Comparative Analysis of Multi-Criteria Decision Making and Life Cycle Assessment Methods for Sustainable Evaluation of Concrete Mixtures

Abstract

:1. Introduction

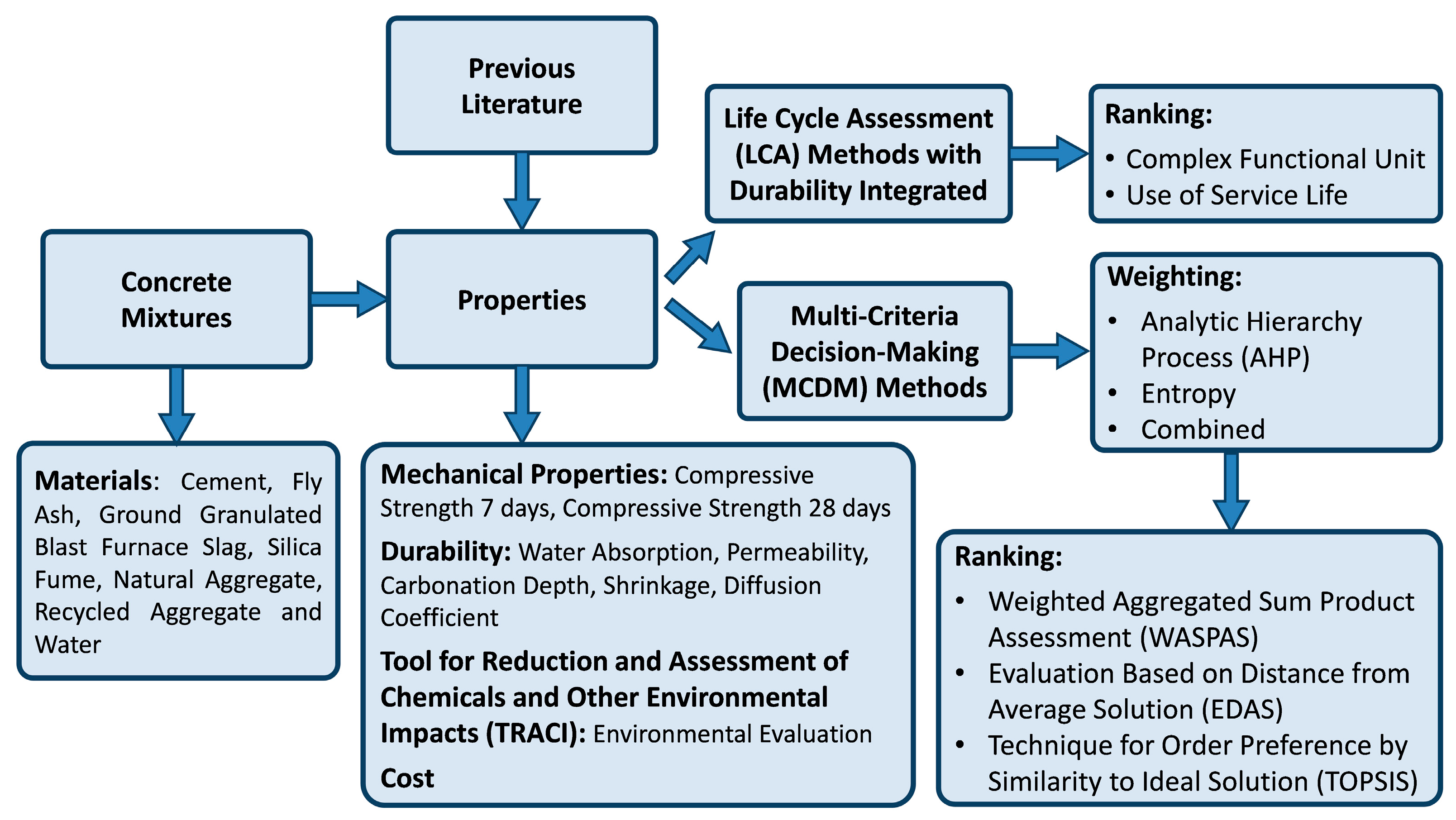

2. Materials and Methods

2.1. Determination of the Mix Design for the Selected Mixtures

2.2. Life Cycle Assessment (LCA) Methods with Integration of Concrete Parameters

2.2.1. LCA Estimation

2.2.2. Goal and Scope Definition

2.2.3. Life Cycle Inventory (LCI)

2.2.4. Life Cycle Impact Assessment (LCIA)

2.3. Cost Analysis

2.4. LCA Methods with Integration of Concrete Parameters

2.4.1. Complex Functional Units

2.4.2. Inclusion of Service Life into the Assessment

2.5. Multi-Criteria Decision-Making Analysis

2.5.1. Weighting of Criteria

- AHP Method

- Entropy Method

- Combined Method

2.5.2. Preference Ranking

- WASPAS

- EDAS

- TOPSIS

3. Results and Discussion

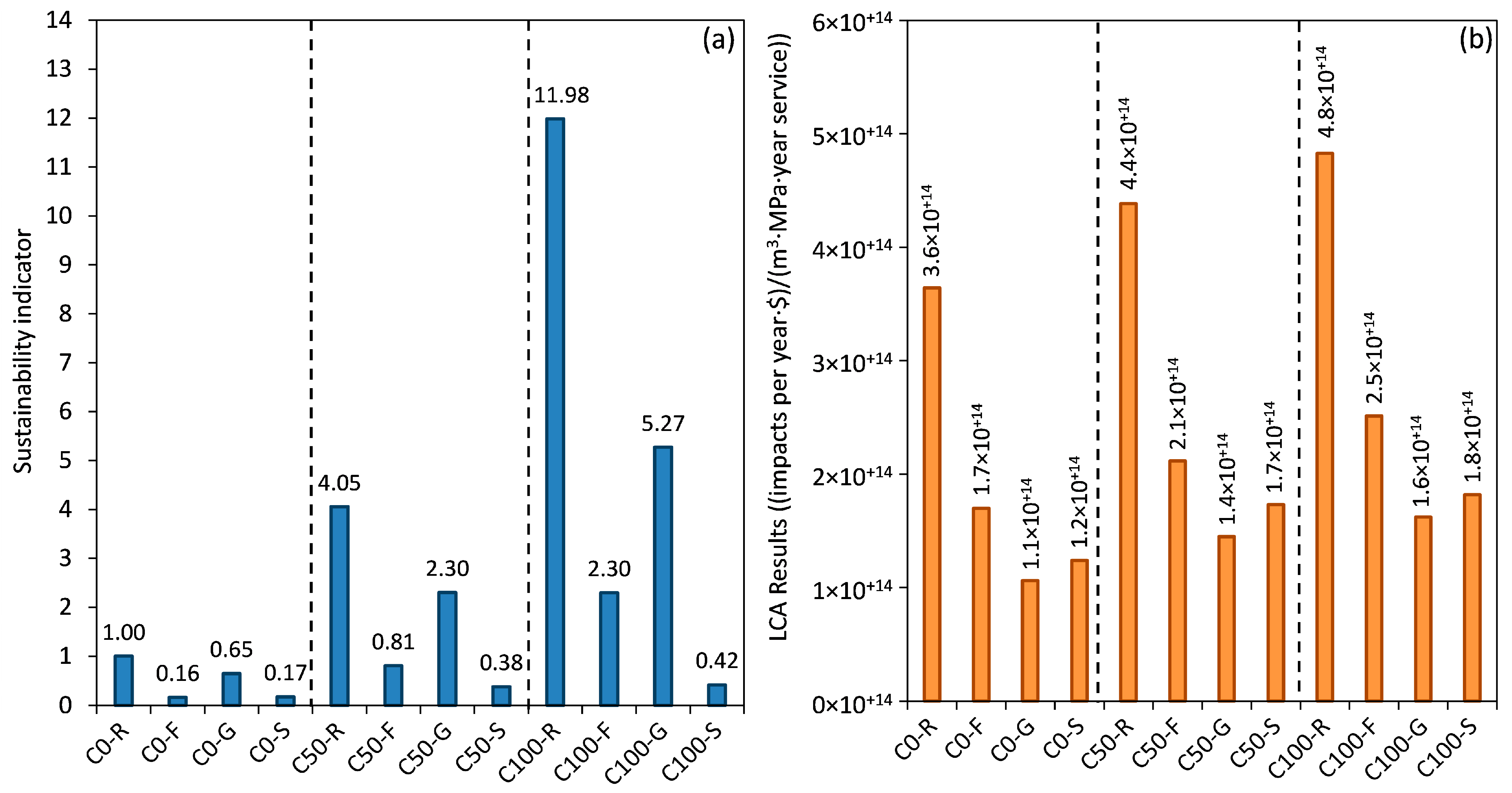

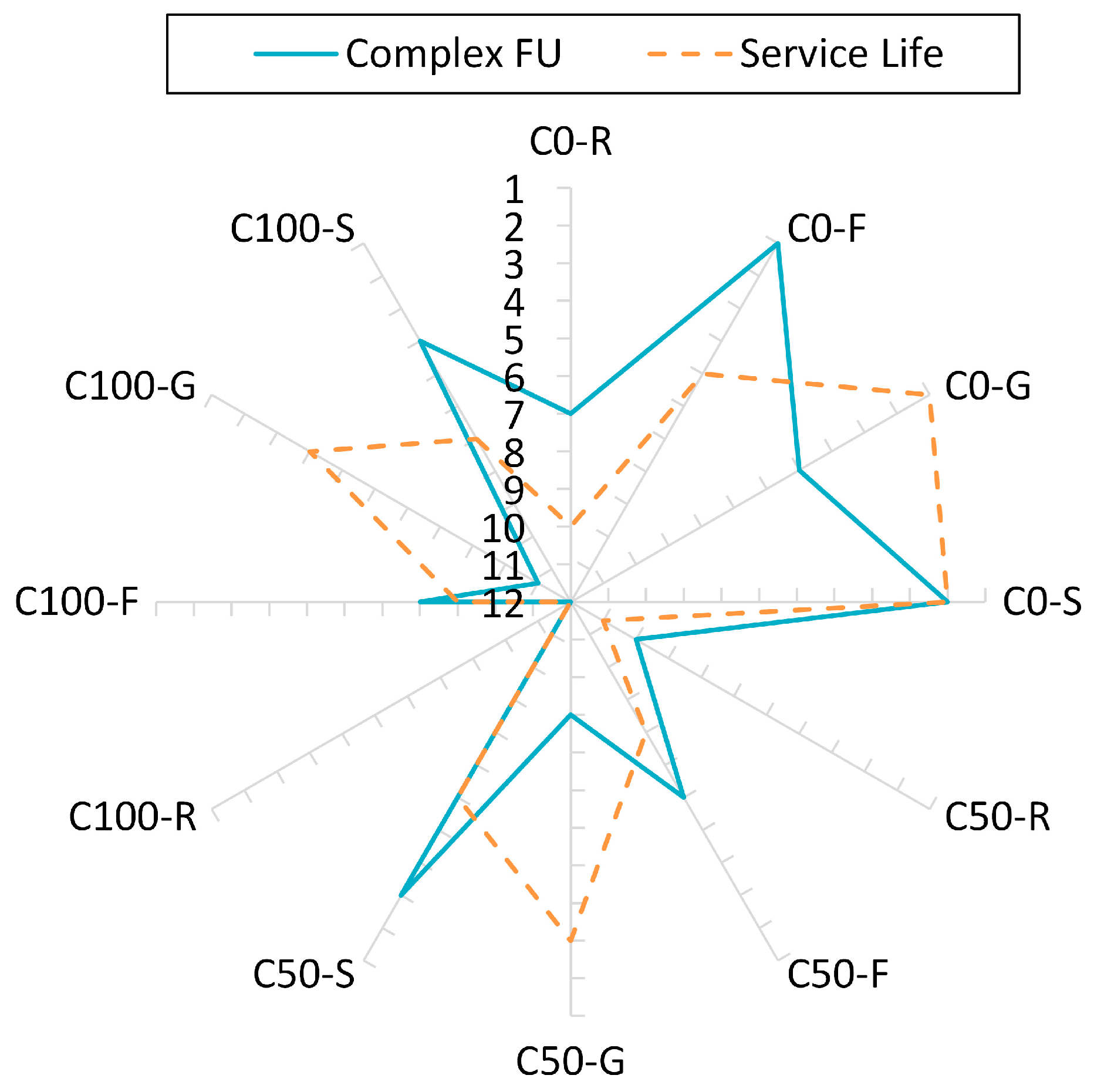

3.1. Results of LCA Methods with Properties Integrated in the Analysis

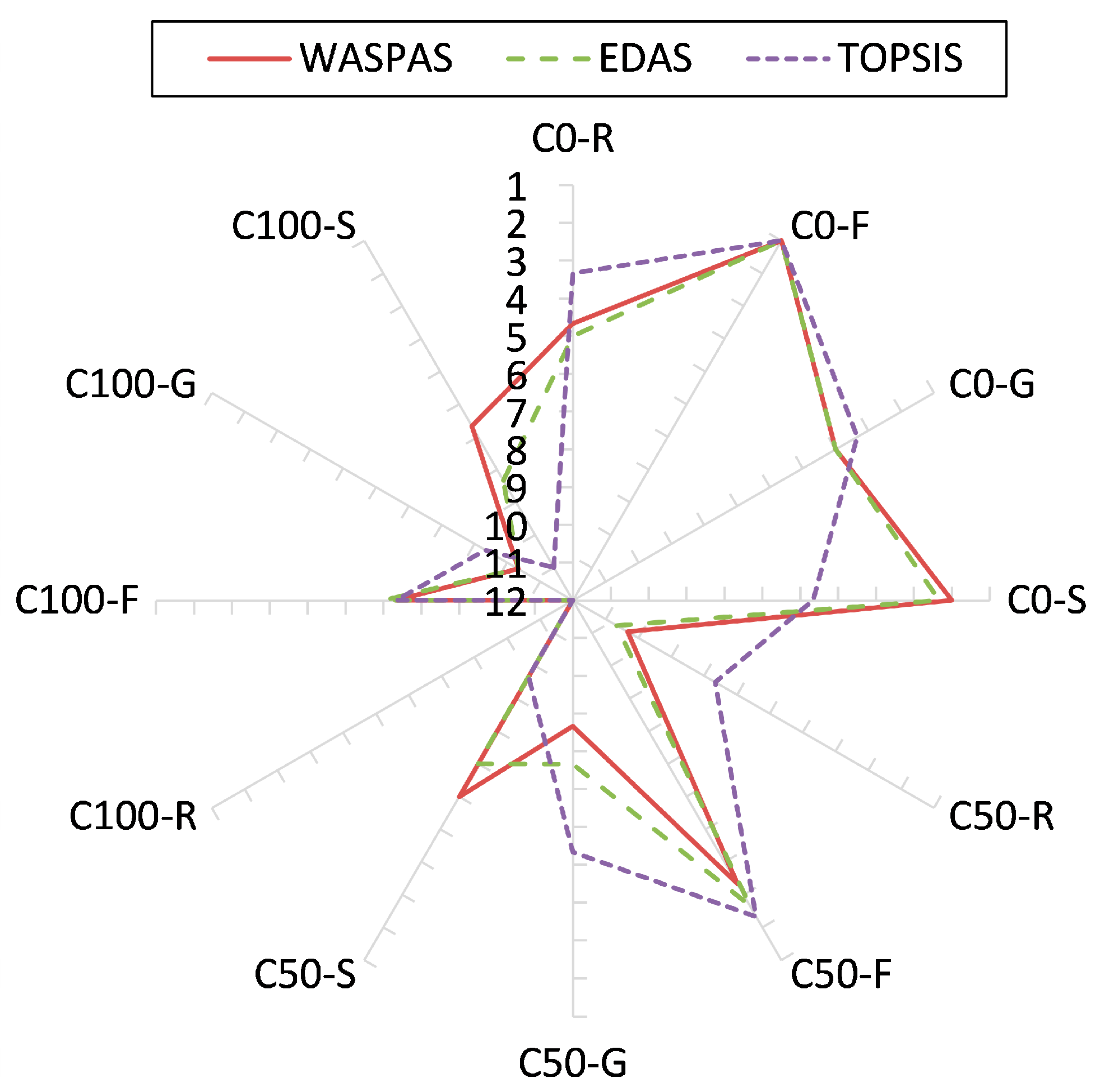

3.2. Multi-Criteria Decision-Making (MCDM) Methods

3.3. LCA Methods with Durability Integrated vs. MCDM Methods

3.4. Sensitivity Analysis

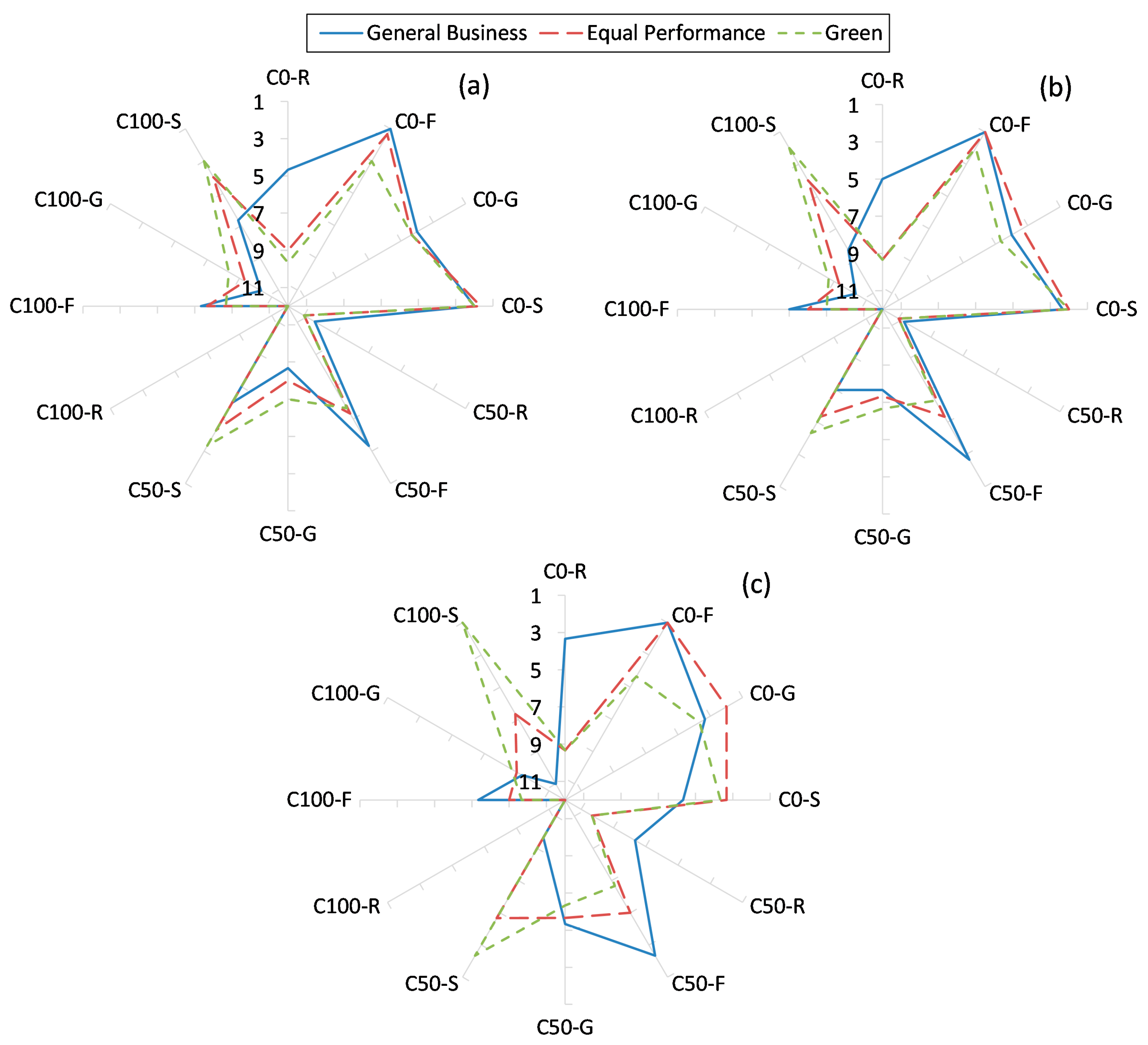

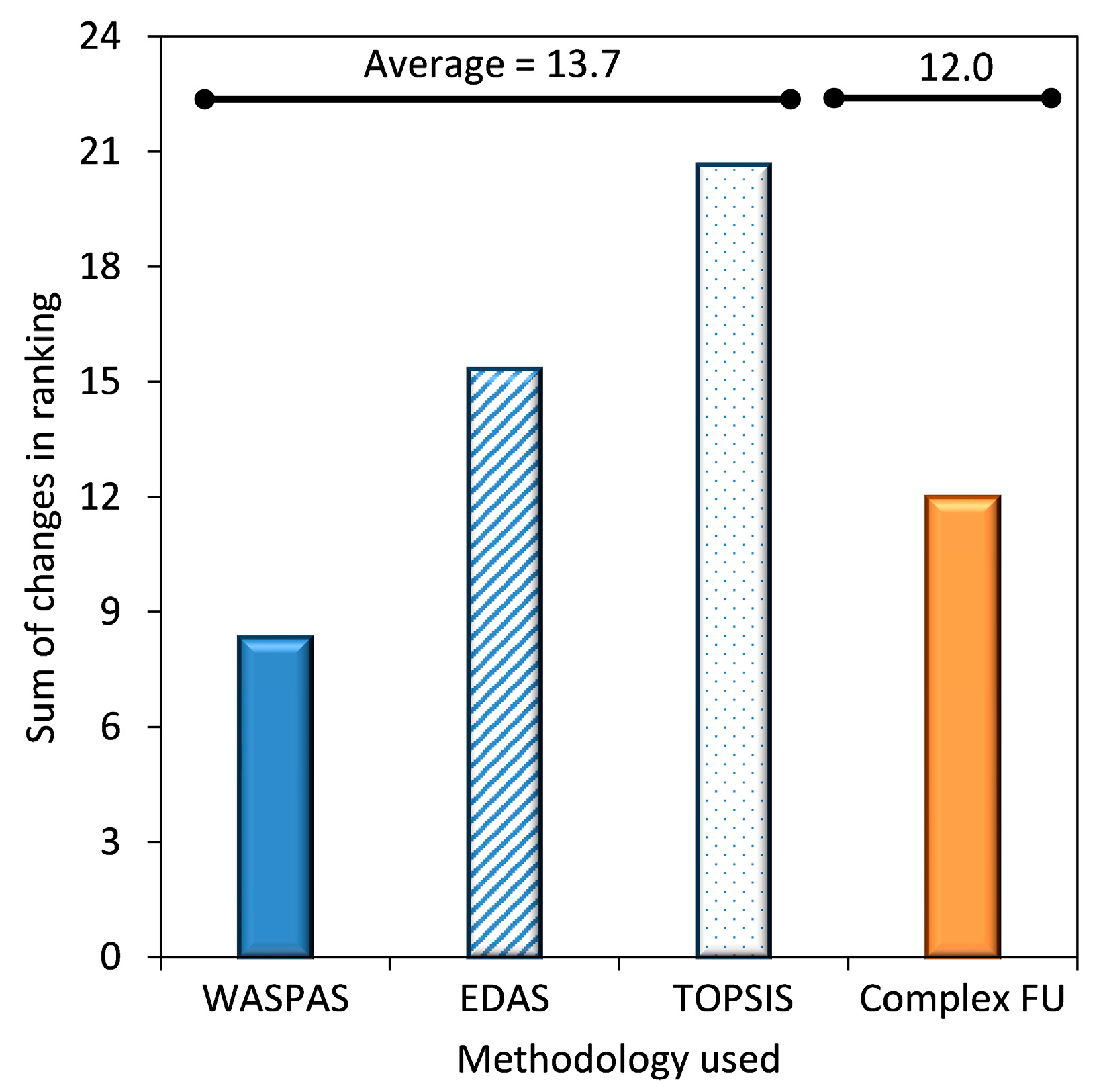

3.4.1. Effect of Weighting Scenarios in the Results of MCDM Methods

3.4.2. Effect of Number of Categories Used in the Analysis

3.4.3. Effect of Number of Concrete Mixtures on the Average Rankings

4. Conclusions

- Unlike MCDM methods, various LCA methods with integrated durability show higher differences, with over twice the standard deviation. This highlights the superior consistency of MCDM methods in analyzing the overall sustainability of concrete materials. Furthermore, MCDM methods offer the advantage of adjustability, allowing for the tailored weighting of properties based on the specific application of the concrete structure. This flexibility enhances the usefulness of MCDM methods in decision-making processes concerning the sustainability of concrete mixtures compared with LCA methods with properties integrated.

- MCDM methods also possess capacity for real-time adaptation through iterative application, thus accommodating evolving project dynamics. Furthermore, MCDM methods advocate active participation by stakeholders throughout the decision-making journey. This collaborative approach fosters transparency, as the decisions made are not solely derived from mathematical calculations but are enriched by inputs from diverse stakeholders. This inclusive process culminates in well-rounded choices aligned with overarching sustainability objectives.

- The results from all the studied methods consistently demonstrate the advantageous impact of SCMs in enhancing the overall sustainable performance of concrete mixtures, considering various parameters in a holistic approach. This reinforces the significance of reducing cement content as a vital step in promoting sustainability in concrete construction. Additionally, the findings underscore the importance of the prudent and careful use of RCA, as varying replacement percentages can lead to diverse outcomes in terms of sustainability, especially when SCMs are also incorporated into the mixture. The interplay between optimal SCM addition and aggregate type highlights the need for a holistic evaluation to determine the most sustainable concrete formulation.

- While various MCDM methods do yield differing results due to their unique reasoning approaches, the choice of a specific MCDM method may not significantly impact the comparison of concrete mixtures, as the observed differences between them were acceptable. This suggests that decision-makers can select a suitable MCDM method based on their preferences and the specific context of the sustainability assessment.

- The sensitivity analysis reveals that weights and the number of concrete parameters play crucial roles in the analysis. This study indicates that both the choice of weight method and the concrete parameters significantly influence the rankings, regardless of the methodology employed. To ensure consistency and enable meaningful comparisons in such analyses, it is recommended to adopt standardized procedures tailored to specific concrete applications. Such standardization will enhance the reliability and relevance of the results, promoting more informed decision-making processes in the context of sustainability assessments for concrete materials.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- International Energy Agency (IEA). Cement Technology Roadmap 2009—Carbon Emissions Reductions up to 2050. 2009. Available online: https://www.iea.org/reports/cement-technology-roadmap-carbon-emissions-reductions-up-to-2050 (accessed on 28 May 2023).

- Skrzypczak, I.; Kokoszka, W.; Zieba, J.; Lesniak, A.; Bajno, D.; Bednarz, L. A Proposal of a Method for Ready-Mixed Concrete Quality Assessment Based on Statistical-Fuzzy Approach. Materials 2020, 13, 5674. [Google Scholar] [CrossRef]

- Andrew, R.M. Global CO2 emissions from cement production, 1928–2017. Earth Syst. Sci. Data 2018, 10, 2213–2239. [Google Scholar] [CrossRef]

- Turner, L.K.; Collins, F.G. Carbon dioxide equivalent (CO2-e) emissions: A comparison between geopolymer and OPC cement concrete. Constr. Build. Mater. 2013, 43, 125–130. [Google Scholar] [CrossRef]

- Li, H.; Liebscher, M.; Yang, J.; Davoodabadi, M.; Li, L.; Du, Y.; Yang, B.; Hempel, S.; Mechtcherine, V. Electrochemical oxidation of recycled carbon fibers for an improved interaction toward alkali-activated composites. J. Clean. Prod. 2022, 368, 133093. [Google Scholar] [CrossRef]

- Li, H.; Wang, L.; Zhang, Y.; Yang, J.; Tsang, D.C.W.; Mechtcherine, V. 3—Biochar for sustainable construction industry. In Current Developments in Biotechnology and Bioengineering; Ngo, H.H., Guo, W., Pandey, A., Varjani, S., Tsang, D.C.W., Eds.; Elsevier: Amsterdam, The Netherlands, 2023; pp. 63–95. [Google Scholar] [CrossRef]

- Martinez-Lage, I.; Vazquez-Burgo, P.; Velay-Lizancos, M. Sustainability evaluation of concretes with mixed recycled aggregate based on holistic approach: Technical, economic and environmental analysis. Waste Manag. 2020, 104, 9–19. [Google Scholar] [CrossRef]

- Moro, C.; Francioso, V.; Schager, M.; Velay-Lizancos, M. TiO2 nanoparticles influence on the environmental performance of natural and recycled mortars: A life cycle assessment. Environ. Impact Assess. Rev. 2020, 84, 106430. [Google Scholar] [CrossRef]

- Marinkovic, S. Life-Cycle Assessment (LCA) of Concrete with Recycled Aggregates (RAs); Woodhead Publishing: Sawston, UK, 2013; pp. 569–604. [Google Scholar] [CrossRef]

- Worrell, E.; Martin, N.; Price, L. Potentials for energy efficiency improvement in the US cement industry. Energy 2000, 25, 1189–1214. [Google Scholar] [CrossRef]

- Madlool, N.A.; Saidur, R.; Rahim, N.A.; Kamalisarvestani, M. An overview of energy savings measures for cement industries. Renew. Sust. Energ. Rev. 2013, 19, 18–29. [Google Scholar] [CrossRef]

- Griffiths, S.; Sovacool, B.K.; Furszyfer Del Rio, D.D.; Foley, A.M.; Bazilian, M.D.; Kim, J.; Uratani, J.M. Decarbonizing the cement and concrete industry: A systematic review of socio-technical systems, technological innovations, and policy options. Renew. Sust. Energ. Rev. 2023, 180, 113291. [Google Scholar] [CrossRef]

- Colangelo, F.; Forcina, A.; Farina, I.; Petrillo, A. Life Cycle Assessment (LCA) of different kinds of concrete containing waste for sustainable construction. Buildings 2018, 8, 70. [Google Scholar] [CrossRef]

- Ding, T.; Xiao, J.; Tam, V.W.Y. A closed-loop life cycle assessment of recycled aggregate concrete utilization in China. Waste Manag. 2016, 56, 367–375. [Google Scholar] [CrossRef] [PubMed]

- De Schepper, M.; Van den Heede, P.; Van Driessche, I.; De Belie, N. Life Cycle Assessment of Completely Recyclable Concrete. Materials 2014, 7, 6010–6027. [Google Scholar] [CrossRef] [PubMed]

- Huang, H.; Ren, X.; Liu, Z.; Wang, F. Development of low-carbon and cost-effective ultra-high performance concrete using carbonated recycled fine aggregate. Constr. Build. Mater. 2023, 399, 132575. [Google Scholar] [CrossRef]

- Moro, C.; Francioso, V.; Lopez-Arias, M.; Velay-Lizancos, M. CO2 curing of mortar with natural and recycled concrete aggregate: An environmental and economic assessment. Constr. Build. Mater. 2023, 399, 132587. [Google Scholar] [CrossRef]

- Gursel, A.P.; Maryman, H.; Ostertag, C. A life-cycle approach to environmental, mechanical, and durability properties of green concrete mixes with rice husk ash. J. Clean. Prod. 2016, 112, 823–836. [Google Scholar] [CrossRef]

- Konečný, P.; Ghosh, P.; Hrabová, K.; Lehner, P.; Teplý, B. Effective methodology of sustainability assessment of concrete mixtures. Mater. Struct. 2020, 53, 98. [Google Scholar] [CrossRef]

- Marinković, S.; Carević, V.; Dragaš, J. The role of service life in Life Cycle Assessment of concrete structures. J. Clean. Prod. 2021, 290, 125610. [Google Scholar] [CrossRef]

- ISO 14040; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization (ISO): Geneva, Switzerland. Available online: https://www.iso.org/standard/37456.html (accessed on 1 May 2023).

- ISO 14044; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organization for Standardization (ISO): Geneva, Switzerland. Available online: https://www.iso.org/standard/38498.html (accessed on 1 May 2023).

- Rahla, K.M.; Mateus, R.; Bragana, L. Comparative sustainability assessment of binary blended concretes using Supplementary Cementitious Materials (SCMs) and Ordinary Portland Cement (OPC). J. Clean. Prod. 2019, 220, 445–459. [Google Scholar] [CrossRef]

- Zhu, H.; Chen, W.; Cheng, S.; Yang, L.; Wang, S.; Xiong, J. Low carbon and high efficiency limestone-calcined clay as supplementary cementitious materials (SCMs): Multi-indicator comparison with conventional SCMs. Constr. Build. Mater. 2022, 341, 127748. [Google Scholar] [CrossRef]

- Tait, M.W.; Cheung, W.M. A comparative cradle-to-gate life cycle assessment of three concrete mix designs. Int. J. Life Cycle Ass. 2016, 21, 847–860. [Google Scholar] [CrossRef]

- Panesar, D.K.; Kanraj, D.; Abualrous, Y. Effect of transportation of fly ash: Life cycle assessment and life cycle cost analysis of concrete. Cem. Concr. Compos. 2019, 99, 214–224. [Google Scholar] [CrossRef]

- Francioso, V.; Lopez-Arias, M.; Moro, C.; Jung, N.; Velay-Lizancos, M. Impact of Curing Temperature on the Life Cycle Assessment of Sugarcane Bagasse Ash as a Partial Replacement of Cement in Mortars. Sustainability 2023, 15, 142. [Google Scholar] [CrossRef]

- Yi, Z.; Wang, T.; Guo, R. Sustainable building material from CO2 mineralization slag: Aggregate for concretes and effect of CO2 curing. J. CO2 Util. 2020, 40, 101196. [Google Scholar] [CrossRef]

- Moro, C.; Francioso, V.; Lopez-Arias, M.; Velay-Lizancos, M. Modification of self-cleaning activity on cement pastes containing nano-TiO2 due to CO2 curing. Constr. Build. Mater. 2022, 330, 127185. [Google Scholar] [CrossRef]

- Shi, X.; Mukhopadhyay, A.; Zollinger, D.; Grasley, Z. Economic input-output life cycle assessment of concrete pavement containing recycled concrete aggregate. J. Clean. Prod. 2019, 225, 414–425. [Google Scholar] [CrossRef]

- Zhang, Y.; Luo, W.; Wang, J.; Wang, Y.; Xu, Y.; Xiao, J. A review of life cycle assessment of recycled aggregate concrete. Constr. Build. Mater. 2019, 209, 115–125. [Google Scholar] [CrossRef]

- Visintin, P.; Xie, T.; Bennett, B. A large-scale life-cycle assessment of recycled aggregate concrete: The influence of functional unit, emissions allocation and carbon dioxide uptake. J. Clean. Prod. 2019, 248, 119243. [Google Scholar] [CrossRef]

- Panesar, D.K.; Seto, K.E.; Churchill, C.J. Impact of the selection of functional unit on the life cycle assessment of green concrete. Int. J. Life Cycle Ass. 2017, 22, 1969–1986. [Google Scholar] [CrossRef]

- Marinkovic, S.; Dragaš, J.; Ignjatovic, I.; Tosic, N. Environmental assessment of green concretes for structural use. J. Clean. Prod. 2017, 154, 633–649. [Google Scholar] [CrossRef]

- Knoeri, C.; Sany-Mengual, E.; Althaus, H.J. Comparative LCA of recycled and conventional concrete for structural applications. Int. J. Life Cycle Ass. 2013, 18, 909–918. [Google Scholar] [CrossRef]

- Li, C.; Li, J.; Ren, Q.; Zheng, Q.; Jiang, Z. Durability of concrete coupled with life cycle assessment: Review and perspective. Cem. Concr. Compos. 2023, 139, 105041. [Google Scholar] [CrossRef]

- Dezhampanah, S.; Nikbin, I.; Charkhtab, S.; Fakhimi, F.; Bazkiaei, S.M.; Mohebbi, R. Environmental performance and durability of concrete incorporating waste tire rubber and steel fiber subjected to acid attack. J. Clean. Prod. 2020, 268, 122216. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, J.; Luo, W.; Wang, J.; Shi, J.; Zhuang, H.; Wang, Y. Effect of compressive strength and chloride diffusion on life cycle CO2 assessment of concrete containing supplementary cementitious materials. J. Clean. Prod. 2019, 218, 450–458. [Google Scholar] [CrossRef]

- Taherdoost, H.; Madanchian, M. Multi-Criteria Decision Making (MCDM) Methods and Concepts. Encyclopedia 2023, 3, 77–87. [Google Scholar] [CrossRef]

- Kurda, R.; de Brito, J.; Silvestre, J.D. CONCRETop—A multi-criteria decision method for concrete optimization. Environ. Impact Assess. Rev. 2019, 74, 73–85. [Google Scholar] [CrossRef]

- Soni, A.; Chakraborty, S.; Kumar Das, P.; Kumar Saha, A. Materials selection of reinforced sustainable composites by recycling waste plastics and agro-waste: An integrated multi-criteria decision making approach. Constr. Build. Mater. 2022, 348, 128608. [Google Scholar] [CrossRef]

- Yoris-Nobile, A.I.; Lizasoain-Arteaga, E.; Slebi-Acevedo, C.J.; Blanco-Fernandez, E.; Alonso-Cañon, S.; Indacoechea-Vega, I.; Castro-Fresno, D. Life cycle assessment (LCA) and multi-criteria decision-making (MCDM) analysis to determine the performance of 3D printed cement mortars and geopolymers. J. Sustain. Cem. Based Mater. 2022, 12, 609–626. [Google Scholar] [CrossRef]

- Shmlls, M.; Abed, M.; Fořt, J.; Horvath, T.; Bozsaky, D. Towards closed-loop concrete recycling: Life cycle assessment and multi-criteria analysis. J. Clean. Prod. 2023, 410, 137179. [Google Scholar] [CrossRef]

- Chen, C.H. A Novel Multi-Criteria Decision-Making Model for Building Material Supplier Selection Based on Entropy-AHP Weighted TOPSIS. Entropy 2020, 22, 259. [Google Scholar] [CrossRef]

- Navarro, I.J.; Martí, J.V.; Yepes, V. Analytic Network Process-Based Sustainability Life Cycle Assessment of Concrete Bridges in Coastal Regions. Sustainability 2022, 14, 688. [Google Scholar] [CrossRef]

- Revilla-Cuesta, V.; Skaf, M.; Espinosa, A.B.; Ortega-López, V. Multi-criteria feasibility of real use of self-compacting concrete with sustainable aggregate, binder and powder. J. Clean. Prod. 2021, 325, 129327. [Google Scholar] [CrossRef]

- Ayan, B.; Abacıoğlu, S.; Basilio, M.P. A Comprehensive Review of the Novel Weighting Methods for Multi-Criteria Decision-Making. Information 2023, 14, 285. [Google Scholar] [CrossRef]

- Limbachiya, M.; Meddah, M.S.; Ouchagour, Y. Performance of Portland/Silica Fume Cement Concrete Produced with Recycled Concrete Aggregate. ACI Mater. J. 2012, 109, 91–100. [Google Scholar] [CrossRef]

- Tüfekçi, M.M.; Çakır, Ö. An Investigation on Mechanical and Physical Properties of Recycled Coarse Aggregate (RCA) Concrete with GGBFS. Int. J. Civ. Eng. 2017, 15, 549–563. [Google Scholar] [CrossRef]

- Habibi, A.; Ramezanianpour, A.M.; Mahdikhani, M.; Bamshad, O. RSM-based evaluation of mechanical and durability properties of recycled aggregate concrete containing GGBFS and silica fume. Constr. Build. Mater. 2021, 270, 121431. [Google Scholar] [CrossRef]

- Çakır, Ö. Experimental analysis of properties of recycled coarse aggregate (RCA) concrete with mineral additives. Constr. Build. Mater. 2014, 68, 17–25. [Google Scholar] [CrossRef]

- Majhi, R.K.; Nayak, A.N.; Mukharjee, B.B. Development of sustainable concrete using recycled coarse aggregate and ground granulated blast furnace slag. Constr. Build. Mater. 2018, 159, 417–430. [Google Scholar] [CrossRef]

- Kurda, R.; de Brito, J.; Silvestre, J.D. Water absorption and electrical resistivity of concrete with recycled concrete aggregates and fly ash. Cem. Concr. Compos. 2019, 95, 169–182. [Google Scholar] [CrossRef]

- Al-Yaqout, A.; El-Hawary, M.; Nouh, K.; Khan, P.B. Corrosion Resistance of Recycled Aggregate Concrete Incorporating Slag. ACI Mater. J. 2020, 117, 111–222. [Google Scholar] [CrossRef]

- Jalilifar, H.; Sajedi, F.; Toosi, V.R. Evaluating the durability of recycled concrete made of coarse recycled aggregate concrete containing silica-fume and natural zeolite. Rev. Construcción 2019, 19, 457–473. [Google Scholar] [CrossRef]

- Zhao, J.; Shumuye, E.D.; Wang, Z.; Bezabih, G.A.; Yi, H. Performance of GGBS Cement Concrete under Natural Carbonation and Accelerated Carbonation Exposure. J. Eng. 2021, 2021, 1–16. [Google Scholar] [CrossRef]

- von Greve-Dierfeld, S.; Lothenbach, B.; Vollpracht, A.; Wu, B.; Huet, B.; Andrade, C.; Medina, C.; Thiel, C.; Gruyaert, E.; Vanoutrive, H.; et al. Understanding the carbonation of concrete with supplementary cementitious materials: A critical review by RILEM TC 281-CCC. Mater. Struct. 2020, 53, 136. [Google Scholar] [CrossRef]

- Ahmad, J.; Martinez-Garcia, R.; Szelag, M.; de-Prado-Gil, J.; Marzouki, R.; Alqurashi, M.; Hussein, E.E. Effects of Steel Fibers (SF) and Ground Granulated Blast Furnace Slag (GGBS) on Recycled Aggregate Concrete. Materials 2021, 14, 7497. [Google Scholar] [CrossRef] [PubMed]

- Limbachiya, M.; Meddah, M.S.; Ouchagour, Y. Use of recycled concrete aggregate in fly-ash concrete. Constr. Build. Mater. 2012, 27, 439–449. [Google Scholar] [CrossRef]

- Yuan, W.B.; Mao, L.; Li, L.Y. A two-step approach for calculating chloride diffusion coefficient in concrete with both natural and recycled concrete aggregates. Sci. Total Environ. 2023, 856, 159197. [Google Scholar] [CrossRef] [PubMed]

- Kou, S.C.; Poon, C.S. Long-term mechanical and durability properties of recycled aggregate concrete prepared with the incorporation of fly ash. Cem. Concr. Compos. 2013, 37, 12–19. [Google Scholar] [CrossRef]

- Ahmed, S.F.U. Properties of Concrete Containing Recycled Fine Aggregate and fly ash. J. Solid Waste Technol. Manag. 2014, 1, 70–78. [Google Scholar] [CrossRef]

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The ecoinvent database version 3 (part I): Overview and methodology. Int. J. Life Cycle Ass. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- Marceau, M.L.; Nisbet, M.A.M.A.; Vangeem, M.G. Life Cycle Inventory of Portland Cement Concrete; PCA R&D Serial No. 3007. 2007. Available online: http://large.stanford.edu/courses/2016/ph240/pourshafeie2/docs/marceau-2007.pdf (accessed on 6 March 2023).

- Kikuchi, T.; Kuroda, Y. Carbon dioxide uptake in demolished and crushed concrete. J. Adv. Concr. Technol. 2011, 9, 115–124. [Google Scholar] [CrossRef]

- Ryberg, M.; Vieira, M.D.M.; Zgola, M.; Bare, J.; Rosenbaum, R.K. Updated US and Canadian normalization factors for TRACI 2.1. Clean Technol. Envir. 2014, 16, 329–339. [Google Scholar] [CrossRef]

- United States Geological Survey (USGS). Mineral Commodity Summaries 2023; United States Geological Survey (USGS): Reston, VA, USA, 2023. [CrossRef]

- Acuity International. CostCenter Cost Engineering Suite. 2022. Available online: https://costcenter.com/about-ptc/ (accessed on 11 March 2023).

- United States Environmental Protection Agency (EPA). Average US Cost of Water. Available online: https://www.epa.gov/watersense/data-and-information-used-watersense#Cost%20of%20Water (accessed on 11 March 2023).

- Ehlen, M.A.; Thomas, M.D.; Bentz, E.C. Life-365 service life prediction modelTM version 2.0. Concr. Int. 2009, 31, 41–46. [Google Scholar]

- Deiveegan, A.; Jayadurgalakshmi, M.; Kumar, T.U. Service Life Prediction of Concrete Structure Using Life-365 Software. Turk. J. Comput. Math. Educ. 2021, 12, 1816–1826. [Google Scholar] [CrossRef]

- Zahid, C.Z.B.; Rezwan, M.M.; Redwan-Ul-Islam; Mohammed, T.U. Service Life Optimization and Life Cycle Assessment of Concrete Using SCMs as Partial Replacement of Cement. J. Phys. Conf. Ser. 2023, 2023, 012008. [Google Scholar] [CrossRef]

- Saaty, T.L. The Analytic Hierarchy Process; McGraw-Hill Company: New York, NY, USA, 1980. [Google Scholar]

- Liu, L.; Zhou, J.; An, X.; Zhang, Y.; Yang, L. Using fuzzy theory and information entropy for water quality assessment in Three Gorges region, China. Expert Syst. Appl. 2010, 37, 2517–2521. [Google Scholar] [CrossRef]

- Qu, W.; Li, J.; Song, W.; Li, X.; Zhao, Y.; Dong, H.; Wang, Y.; Zhao, Q.; Qi, Y. Entropy-Weight-Method-Based Integrated Models for Short-Term Intersection Traffic Flow Prediction. Entropy 2022, 24, 849. [Google Scholar] [CrossRef] [PubMed]

- Ding, X.; Chong, X.; Bao, Z.; Xue, Y.; Zhang, S. Fuzzy Comprehensive Assessment Method Based on the Entropy Weight Method and Its Application in the Water Environmental Safety Evaluation of the Heshangshan Drinking Water Source Area, Three Gorges Reservoir Area, China. Water 2017, 9, 329. [Google Scholar] [CrossRef]

- Wang, E.; Alp, N.; Shi, J.; Wang, C.; Zhang, X.; Chen, H. Multi-criteria building energy performance benchmarking through variable clustering based compromise TOPSIS with objective entropy weighting. Energy 2017, 125, 197–210. [Google Scholar] [CrossRef]

- Mardani, A.; Nilashi, M.; Zakuan, N.; Loganathan, N.; Soheilirad, S.; Saman, M.Z.M.; Ibrahim, O. A systematic review and meta-Analysis of SWARA and WASPAS methods: Theory and applications with recent fuzzy developments. Appl. Soft Comput. 2017, 57, 265–292. [Google Scholar] [CrossRef]

- Keshavarz Ghorabaee, M.; Zavadskas, E.K.; Olfat, L.; Turskis, Z. Multi-Criteria Inventory Classification Using a New Method of Evaluation Based on Distance from Average Solution (EDAS). Informatica 2015, 26, 435–451. [Google Scholar] [CrossRef]

- Keshavarz Ghorabaee, M.; Amiri, M.; Salehi Sadaghiani, J.; Hassani Goodarzi, G. Multiple criteria group decision-making for supplier selection based on COPRAS method with interval type-2 fuzzy sets. Int. J. Adv. Manuf. Technol. 2014, 75, 1115–1130. [Google Scholar] [CrossRef]

- Rashid, T.; Ali, A.; Chu, Y.M. Hybrid BW-EDAS MCDM methodology for optimal industrial robot selection. PLoS ONE 2021, 16, e0246738. [Google Scholar] [CrossRef]

- Hwang, C.-L.; Yoon, K. (Eds.) Methods for Multiple Attribute Decision Making. In Multiple Attribute Decision Making: Methods and Applications A State-of-the-Art Survey; Springer: Berlin/Heidelberg, Germany, 1981; pp. 58–191. [Google Scholar] [CrossRef]

| Mixture | OPC (kg/m3) | FA Class F (kg/m3) | GGBFS (kg/m3) | SF (kg/m3) | FNA * (kg/m3) | CAN * (kg/m3) | FRCA * (kg/m3) | CRCA * (kg/m3) | Water (kg/m3) |

|---|---|---|---|---|---|---|---|---|---|

| C0-R | 400.0 | 0.0 | 0.0 | 0.0 | 734.6 | 1060.3 | 0.0 | 0.0 | 180.0 |

| C0-F | 320.0 | 80.0 | 0.0 | 0.0 | 734.6 | 1060.3 | 0.0 | 0.0 | 180.0 |

| C0-G | 280.0 | 0.0 | 120.0 | 0.0 | 734.6 | 1060.3 | 0.0 | 0.0 | 180.0 |

| C0-S | 360.0 | 0.0 | 0.0 | 40.0 | 734.6 | 1060.3 | 0.0 | 0.0 | 180.0 |

| C50 R | 400.0 | 0.0 | 0.0 | 0.0 | 367.3 | 530.2 | 320.0 | 480.1 | 180.0 |

| C50-F | 320.0 | 80.0 | 0.0 | 0.0 | 367.3 | 530.2 | 320.0 | 480.1 | 180.0 |

| C50-G | 280.0 | 0.0 | 120.0 | 0.0 | 367.3 | 530.2 | 320.0 | 480.1 | 180.0 |

| C50-S | 360.0 | 0.0 | 0.0 | 40.0 | 367.3 | 530.2 | 320.0 | 480.1 | 180.0 |

| C100-R | 400.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 640.1 | 960.1 | 180.0 |

| C100-F | 320.0 | 80.0 | 0.0 | 0.0 | 0.0 | 0.0 | 640.1 | 960.1 | 180.0 |

| C100-G | 280.0 | 0.0 | 120.0 | 0.0 | 0.0 | 0.0 | 640.1 | 960.1 | 180.0 |

| C100-S | 360.0 | 0.0 | 0.0 | 40.0 | 0.0 | 0.0 | 640.1 | 960.1 | 180.0 |

| Mixture | CS * 7 Days (MPa) | CS * 28 Days (MPa) | WA * (%) | Permeability (Ω ∙ m) | CD * (mm) | Shrinkage (με) | DC * (m2/s) |

|---|---|---|---|---|---|---|---|

| C0-R | 41.9 | 47.6 | 4.9 | 98.0 | 5.0 | 280.0 | 3.7 × 10–12 |

| C0-F | 36.7 | 54.9 | 4.2 | 197.0 | 5.3 | 195.0 | 2.4 × 10–12 |

| C0-G | 29.5 | 42.7 | 4.7 | 120.3 | 7.0 | 233.3 | 2.4 × 10–12 |

| C0-S | 45.8 | 56.0 | 4.5 | 140.0 | 7.0 | 190.0 | 1.2 × 10–12 |

| C50 R | 42.0 | 44.4 | 6.9 | 76.5 | 5.3 | 425.0 | 4.6 × 10–12 |

| C50-F | 43.0 | 53.2 | 6.0 | 150.0 | 5.6 | 425.0 | 3.0 × 10–12 |

| C50-G | 31.5 | 40.1 | 6.5 | 98.2 | 7.4 | 354.2 | 3.0 × 10–12 |

| C50-S | 44.6 | 49.3 | 6.8 | 120.0 | 7.4 | 150.0 | 1.5 × 10–12 |

| C100-R | 43.8 | 44.3 | 7.5 | 66.0 | 5.6 | 810.0 | 5.4 × 10–12 |

| C100-F | 40.9 | 50.7 | 6.5 | 135.0 | 6.1 | 695.0 | 3.5 × 10–12 |

| C100-G | 33.5 | 41.6 | 7.3 | 105.6 | 7.8 | 675.0 | 3.5 × 10–12 |

| C100-S | 47.7 | 53.2 | 6.5 | 120.0 | 7.8 | 160.0 | 1.8 × 10–12 |

| Mixture | Unit | AP * (kg SO2 eq.) | GWP * (kg CO2 eq.) | EP * (kg N eq.) | ODP * (kg CFC-11 eq.) | PMF * (kg PM2.5 eq.) | SMF * (kg O3 eq.) | ET-FW * (CTUe) | HT-C * (CTUh) | HT-NC * (CTUh) |

|---|---|---|---|---|---|---|---|---|---|---|

| OPC | kg | 1.6 × 10–3 | 8.8 × 10–1 | 7.6 × 10–4 | 2.3 × 10–9 | 2.2 × 10–4 | 3.4 × 10–2 | 3.3 | 1.9 × 10–8 | 1.1 × 10–7 |

| FA | kg | 1.7 × 10–4 | 2.8 × 10–2 | 8.5 × 10–3 | 6.5 × 10–10 | 2.8 × 10–5 | 4.9 × 10–3 | 4.2 × 10+1 | 6.0 × 10–8 | 3.4 × 10–6 |

| GGBFS | kg | 1.0 × 10–3 | 1.0 × 10–1 | 2.7 × 10–4 | 1.0 × 10–9 | 1.1 × 10–4 | 6.2 × 10–3 | 1.4 | 8.3 × 10–9 | 2.5 × 10–8 |

| SF | kg | 1.7 × 10–5 | 3.4 × 10–3 | 4.0 × 10–6 | 6.2 × 10–11 | 2.4 × 10–6 | 4.7 × 10–4 | 3.4 × 10–2 | 3.2 × 10–10 | 7.6 × 10–10 |

| FNA | kg | 2.4 × 10–4 | 3.5 × 10–2 | 6.9 × 10–5 | 2.6 × 10–10 | 3.1 × 10–5 | 3.5 × 10–3 | 2.2 × 10–1 | 2.2 × 10–9 | 6.7 × 10–9 |

| CNA | kg | 5.4 × 10–5 | 1.0 × 10–2 | 2.8 × 10–5 | 1.1 × 10–10 | 1.2 × 10–5 | 9.2 × 10–4 | 1.3 × 10–1 | 1.8 × 10–9 | 2.3 × 10–9 |

| FRCA | kg | 3.7 × 10–5 | −6.5 × 10–3 | 3.6 × 10–6 | 7.3 × 10–11 | 3.6 × 10–5 | 1.2 × 10–3 | 9.6 × 10–3 | 2.3 × 10–10 | 1.5 × 10–10 |

| CRCA | kg | 3.7 × 10–5 | −6.5 × 10–3 | 3.6 × 10–6 | 7.3 × 10–11 | 3.6 × 10–5 | 1.2 × 10–3 | 9.6 × 10–3 | 2.3 × 10–10 | 1.5 × 10–10 |

| Water | kg | 2.0 × 10–6 | 4.3 × 10–4 | 1.3 × 10–6 | 5.7 × 10–12 | 5.7 × 10–7 | 2.7 × 10–5 | 5.6 × 10–3 | 4.6 × 10–11 | 1.1 × 10–10 |

| Transportation | t × km | 1.0 × 10–3 | 1.9 × 10–1 | 2.0 × 10–4 | 3.1 × 10–9 | 1.2 × 10–4 | 3.0 × 10–2 | 1.7 | 1.4 × 10–8 | 4.5 × 10–8 |

| Concrete Production | m3 | 1.1 × 10–1 | 4.7 | 3.6 × 10–3 | 3.7 × 10–9 | 3.8 × 10–3 | 2.0 | 3.5 | 2.3 × 10–8 | 7.9 × 10–8 |

| Material | Unit Price | Source |

|---|---|---|

| OPC | $130.0/ton | US Geological Survey, 2023 [67] |

| FA Class F | $51.5/ton | Average of several USA providers |

| GGBFS | $53.0/ton | US Geological Survey, 2023 [67] |

| SF | $475.0/ton | Average of several USA providers |

| NA | $11.0/ton | US Geological Survey, 2023 [67] |

| RCA | $24.0/ton | Costcenter by Acuity International, 2022 [68] |

| Water | $1.5/ton | EPA WaterSense, 2019 [69] |

| Mixture | TRACI (Impacts per Year) | Cost ($) |

|---|---|---|

| C0-R | 3.44 × 10+15 | 72.0 |

| C0-F | 3.01 × 10+15 | 65.7 |

| C0-G | 2.75 × 10+15 | 62.8 |

| C0-S | 3.18 × 10+15 | 85.8 |

| C50 R | 3.21 × 10+15 | 81.4 |

| C50-F | 2.77 × 10+15 | 75.1 |

| C50-G | 2.51 × 10+15 | 72.1 |

| C50-S | 2.94 × 10+15 | 95.2 |

| C100-R | 2.97 × 10+15 | 90.7 |

| C100-F | 2.54 × 10+15 | 84.4 |

| C100-G | 2.28 × 10+15 | 81.4 |

| C100-S | 2.71 × 10+15 | 104.5 |

| Importance Scale | Interpretation |

|---|---|

| 1 | Both criteria are equally important |

| 3 | One criterion is slightly more important over other |

| 5 | One criterion is more important over other |

| 7 | One criterion is strongly more important over other |

| 9 | One criterion is extremely more important over other |

| 2, 4, 6, 8 | Intermediate values |

| n | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| RI | 0.00 | 0.00 | 0.58 | 0.90 | 1.12 | 1.24 |

| Parameter | Weighting Method Used | ||

|---|---|---|---|

| AHP | Entropy | Combined | |

| Mechanical Properties | 40.0% | 40.0% | 40.0% |

| Compressive Strength—7 days | 10.0% | 25.2% | 14.5% |

| Compressive Strength—28 days | 30.0% | 14.8% | 25.5% |

| Durability | 10.0% | 10.0% | 10.0% |

| Water Absorption | 1.3% | 0.6% | 0.4% |

| Permeability | 2.7% | 1.3% | 1.8% |

| Carbonation Depth | 0.8% | 0.4% | 0.2% |

| Shrinkage | 0.4% | 5.2% | 1.2% |

| Diffusion Coefficient | 4.7% | 2.6% | 6.5% |

| TRACI | 10.0% | 10.0% | 10.0% |

| Cost | 40.0% | 40.0% | 40.0% |

| Mixture | Method | ||||

|---|---|---|---|---|---|

| WASPAS | EDAS | TOPSIS | Complex FU | Service Life | |

| C0-R | 4.7 | 5.0 | 3.3 | 7.0 | 10.0 |

| C0-F | 1.0 | 1.0 | 1.0 | 1.0 | 5.0 |

| C0-G | 4.0 | 4.0 | 3.3 | 5.0 | 1.0 |

| C0-S | 2.0 | 2.3 | 5.7 | 2.0 | 2.0 |

| C50 R | 10.3 | 10.7 | 7.7 | 10.0 | 11.0 |

| C50-F | 3.3 | 2.7 | 2.3 | 6.0 | 8.0 |

| C50-G | 8.7 | 7.7 | 5.3 | 9.0 | 3.0 |

| C50-S | 6.0 | 7.0 | 9.7 | 3.0 | 6.0 |

| C100-R | 12.0 | 12.0 | 12.0 | 12.0 | 12.0 |

| C100-F | 7.3 | 7.0 | 7.3 | 8.0 | 9.0 |

| C100-G | 10.3 | 10.3 | 9.3 | 11.0 | 4.0 |

| C100-S | 6.7 | 8.3 | 11.0 | 4.0 | 7.0 |

| Mixture | WASPAS | EDAS | TOPSIS | Complex FU | Service Life |

|---|---|---|---|---|---|

| C0-R | 4.0 | 4.0 | 3.7 | 4.0 | 4.0 |

| C0-F | 1.0 | 1.0 | 1.0 | 1.0 | 3.0 |

| C0-G | 3.0 | 2.7 | 2.0 | 3.0 | 2.0 |

| C0-S | 2.0 | 2.3 | 3.3 | 2.0 | 1.0 |

| C50 R | 4.0 | 4.0 | 3.0 | 4.0 | 4.0 |

| C50-F | 1.0 | 1.0 | 1.0 | 2.0 | 3.0 |

| C50-G | 3.0 | 2.3 | 2.0 | 3.0 | 2.0 |

| C50-S | 2.0 | 2.7 | 4.0 | 1.0 | 1.0 |

| C100-R | 4.0 | 4.0 | 3.0 | 4.0 | 4.0 |

| C100-F | 1.3 | 1.0 | 1.0 | 2.0 | 3.0 |

| C100-G | 3.0 | 3.0 | 2.0 | 3.0 | 2.0 |

| C100-S | 1.7 | 2.0 | 4.0 | 1.0 | 1.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moro, C. Comparative Analysis of Multi-Criteria Decision Making and Life Cycle Assessment Methods for Sustainable Evaluation of Concrete Mixtures. Sustainability 2023, 15, 12746. https://doi.org/10.3390/su151712746

Moro C. Comparative Analysis of Multi-Criteria Decision Making and Life Cycle Assessment Methods for Sustainable Evaluation of Concrete Mixtures. Sustainability. 2023; 15(17):12746. https://doi.org/10.3390/su151712746

Chicago/Turabian StyleMoro, Carlos. 2023. "Comparative Analysis of Multi-Criteria Decision Making and Life Cycle Assessment Methods for Sustainable Evaluation of Concrete Mixtures" Sustainability 15, no. 17: 12746. https://doi.org/10.3390/su151712746