Abstract

Sustainability is understood as a balanced integration of economic, ecological, and social aspects. Sustainable manufacturing can be considered one of the most important issues to address in the pursuit of sustainable development. The main purpose of the paper is to identify the most important directions of research to date and to indicate new and emerging areas of research concerned with the usage of decision-making methods in sustainability assessment in steel manufacturing companies. A systematic review was based on the publications indexed in the Web of Science and Scopus databases. In the analysis, the correspondence analysis and log-linear model were applied. To sum up, this study examines decision-making modalities and sustainable performance in terms of approaches that influence sustainability in steel manufacturing. Firstly, the study determined key decision-making aspects, such as the appropriate material identification for the manufacturing process and material labeling for the manufacturing process, which is essential for sustainable metal products. Secondly, the identification of sustainability indicators is considered vital in the hierarchical process as their integration is essential for the decision-making process and its outcome. Furthermore, system efficiency and productivity, alongside increasing attention to environmental protection, have led to significant changes in all production systems. In addition, many factors play an important role in the selection of suppliers, such as increasing the importance of the environment, increasing the recycling rate of the products, and ensuring sustainability performance. However, companies in the steel manufacturing industry rely little on the application of decision-making to assess sustainability.

1. Introduction

Manufacturing companies are increasingly being confronted with sustainability challenges in economic, environmental, and social terms. Sustainable manufacturing can be considered one of the most important obstacles in the pursuit of sustainable development. A lot of studies can be identified regarding comprehensive reviews that were conducted to better understand sustainable manufacturing. The reason for such is that more sustainable solutions need to be found that can reduce the negative environmental impact of manufacturing processes [1]. Steel companies are also becoming increasingly aware of sustainability challenges. In fact, within the European Union, the steel industry holds significant importance as a driving force behind sustainable growth, the enhancement of value, and the generation of exceptional occupational prospects [2]. In that light, the steel manufacturing sector faces significant environmental, economic, and social challenges that require urgent attention. Environmental concerns encompass greenhouse gas emissions, air pollution, water and resource usage, and waste generation. Utilizing secondary materials through recycling is among the viable approaches taken to address these issues [3]. Economic challenges arise from global competition, fluctuating demand, and the need for technological advancements. Social challenges involve employment and labor conditions, occupational health and safety, and community impact. Social issues have been exacerbated by the recent COVID-19 pandemic, leading to significant issues for steel companies that impact their supply chain, demand, labor force, pricing, and compliance with regulations [4]. Adaptability, resilience, and strategic planning are crucial for steel companies to navigate through these challenges and mitigate their effects. Addressing these challenges, therefore, necessitates sustainable practices, digitalization [5], and stakeholder collaboration to foster a more environmentally friendly, economically viable, and socially responsible steel manufacturing sector. In this sense, digitalization in the European steel industry requires the participation of numerous prominent actors [6]. There are contradictions between the strong potential and the backward practice status of steel industries. This has been shown by [7], who created a decision framework to help steel companies choose the best Reverse Logistic (RL) modes and effectively use the steel multi-criteria, decision-making method as a resource. The scientific contribution of this work is two-fold. Firstly, it emphasizes the importance of integrating key sustainability indicators into the decision-making process. This recognition highlights the significance of considering sustainability factors when making decisions in the steel manufacturing industry. Secondly, the authors of this paper aim to address a research gap by identifying the most significant research directions to date and exploring emerging areas related to the utilization of decision-making methods in sustainability assessment for steel manufacturing companies. The authors had not found previous studies associated with this topic. Therefore, this study aims to fill this knowledge gap and contribute to the existing body of research in this field. In order to achieve this objective, the authors have formulated the following research questions to guide their investigation:

- What lines of research dominate the publications dealing with the sustainability assessment of steel-manufacturing enterprises?

- Are there any links between these research areas and how they are collaborating?

A systematic review was based on the publications indexed in the Web of Science and Scopus databases. In the analysis, the correspondence analysis and log-linear model were applied. After the introductory section, the subsequent part of this document proceeds as follows: Section 2 provides an explanation of a literature review, Section 3 outlines the methodology employed in conducting the literature review, Section 4 highlights the principal discoveries derived from the study, Section 5 critically analyzes the obtained results, and, lastly, the Section 6 presents a summary of the key outcomes along with future prospects.

2. Literature Review

The following literature review provides a comprehensive analysis of the usage of multi-criteria, decision-making methods for sustainability assessment, with a particular focus on their application in the steel production and manufacturing industries. The review encompasses various studies that have explored alternative approaches, decision frameworks, and assessment methodologies to enhance sustainability performance and optimize processes in these sectors. Topics covered include the feasibility of smart and sustainable machining processes, material selection and manufacturing process considerations, sustainability performance assessment in the steel industry, and the evaluation of environmental, economic, and social impacts at the work cell level. Additionally, the review delves into studies that have examined the sustainability performance of emissions trading schemes, the development of decision models for optimizing environmental performance, and the selection of appropriate supplier evaluation frameworks. The literature review also highlights the importance of considering alternative materials, energy-efficient technologies, and cleaner production approaches in achieving sustainable outcomes.

2.1. Steel Production

In the field of steel production, several studies have focused on optimizing processes and enhancing sustainability. In the paper by [8], the feasibility of Time Control Machining (TCM) using vibration analysis in milling 17-4 stainless steel was investigated, and a positive trend was observed between workpiece surface roughness and cutting tool vibration in the time steps where tool wear was predicted. The result of the decision framework shows a clear preference for smart processing alternatives over conventional processing. Overall, editing with TCM and Computational Fluid Dynamics (CFDs) proved to be the preferred method. Another approach taken to study the realizable impacts of screw manufacturing was to select an appropriate material and choose the manufacturing process of the screw, considering environmental aspects without sacrificing the economic aspect. Decision-making processes focused on economic aspects to achieve synergy outcomes between economic and environmental impacts. As a result, low-carbon steel was chosen for the forging process while cast iron excelled in the machining process. Interestingly, the use of stainless steel was not recommended for both processes [9]. Assessing the sustainability performance of the steel industry has been a key area of research. An assessment conducted from 2003 to 2006 revealed varying priorities, with the highest priority observed in 2005 and the lowest in 2004 [10]. Company valuation was identified as a crucial management function that reflects the impact of decisions on value creation and competitiveness. Utilizing the Monte Carlo method, researchers determined the behavior of cash flows for Gerdau S.A. over five years (2017–2021), allowing for the identification of risks within the steel sector [11]. Studies conducted in South Korea examined the sustainable performance of the emissions trading scheme (ETS) in terms of production efficiency, focusing on data from companies in the steel industry, a representative greenhouse gas emitter. The findings indicate that many steel companies are increasing their economies of scale, resulting in improved efficiency as they expand their operations [12]. To assess the sustainable performance of the steel industry, a methodology was developed to create a Composite Sustainability Performance Index (CSPI) that considers economic, environmental, and social dimensions. The aim was to introduce sustainability into decision-making processes, and the Analytical Hierarchy Process (AHP) was employed to determine the weights at different levels of the model [13]. In the context of steelmaking, a predictive model for optimizing environmental performance in Electric Arc Furnaces (EAFs) was briefly described. The model identified process inputs that minimize various environmental measures, highlighting opportunities for enhancing sustainability in steel production [14].

2.2. Manufacturing

To assess broader sustainability impacts, economic, environmental, and social impact assessments must be conducted at the work cell level. Researchers have employed this approach in a case study involving a representative processing cell for stainless-steel knife production [15]. The study compared economic, environmental, and social impact results across three production scenarios using the Sustainable Manufacturing Assessment Framework. The case study revealed that the cost of cutting tools significantly contributes to the overall production cost of the work cell under investigation. Notwithstanding, the extent of the ecological and social impacts varies by cycle time [15]. In addition, [16] established a tree of sustainable requirements that must correspond to the structures carried out in two main areas: the development of the material itself and the measures taken to carry out the work on site, which may have an impact on the environment. The main result of this is the development of a method that enables an evaluation process for indicators and weights. A mathematical model of the rational selection of the position plan according to the structural code of the workpiece was verified in some practical case studies, the aim of which was to provide a scientific approach to the rational selection of a locator diagram for complex-shaped parts. As a result, a decision-making approach was applied to the rational selection of the position diagram for each bracket-like part. The proposed solutions improved the production planning phase for machine building, automotive, and other industries [17]. Discussing the interaction between criteria may lead to extending our proposed dynamic framework to consider the intrinsic dependencies between criteria with a combined dynamic decision-making approach based on the Analytical Hierarchy Process (AHP), which is used to select the best supplier. The main contributions include the determination of the most important criteria for supplier selection at a steel bar manufacturer in Taiwan and the proposal of a simple and quick analysis of the appropriate evaluation framework for supplier selection [18]. However, a comparative study between mineral and vegetable oil was carried out with experimental activity to study the technical performances of the two media in terms of the dimensional and metallurgical properties of the quenched parts. Interestingly, it indicated better component distortion control and comparable metallurgical microstructure when vegetable oil was used for quenching [19]. To improve decision making under uncertainty and enhance sustainability in large manufacturing plants, researchers pioneered a combined neutrosophic gray AHP (NG-AHP) method. This method effectively captured uncertainties in subjective judgments, emphasizing the importance of research for group decisions [20]. The calculation results show the effectiveness of the proposed method in adequately capturing uncertainties in the subjective judgments of decision-makers. In addition, the results demonstrate the importance of research for group decisions under uncertainty. The practical result shows that, to become a more sustainable agile steelmaker in the fall country, they should first focus on organizational management agility as the main evaluation criterion, followed by manufacturing process agility, product design agility, information system integration, and capability, respectively, for partnership formation. In addition, sustainability is understood as a balanced integration of economic, ecological, and social aspects. Research identifies and categorizes the most-used sustainable KPIs and analyzes the methods of their evaluation in the metallurgical industry according to the Analytic Hierarchy Process (AHP) method. This proves that the AHP method is a suitable instrument for the aggregated assessment of sustainability and its dimensions in the metallurgical industry [21]. Furthermore, a review and comparison of sustainability frameworks with models aiming to propose an overarching strategic planning process for the selection of sustainable production (SP) indicators in manufacturing were proposed by [22], who demonstrated the conceptual model used to offer decision support for steel organizations. This research suggests that society’s recognition of the value of recyclable and reusable materials, like steel, will play a significant role in achieving a sustainable future.

2.3. Environmental Impact

Environmental impact assessments in the steel industry have explored various aspects, addressing both challenges and opportunities for improving sustainability. Grinding, a commonly used process in steel manufacturing, has been identified as environmentally harmful due to its significant energy input and liquid application, which can lead to pollution. However, reducing cooling lubricants in the process can increase the cutting temperature and negatively affect the substrate. These aspects are often overlooked in traditional lifecycle inventory analyses. To address this, a study introduced a new sustainability indicator based on the rolling contact fatigue life of components determined by the grinding process [23]. In India, a study focused on analyzing Environmental Sustainability Enablers (ESEs) for a steel manufacturing company to enhance environmental sustainability. The study classified 18 relevant ESEs into cause–effect groups and assessed their interactions. Notably, five ESEs—competitors’ environmental sustainability strategy, environmental compliance certification, government regulations and incentives, the influence of external factors, and the air pollution control system—were identified as prominent in the cause group [24]. Another study aimed to drive the green transformation of economic development and control air pollution in the steel industry through industrial restructuring and the implementation of cleaner manufacturing approaches. A dynamic optimization simulation was conducted for the period 2016 to 2025 using a green economy transformation decision model. The simulation results confirmed the existing negative development trend and demonstrated the potential for positive economic growth, accompanied by an acceptable level of pollution, through increased investments in clean production technologies [25]. Furthermore, research focused on the development and deployment of alternative energy-efficient ironmaking technologies, including CO2 capture. The study evaluated the sustainability aspects—technical, economic, environmental, and social—of Carbon Capture and Storage (CCS) systems in the steel industry. A hybrid multi-criteria decision model integrating Delphi, a 2-tuple decision-making trial and evaluation laboratory, and fuzzy AHP was proposed to select dimensions and critical factors for evaluating alternative iron-making technologies utilizing CCS systems [26]. Overall, this review synthesizes a wide range of literature to present a comprehensive understanding of the current state of research and provides valuable insights for decision-makers in the steel production and manufacturing domains.

3. Materials and Methods

In this work, a research procedure covering the following stages was used to identify research directions in the field of the application of decision-making models in the assessment of sustainable development in steel-producing enterprises:

Stage 1. Building a database of publications from the scope of research analyzed in the thesis. The purpose of this stage of the study is to identify publications indexed in the Web of Science (WoS) database, which present analyses and research results on issues from the scope analyzed in the work. Selected keywords were used to identify publications in the WoS database. Their scope and subsequent analyzed variants are presented in Table 1.

Table 1.

Results of searching for publications in the WoS database for given keywords.

Stage 2. Analysis of the co-occurrence of keywords appearing most often in the analyzed works. At this stage of the study, keywords repeated with high frequency in the researched works were divided into clusters (clusters of co-occurring keywords). This stage of the research aimed to identify the relationships between the keywords selected in the first stage of the research and other terms appearing in the analyzed works. The results of the clustering were visualized on maps.

Stage 3. Identification of relationships connecting key research threads appearing in the analyzed works. The results of this stage of the study were visualized on a cognitive map.

The cognitive map makes it possible to determine the structure of cause-and-effect relationships between the conditions of the studied phenomenon [27] or its components. A cognitive map (CM), commonly known as an association map, is a solution that was first used in the humanities by Robert Axelrod in 1976. The basis for its creation is cause–effect relationships (associations) of a complex nature, presented as a simple graph. The vertices in the model presented in this way represent the factors related to the analyzed problem (in this paper, these will be the main research threads identified in the analyzed works), and the edges describe the relationships (positive or negative impact) between them. The direction of the arrows and the indicator accompanying them show the type of dependence and its strength (usually in the range from −1 to 1). In the work, all relationships between the analyzed research threads have a positive direction, which means that a relatively large number of publications in one field also corresponds to a relatively large number of works in the area related to it. An expert approach was used to build the cognitive map using simple calculation procedures and expert analysis of the content of the identified publications. In the literature on the subject, there are more and more examples of using this tool to diagnose various types of phenomena, including modeling [28,29,30], knowledge management [31,32], political and social issues [33], engineering and technology management [29], agriculture and ecological modeling [30], management [34], forecasting [35,36], medical decision support and classification tasks [30,37], and sustainable financial systems [30,38].

Cognitive maps are analyzed considering the relationships between individual research areas. It is also important to determine the density of the map. The density (or clustering coefficient) of the cognitive map (D) is a connectivity index that shows how the analyzed research areas identified during the analyses of the collected publications are connected [39]. The following formula is used to determine the clustering factor:

According to the presented formula, the number of existing connections on the map is divided by the maximum possible number of connections that may occur between the analyzed research areas [40]. If the map density is high, then many connections between the identified areas are observed.

4. Results

4.1. Identification of Publications Referring to the Scope of Research Analyzed in the Work

Selected combinations of keywords were used for an in-depth analysis of publications in the analyzed scope. In publication databases, including the Web of Science (WoS) database, it is possible to search for publications referring to keywords, indicated individually or in logical combinations. Table 1 below presents the search results for publications available in the Web of Science database for keywords related to the research analyzed in the scope.

The information presented in Table 1 shows that there are currently 774 publications available in the WoS database (as of 15 February 2023) referring to the terms steel company or firm or manufacture and sustainability and model, where the “*” character in the search formula replaces the various possible endings of individual terms, the so-called flexible ends. In works in this field, various types of models are discussed, ranging from heuristic models to mathematical models. On the other hand, narrowing the search to papers in which issues related to decisions or even decision-making models are discussed results in their limitation to 193 and 92 papers, respectively. An even smaller number of publications was obtained by searching in the WoS database for works directly referring to a specific class of models or methods used in their creation, i.e., multi-criteria decision support (MCDA) methods. The result of the search, as shown in the last row of Table 1, is only 25 works.

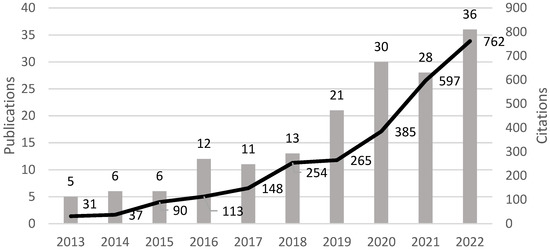

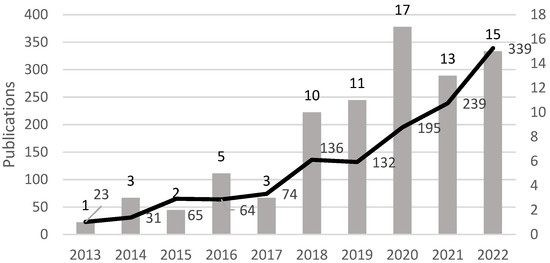

Figure 1 and Figure 2 compare the search results of publications referring to the list of keywords in the second and third search methods. The comparison of the information presented in both figures shows that, in both cases, there has been an increase in interest in the works in the analyzed field, which has been observed over the last few years. Despite a visible increase in the number of citations, the increase in the number of scientific papers is not impressive. These differences indicate the existence of a research gap and, very likely, a search by other authors for publications referring to scientific reports in the field of application of the theory of decision-making in the conditions of the sustainable development of the metal industry.

Figure 1.

Scientific papers and their citations identified in the WoS database according to the second search method. Source: own elaboration.

Figure 2.

Scientific papers and their citations identified in the WoS database according to the third search method. Source: own elaboration.

Later in the work, an in-depth analysis of the content of works identified according to the third search method was carried out. These are mainly works related to the field of environmental science, environmental engineering (39), engineering manufacturing or industrial engineering (31 publications), green sustainable science technology (23), and management (7), and were published mainly by authors from China (16 publications), USA (14), UK (9), and India (9).

Due to the relatively small number of publications in the analyzed field, a concentration of citations is also visible, albeit only on a few publications. The list of the most frequently cited works (according to the third search method) is presented in Table 2.

Table 2.

Top 10 most cited papers according to the third search method from Table 1.

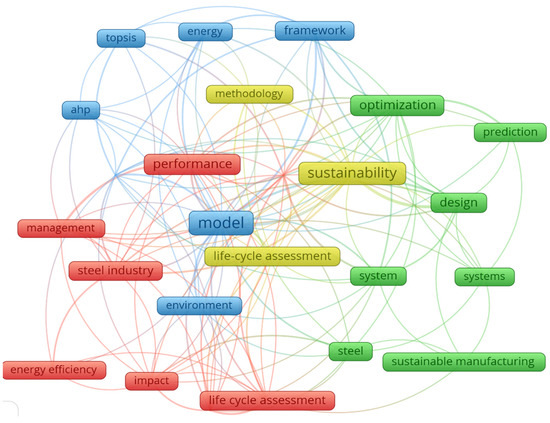

4.2. Results of the Analysis of the Co-Occurrence of Keywords in the Identified Publications

The VOSviewer program was used to analyze the links between the keywords indicated by the authors of the analyzed works and the keywords most frequently repeated in them. It is a tool used for constructing and visualizing bibliometric networks. Figure 3 shows a map of the co-occurrence networks of important terms extracted from a body of scientific literature.

Figure 3.

Map of co-occurrence networks. Source: own elaboration.

The information presented in Figure 3 shows that, based on the keywords identified in the analyzed works, it is possible to distinguish four clusters, which include the following keywords:

- Cluster 1: energy efficiency, impact, life cycle assessment (LCA), management, performance, selection, and steel industry.

- Cluster 2: design, optimization, prediction, steel, sustainable manufacturing, system(s),

- Cluster 3: AHP, decision-making, energy, environment, framework, model, TOPSIS,

- Cluster 4; Life cycle assessment (LCA), methodology, sustainability.

The obtained division of keywords shows that, in principle, in each cluster, there are keywords describing various types of methods (models) used to describe the phenomenon studied in the work. These are mainly models that were found in the field of life cycle assessment; however, importantly, the models in the analyzed works are also used in certain types of decision models, or multi-criteria decision support methods, which are used in the creation of these types of models. These are, in particular, Analytic Hierarchy Process (AHP) and TOPSIS.

AHP is a multi-criteria method of hierarchical analysis of decision problems. It enables the decomposition of a complex decision problem and the creation of a final ranking for a finite set of variants [50]. The criteria in AHP included a systematic review of the literature. (Procedia Computer Science, 55, 1123–1132). TOPSIS, on the other hand, is a multi-criteria method of decision analysis and a technique for examining the order of preferences according to the similarity to the ideal solution [51]. Topsis for MODM. (European Journal of Operational Research, 76(3), 486–500).

In the analyzed set of publications, 31 works in this field were identified. These are works in which these methods or their extensions are used, for example, to:

- Evaluate the sustainability performance of steel industries from 2003 until 2006 [52]. An integrated D-MARCOS method for supplier selection in the steel industry. Decision Making: Applications in Management and Engineering, 3(2), 49–69;

- Select the best supplier in steel companies [18]. An Inner Dependence Analysis Dynamic Decision-Making Framework. Sustainability, 14(10), 5968; [53]. Two-Stage Fuzzy MCDM for Green Supplier Selection in Steel Industry. Intelligent Automation and Soft Computing, 33(2);

- Achieve a sustainable supplier selection [54]. Sustainable supplier selection in the retail industry: A TOPSIS-and ANFIS-based evaluating methodology. International journal of engineering business management, 12, 1847979019899542;

- Provide an analysis of the alternatives for smart and sustainable machining processes to provide visibility and clarity on the factors that can affect production performance [8]. Data-Driven, Multi-Criteria Decision-Making for Smart and Sustainable Machining. In ASME International Mechanical Engineering Congress and Exposition (Vol. 85567, p. V02BT02A064). American Society of Mechanical Engineers;

- Identify the criteria for selecting green building materials (GBMs) and assess their sustainability [55]. A decision-making model for supporting the selection of green building materials. International Journal of Construction Management, 1–12;

- Investigate the viable impacts of screw manufacturing and choose the suitable material and selected manufacturing process of the screw by considering environmental aspects [9]. Decision Making of Screw Manufacturing for the Best Environmental and Economic Combination by Using AHP. In Applied Mechanics and Materials (Vol. 465, pp. 1065–1069). Trans Tech Publications Ltd. (Stafa-Zurich, Switzerland);

- Help designers and manufacturers make the best choices regarding the material they use in production [56]. AHP-MARCOS, a hybrid model for selecting gears and cutting fluids. Materials Today: Proceedings, 52, 1397–1405.

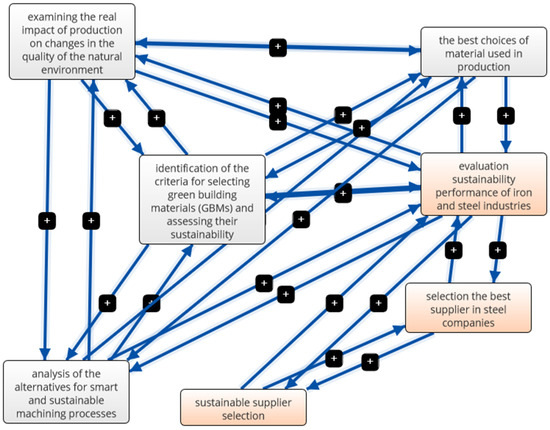

4.3. The Results of Identifying Relationships Connecting Key Research Threads

Figure 3 shows a map with connections between the second research areas identified at this stage. The Mental Modeler software, available at https://www.mentalmodeler.com, was used for this purpose.

On the other hand, Figure 4 presents a collective map that considers all the criteria analyzed in the work. The FCMapper_bugfix_27.1.2016 and Mental Modeller softwares were used for this purpose.

Figure 4.

Map of relations between research areas identified on the second step of the research procedure. Source: own elaboration. “+” means positive relationships between areas.

The map presented in Figure 3 shows the relationships between the identified research areas. It shows the division of the identified research areas into two groups. The first group includes publications in which the authors’ attention is focused on production issues, while the second group includes works referring to issues related to the selection of suppliers. In both groups, issues related to sustainable development are important. The relations between the identified research areas shown on the map are two-sided (arrowheads indicate the direction of links between the areas), which means that the issues identified on the map are simultaneously presented, e.g., as a background for the conducted research, or as an element of literature review, etc. The map density coefficient (formula 1) was 0.62. A total of 26 connections between the seven analyzed research areas were visualized on the map.

5. Discussion

Regarding the decision-making modalities and sustainable performance of steel manufacturing companies, the empirical and theoretical literature of this study discusses various approaches that may influence sustainability in steel manufacturing companies. We can further outline the relationship between those important factors. The first group of issues is related to the decision-making modalities in steel manufacturing companies. In terms of the appropriate material identification for the manufacturing process, material labeling for the manufacturing process is essential for sustainable metal products. Material selection is considered a complex process due to the involvement of multiple processing elements and outcomes. The material selection process, which involves multiple decision parameters and criteria, can be effectively managed using multi-criteria decision-making approaches (MCDM). These facilitate distributed manufacturing and on-demand production while reducing costs and energy consumption over the longest sustainable period [8,18,57,58]. As for the perspective of supplier performance evaluation, supplier performance is evaluated from the aspects of enterprise ability, service level, and customer satisfaction. Achieving a supply chain that is resilient to potentially unforeseen disruptions such as strikes remains a vital concern of decision-makers in the steel manufacturing industry. To create a resilient reactive supply chain plan, the purchasing department needs to pay the strictest attention to sourcing decisions to ensure continuous sustainability [10,59,60,61,62,63]. On the other side, the steel manufacturing industry has responded to economic, social, and environmental challenges through the adoption of sustainability pillars. The identification of sustainability indicators is considered key in the hierarchical process, and the integration of key sustainability indicators is essential for the decision-making process and its outcome [10,13,16,55,64]. As for strategic planning, the key purpose includes the selection of sustainable production (SP) indicators within the manufacturing sector, which point toward radical, systematic, and goal-oriented changes in organizational strategic sustainable development. Steel manufacturing companies use it as a conceptual model to guide strategic decision-making support for sustainability [1,13,45,65]. In terms of system efficiency and productivity, increasing attention to environmental protection has led to significant changes in all production systems. In addition, the efficiency and productivity of the system should be improved, and the design of the manufacturing system must consider environmental constraints. The second group of issues relates to sustainability performance in steel manufacturing. Regarding production efficiency, the cost directly impacts the manufacturing setup, profitability, and sustainability in the long run. In most industries, ineffective maintenance management can result in the loss of capital and inefficient human resource deployment. This, in turn, affects the plants’ ability to manufacture quality steel that is competitive in the market [13,58,66,67]. Lastly, in terms of product quality and customer satisfaction, increasing customer satisfaction by producing quality products at low cost is a major concern for businesses. For this reason, companies must choose suppliers that best meet their needs and those of their customers. In addition, many factors play an important role in the selection of suppliers, such as increasing the importance of the environment, increasing the recycling rate of the products, and ensuring sustainability performance [43,68,69]. To sum up, the application of multi-criteria decision-making models in steel manufacturing companies contributes significantly to the existing literature by addressing various decision-making challenges and enhancing sustainability outcomes. By employing MCDM approaches, such as material selection and supplier performance evaluation, decision-makers can effectively manage the complex decision parameters and criteria involved in these processes [8,10,18,57,58,59,60,61,62,63]. The integration of key sustainability indicators within the hierarchical decision-making process enables the identification and evaluation of sustainability aspects, supporting strategic planning and organizational sustainable development [1,10,13,16,45,55,64,65]. Furthermore, MCDM models help evaluate and optimize the efficiency, productivity, and environmental constraints of manufacturing systems, facilitating the consideration of multiple decision-making aspects such as costs, staff health, and operational safety [13,66]. The utilization of MCDM models in steel manufacturing companies not only provides practical insights and guidance for decision-makers but also contributes to the literature by offering a systematic and comprehensive approach to addressing sustainability challenges. These models enhance our understanding of the complex interplay between decision-making factors and their impact on sustainability outcomes, thereby advancing knowledge in the field and paving the way for more informed and sustainable practices in the steel manufacturing industry [13,43,58,67,68,69,70].

6. Conclusions

The analyses conducted in this study highlight the relative scarcity of research on the application of decision-making methods in assessing sustainability issues specifically within steel-manufacturing companies. This research gap underscores the innovation and novelty of this work, which contributes to expanding the existing literature on the subject. By incorporating sustainability considerations, decision-making processes in manufacturing can effectively evaluate and balance the diverse and, at times, conflicting aspects involved. A key objective for businesses is to enhance customer satisfaction by delivering quality products at reduced costs. Furthermore, the growing emphasis on environmental protection has necessitated substantial transformations in production systems. The innovation of this study lies in its exploration of decision-making methods as a means to address these challenges and promote sustainable practices in the steel manufacturing industry. Through the integration of sustainability criteria, decision-makers are empowered to make informed choices that optimize multiple facets, ultimately fostering long-term success and resilience in this sector.

6.1. Limitation of Research

The most important limitation of the conducted research is the access to relevant literature sources, i.e., works in which the results of analyses from a rather narrow scope are presented, which includes the use of a decision-making approach to the sustainable development of steel production companies. The results of the identification of publications in this field are also greatly affected by the choice of keywords, which, when adding more keywords, can significantly change the search results. Keywords were expertly selected by the authors. Different sets of keywords were tested, and both the number of publications and their scope were verified. A set of keywords was sought that best reflected the area of research analyzed in the paper.

6.2. Future Research Directions

In subsequent works in this field, the authors will attempt to use advanced methods of multidimensional data analysis to identify new and emerging research threads based on keywords repeated in the reviewed works. Also, as part of the industrial (implementation) Ph.D. thesis of one of the authors, future research directions include proposing criteria for the sustainability assessment for steel manufacturing companies and the usage of multi-criteria decision-making methods for the evaluation of those criteria.

Author Contributions

Conceptualization, R.D.; methodology, R.D. and K.C.; software, K.C.; validation, R.D., J.S., K.C. and K.S.-D.; formal analysis, R.D., J.S., C.D., K.C. and K.S.-D.; investigation, R.D., J.S., C.D., K.C. and K.S.-D.; resources, R.D. and K.C.; data curation, R.D., J.S., K.C. and C.D.; writing—original draft preparation, R.D., J.S., K.C. and C.D.; writing—review and editing, K.C. and K.S.-D.; visualization, K.C. and K.S.-D.; supervision, K.S.-D.; project administration, R.D.; funding acquisition, R.D. and K.S.-D. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data available on request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Malek, J.; Desai, T.N. A systematic literature review to map literature focus of sustainable manufacturing. J. Clean. Prod. 2020, 256, 120345. [Google Scholar]

- Rieger, J.; Colla, V.; Matino, I.; Branca, T.; Stubbe, G.; Panizza, A.; Brondi, C.; Falsafi, M.; Hage, J.; Wang, X.; et al. Residue valorization in the iron and steel industries: Sustainable solutions for a cleaner and more competitive future Europe. Metals 2021, 11, 1202. [Google Scholar]

- Panasiyk, D.; Laratte, B.; Remy, S. Steel stock analysis in Europe from 1945 to 2013. Procedia CIRP 2016, 48, 348–351. [Google Scholar]

- Kitamura, Y.; Karkour, S.; Ichisugi, Y.; Itsubo, N. Evaluation of the Economic, Environmental, and Social Impacts of the COVID-19 Pandemic on the Japanese Tourism Industry. Sustainability 2020, 12, 10302. [Google Scholar]

- Neef, C.; Hirzel, S.; Arens, M. Industry 4.0 in the European Iron and Steel Industry: Towards an Overview of Implementations and Perspectives; Fraunhofer Institute for Systems and Innovation Research ISI: Karlsruhe, Germany, 2018. [Google Scholar]

- Arens, M. Policy support for and R&D activities on digitising the European steel industry. Resour. Conserv. Recycl. 2019, 143, 244–250. [Google Scholar]

- Gu, W.; Wang, C.; Dai, S.; Wei, L.; Chiang, I.R. Optimal strategies for reverse logistics network construction: A multi-criteria decision method for Chinese iron and steel industry. Res. Policy 2021, 74, 101353. [Google Scholar]

- Bhatia, P.; Liu, Y.; Nagaraj, S.; Achanta, V.; Pulaparthi, B.; Diaz-Elsayed, N. Data-Driven Multi-Criteria Decision-Making for Smart and Sustainable Machining. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Virtual, 1–5 November 2021; American Society of Mechanical Engineers: New York, NY, USA; Volume 85567, p. V02BT02A064. [Google Scholar]

- Azlan, M.A.; Buja, A.A.; Kiong, S.C.; Nor, N.H.M.; Azlis-Sani, J. Decision Making of Screw Manufacturing for the Best Environmental and Economic Combination by Using AHP. Appl. Mech. Mater. 2013, 465–466, 1065–1069. [Google Scholar] [CrossRef]

- Mohammadreza, A.; Daroonparvar, M.; Meysam, K.; Daroonparvar, D. Assessment of Performance Sustainability in Iron and Steel Industries based on Using Fuzzy Hierarchical Decision Making. In Proceedings of the International Conference on Management (Icm 2011), Penang, Malaysia, 13–14 June 2011. [Google Scholar]

- Cardoso, G.F.; Souza, G.S.; Carvalho, L.F.; de Sousa Ribeiro, K.C. Stochastic analysis of a steel firm. Rev. Cienc. Adm. 2018, 24. [Google Scholar]

- Choi, Y.; Yu, Y.; Lee, H.S. A study on the sustainable performance of the steel industry in Korea based on SBM-DEA. Sustainability 2018, 10, 173. [Google Scholar]

- Singh, R.K.; Murty, H.R.; Gupta, S.K.; Dikshit, A.K. Development of composite sustainability performance index for steel industry. Ecol. Indic. 2007, 7, 565–588. [Google Scholar]

- Sutherland, J.W.; Haapala, K.R. Optimization of steel production to improve lifecycle environmental performance. Cirp Ann.-Manuf. Technol. 2007, 56, 5–8. [Google Scholar] [CrossRef]

- Zhang, H.; Haapala, K.R. Integrating sustainable manufacturing assessment into decision making for a production work cell. J. Clean. Prod. 2015, 105, 52–63. [Google Scholar] [CrossRef]

- Cuadrado, J.; Blanco, J.M.; Orbe, A.; Larrauri, M.; García, H.; Marcos, I. Learning to Make Sustainable Decisions in Construction Engineering; Index of Environmental Sensitivity in the Design of Structures. In Proceedings of the 7th International Conference on Education and New Learning Technologies, Barcelona, Spain, 6–8 July 2015; pp. 3485–3493. [Google Scholar]

- Ivanov, V.; Botko, F.; Kolos, V.; Pavlenko, I.; Hatala, M.; Antosz, K.; Trojanowska, J. Locating Chart Choice Based on the Decision-Making Approach. Materials 2022, 15, 3557. [Google Scholar] [CrossRef]

- Liu, Y.N.; Wu, H.H. An Inner Dependence Analysis Dynamic Decision-Making Framework. Sustainability 2022, 14, 5968. [Google Scholar] [CrossRef]

- Lenzi, F.; Campana, G.; Lopatriello, A.; Mele, M.; Zanotti, A. About the Use of mineral and vegetable Oils to improve the Sustainability of Steel Quenching. Procedia Manuf. 2019, 33, 701–708. [Google Scholar] [CrossRef]

- Vafadarnikjoo, A.; Scherz, M. A hybrid neutrosophic-grey analytic hierarchy process method: Decision-making modelling in uncertain environments. Math. Probl. Eng. 2021, 2021, 1239505. [Google Scholar] [CrossRef]

- Lenort, R.; Staš, D.; Wicher, P.; Holman, D.; Ignatowicz, K. Comparative study of sustainable key performance indicators in metallurgical industry. Rocz. Ochr. Sr. 2017, 19, 36–51. [Google Scholar]

- Kianian, B.; Daly, E.; Andersson, C. Towards guidelines for selection of production performance indicators to measure sustainability performance. Procedia Manuf. 2018, 25, 570–577. [Google Scholar] [CrossRef]

- Bordin, F.M.; Linke, B.S.; Fredel, M.C.; Weingaertner, W.L. Grinding sustainability analysis using a fatigue failure-related product life indicator. CIRP J. Manuf. Sci. Technol. 2022, 38, 1–15. [Google Scholar] [CrossRef]

- Goyal, S.; Routroy, S.; Singhal, A. Analyzing environment sustainability enablers using fuzzy DEMATEL for an Indian steel manufacturing company. J. Eng. Des. Technol. 2019, 17, 300–329. [Google Scholar] [CrossRef]

- Xu, F.; Cui, F.; Xiang, N. Roadmap of green transformation for a steel-manufacturing intensive city in China driven by air pollution control. J. Clean. Prod. 2021, 283, 124643. [Google Scholar] [CrossRef]

- Quader, M.A.; Ahmed, S.; Dawal, S.Z.; Nukman, Y. Present needs, recent progress, and future trends of energy-efficient Ultra-Low Carbon Dioxide (CO2) Steelmaking (ULCOS) program. Renew. Sustain. Energy Rev. 2016, 55, 537–549. [Google Scholar] [CrossRef]

- Godlewska-Majkowska, H.; Komor, A. Regionalne grupy strategiczne jako instrument analizy lokalizacji przedsiębiorstw na przykładzie przemysłu motoryzacyjnego. Eur. Reg. 2014, 20, 127–147. [Google Scholar]

- Ozesmi, U.; Tan, C.O. Cognitive maps of complex systems show hierarchical structure and scale-free properties. arXiv 2006, arXiv:q-bio/0612030. [Google Scholar]

- Bueno, S.; Salmeron, J.L. Benchmarking main activation functions in fuzzy cognitive maps. Expert Syst. Appl. 2009, 36, 5221–5229. [Google Scholar] [CrossRef]

- Papageorgiou, L.G. Supply chain optimisation for the process industries: Advances and opportunities. Comput. Chem. Eng. 2009, 33, 1931–1938. [Google Scholar] [CrossRef]

- Taber, R. Knowledge processing with fuzzy cognitive maps. Expert Syst. Appl. 1991, 2, 83–87. [Google Scholar] [CrossRef]

- Wei, W.; Ma, G.H.; Hu, G.; Yu, D.; Mcleish, T.; Su, Z.G.; Shen, Z.Y. Preparation of hierarchical hollow CaCO3 particles and the application as anticancer drug carrier. J. Am. Chem. Soc. 2008, 130, 15808–15810. [Google Scholar] [CrossRef]

- Andreou, A.S.; Mateou, N.H.; Zombanakis, G.A. Evolutionary fuzzy cognitive maps: A hybrid system for crisis management and political decision making. In Proceedings of the Conference Proceedings on Computational Intelligence for Modelling Control and Automation, Vienna, Austria, 14 February 2003. [Google Scholar]

- Isaac, M.; Van Vuuren, D.P. Modeling global residential sector energy demand for heating and air conditioning in the context of climate change. Energy Policy 2009, 37, 507–521. [Google Scholar] [CrossRef]

- Song, C.; Qu, Z.; Blumm, N.; Barabási, A.L. Limits of predictability in human mobility. Science 2010, 327, 1018–1021. [Google Scholar] [CrossRef]

- Furfaro, R.; Kargel, J.S.; Lunine, J.I.; Fink, W.; Bishop, M.P. Identification of cryovolcanism on Titan using fuzzy cognitive maps. Planet. Space Sci. 2010, 58, 761–779. [Google Scholar] [CrossRef]

- Kannappan, A.; Tamilarasi, A.; Papageorgiou, E.I. Analyzing the performance of fuzzy cognitive maps with non-linear hebbian learning algorithm in predicting autistic disorder. Expert Syst. Appl. 2011, 38, 1282–1292. [Google Scholar] [CrossRef]

- Ziolo, M.; Filipiak, B.Z.; Bąk, I.; Cheba, K. How to design more sustainable financial systems: The roles of environmental, social, and governance factors in the decision-making process. Sustainability 2019, 11, 5604. [Google Scholar] [CrossRef]

- Özesmi, U.; Özesmi, S.L. Ecological models based on people’s knowledge: A multi-step fuzzy cognitive mapping approach. Ecol. Model. 2004, 176, 43–64. [Google Scholar] [CrossRef]

- Hage, P.; Harary, F. Arapesh sexual symbolism, primitive thought, and Boolean groups. L’Homme 1983, 23, 57–77. [Google Scholar] [CrossRef]

- Ibn-Mohammed, T.; Koh, S.C.L.; Reaney, I.M.; Acquaye, A.; Schileo, G.; Mustapha, K.B.; Greenough, R. Perovskite solar cells: An integrated hybrid lifecycle assessment and review in comparison with other photovoltaic technologies. Renew. Sustain. Energy Rev. 2017, 80, 1321–1344. [Google Scholar] [CrossRef]

- Chaabane, A.; Ramudhin, A.; Paquet, M. Designing supply chains with sustainability considerations. Prod. Plan. Control 2011, 22, 727–741. [Google Scholar] [CrossRef]

- Zhou, Z.; Zhao, W.; Chen, X.; Zeng, H. MFCA extension from a circular economy perspective: Model modifications and case study. J. Clean. Prod. 2017, 149, 110–125. [Google Scholar] [CrossRef]

- Dubreuil, A.; Young, S.B.; Atherton, J.; Gloria, T.P. Metals recycling maps and allocation procedures in life cycle assessment. Int. J. Life Cycle Assess. 2010, 15, 621–634. [Google Scholar] [CrossRef]

- Khan, A.M.; Jamil, M.; Salonitis, K.; Sarfraz, S.; Zhao, W.; He, N.; Mia, M.; Zhao, G. Multi-objective optimization of energy consumption and surface quality in nanofluid SQCL assisted face milling. Energies 2019, 12, 710. [Google Scholar] [CrossRef]

- Lake, A.; Acquaye, A.; Genovese, A.; Kumar, N.; Koh, S.C.L. An application of hybrid life cycle assessment as a decision support framework for green supply chains. Int. J. Prod. Res. 2015, 53, 6495–6521. [Google Scholar] [CrossRef]

- Du, G.; Karoumi, R. Life cycle assessment of a railway bridge: Comparison of two superstructure designs. Struct. Infrastruct. Eng. 2013, 9, 1149–1160. [Google Scholar] [CrossRef]

- Mirabella, N.; Castellani, V.; Sala, S. LCA for assessing environmental benefit of eco-design strategies and forest wood short supply chain: A furniture case study. Int. J. Life Cycle Assess. 2014, 19, 1536–1550. [Google Scholar] [CrossRef]

- Jia, R.; Liu, Y.; Bai, X. Sustainable supplier selection and order allocation: Distributionally robust goal programming model and tractable approximation. Comput. Ind. Eng. 2020, 140, 106267. [Google Scholar] [CrossRef]

- de FSM Russo, R.; Camanho, R. Criteria in AHP: A systematic review of literature. Procedia Comput. Sci. 2015, 55, 1123–1132. [Google Scholar] [CrossRef]

- Lai, Y.J.; Liu, T.Y.; Hwang, C.L. Topsis for MODM. Eur. J. Oper. Res. 1994, 76, 486–500. [Google Scholar] [CrossRef]

- Chakraborty, S.; Chattopadhyay, R.; Chakraborty, S. An integrated D-MARCOS method for supplier selection in an iron and steel industry. Decis. Mak. Appl. Manag. Eng. 2020, 3, 49–69. [Google Scholar]

- Wang, C.N.; Nguyen, T.L.; Dang, T.T. Two-Stage Fuzzy MCDM for Green Supplier Selection in Steel Industry. Intell. Autom. Soft Comput. 2022, 33, 1245–1260. [Google Scholar] [CrossRef]

- Okwu, M.O.; Tartibu, L.K. Sustainable supplier selection in the retail industry: A TOPSIS-and ANFIS-based evaluating methodology. Int. J. Eng. Bus. Manag. 2020, 12, 1847979019899542. [Google Scholar] [CrossRef]

- Al-Atesh, E.A.; Rahmawati, Y.; Zawawi, N.A.W.A.; Utomo, C. A decision-making model for supporting selection of green building materials. Int. J. Constr. Manag. 2021, 23, 922–933. [Google Scholar] [CrossRef]

- Varghese, B.; Karande, P. AHP-MARCOS, a hybrid model for selecting gears and cutting fluids. Mater. Today Proc. 2022, 52, 1397–1405. [Google Scholar] [CrossRef]

- Malaga, A.K.; Agrawal, R.; Wankhede, V.A. Material selection for metal additive manufacturing process. Mater. Today Proc. 2022, 66, 1744–1749. [Google Scholar] [CrossRef]

- Chakraborty, S.; Mitra, A. A hybrid multi-criteria decision-making model for optimal coal blending. J. Model. Manag. 2019, 14, 339–359. [Google Scholar] [CrossRef]

- Wu, F.; Zhang, J. Planning the competitive city-region: The emergence of strategic development plan in China. Urban Aff. Rev. 2007, 42, 714–740. [Google Scholar]

- Mohammed, A.; Yazdani, M.; Oukil, A.; Santibanez Gonzalez, E.D.R. A Hybrid MCDM Approach towards Resilient Sourcing. Sustainability 2021, 13, 2695. [Google Scholar] [CrossRef]

- Pourmehdi, M.; Paydar, M.M.; Asadi-Gangraj, E. Reaching sustainability through collection center selection considering risk: Using the integration of Fuzzy ANP-TOPSIS and FMEA. Soft Comput. 2021, 25, 10885–10899. [Google Scholar] [CrossRef]

- Ghosh, S.; Mandal, M.C.; Ray, A. Green supply chain management framework for supplier selection: An integrated multi-criteria decision-making approach. Int. J. Manag. Sci. Eng. Manag. 2021, 17, 205–219. [Google Scholar] [CrossRef]

- Nguyen, T.-L.; Nguyen, P.-H.; Pham, H.-A.; Nguyen, T.-G.; Nguyen, D.-T.; Tran, T.-H.; Le, H.-C.; Phung, H.-T. A Novel Integrating Data Envelopment Analysis and Spherical Fuzzy MCDM Approach for Sustainable Supplier Selection in Steel Industry. Mathematics 2022, 10, 1897. [Google Scholar] [CrossRef]

- Bianchi, P.F.; Yepes, V.; Vitorio, P.C.; Kripka, M. Study of Alternatives for the Design of Sustainable Low-Income Housing in Brazil. Sustainability 2021, 13, 4757. [Google Scholar] [CrossRef]

- Jelodari, E.; Medini, K.; Delorme, X. Sustainable Multi-period Production with Core and Adjacent Product Portfolio. In Advances in Production Management Systems. Smart Manufacturing and Logistics Systems: Turning Ideas into Action. APMS 2022. IFIP Advances in Information and Communication Technology; Kim, D.Y., von Cieminski, G., Romero, D., Eds.; Springer: Cham, Switzerland, 2022; Volume 664. [Google Scholar] [CrossRef]

- Pellegrini, M.; Roda, M.; Lupardi, E.; Di Geronimo, N.; Giannaccare, G.; Schiavi, C. The impact of COVID-19 pandemic on ophthalmological emergency department visits. Acta Ophthalmol. 2020, 98, e1058. [Google Scholar] [CrossRef]

- Shah, K.; Khurshid, H.; Haq, I.; Shah, S.; Ali, Z. Forecasting Machine Failure Using DMG and Weibull Analysis in an Automotive Industry: A Case Study. Mehran Univ. Res. J. Eng. Technol. 2021, 40, 435–442. [Google Scholar] [CrossRef]

- De Miranda Lammoglia, J.A.; Brandalise, N.; Hernandez, C.T. Analytical hierarchy process-boor applied for the best lean project selection for production lines. Indep. J. Manag. Prod. 2020, 11, 054–064. [Google Scholar] [CrossRef]

- Arslankaya, S.; Çelik, M.T. Green supplier selection in steel door industry using fuzzy AHP and fuzzy Moora methods. Emerg. Mater. Res. 2021, 10, 357–369. [Google Scholar] [CrossRef]

- Prado-Galinanes, H.J.; Domingo, R. Quantifying the impact of production globalization through application of the Life Cycle Inventory methodology and its influence on decision making in industry. Processes 2021, 9, 1271. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).