Comparative Study of Different Perovskite Active Layers for Attaining Higher Efficiency Solar Cells: Numerical Simulation Approach

Abstract

:1. Introduction

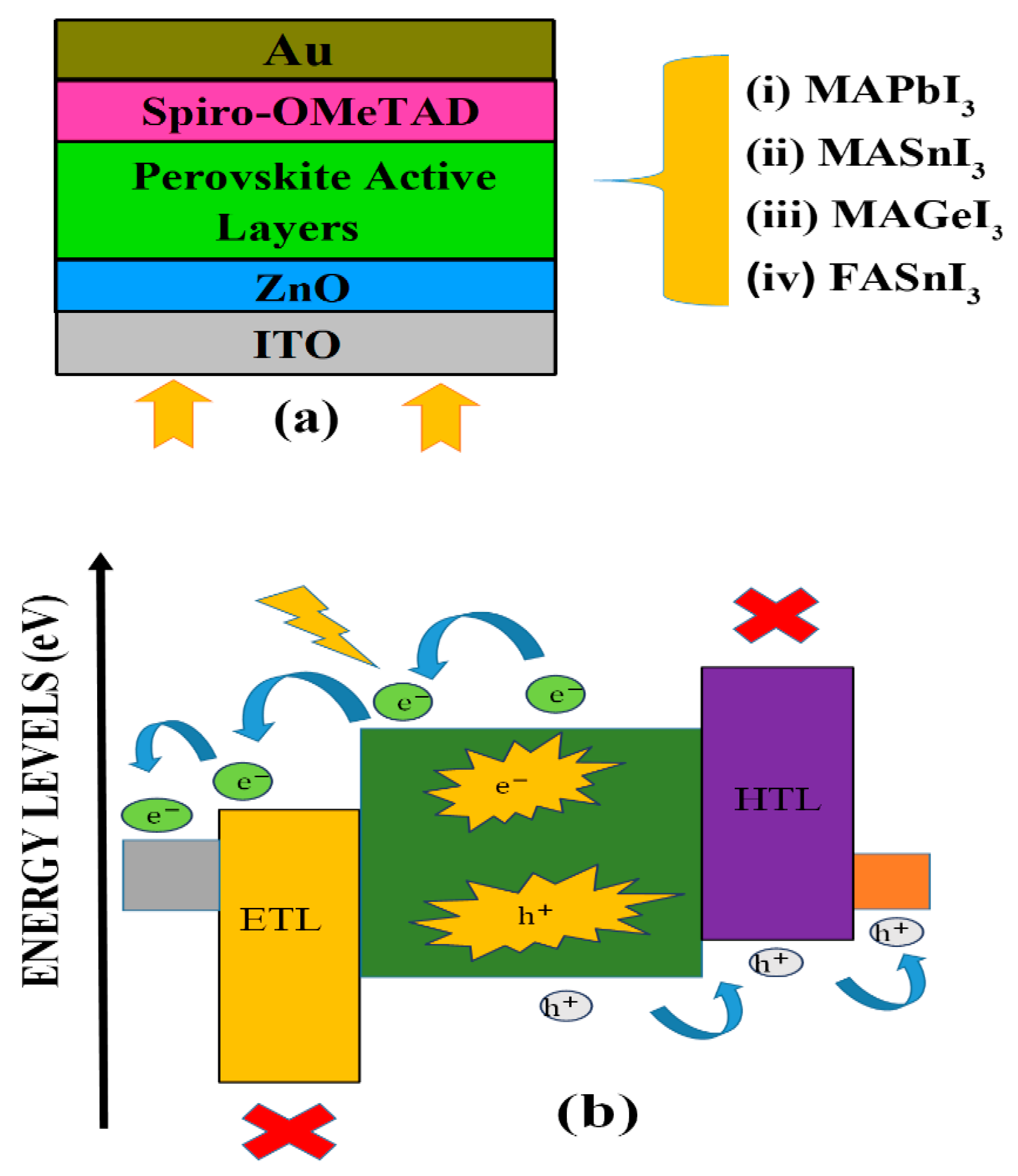

2. Device Structure and Optimization Methodology

3. Mathematical Modeling

4. Results and Discussion

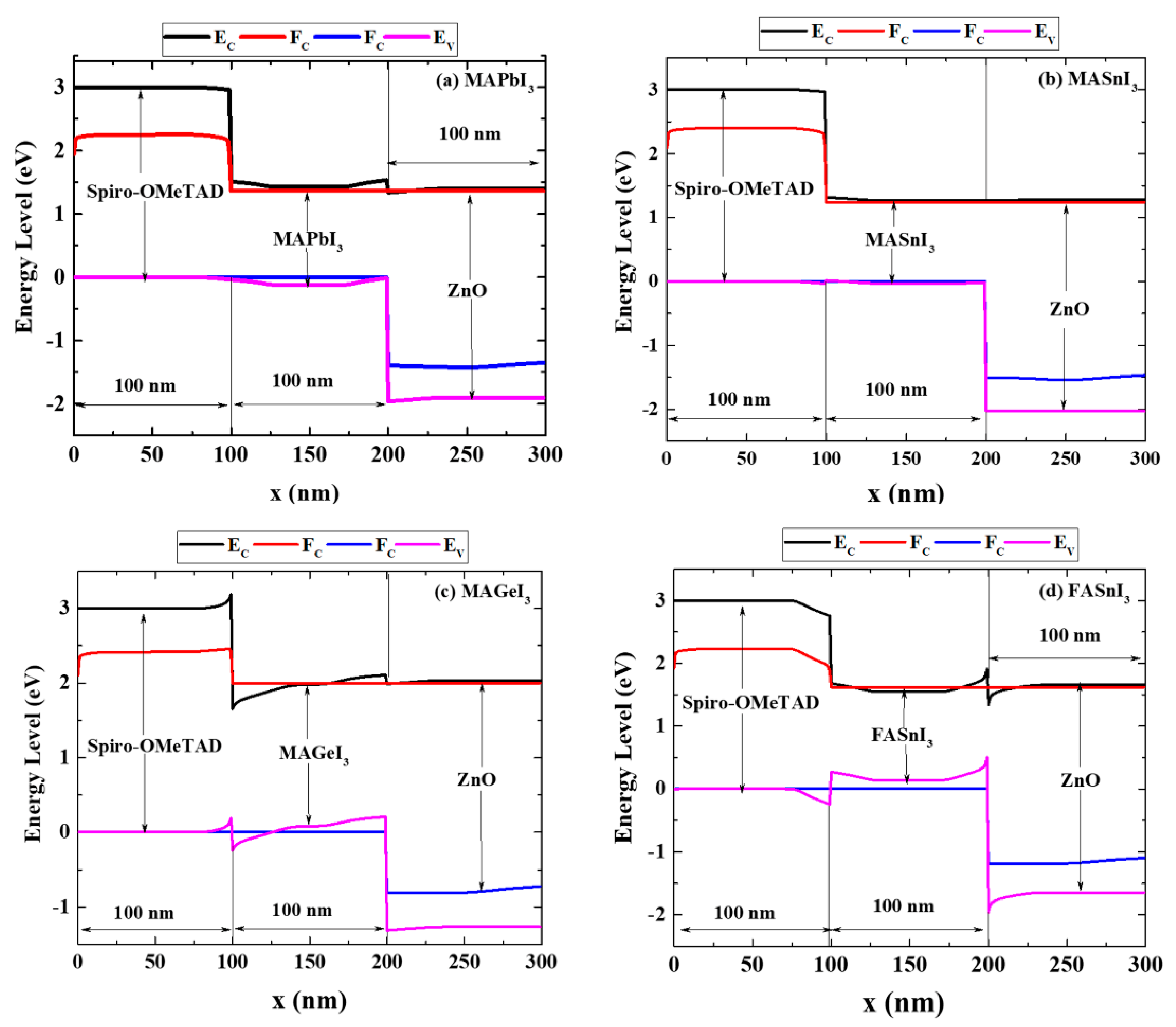

4.1. Study of Band Alignment of the PSC Devices

4.2. Influence of PAL Thickness on the PSC Outputs

4.3. Influence of Temperature on the PCE

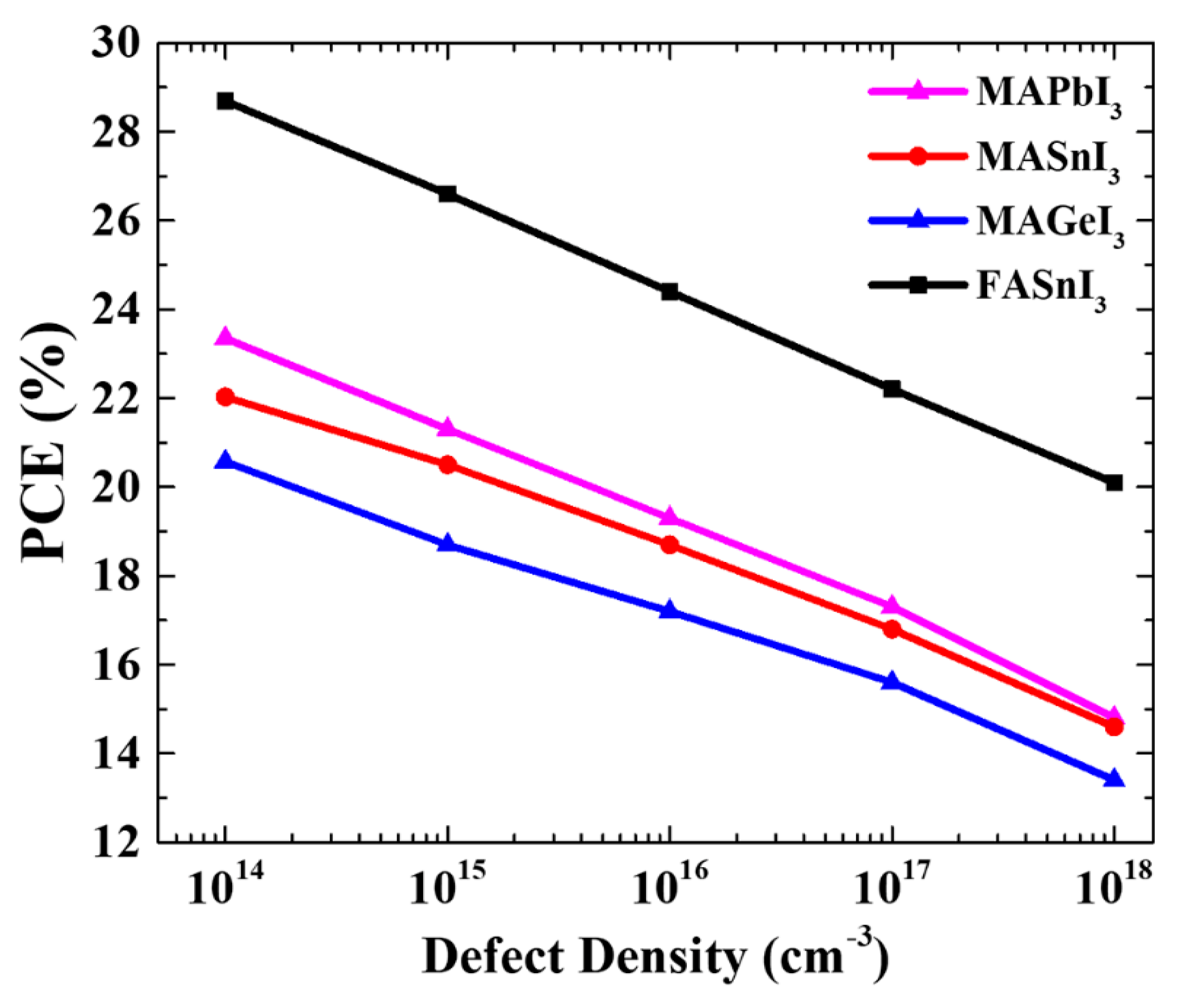

4.4. Influence of the Defect Density on the PCE

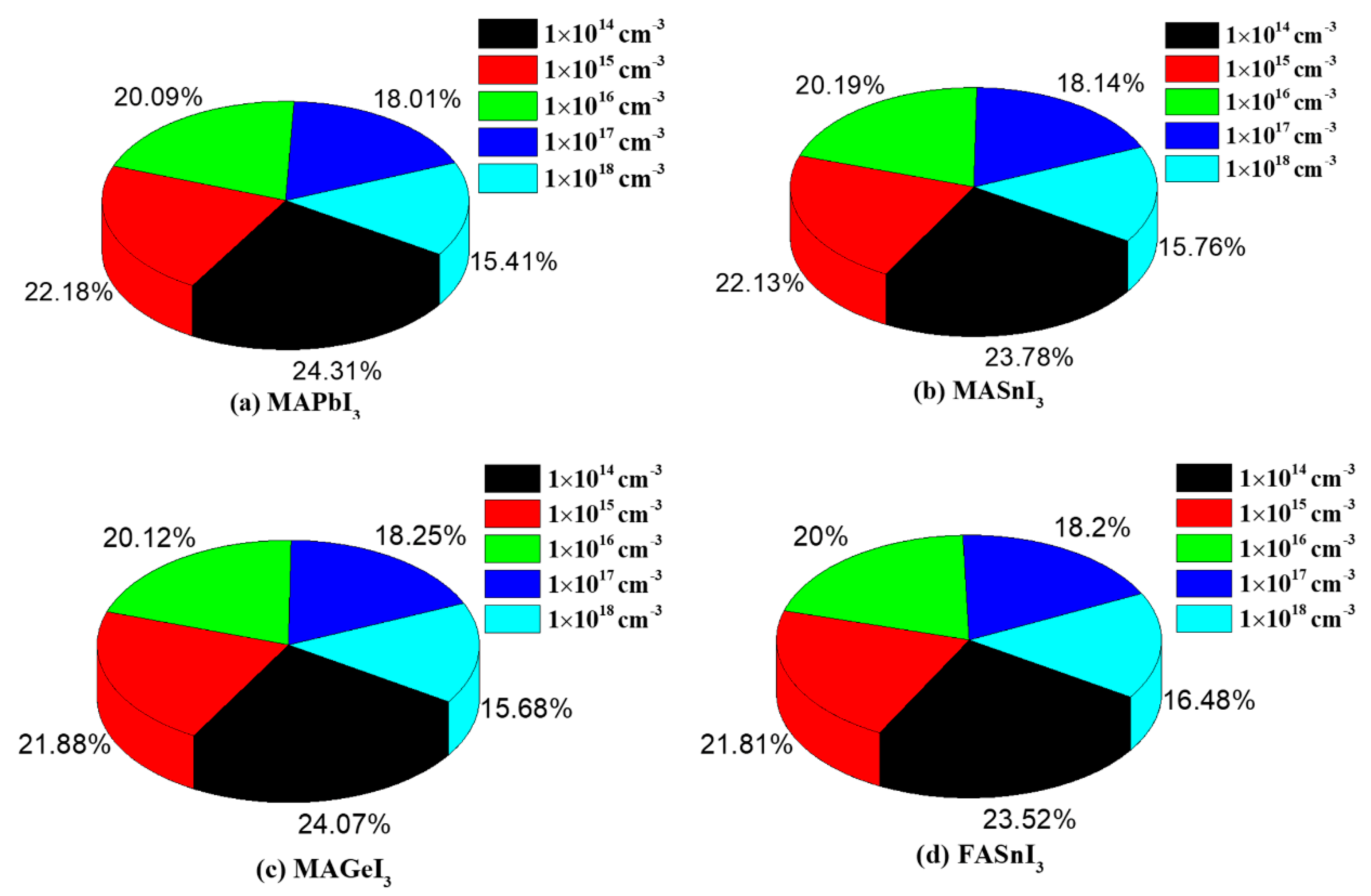

4.5. Pi-Diagram Analysis on the Efficiency of PSC

4.6. EQE and J-V Parameters of PSC

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Snaith, H.J. Perovskites: The Emergence of a New Era for Low-Cost, High-Efficiency Solar Cells. J. Phys. Chem. Lett. 2013, 4, 3623–3630. [Google Scholar] [CrossRef]

- Ebner, M.; Marone, F.; Stampanoni, M.; Wood, V. Visualization and Quantification of Electrochemical and Mechanical Degradation in Li Ion Batteries. Science 2013, 342, 716–720. [Google Scholar] [CrossRef] [PubMed]

- Conings, B.; Drijkoningen, J.; Gauquelin, N.; Babayigit, A.; D’Haen, J.; D’Olieslaeger, L.; Ethirajan, A.; Verbeeck, J.; Manca, J.; Mosconi, E.; et al. Intrinsic Thermal Instability of Methylammonium Lead Trihalide Perovskite. Adv. Energy Mater. 2015, 5, 1500477. [Google Scholar] [CrossRef]

- Isikgor, F.H.; Zhumagali, S.; Merino, L.V.T.; De Bastiani, M.; McCulloch, I.; De Wolf, S. Molecular Engineering of Contact Interfaces for High-Performance Perovskite Solar Cells. Nat. Rev. Mater. 2022, 8, 89–108. [Google Scholar] [CrossRef]

- Bati, A.S.R.; Zhong, Y.L.; Burn, P.L.; Nazeeruddin, M.K.; Shaw, P.E.; Batmunkh, M. Next-Generation Applications for Integrated Perovskite Solar Cells. Commun. Mater. 2023, 4, 2. [Google Scholar] [CrossRef]

- Min, J.; Demchyshyn, S.; Sempionatto, J.R.; Song, Y.; Hailegnaw, B.; Xu, C.; Yang, Y.; Solomon, S.; Putz, C.; Lehner, L.E.; et al. An Autonomous Wearable Biosensor Powered by a Perovskite Solar Cell. Nat. Electron. 2023. [Google Scholar] [CrossRef]

- Li, G.; Su, Z.; Canil, L.; Hughes, D.; Aldamasy, M.H.; Dagar, J.; Trofimov, S.; Wang, L.; Zuo, W.; Jerónimo-Rendon, J.J.; et al. Highly Efficient P-i-n Perovskite Solar Cells That Endure Temperature Variations. Science 2023, 379, 399–403. [Google Scholar] [CrossRef]

- Yang, M.; Tian, T.; Fang, Y.; Li, W.-G.; Liu, G.; Feng, W.; Xu, M.; Wu, W.-Q. Reducing Lead Toxicity of Perovskite Solar Cells with a Built-in Supramolecular Complex. Nat. Sustain. 2023. [Google Scholar] [CrossRef]

- Xiao, H.; Zuo, C.; Yan, K.; Jin, Z.; Cheng, Y.; Tian, H.; Xiao, Z.; Liu, F.; Ding, Y.; Ding, L. Highly Efficient and Air-Stable Inorganic Perovskite Solar Cells Enabled by Polylactic Acid Modification. Adv. Energy Mater. 2023. [Google Scholar] [CrossRef]

- Park, S.M.; Wei, M.; Xu, J.; Atapattu, H.R.; Eickemeyer, F.T.; Darabi, K.; Grater, L.; Yang, Y.; Liu, C.; Teale, S.; et al. Engineering Ligand Reactivity Enables High-Temperature Operation of Stable Perovskite Solar Cells. Science 2023, 381, 209–215. [Google Scholar] [CrossRef]

- Mohammed, M.K.A.; Al-Mousoi, A.K.; Kumar, A.; Katae, A.R.J.; Khaleel, O.A.; Ahmed, D.S.; Hossain, M.K. Fluorinated Carbon Nanotubes: A Low-Cost Hole Transport Layer for Perovskite Solar Cells. J. Mater. Sci. 2023, 58, 11748–11760. [Google Scholar] [CrossRef]

- Peng, W.; Mao, K.; Cai, F.; Meng, H.; Zhu, Z.; Li, T.; Yuan, S.; Xu, Z.; Feng, X.; Xu, J.; et al. Reducing Nonradiative Recombination in Perovskite Solar Cells with a Porous Insulator Contact. Science 2023, 379, 683–690. [Google Scholar] [CrossRef] [PubMed]

- McMeekin, D.P.; Holzhey, P.; Fürer, S.O.; Harvey, S.P.; Schelhas, L.T.; Ball, J.M.; Mahesh, S.; Seo, S.; Hawkins, N.; Lu, J.; et al. Intermediate-Phase Engineering via Dimethylammonium Cation Additive for Stable Perovskite Solar Cells. Nat. Mater. 2023, 22, 73–83. [Google Scholar] [CrossRef]

- Liu, M.; Johnston, M.B.; Snaith, H.J. Efficient Planar Heterojunction Perovskite Solar Cells by Vapour Deposition. Nature 2013, 501, 395–398. [Google Scholar] [CrossRef]

- Riaz, M.; Earles, S.K.; Kadhim, A.; Azzahrani, A. Computer Analysis of Microcrystalline Silicon Hetero-Junction Solar Cell with Lumerical FDTD/DEVICE. Int. J. Comput. Mater. Sci. Eng. 2017, 06, 1750017. [Google Scholar] [CrossRef]

- Ahmed, M.I.; Habib, A.; Javaid, S.S. Perovskite Solar Cells: Potentials, Challenges, and Opportunities. Int. J. Photoenergy 2015, 2015, 1–13. [Google Scholar] [CrossRef]

- (Balu) Balachandran, U.; Lee, T.H.; Park, C.Y.; Emerson, J.E.; Picciolo, J.J.; Dorris, S.E. Dense Cermet Membranes for Hydrogen Separation. Sep. Purif. Technol. 2014, 121, 54–59. [Google Scholar] [CrossRef]

- Tchognia, J.H.N.; Arba, Y.; Dakhsi, K.; Hartiti, B.; Ridah, A.; Tchognia, J.H.N.; Ndjaka, J.-M.; Thevenin, P. Optimization of the Output Parameters in Kesterite-Based Solar Cells by AMPS-1D. In Proceedings of the 2015 3rd International Renewable and Sustainable Energy Conference (IRSEC), Marrakech, Morocco, 10–13 December 2015; pp. 1–6. [Google Scholar]

- Kojima, A.; Teshima, K.; Shirai, Y.; Miyasaka, T. Organometal Halide Perovskites as Visible-Light Sensitizers for Photovoltaic Cells. J. Am. Chem. Soc. 2009, 131, 6050–6051. [Google Scholar] [CrossRef]

- Kwon, H.-C.; Ma, S.; Yun, S.-C.; Jang, G.; Yang, H.; Moon, J. A Nanopillar-Structured Perovskite-Based Efficient Semitransparent Solar Module for Power-Generating Window Applications. J. Mater. Chem. A 2020, 8, 1457–1468. [Google Scholar] [CrossRef]

- Noh, J.H.; Im, S.H.; Heo, J.H.; Mandal, T.N.; Seok, S. Il Chemical Management for Colorful, Efficient, and Stable Inorganic–Organic Hybrid Nanostructured Solar Cells. Nano Lett. 2013, 13, 1764–1769. [Google Scholar] [CrossRef]

- Tan, H.Q.; Zhao, X.; Birgersson, E.; Lin, F.; Xue, H. Optoelectronic Modeling and Sensitivity Analysis of a Four-Terminal All-Perovskite Tandem Solar Cell – Identifying Pathways to Improve Efficiency. Sol. Energy 2021, 216, 589–600. [Google Scholar] [CrossRef]

- Jiang, Y.; Juarez-Perez, E.J.; Ge, Q.; Wang, S.; Leyden, M.R.; Ono, L.K.; Raga, S.R.; Hu, J.; Qi, Y. Post-Annealing of MAPbI3 Perovskite Films with Methylamine for Efficient Perovskite Solar Cells. Mater. Horiz. 2016, 3, 548–555. [Google Scholar] [CrossRef]

- Chen, L.-C.; Weng, C.-Y. Optoelectronic Properties of MAPbI3 Perovskite/Titanium Dioxide Heterostructures on Porous Silicon Substrates for Cyan Sensor Applications. Nanoscale Res. Lett. 2015, 10, 404. [Google Scholar] [CrossRef] [PubMed]

- Azri, F.; Meftah, A.; Sengouga, N.; Meftah, A. Electron and Hole Transport Layers Optimization by Numerical Simulation of a Perovskite Solar Cell. Sol. Energy 2019, 181, 372–378. [Google Scholar] [CrossRef]

- Raoui, Y.; Ez-Zahraouy, H.; Tahiri, N.; El Bounagui, O.; Ahmad, S.; Kazim, S. Performance Analysis of MAPbI3 Based Perovskite Solar Cells Employing Diverse Charge Selective Contacts: Simulation Study. Sol. Energy 2019, 193, 948–955. [Google Scholar] [CrossRef]

- Bhattarai, S.; Das, T.D. Optimization of Carrier Transport Materials for the Performance Enhancement of the MAGeI3 Based Perovskite Solar Cell. Sol. Energy 2021, 217, 200–207. [Google Scholar] [CrossRef]

- Zhao, F.; Feng, Y.; Feng, W. Germanium-based Monoelemental and Binary Two-dimensional Materials: Theoretical and Experimental Investigations and Promising Applications. InfoMat 2022, 4, e12365. [Google Scholar] [CrossRef]

- Guo, H.; Hou, F.; Ren, X.; Ning, X.; Wang, Y.; Yang, H.; Wei, J.; Guo, J.; Li, T.; Zhu, C.; et al. Recent Progresses on Transparent Electrodes and Active Layers Toward Neutral, Color Semitransparent Perovskite Solar Cells. Sol. RRL 2023. [Google Scholar] [CrossRef]

- Meng, X.; Lin, J.; Liu, X.; He, X.; Wang, Y.; Noda, T.; Wu, T.; Yang, X.; Han, L. Highly Stable and Efficient FASnI3-Based Perovskite Solar Cells by Introducing Hydrogen Bonding. Adv. Mater. 2019, 31, 1903721. [Google Scholar] [CrossRef]

- Kayesh, M.E.; Chowdhury, T.H.; Matsuishi, K.; Kaneko, R.; Kazaoui, S.; Lee, J.-J.; Noda, T.; Islam, A. Enhanced Photovoltaic Performance of FASnI3-Based Perovskite Solar Cells with Hydrazinium Chloride Coadditive. ACS Energy Lett. 2018, 3, 1584–1589. [Google Scholar] [CrossRef]

- Gu, W.; Xu, X.; Chen, J.; Ma, B.; Qin, M.; Zhu, W.; Qian, J.; Qin, Z.; Shen, W.; Lu, Y.; et al. Oriented Perovskite Crystal towards Efficient Charge Transport in FASnI3 Perovskite Solar Cells. Sol. RRL 2020, 4, 2000153. [Google Scholar] [CrossRef]

- Meng, X.; Wang, Y.; Lin, J.; Liu, X.; He, X.; Barbaud, J.; Wu, T.; Noda, T.; Yang, X.; Han, L. Surface-Controlled Oriented Growth of FASnI3 Crystals for Efficient Lead-Free Perovskite Solar Cells. Joule 2020, 4, 902–912. [Google Scholar] [CrossRef]

- Zillner, J.; Boyen, H.; Schulz, P.; Hanisch, J.; Gauquelin, N.; Verbeeck, J.; Küffner, J.; Desta, D.; Eisele, L.; Ahlswede, E.; et al. The Role of SnF2 Additive on Interface Formation in All Lead-Free FASnI3 Perovskite Solar Cells. Adv. Funct. Mater. 2022, 32, 2109649. [Google Scholar] [CrossRef]

- Liu, X.; Wu, T.; Chen, J.-Y.; Meng, X.; He, X.; Noda, T.; Chen, H.; Yang, X.; Segawa, H.; Wang, Y.; et al. Templated Growth of FASnI3 Crystals for Efficient Tin Perovskite Solar Cells. Energy Environ. Sci. 2020, 13, 2896–2902. [Google Scholar] [CrossRef]

- Chiang, C.-H.; Lin, J.-W.; Wu, C.-G. One-Step Fabrication of a Mixed-Halide Perovskite Film for a High-Efficiency Inverted Solar Cell and Module. J. Mater. Chem. A 2016, 4, 13525–13533. [Google Scholar] [CrossRef]

- Dong, Z.; Li, W.; Wang, H.; Jiang, X.; Liu, H.; Zhu, L.; Chen, H. High-Temperature Perovskite Solar Cells. Sol. RRL 2021, 5, 2100370. [Google Scholar] [CrossRef]

- Devi, C.; Mehra, R. Device Simulation of Lead-Free MASnI3 Solar Cell with CuSbS2 (Copper Antimony Sulfide). J. Mater. Sci. 2019, 54, 5615–5624. [Google Scholar] [CrossRef]

- Thakur, A.; Singh, D.; Kaur Gill, S. Numerical Simulations of 26.11% Efficient Planar CH3NH3PbI3 Perovskite n-i-p Solar Cell. Mater. Today Proc. 2022, 71, 195–201. [Google Scholar] [CrossRef]

- Pandey, R.; Khanna, A.; Singh, K.; Patel, S.K.; Singh, H.; Madan, J. Device Simulations: Toward the Design of >13% Efficient PbS Colloidal Quantum Dot Solar Cell. Sol. Energy 2020, 207, 893–902. [Google Scholar] [CrossRef]

- Dureja, T.; Garg, A.; Bhalla, S.; Bhutani, D.; Khanna, A. Double Lead-Free Perovskite Solar Cell for 19.9% Conversion Efficiency: A SCAPS-1D Based Simulation Study. Mater. Today Proc. 2022, 71, 239–242. [Google Scholar] [CrossRef]

- Divitini, G.; Cacovich, S.; Matteocci, F.; Cinà, L.; Di Carlo, A.; Ducati, C. In Situ Observation of Heat-Induced Degradation of Perovskite Solar Cells. Nat. Energy 2016, 1, 15012. [Google Scholar] [CrossRef]

- Li, X.; Yang, J.; Jiang, Q.; Lai, H.; Li, S.; Xin, J.; Chu, W.; Hou, J. Low-Temperature Solution-Processed ZnSe Electron Transport Layer for Efficient Planar Perovskite Solar Cells with Negligible Hysteresis and Improved Photostability. ACS Nano 2018, 12, 5605–5614. [Google Scholar] [CrossRef]

- Mathur, A.S.; Dubey, S.; Nidhi; Singh, B.P. Study of Role of Different Defects on the Performance of CZTSe Solar Cells Using SCAPS. Optik 2020, 206, 163245. [Google Scholar] [CrossRef]

- Tan, H.; Che, F.; Wei, M.; Zhao, Y.; Saidaminov, M.I.; Todorović, P.; Broberg, D.; Walters, G.; Tan, F.; Zhuang, T.; et al. Dipolar Cations Confer Defect Tolerance in Wide-Bandgap Metal Halide Perovskites. Nat. Commun. 2018, 9, 3100. [Google Scholar] [CrossRef]

- Alipour, H.; Ghadimi, A. Optimization of Lead-Free Perovskite Solar Cells in Normal-Structure with WO3 and Water-Free PEDOT: PSS Composite for Hole Transport Layer by SCAPS-1D Simulation. Opt. Mater. 2021, 120, 111432. [Google Scholar] [CrossRef]

- Hossain, M.K.; Toki, G.F.I.; Kuddus, A.; Mohammed, M.K.A.; Pandey, R.; Madan, J.; Bhattarai, S.; Rahman, M.F.; Dwivedi, D.K.; Amami, M.; et al. Optimization of the Architecture of Lead-Free CsSnCl3-Perovskite Solar Cells for Enhancement of Efficiency: A Combination of SCAPS-1D and WxAMPS Study. Mater. Chem. Phys. 2023, 308, 128281. [Google Scholar] [CrossRef]

- Roy, P.; Kumar Sinha, N.; Tiwari, S.; Khare, A. A Review on Perovskite Solar Cells: Evolution of Architecture, Fabrication Techniques, Commercialization Issues and Status. Sol. Energy 2020, 198, 665–688. [Google Scholar] [CrossRef]

- Rahman, M.S.; Miah, S.; Marma, M.S.W.; Ibrahim, M. Numerical Simulation of CsSnI3-Based Perovskite Solar Cells: Influence of Doped-ITO Front Contact. In Proceedings of the 2020 IEEE REGION 10 CONFERENCE (TENCON), Osaka, Japan, 16–19 November 2020; pp. 140–145. [Google Scholar] [CrossRef]

- Khatoon, S.; Chakraborty, V.; Yadav, S.K.; Diwakar, S.; Singh, J.; Singh, R.B. Simulation Study of CsPbIxBr1-x and MAPbI3 Heterojunction Solar Cell Using SCAPS-1D. Sol. Energy 2023, 254, 137–157. [Google Scholar] [CrossRef]

- Zhang, X.; Zhou, H.; Hu, C.; Zhao, Y.; Ma, X.; Wu, J.; Qi, Y.; Fang, W.; Jia, S.; Yu, J. Performance Analysis of All-Inorganic Cs3Sb2I9 Perovskite Solar Cells with Micro-Offset Energy Level Structure by SCAPS-1D Simulation and First-Principles Calculation. Sol. Energy Mater. Sol. Cells 2023, 260, 112487. [Google Scholar] [CrossRef]

- Mushtaq, S.; Tahir, S.; Ashfaq, A.; Sebastian Bonilla, R.; Haneef, M.; Saeed, R.; Ahmad, W.; Amin, N. Performance Optimization of Lead-Free MASnBr3 Based Perovskite Solar Cells by SCAPS-1D Device Simulation. Sol. Energy 2023, 249, 401–413. [Google Scholar] [CrossRef]

- Hossain, M.K.; Toki, G.F.I.; Kuddus, A.; Rubel, M.H.K.; Hossain, M.M.; Bencherif, H.; Rahman, M.F.; Islam, M.R.; Mushtaq, M. An Extensive Study on Multiple ETL and HTL Layers to Design and Simulation of High-Performance Lead-Free CsSnCl3-Based Perovskite Solar Cells. Sci. Rep. 2023, 13, 2521. [Google Scholar] [CrossRef] [PubMed]

- Ravidas, B.K.; Roy, M.K.; Samajdar, D.P. Investigation of Photovoltaic Performance of Lead-Free CsSnI3-Based Perovskite Solar Cell with Different Hole Transport Layers: First Principle Calculations and SCAPS-1D Analysis. Sol. Energy 2023, 249, 163–173. [Google Scholar] [CrossRef]

- Park, N.-G. Methodologies for High Efficiency Perovskite Solar Cells. Nano Converg. 2016, 3, 15. [Google Scholar] [CrossRef] [PubMed]

- Metin, B.; Kavasoglu, N.; Kavasoglu, A.S. AFORS-HET Simulation for Investigating the Performance of ZnO/n-CdS/p-CdTe /Ag Solar Cell Depending on CdTe Acceptor Concentration and Temperature. Phys. B Condens. Matter 2023, 649, 414504. [Google Scholar] [CrossRef]

- Kumar, M.; Kumar, S. 24.13% Efficient TiO2/i–a–Si:H/p–c–Si Heterojunction Solar Cell by AFORS-HET Numerical Simulation. Opt. Quantum Electron. 2023, 55, 441. [Google Scholar] [CrossRef]

- Singh, A.; Ghosh, R.; Agarwal, P. Selection of Materials and Optimization of Antireflection Coatings for Silicon Solar Cells Using Sentaurus TCAD. J. Mater. Sci. Mater. Electron. 2023, 34, 1235. [Google Scholar] [CrossRef]

- Okil, M.; Shaker, A.; Ahmed, I.S.; Abdolkader, T.M.; Salem, M.S. Evaluation of a Proposed Barium Di-Silicide Tandem Solar Cell Using TCAD Numerical Simulation. Opt. Quantum Electron. 2023, 55, 475. [Google Scholar] [CrossRef]

- Boukortt, N.E.I.; Patanè, S.; AlAmri, A.M.; AlAjmi, D.; Bulayyan, K.; AlMutairi, N. Numerical Investigation of Perovskite and U-CIGS Based Tandem Solar Cells Using Silvaco TCAD Simulation. Silicon 2023, 15, 293–303. [Google Scholar] [CrossRef]

- Seboui, Z.; Dabbabi, S. First Investigation on CZTS Electron Affinity and Thickness Optimization Using SILVACO-Atlas 2D Simulation. Simul. Model. Pract. Theory 2023, 126, 102758. [Google Scholar] [CrossRef]

- Mahmoud, A.H.K.; Hameed, M.F.O.; Hussein, M.; Obayya, S.S.A. Optical and Electrical Characteristics of Highly Efficient Flower-Shaped Silicon Nanowires Solar Cell. Opt. Quantum Electron. 2023, 55, 341. [Google Scholar] [CrossRef]

- Agnihotri, S.K.; Prashant, D.V.; Samajdar, D.P. Theoretical Insights into the Coupled Optoelectronic Analysis of InP Truncated Nanopyramid/Germanium Ttandem Solar Cells. Sol. Energy 2023, 249, 327–335. [Google Scholar] [CrossRef]

- Teimouri, R.; Heydari, Z.; Ghaziani, M.P.; Madani, M.; Abdy, H.; Kolahdouz, M.; Asl-Soleimani, E. Synthesizing Li Doped TiO2 Electron Transport Layers for Highly Efficient Planar Perovskite Solar Cell. Superlattices Microstruct. 2020, 145, 106627. [Google Scholar] [CrossRef]

- Liu, G.; Zhong, Y.; Mao, H.; Yang, J.; Dai, R.; Hu, X.; Xing, Z.; Sheng, W.; Tan, L.; Chen, Y. Highly Efficient and Stable ZnO-Based MA-Free Perovskite Solar Cells via Overcoming Interfacial Mismatch and Deprotonation Reaction. Chem. Eng. J. 2022, 431, 134235. [Google Scholar] [CrossRef]

- Abena, A.M.N.; Ngoupo, A.T.; Abega, F.X.A.; Ndjaka, J.M.B. Numerical Investigation of Solar Cells Based on Hybrid Organic Cation Perovskite with Inorganic HTL via SCAPS-1D. Chin. J. Phys. 2022, 76, 94–109. [Google Scholar] [CrossRef]

- Pindolia, G.; Shinde, S.M.; Jha, P.K. Optimization of an Inorganic Lead Free RbGeI3 Based Perovskite Solar Cell by SCAPS-1D Simulation. Sol. Energy 2022, 236, 802–821. [Google Scholar] [CrossRef]

- Bhattarai, S.; Hossain, I.; Maiti, M.; Pandey, R.; Madan, J. Performance Analysis and Optimization of All-Inorganic CsPbI3-Based Perovskite Solar Cell. Indian J. Phys. 2023, 97, 2629–2637. [Google Scholar] [CrossRef]

- Bhattarai, S.; Pandey, R.; Madan, J.; Mhamdi, A.; Bouazizi, A.; Muchahary, D.; Gogoi, D.; Sharma, A.; Das, T.D. Investigation of Carrier Transport Materials for Performance Assessment of Lead-Free Perovskite Solar Cells. IEEE Trans. Electron Devices 2022, 69, 3217–3224. [Google Scholar] [CrossRef]

- Tara, A.; Bharti, V.; Sharma, S.; Gupta, R. Device Simulation of FASnI3 Based Perovskite Solar Cell with Zn(O0.3, S0.7) as Electron Transport Layer Using SCAPS-1D. Opt. Mater. 2021, 119, 111362. [Google Scholar] [CrossRef]

- Bhattarai, S.; Sharma, A.; Das, T.D. Efficiency Enhancement of Perovskite Solar Cell by Using Doubly Carrier Transport Layers with a Distinct Bandgap of MAPbI3 Active Layer. Optik 2020, 224, 165430. [Google Scholar] [CrossRef]

- Rai, S.; Pandey, B.K.; Dwivedi, D.K. Modeling of Highly Efficient and Low Cost CH3NH3Pb(I1-xClx)3 Based Perovskite Solar Cell by Numerical Simulation. Opt. Mater. 2020, 100, 109631. [Google Scholar] [CrossRef]

- Abdelaziz, S.; Zekry, A.; Shaker, A.; Abouelatta, M. Investigating the Performance of Formamidinium Tin-Based Perovskite Solar Cell by SCAPS Device Simulation. Opt. Mater. 2020, 101, 109738. [Google Scholar] [CrossRef]

| Parameters Symbol | ZnO | MAPbI3 | MASnI3 | MAGeI3 | FASnI3 | Spiro-OMeTAD |

|---|---|---|---|---|---|---|

| d | 100 | 200–800 | 100 | 100 | 100 | 100 |

| Eg (eV) | 3.3 | 1.55 | 1.3 | 1.9 | 1.41 | 3.0 |

| χ (eV) | 4.1 | 3.9 | 4.1 | 3.98 | 3.52 | 2.45 |

| ɛr | 9 | 6.5 | 8.2 | 10 | 8.2 | 3 |

| Nc (m−3) | 4 × 1018 | 2.2 × 1018 | 1 × 1018 | 1 × 1016 | 1 × 1018 | 1 × 1019 |

| Nv (m−3) | 4 × 1019 | 1.8 × 1019 | 1 × 1018 | 1 × 1015 | 1 × 1018 | 1 × 1019 |

| ve (cm/s) | 1 × 107 | 1 × 107 | 1 × 107 | 1 × 107 | 1 × 107 | 1 × 107 |

| vh (cm/s) | 1 × 107 | 1 × 107 | 1 × 107 | 1 × 107 | 1 × 107 | 1 × 107 |

| µn (cm2/Vs) | 100 | 2 | 1.6 | 1.62 × 101 | 22 | 2 × 10−4 |

| µp (cm2/Vs) | 25 | 2 | 1.6 | 1.01 × 101 | 22 | 2 × 10−4 |

| Nd (cm−3) | 1 × 1018 | 5.21 × 109 | 0 | 1 × 109 | 0 | 0 |

| Na (cm−3) | 1 × 105 | 5.21 × 109 | 1 × 1015 | 1 × 109 | 7 × 1016 | 2 × 1018 |

| Nt (cm−3) | 1 × 1015 | 1 × 1014 | 1 × 1014 | 1 × 1014 | 1 × 1014 | 1 × 1015 |

| References | [69] | [25] | [69] | [27] | [70] | [27] |

| Parameters | Spiro-OMeTAD/PAL | PAL/ZnO |

|---|---|---|

| Defect types | Neutral | Neutral |

| Cap. cross-section electrons (cm2) | 1 × 10−19 | 1 × 10−19 |

| Cap. cross-section holes (cm2) | 1 × 10−19 | 1 × 10−19 |

| Energy distributions | single | single |

| Reference for defect energy level | Above the highest EV | Above the highest EV |

| Energy wrt reference (eV) | 0.6 | 0.6 |

| Total density (integrated over all energies) (cm−2) | 1 × 1010 | 1 × 1010 |

| PSC Device Structures | VOC (V) | Jsc (mA cm−2) | FF (%) | PCE (%) |

|---|---|---|---|---|

| ITO/ZnO/MAPbI3/Spiro-OMeTAD/Au | 1.161 | 23.8 | 84.48 | 23.35 |

| ITO/ZnO/MASnI3/Spiro-OMeTAD/Au | 0.874 | 33.55 | 74.62 | 21.88 |

| ITO/ZnO/MAGeI3/Spiro-OMeTAD/Au | 1.47 | 19.22 | 66.76 | 18.95 |

| ITO/ZnO/FASnI3/Spiro-OMeTAD/Au | 1.127 | 30.13 | 86.146 | 28.69 |

| ITO/ZnO/MAPbI3/CuSCN/Ag [25] | 1.27 | 21.89 | 83.70 | 23.30 |

| FTO/PCBM/MAPbI3/PEDOT: PSS + WO3/Cu [38] | 0.86 | 23.23 | 74.94 | 14.96 |

| FTO/Zn(O0.3, S0.7)/FASnI3/CuSCN/Au [70] | 1.086 | 28.12 | 84.96 | 25.94 |

| FTO/TiO2/FASnI3/Spiro-OMeTAD/Au [73] | 0.915 | 22.65 | 67.74 | 14.03 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bhattarai, S.; Mohammed, M.K.A.; Madan, J.; Pandey, R.; Abdelkader, H.; Farhat, L.B.; Amami, M.; Hossain, M.K. Comparative Study of Different Perovskite Active Layers for Attaining Higher Efficiency Solar Cells: Numerical Simulation Approach. Sustainability 2023, 15, 12805. https://doi.org/10.3390/su151712805

Bhattarai S, Mohammed MKA, Madan J, Pandey R, Abdelkader H, Farhat LB, Amami M, Hossain MK. Comparative Study of Different Perovskite Active Layers for Attaining Higher Efficiency Solar Cells: Numerical Simulation Approach. Sustainability. 2023; 15(17):12805. https://doi.org/10.3390/su151712805

Chicago/Turabian StyleBhattarai, Sagar, Mustafa K. A. Mohammed, Jaya Madan, Rahul Pandey, Hima Abdelkader, Lamia Ben Farhat, Mongi Amami, and M. Khalid Hossain. 2023. "Comparative Study of Different Perovskite Active Layers for Attaining Higher Efficiency Solar Cells: Numerical Simulation Approach" Sustainability 15, no. 17: 12805. https://doi.org/10.3390/su151712805

APA StyleBhattarai, S., Mohammed, M. K. A., Madan, J., Pandey, R., Abdelkader, H., Farhat, L. B., Amami, M., & Hossain, M. K. (2023). Comparative Study of Different Perovskite Active Layers for Attaining Higher Efficiency Solar Cells: Numerical Simulation Approach. Sustainability, 15(17), 12805. https://doi.org/10.3390/su151712805