Microscopic Flow of CO2 in Complex Pore Structures: A Recent 10-Year Review

Abstract

:1. Introduction

2. Flow Experiments of CO2 in Complex Pore Structures

2.1. Traditional Characterization of Pore Structures during CO2 Microscopic Flow

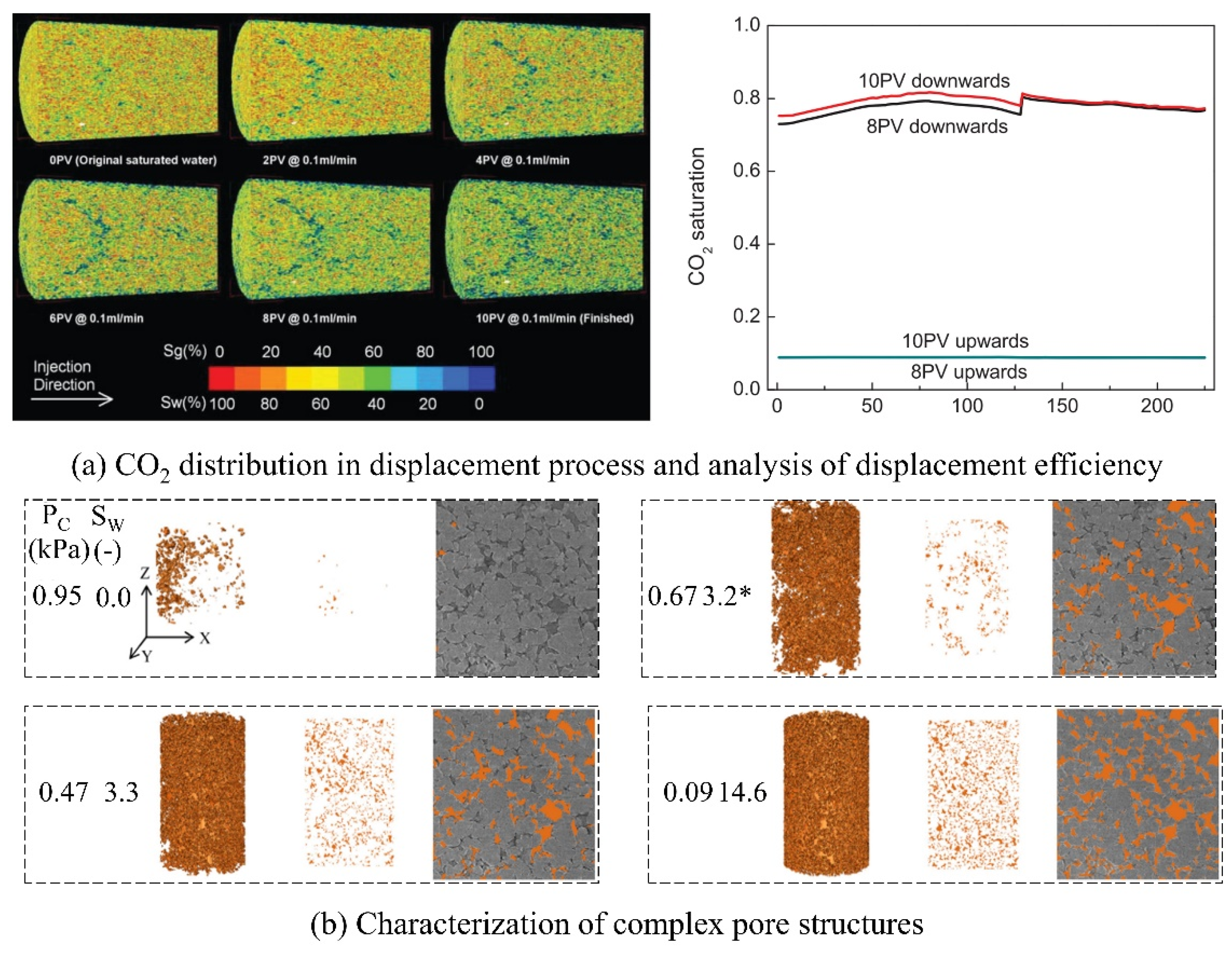

2.2. Effects of the Porosity and Permeability Characteristics on the Microscopic Flow Mechanism of CO2

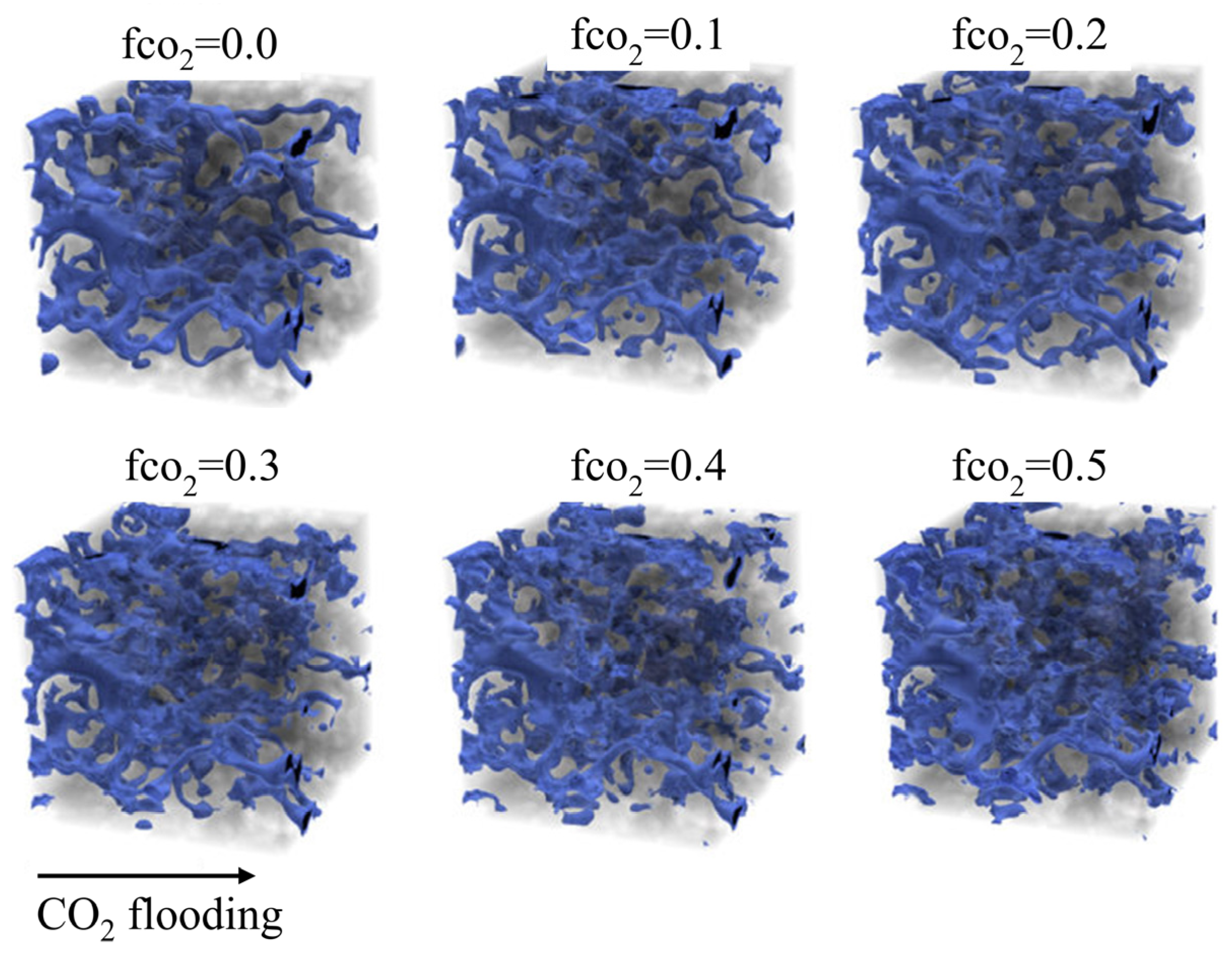

2.3. Two-Phase Flow Law in CO2 Microscopic Flow

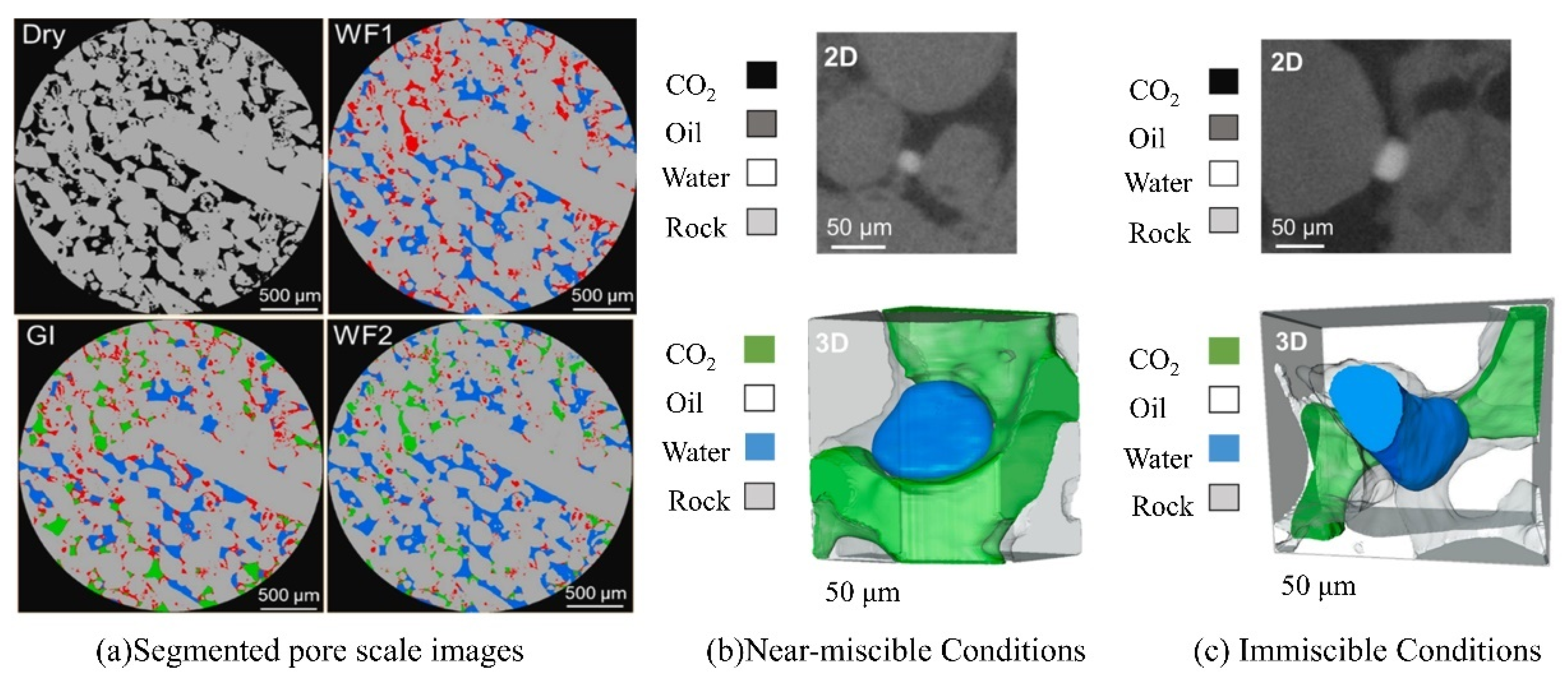

2.4. Microscopic Flow of CO2 in Different Phase States

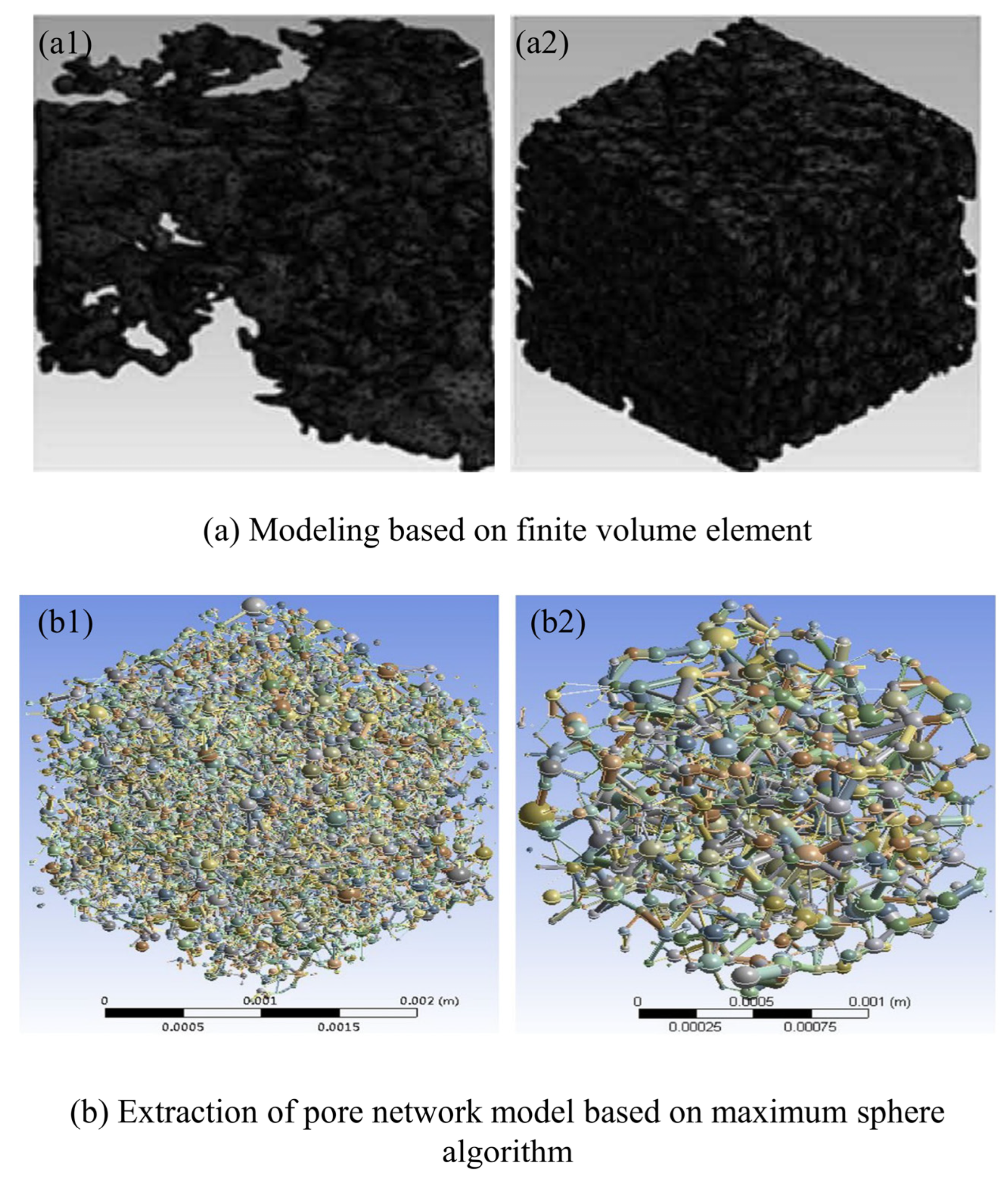

3. Theoretical Model of CO2 Flow in Pore Structures

4. Numerical Simulation of CO2 Flow in Pore Structures

4.1. Numerical Simulation Based on LBM

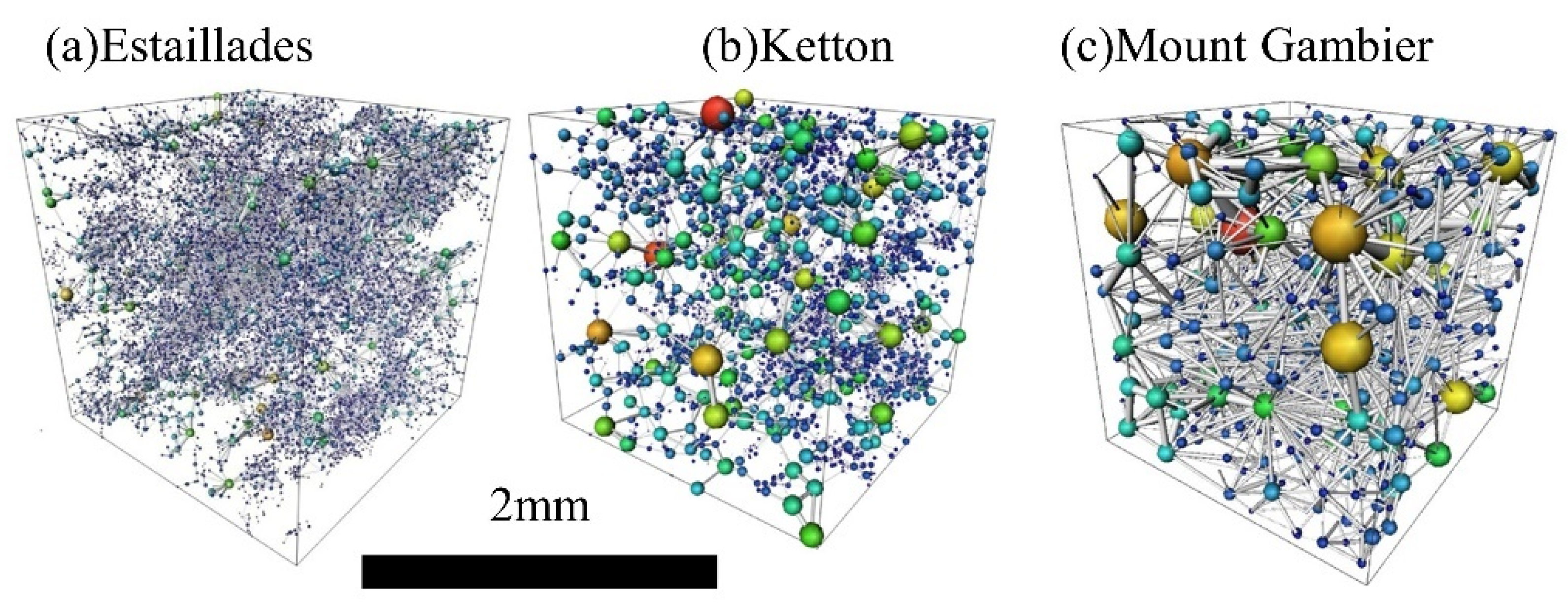

4.2. Numerical Simulation Based on the PNModel

5. Conclusions and Outlook

- Future studies should conduct real-time CT scanning experiments for CO2 displacement in combination with the research and development of a CO2 microscopic flow real-time CT scanning clamping device to achieve the real-time visualization and quantitative description of the CO2 flow behavior in complex pore structures.

- The flow mechanism of single-phase CO2 in complex pore structures has been extensively studied, but few studies investigated the micro-flow mechanism of multi-phase CO2. Therefore, more attention should be paid to the microscopic flow mechanism of multi-phase CO2 in complex pore structures in the future.

- CO2 geological storage should meet the needs of long-term storage and wide ranges. Therefore, the flow mechanism of CO2 in multiscale complex pore structures should be explored to upgrade from micro, mesoscopic to macro scales, which is of great importance for evaluating the long-term safety of CO2 geological storage.

- In the process of CO2 flow, chemical reactions occur on the pore surface, and the dissolution or precipitation of minerals changes the pore structures, which has a non-negligible impact on the microscopic flow mechanism of CO2. In the future, attention should be paid to the influence of changes in the pore structures caused by chemical reactions on the microscopic flow mechanism of CO2. The effects of wettability and damage are considered in the theoretical model study.

- The pore structures of the natural core are very complex, and the characteristics of the pore structure complexity and wettability are often simplified or ignored in the modeling process. In the future, advanced imaging technology should be combined with the complexity of the pore structure, the accuracy of the numerical model should be improved, and a numerical model that is closer to the natural core should be established for numerical simulations.

- The utilization of artificial intelligence (AI) for characterizing complex pore structures and forecasting fluid flows is also a prospective research focus within this domain.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Symbol | Significance | Units |

| q | Flow flux | m3/s |

| k | Absolute permeability | m2 |

| kr | Relative permeability | Dimensionless |

| μ | Viscosity of a fluid | Pa·s |

| ∇P | Pressure gradient | Pa |

| Flux | m/s | |

| φ | Porosity | Dimensionless |

| K | Absolute permeability | m2 |

| μi | Viscosity of the fluid | Pa·s |

| ρi | Density of the fluid | kg/m3 |

| g | Gravity constant | m/s2 |

| Pcr | Critical pressure | Pa |

| Psat | Hydrostatic pressure | Pa |

| q | Injection rate | m/s |

| L | Location of the bottom of the porous media | m |

| Zp | Location of the top of the porous media | m |

| keff | Vertical (harmonic) averaged effective permeability | m2 |

| Qi | Flow rate | m3/s |

| kri | Relative permeability | Dimensionless |

| kabs | Absolute permeability | m2 |

| A | Cross-sectional area of the sample | m2 |

| ΔP | Pressure difference | Pa |

| v | Darcy velocity | m/s |

| ρ | Density of the fluid | kg/m3 |

| P | Pressure of the fluid phase | Pa |

| Pc | Capillary pressure | Pa |

| γ | Interfacial tension | N/m |

| θ | Contact angle | ° |

| h | Height of the channel | mm |

| w | Width of the channel | mm |

References

- Yu, S.; Zhang, Q.; Hao, J.L.; Ma, W.; Sun, Y.; Wang, X.; Song, Y. Development of an extended STIRPAT model to assess the driving factors of household carbon dioxide emissions in China. J. Environ. Manag. 2023, 325, 116502. [Google Scholar] [CrossRef]

- Safaei-Farouji, M.; Vo Thanh, H.; Sheini Dashtgoli, D.; Yasin, Q.; Radwan, A.E.; Ashraf, U.; Lee, K.-K. Application of robust intelligent schemes for accurate modelling interfacial tension of CO2 brine systems: Implications for structural CO2 trapping. Fuel 2022, 319, 123821. [Google Scholar] [CrossRef]

- Park, J.H.; Yang, J.; Kim, D. Review of recent technologies for transforming carbon dioxide to carbon materials. Chem. Eng. J. 2022, 427, 130980. [Google Scholar] [CrossRef]

- Wu, S.; Wang, L.; Cai, Q.; Yan, X. Potential impact assessment for China’s dry and wet areas under global warming targets. Phys. Chem. Earth Parts A/B/C 2020, 116, 102838. [Google Scholar] [CrossRef]

- Gan, M.; Zhang, L.; Miao, X.; Oladyshkin, S.; Cheng, X.; Wang, Y.; Shu, Y.; Su, X.; Li, X. Application of computed tomography (CT) in geologic CO2 utilization and storage research: A critical review. J. Nat. Gas Sci. Eng. 2020, 83, 103591. [Google Scholar] [CrossRef]

- Yanzhong, W.; Nianmin, Z.; Xu, C.; Yingchang, C.; Guanghui, Y.; Gluyas, J.G.; Miruo, L. Geologic CO2 storage in arkosic sandstones with CaCl2-rich formation water. Chem. Geol. 2020, 558, 119867. [Google Scholar] [CrossRef]

- Medina-Martos, E.; Gálvez-Martos, J.-L.; Almarza, J.; Lirio, C.; Iribarren, D.; Valente, A.; Dufour, J. Environmental and economic performance of carbon capture with sodium hydroxide. J. CO2 Util. 2022, 60, 101991. [Google Scholar] [CrossRef]

- Araki, S.; Yamashita, R.; Li, K.; Yamamoto, H. Preparation and gas permeation properties of all-silica CHA zeolite hollow fiber membranes prepared on amorphous-silica hollow fibers. J. Membr. Sci. 2021, 634, 119338. [Google Scholar] [CrossRef]

- Bui, M.; Adjiman, C.S.; Bardow, A.; Anthony, E.J.; Boston, A.; Brown, S.; Fennell, P.S.; Fuss, S.; Galindo, A.; Hackett, L.A.; et al. Carbon capture and storage (CCS): The way forward. Energy Environ. Sci. 2018, 11, 1062–1176. [Google Scholar] [CrossRef]

- Cao, C.; Liu, H.; Hou, Z.; Mehmood, F.; Feng, W. A Review of CO2 Storage in View of Safety and Cost-Effectiveness. Energies 2020, 13, 600. [Google Scholar] [CrossRef]

- Ragui, K.; Bennacer, R.; Chen, L. Pore-scale modeling on supercritical CO2 invasion in 3D micromodel with randomly arranged spherical cross-sections. Energy Rep. 2021, 7, 33–42. [Google Scholar] [CrossRef]

- Lassen, R.N.; Plampin, M.R.; Sakaki, T.; Illangasekare, T.H.; Gudbjerg, J.; Sonnenborg, T.O.; Jensen, K.H. Effects of geologic heterogeneity on migration of gaseous CO2 using laboratory and modeling investigations. Int. J. Greenh. Gas Control 2015, 43, 213–224. [Google Scholar] [CrossRef]

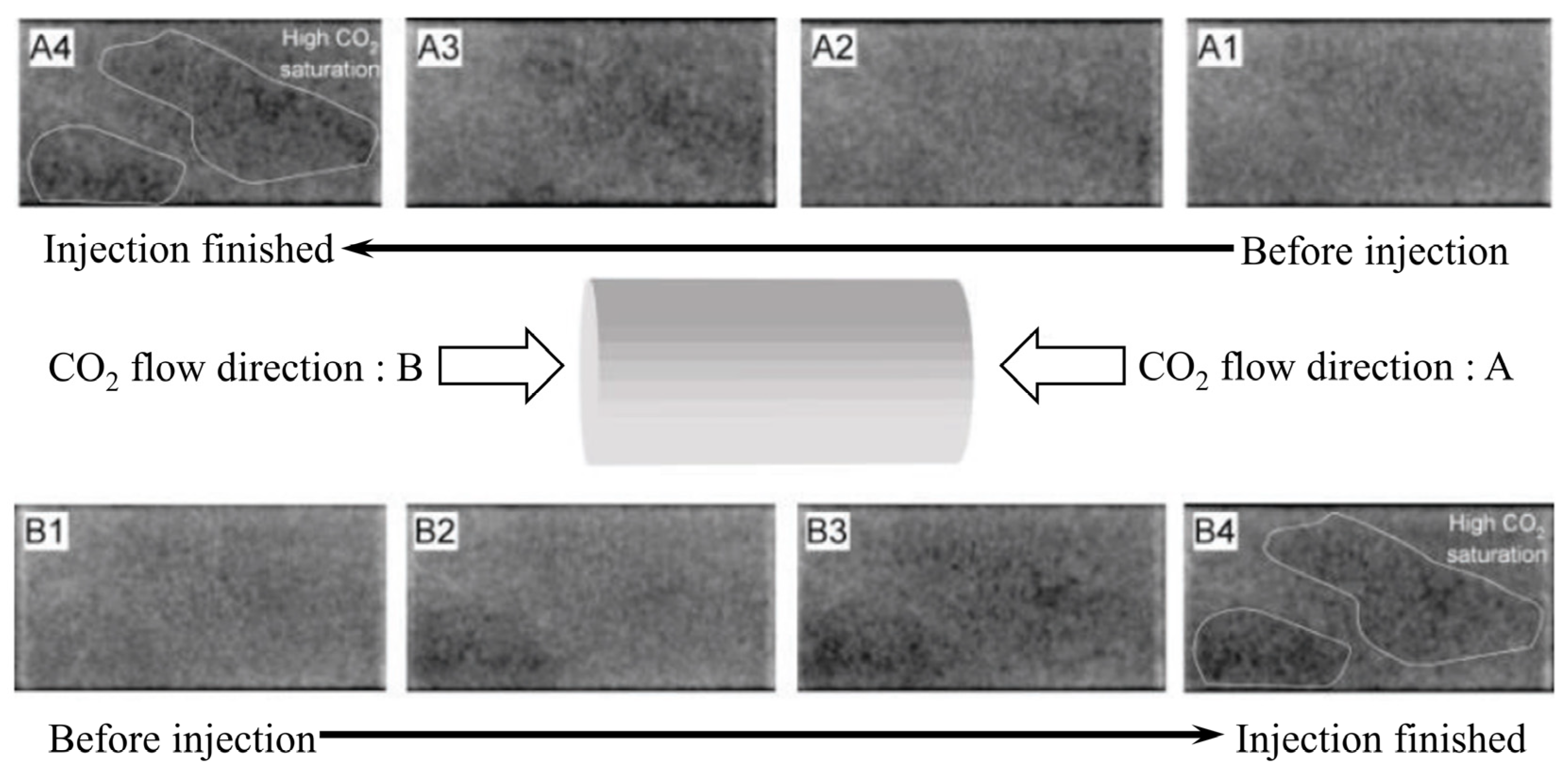

- Zhang, Y.; Kogure, T.; Nishizawa, O.; Xue, Z. Different flow behavior between 1-to-1 displacement and co-injection of CO2 and brine in Berea sandstone: Insights from laboratory experiments with X-ray CT imaging. Int. J. Greenh. Gas Control 2017, 66, 76–84. [Google Scholar] [CrossRef]

- Saleem, U.; Dewar, M.; Chaudhary, T.N.; Sana, M.; Lichtschlag, A.; Alendal, G.; Chen, B. Numerical modelling of CO2 migration in heterogeneous sediments and leakage scenario for STEMM-CCS field experiments. Int. J. Greenh. Gas Control 2021, 109, 103339. [Google Scholar] [CrossRef]

- Cheng, X.; Mei, K.; Li, Z.; Zhang, X.; Guo, X. Research on the Interface Structure during Unidirectional Corrosion for Oil-Well Cement in H2S Based on Computed Tomography Technology. Ind. Eng. Chem. Res. 2016, 55, 10889–10895. [Google Scholar] [CrossRef]

- Xu, L.; Li, Q.; Myers, M.; Chen, Q.; Li, X. Application of nuclear magnetic resonance technology to carbon capture, utilization and storage: A review. J. Rock Mech. Geotech. Eng. 2019, 11, 892–908. [Google Scholar] [CrossRef]

- Hefny, M.; Qin, C.; Saar, M.O.; Ebigbo, A. Synchrotron-based pore-network modeling of two-phase flow in Nubian Sandstone and implications for capillary trapping of carbon dioxide. Int. J. Greenh. Gas Control 2020, 103, 103164. [Google Scholar] [CrossRef]

- Berg, S.; Oedai, S.; Ott, H. Displacement and mass transfer between saturated and unsaturated CO2–brine systems in sandstone. Int. J. Greenh. Gas Control 2013, 12, 478–492. [Google Scholar] [CrossRef]

- Dalton, L.E.; Klise, K.A.; Fuchs, S.; Crandall, D.; Goodman, A. Methods to measure contact angles in scCO2-brine-sandstone systems. Adv. Water Resour. 2018, 122, 278–290. [Google Scholar] [CrossRef]

- Liu, Q.; Liu, J.; Pei, G.; Zhu, Z.; Lei, Y. A New Method for Artificial Core Reconstruction of a Fracture-Control Matrix Unit. Adv. Civ. Eng. 2020, 2020, 7469584. [Google Scholar] [CrossRef]

- Liu, Q.; Song, R.; Liu, J.; Pei, G.; Lei, Y. Mass transfer model of fracture-controlled matrix unit: Model derivation and experimental verification based on fractal theory and micro-CT scanning technology. Energy Rep. 2020, 6, 3067–3079. [Google Scholar] [CrossRef]

- Liu, Q.; Liang, B.; Liu, J.; Sun, W.; Lei, Y. Imbibition oil recovery of single fracture-controlled matrix unit: Model construction and numerical simulation. Capillarity 2022, 5, 32–40. [Google Scholar] [CrossRef]

- Liu, Q.; Liu, J.; Liang, B.; Sun, W.; He, J.; Lei, Y.; Sheng, G. The Influence of Pore Structure of the Core-Scale Fracture-Controlled Matrix Unit on Imbibition: Model Construction and Definition of the Fractal Coefficient. Lithosphere 2022, 2022, 6245345. [Google Scholar] [CrossRef]

- Liu, Q.; Song, R.; Liu, J.; Lei, Y.; Zhu, X. Pore-scale visualization and quantitative analysis of the spontaneous imbibition based on experiments and micro-CT technology in low-permeability mixed-wettability rock. Energy Sci. Eng. 2020, 8, 1840–1856. [Google Scholar] [CrossRef]

- Liu, Q.; Li, J.; Liang, B.; Liu, J.; Sun, W.; He, J.; Lei, Y. Complex wettability behavior triggering mechanism on imbibition: A model construction and comparative study based on analysis at multiple scales. Energy 2023, 275, 127434. [Google Scholar] [CrossRef]

- Liu, J.-j.; Song, R.; Cui, M.-m. Improvement of predictions of petrophysical transport behavior using three-dimensional finite volume element model with micro-CT images. J. Hydrodyn. 2015, 27, 234–241. [Google Scholar] [CrossRef]

- Song, R.; Liu, J.; Cui, M. Single- and two-phase flow simulation based on equivalent pore network extracted from micro-CT images of sandstone core. Springerplus 2016, 5, 817. [Google Scholar] [CrossRef]

- Krause, M.; Perrin, J.-C.; Kuo, C.-W.; Benson, S.M. Characterization of CO2 storage properties using core analysis techniques and thin section data. Energy Procedia 2009, 1, 2969–2974. [Google Scholar] [CrossRef]

- Zou, X.Y.; Li, X.Q.; Zhang, J.Z.; Li, H.; Guo, M.; Zhao, P. Characteristics of Pore Structure and Gas Content of the Lower Paleozoic Shale from the Upper Yangtze Plate, South China. Energies 2021, 14, 7603. [Google Scholar] [CrossRef]

- Dai, X.; Wang, M.; Weia, C.; Zhang, J.; Wang, X.; Zou, M. Factors affecting shale microscopic pore structure variation during interaction with supercritical CO2. J. CO2 Util. 2020, 38, 194–211. [Google Scholar] [CrossRef]

- Ozotta, O.; Liu, K.; Gentzis, T.; Carvajal-Ortiz, H.; Ostadhassan, M. Pore Structure Alteration of Organic-Rich Shale with Sc-CO2 Exposure: The Bakken Formation. Energy Fuels 2021, 35, 5074–5089. [Google Scholar] [CrossRef]

- Du, Y.; Sang, S.; Pan, Z.; Wang, W.; Liu, S.; Fu, C.; Zhao, Y.; Zhang, J. Experimental study of supercritical CO2-H2O-coal interactions and the effect on coal permeability. Fuel 2019, 253, 369–382. [Google Scholar] [CrossRef]

- Khather, M.; Saeedi, A.; Rezaee, R.; Noble, R.R.P. Experimental evaluation of carbonated brine-limestone interactions under reservoir conditions-emphasis on the effect of core scale heterogeneities. Int. J. Greenh. Gas Control 2018, 68, 128–145. [Google Scholar] [CrossRef]

- Pearce, J.K.; Dawson, G.K.W.; Golab, A.; Knuefing, L.; Sommacal, S.; Rudolph, V.; Golding, S.D. A combined geochemical and μCT study on the CO2 reactivity of Surat Basin reservoir and cap-rock cores: Porosity changes, mineral dissolution and fines migration. Int. J. Greenh. Gas Control 2019, 80, 10–24. [Google Scholar] [CrossRef]

- Brattekås, B.; Haugen, M. Explicit tracking of CO2-flow at the core scale using micro-Positron Emission Tomography (μPET). J. Nat. Gas Sci. Eng. 2020, 77, 103268. [Google Scholar] [CrossRef]

- Clarkson, C.R.; Solano, N.; Bustin, R.M.; Bustin, A.M.M.; Chalmers, G.R.L.; He, L.; Melnichenko, Y.B.; Radliński, A.P.; Blach, T.P. Pore structure characterization of North American shale gas reservoirs using USANS/SANS, gas adsorption, and mercury intrusion. Fuel 2013, 103, 606–616. [Google Scholar] [CrossRef]

- Tang, Y.; Hou, C.; He, Y.; Wang, Y.; Chen, Y.; Rui, Z. Review on Pore Structure Characterization and Microscopic Flow Mechanism of CO2. Flooding in Porous Media. Energy Technol. 2020, 9, 2000787. [Google Scholar] [CrossRef]

- Yan, H.; Zhang, J.; Zhou, N.; Li, M. Application of hybrid artificial intelligence model to predict coal strength alteration during CO(2) geological sequestration in coal seams. Sci. Total Environ. 2020, 711, 135029. [Google Scholar] [CrossRef]

- Zhang, H.; Thanh, H.V.; Rahimi, M.; Al-Mudhafar, W.J.; Tangparitkul, S.; Zhang, T.; Dai, Z.; Ashraf, U. Improving predictions of shale wettability using advanced machine learning techniques and nature-inspired methods: Implications for carbon capture utilization and storage. Sci. Total Environ. 2023, 877, 162944. [Google Scholar] [CrossRef]

- Kitamura, K.; Kogure, T.; Nishizawa, O.; Xue, Z. Experimental and Numerical Study of Residual CO2 Trapping in Porous Sandstone. Energy Procedia 2013, 37, 4093–4098. [Google Scholar] [CrossRef]

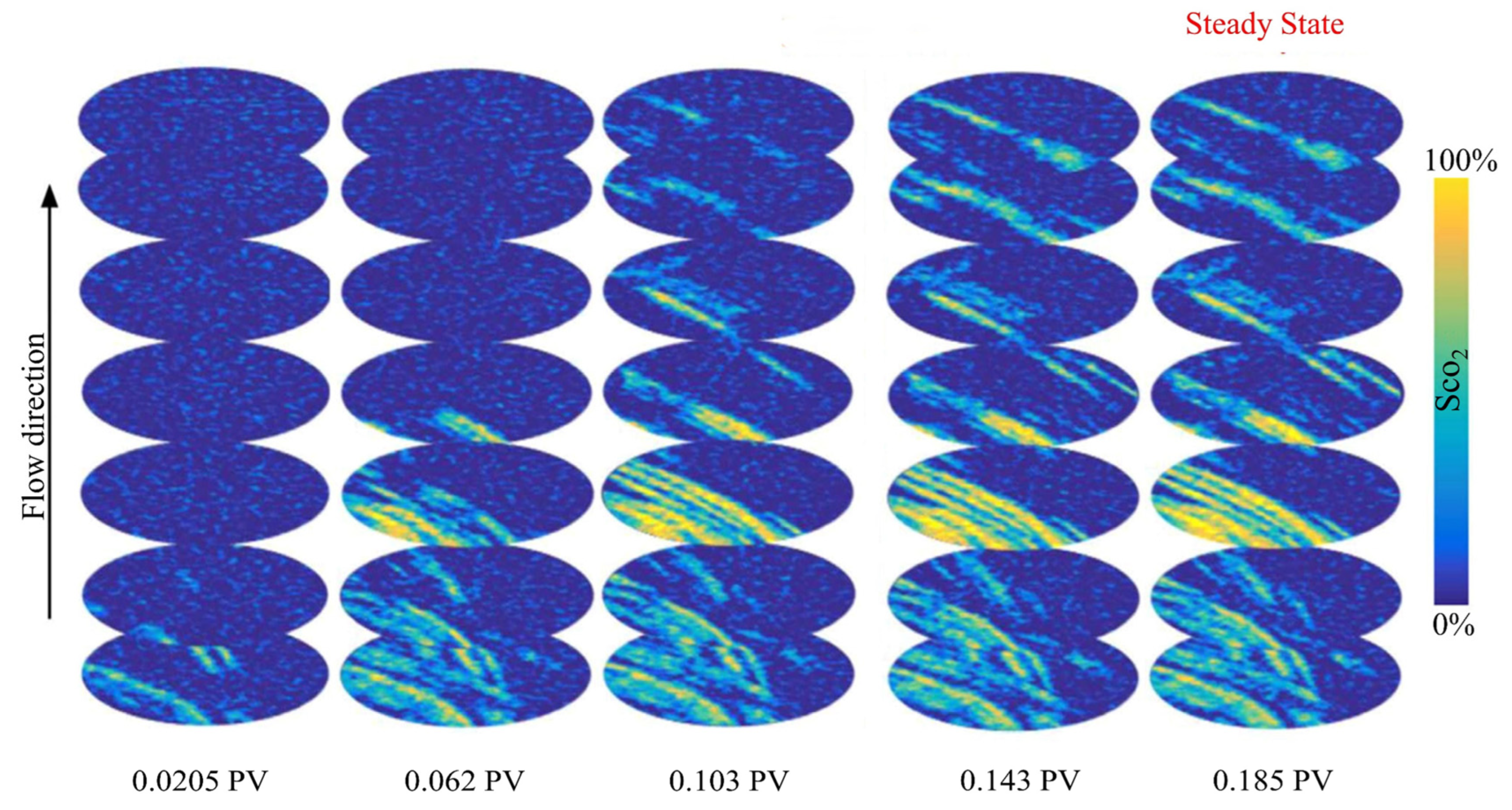

- Krishnamurthy, P.G.; Senthilnathan, S.; Yoon, H.; Thomassen, D.; Meckel, T.; DiCarlo, D. Comparison of Darcy’s law and invasion percolation simulations with buoyancy-driven CO2-brine multiphase flow in a heterogeneous sandstone core. J. Pet. Sci. Eng. 2017, 155, 54–62. [Google Scholar] [CrossRef]

- Yan, W.; Crandall, D.; Bruner, K.; Ning, W.; Gill, M.; Xiaochun, L.; Bromhal, G. Core and Pore Scale Characterization of Liujiagou Outcrop Sandstone, Ordos basin, China for CO2 Aquifer Storage. Energy Procedia 2013, 37, 5055–5062. [Google Scholar] [CrossRef]

- Al-Bayati, D.; Saeedi, A.; Myers, M.; White, C.; Xie, Q. Insights into immiscible supercritical CO2 EOR: An XCT scanner assisted flow behaviour in layered sandstone porous media. J. CO2 Util. 2019, 32, 187–195. [Google Scholar] [CrossRef]

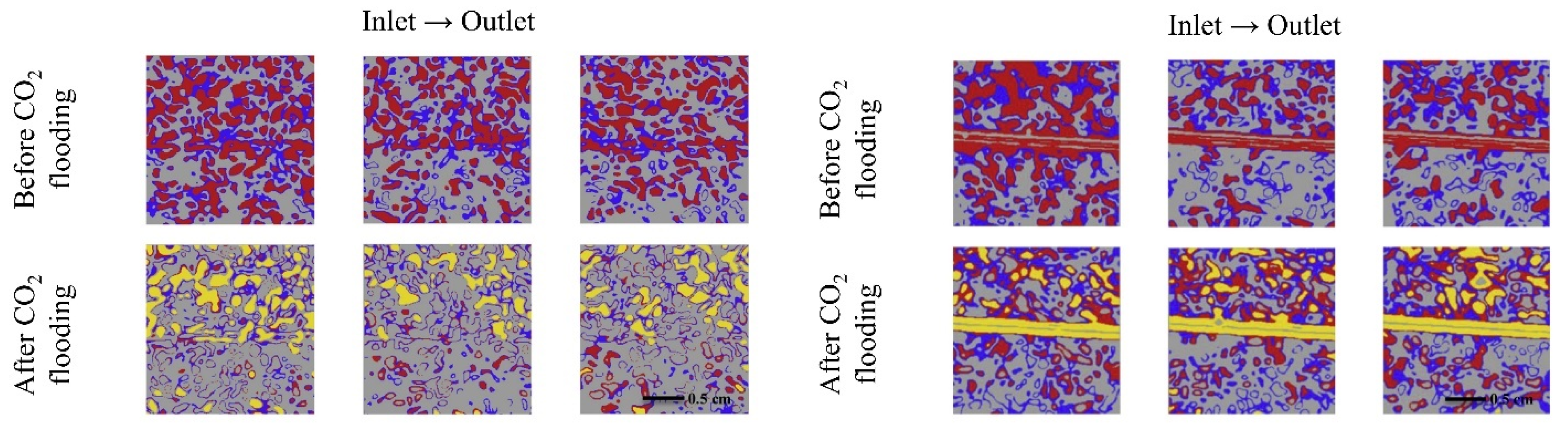

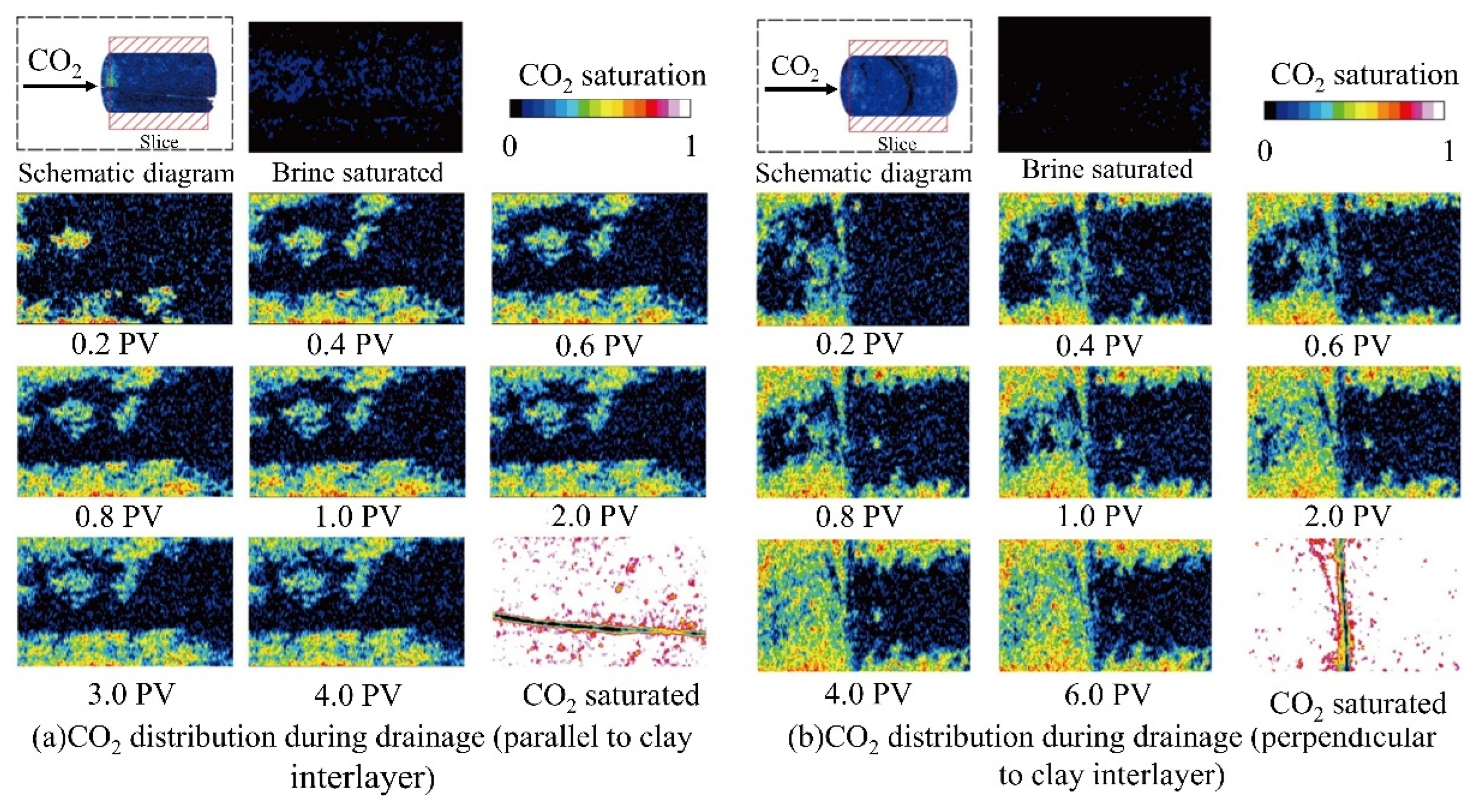

- Xu, L.; Li, Q.; Myers, M.; White, C.; Tan, Y. Experimental and numerical investigation of supercritical CO2 migration in sandstone with multiple clay interlayers. Int. J. Greenh. Gas Control 2021, 104, 103194. [Google Scholar] [CrossRef]

- Xu, L.; Myers, M.; Li, Q.; White, C.; Zhang, X. Migration and storage characteristics of supercritical CO2 in anisotropic sandstones with clay interlayers based on X-CT experiments. J. Hydrol. 2020, 580, 124239. [Google Scholar] [CrossRef]

- Zhu, Q.; Zhou, Q.; Li, X. Numerical simulation of displacement characteristics of CO2 injected in pore-scale porous media. J. Rock Mech. Geotech. Eng. 2016, 8, 87–92. [Google Scholar] [CrossRef]

- Kogure, T.; Nishizawa, O.; Chiyonobu, S.; Yazaki, Y.; Shibatani, S.; Xue, Z. Effect of Sub-core Scale Heterogeneity on Relative Permeability Curves of Porous Sandstone in a Water-supercritical CO2 System. Energy Procedia 2013, 37, 4491–4498. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, H.; Shen, Z.; Song, Y. Estimation of CO2 Storage Capacity in Porous Media by using X-ray Micro-CT. Energy Procedia 2013, 37, 5201–5208. [Google Scholar] [CrossRef]

- Lv, P.; Liu, Y.; Yang, W. Investigation on CO2 permeation in water-saturated porous media with disordered pore sizes. Exp. Therm. Fluid Sci. 2020, 119, 110207. [Google Scholar] [CrossRef]

- Teng, Y.; Liu, Y.; Lu, G.; Jiang, L.; Wang, D.; Song, Y. Experimental Evaluation of Injection Pressure and Flow Rate Effects on Geological CO2 Sequestration Using MRI. Energy Procedia 2017, 114, 4986–4993. [Google Scholar] [CrossRef]

- Zhang, Y.; Park, H.; Nishizawa, O.; Kiyama, T.; Xue, Z. Fluid Distribution Effects on P-wave Velocity of CO2/brine Saturated Rocks: A Comparison Study and Implications for CO2 Storage Monitoring Using Seismic Method. Energy Procedia 2017, 114, 3786–3792. [Google Scholar] [CrossRef]

- Herring, A.L.; Andersson, L.; Newell, D.L.; Carey, J.W.; Wildenschild, D. Pore-scale observations of supercritical CO2 drainage in Bentheimer sandstone by synchrotron x-ray imaging. Int. J. Greenh. Gas Control 2014, 25, 93–101. [Google Scholar] [CrossRef]

- Liu, Y.; Teng, Y.; Lu, G.; Jiang, L.; Zhao, J.; Zhang, Y.; Song, Y. Experimental study on CO2 diffusion in bulk n-decane and n-decane saturated porous media using micro-CT. Fluid Phase Equilib. 2016, 417, 212–219. [Google Scholar] [CrossRef]

- Khalil, M.; Liu, N.; Lee], R. Effect of particle hydrophobicity on CO2 foam generation and foam flow behavior in porous media. Fuel 2014, 126, 104–108. [Google Scholar]

- Xue, Z.; Nishio, S.; Hagiwara, N.; Matsuoka, T. Microbubble Carbon Dioxide Injection for Enhanced Dissolution in Geological Sequestration and Improved Oil Recovery. Energy Procedia 2014, 63, 7939–7946. [Google Scholar] [CrossRef]

- Patmonoaji, A.; Zhang, Y.; Xue, Z.; Park, H.; Suekane, T. Experimental and numerical simulation of supercritical CO2 microbubble injection into a brine-saturated porous medium. Int. J. Greenh. Gas Control 2019, 91, 102830. [Google Scholar] [CrossRef]

- Zhai, H.; Xue, Z.; Park, H.; Aizawa, Y.; Baba, Y.; Zhang, Y. Migration characteristics of supercritical CO2 microbubble flow in the Berea sandstone revealed by voxel-based X-ray computed tomography imaging analysis. J. Nat. Gas Sci. Eng. 2020, 77, 103233. [Google Scholar] [CrossRef]

- Du, D.; Wang, D.; Jia, N.; Lyu, W.; Qin, J.; Wang, C.; Sun, S.; Li, Y. Experiments on CO2 foam seepage characteristics in porous media. Pet. Explor. Dev. 2016, 43, 499–505. [Google Scholar] [CrossRef]

- McLendon, W.J.; Koronaios, P.; Enick, R.M.; Biesmans, G.; Salazar, L.; Miller, A.; Soong, Y.; McLendon, T.; Romanov, V.; Crandall, D. Assessment of CO2-soluble non-ionic surfactants for mobility reduction using mobility measurements and CT imaging. J. Pet. Sci. Eng. 2014, 119, 196–209. [Google Scholar] [CrossRef]

- Du, D.; Li, Y.; Zhang, D.; Dong, X.; Wang, F.; Chao, K. Experimental study on the inlet behavior of CO2 foam three phase displacement processes in porous media. Exp. Therm. Fluid Sci. 2019, 103, 247–261. [Google Scholar] [CrossRef]

- Alhosani, A.; Lin, Q.; Scanziani, A.; Andrews, E.; Zhang, K.; Bijeljic, B.; Blunt, M.J. Pore-scale characterization of carbon dioxide storage at immiscible and near-miscible conditions in altered-wettability reservoir rocks. Int. J. Greenh. Gas Control 2021, 105, 103232. [Google Scholar] [CrossRef]

- Qin, Z.; Arshadi, M.; Piri, M. Near-miscible supercritical CO2 injection in oil-wet carbonate: A pore-scale experimental investigation of wettability state and three-phase flow behavior. Adv. Water Resour. 2021, 158, 104057. [Google Scholar] [CrossRef]

- Hao, Y.; Li, Z.; Su, Y.; Kong, C.; Chen, H.; Meng, Y. Experimental investigation of CO2 storage and oil production of different CO2 injection methods at pore-scale and core-scale. Energy 2022, 254, 124349. [Google Scholar] [CrossRef]

- Horton; George, W. Darcy’s Law. Am. J. Phys. 1964, 32, 569. [Google Scholar] [CrossRef]

- Mathias, S.A.; Gluyas, J.G.; Bryant, S.L.; Wilson, D. On the importance of relative permeability data for estimating CO2 injectivity in brine aquifers. Int. J. Greenh. Gas Control 2013, 12, 200–212. [Google Scholar] [CrossRef]

- Porter, M.L.; Plampin, M.R.; Pawar, R.; Illangasekare, T. CO2 leakage in shallow aquifers: A benchmark modeling study of CO2 gas evolution in heterogeneous porous media. Int. J. Greenh. Gas Control 2015, 39, 51–61. [Google Scholar] [CrossRef]

- Islam, A.W.; Sharif, M.; Carlson, E.S. Numerical investigation of double diffusive natural convection of CO2 in a brine saturated geothermal reservoir. Geothermics 2013, 48, 101–111. [Google Scholar] [CrossRef]

- Feng, G.; Xu, T.; Tian, H.; Lu, M.; Connell, L.D.; Lei, H.; Shi, Y. Three-phase non-isothermal flow behavior of CO2-brine leakage from wellbores. Int. J. Greenh. Gas Control 2017, 64, 183–193. [Google Scholar] [CrossRef]

- Wang, D.; Zhao, M.; Song, Y.; Xu, H.; Ma, X. Influence of Capillary Pressure and Injection Rate as well as Heterogeneous and Anisotropic Permeability on CO2 Transport and Displacement Efficiency in Water-Saturated Porous Media. Energy Procedia 2013, 37, 3945–3951. [Google Scholar] [CrossRef]

- Chapman, E.M.; Yang, J.; Crawshaw, J.P.; Boek, E.S. Pore Scale Models for Imbibition of CO2 Analogue Fluids in Etched Micro-model||junctions Using Micro-fluidic Experiments and Direct Flow Calculations. Energy Procedia 2013, 37, 3680–3686. [Google Scholar] [CrossRef]

- Ovaysi, S.; Piri, M. Pore-scale dissolution of CO2+SO2 in deep saline aquifers. Int. J. Greenh. Gas Control 2013, 15, 119–133. [Google Scholar] [CrossRef]

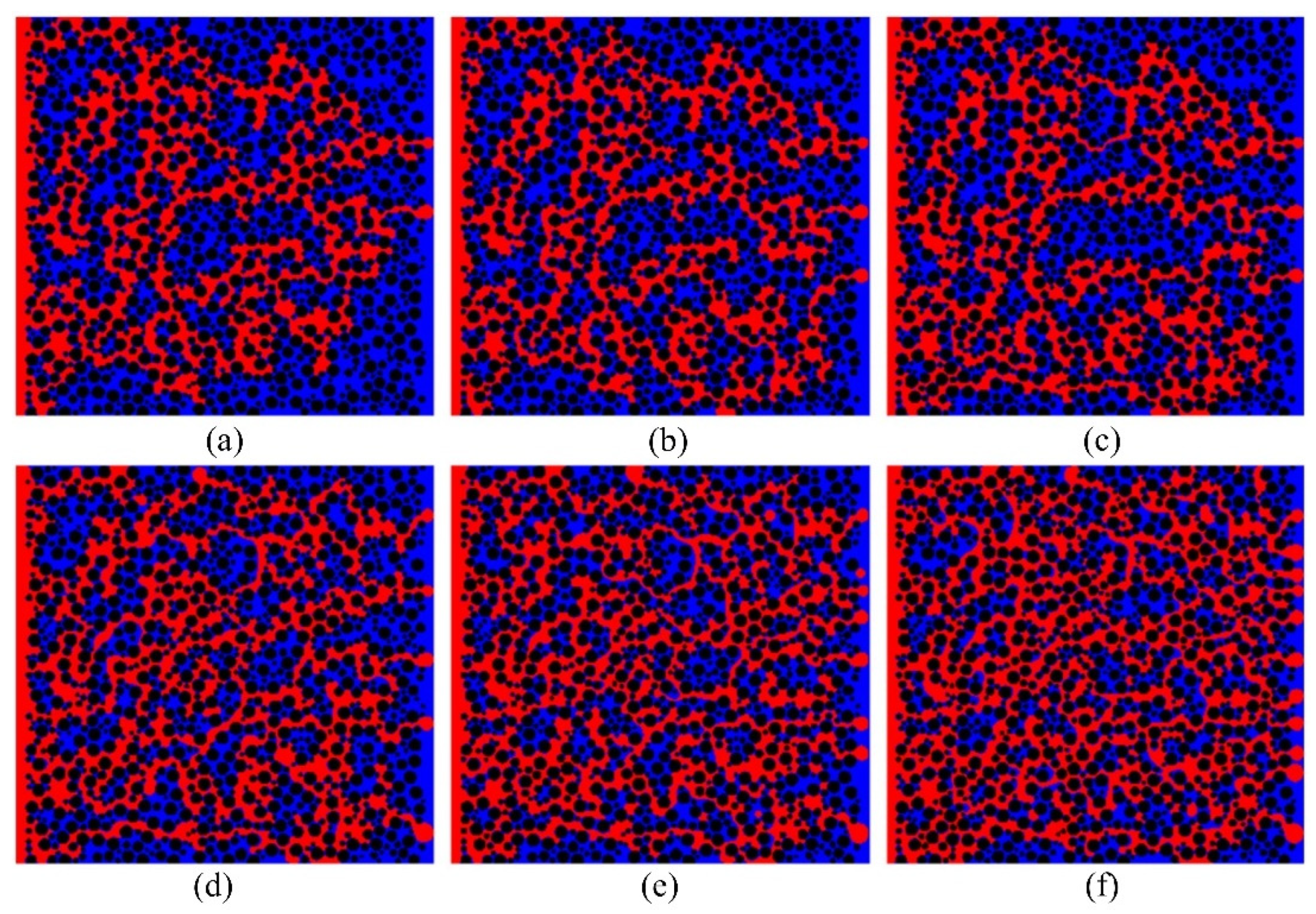

- Kohanpur, A.H.; Rahromostaqim, M.; Valocchi, A.J.; Sahimi, M. Two-phase flow of CO2-brine in a heterogeneous sandstone: Characterization of the rock and comparison of the lattice-Boltzmann, pore-network, and direct numerical simulation methods. Adv. Water Resour. 2020, 135, 103469. [Google Scholar] [CrossRef]

- Liu, H.; Valocchi, A.J.; Werth, C.; Kang, Q.; Oostrom, M. Pore-scale simulation of liquid CO2 displacement of water using a two-phase lattice Boltzmann model. Adv. Water Resour. 2014, 73, 144–158. [Google Scholar] [CrossRef]

- Hu, R.; Wan, J.; Kim, Y.; Tokunaga, T.K. Wettability effects on supercritical CO2–brine immiscible displacement during drainage: Pore-scale observation and 3D simulation. Int. J. Greenh. Gas Control 2017, 60, 129–139. [Google Scholar] [CrossRef]

- Ferrari, A.; Lunati, I. Direct numerical simulations of interface dynamics to link capillary pressure and total surface energy. Adv. Water Resour. 2013, 57, 19–31. [Google Scholar] [CrossRef]

- Venkateswaran, S. Efficient Implementation of Turbulence Modeling for CFD; Springer: Berlin/Heidelberg, Germany, 1994; pp. 363–367. [Google Scholar]

- Liu, X.; Godbole, A.; Lu, C.; Michal, G.; Linton, V. Investigation of the consequence of high-pressure CO2 pipeline failure through experimental and numerical studies. Appl. Energy 2019, 250, 32–47. [Google Scholar] [CrossRef]

- Chen, W.; Chen, S.; Yuan, X.; Zhang, H.; Yu, K. Three-dimensional simulation of interfacial convection in CO2–ethanol system by hybrid lattice Boltzmann method with experimental validation. Chin. J. Chem. Eng. 2015, 23, 356–365. [Google Scholar] [CrossRef]

- Jiang, F.; Hu, C. Numerical simulation of a rising CO2 droplet in the initial accelerating stage by a multiphase lattice Boltzmann method. Appl. Ocean. Res. 2014, 45, 1–9. [Google Scholar] [CrossRef]

- Tang, M.; Zhan, H.; Lu, S.; Ma, H.; Tan, H. Pore Scale CO2 Displacement Simulation Based on Three Fluid Phase Lattice Boltzmann Method. Energy Fuels 2019, 33, 10039–10055. [Google Scholar] [CrossRef]

- Chang, C.; Kneafsey, T.J.; Zhou, Q.; Oostrom, M.; Ju, Y. Scaling the impacts of pore-scale characteristics on unstable supercritical CO2-water drainage using a complete capillary number. Int. J. Greenh. Gas Control 2019, 86, 11–21. [Google Scholar] [CrossRef]

- Jiang, F.; Tsuji, T. Numerical investigations on the effect of initial state CO2 topology on capillary trapping efficiency. Int. J. Greenh. Gas Control 2016, 49, 179–191. [Google Scholar] [CrossRef]

- Yang, G.; Chen, Y.; Chen, S.; Wang, M. Implementation of a direct-addressing based lattice Boltzmann GPU solver for multiphase flow in porous media. Comput. Phys. Commun. 2023, 291, 108828. [Google Scholar] [CrossRef]

- Fakhari, A.; Li, Y.; Bolster, D.; Christensen, K.T. A phase-field lattice Boltzmann model for simulating multiphase flows in porous media: Application and comparison to experiments of CO2 sequestration at pore scale. Adv. Water Resour. 2018, 114, 119–134. [Google Scholar] [CrossRef]

- Bakhshian, S.; Hosseini, S.A. Pore–scale analysis of supercritical CO2–brine immiscible displacement under fractional–wettability conditions. Adv. Water Resour. 2019, 126, 96–107. [Google Scholar] [CrossRef]

- Guo, R.; Dalton, L.E.; Fan, M.; McClure, J.; Zeng, L.; Crandall, D.; Chen, C. The role of the spatial heterogeneity and correlation length of surface wettability on two-phase flow in a CO2-water-rock system. Adv. Water Resour. 2020, 146, 103763. [Google Scholar] [CrossRef]

- Guo, R.; Dalton, L.; Crandall, D.; McClure, J.; Wang, H.; Li, Z.; Chen, C. Role of heterogeneous surface wettability on dynamic immiscible displacement, capillary pressure, and relative permeability in a CO2-water-rock system. Adv. Water Resour. 2022, 165, 104226. [Google Scholar] [CrossRef]

- Atia, A.; Mohammedi, K. Pore-scale study based on lattice Boltzmann method of density driven natural convection during CO2 injection project. Chin. J. Chem. Eng. 2015, 23, 1593–1602. [Google Scholar] [CrossRef]

- Wang, H.; Su, Y.; Wang, W.; Jin, Z.; Chen, H. CO2-oil diffusion, adsorption and miscible flow in nanoporous media from pore-scale perspectives. Chem. Eng. J. 2022, 450, 137957. [Google Scholar] [CrossRef]

- Yin, Y.; Qu, Z.; Prodanović, M.; Landry, C.J. Identifying the dominant transport mechanism in single nanoscale pores and 3D nanoporous media. Fundam. Res. 2023, 3, 409–421. [Google Scholar] [CrossRef]

- Sha, X.; Chen, L.; Zhu, X.; Wang, S.; Feng, Q.; Tao, W.-Q. Pore-scale study of three-phase reactive transport processes in porous media. Phys. Fluids 2022, 34, 123318. [Google Scholar] [CrossRef]

- Vogel, H.J.; Tlke, J.; Schulz, V.P.; Krafczyk, M.; Roth, K. Comparison of a Lattice-Boltzmann Model, a Full-Morphology Model, and a Pore Network Model for Determining Capillary Pressure–Saturation Relationships. Vadose Zone J. 2005, 4, 380–388. [Google Scholar] [CrossRef]

- Blunt, M.J.; Bijeljic, B.; Dong, H.; Gharbi, O.; Iglauer, S.; Mostaghimi, P.; Paluszny, A.; Pentland, C. Pore-scale imaging and modelling. Adv. Water Resour. 2013, 51, 197–216. [Google Scholar] [CrossRef]

- Bensinger, J.; Beckingham, L.E. CO2 storage in the Paluxy formation at the Kemper County CO2 storage complex: Pore network properties and simulated reactive permeability evolution. Int. J. Greenh. Gas Control 2020, 93, 102887. [Google Scholar] [CrossRef]

- Campos, R.; Barrios, I.; Lillo, J. Experimental CO2 injection: Study of physical changes in sandstone porous media using Hg porosimetry and 3D pore network models. Energy Rep. 2015, 1, 71–79. [Google Scholar] [CrossRef]

- Benali, B.; Føyen, T.L.; Alcorn, Z.P.; Haugen, M.; Gauteplass, J.; Kovscek, A.R.; Fernø, M.A. Pore-scale bubble population dynamics of CO2-foam at reservoir pressure. Int. J. Greenh. Gas Control 2022, 114, 103607. [Google Scholar] [CrossRef]

- Liu, B.; Suzuki, A.; Ito, T. Estimating the seepage effect of SC-CO2 and water fracturing with a steady-state flow model considering capillary and viscous forces at the pore scale. J. Pet. Sci. Eng. 2020, 184, 106483. [Google Scholar] [CrossRef]

- Cao, S.C.; Dai, S.; Jung, J. Supercritical CO2 and brine displacement in geological carbon sequestration: Micromodel and pore network simulation studies. Int. J. Greenh. Gas Control 2016, 44, 104–114. [Google Scholar] [CrossRef]

- Basirat, F.; Yang, Z.; Niemi, A. Pore-scale modeling of wettability effects on CO2–brine displacement during geological storage. Adv. Water Resour. 2017, 109, 181–195. [Google Scholar] [CrossRef]

| No. | Size (10−3 m) | Element Number | Porosity | kx/mD | ky/mD | Kz/mD | Kz/mD(exp.) |

|---|---|---|---|---|---|---|---|

| a1 | 1.326 | 338,899 | 17.83% | 8.26 | 5.15 | 3.56 | 3.35 |

| a2 | 2.136 | 561,158 | 47.62% | 1646.92 | 1843.57 | 1245.11 | - |

| No. | Size (mm) | Number of Pores | Number of Throats | Average Connection Number | Porosity of EPNM (%) | Experimental Porosity (%) | EPNM/mD |

|---|---|---|---|---|---|---|---|

| b1 | 2.14 | 6298 | 12,558 | 3.92 | 19.27 | 18.73 | 1210 |

| b2 | 1.46 | 810 | 1563 | 3.72 | 13.71 | 13.11 | 872 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Q.; Li, J.; Liang, B.; Sun, W.; Liu, J.; Lei, Y. Microscopic Flow of CO2 in Complex Pore Structures: A Recent 10-Year Review. Sustainability 2023, 15, 12959. https://doi.org/10.3390/su151712959

Liu Q, Li J, Liang B, Sun W, Liu J, Lei Y. Microscopic Flow of CO2 in Complex Pore Structures: A Recent 10-Year Review. Sustainability. 2023; 15(17):12959. https://doi.org/10.3390/su151712959

Chicago/Turabian StyleLiu, Qiang, Jialong Li, Bing Liang, Weiji Sun, Jianjun Liu, and Yun Lei. 2023. "Microscopic Flow of CO2 in Complex Pore Structures: A Recent 10-Year Review" Sustainability 15, no. 17: 12959. https://doi.org/10.3390/su151712959