Integrating Life Cycle Assessment and Machine Learning to Enhance Black Soldier Fly Larvae-Based Composting of Kitchen Waste

Abstract

:1. Introduction

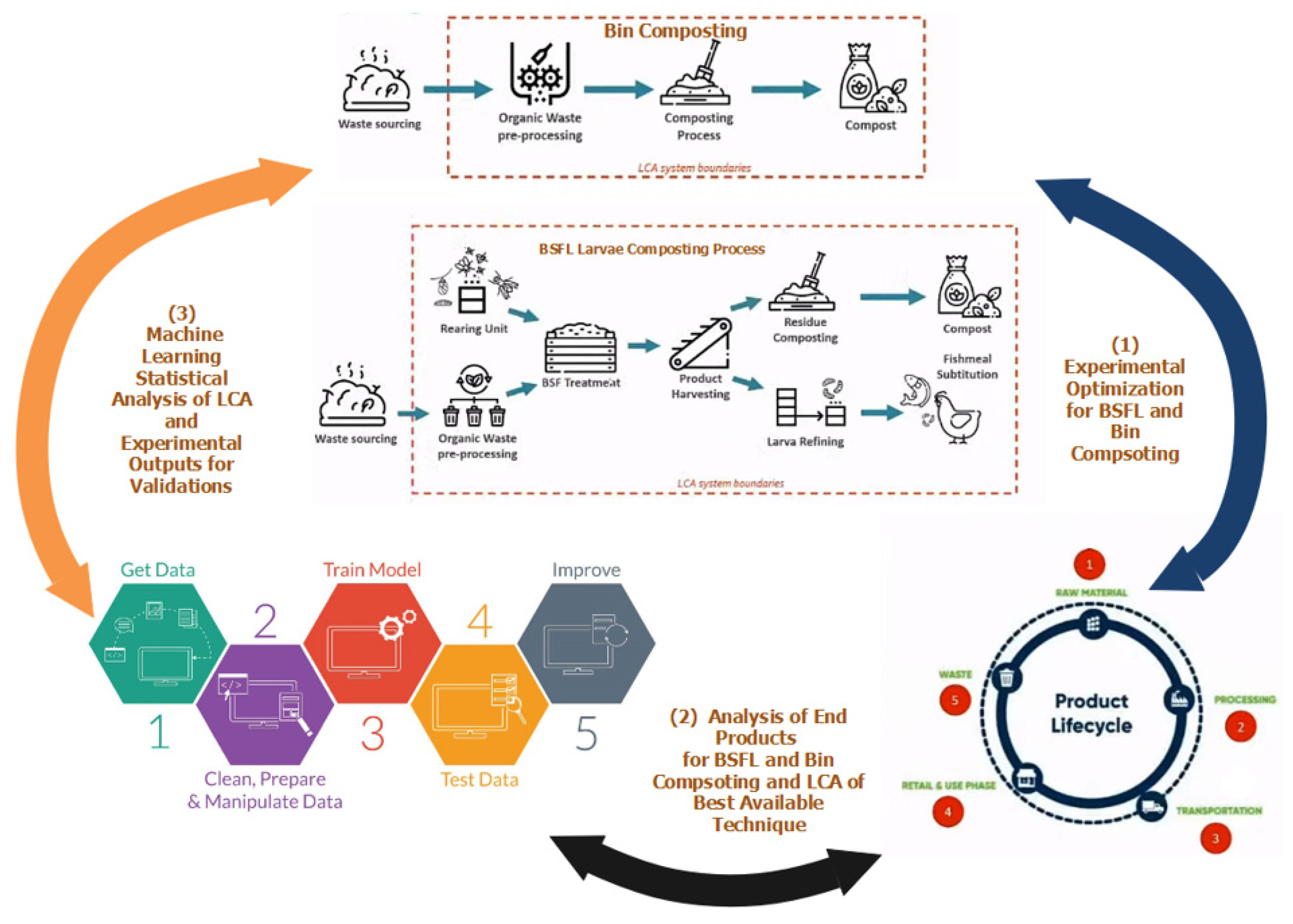

2. Methodology

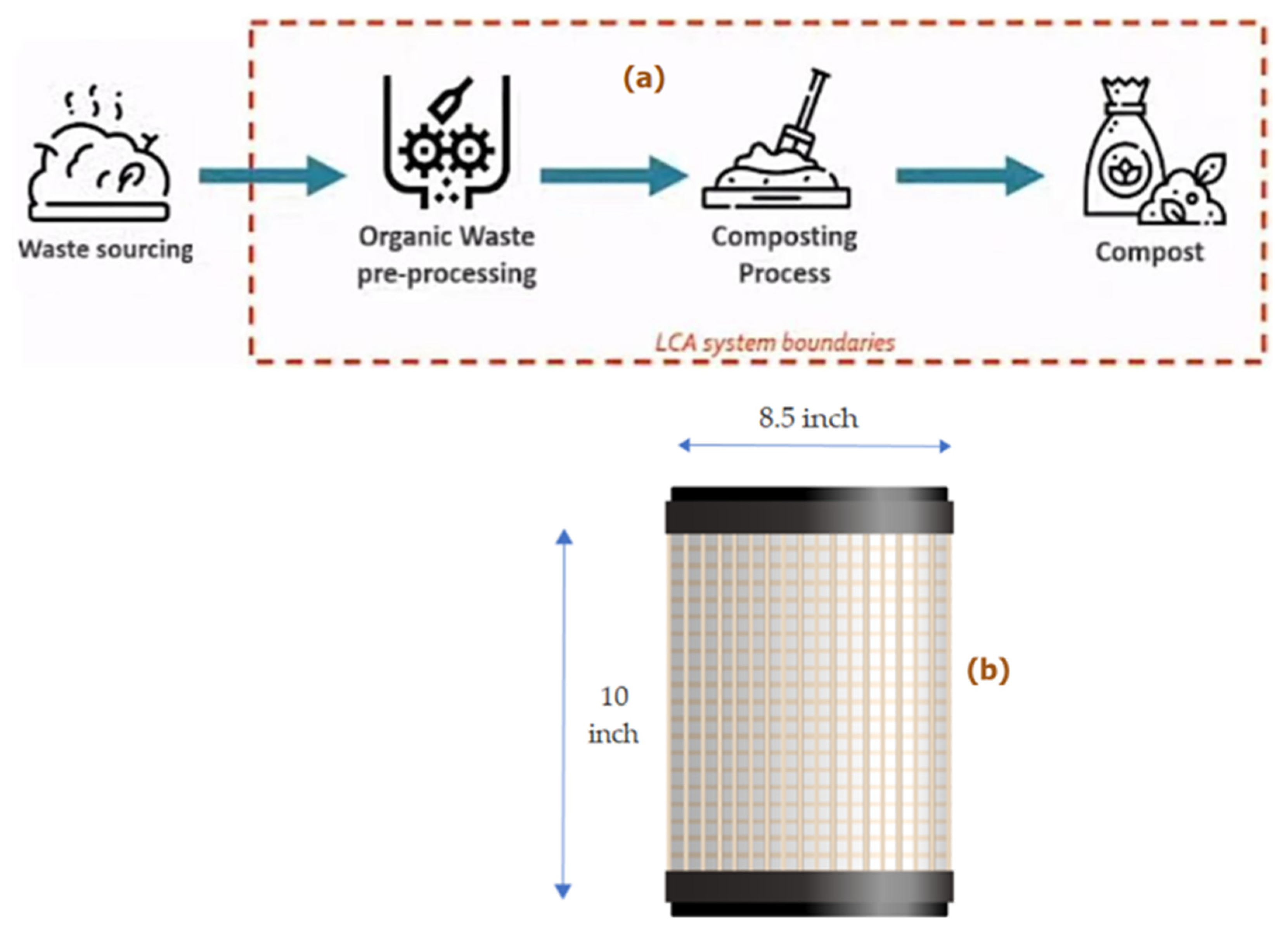

2.1. Waste Sample Collection, Preparation, and Waste Container

2.2. Waste Treatment and Process Optimization

2.3. Comparative Analysis of Waste Treatment and Compost

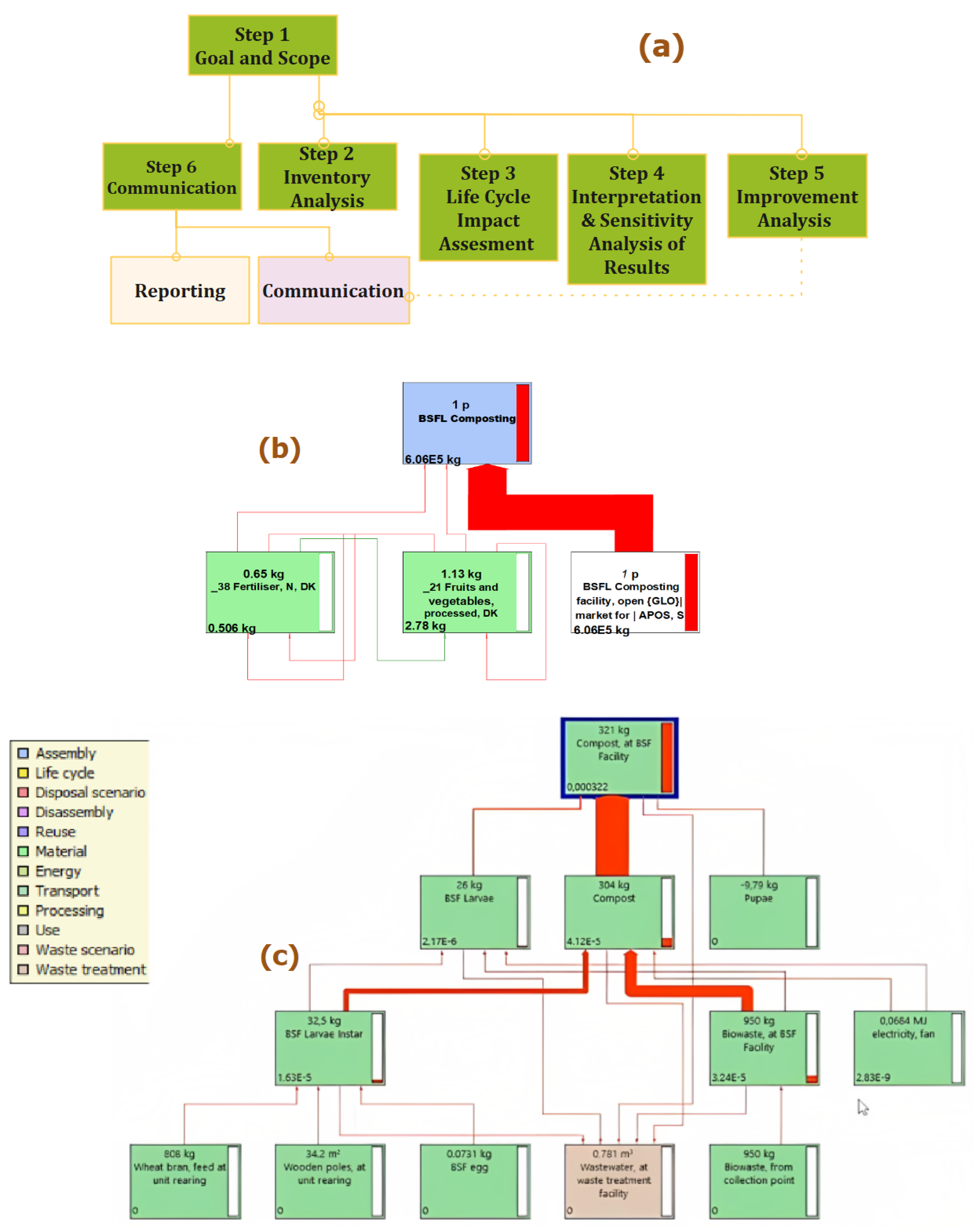

2.4. Life Cycle Assessment of BSFL Technology and Machine Learning Modeling for Predictive Modeling and Optimization Validation of Waste Treatment and Compost

3. Results and Discussion

3.1. BSFL Experimentation: Composting and Process Conditions Optimization

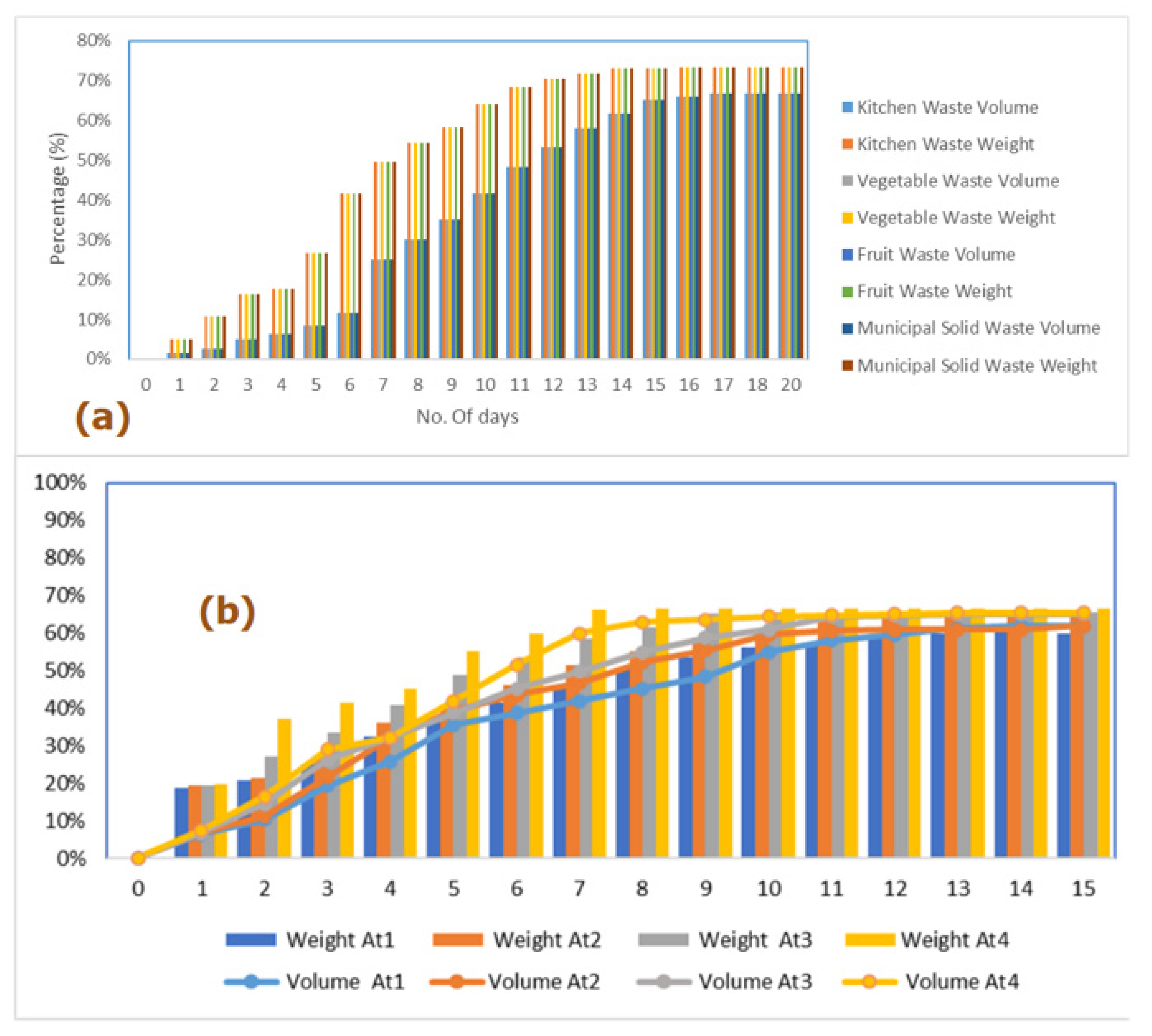

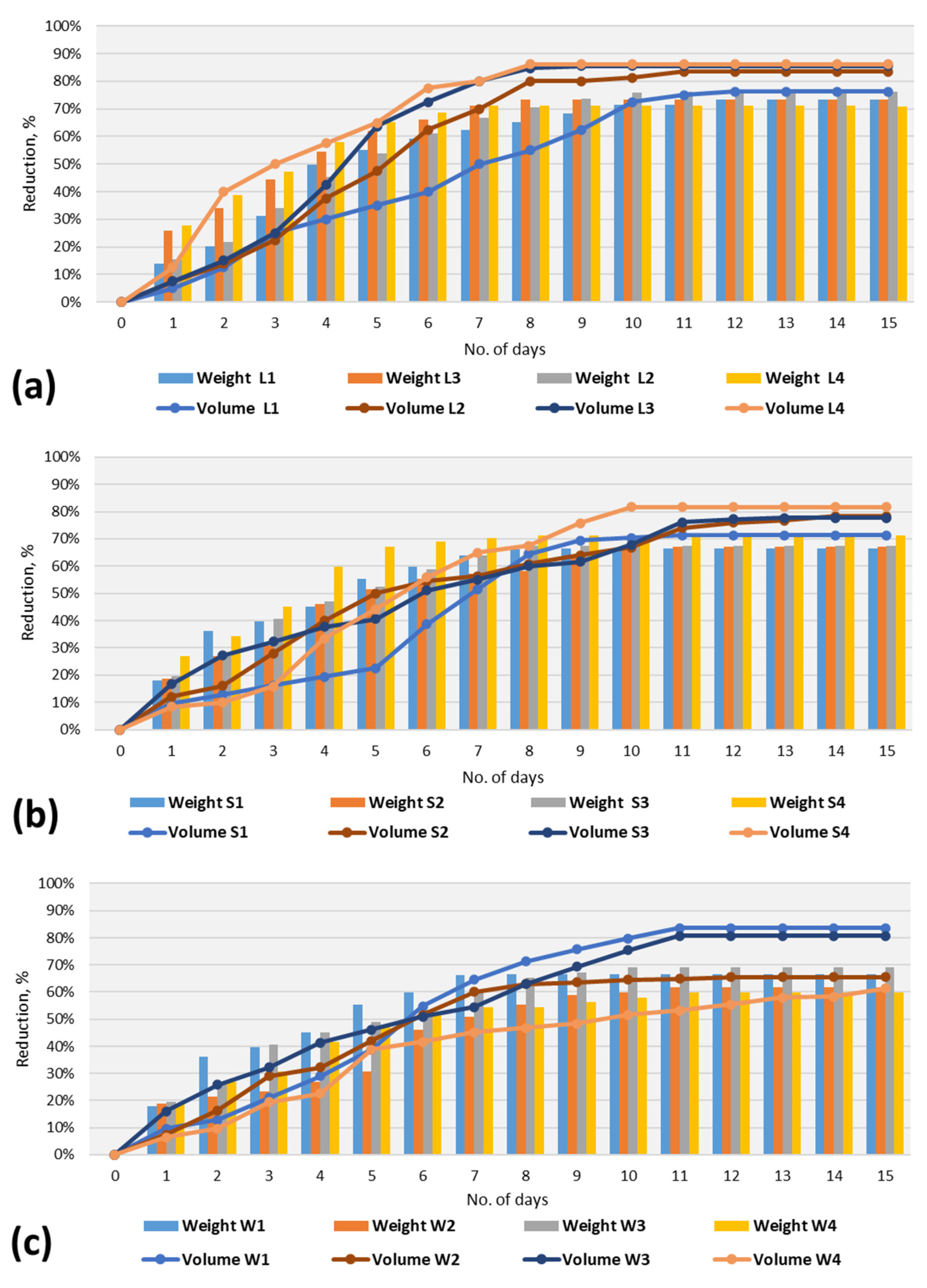

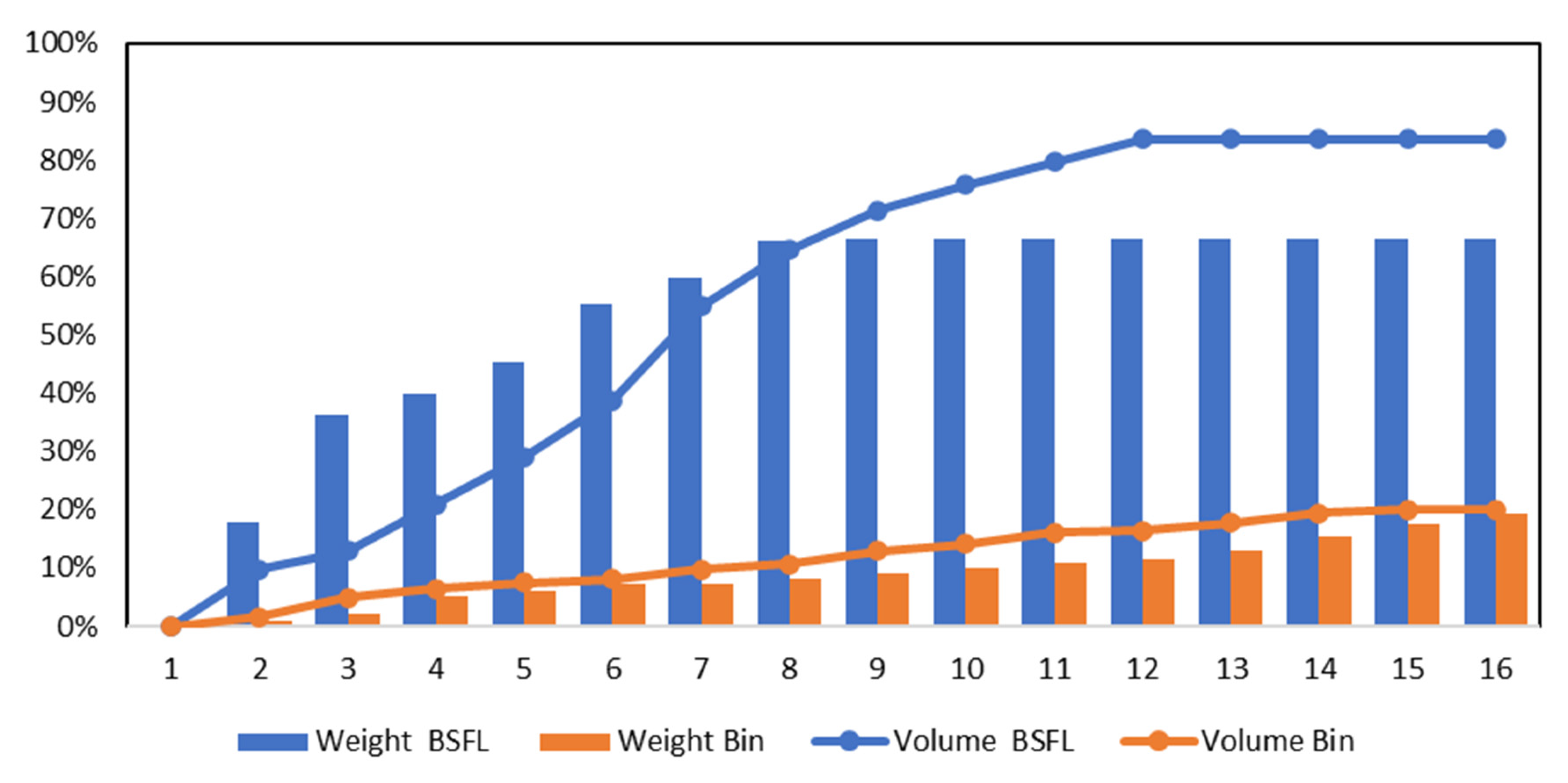

3.2. Effect of Time on Composting with BSFL

3.3. Effect of Aeration Frequency

3.4. Effect of No. of Larvae

3.5. Effect of Surface Area

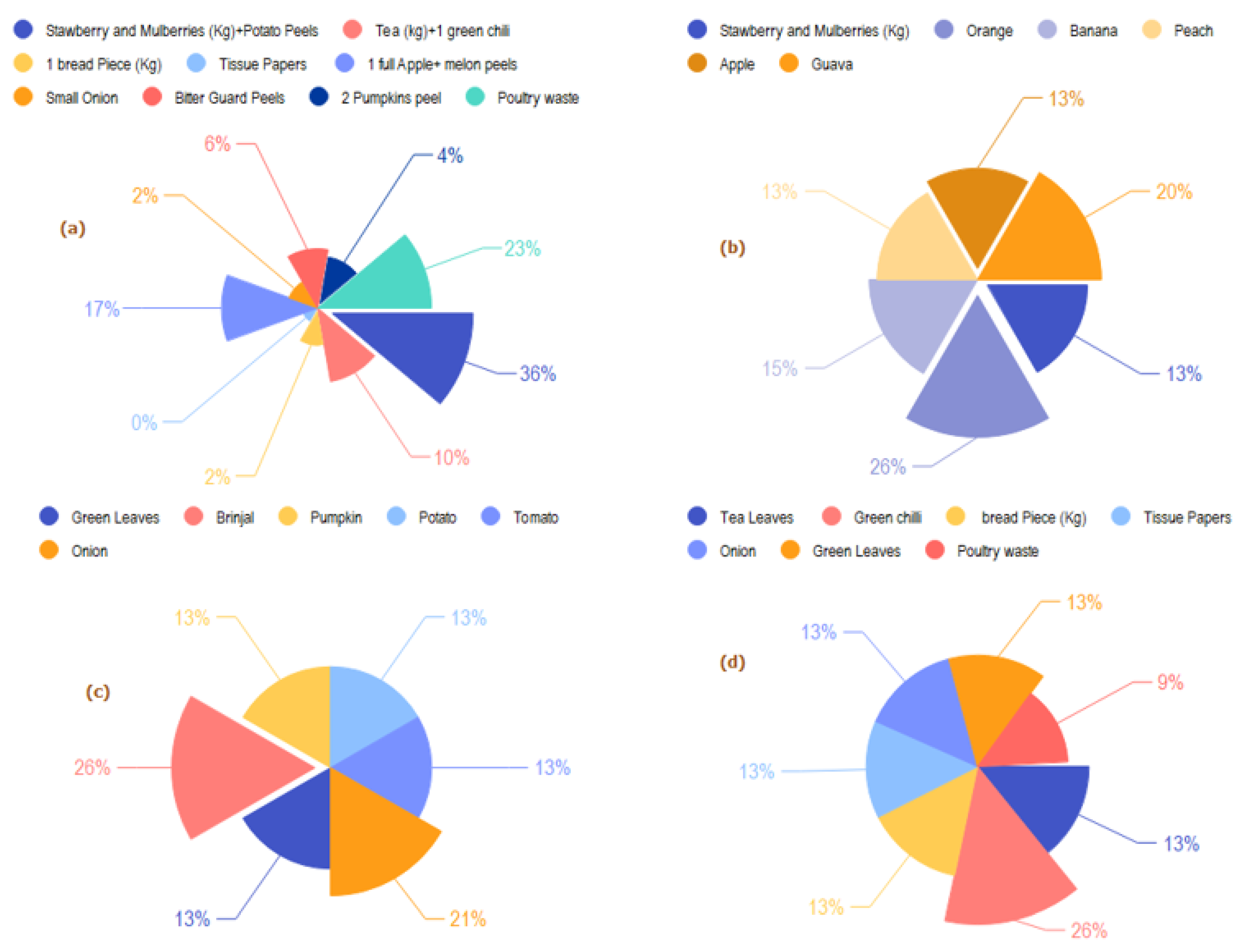

3.6. Effect of Waste Composition

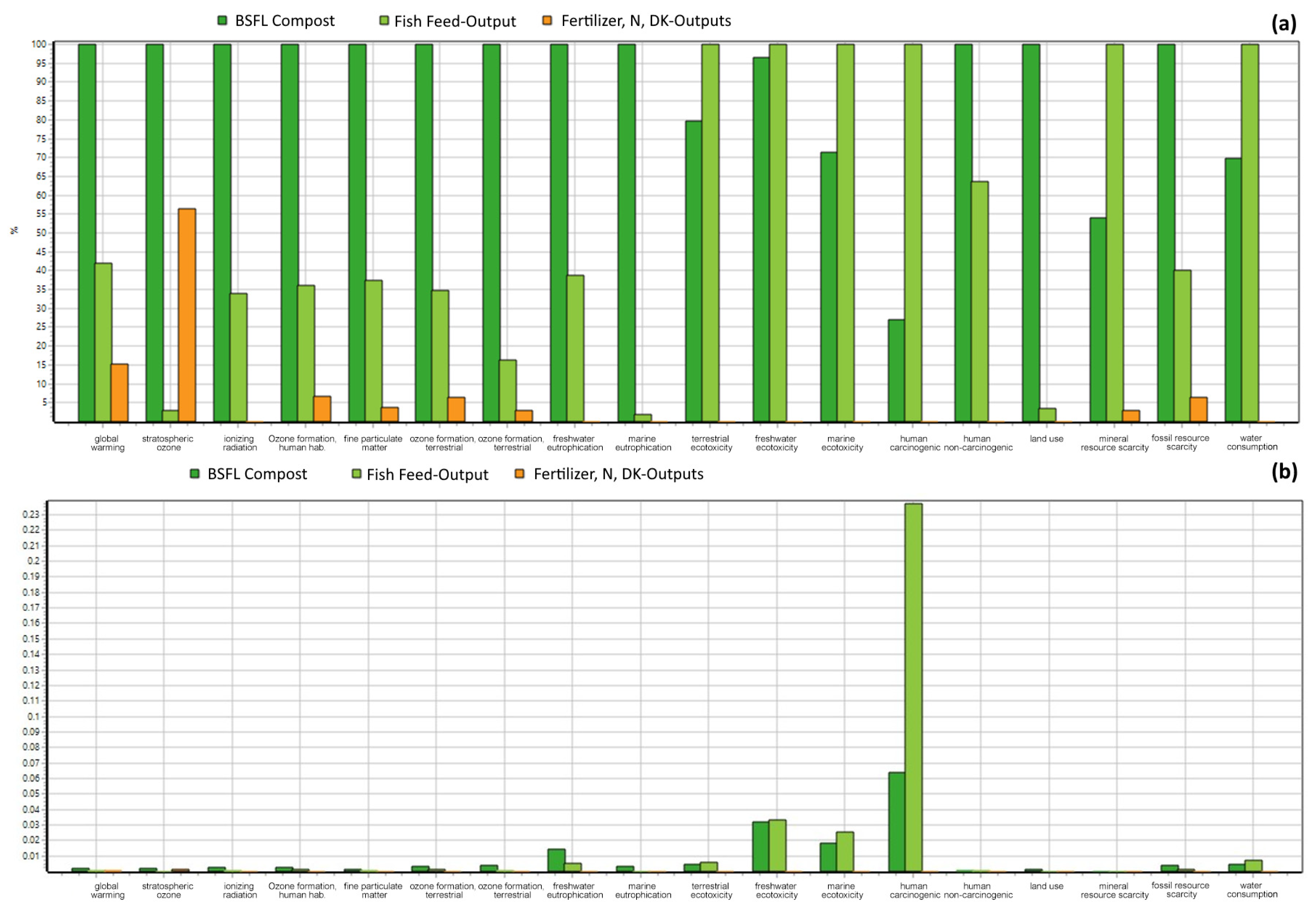

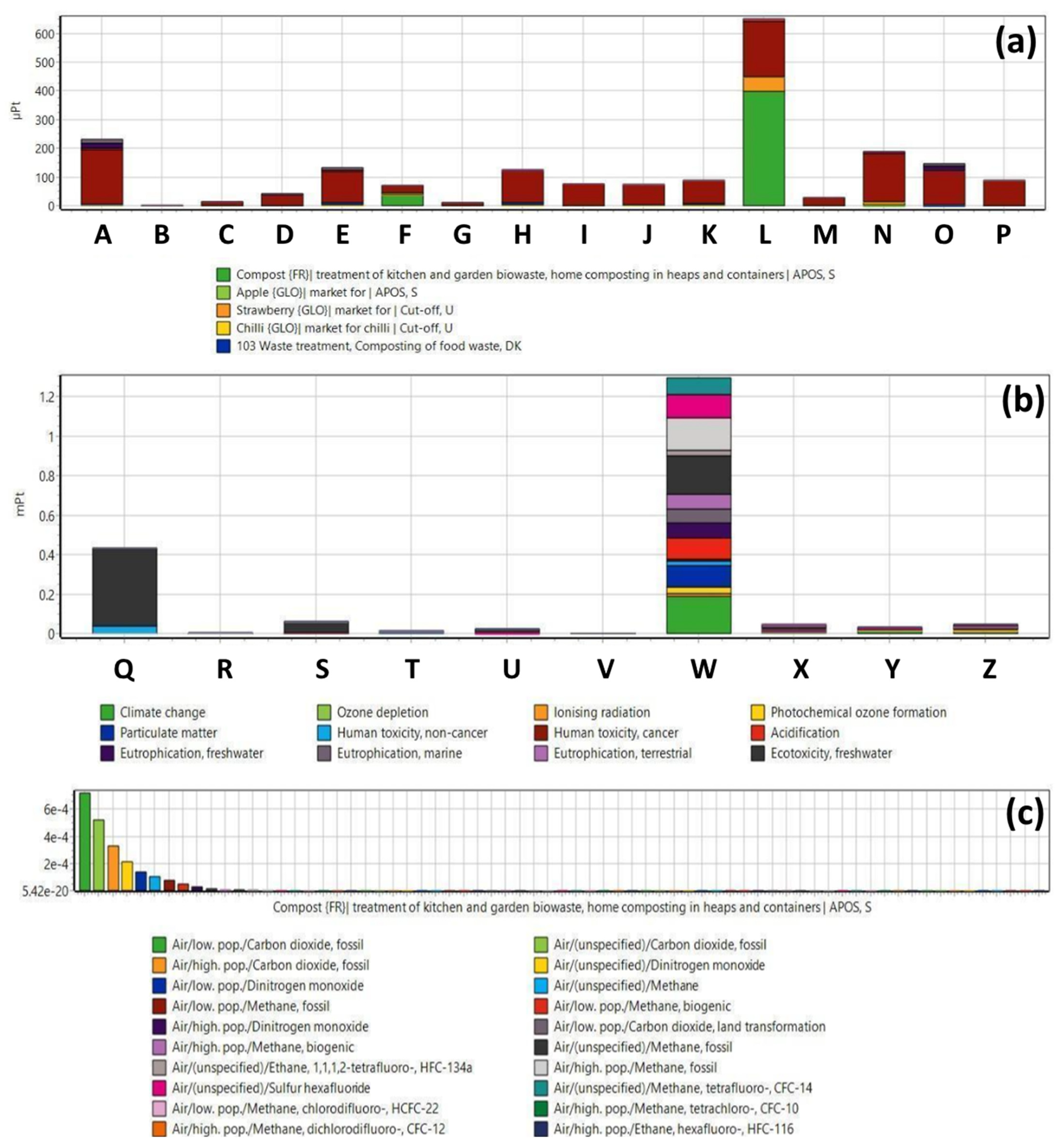

3.7. Life Cycle Assessment of BSFL

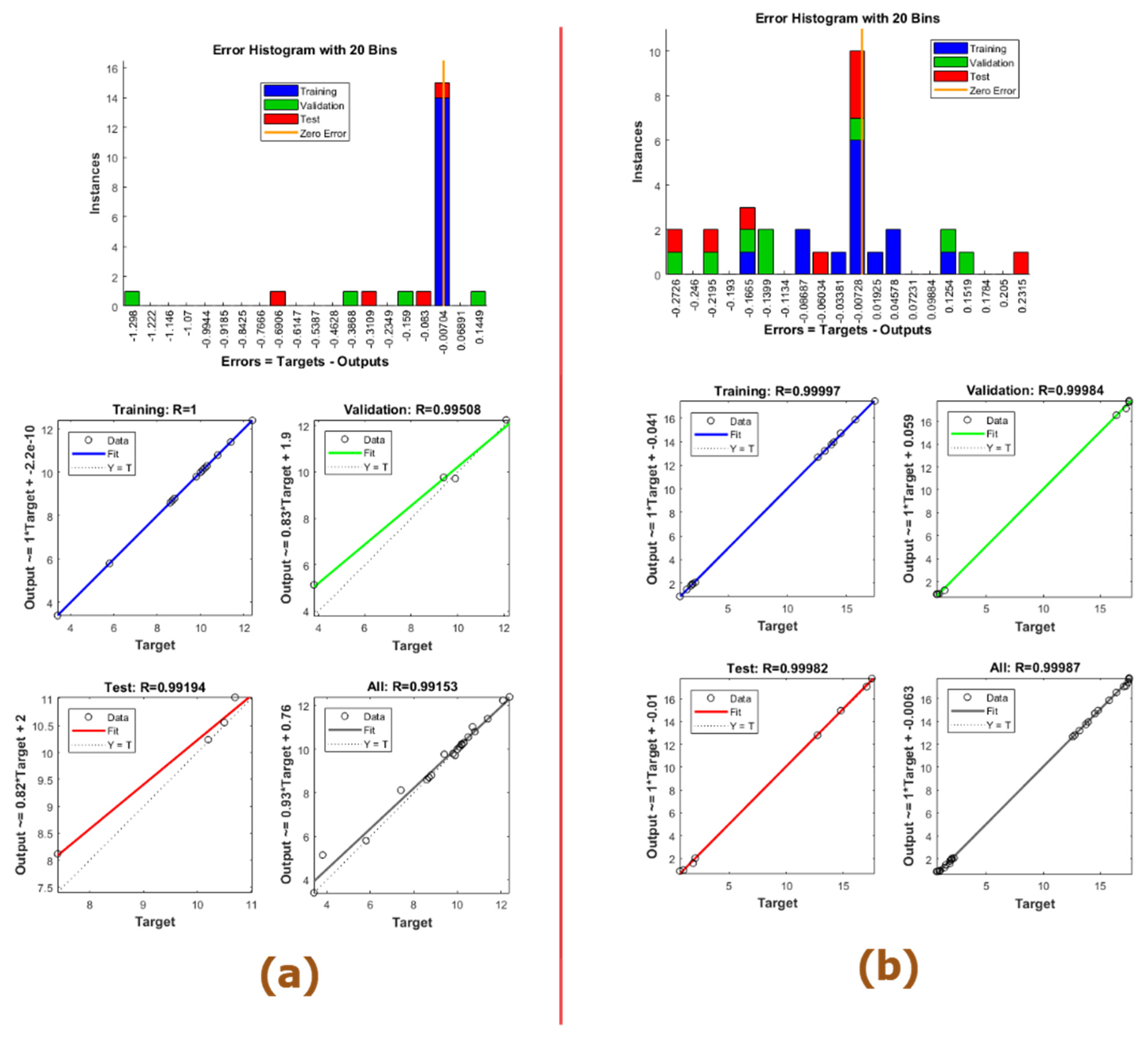

3.8. Machine Learning and Modeling for BSFL Composting

3.9. Comparative Analysis of Current BSFL, LCA, and Data-Driven Research Work with Conventional Systems

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Shaw, C.; Knopf, K.; Klatt, L.; Marin Arellano, G.; Kloas, W. Closing Nutrient Cycles through the Use of System-Internal Resource Streams: Implications for Circular Multitrophic Food Production Systems and Aquaponic Feed Development. Sustainability 2023, 15, 7374. [Google Scholar] [CrossRef]

- Rehman, K.u.; Hollah, C.; Wiesotzki, K.; Heinz, V.; Aganovic, K.; Rehman, R.u.; Petrusan, J.-I.; Zheng, L.; Zhang, J.; Sohail, S.; et al. Insect-Derived Chitin and Chitosan: A Still Unexploited Resource for the Edible Insect Sector. Sustainability 2023, 15, 4864. [Google Scholar] [CrossRef]

- Saleem, F.; Abbas, A.; Rehman, A.; Khoja, A.H.; Naqvi, S.R.; Arshad, M.Y.; Zhang, K.; Harvey, A. Decomposition of benzene as a biomass gasification tar in CH4 carrier gas using non-thermal plasma: Parametric and kinetic study. J. Energy Inst. 2022, 102, 190–195. [Google Scholar] [CrossRef]

- Asnani, P.U.; Zurbrugg, C. Improving Municipal Solid Waste Management in India: A Sourcebook for Policymakers and Practitioners; World Bank Publications: Washington, DC, USA, 2007. [Google Scholar]

- Čaloudová, J.; Křištofová, K.; Pospiech, M.; Klempová, T.; Slaný, O.; Čertík, M.; Marcinčák, S.; Makiš, A.; Javůrková, Z.; Pečová, M.; et al. Effects of Biofermented Feed on Zophobas morio: Growth Ability, Fatty Acid Profile, and Bioactive Properties. Sustainability 2023, 15, 9709. [Google Scholar] [CrossRef]

- Hoornweg, D.; Bhada-Tata, P. What a waste: A global review of solid waste management. Urban Dev. Ser. Knowl. Pap. 2012, 15, 87–88. [Google Scholar]

- Mundhe, N.; Jaybhaye, R.; Dorik, B. Assessment of municipal solid waste management of Pune city using geospatial tools. Int. J. Comput. Appl. 2014, 100. [Google Scholar] [CrossRef]

- Rathi, S. Optimization model for integrated municipal solid waste management in Mumbai, India. Environ. Dev. Econ. 2007, 12, 105–121. [Google Scholar] [CrossRef]

- Epstein, E. The Science of Composting; CRC Press: Boca Raton, FL, USA, 1996. [Google Scholar]

- Arshad, M.Y.; Saeed, M.A.; Tahir, M.W.; Pawlak-Kruczek, H.; Ahmad, A.S.; Niedzwiecki, L. Advancing Sustainable Decomposition of Biomass Tar Model Compound: Machine Learning, Kinetic Modeling, and Experimental Investigation in a Non-Thermal Plasma Dielectric Barrier Discharge Reactor. Energies 2023, 16, 5835. [Google Scholar] [CrossRef]

- Mohsin, M.; Anwar, M.; Iqbal, M. Practice and conditions of solid waste management in Ahmedpur East, Bahawalpur, Pakistan: A way forward. Sindh Univ. Res. J. SURJ (Sci. Ser.) 2016, 48. [Google Scholar]

- Ayeleru, O.; Okonta, F.; Ntuli, F. Municipal solid waste generation and characterization in the City of Johannesburg: A pathway for the implementation of zero waste. Waste Manag. 2018, 79, 87–97. [Google Scholar] [CrossRef]

- Jorge, D.; Edwards, C.; Subler, S. A comparison Of Vermicomposting And Composting. Biocycle 1997, 38, 57–59. [Google Scholar]

- Diener, S.; Solano, N.M.S.; Gutiérrez, F.R.; Zurbrügg, C.; Tockner, K. Biological treatment of municipal organic waste using black soldier fly larvae. Waste Biomass Valorization 2011, 2, 357–363. [Google Scholar] [CrossRef]

- Wainaina, S.; Awasthi, M.K.; Sarsaiya, S.; Chen, H.; Singh, E.; Kumar, A.; Ravindran, B.; Awasthi, S.K.; Liu, T.; Duan, Y. Resource recovery and circular economy from organic solid waste using aerobic and anaerobic digestion technologies. Bioresour. Technol. 2020, 301, 122778. [Google Scholar] [CrossRef] [PubMed]

- da Silva, G.D.P.; Hesselberg, T. A review of the use of black soldier fly larvae, Hermetia illucens (Diptera: Stratiomyidae), to compost organic waste in tropical regions. Neotrop. Entomol. 2020, 49, 151–162. [Google Scholar] [CrossRef]

- Pathak, A.K.; Kumar, R.; Singh, V.K.; Agrawal, R.; Rai, S.; Rai, A.K. Assessment of LIBS for spectrochemical analysis: A review. Appl. Spectrosc. Rev. 2012, 47, 14–40. [Google Scholar] [CrossRef]

- Sullivan, D.M.; Miller, R.O. Compost quality attributes, measurements, and variability. In Compost Utilization in Horticultural Cropping Systems; Oregon State University: Corvallis, OR, USA, 2001; pp. 95–120. [Google Scholar]

- Gul, H.; Arshad, M.Y.; Tahir, M.W. Production of H2 via sorption enhanced auto-thermal reforming for small scale Applications-A process modeling and machine learning study. Int. J. Hydrogen Energy 2023. [Google Scholar] [CrossRef]

- Aragon-Briceño, C.I.; Ross, A.B.; Camargo-Valero, M.A. Strategies for the Revalorization of Sewage Sludge in a Waste Water Treatment Plant Through the Integration of Hydrothermal Processing. Waste Biomass Valorization 2023, 14, 105–126. [Google Scholar] [CrossRef]

- Yar, A.; Arshad, M.Y.; Asghar, F.; Amjad, W.; Asghar, F.; Hussain, M.I.; Lee, G.H.; Mahmood, F. Machine Learning-Based Relative Performance Analysis of Monocrystalline and Polycrystalline Grid-Tied PV Systems. Int. J. Photoenergy 2022, 2022, 3186378. [Google Scholar] [CrossRef]

- Kumari, A.; Madhaw, M.; Majumder, C.B.; Arora, A.; Dixit, G. Application of statistical learning theory for thermodynamic modeling of natural gas hydrates. Petroleum 2021, 7, 502–508. [Google Scholar] [CrossRef]

- Manga, M.; Aragón-Briceño, C.; Boutikos, P.; Semiyaga, S.; Olabinjo, O.; Muoghalu, C.C. Biochar and Its Potential Application for the Improvement of the Anaerobic Digestion Process: A Critical Review. Energies 2023, 16, 4051. [Google Scholar] [CrossRef]

- Shi, C.-F.; Yang, H.-T.; Chen, T.-T.; Guo, L.-P.; Leng, X.-Y.; Deng, P.-B.; Bi, J.; Pan, J.-G.; Wang, Y.-M. Artificial neural network-genetic algorithm-based optimization of aerobic composting process parameters of Ganoderma lucidum residue. Bioresour. Technol. 2022, 357, 127248. [Google Scholar] [CrossRef]

- Aydın Temel, F. Evaluation of the influence of rice husk amendment on compost quality in the composting of sewage sludge. Bioresour. Technol. 2023, 373, 128748. [Google Scholar] [CrossRef] [PubMed]

- Dragoi, E.; Godini, K.; Koolivand, A. Modeling of oily sludge composting process by using artificial neural networks and differential evolution: Prediction of removal of petroleum hydrocarbons and organic carbon. Environ. Technol. Innov. 2021, 21, 101338. [Google Scholar] [CrossRef]

- Somroo, A.A.; ur Rehman, K.; Zheng, L.; Cai, M.; Xiao, X.; Hu, S.; Mathys, A.; Gold, M.; Yu, Z.; Zhang, J. Influence of Lactobacillus buchneri on soybean curd residue co-conversion by black soldier fly larvae (Hermetia illucens) for food and feedstock production. Waste Manag. 2019, 86, 114–122. [Google Scholar] [CrossRef]

- Peguero, D.A.; Gold, M.; Vandeweyer, D.; Zurbrügg, C.; Mathys, A. A review of pretreatment methods to improve agri-food waste bioconversion by black soldier fly larvae. Front. Sustain. Food Syst. 2022, 5. [Google Scholar] [CrossRef]

- Bram Dortmans, S.D.; Verstappen, B.; Zurbrügg, C. Black Soldier Fly Biowaste Processing—A Step-by-Step Guide; Eawag-Swiss Federal Institute of Aquatic Science and Technology: Dübendorf, Switzerland, 2017. [Google Scholar]

- Gold, M.; Spiess, R.; Zurbrügg, C.; Kreuzer, M.; Mathys, A. Digestibility of different dietary fibres by black soldier fly larvae. Bornimer Agrartech. Ber. 2018, 100, 129–131. [Google Scholar]

- Gold, M.; Cassar, C.M.; Zurbrügg, C.; Kreuzer, M.; Boulos, S.; Diener, S.; Mathys, A. Biowaste treatment with black soldier fly larvae: Increasing performance through the formulation of biowastes based on protein and carbohydrates. Waste Manag. 2020, 102, 319–329. [Google Scholar] [CrossRef]

- Mahmood, S.; Tabinda, A.B.; Ali, A.; Zurbrügg, C. Reducing the space footprint of Black Soldier Fly Larvae waste treatment by increasing waste feeding layer thickness. Pol. J. Environ. Stud. 2021, 30, 771–779. [Google Scholar] [CrossRef]

- Bosch, G.; Van Zanten, H.; Zamprogna, A.; Veenenbos, M.; Meijer, N.; Van der Fels-Klerx, H.; Van Loon, J. Conversion of organic resources by black soldier fly larvae: Legislation, efficiency and environmental impact. J. Clean. Prod. 2019, 222, 355–363. [Google Scholar] [CrossRef]

- Kim, C.-H.; Ryu, J.; Lee, J.; Ko, K.; Lee, J.-y.; Park, K.Y.; Chung, H. Use of Black Soldier Fly Larvae for Food Waste Treatment and Energy Production in Asian Countries: A Review. Processes 2021, 9, 161. [Google Scholar] [CrossRef]

- Mahmood, S.; Zurbrügg, C.; Tabinda, A.B.; Ali, A.; Ashraf, A. Sustainable Waste Management at Household Level with Black Soldier Fly Larvae (Hermetia illucens). Sustainability 2021, 13, 9722. [Google Scholar] [CrossRef]

- Diener, S. Valorisation of Organic Solid Waste Using the Black Soldier Fly, Hermetia Illucens, in Low and Middle-Income Countries. Ph.D. Thesis, ETH Zurich, Zurich, Switzerland, 2010. [Google Scholar]

- Lu, Y.; Zhang, S.; Sun, S.; Wu, M.; Bao, Y.; Tong, H.; Ren, M.; Jin, N.; Xu, J.; Zhou, H. Effects of different nitrogen sources and ratios to carbon on larval development and bioconversion efficiency in food waste treatment by black soldier fly larvae (Hermetia illucens). Insects 2021, 12, 507. [Google Scholar] [CrossRef] [PubMed]

- Bayram, B.; Ozkan, G.; Kostka, T.; Capanoglu, E.; Esatbeyoglu, T. Valorization and application of fruit and vegetable wastes and by-products for food packaging materials. Molecules 2021, 26, 4031. [Google Scholar] [CrossRef]

- Ortega, F.; Versino, F.; López, O.V.; García, M.A. Biobased composites from agro-industrial wastes and by-products. Emergent Mater. 2022, 5, 873–921. [Google Scholar] [CrossRef] [PubMed]

- Lalander, C.; Diener, S.; Magri, M.E.; Zurbrügg, C.; Lindström, A.; Vinnerås, B. Faecal sludge management with the larvae of the black soldier fly (Hermetia illucens) — From a hygiene aspect. Sci. Total Environ. 2013, 458-460, 312–318. [Google Scholar] [CrossRef] [PubMed]

- Výtisk, J.; Čespiva, J.; Jadlovec, M.; Kočí, V.; Honus, S.; Ochodek, T. Life cycle assessment applied on alternative production of carbon-based sorbents—A comparative study. Sustain. Mater. Technol. 2023, 35, e00563. [Google Scholar] [CrossRef]

- Ordoñez, B.M.; Santana, T.M.; Carneiro, D.P.; dos Santos, D.K.M.; Parra, G.A.P.; Moreno, L.C.C.; Teixeira Filho, N.P.; Aguilar, F.A.A.; Yamamoto, F.Y.; Gonçalves, L.U. Whole Black Soldier Fly Larvae (Hermetia illucens) as Dietary Replacement of Extruded Feed for Tambaqui (Colossoma macropomum) Juveniles. Aquac. J. 2022, 2, 246–256. [Google Scholar] [CrossRef]

- Guo, H.; Jiang, C.; Zhang, Z.; Lu, W.; Wang, H. Material flow analysis and life cycle assessment of food waste bioconversion by black soldier fly larvae (Hermetia illucens L.). Sci. Total Environ. 2020, 750, 141656. [Google Scholar] [CrossRef]

- Boakye-Yiadom, K.A.; Ilari, A.; Duca, D. Greenhouse Gas Emissions and Life Cycle Assessment on the Black Soldier Fly (Hermetia illucens L.). Sustainability 2022, 14, 10456. [Google Scholar] [CrossRef]

- Formica, M.; Frigo, S.; Gabbrielli, R. Development of a new steady state zero-dimensional simulation model for woody biomass gasification in a full scale plant. Energy Convers. Manag. 2016, 120, 358–369. [Google Scholar] [CrossRef]

- Kalbasi, A.; Mukhtar, S.; Hawkins, S.; Auvermann, B. Carcass composting for management of farm mortalities: A review. Compost. Sci. Util. 2005, 13, 180–193. [Google Scholar] [CrossRef]

| Parameter | Tested Range |

|---|---|

| Time | 1 to 20 days |

| Aeration frequency | 1, 2, 3 and 4 per day (referred as At1, At2, At3, and At4) |

| Number of larvae | 300, 600, 900, and 1200 per kg of waste (referred as L1, L2, L3 and L4) |

| Surface area | 56.7″, 78.5″, 113″, and 176.6″ (inch square) (referred as S1, S2, S3, and S4) |

| Waste composition | Kitchen Waste, Fruit Waste, Vegetable Waste, and Municipal Waste (referred to as W1, W2, W3, W4) |

| Impact Category | Unit | BSFL Compost [45]|Treatment of Kitchen and Garden Biowaste, Home Composting in Heaps and Containers|APOS, S-Inputs | Fish Feed-Output | Fertilizer, N, DK-Outputs |

|---|---|---|---|---|

| Water consumption | m3 | 1.30 | 1.86 | 0.00 |

| Fossil resource scarcity | kg oil eq | 3.89 | 1.56 | 0.25 |

| Mineral resource scarcity | kg Cu eq | 0.060 | 0.113 | 0.003 |

| Land use | m2/a crop eq | 7.57 | 0.27 | 0.00 |

| Human non-carcinogenic toxicity | kg 1,4-DCB | 14.26 | 4.67 | 0.00 |

| Human carcinogenic toxicity | kg 1,4-DCB | 0.15 | 0.61 | 0.00 |

| Marine ecotoxicity | kg 1,4-DCB | 0.161 | 0.058 | 0.000 |

| Freshwater ecotoxicity | kg 1,4-DCB | 0.317 | 0.014 | 0.000 |

| Terrestrial ecotoxicity | kg 1,4-DCB | 66.85 | 84.10 | 0.00 |

| Marine eutrophication | kg N eq | 0.0153 | 0.0001 | 0.0000 |

| Freshwater eutrophication | kg P eq | 0.0036 | 0.0005 | 0.0000 |

| Terrestrial acidification | kg SO2 eq | 0.166 | 0.027 | 0.005 |

| Ozone formation, Terrestrial ecosystems | kg NOx eq | 0.060 | 0.021 | 0.004 |

| Fine particulate matter Formation | kg PM2.5 eq | 0.035 | 0.013 | 0.001 |

| Ozone formation, Human health | kg NOx eq | 0.057 | 0.020 | 0.004 |

| Ionizing radiation | kBq Co-60 eq | 0.122 | 0.049 | 0.000 |

| Stratospheric ozone depletion | kg CFC11 eq | 112.8 × 10−6 | 3.1 × 10−6 | 63.5 × 10−6 |

| Global warming | kg CO2 eq | 17.67 | 7.41 | 2.71 |

| ANN Algorithm | ANN Segment | MSE | R | Predicted Volume Reduction | Experimental Volume Reduction | Predicted CO2 Equivalent | Actual CO2 Equivalent | Accuracy |

|---|---|---|---|---|---|---|---|---|

| Levenberg–Marquardt | Training | 1.23 × 10−19 | 1.000 | 64.9% | 65.0% | 17.64 | 16.67 | 99.8% |

| Validation | 4.23 × 10−1 | 0.999 | ||||||

| Testing | 0.137 | 0.991 | ||||||

| Scaled Conjugate Gradient | Training | 0.004 | 0.997 | 62.2% | 65.0% | 16.90 | 16.67 | 95.6% |

| Validation | 0.016 | 0.998 | ||||||

| Testing | 0.674 | 0.990 |

| Parameters | Current Study (Bin Composting) | Current Study (BSFL) | Best Quality Value by Conventional Method [18] |

|---|---|---|---|

| pH | 5.4 | 8.5 | 7.2–7.8 |

| Moisture Content | 63.4% | 67% | 60 |

| C/N | 14.5 | 12.1 | >11.0 |

| N (mg/L) | 20.6 | 33.6 | >18.7 |

| P (mg/kg) | 70 | 350 | >200 |

| TDS (mg/L) | 960 | 1250 | 2000 |

| Conductivity (dS/m) | 2.04 | 2.5 | 2–6 |

| Na (mg/kg) | 800 | 1700 | >1500 |

| K (mg/kg) | 500 | 1100 | 2000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arshad, M.Y.; Saeed, S.; Raza, A.; Ahmad, A.S.; Urbanowska, A.; Jackowski, M.; Niedzwiecki, L. Integrating Life Cycle Assessment and Machine Learning to Enhance Black Soldier Fly Larvae-Based Composting of Kitchen Waste. Sustainability 2023, 15, 12475. https://doi.org/10.3390/su151612475

Arshad MY, Saeed S, Raza A, Ahmad AS, Urbanowska A, Jackowski M, Niedzwiecki L. Integrating Life Cycle Assessment and Machine Learning to Enhance Black Soldier Fly Larvae-Based Composting of Kitchen Waste. Sustainability. 2023; 15(16):12475. https://doi.org/10.3390/su151612475

Chicago/Turabian StyleArshad, Muhammad Yousaf, Salaha Saeed, Ahsan Raza, Anum Suhail Ahmad, Agnieszka Urbanowska, Mateusz Jackowski, and Lukasz Niedzwiecki. 2023. "Integrating Life Cycle Assessment and Machine Learning to Enhance Black Soldier Fly Larvae-Based Composting of Kitchen Waste" Sustainability 15, no. 16: 12475. https://doi.org/10.3390/su151612475