholes, such as 13-8#, 14-7#, 16-7#, 17-10#, 18-6#, etc., and their surrounding areas, accounting for approximately 14.23% of the total area. The four indicators of equivalent sandstone thickness, flushing fluid consumption, fault classification, and the ratio of sandstone and mudstone of the above drilling holes are all relatively large, and the core recovery rate value is relatively small, which conforms to the general characteristics of water abundance. The flushing fluid consumption in drilling is the highest. The equivalent sandstone thickness of boreholes 16-7# is the highest. The ratio of sandstone and mudstone in boreholes 18-6# is the highest. The orange area is mainly concentrated in the western part of the study area, with a small portion in the eastern region, accounting for 21.68% of the total area. The light green area has the largest distribution scope, accounting for 28.79% of the total area. The proportion of the yellow transition area and the green, safe area to the total area of the study area is 18.96% and 16.34%, respectively. Overall, there is little difference in the corresponding areas of different levels of water abundance in this study area, and the strong water inrush risks area is mainly concentrated in the central and eastern regions.

4.4. Verification of Evaluation Results

Vulnerability fitting percentage (

VFP) is introduced to verify the accuracy of the prediction model [

41]. We select geological drilling holes, water inrush sites, and input models for drainage test holes in various water inrush risk areas for fitting analysis. If the

VFP value is greater than 90%, it proves that the model has a good predictive effect on the risk of roof water inrush, which meets the actual situation. Otherwise, it is necessary to adjust the model parameters to meet the requirements. The specific formula for

VFP is as follows:

where

VFP is the vulnerability fitting percentage of water inrush risk,

DF is the accurate number of verification points for model prediction in the mine (geological drilling, water inflow points, and drainage test holes), and the number of identical points measured;

DS is the total number of known verification points.

We fit the water inrush hazard map using the actual verification point position, including geological drilling holes, water inrush sites, and drainage test drilling holes, as shown in

Figure 6. Firstly, geological drilling holes (14-7#, 16-4#, 16-7#, 21-3#, 23-2#, 25-3#, and 28-6#) verify the accuracy of identifying danger zones at various levels in the roof water inrush danger and safety areas of the study area.

The AT value at the location of the 28-6# borehole is 40.22 m, with a thin aquifer and a large impermeable layer. The waterproof ability is high, and the risk of water inrush is weak. In the AHP model, it is classified as a relatively dangerous area for water inrush, indicating that the model’s prediction effect is different from the actual situation. However, in the AHP–PCA–IGT model, it is divided into transition regions, demonstrating superior prediction performance. The equivalent aquifer thickness at the positions of 21-3# drilling hole is relatively thick, with a good water storage effect. The development of fault structures is relatively concentrated, and the risk of water inrush is high. In the AHP model, it is classified as a transitional area, but in the AHP–PCA–IGT model, it is classified as a relatively dangerous area, which is more scientific and accurate. The remaining three geological boreholes (14-7#, 16-7#, 23-2#, and 25-3#) have a relatively thin impermeable layer, strong water-bearing capacity, and concentrated development of faults and small fissures, making them prone to water inrush disasters zone. Therefore, they are accurately classified as hazardous areas in the two models.

After advanced exploration and drilling (2#, Y-7#, 13-9#, and 15-4#) measurement, the water inflow was determined to be 26 m

3/h, 12 m

3/h, 2 m

3/h, and 1.5 m

3/h, which were divided into relatively less dangerous areas by both models, demonstrating the superiority and good prediction effect of the model. Simultaneously, the measured unit water inflow value of the 24-10# is relatively large through pumping tests, which is 1.839 L/(s·m). It is classified as a relatively hazardous area in the AHP and AHP–PCA–IGT models, which is in line with the actual situation. The other three drainage test boreholes (16-3#, 17-3#, and T-07#) with smaller values and were classified as safe areas, as shown in

Figure 6 and

Table 7.

Taking the above results into formula (20), the VFP values of the AHP and AHP–PCA–IGT models were calculated to be 86.67% and 100.00%, respectively. Through comparative analysis, it is found that compared to the AHP model, the VFP value of the AHP–PCA–IGT evaluation model is higher, which is basically consistent with the actual situation. Therefore, this model’s prediction results are relatively accurate, and the main areas with relatively high risks and high risks are located in a small part of the western and eastern regions. Before mine production, advanced detection and prevention of roof water inrush disasters should be strengthened in this area.