Reduction in Soil Compaction by Utilization of Waste Tire Rubber

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

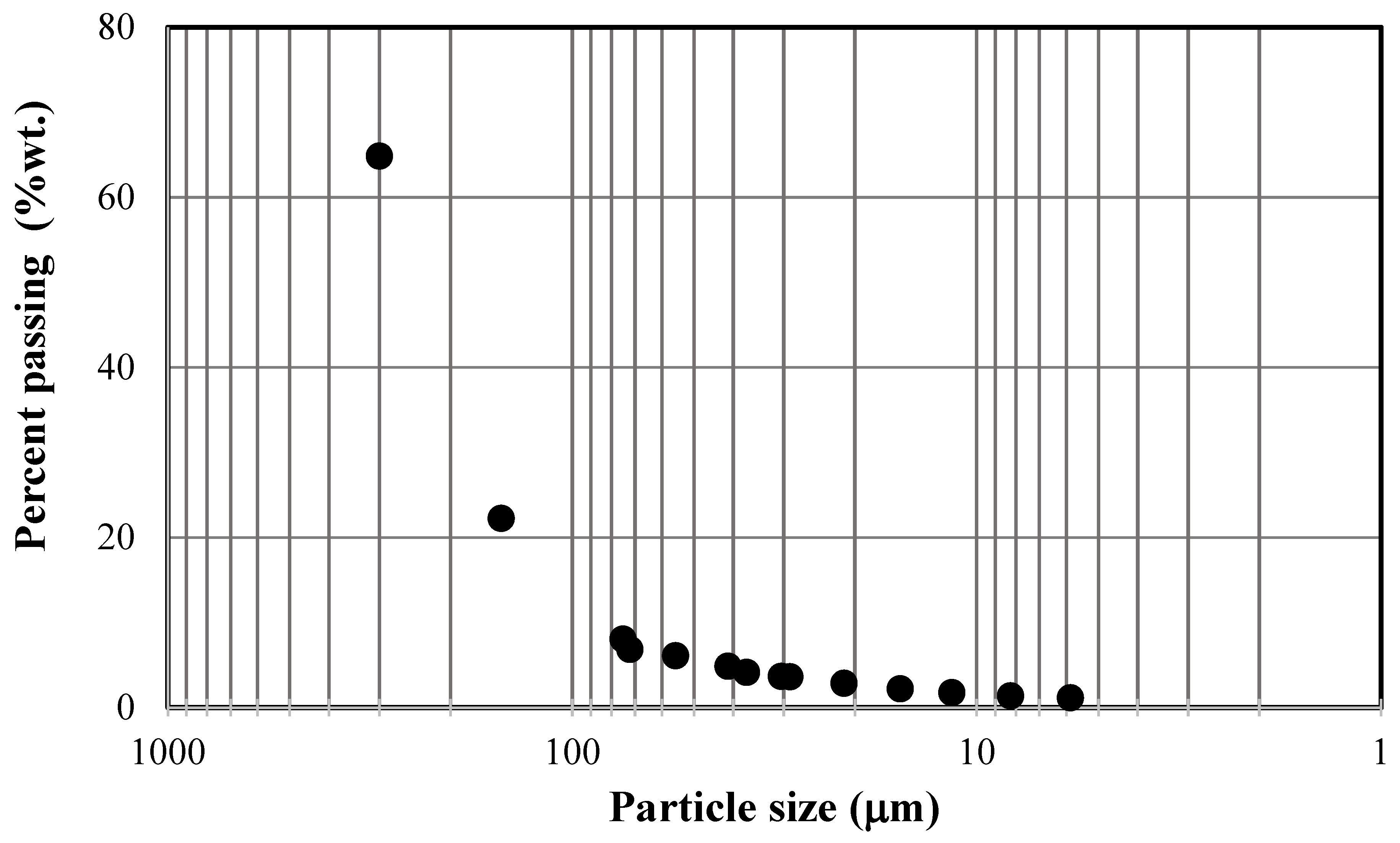

2.2. Characterization of the Soil Sample

2.3. Preparation of the Compacted Soils

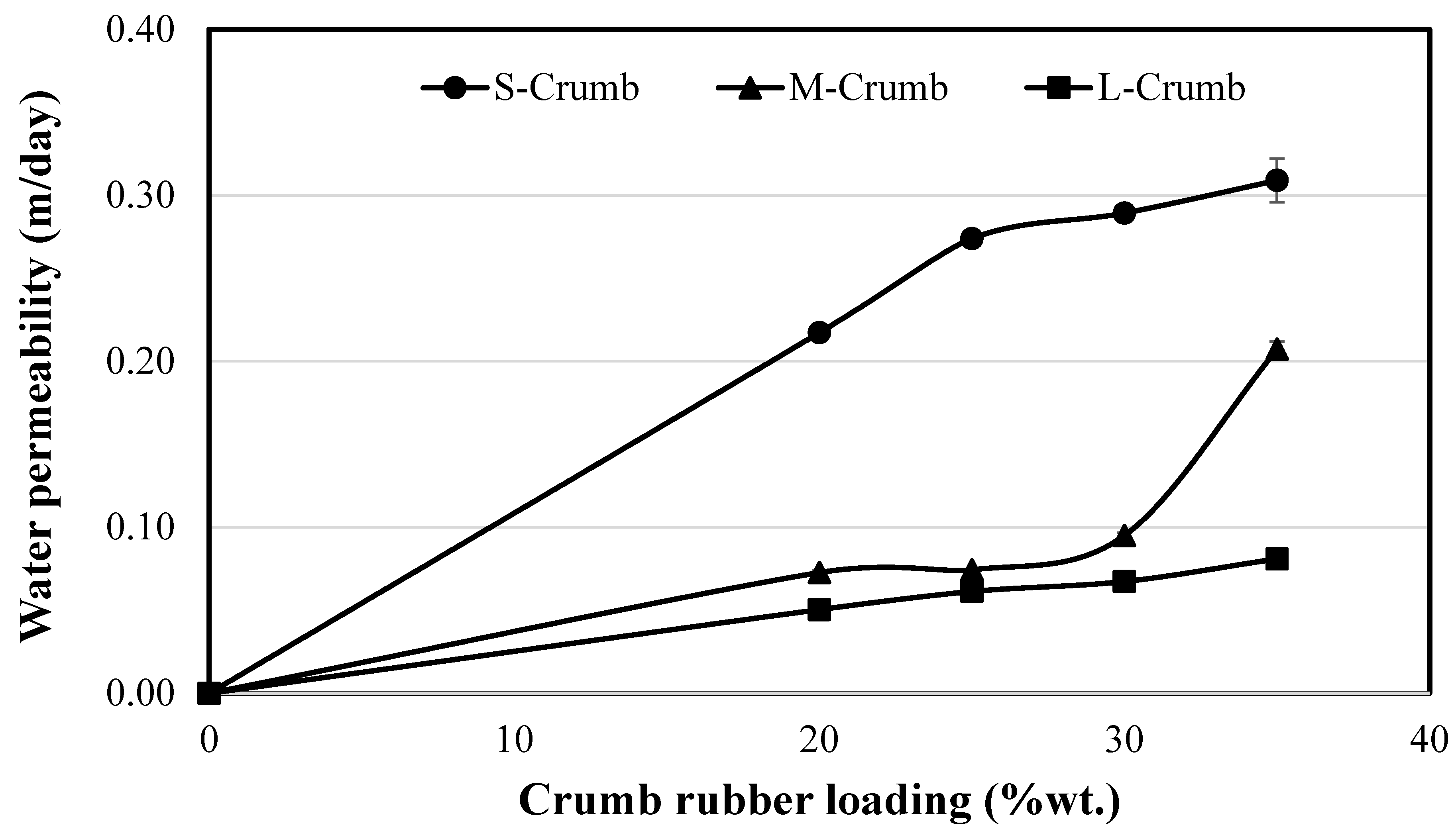

2.4. Properties of the Compacted Soils Filled with Crumb Rubber Samples

2.5. Determination of Contaminated Water Quality

2.6. Application of Crumb Rubber in the Field Test

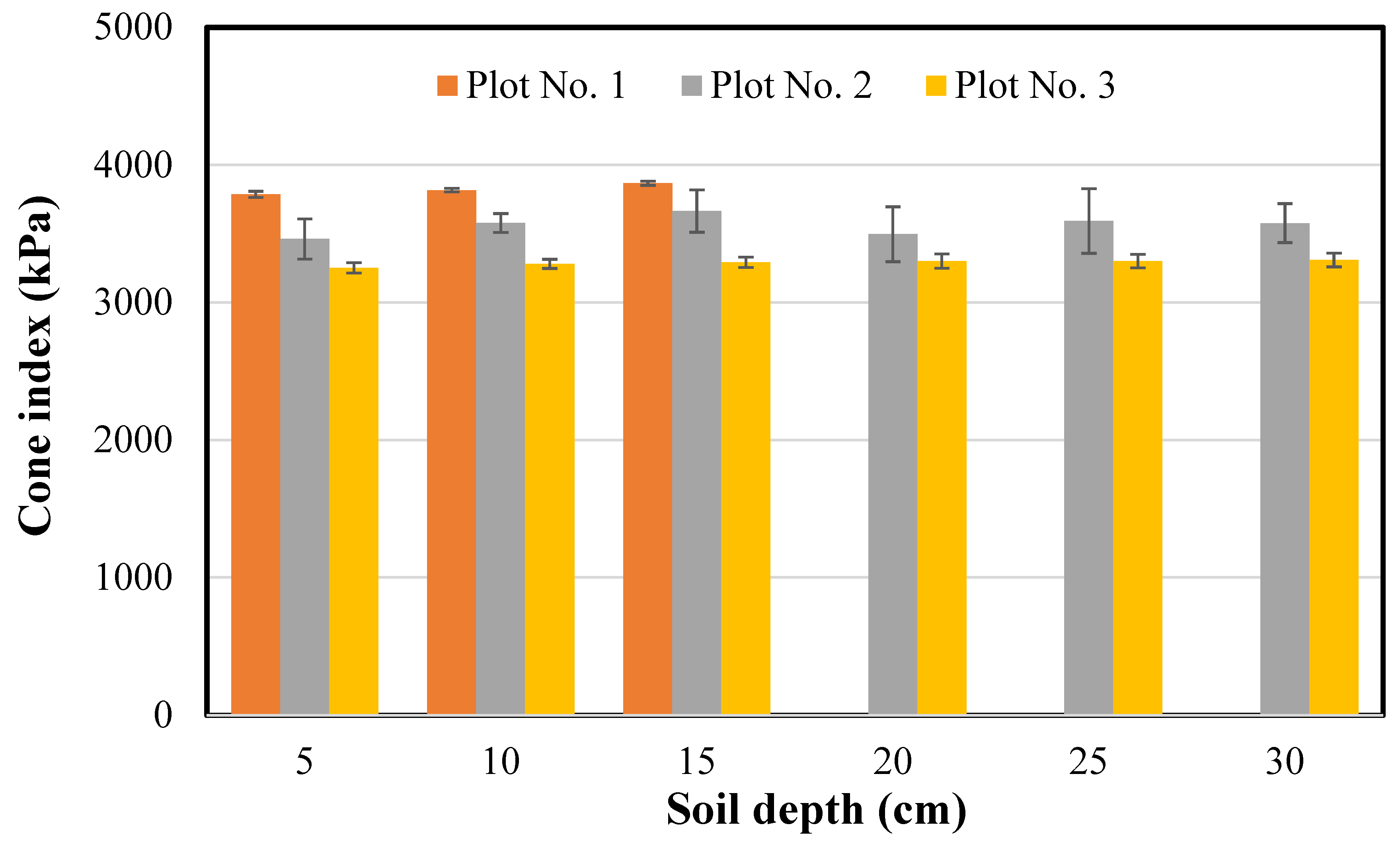

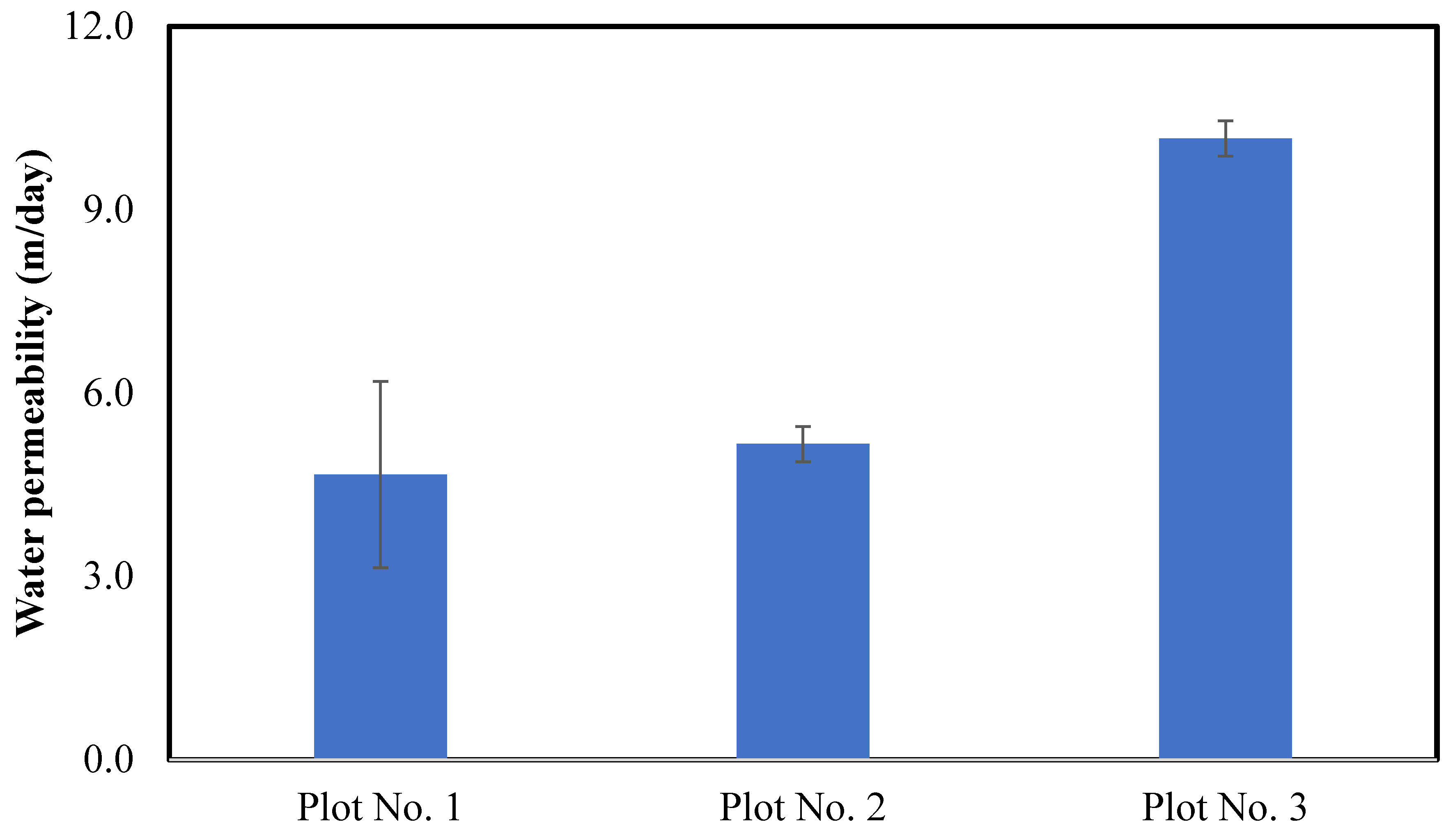

3. Results and Discussion

3.1. Characterization of the Soil Sample

3.2. Preparation of the Compacted Soils

3.3. Properties of the Compacted Soils Filled with Crumb Rubber Samples

3.4. Determination of Contaminated Water Quality

3.5. Application of Crumb Rubber in the Field Test

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Djandja, O.S.; Wang, Z.; Duan, P.; Wang, F.; Xu, Y. Hydrotreatment of pyrolysis oil from waste tire in tetralin for production of high-quality hydrocarbon rich fuel. Fuel 2021, 285, 119185. [Google Scholar] [CrossRef]

- Farzad, S.; Mandegari, M.; Gorgens, J.F. A novel approach for valorization of waste tires into chemical and fuel (limonene and diesel) through pyrolysis: Process development and techno economic analysis. Fuel Process. Technol. 2021, 224, 107006. [Google Scholar] [CrossRef]

- Idris, R.; Chong, C.T.; Ani, F.N. Microwave-induced pyrolysis of waste truck tyres with carbonaceous susceptor for the production of diesel-like fuel. J. Energy Inst. 2019, 92, 1831–1841. [Google Scholar] [CrossRef]

- Karagöz, M. Investigation of performance and emission characteristics of an CI engine fuelled with diesel—Waste tire oil—Butanol blends. Fuel 2020, 282, 118872. [Google Scholar] [CrossRef]

- Farhan, A.H.; Dawson, A.R.; Thom, N.H. Compressive behaviour of rubberized cement-stabilized aggregate mixtures. Constr. Build. Mater. 2020, 262, 120038. [Google Scholar] [CrossRef]

- Groenevelt, P.H.; Grunthal, P.E. Utilisation of crumb rubber as a soil amendment for sports turf. Soil Tillage Res. 1998, 47, 169–172. [Google Scholar] [CrossRef]

- Hamada, K.; Inoue, H.; Mochizuki, H.; Miyamoto, T.; Asakura, M.; Shimizu, Y. Effect of hardpan on the vertical distribution of water stress in a converted paddy field. Soil Tillage Res. 2021, 214, 105161. [Google Scholar] [CrossRef]

- Wang, Q.Z.; Wang, N.N.; Tseng, M.L.; Huang, Y.M.; Li, N.L. Waste tire recycling assessment: Road application potential and carbon emissions reduction analysis of crumb rubber modified asphalt in China. J. Clean. Prod. 2020, 249, 119411. [Google Scholar] [CrossRef]

- Yu, P.; Manalo, A.; Ferdous, W.; Abousnin, R.; Salih, C.; Heyer, T.; Schubel, P. Investigation on the physical, mechanical and microstructural properties of epoxy polymer matrix with crumb rubber and short fibres for composite railway sleepers. Constr. Build. Mater. 2021, 295, 123700. [Google Scholar] [CrossRef]

- Marçal, R.; Lodi, P.C.; Correia, N.D.S.; Giacheti, H.L.; Rodrigues, R.A.; McCartney, J.S. Reinforcing Effect of Polypropylene Waste Strips on Compacted Lateritic Soils. Sustainability 2020, 12, 9572. [Google Scholar] [CrossRef]

- Tasalloti, A.; Chiaro, G.; Murali, A.; Banasiak, L. Physical and Mechanical Properties of Granulated Rubber Mixed with Granular Soils—A Literature Review. Sustainability 2021, 13, 4309. [Google Scholar] [CrossRef]

- Robert, C.M.; Parviz, N.S.; Jan, E.C. Soil amendment with rubber particles. United State Patent 5,014,462, 14 May 1991. [Google Scholar]

- Batey, T. Soil compaction and soil management-a review. Soil Use Manag. 2009, 25, 335–345. [Google Scholar] [CrossRef]

- Shaheb, M.R.; Venkatesh, R.; Shearer, S.A. A review on the effect of soil compaction and its management for sustainable crop production. Biosyst. Eng. 2021, 46, 417–439. [Google Scholar] [CrossRef]

- Soane, B.D.; van Ouwerkerk, C. Soil Compaction in Crop Production, 1st ed.; Elsevier Science B.V.: Amsterdam, The Netherlands, 1994; pp. 1–22. [Google Scholar]

- Zabrodskyi, A.; Šarauskis, E.; Kukharets, S.; Juostas, A.; Vasiliauskas, G.; Andriušis, A. Analysis of the Impact of Soil Compaction on the Environment and Agricultural Economic Losses in Lithuania and Ukraine. Sustainability 2021, 13, 7762. [Google Scholar] [CrossRef]

- Xiao, Z.; Yu, N.; An, J.; Zou, H.; Zhang, Y. Soil Compressibility and Resilience Based on Uniaxial Compression Loading Test in Response to Soil Water Suction and Soil Organic Matter Content in Northeast China. Sustainability 2022, 14, 2620. [Google Scholar] [CrossRef]

- Ramos, M.F.; Almeida, W.R.d.S.; Amaral, R.d.L.d.; Suzuki, L.E.A.S. Degree of compactness and soil quality of peach orchards with different production ages. Soil Tillage Res. 2022, 219, 105324. [Google Scholar] [CrossRef]

- Bengough, A.G.; McKenzie, B.M.; Hallett, P.D.; Valentine, T.A. Root elongation, water stress, and mechanical impedance: A review of limiting stresses and beneficial root tip traits. J. Exp. Bot. 2011, 62, 59–68. [Google Scholar] [CrossRef] [Green Version]

- Yue, L.; Wang, Y.; Wang, L.; Yao, S.; Cong, C.; Ren, L.; Zhang, B. Impacts of soil compaction and historical soybean variety growth on soil macropore structure. Soil Tillage Res. 2021, 214, 105166. [Google Scholar] [CrossRef]

- Hamzaa, M.A.; Anderson, W.K. Soil compaction in cropping systems A review of the nature, causes and possible solutions. Soil Tillage Res. 2005, 82, 121–145. [Google Scholar] [CrossRef]

- Busscher, W.J.; Novak, J.M.; Ahmedna, M. Physical effects of organic matter amendment of a southeastern US coastal loamy sand. Soil Sci. 2011, 176, 661–667. [Google Scholar] [CrossRef]

- Carter, M.R. Soil quality for sustainable land management: Organic matter and aggregation interactions that maintain soil functions. Agron. J. 2002, 94, 38–47. [Google Scholar] [CrossRef]

- Thomas, G.W.; Haszler, G.R.; Blevins, R.I. The effect of organic matter and tillage on maximum compatibility of soils using the proctor test. Soil Sci. 1996, 161, 502–508. [Google Scholar] [CrossRef]

- Tim Chamen, W.C.; Moxey, A.P.; Towers, W.; Balana, B.; Hallett, P.D. Mitigating arable soil compaction: A review and analysis of available cost and benefit data. Soil Tillage Res. 2015, 146, 10–25. [Google Scholar] [CrossRef]

- Fang, J.; Zeng, D.; Tian, X.; Duwal, K.B. Soil Compaction Mechanism and Improvement in Farmland. Sustainability 2023, 15, 6801. [Google Scholar] [CrossRef]

- Chang, A.C.; Lund, L.J.; Page, A.L.; Warneke, J.E. Physical properties of fly ash-amended soils. J. Environ. Qual. 1977, 6, 267–270. [Google Scholar] [CrossRef]

- Murphy, P.N.C.; Stevens, R.J. Lime and gypsum as source measures to decrease phosphorus loss from soils to water. Water Air Soil Pollut. 2010, 212, 101–111. [Google Scholar] [CrossRef]

- Wang, Y.; Amundson, R.; Niu, X.F. Seasonal and altitudinal variation in decomposition of soil organic matter inferred from radiocarbon measurements of soil CO2 flux. Glob. Biogeochem. Cycles 2000, 14, 199–211. [Google Scholar] [CrossRef]

- ISO 11277-2020; Soil Quality—Determination of Particle Size Distribution in Mineral Soil Material—Method by Sieving and Sedimentation. International Organization for Standardization: Geneva, Switzerland, 2020.

- ISO 10390-2017; Soil Quality—Determination of pH. International Organization for Standardization: Geneva, Switzerland, 2017.

- ISO 11272-2017; Soil Quality—Determination of Dry Bulk Density. International Organization for Standardization: Geneva, Switzerland, 2017.

- ISO 17892-11-2019; Geotechnical Investigation and Testing—Laboratory Testing of Soil—Part 11: Permeability Tests. International Organization for Standardization: Geneva, Switzerland, 2019.

- ISO 22282-5-2012; Geotechnical Investigation and Testing—Geohydraulic Testing—Part 5: Infiltrometer Tests. International Organization for Standardization: Geneva, Switzerland, 2012.

- Meek, B.D.; Rechel, E.A.; Carter, L.M.; Tar, W.R.D. Soil compaction and its effect on alfalfa in zone production systems. Soil Sci. Soc. Am. J. 1988, 51, 233–236. [Google Scholar] [CrossRef]

- Tekeste, M.Z.; Raper, R.L.; Schwab, E.B. Soil Drying effects on soil strength and depth of hardpan layers as determined from cone index data. Agric. Eng. Inter. 2008, 10, 1–17. [Google Scholar]

- Ekwue, E.I.; Stone, R.J. Organic matter effects on the strength properties of compacted agricultural soils. Am. Soc. Agric. Eng. 1995, 38, 357–365. [Google Scholar] [CrossRef]

- Heideman, G.; Noordermeer, J.; Baarle, B.V. Effect of Zinc complexes as activator for sulfur vulcanization in various rubbers. Rubber Chem. Technol. 2005, 78, 245–257. [Google Scholar] [CrossRef]

- Mark, J.E.; Erman, B.; Roland, M. The Science and Technology of Rubber, 4th ed.; Elsevier: Boston, MA, USA, 2013; pp. 449–454. [Google Scholar]

- Thaptong, P.; Boonbumrung, A.; Jittham, P.; Sae-oui, P. Potential use of a novel composite zinc oxide as eco-friendly activator in Tire tread compound. J. Polym. Res. 2019, 26, 226. [Google Scholar] [CrossRef]

- Boopasiri, S.; Sae-Oui, P.; Siriwong, C. Fabrication of microcrystalline cellulose/zinc oxide hybrid composite by hydrothermal synthesis and its application in rubber compounding. J. Appl. Polym. Sci. 2021, 139, 25065. [Google Scholar] [CrossRef]

- Baker, T.J.; Tyler, T.R.; Galloway, T.S. Impacts of metal and metal oxide nanoparticles on marine organisms. Environ. Pollut. 2014, 186, 257–271. [Google Scholar] [CrossRef] [PubMed]

- Sanchez-Quiles, D.; Tovar-Sanchez, A. Sunscreens as a Source of Hydrogen Peroxide Production in Coastal Waters. Environ. Sci. Technol. 2014, 48, 9037–9042. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bodar, C.W.M. Environmental Risk Limits for Zinc. RIVM letter report 11235/2007. Available online: https://www.google.com.hk/url?sa=t&rct=j&q=&esrc=s&source=web&cd=&cad=rja&uact=8&ved=2ahUKEwiw5KzA986AAxWXqFYBHS3dDcUQFnoECAgQAQ&url=https%3A%2F%2Fwww.rivm.nl%2Fbibliotheek%2Frapporten%2F601782004.pdf&usg=AOvVaw2ZBrY2PSzowVnhliwZtE3e&opi=89978449 (accessed on 9 July 2023).

- Lindsay, W.L. Zinc in soils and plant nutrition. Adv. Agron. 1972, 24, 147–186. [Google Scholar] [CrossRef]

- Samreen, T.; Humaira; Shah, H.U.; Ullah, S.; Javid, M. Zinc effect on growth rate, chlorophyll, protein and mineral contents of hydroponically grown mungbeans plant (Vigna radiata). Arab. J. Chem. 2017, 10, S1802–S1807. [Google Scholar] [CrossRef] [Green Version]

- Zeng, H.; Wu, H.; Yan, F.; Yi, K.; Zhu, Y. Molecular regulation of zinc deficiency responses in plants. J. Plant Physiol. 2017, 261, 153419. [Google Scholar] [CrossRef]

- Lin, L.R.; He, Y.B.; Chen, J.Z. The influence of soil drying- and tillage-induced penetration resistance on maize root growth in a clayey soil. J. Integr. Agric. 2016, 15, 1112–1120. [Google Scholar] [CrossRef]

| Properties | S-Crumb | M-Crumb | L-Crumb |

|---|---|---|---|

| Particle size range * (mm) | 0.8–1.0 | 4–6 | >50 |

| Density (g/cm3) | 1.11 | 1.11 | 1.11 |

| pH ** | 7.2 | 7.2 | 7.3 |

| Materials | Loading (%wt.) | ||||

|---|---|---|---|---|---|

| Clay loam soil | 100 | 80 | 75 | 70 | 65 |

| Waste tire rubber * | 0 | 20 | 25 | 30 | 35 |

| Test Items | Concentration (Parts Per Million: ppm) | |

|---|---|---|

| Specification * | Value | |

| Calcium carbonate (CaCO3) | <500 | 170 ± 7 |

| Sulfate (SO42−) | <250 | 75 ± 3 |

| Chloride (Cl−) | <250 | 31 ± 1 |

| Nitrate (NO3−) | <50 | 1.13 ± 0.03 |

| Fluoride (F−) | <0.7 | N/D |

| Ferric (Fe) | <0.5 | 0.20 ± 0.04 |

| Manganese (Mn) | <0.3 | 0.043 ± 0.002 |

| Copper (Cu) | <1.0 | N/D |

| Zinc (Zn) | <3.0 | 35.2 ± 0.4 |

| Lead (Pb) | <0.01 | 0.0020 ± 0.0002 |

| Chromium (Cr) | <0.05 | N/D |

| Cadmium (Cd) | <0.003 | N/D |

| Arsenic (As) | <0.01 | N/D |

| Mercury (Hg) | <0.001 | N/D |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pattanawanidchai, S.; Sae-Oui, P.; Na-Lumpang, T.; Loykulnant, S.; Kuankhamnuan, T. Reduction in Soil Compaction by Utilization of Waste Tire Rubber. Sustainability 2023, 15, 12174. https://doi.org/10.3390/su151612174

Pattanawanidchai S, Sae-Oui P, Na-Lumpang T, Loykulnant S, Kuankhamnuan T. Reduction in Soil Compaction by Utilization of Waste Tire Rubber. Sustainability. 2023; 15(16):12174. https://doi.org/10.3390/su151612174

Chicago/Turabian StylePattanawanidchai, Sirichai, Pongdhorn Sae-Oui, Thipjak Na-Lumpang, Surapich Loykulnant, and Thirapong Kuankhamnuan. 2023. "Reduction in Soil Compaction by Utilization of Waste Tire Rubber" Sustainability 15, no. 16: 12174. https://doi.org/10.3390/su151612174

APA StylePattanawanidchai, S., Sae-Oui, P., Na-Lumpang, T., Loykulnant, S., & Kuankhamnuan, T. (2023). Reduction in Soil Compaction by Utilization of Waste Tire Rubber. Sustainability, 15(16), 12174. https://doi.org/10.3390/su151612174