Carbon Emission Evaluation of Roadway Construction at Contaminated Sites Based on Life Cycle Assessment Method

Abstract

:1. Introduction

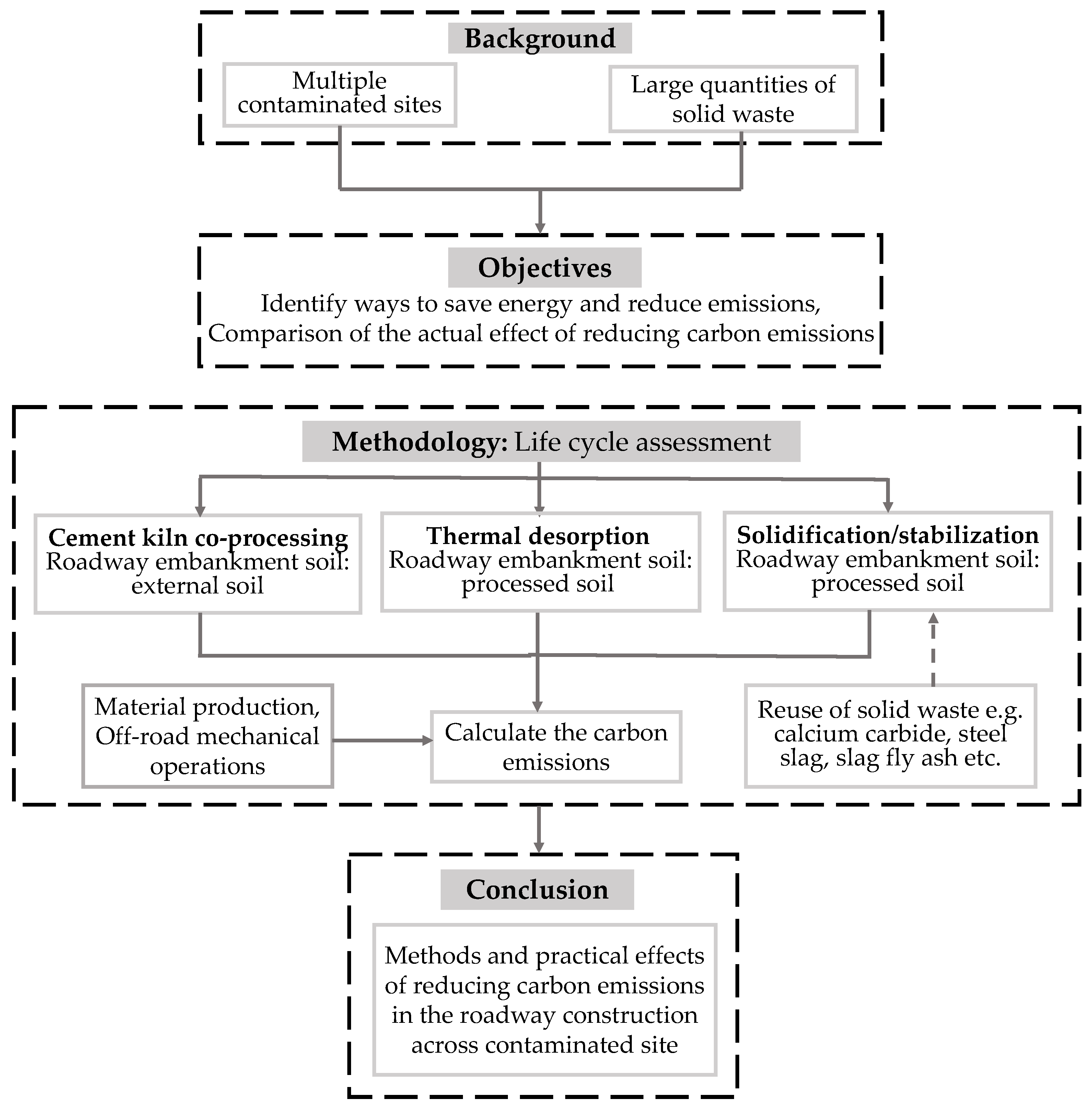

2. LCA Method

3. Case Study

3.1. Background

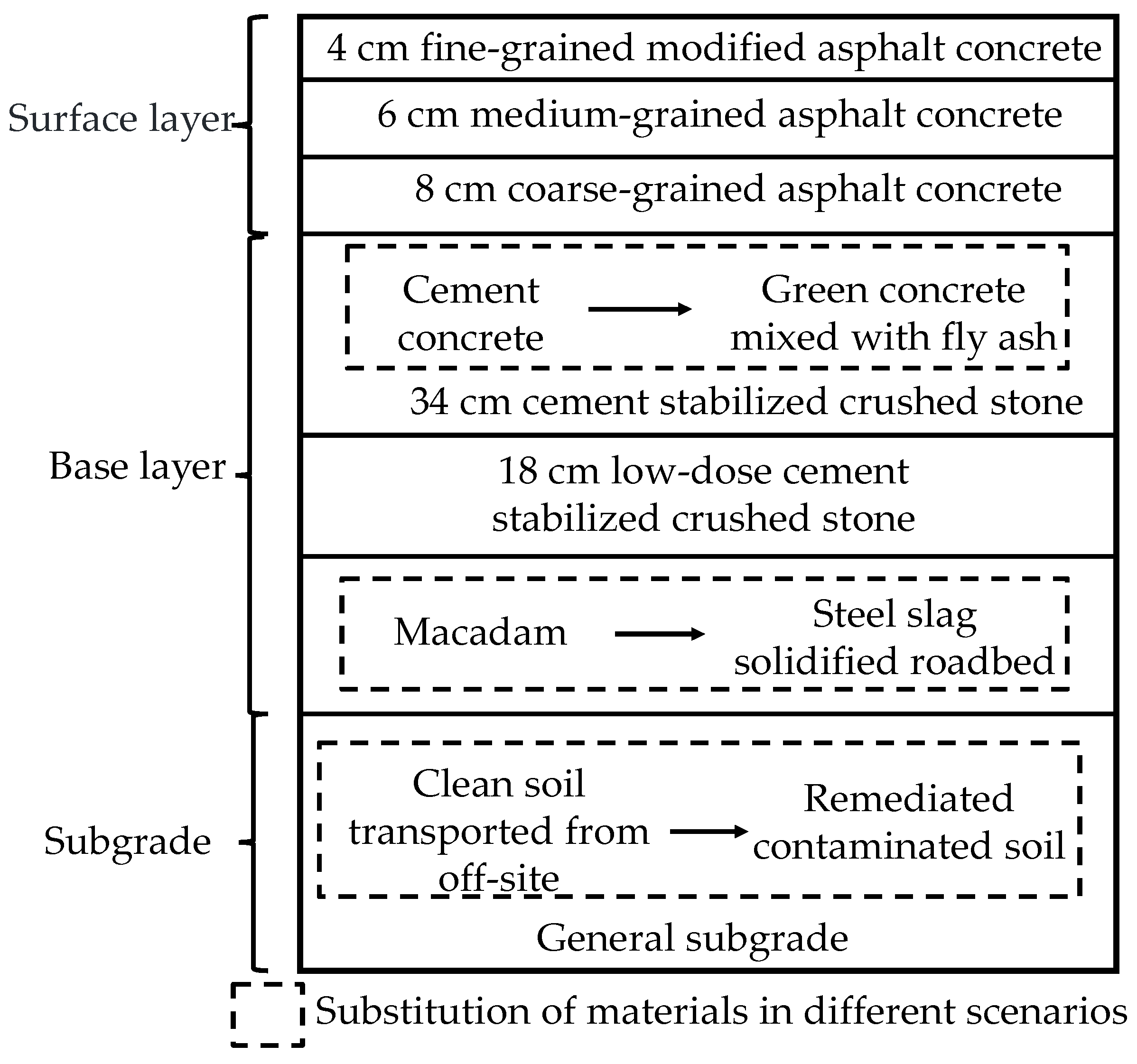

3.2. System Boundaries

3.3. Inventory Analysis and CO2 Emissions Calculation

| Material/Fuel | Unit | Emission Factor |

|---|---|---|

| Water | kg/t | 0.17 |

| Quick lime | kg/kg | 1.34 |

| C30 concrete | kg/m3 | 321.30 |

| Activated carbon | kg/kg | 9.97 |

| Naoh | kg/kg | 1.97 |

| Waste water | kg/t | 1.06 |

| MgO | kg/kg | 1.06 |

| Ca(OH)2 | kg/kg | 1.017 |

| FeCl3 | kg/kg | 0.18 |

| CaO | kg/kg | 0.50 |

| Al2(SO4)3 | kg/kg | 0.50 |

| Al2O3 | kg/kg | 1.23 |

| Dicalcium phosphate | kg/kg | 2.70 |

| Fly ash | kg/kg | 0 |

| Material/Fuel | Unit | Emission Factor |

|---|---|---|

| Cement a | ||

| P.s. 32.5 | kg/t | 677.68 |

| P.o. 42.5 | kg/t | 920.028 |

| P.i. 52.5 | kg/t | 1041.577 |

| Building materials b | ||

| Sand | kg/m3 | 2.56 |

| Rubble (cleft stone, block stone) | kg/m3 | 3.37 |

| Gravel (2 cm, 4 cm, 6 cm, 8 cm) | kg/m3 | 3.3 |

| Asphalt c | ||

| Bitumen | kg/t | 174.24 |

| Modified asphalt | kg/t | 295.91 |

| Fuel d | ||

| Diesel | kg/kg | 4.62 |

| Fuel oil | kg/kg | 4.36 |

| Electricity | kg/kwh | 0.983 |

| Transportation Vehicle | Specification | Fuel/Energy Type | Fuel Efficiency | Unit (Per Vehicle Per 8 h) |

|---|---|---|---|---|

| Dump truck | 10–12 t | diesel | 58.46 | kg |

| Lorry | 10–12 t | diesel | 42.1 | kg |

| Off-road machinery | ||||

| Bulldozer | 75–90 kw | diesel | 294.83 | kg |

| Excavator | 0.8–1.0 m3 | diesel | 226.405 | kg |

| Loader | 1–1.5 m3 | diesel | 280.28 | kg |

| Grader | 120–150 kw | diesel | 441.98 | kg |

| Road roller | 10–12 t | diesel | 165.18 | kg |

| Asphalt mixing station | 60–120 L | fuel oil | 2692.8 | kg |

| electricity | 1588.67 | kwh | ||

| Concrete batching plant | 50–60 L | electricity | 619.46 | kwh |

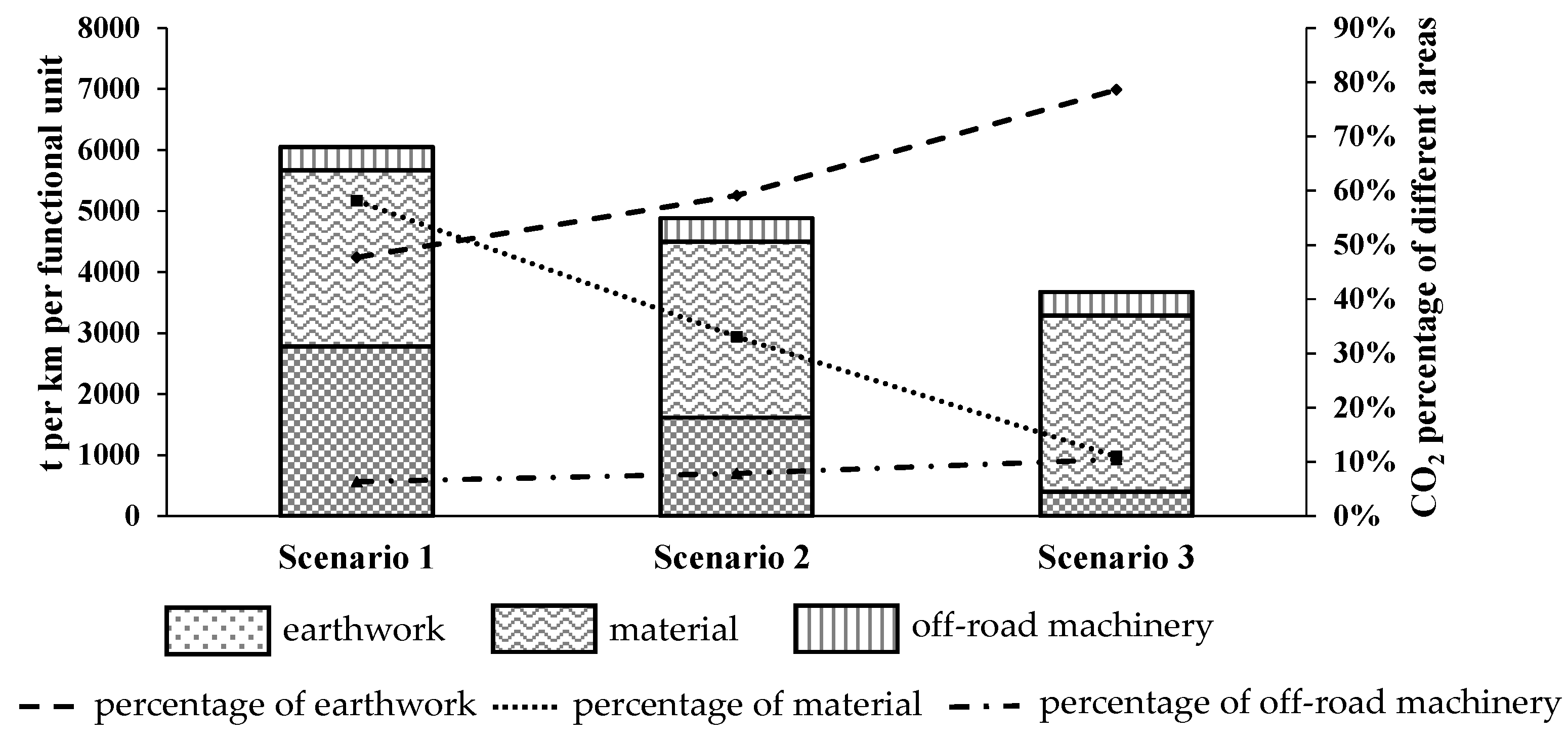

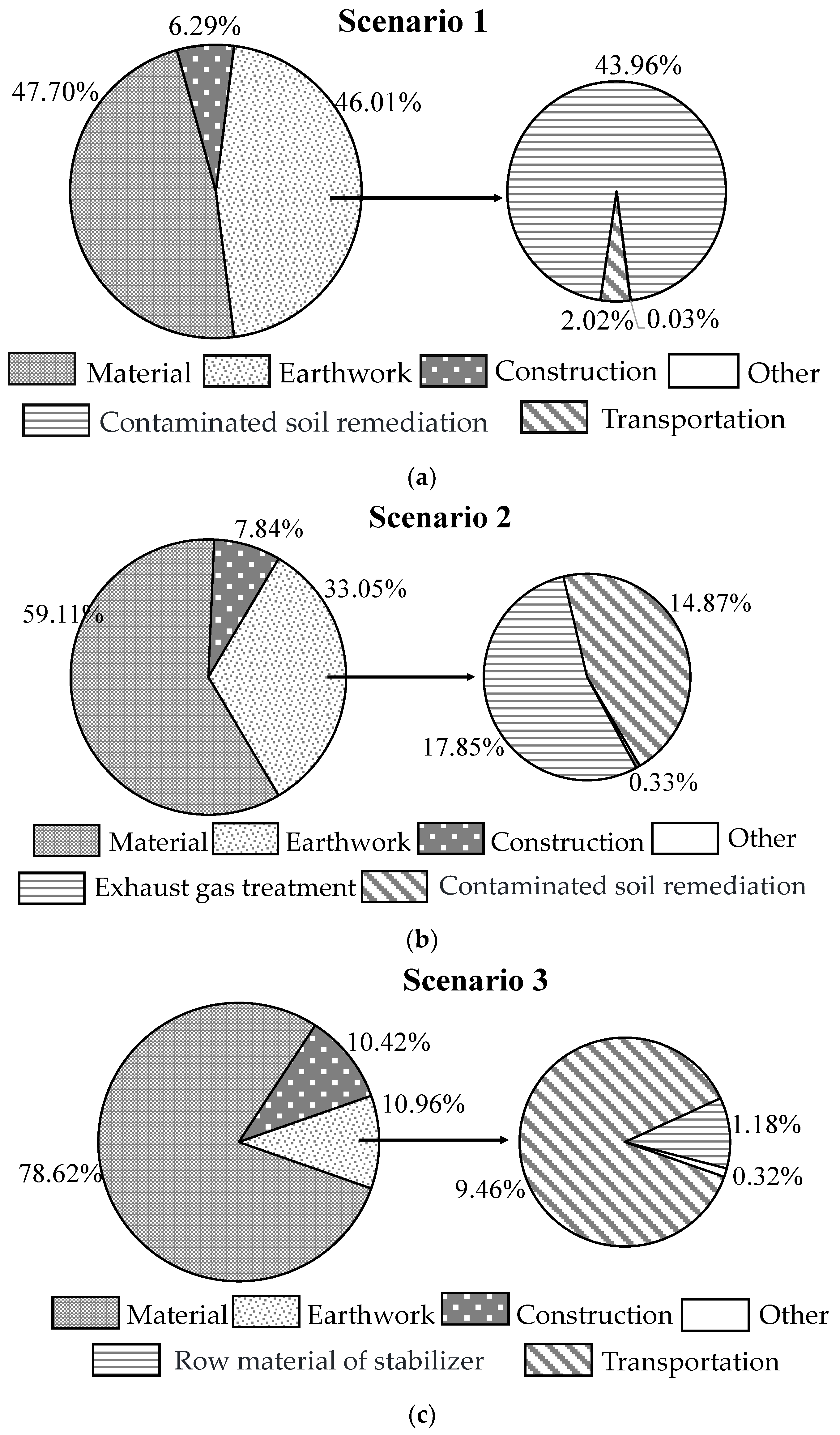

4. Results and Discussion

5. Conclusions

- (1)

- Among the three described scenarios, Scenario 3 had the lowest carbon emissions of 3671.154 t per basic unit, followed by Scenario 2 with 4882.290 t per basic unit, and Scenario 1 generated the highest carbon emissions of 6050.774 t per basic unit. Thermal desorption and S/S methods reduced overall carbon emissions by 19.32% and 39.33%, respectively, compared to the traditional cement kiln co-disposal method.

- (2)

- The analysis of carbon emissions from the three different remediation methods for contaminated soil indicate that use of the traditional cement kiln co-disposal method should be avoided or reduced due to its high carbon emissions. In thermal desorption remediation, primary remediation and tail gas treatment contributed to approximately 15% of carbon emissions, playing a significant role in the overall emissions of the remediation process. For S/S, the carbon emissions primarily came from the production of solidifiers/stabilizers, accounting for nearly 10% of the total emissions. To reduce these emissions, measures such as using eco-friendly, low-carbon raw materials and controlling transportation distances can be implemented.

- (3)

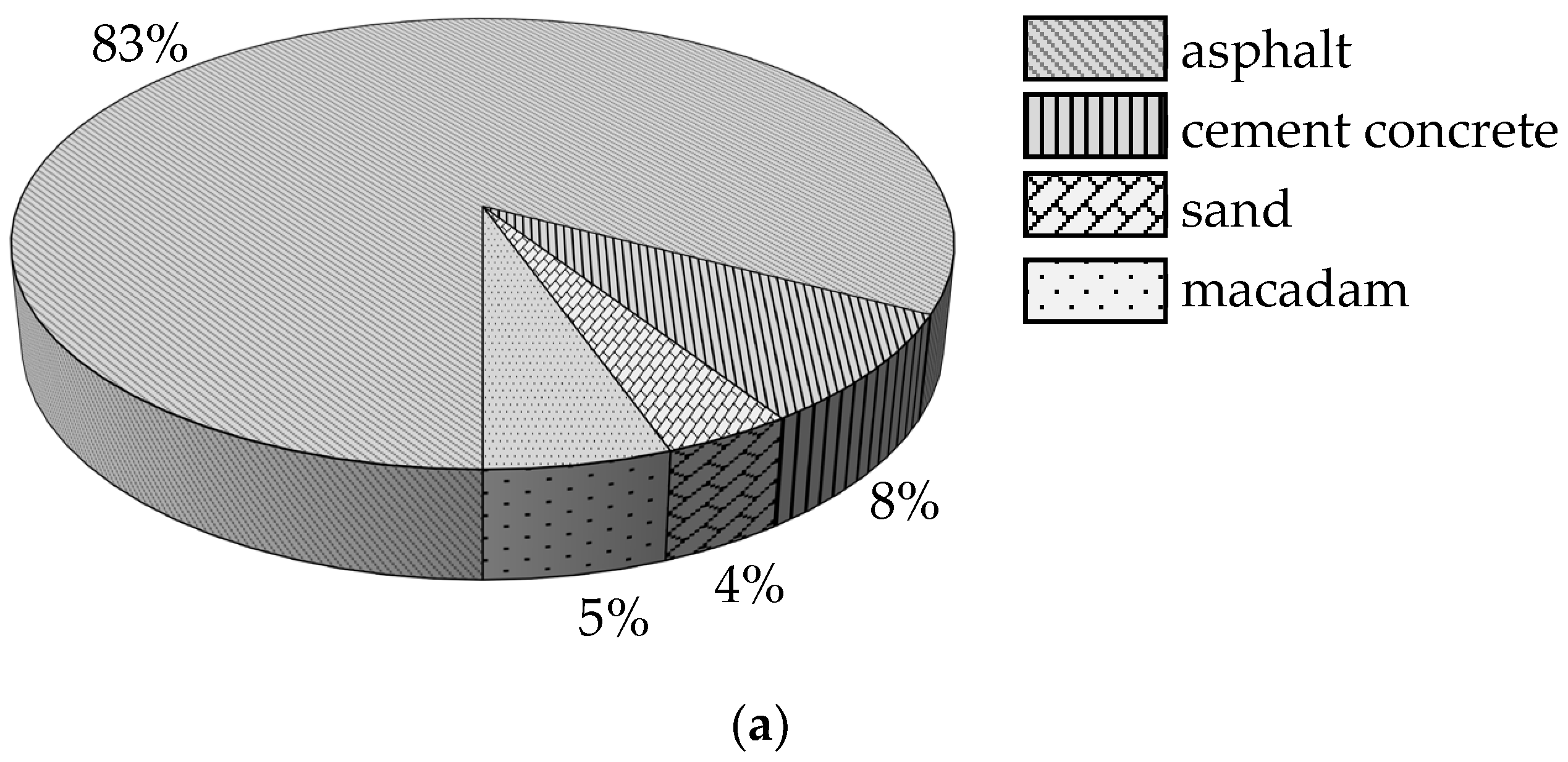

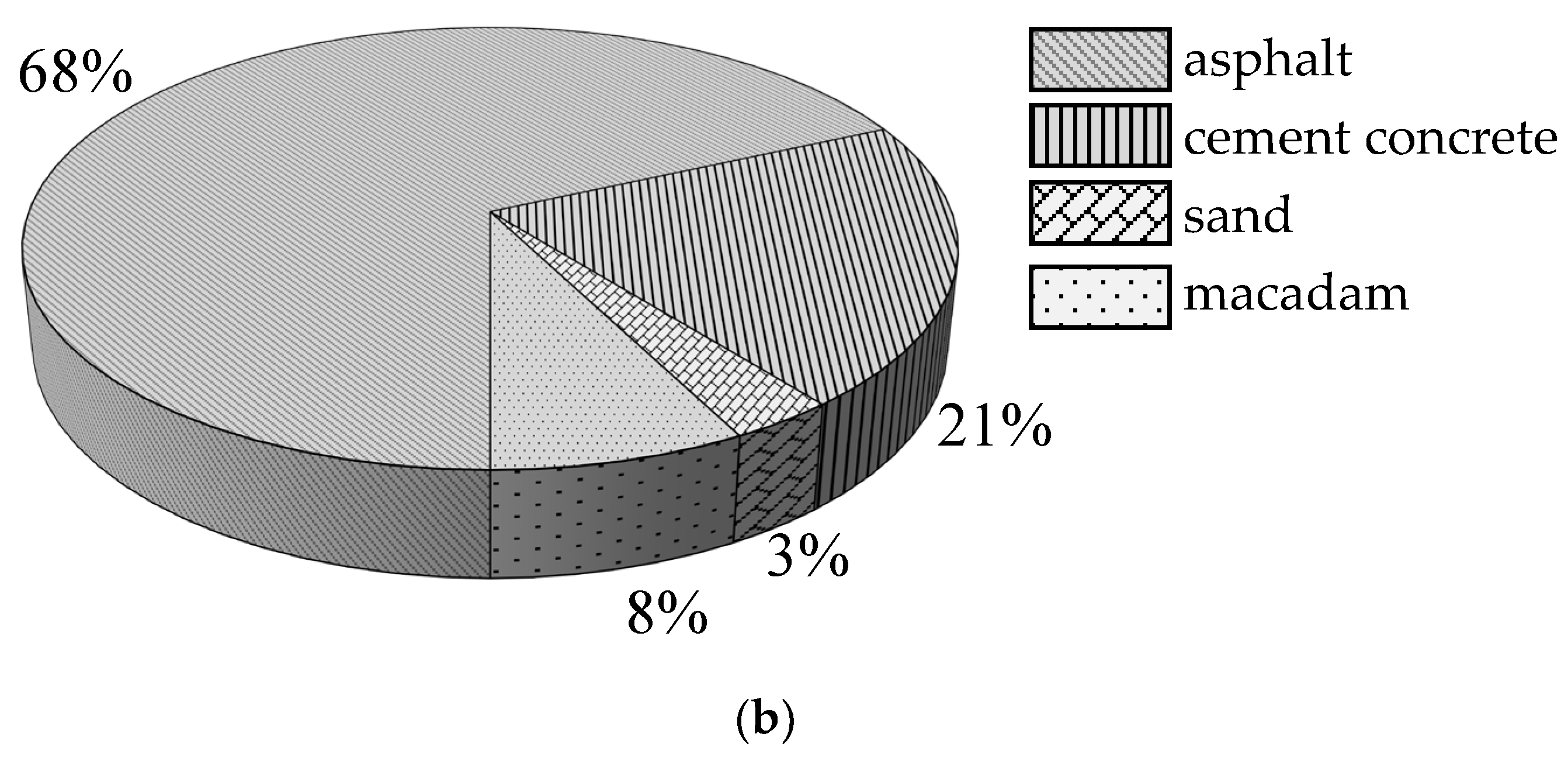

- In roadway construction, material production was a significant contributor to carbon emissions, constituting over 45% and up to 76.82% of the total emissions. Among the materials used, asphalt had the highest proportion of carbon emissions, exceeding two-thirds of the total emissions in material production, followed by cement concrete. To mitigate these emissions, one effective approach is the reuse of solid waste, which reduced carbon emissions by 498.98 t per basic unit. By recycling and reusing solid waste materials, the need for new production of materials and their associated carbon emissions can be minimized.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Agreement, P. Paris agreement. In Report of the Conference of the Parties to the United Nations Framework Convention on Climate Change (21st Session, 2015: Paris), Paris, France, 12 December 2015; Retrived December; HeinOnline: Buffalo, NY, USA, 2015; Volume 4. [Google Scholar]

- Shi, X.; Zheng, Y.; Lei, Y.; Xue, W.; Yan, G.; Liu, X.; Cai, B.; Tong, D.; Wang, J. Air quality benefits of achieving carbon neutrality in China. Sci. Total Environ. 2021, 795, 148784. [Google Scholar] [CrossRef]

- Zhang, Y.J.; Da, Y.B. The decomposition of energy-related carbon emission and its decoupling with economic growth in China. Renew. Sustain. Energy Rev. 2015, 41, 1255–1266. [Google Scholar] [CrossRef]

- Barandica, J.M.; Fernández-Sánchez, G.; Berzosa, Á.; Delgado, J.A.; Acosta, F.J. Applying life cycle thinking to reduce greenhouse gas emissions from road projects. J. Clean. Prod. 2013, 57, 79–91. [Google Scholar] [CrossRef]

- Huang, Y.; Bird, R.N.; Heidrich, O. A review of the use of recycled solid waste materials in asphalt pavements. Resour. Conserv. Recycl. 2007, 52, 58–73. [Google Scholar] [CrossRef]

- Muench, S.T. Roadway construction sustainability impacts: Review of life-cycle assessments. Transp. Res. Rec. 2010, 2151, 36–45. [Google Scholar] [CrossRef]

- Du, Y.J.; Jin, F.; Liu, S.Y.; Chen, L.; Zhang, F. Review of Stabilization/solidification technique for remediation of heavy metals contaminated lands. Rock Soil Mech. 2011, 32, 116–124. [Google Scholar]

- Chang, J.S.; Cho, Y.C.; Lin, Y.P. Regeneration of heavy metal contaminated soils for cement production by cement kiln co-processing. Resour. Conserv. Recycl. 2022, 176, 105909. [Google Scholar] [CrossRef]

- Shen, Z.; Jin, F.; O’Connor, D.; Hou, D. Solidification/stabilization for soil remediation: An old technology with new vitality. Environ. Sci. Technol. 2019, 53, 11615–11617. [Google Scholar] [CrossRef]

- Napia, C.; Sinsiri, T.; Jaturapitakkul, C.; Chindaprasirt, P. Leaching of heavy metals from solidified waste using Portland cement and zeolite as a binder. Waste Manag. 2012, 32, 1459–1467. [Google Scholar] [CrossRef]

- Anastasiadou, K.; Christopoulos, K.; Mousios, E.; Gidarakos, E. Solidification/stabilization of fly and bottom ash from medical waste incineration facility. J. Hazard. Mater. 2012, 207–208, 165–170. [Google Scholar] [CrossRef]

- Gupta, A.; Arora, V.K.; Biswas, S. Use of contaminated dredged soil in different pavement layers after thermal treatment and stabilization/solidification. J. Eng. Sci. Technol. 2019, 14, 2034–2051. [Google Scholar]

- Ahmad, S.; Ba-Naimoon, M.S.; Bahraq, A.A.; Al-Amoudi, O.S.; Maslehuddin, M.; Al-Malack, M.H. Stabilization/Solidification of Petroleum Oil-Contaminated Soil using Different Stabilizers to Deliver a Pavement Subbase Material. Arab. J. Sci. Eng. 2022, 47, 13687–13697. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Soomro, M.; Evangelista, A.C.J. A review of recycled aggregate in concrete applications (2000–2017). Constr. Build. Mater. 2018, 172, 272–292. [Google Scholar] [CrossRef]

- Li, J.; Xiao, F.; Zhang, L.; Amirkhanian, S.N. Life cycle assessment and life cycle cost analysis of recycled solid waste materials in highway pavement: A review. J. Clean. Prod. 2019, 233, 1182–1206. [Google Scholar] [CrossRef]

- Carpenter, A.C.; Gardner, K.H. Use of Industrial By-Products in Urban Roadway Infrastructure: Argument for Increased Industrial Ecology. J. Ind. Ecol. 2009, 13, 965–977. [Google Scholar] [CrossRef]

- Vieira, C.S.; Pereira, P.M. Use of recycled construction and demolition materials in geotechnical applications: A review. Resour. Conserv. Recycl. 2015, 103, 192–204. [Google Scholar] [CrossRef]

- Du, Y.J.; Jiang, N.J.; Liu, S.Y.; Horpibulsuk, S.; Arulrajah, A. Field evaluation of soft highway subgrade soil stabilized with calcium carbide residue. Soils Found. 2016, 56, 301–314. [Google Scholar] [CrossRef]

- Wei, Y.; Chai, J.; Qin, Y.; Xu, Z.; Zhang, X. Performance evaluation of green-concrete pavement material containing selected C&D waste and FA in cold regions. J. Mater. Cycles Waste Manag. 2019, 21, 1550–1562. [Google Scholar]

- Phummiphan, I.; Horpibulsuk, S.; Rachan, R.; Arulrajah, A.; Shen, S.L.; Chindaprasirt, P. High calcium fly ash geopolymer stabilized lateritic soil and granulated blast furnace slag blends as a pavement base material. J. Hazard. Mater. 2018, 341, 257–267. [Google Scholar] [CrossRef]

- Smith, S.H.; Durham, S.A. A cradle to gate LCA framework for emissions and energy reduction in concrete pavement mixture design. Int. J. Sustain. Built Environ. 2016, 5, 22–33. [Google Scholar] [CrossRef]

- Huang, Y.; Hakim, B.; Zammataro, S. Measuring the carbon footprint of road construction using CHANGER. Int. J. Pavement Eng. 2013, 14, 590–600. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, Y.; Li, D. Estimation and uncertainty analysis on carbon dioxide emissions from construction phase of real highway projects in China. J. Clean. Prod. 2017, 144, 337–346. [Google Scholar] [CrossRef]

- Mao, R.; Duan, H.; Dong, D.; Zuo, J.; Song, Q.; Liu, G.; Hu, M.; Zhu, J.; Dong, B. Quantification of carbon footprint of urban roads via life cycle assessment: Case study of a megacity-Shenzhen, China. J. Clean. Prod. 2017, 166, 40–48. [Google Scholar] [CrossRef]

- Keijzer, E.E.; Leegwater, G.A.; de Vos-Effting, S.E.; De Wit, M.S. Carbon footprint comparison of innovative techniques in the construction and maintenance of road infrastructure in The Netherlands. Environ. Sci. Policy 2015, 54, 218–225. [Google Scholar] [CrossRef]

- ISO 14040; Environmental Management: Life-Cycle Assessment: Principles and Framework. International Organization for Standardization (ISO): Geneva, Switzerland, 2006.

- ISO 14044; Environmental Management: Life Cycle Assessment: Requirements and Guidelines. International Organization for Standardization (ISO): Geneva, Switzerland, 2006.

- Finnveden, G.; Hauschild, M.Z.; Ekvall, T.; Guinée, J.; Heijungs, R.; Hellweg, S.; Koehler, A.; Pennington, D.; Suh, S. Recent developments in life cycle assessment. J. Environ. Manag. 2009, 91, 1–21. [Google Scholar] [CrossRef]

- Lv, T.; Gao, S.; Hong, W.; Huang, S.; Liu, X.; Zhao, H. Application of LCA in Expressway Energy Consumption Analysis in South China. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2018; Volume 199, p. 032038. [Google Scholar]

- Santero, N. Life Cycle Assessment of Pavements: A Critical Review of Existing Literature and Research; Portland Cement Association: Skokie, IL, USA, 2010. [Google Scholar]

- Conway-Schempf, N.; Hall, P. Economic Input-Output Life Cycle Assessment of Asphalt versus Steel Reinforced Concrete for Pavement Construction. 1999. Available online: https://p2infohouse.org/ref/21/20345.pdf (accessed on 12 June 2023).

- Hendrickson, C.T.; Lave, L.B.; Matthews, H.S. Environmental Life Cycle Assessment of Goods and Services: An Input-Output Approach; Resources for the Future; Routledge: Oxford, UK, 2006. [Google Scholar]

- Jiao, S.J.; Li, L.F.; Li, Y.W. Analysis on Influence Factors for the Whole Life-cycle Carbon Emissions of Highway and Carbon Accounting. Adv. Mater. Res. 2014, 869, 826–831. [Google Scholar] [CrossRef]

- Xue, C.J.; Fang, Z.Q. Path of carbon emission peaking and carbon neutrality in soil remediation. Environ. Eng. 2022, 40, 231–238. (In Chinese) [Google Scholar]

- Liu, S.; Chen, P.; Song, H.; Chen, K.; Li, H.; Wang, F.K.; Li, P.H.; Tong, X.R. Carbon emissions and emission reduction strategy for remediation of contaminated soil by ex-situ thermal desorption in East China. Chin. J. Environ. Eng. 2022, 16, 2663–2671. (In Chinese) [Google Scholar]

- Zhou, S.J.; Sun, H.Y.; Li, Y.Z.; Yuan, H.; Feng, Y.S.; Yang, Y.L.; Du, Y.J. Carbon emission calculation method for contaminated soil stabilization and case study. China Environ. Sci. 2022, 42, 4840–4848. (In Chinese) [Google Scholar]

- Şanal, İ. Fresh-state performance design of green concrete mixes with reduced carbon dioxide emissions. Greenh. Gases Sci. Technol. 2018, 8, 1134–1145. [Google Scholar] [CrossRef]

- Gu, X.; Yu, B.; Dong, Q.; Deng, Y. Application of secondary steel slag in subgrade: Performance evaluation and enhancement. J. Clean. Prod. 2018, 181, 102–108. [Google Scholar] [CrossRef]

- JTG B01-2014; Highway Engineering Technical Standard. China Communication Press: Beijing, China, 2014. (In Chinese)

- Liu, N.; Wang, Y.; Bai, Q.; Liu, Y.; Wang, P.S.; Xue, S.; Yu, Q.; Li, Q. Road life-cycle carbon dioxide emissions and emission reduction technologies: A review. J. Traffic Transp. Eng. 2022, 9, 532–555. [Google Scholar] [CrossRef]

- Inyim, P.; Pereyra, J.; Bienvenu, M.; Mostafavi, A. Environmental assessment of pavement infrastructure: A systematic review. J. Environ. Manag. 2016, 176, 128–138. [Google Scholar] [CrossRef]

- Fang, H.; Cao, Z.L.; Feng, Z.H.; Chen, S.X. Carbon emission accounting method and empirical research of highway on full life cycle theory. Highw. Eng. 2021, 46, 92–97, 124. (In Chinese) [Google Scholar]

- Eggleston, H.S.; Buendia, L.; Miwa, K.; Ngara, T.; Tanabe, K. 2006 IPCC Guidelines for National Greenhouse Gas Inventories; IPCC: Tokyo, Japan, 2006. [Google Scholar]

- Gong, Z.; Zhang, Z. Quantitative assessment of the embodied environmental profile of building materials. J.Tsinghua Univ. 2004, 44, 1209–1213. [Google Scholar]

- Zhang, Y. Life Cycle Assessment on the Reduction of Carbon Dioxide Emission of Building; National Cheng Kung University: Tainan City, Taiwan, 2002; Volume 32, pp. 13–15. [Google Scholar]

- Blomberg, T.; Barnes, J.; Bernard, F.; Dewez, P.; Le Clerc, S.; Pfitzmann, M.; Taylor, R. Life Cycle Inventory: Bitumen; European Bitumen Association: Brussels, Belgium, 2011. [Google Scholar]

- Dou, X.; Chen, D.; Hu, Y.; Feng, Y.; Dai, X. Carbonization of heavy metal impregnated sewage sludge oriented towards potential co-disposal. J. Hazard. Mater. 2017, 321, 132–145. [Google Scholar] [CrossRef]

- Mondal, A.; Ransinchung, R.N.; Choudhary, J. Sustainable recycling of industrial waste fillers and reclaimed asphalt pavement to produce environmentally feasible warm mix asphalt. Innov. Infrastruct. Solut. 2022, 8, 34. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, L.; Li, Y.; Qian, C.; Du, Y. Carbon Emission Evaluation of Roadway Construction at Contaminated Sites Based on Life Cycle Assessment Method. Sustainability 2023, 15, 12642. https://doi.org/10.3390/su151612642

Zheng L, Li Y, Qian C, Du Y. Carbon Emission Evaluation of Roadway Construction at Contaminated Sites Based on Life Cycle Assessment Method. Sustainability. 2023; 15(16):12642. https://doi.org/10.3390/su151612642

Chicago/Turabian StyleZheng, Luorui, Yingzhen Li, Cheng Qian, and Yanjun Du. 2023. "Carbon Emission Evaluation of Roadway Construction at Contaminated Sites Based on Life Cycle Assessment Method" Sustainability 15, no. 16: 12642. https://doi.org/10.3390/su151612642

APA StyleZheng, L., Li, Y., Qian, C., & Du, Y. (2023). Carbon Emission Evaluation of Roadway Construction at Contaminated Sites Based on Life Cycle Assessment Method. Sustainability, 15(16), 12642. https://doi.org/10.3390/su151612642