Study on the Impact of Different Parameters on Prediction of Crown Deformations in Underground Caverns

Abstract

:1. Introduction

2. Overview of Factors Affecting Crown Deformation

Methodologies Used for the Prediction of Displacements

- Support vector machines (SVMs): SVMs are machine learning algorithms that can classify data or predict continuous values. SVMs have been used to predict crown deformations by developing models that relate deformation to various parameters, such as rock mass properties, in situ stresses, and excavation methods.

- Artificial neural networks (ANNs): ANNs are another type of machine learning algorithm that can be used to predict crown deformations. ANNs are trained on datasets that contain information about crown deformation and the factors that affect it. Once an ANN is trained, it can be used to predict crown deformation for new projects.

- Monte Carlo simulation: Monte Carlo simulation is a statistical method that can be used to estimate the probability of various outcomes. Monte Carlo simulation has been used to predict crown deformations by simulating the excavation of an underground cavern multiple times with different random values for the input parameters. The results of the simulations can then be used to estimate the probability of different levels of crown deformation.

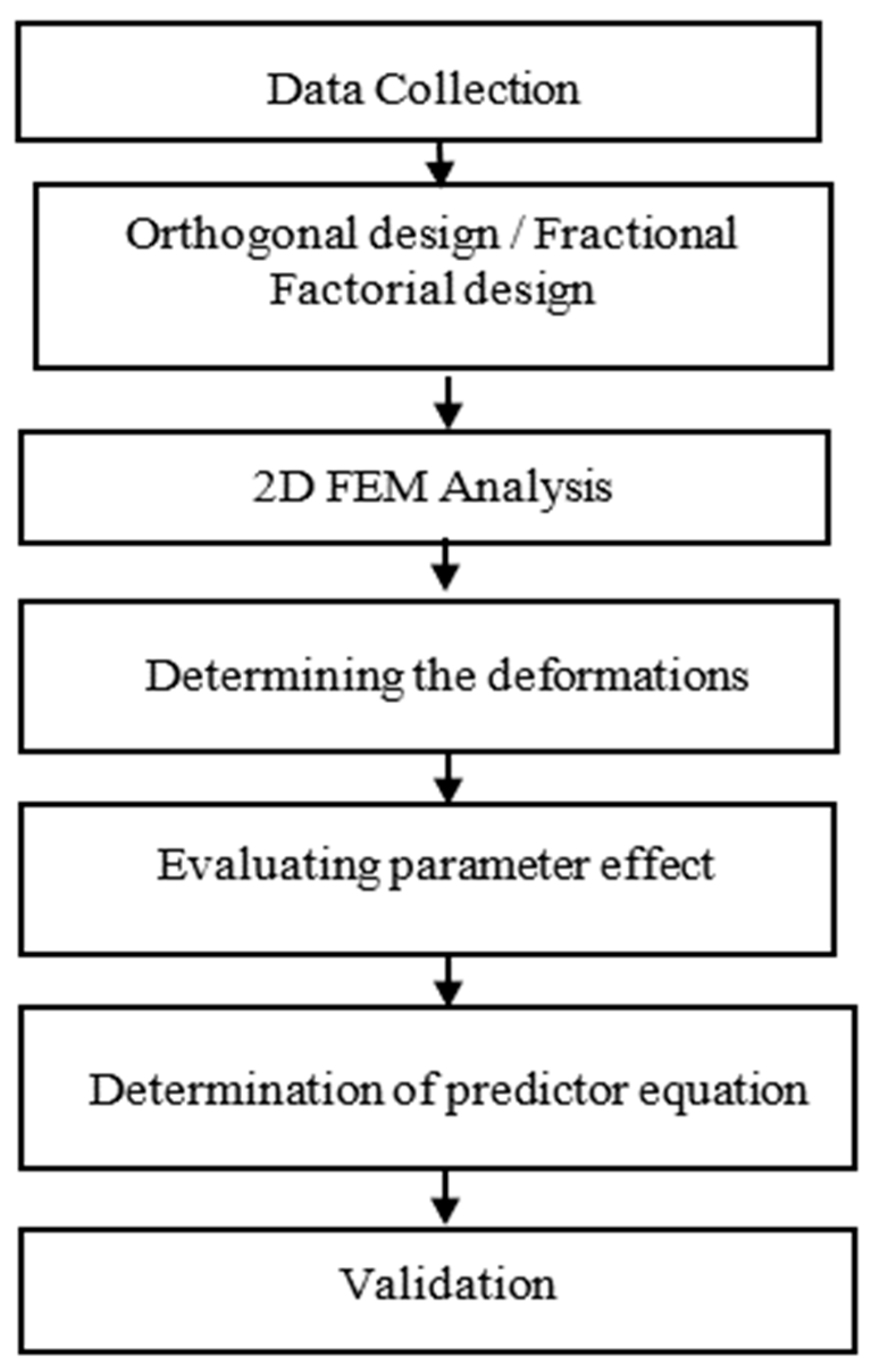

3. Study Methodology

3.1. Data Collection

- Geometrical data include the size and shape of the cavern, the rock cover, and the in situ stress conditions;

- Rock mass properties include the rock mass rating, the strength parameters for compression, tension, cohesion, friction angle, and Poisson’s ratio;

- Mechanical characteristics of intact rock samples, such as the uniaxial compressive strength and the tensile strength;

- Instrumentation data; in particular, the measurements of crown displacement made with extensometers.

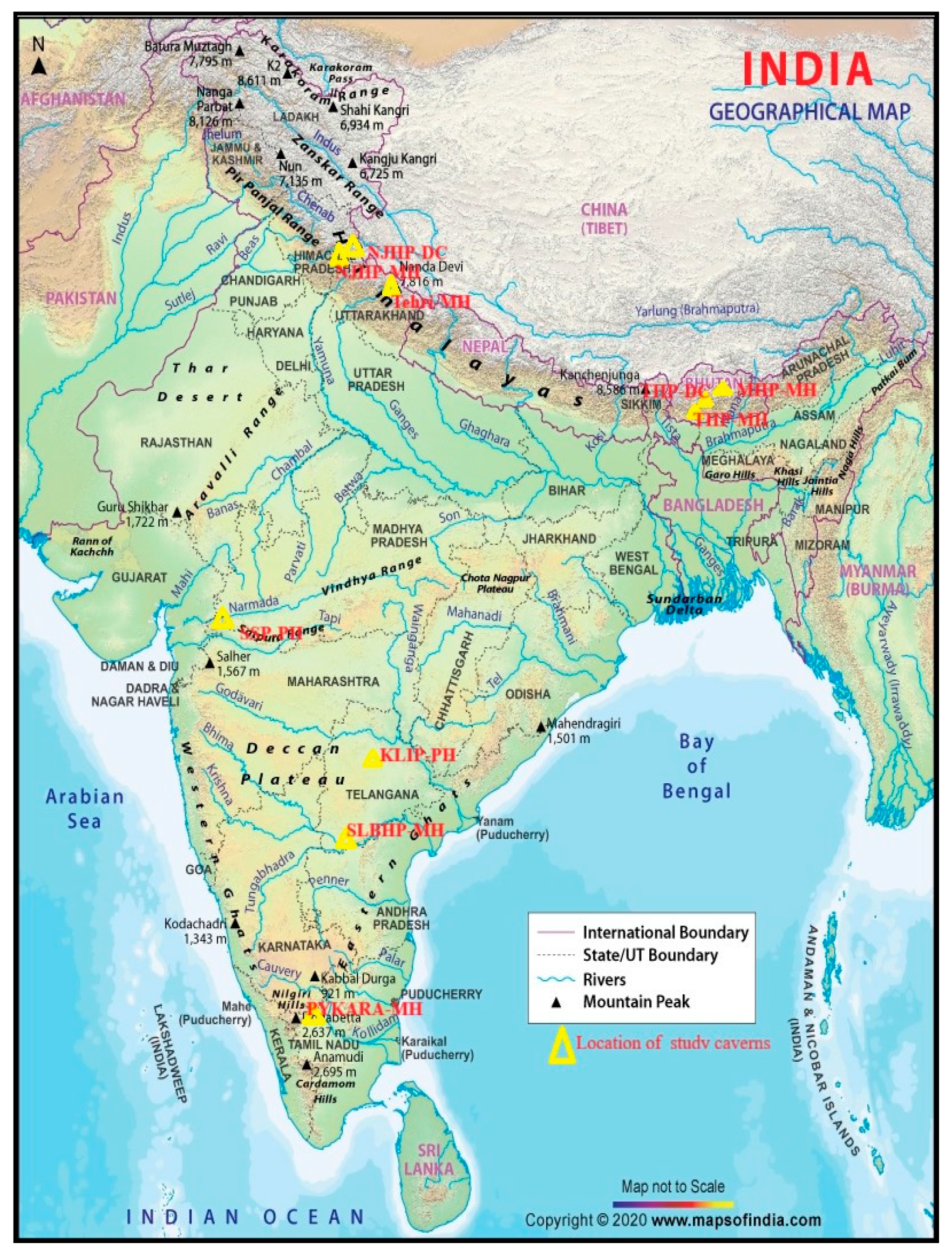

3.2. Description and Overview of the Data Collected

- Geometry: The dimensions of the caverns range from 100 to 525 m in length, 14 to 26 m in width, and 18.55 to 57 m in height.

- Overburden depth: The rock cover of the caverns ranges from 42 to 532 m.

- Rock type: The surrounding rock of the caverns ranges from soft rock to medium-hard rocks, such as phyllites and charnockite. The amygdaloidal and porphyritic basalt flows that make up the rocks of the Sardar Sarovar Project underground powerhouse cavern are separated by pockets of agglomerate [6]. The Tala Powerhouse Cavern is located on the southern slopes of the eastern Himalayas, not far from the MCT (Main Central Thrust). This major thrust zone is the boundary between the Lesser and Higher Himalayas. Most of the rocks in the powerhouse are phyllitic quartzite, quartzite, phyllites, and amphibolite schist.

- Physico-mechanical properties: The specimens were prepared from intact rock samples from the project sites. Following ISRM guidelines, specimens were examined at the NIRM laboratory to determine their physical and mechanical characteristics during cavern design and construction [26]. These are needed as input data for numerical modelling.

- The following are the physico-mechanical properties of the intact rock samples:

- Uniaxial compressive strength (UCS): The UCS ranges from 34 to 250 MPa for undamaged rock samples;

- Young’s modulus (Ei): The intact rock’s Young’s modulus ranges from 20 to 100 GPa;

- Poisson’s ratio (υ) and tensile strength (σt): These parameters range from 0.16 to 0.38 and 0.03 to 1.7 MPa, respectively;

- Internal friction has an angle (φ) ranging from 32.84° to 68.41°;

- Cohesion (c): The samples’ cohesion values range from 0.48 to 3.09 MPa.

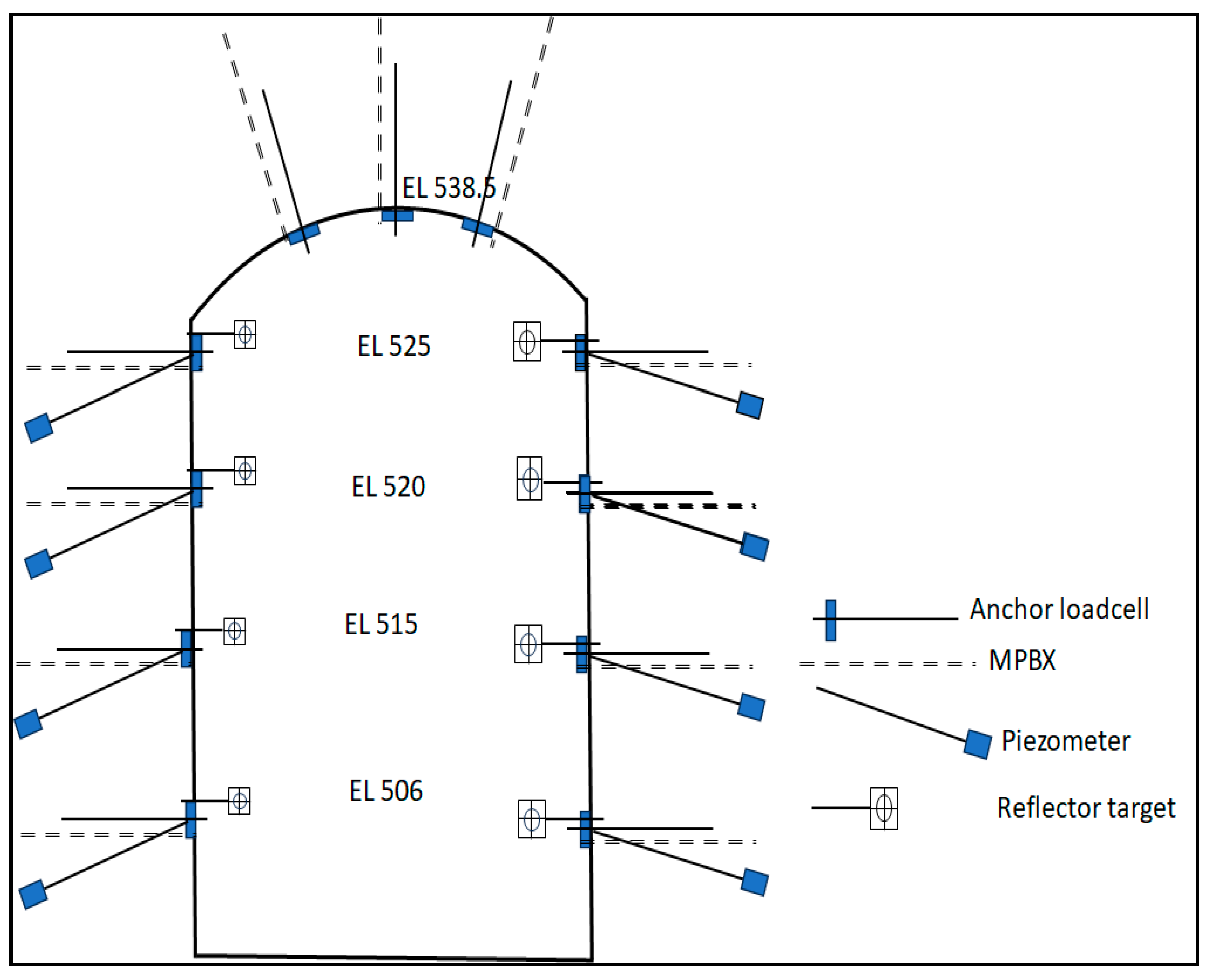

4. Instrumentation and Monitoring

- Extensometers: These devices measure deformations in the surrounding rock mass;

- Anchor load cells: These devices measure the load on support elements, such as bolts and anchors;

- Piezometers: These devices measure pore water pressure in the rock mass;

- Convergence targets: These devices measure the convergence of the roof and side walls of the cavern;

- Rock bolt stress meters: These devices measure the stress buildup along the length of rock bolts.

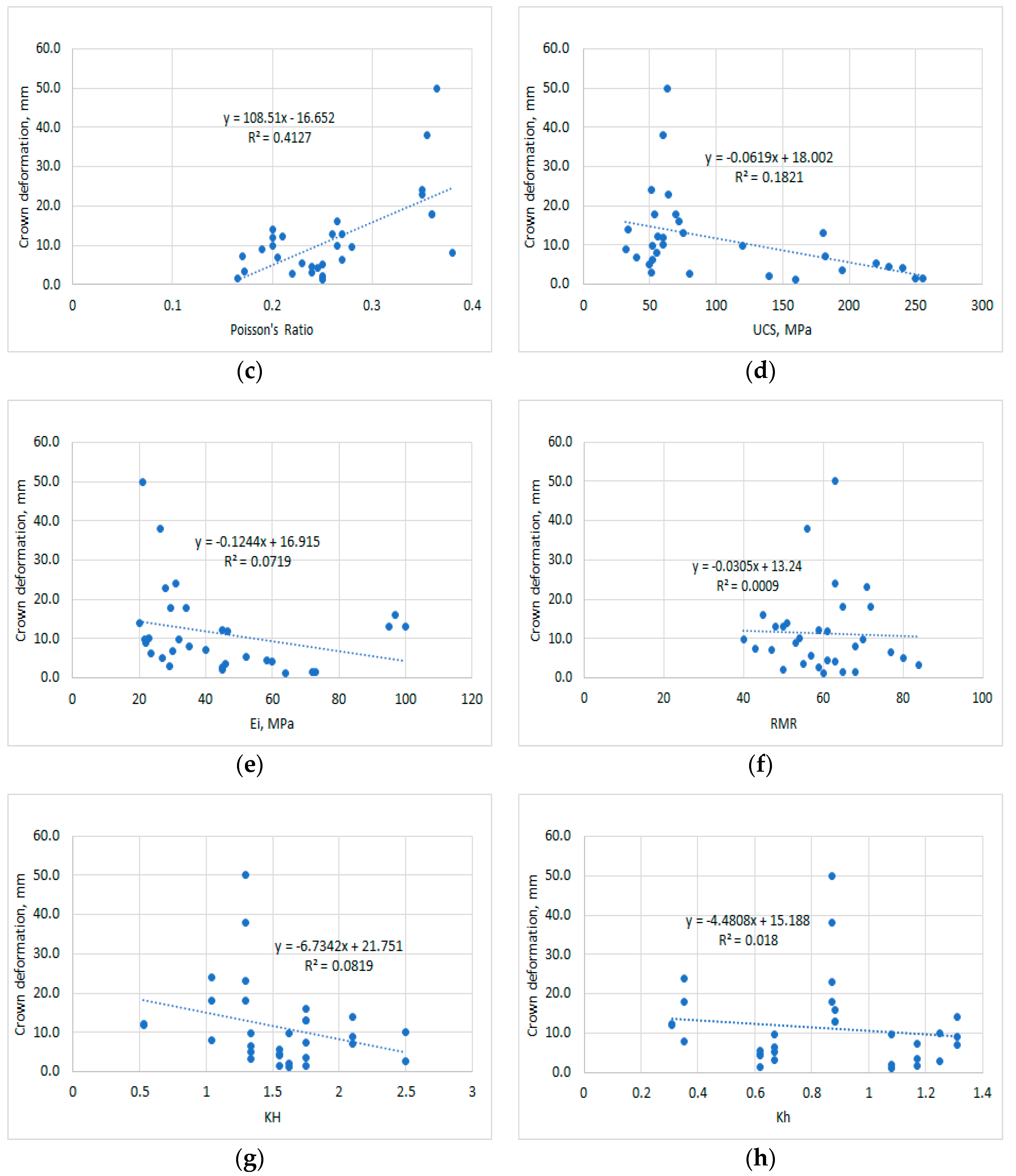

5. Data Analysis

- There is a strong positive correlation between crown displacement rock cover and Poisson’s ratio;

- There is a weak negative correlation between crown displacement and UCS (Young’s modulus);

- There is no significant correlation between crown displacement and other rock mass properties such as RMR, cohesion, and tensile strength; however, there is some nonlinear relation between these parameters and crown displacements.

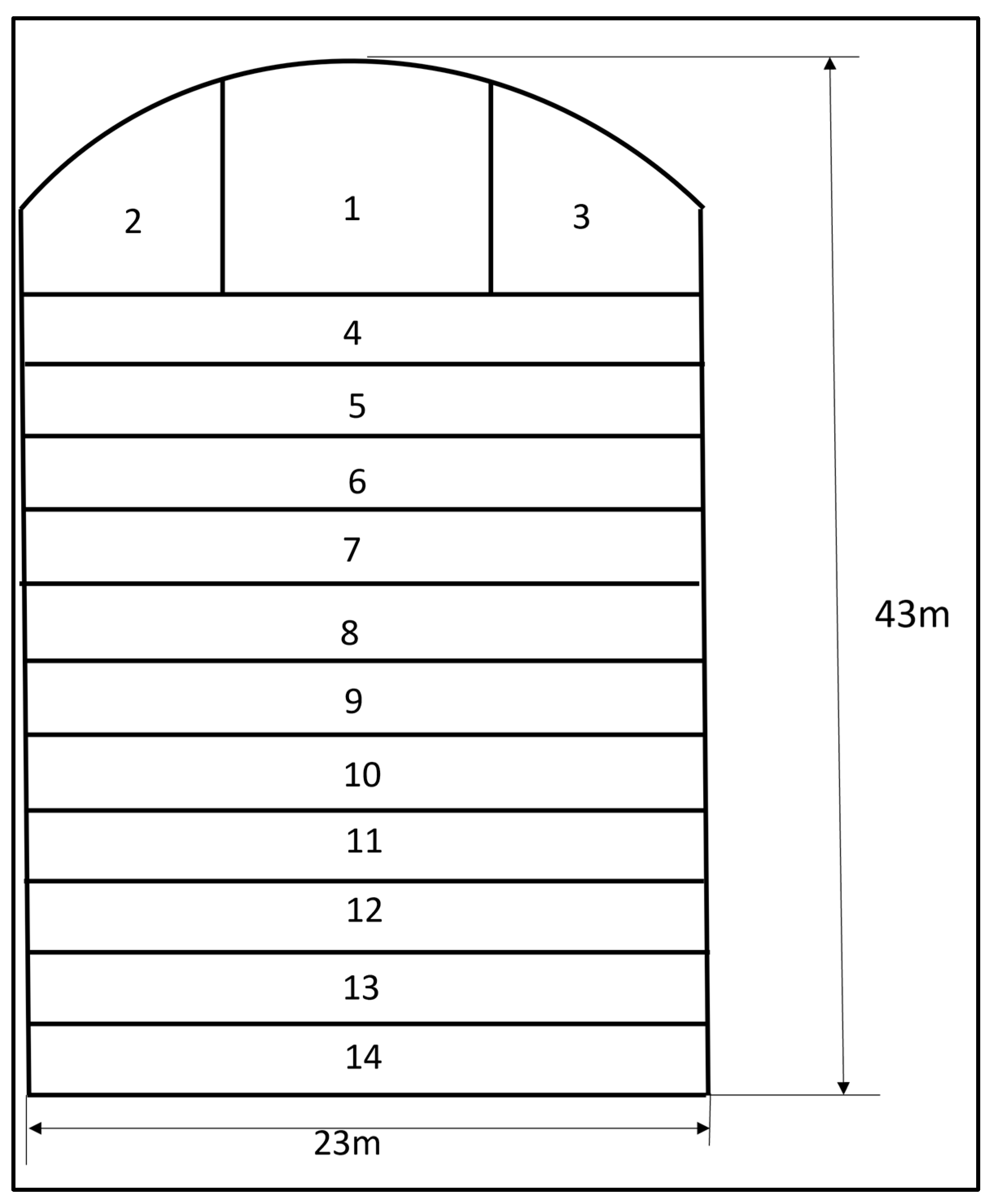

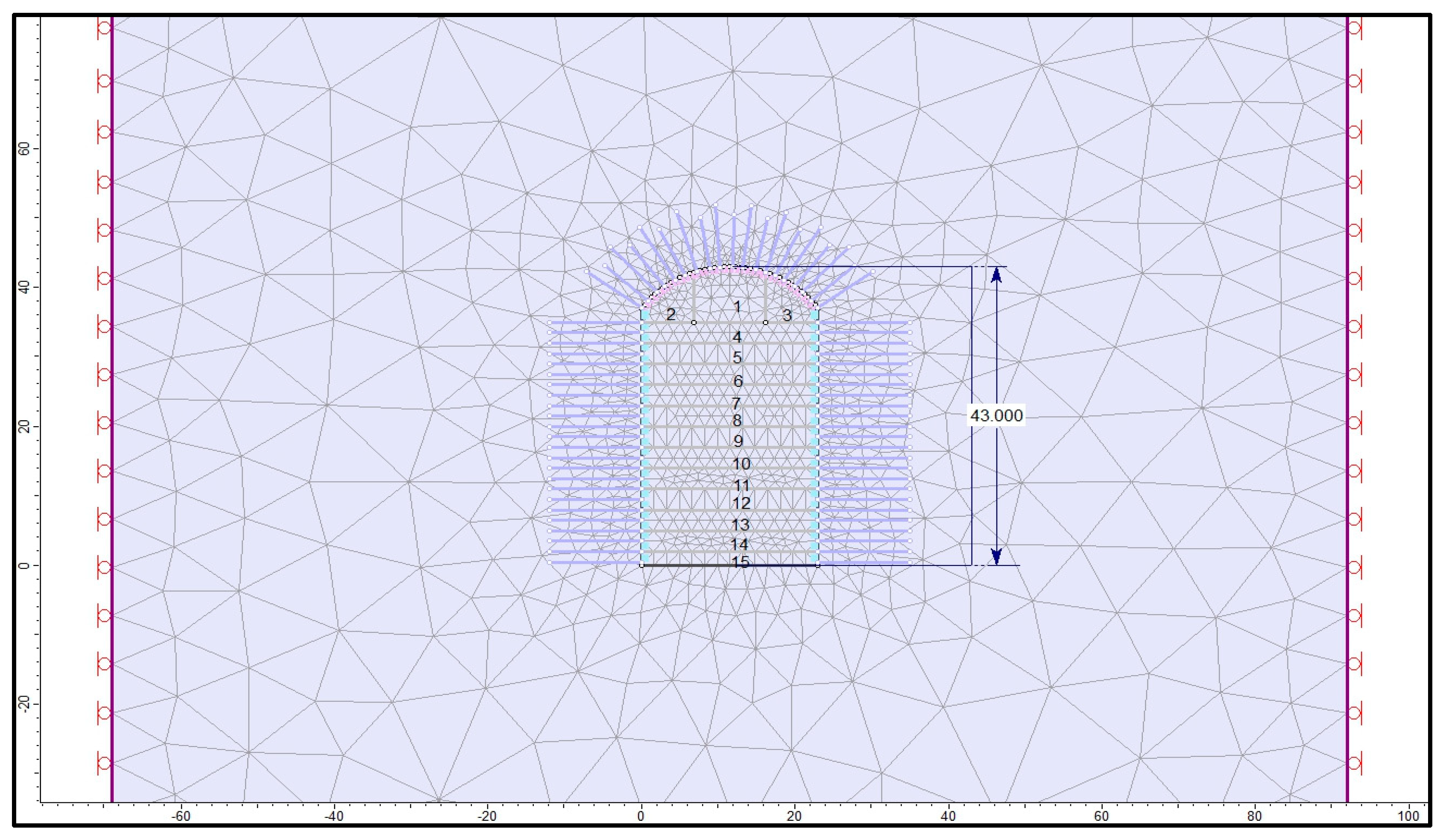

5.1. Numerical Modeling of Underground Caverns

5.2. Parametric Study on Crown Deformations of a Cavern (Case Study MHP-MH)

5.2.1. Design of Experiments and Fractional Factorial Work

- Rock mass rating of the cavern crown (RMR) :43–65;

- Uniaxial compressive strength (UCS) :182–250 MPa;

- Young’s modulus of intact rock (Ei) :40–72 GPa;

- Poisson’s ratio (υ) :0.16–0.17;

- Tensile strength (σt) :0.18–1.3 MPa;

- Internal friction angle (Φ) :58.36–63.23 degrees;

- Cohesion (C) :1.42–5.16 MPa.

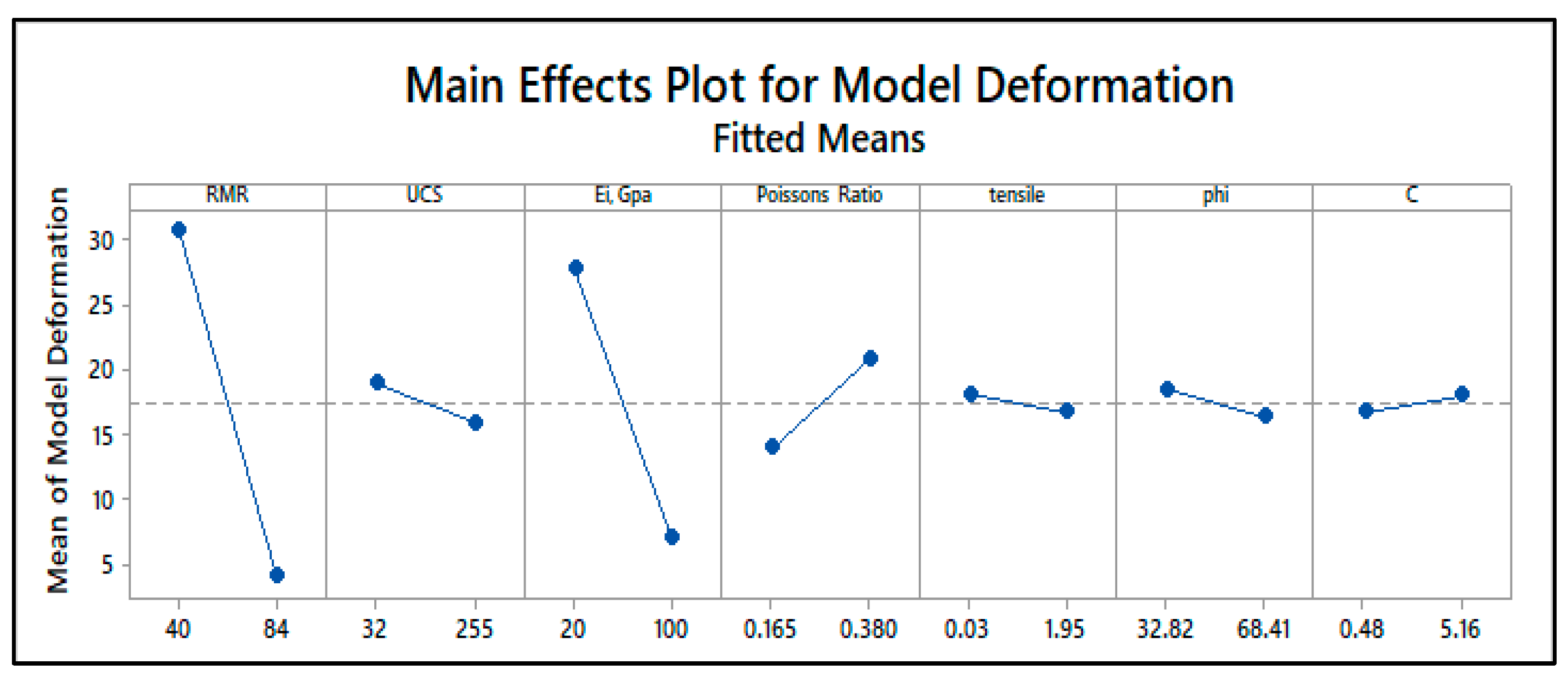

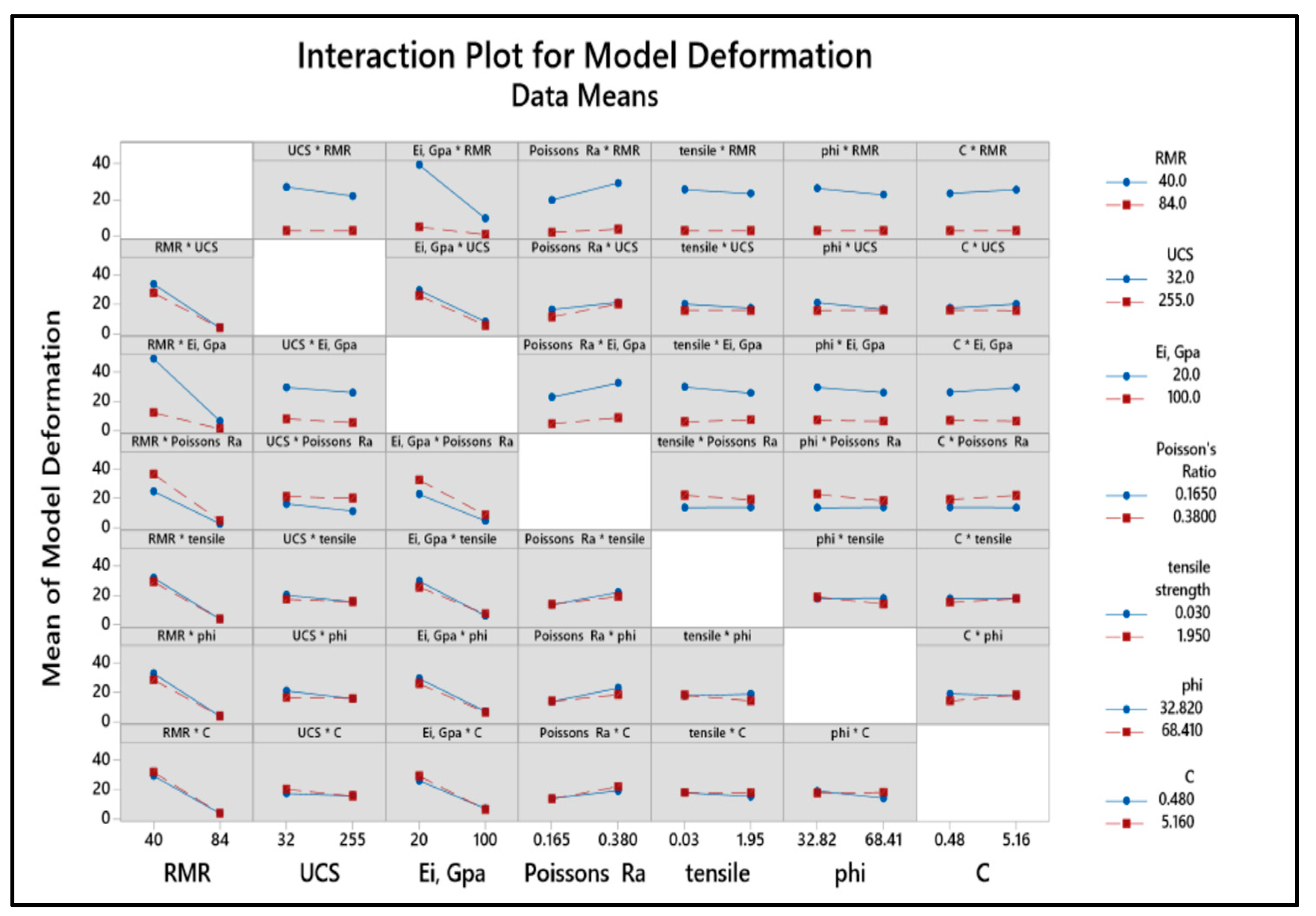

5.2.2. Main and Interaction Effects

- Rock mass rating (RMR);

- Uniaxial compressive strength (UCS);

- Young’s modulus of intact rock (Ei);

- Poisson’s ratio (υ);

- Tensile strength (σt);

- Internal friction angle (φ);

- Cohesion (C).

- RMR: As RMR increases, crown deformation decreases;

- UCS: As UCS increases, crown deformation slightly decreases or does not change significantly;

- Ei: As Ei increases, crown deformation decreases;

- υ: As PR increases, crown deformation increases;

- σt: σt has no significant effect on crown deformation;

- φ: As φ increases, crown deformation slightly decreases;

- C: C has no significant effect on crown deformation.

5.3. Development of Regression Equation

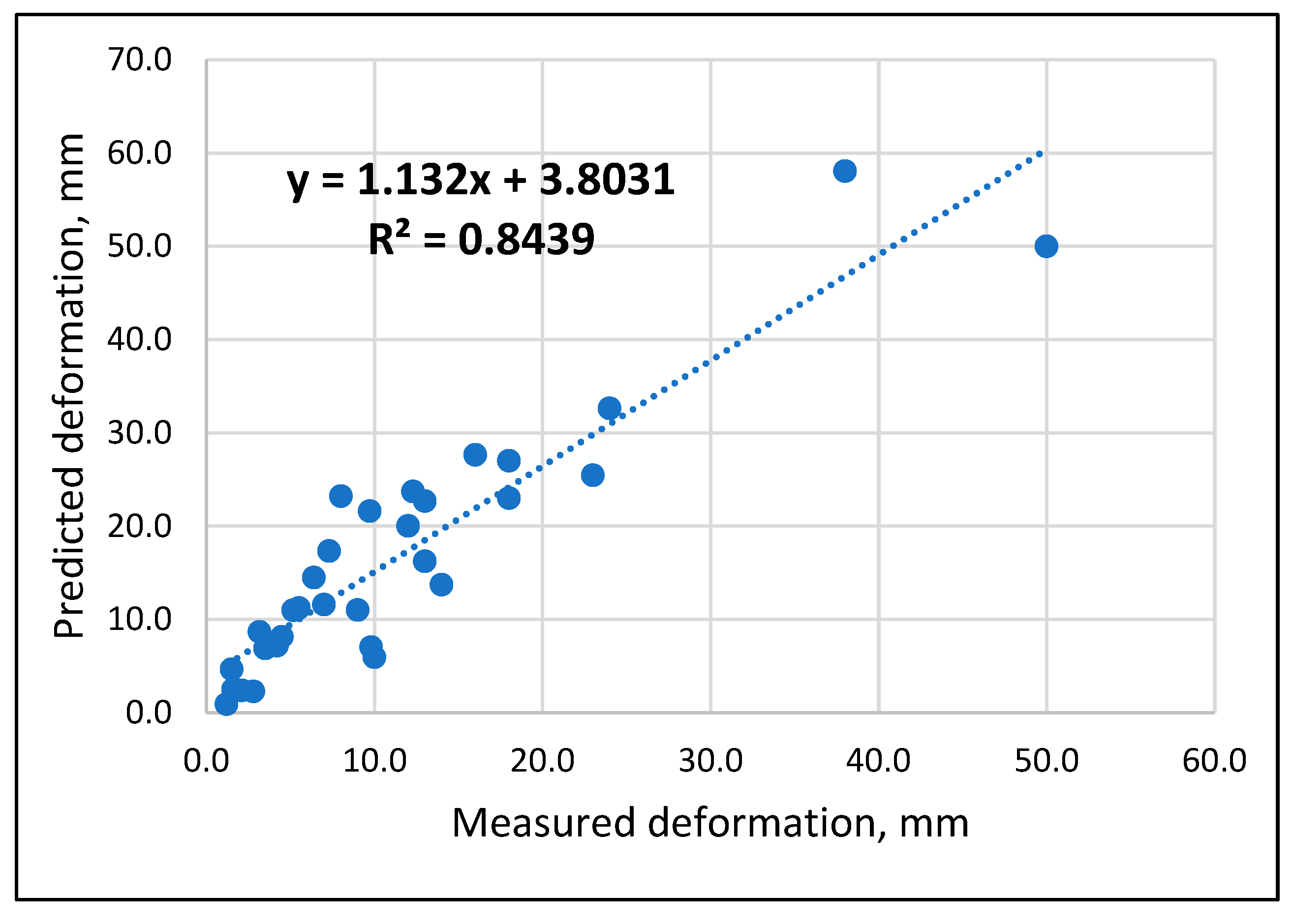

5.4. Validation of the Equation

- The exercise was conducted for ten caverns;

- The observed deformations were measured using monitoring instruments;

- The predicted deformations were obtained using the developed equation;

- The correlation coefficient (R2) of deformation was calculated for each cavern;

- The average correlation coefficient for all ten caverns was 0.84.

6. Discussion and Conclusions

- Rock mass rating (RMR);

- Uniaxial compressive strength (UCS);

- Young’s modulus of intact rock (Ei);

- Poisson’s ratio;

- Angle of internal friction (Φ);

- Width of the cavern;

- Height of the cavern;

- Rock cover;

- KH (horizontal stress coefficient);

- Kh_1 (vertical stress coefficient).

- The most significant factors affecting crown deformation are RMR, UCS, Ei, and Poisson’s ratio;

- The width and height of the cavern, rock cover, and stress ratios also significantly affect crown deformation;

- The developed equation can be used to predict crown deformation with high accuracy for a wide range of caverns;

- The fractional factorial of designs in design of experiments (DOE) is very useful in building the models and no complication calculations are needed;

- The rock mass parameters’ combinations were taken in models using fractional factorial analysis to cover all types of rock mass conditions;

- The results of this study can be used to improve the design and construction of underground caverns;

- The prediction values agreed well with the measured values, and the largest relative error was 15–20%;

- Since the behavior of the rock mass conditions are site-specific and all parameters are available by the time of construction, these are to be included in deformation prediction;

- Based on the study, the main influential parameters in crown deformations are rock mass rating, Young’s modulus, uniaxial compressive strength of the intact rock samples, and the shear strength parameters;

- The predicted deformations can be used for optimal range selection for the extensometers and other deformation measurement instruments;

- The predicted deformations can be used for Setting the warning/alert signals;

- Finally, the prediction capability of the regression model may further improve with the addition of a greater number of case studies.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhu, W.S.; Sui, B.; Li, X.J.; Li, S.C.; Wang, W.T. A methodology for studying the high wall displacement of large scale underground cavern complexes and it’s applications. Tunn. Undergr. Space Technol. 2008, 23, 651–664. [Google Scholar] [CrossRef]

- Saure, E.; Marcher, T.; John, M. Decisive Design Basis and Parameters for Power Plant Caverns; CRC Press: Geneva, Switzerland, 2013. [Google Scholar]

- Usmani, A.; Pal, S.; Nanda, A. Continuum and Discontinuum Analysis of Rock Caverns. Indian Geotech. J. 2018, 48, 663–676. [Google Scholar] [CrossRef]

- Dwivedi, R.D.; Singh, M.; Viladkar, M.N.; Goel, R.K. Parametric Analysis of an Empirical Correlation Predicting Deformation of Squeezing Tunnels. In Proceedings of the National Seminar on Innovative Practices in Rock Mechanics, Bengaluru, India, 6–7 February 2014. [Google Scholar]

- Naik, S.R.; Sastry, V.R.; Mishra, A. Effect of Orientation on Stability of Caverns—A Numerical Modelling Study. In Proceedings of the 10th Asian Rock Mechanics Symposium (ARMS10), Singapore, 29 October 2018. [Google Scholar]

- Prakash, I. Application of observational method in successful construction of underground structures, Sardar Sarovar (Narmada) project. In Proceedings of the Seventh International Conference on Case Histories in Geotechnical Engineering, Chicago, IL, USA, 1 May 2013. [Google Scholar]

- Van Kien, D.; Anh, D.N.; Thai, D.N. Numerical Simulation of the Stability of Rock Mass around Large Underground Cavern. Civ. Eng. J. 2022, 8, 81–91. [Google Scholar] [CrossRef]

- Kontogianni, V.A.; Stiros, S.C. Predictions and observations of convergence in shallow tunnels: Case histories in Greece. Eng. Geol. 2002, 63, 333–345. [Google Scholar] [CrossRef]

- Kuili, S.; Sastry, V.R. Prediction and Assessment of Lateral Displacement of Rock Mass Along the Length of the Horseshoe Cavern-A Numerical Modelling Approach Stability analysis of cavern under static and dynamic loads: A numerical modelling approach View project. Int. J. Geol. Geotech. Eng. 2017, 3, 17–28. [Google Scholar]

- Abdollahipour, A.; Rahmannejad, R. Investigating the effects of lateral stress to vertical stress ratios and caverns shape on the cavern stability and sidewall displacements. Arab. J. Geosci. 2013, 6, 4811–4819. [Google Scholar] [CrossRef]

- Feng, X.T.; Zhao, H.; Li, S. Modeling non-linear displacement time series of geo-materials using evolutionary support vector machines. Int. J. Rock Mech. Min. Sci. 2004, 41, 1087–1107. [Google Scholar] [CrossRef]

- Małkowski, P.; Juszyński, D. Roof fall hazard assessment with the use of artificial neural network. Int. J. Rock Mech. Min. Sci. 2021, 143, 104701. [Google Scholar] [CrossRef]

- Ma, H.P.; Daud, N.N.N.; Yusof, Z.M.; Yaacon, W.Z.; He, H.J. Stability Analysis of Surrounding Rock of an Underground Cavern Group and Excavation Scheme Optimization: Based on an Optimized DDARF Method. Appl. Sci. 2023, 13, 2152. [Google Scholar] [CrossRef]

- Basin, R.; Pabst, T.; Li, C. Rock Characterisation, Modelling and Engineering Design Methods. In Proceedings of the 3rd ISRM SINOROCK 2013 Symposium, Shanghai, China, 18–20 June 2013. [Google Scholar]

- Gupta, A.K.; Goyal, D.P.; Mishra, R.K.; Khazanchi, R.N. Instability Problems in Desilting Caverns of Tala hydroelectric project, Bhutan. In Proceedings of the SRM India Symp. on Advancing Rock Mechanics Frontiers to Meet the Challenges of 21st Century, New Delhi, India, 24–27 September 2002. [Google Scholar]

- Mishra, A.K.; Chaudhary, R.K.; Punetha, P.; Ahmed, I. Geological and Geotechnical Challenges Faced during Excavation of Powerhouse and Head Race Tunnel for Mangdechhu Project, Bhutan, India. Hydro Nepal J. Water Energy Environ. 2018, 23, 30–41. [Google Scholar] [CrossRef]

- Bhasin, R.K.; Barton, N.; Grimstad, E.; Chryssanthakis, P.; Shende, F.P. Comparison of predicted and measured performance of a large cavern in the Himalayas. Int. J. Rock Mech. Min. Sci. Geomech. 1996, 33, 607–613. [Google Scholar] [CrossRef]

- Dasgupta, B.; Singh, R.; Sharma, V.M. Numerical modelling of desilting chambers for Nathpa Jhakri Hydroelectric Project. In Proceedings of the 9th ISRM Congress 99, Paris, France, 25 August 1999. [Google Scholar]

- Dasgupta, B.; Sharma, M.K.; Verman, M.; Sharma, V.M. Design of underground caverns for Tehri Hydro Power project, India by numerical modelling. In Proceedings of the 9th ISRM Congress 99, Paris, France, 25 August 1999. [Google Scholar]

- Dasgupta, B.; Dham, R.; Lorig, L.J. Three dimensional discontinuum analysis of the underground powerhouse for SardarSarovar Project, India. In Proceedings of the 8th ISRM Congress, Tokyo, Japan, 25 September 1995. [Google Scholar]

- Varman, M.; Jethwa, J.L.; Singh, B. Monitoring of a large underground power house cavity. In Proceedings of the 9th ISRM Congress, Aachen, Germany, 16 September 1991. [Google Scholar]

- Venkateswarlu, V.; Srinivasulu, T.; Nagaraj, C.; Sudhakar, K. Instrumentation and Strata Monitoring at Srisailam Left Bank Hydro electric scheme. Project Report, NIRM, Kolar Gold Fields, 30 November 1996.

- Naitani, A.K.; Singh, L.G.; Rawat, D.S.; Jain, P. Engineering Geological Investigations of the Extension of Surge Pool and Pump House Caverns, Kaleswaram Lift Irrigation Project-Package8, Telangana, India, Project Report, NIRM, India. 31 January 2017.

- Purushothaman, C. Planning design and construction of transformer cavern for an underground hydroelectric project. In Proceedings of the ISRM International Symposium 2010 and 6th Asian Rock Mechanics Symposium—Advances in Rock Engineering, Newdelhi, India, 23 October 2010. [Google Scholar]

- Venkateswarlu, V.; Nagaraj, C. Instrumentation for monitoring the underground caverns at Pykara Ultimate Stage Hydro Electric Project, Project Report, NIRM, Kolar Gold Fields, India, 31 March 2000.

- Jayanthu, S.; Rao, G.M.N.; Udaykumar, S. Physico mechanical properties of Rocks—A data bank. Kolar Gold Fields. 2006.

- Song, S.; Feng, X.; Liao, C.; Cai, D.; Liu, Z.; Yang, Y. Measures for controlling large deformations of underground caverns under high in-situ stress condition—A case study of Jinping I hydropower station. J. Rock Mech. Geotech. Eng. 2016, 8, 605–618. [Google Scholar] [CrossRef]

- Mandal, P.K.; Singh, A.K.; Kumar, R.; Singh, R. Instrumentation and monitoring strategies for study of ground movement during underground extraction of coal. Min. Eng. J. 2006, 8, 15–27. [Google Scholar]

- Kellaway, M.; Taylor, D.; Keyter, G.J. The use of Geotechnical Instrumentation to Monitor Ground Displacements during Excavation of Ingula power caverns, For Model Calibration and Design Purposes. In Proceedings of the Southern African Institute of Mining and Metallurgy South African Tunnelling 2012-Lessons Learnt on Major Projects, Ladysmith, South Africa, 3 December 2012. [Google Scholar]

- Montgomery, D.C. Engineering Statistics; RGHN; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Lye, L.M. Some Applications of Statistical Design of Experiment Methodology in Civil Engineering. In Proceedings of the Annual Conference of the Canadian Society for Civil Engineering, Moncton, NB, Canada, 4–7 June 2003. [Google Scholar]

- Sinha, R.K.; Jawed, M.; Sengupta, S. An approach for support design in depillaring panels of coal mines. Arab. J. Geosci. 2019, 12, 666. [Google Scholar] [CrossRef]

- Ruan, J.-K.; Zhu, W.-W. Sensitivity Analysis of Influencing Factors of Building Slope Stability Based on Orthogonal Design and Finite Element Calculation. E3S Web Conf. 2018, 53, 03076. [Google Scholar]

| Sr No | Cavern Name | Width, m | Height, m | Rock Cover, m | Rock Mass Rating, RMR | Stress Ratios (KH, Kh) | UCS, MPa | Young’s Modulus, Ei, GPa | Tensile Strength, σt MPa | Poisson’s Ratio, υ | Friction Angle, Φ | Cohesion, C MPa | Rock Types | Issues Encountered during Construction | References |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | THP-MH * | 20.4 | 44.5 | 500 | 56–72 | 1.30, 0.87 | 60–70 | 21–29.5 | 0.64–1.7 | 0.35–0.365 | 32.82–35.73 | 1.81–3.09 | Phyllites, Philitic quartzite, and quartzite bands | The roof collapse occurred during construction; vertical and horizontal cracks occurred on shotcrete at high walls | [5,14] |

| 2 | THP-DC * | 13.9 | 18.5 | 140 | 47–53 | 2.10, 1.30 | 34–40 | 20–30 | 0.03–0.05 | 0.19–0.20 | 46.35–50.08 | 0.65–0.78 | Predominantly muscovite-biotite genesis with miner bands of biotite schist, quartzite, and clac silicate rocks; general rock types are good to moderately good | Major cracks occurred in the crown area during bench excavations | [15] |

| 3 | MHP-MH * | 23 | 43 | 180 | 43–65 | 1.75, 1.17 | 182–250 | 40–72 | 0.18–1.3 | 0.165–0.172 | 58.4–63.23 | 1.71–5.16 | Biotite schist, quartzite, pegmatite with micaceous schist, granite intrusions | [16] | |

| 4 | NJHP-MH * | 20 | 45 | 300 | 70–84 | 1.34, 0.67 | 50–52 | 21.5–29 | 0.16–0.70 | 0.24–0.28 | 51.27–53.95 | 1.9–2.77 | Major rock types encountered are augen gneiss and gneiss | No failures on a rock; minor cracks occurred on the shotcrete while benching | [17] |

| 5 | NJHP-DC * | 16.3 | 27.5 | 450 | 63–68 | 1.04, 0.35 | 51–55 | 31–35 | 0.17–0.32 | 0.35–0.38 | 41.51–43.38 | 1.89–2.01 | Predominantly massive augen gneiss and gneiss with minor bands of biotite schist | Rockfall occurred in chambers 3 and 4 | [18] |

| 6 | Tehri-MH * | 22 | 47 | 370 | 59–61 | 0.53, 0.31 | 56–60 | 45–46.5 | 0.17–0.21 | 0.20–0.21 | 41.0–42.08 | 1.48–1.61 | Massive thinly bedded phyllitic quartzite | No failures | [19] |

| 7 | SSP-PH * | 23 | 57 | 47.5 | 54–59 | 2.5, 1.25 | 60–80 | 23–45 | 0.06–0.13 | 0.20–0.22 | 58.9–61.53 | 0.5–0.75 | Deccan trap group-porphyritic basalt, amygdaloidal basalt, and agglomerate | Vertical cracks occurred in the crown and walls during construction | [20,21] |

| 8 | SLBHP-MH * | 25.7 | 53 | 233 | 57–68 | 1.55, 0.62 | 220–255 | 52–73 | 0.74–1.95 | 0.23–0.25 | 51.3–53.38 | 2.51–4.95 | Hard siltstones; pinkish, fine-grained, and hard crystalline rock | No major problems associated with construction | [22] |

| 9 | KLIPP8-PH * | 25 | 34 | 42 | 40–60 | 1.62, 1.08 | 120–160 | 32–64 | 0.03–0.14 | 0.25–0.265 | 64.26–68.41 | 0.48–1.03 | Granite | A wedge fall occurred in one place | [23] |

| 10 | PYKARA-MH * | 20.2 | 37 | 532 | 45–50 | 1.75, 0.88 | 72–180 | 95–100 | 0.03–0.11 | 0.26–0.27 | 49.92–57.51 | 1.2–1.88 | Massive charnokite and migmatite gneiss | No problems noticed during construction | [24,25] |

| Width, m | Height, m | Rock Cover, m | KH | Kh | RMR | UCS, MPa | Ei, GPa | Poisson’s Ratio υ | Tensile Strength, σt | Friction Angle, Φ | Cohesion (C), MPa | Deformation (mm) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Width, m | 1.0 | ||||||||||||

| Height, m | 0.8 | 1.0 | |||||||||||

| Rock Cover, m | −0.3 | 0.0 | 1.0 | ||||||||||

| KH | 0.0 | −0.1 | −0.6 | 1.0 | |||||||||

| Kh | 0.0 | −0.2 | −0.6 | 0.9 | 1.0 | ||||||||

| RMR | 0.0 | 0.3 | 0.2 | −0.4 | −0.5 | 1.0 | |||||||

| UCS, MPa | 0.7 | 0.4 | −0.3 | 0.2 | 0.1 | −0.1 | 1.0 | ||||||

| Ei, GPa | 0.4 | 0.1 | 0.2 | 0.1 | 0.0 | −0.3 | 0.6 | 1.0 | |||||

| Poisson’s Ratio υ | −0.2 | −0.1 | 0.7 | −0.5 | −0.5 | 0.3 | −0.3 | −0.2 | 1.0 | ||||

| Tensile strength, σt | 0.4 | 0.5 | 0.2 | −0.2 | −0.2 | 0.5 | 0.5 | 0.1 | 0.2 | 1.0 | |||

| Friction angle (Φ) | 0.5 | 0.1 | −0.7 | 0.5 | 0.4 | −0.3 | 0.5 | 0.3 | −0.6 | −0.2 | 1.0 | ||

| C, MPa | 0.3 | 0.4 | 0.2 | −0.3 | −0.4 | 0.6 | 0.6 | 0.3 | 0.1 | 0.9 | −0.1 | 1.0 | |

| Deformation (mm) | −0.3 | −0.1 | 0.6 | −0.3 | −0.1 | 0.0 | −0.4 | −0.3 | 0.6 | 0.0 | −0.7 | −0.1 | 1.0 |

| RMR | UCS, MPa | Ei, GPa | Poisson’s Ratio | Tensile Strength, MPa | Friction Angle, Degree | C, MPa | Deformation, mm |

|---|---|---|---|---|---|---|---|

| 40 | 32 | 100 | 0.165 | 0.03 | 68.41 | 5.16 | 11.2 |

| 40 | 255 | 20 | 0.165 | 1.95 | 32.82 | 5.16 | 32.6 |

| 84 | 32 | 100 | 0.38 | 1.95 | 32.82 | 5.16 | 1.72 |

| 40 | 32 | 100 | 0.38 | 1.95 | 68.41 | 5.16 | 16.9 |

| 84 | 255 | 100 | 0.165 | 0.03 | 68.41 | 5.16 | 0.976 |

| 40 | 255 | 20 | 0.38 | 1.95 | 32.82 | 0.48 | 58.7 |

| 84 | 32 | 100 | 0.165 | 0.03 | 32.82 | 5.16 | 0.979 |

| 84 | 32 | 20 | 0.165 | 1.95 | 32.82 | 5.16 | 4.8 |

| 84 | 32 | 100 | 0.38 | 0.03 | 32.82 | 0.48 | 1.72 |

| 84 | 32 | 100 | 0.38 | 1.95 | 68.41 | 0.48 | 1.72 |

| 84 | 32 | 20 | 0.38 | 0.03 | 32.82 | 5.16 | 8.38 |

| 84 | 32 | 20 | 0.38 | 0.03 | 68.41 | 0.48 | 8.39 |

| 84 | 255 | 100 | 0.165 | 0.03 | 32.82 | 0.48 | 0.976 |

| 40 | 32 | 100 | 0.38 | 0.03 | 32.82 | 5.16 | 16.2 |

| 40 | 32 | 20 | 0.165 | 0.03 | 68.41 | 0.48 | 51.1 |

| 40 | 32 | 20 | 0.38 | 0.03 | 68.41 | 5.16 | 72.4 |

| 40 | 32 | 100 | 0.165 | 1.95 | 68.41 | 0.48 | 11.2 |

| 40 | 255 | 20 | 0.38 | 0.03 | 68.41 | 0.48 | 58.8 |

| 40 | 255 | 100 | 0.165 | 1.95 | 32.82 | 0.48 | 7.27 |

| 40 | 32 | 100 | 0.38 | 1.95 | 32.82 | 0.48 | 31.8 |

| 40 | 255 | 20 | 0.165 | 0.03 | 68.41 | 5.16 | 32.7 |

| 40 | 255 | 100 | 0.38 | 1.95 | 68.41 | 0.48 | 12.7 |

| 84 | 255 | 100 | 0.165 | 1.95 | 32.82 | 5.16 | 0.977 |

| 40 | 255 | 100 | 0.165 | 0.03 | 68.41 | 0.48 | 7.27 |

| 40 | 255 | 20 | 0.38 | 1.95 | 68.41 | 5.16 | 58.8 |

| 84 | 255 | 20 | 0.165 | 0.03 | 68.41 | 0.48 | 4.79 |

| 40 | 32 | 20 | 0.165 | 1.95 | 32.82 | 0.48 | 51.2 |

| 84 | 255 | 20 | 0.165 | 1.95 | 32.82 | 0.48 | 4.8 |

| 40 | 255 | 100 | 0.38 | 0.03 | 68.41 | 5.16 | 12.7 |

| 40 | 255 | 100 | 0.165 | 0.03 | 32.82 | 5.16 | 7.27 |

| 40 | 255 | 100 | 0.38 | 0.03 | 32.82 | 0.48 | 12.7 |

| 84 | 32 | 20 | 0.165 | 1.95 | 68.41 | 0.48 | 4.8 |

| 40 | 32 | 20 | 0.38 | 1.95 | 68.41 | 0.48 | 9.39 |

| 84 | 255 | 20 | 0.165 | 0.03 | 32.82 | 5.16 | 4.79 |

| 84 | 32 | 20 | 0.38 | 1.95 | 68.41 | 5.16 | 8.39 |

| 84 | 32 | 100 | 0.165 | 1.95 | 32.82 | 0.48 | 0.979 |

| 84 | 255 | 20 | 0.165 | 1.95 | 68.41 | 5.16 | 4.79 |

| 84 | 32 | 20 | 0.165 | 0.03 | 68.41 | 5.16 | 4.8 |

| 40 | 255 | 100 | 0.165 | 1.95 | 68.41 | 5.16 | 7.27 |

| 40 | 255 | 20 | 0.165 | 1.95 | 68.41 | 0.48 | 32.7 |

| 40 | 32 | 100 | 0.165 | 0.03 | 32.82 | 0.48 | 7.27 |

| 40 | 255 | 20 | 0.165 | 0.03 | 32.82 | 0.48 | 32.7 |

| 84 | 255 | 20 | 0.38 | 0.03 | 68.41 | 5.16 | 8.27 |

| 40 | 32 | 100 | 0.38 | 0.03 | 68.41 | 0.48 | 13.6 |

| 84 | 32 | 100 | 0.38 | 0.03 | 68.41 | 5.16 | 1.72 |

| 84 | 32 | 20 | 0.165 | 0.03 | 32.82 | 0.48 | 4.8 |

| 40 | 32 | 20 | 0.38 | 0.03 | 32.82 | 0.48 | 72.5 |

| 84 | 255 | 20 | 0.38 | 1.95 | 32.82 | 5.16 | 8.28 |

| 84 | 255 | 100 | 0.38 | 0.03 | 32.82 | 5.16 | 1.69 |

| 84 | 255 | 100 | 0.165 | 1.95 | 68.41 | 0.48 | 0.975 |

| 84 | 255 | 100 | 0.38 | 0.03 | 68.41 | 0.48 | 1.69 |

| 84 | 255 | 20 | 0.38 | 0.03 | 32.82 | 0.48 | 8.27 |

| 84 | 32 | 100 | 0.165 | 1.95 | 68.41 | 5.16 | 0.943 |

| 40 | 32 | 20 | 0.38 | 1.95 | 32.82 | 5.16 | 67.9 |

| 40 | 32 | 20 | 0.165 | 1.95 | 68.41 | 5.16 | 48 |

| 84 | 32 | 20 | 0.38 | 1.95 | 32.82 | 0.48 | 8.08 |

| 40 | 255 | 20 | 0.38 | 0.03 | 32.82 | 5.16 | 56.6 |

| 84 | 255 | 20 | 0.38 | 1.95 | 68.41 | 0.48 | 7.98 |

| 40 | 32 | 100 | 0.165 | 1.95 | 32.82 | 5.16 | 10.7 |

| 84 | 255 | 100 | 0.38 | 1.95 | 68.41 | 5.16 | 1.63 |

| 84 | 32 | 100 | 0.165 | 0.03 | 68.41 | 0.48 | 0.942 |

| 40 | 255 | 100 | 0.38 | 1.95 | 32.82 | 5.16 | 12.2 |

| 84 | 255 | 100 | 0.38 | 1.95 | 32.82 | 0.48 | 1.63 |

| 40 | 32 | 20 | 0.165 | 0.03 | 32.82 | 5.16 | 48 |

| Cavern Name | RMR | UCS | Ei | P-Ratio | Tensile Strength | Phi | C | |

|---|---|---|---|---|---|---|---|---|

| MHP-MH | Effect | −26.77 | −3.03 | −20.91 | 6.84 | −1.39 | −2.15 | 1.29 |

| Ranking | 1st | 3rd | 2nd | 7th | 5th | 4th | 6th | |

| THP-MH | Effect | −255.6 | −187.4 | −218.0 | −6.6 | −33.7 | −35.9 | 1.1 |

| Ranking | 1st | 3rd | 2nd | 6th | 5th | 4th | 7th | |

| THP-DC | Effect | −9.23 | −0.64 | −7.71 | 2.62 | 0.029 | −0.12 | 0.06 |

| Ranking | 1st | 3rd | 2nd | 7th | 6th | 4th | 5th | |

| NJHP-MH | Effect | −51.72 | −17.78 | −41.98 | 4.74 | 0.94 | −0.34 | −0.39 |

| Ranking | 1st | 3rd | 2nd | 7th | 6th | 5th | 4th | |

| NJHP-DC | Effect | −260.9 | −198.0 | −186.2 | −14.5 | 0.6 | −0.8 | 0.6 |

| Ranking | 1st | 2nd | 3rd | 4th | 6th | 5th | 7th | |

| Tehri-PH | Effect | −99.9 | −42.15 | −76.98 | −2.33 | 1.32 | −1.24 | 1.06 |

| Ranking | 1st | 3rd | 2nd | 4th | 7th | 5th | 6th | |

| SSP-PH | Effect | −8.49 | −0.041 | −7.66 | 4.71 | −0.63 | −0.84 | 0.68 |

| Ranking | 1st | 5th | 2nd | 7th | 4th | 3rd | 6th | |

| SLBHP-MH | Effect | −60.2 | −24.82 | −46.7 | 2.59 | 0.09 | 0.02 | 0.10 |

| Ranking | 1st | 3rd | 2nd | 7th | 4th | 5th | 6th | |

| KLIP-P8-PH | Effect | −58.93 | −0.03 | −4.83 | 1.40 | −0.001 | −0.08 | 0.08 |

| Ranking | 1st | 4th | 2nd | 3rd | 5th | 6th | 7th | |

| PYKARA-MH | Effect | −85.86 | −28.94 | −69.32 | 11.80 | −1.27 | −1.20 | −1.21 |

| Ranking | 1st | 3rd | 2nd | 7th | 4th | 6th | 5th |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sudhakar, K.; Sinha, R.K.; Naik, S.R. Study on the Impact of Different Parameters on Prediction of Crown Deformations in Underground Caverns. Sustainability 2023, 15, 12851. https://doi.org/10.3390/su151712851

Sudhakar K, Sinha RK, Naik SR. Study on the Impact of Different Parameters on Prediction of Crown Deformations in Underground Caverns. Sustainability. 2023; 15(17):12851. https://doi.org/10.3390/su151712851

Chicago/Turabian StyleSudhakar, Kadiyala, Rabindra Kumar Sinha, and Sripad Ramachandra Naik. 2023. "Study on the Impact of Different Parameters on Prediction of Crown Deformations in Underground Caverns" Sustainability 15, no. 17: 12851. https://doi.org/10.3390/su151712851

APA StyleSudhakar, K., Sinha, R. K., & Naik, S. R. (2023). Study on the Impact of Different Parameters on Prediction of Crown Deformations in Underground Caverns. Sustainability, 15(17), 12851. https://doi.org/10.3390/su151712851