Analysis of the Pore Structure and Fractal Characteristics of Coal and Gas Outburst Coal Seams Based on Matrix Compression Correction

Abstract

:1. Introduction

2. Experiments and Methods

2.1. Samples

2.2. Experiments Procedure

3. Analysis of Experimental Results

4. Discussion

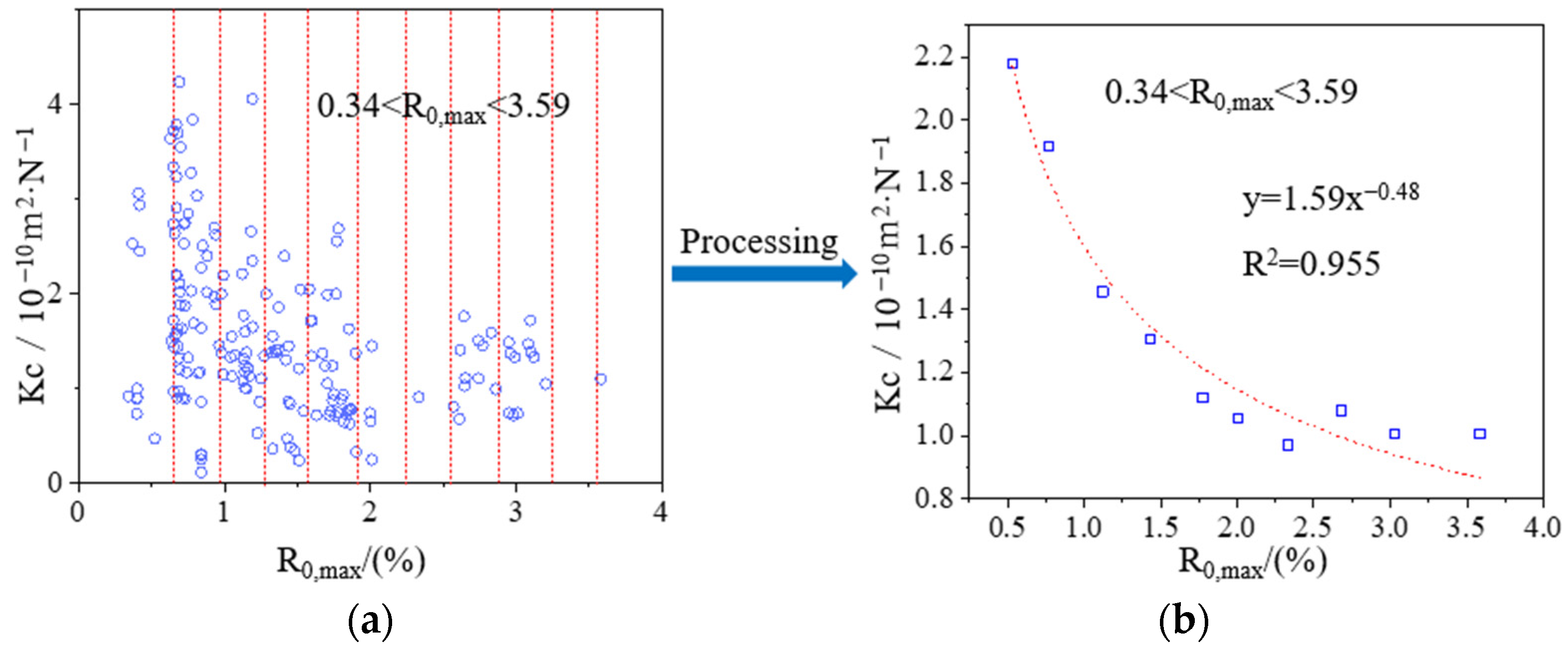

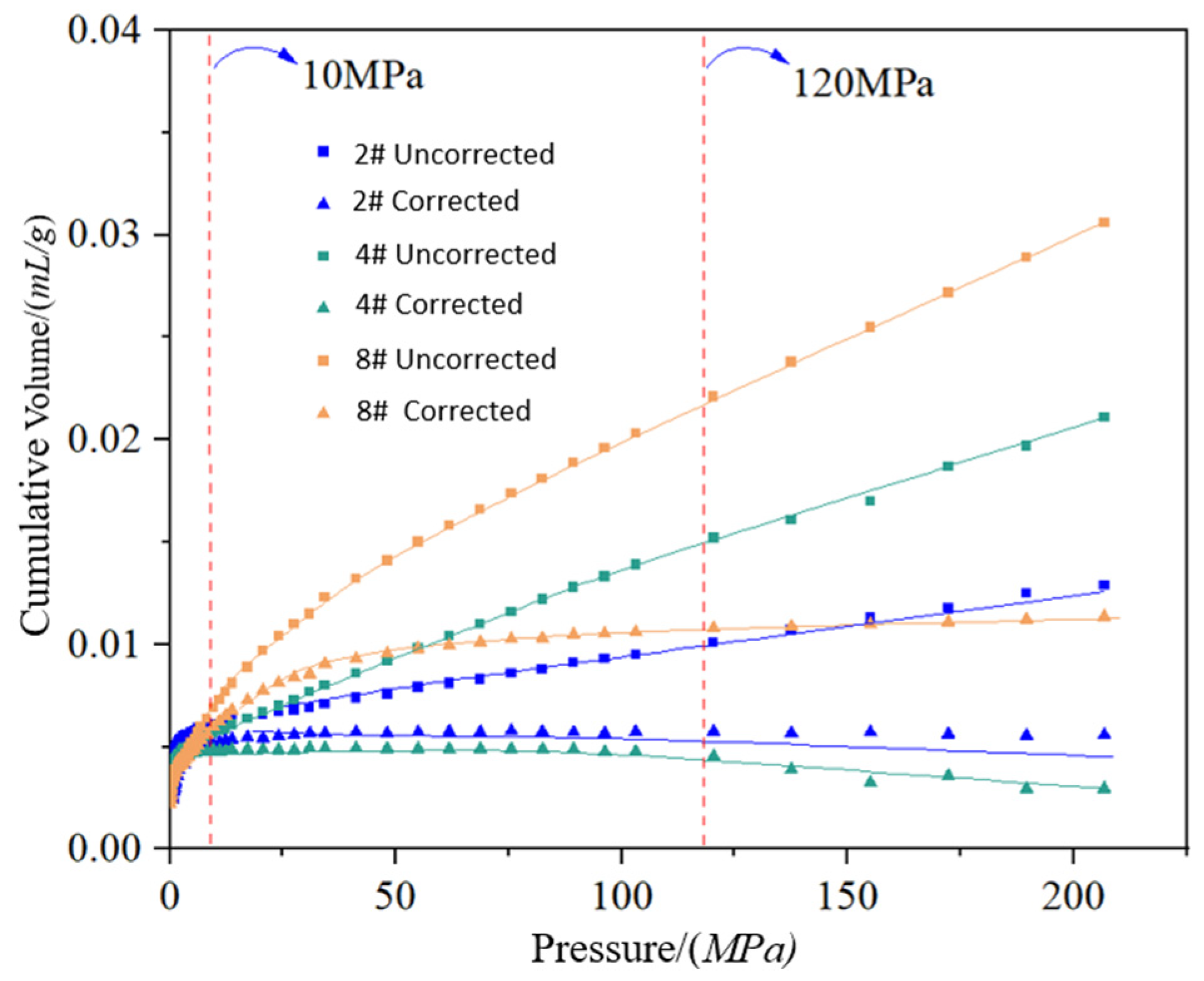

4.1. Matrix Compressibility and Volume Correction

4.2. Characteristics of the Physical Parameters of Outburst Coal Seams

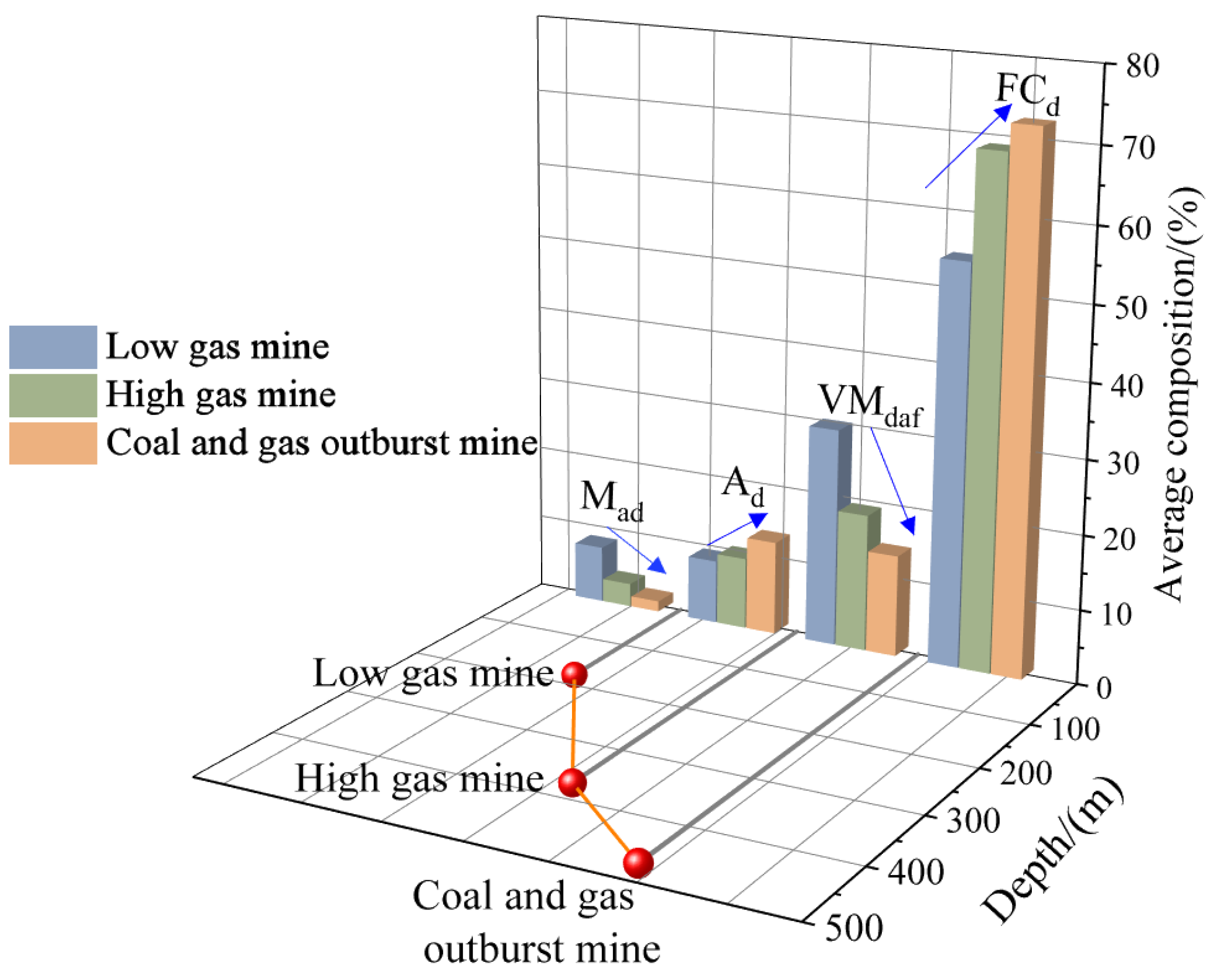

4.3. Pore Characteristics of Outburst Coal Seam

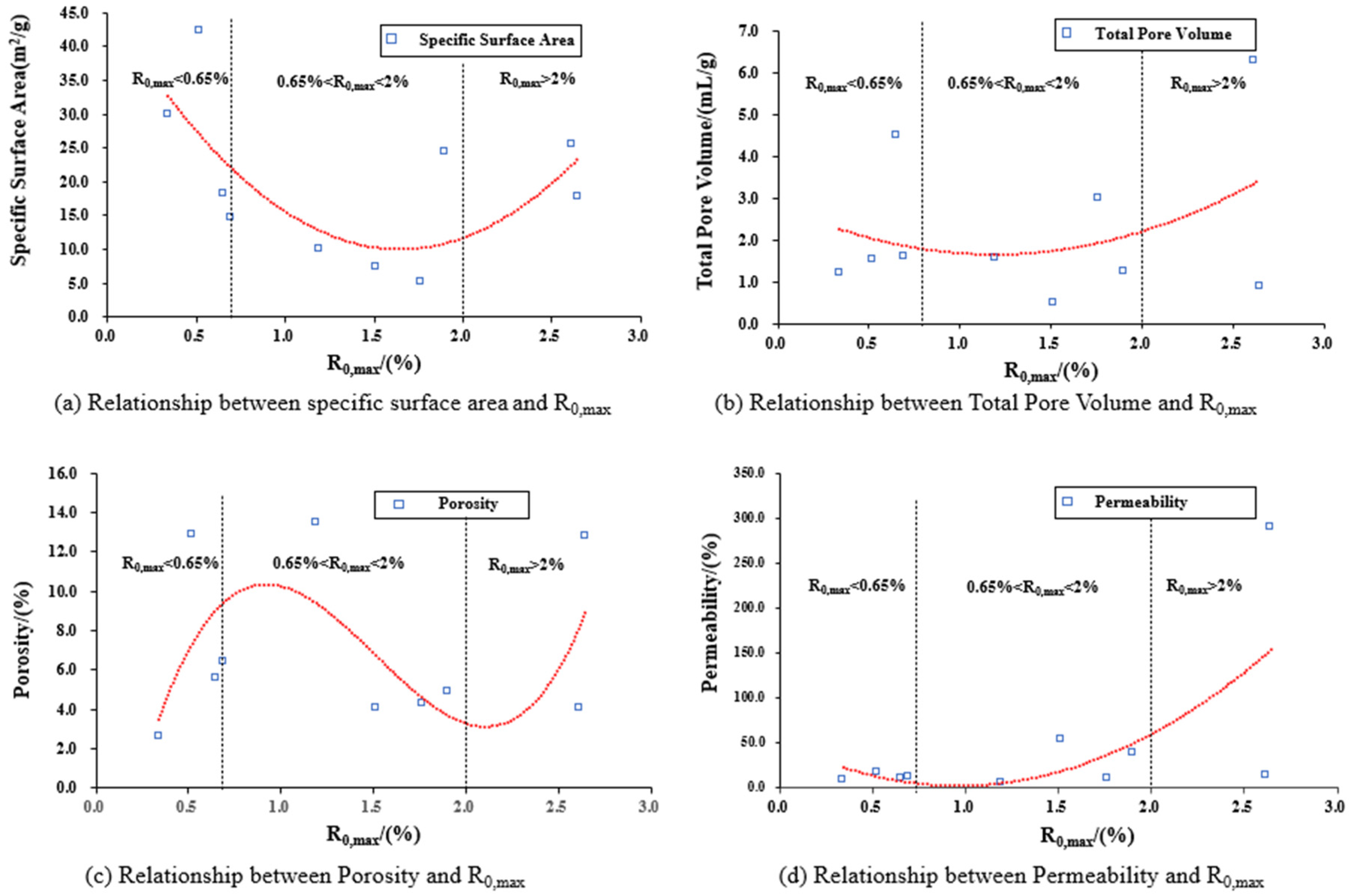

4.3.1. Pore Structure Analysis

4.3.2. Pore Size Distribution Analysis

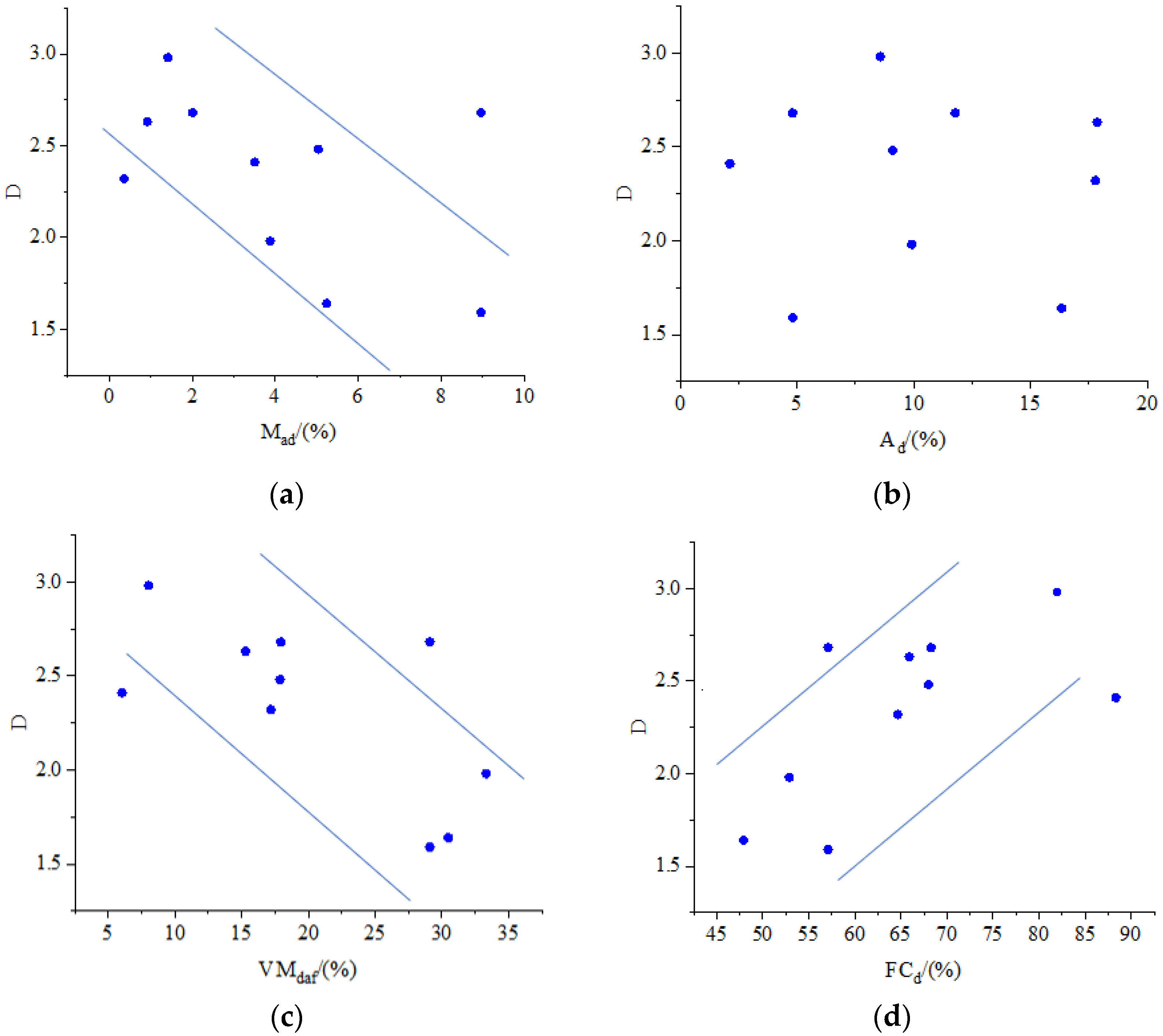

4.3.3. Fractal Characteristics of Pore Structures

5. Conclusions

Research and Prospects

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, X.B.; Yan, J.W. Physical conditions and process of gas outburst coal formation. China Work. Saf. Sci. Technol. 2014, 10, 48–53. [Google Scholar]

- Li, C.; Wu, S.; Zheng, C.; Sun, X.; Jiang, X. Study on temporal and spatial evolution characteristics of overburden deformation and gas emission during the longwall working face initial mining phase. J. Geophys. Eng. 2022, 19, 534–549. [Google Scholar] [CrossRef]

- Zou, Q.; Liu, H.; Jiang, Z.; Wu, X. Gas flow laws in coal subjected to hydraulic slotting and a prediction model for its permeability-enhancing effect. Energy Sources Part A Recovery Util. Environ. Eff. 2021, 43, 1–15. [Google Scholar] [CrossRef]

- Cheng, Y.; Yang, L. Study on structural coal and the relationship between coal and gas outburst. J. Coal 2021, 46, 180–198. [Google Scholar]

- Xie, H. Research framework and anticipated results of deep rock mechanics and mining theory. Adv. Eng. Sci. 2017, 49, 1–16. [Google Scholar]

- Li, X.; Li, Z.; Zhang, L.; Gao, J.; Nie, B.; Meng, Y. Pore structure characterization of various rank coals and its effect on gas desorption and diffusion. J. China Coal Soc. 2019, 44, 142–156. [Google Scholar]

- Meng, Z.; Zhang, K.; Shen, Z. Analysis on the difference of methane diffusion performance between structural coal and primary structural coal. Coal Field Geol. Explor. 2022, 50, 102–109. [Google Scholar]

- Ren, J.; Song, Z.; Li, B.; Liu, J.; Lv, R.; Liu, G. Structure feature and evolution mechanism of pores in different metamorphism and deformation coals. Fuel 2020, 283, 119292. [Google Scholar] [CrossRef]

- Chen, Y.; Liu, R.; Wang, G.; Ma, J.; Wu, J.; Wang, P.; Wu, K.; Guo, X. Pore and gas desorption characteristics of primary coal with different degrees of metamorphism. Energy Sci. Eng. 2023. Early View. [Google Scholar] [CrossRef]

- Yu, S.; Bo, J.; Fengli, L.; Jiegang, L. Structure and fractal characteristic of micro- and meso-pores in low middle-rank tectonic deformed coals by CO2 and N2 adsorption. Microporous Mesoporous Mater. 2017, 253, 191–202. [Google Scholar] [CrossRef]

- Shao, P.; Wang, X.; Song, Y.; Li, Y. Study on the characteristics of matrix compressibility and its influence factors for different rank coals. J. Nat. Gas Sci. Eng. 2018, 56, 93–106. [Google Scholar] [CrossRef]

- Li, X.; Xue, H.; Chen, L.; Shen, Z.H.; Xu, M.; Xu, S.H. Microporous structure of outburst coal seams in Guizhou area and its influence on gas flow characteristics. Coal Sci. Technol. 2020, 48, 67–74. [Google Scholar]

- Zhang, J.; Hou, X.; Zhou, G.; Wang, Y.; Chen, L.; Fang, H.; Zheng, C. Quantifying and Controller Determination of Shale Matrix Compressibility: Implications for Pore Structure and Gas Flow Behavior Analyses. Nat. Resour. Res. 2023. [Google Scholar] [CrossRef]

- Yue, J.; Wang, Z.; Chen, J.; Zheng, M.; Wang, Q.; Lou, X. Investigation of pore structure characteristics and adsorption characteristics of coals with different destruction types. Adsorpt. Sci. Technol. 2019, 37, 623–648. [Google Scholar] [CrossRef]

- Chen, X.J.; Zhao, S.; Si, Z.X.; Qi, L.; Kang, N. Fractal characteristics of pore structure of coal with different metamorphic degrees and its effect on gas adsorption characteristics. Coal Sci. Technol. 2020, 48, 118–124. [Google Scholar]

- Zhu, J.; He, F.; Zhang, Y.; Zhang, R.; Zhang, B. Fractal Analysis in Pore Size Distributions of Different Bituminous Coals. Sci. Rep. 2019, 9, 18162. [Google Scholar] [CrossRef]

- Zhang, B.; Zhu, J.; He, F.; Jiang, Y. Compressibility and fractal dimension analysis in the bituminous coal specimens. AIP Adv. 2018, 8, 075118. [Google Scholar] [CrossRef]

- Jiancheng, J.; Miaofeng, Z.; Yaping, L. Geological background and structural deformation characteristics of coal bearing areas in China. J. Anhui Univ. Sci. Technol. 2009, 29, 1–8. [Google Scholar]

- GB40880-2021; Specification for Coal Mine Gas Classification Identification. National Mine Safety Administration: Beijing, China, 2021.

- ASTM. Standard Practice for Preparing Coal Samples for Analysis; American Society for Testing and Materials: West Conshohocken, PA, USA, 2007. [Google Scholar]

- ISO7404-5-1994; Methods for the Petrographic Analysis of Bituminous Coal and Anthracite. International Organization for Standardization: Geneva, Switzerland, 1994.

- GB/T 8899-2013; Determination of Maceral Group Composition and Minerals in Coal. CHINA NATIONAL COAL ASSOCIATION: Beijing, China, 2013.

- GB/T 21650.1-2008; Pore Size Distribution and Porosity of Solid Materials by Mercury Porosimetry and Gas Adsorption—Part 1:Mercury Porosimetry. Particle Characterization including Sieving other Sizing Methods and Sieves. The Standardization Administration of China: Beijing, China, 2008.

- Liu, L.L.; Cui, Z.H.; Wang, J.J.; Xia, Z.H.; Duan, L.J.; Yang, Y.; Li, T. Pore Size Distribution Characteristics of High Rank Coal with Various Grain Sizes. ACS Omega 2020, 31, 19785–19795. [Google Scholar] [CrossRef]

- Sun, B.; Yang, Q.; Zhu, J.; Shao, T.; Yang, Y.; Hou, C.; Li, G. Pore size distributions and pore multifractal characteristics of medium and low-rank coals. Sci. Rep. 2020, 10, 22353. [Google Scholar] [CrossRef]

- Wang, H.; Wang, Y.; Gao, S.; Cheng, J. Classification of low rank coal rank types by geophysical logging. Neijiang Sci. Technol. 2013, 34, 70–71. [Google Scholar]

- Li, W.; Bai, X.; Yang, J.; Chen, W.; Ma, W. Correspondence between mean maximum reflectance of vitrinite and classification of bituminous coals. J. China Coal Soc. 2006, 31, 342–345. [Google Scholar]

- Fu, H.; Tang, D.; Xu, T.; Xu, H.; Tao, S.; Li, S.; Wang, L. Characteristics of pore structure and fractal dimension of low-rank coal: A case study of Lower Jurassic Xishanyao coal in the southern Junggar Basin, NW China. Fuel 2017, 193, 254–264. [Google Scholar] [CrossRef]

- Guo, X.; Yao, Y.; Liu, D. Characteristics of Coal Matrix Compressibility: An Investigation by Mercury Intrusion Porosimetry. Energy Fuels 2014, 28, 3673–3678. [Google Scholar] [CrossRef]

- Han, B.; Qin, Y.; Zhang, Z.; Wang, G.; Yu, P. Study on compressibility of coal based on mercury intrusion test and correction of compressibility. Coal Sci. Technol. 2015, 43, 68–72. [Google Scholar]

- Jin, Y.; Zhao, M.; Liu, S.; Liu, X. Influence of coal matrix compression on pore fractal characteristics based on mercury intrusion method. China Coal 2018, 44, 103–109. [Google Scholar]

- Cai, Y.; Li, Q.; Liu, D.; Zhou, Y.; Lv, D. Insights into matrix compressibility of coals by mercury intrusion porosimetry and N 2 adsorption. Int. J. Coal Geol. 2018, 200, 199–212. [Google Scholar] [CrossRef]

- Li, W.; Liu, H.; Song, X. Multifractal analysis of Hg pore size distributions of tectonically deformed coals. Int. J. Coal Geol. 2015, 144, 138–152. [Google Scholar] [CrossRef]

- Zheng, S.; Yao, Y.; Zhang, S.; Liu, Y.; Yang, J. Insights into Multifractal Characterization of Coals by Mercury Intrusion Porosimetry. Energies 2019, 12, 4743. [Google Scholar] [CrossRef]

- Han, J.; Zhang, H.W.; Li, S.; Song, W.H. The characteristic of in situ stress in outburst area of China. Saf. Sci. 2012, 50, 878–884. [Google Scholar] [CrossRef]

- Chen, P.; Tang, X. Study on low temperature nitrogen adsorption method and micropore characteristics in coal. J. Coal 2001, 29, 28–30. [Google Scholar]

| Coal Samples | Mine | Depth /(m) | Coal Accumulation Period | Gas Grade | Rank |

|---|---|---|---|---|---|

| 1# | Huolinhe Coal Mine, Inner Mongolia | 120 | Late Jurassic Early Cretaceous | Low gas | Lignite |

| 2# | Boertai Coal Mine, Inner Mongolia | 160 | Early Middle Jurassic | Low gas | Long flame coal |

| 3# | luzigou Coal Mine, Shanxi Zhongneng | 260 | Carboniferous Permian | Low gas | Gas coal |

| 4# | Guandi Coal Mine, Shanxi | 350 | Early Middle Jurassic | High gas | Lean coal |

| 5# | Fenxi Hexi Coal Mine, Shanxi | 360 | Carboniferous Permian | High gas | Lean coal |

| 6# | Xinyu Coal, Shanxi | 380 | Carboniferous Permian | High gas | Gas coal |

| 7# | Tashan Coal Mine, Shanxi | 400 | Carboniferous Permian | High gas | Gas coal |

| 8# | Xinfeng Coal Mine, Henan | 436 | Carboniferous Permian | Coal and gas outburst | Anthracite |

| 9# | Baoan Coal Mine, Shanxi | 480 | Late Carboniferous Permian | Coal and gas outburst | Anthracite |

| 10# | Jiulishan Coal Mine, Henan | 500 | Carboniferous Permian | Coal and gas outburst | Anthracite |

| Coal Samples | Mad/ (%) | Ad/ (%) | Vdaf/(%) | FCd/(%) | R0,max/ (%) | Skeleton Density/(g/mL) | Porosity/ (%) | Permeability/(md) |

|---|---|---|---|---|---|---|---|---|

| 1# | 8.96 | 4.82 | 29.11 | 57.11 | 0.42 | 1.47 | 2.64 | 8.87 |

| 2# | 8.96 | 4.82 | 29.11 | 57.11 | 0.52 | 1.44 | 12.87 | 16.97 |

| 3# | 5.24 | 16.34 | 30.50 | 47.92 | 1.19 | 1.30 | 13.45 | 5.71 |

| 4# | 3.88 | 9.92 | 33.32 | 52.88 | 0.65 | 1.24 | 5.60 | 10.89 |

| 5# | 0.36 | 17.79 | 17.19 | 64.66 | 0.69 | 1.37 | 6.39 | 12.27 |

| 6# | 3.50 | 2.13 | 6.03 | 88.34 | 1.51 | 1.23 | 4.02 | 53.88 |

| 7# | 5.04 | 9.10 | 17.88 | 67.98 | 1.76 | 1.28 | 4.24 | 10.40 |

| 8# | 0.92 | 17.86 | 15.30 | 65.92 | 1.90 | 1.39 | 4.92 | 38.22 |

| 9# | 2.01 | 11.78 | 17.93 | 68.28 | 2.62 | 1.35 | 4.08 | 14.08 |

| 10# | 1.41 | 8.58 | 8.06 | 81.95 | 2.64 | 1.37 | 12.83 | 30.33 |

| Coal Samples | Kc/ (10−10 m2·N−1) | ΔV/ (6 nm~10 μm Uncorrected) | ΔV/ (6 nm~10 μm Corrected) | Error/ (%) |

|---|---|---|---|---|

| 1# | 2.41 | 0.0491 | 0.0073 | 85.09 |

| 2# | 2.06 | 0.0129 | 0.0063 | 50.93 |

| 3# | 1.46 | 0.0394 | 0.0156 | 60.41 |

| 4# | 1.96 | 0.0211 | 0.0058 | 72.51 |

| 5# | 1.90 | 0.0119 | 0.0025 | 79.00 |

| 6# | 1.30 | 0.0355 | 0.0179 | 49.58 |

| 7# | 1.21 | 0.1350 | 0.1080 | 20.00 |

| 8# | 1.17 | 0.0306 | 0.0097 | 68.30 |

| 9# | 1.00 | 0.0328 | 0.0109 | 66.77 |

| 10# | 0.99 | 0.0216 | 0.0047 | 78.24 |

| Coal Samples | Total Pore Volume/ (10−2 mL/g) | Specific Surface Area/ (m2/g) | Average Aperture/ (nm) |

|---|---|---|---|

| 1# | 1.21 | 29.90 | 9.60 |

| 2# | 1.54 | 42.32 | 29.20 |

| 3# | 1.58 | 10.12 | 5.50 |

| 4# | 4.51 | 18.17 | 6.90 |

| 5# | 1.63 | 14.57 | 13.50 |

| 6# | 0.49 | 7.31 | 4.60 |

| 7# | 3.00 | 5.19 | 4.50 |

| 8# | 1.27 | 24.35 | 20.42 |

| 9# | 6.28 | 25.42 | 17.95 |

| 10# | 0.90 | 17.65 | 23.19 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, Y.; Cao, J.; Zhang, S.; Li, Z. Analysis of the Pore Structure and Fractal Characteristics of Coal and Gas Outburst Coal Seams Based on Matrix Compression Correction. Sustainability 2023, 15, 12670. https://doi.org/10.3390/su151712670

Gao Y, Cao J, Zhang S, Li Z. Analysis of the Pore Structure and Fractal Characteristics of Coal and Gas Outburst Coal Seams Based on Matrix Compression Correction. Sustainability. 2023; 15(17):12670. https://doi.org/10.3390/su151712670

Chicago/Turabian StyleGao, Yabin, Jing Cao, Shaoqi Zhang, and Ziwen Li. 2023. "Analysis of the Pore Structure and Fractal Characteristics of Coal and Gas Outburst Coal Seams Based on Matrix Compression Correction" Sustainability 15, no. 17: 12670. https://doi.org/10.3390/su151712670

APA StyleGao, Y., Cao, J., Zhang, S., & Li, Z. (2023). Analysis of the Pore Structure and Fractal Characteristics of Coal and Gas Outburst Coal Seams Based on Matrix Compression Correction. Sustainability, 15(17), 12670. https://doi.org/10.3390/su151712670