Effects of Geometric Parameters and Heat-Transfer Fluid Injection Direction on Enhanced Phase-Change Energy Storage in Vertical Shell-and-Tube System

Abstract

:1. Introduction

2. Numerical Simulation

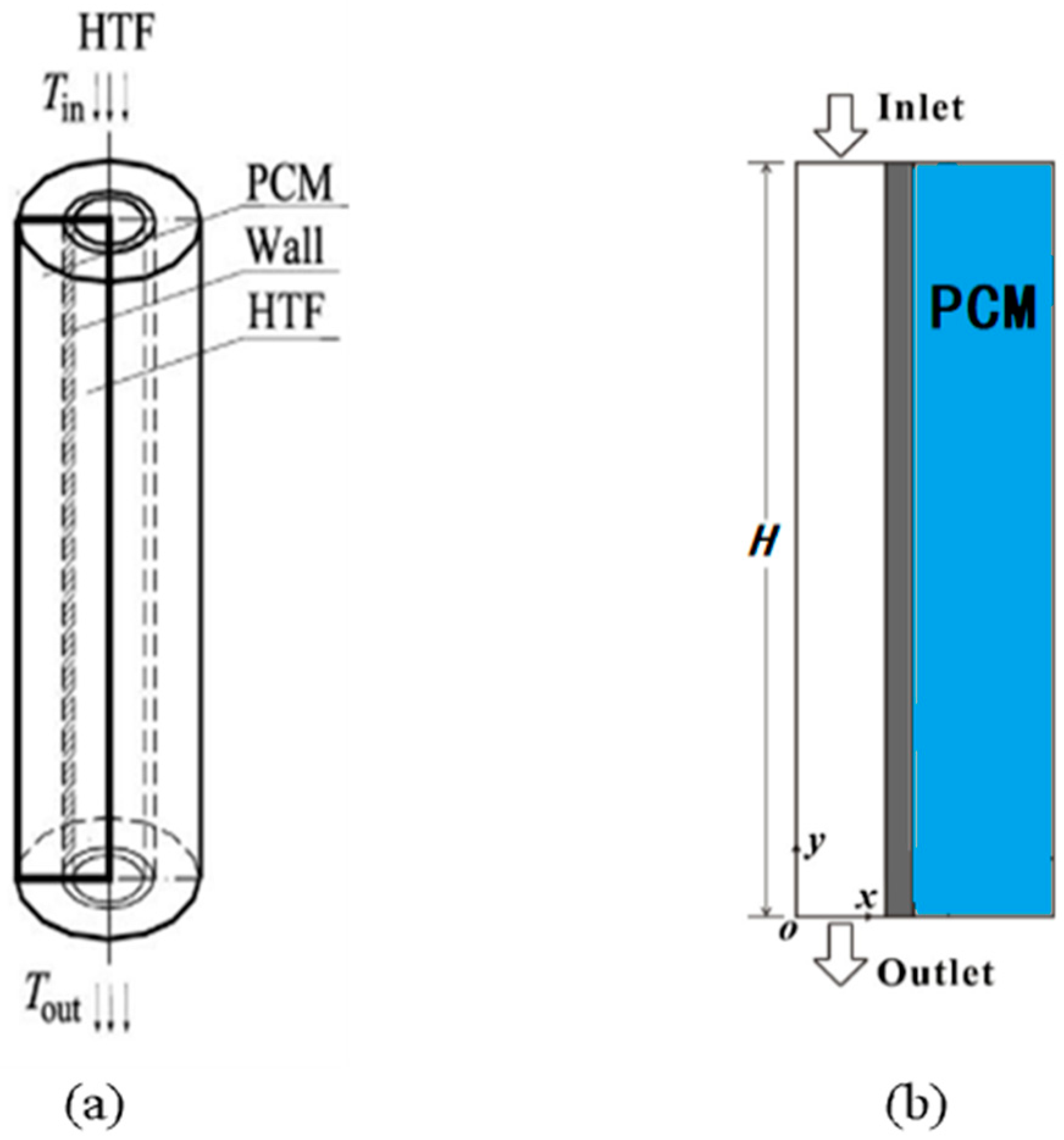

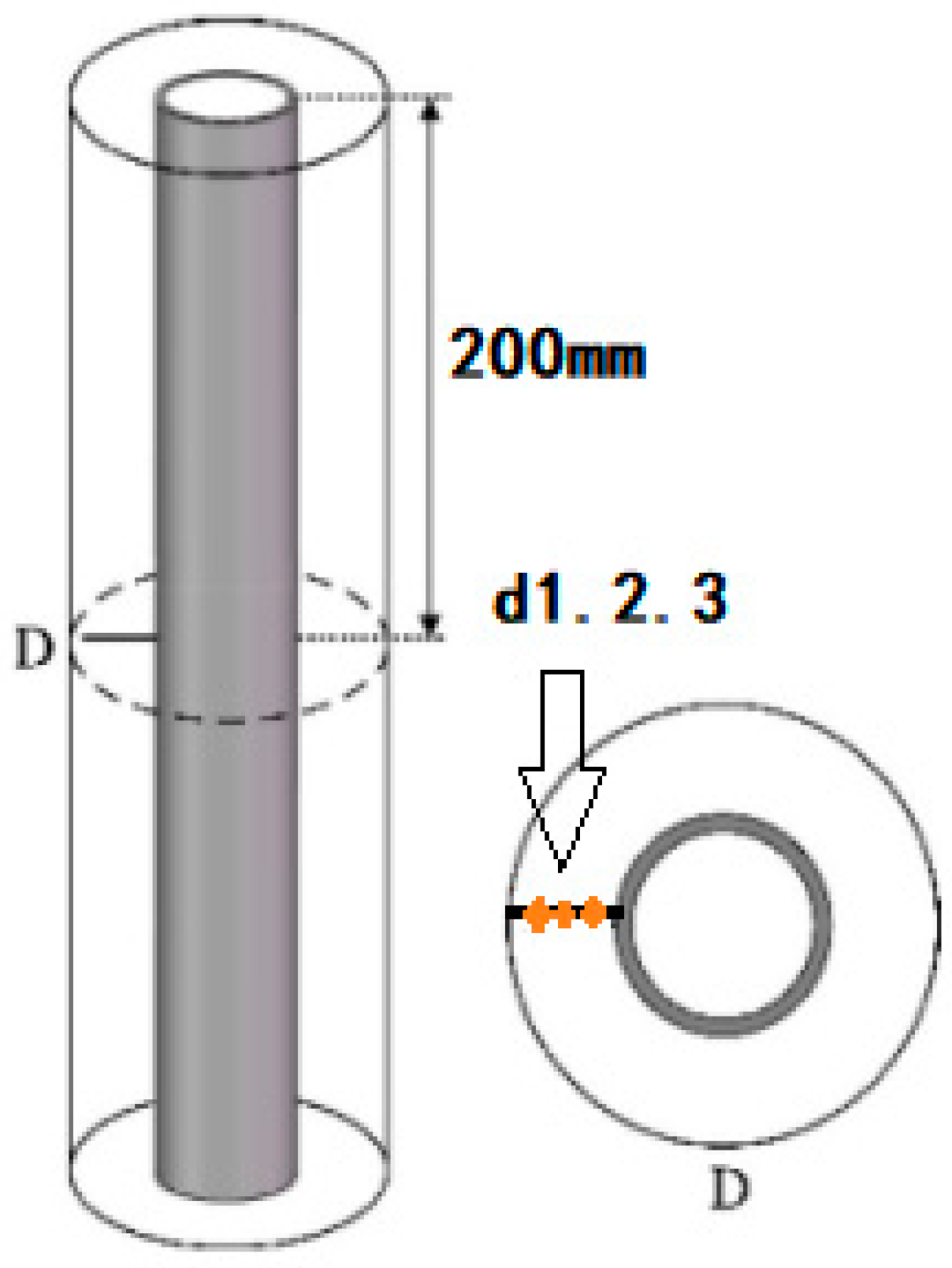

2.1. Physical Models and Computational Domains

2.2. Governing Equation

2.3. Initial and Boundary Conditions

2.4. Numerical Process

2.5. Grid Independence Verification and Time Step Determination

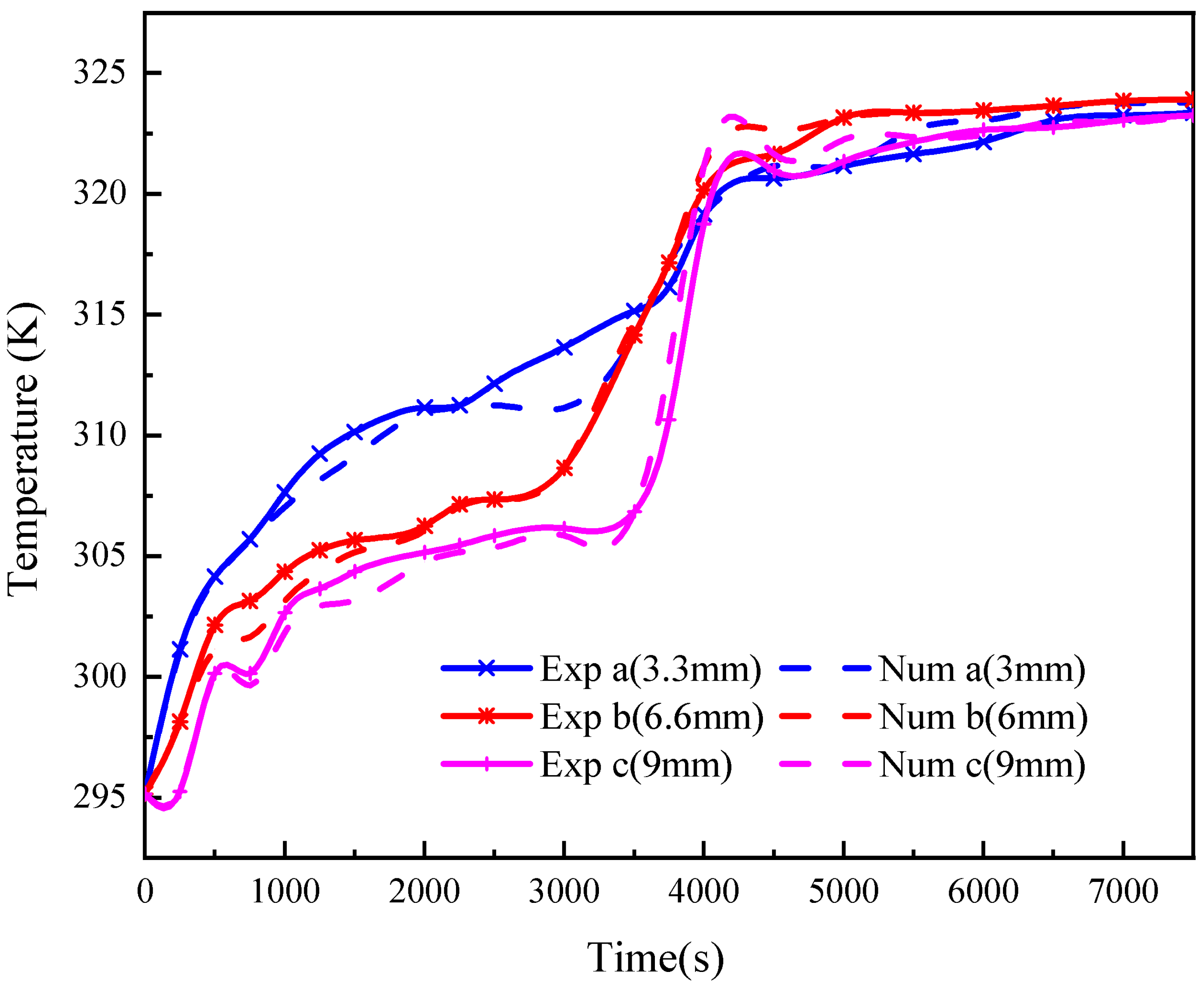

2.6. Verification of Experiments and Simulations

3. Results and Discussion

3.1. Effect of HTF Injection Direction on PCM Melting

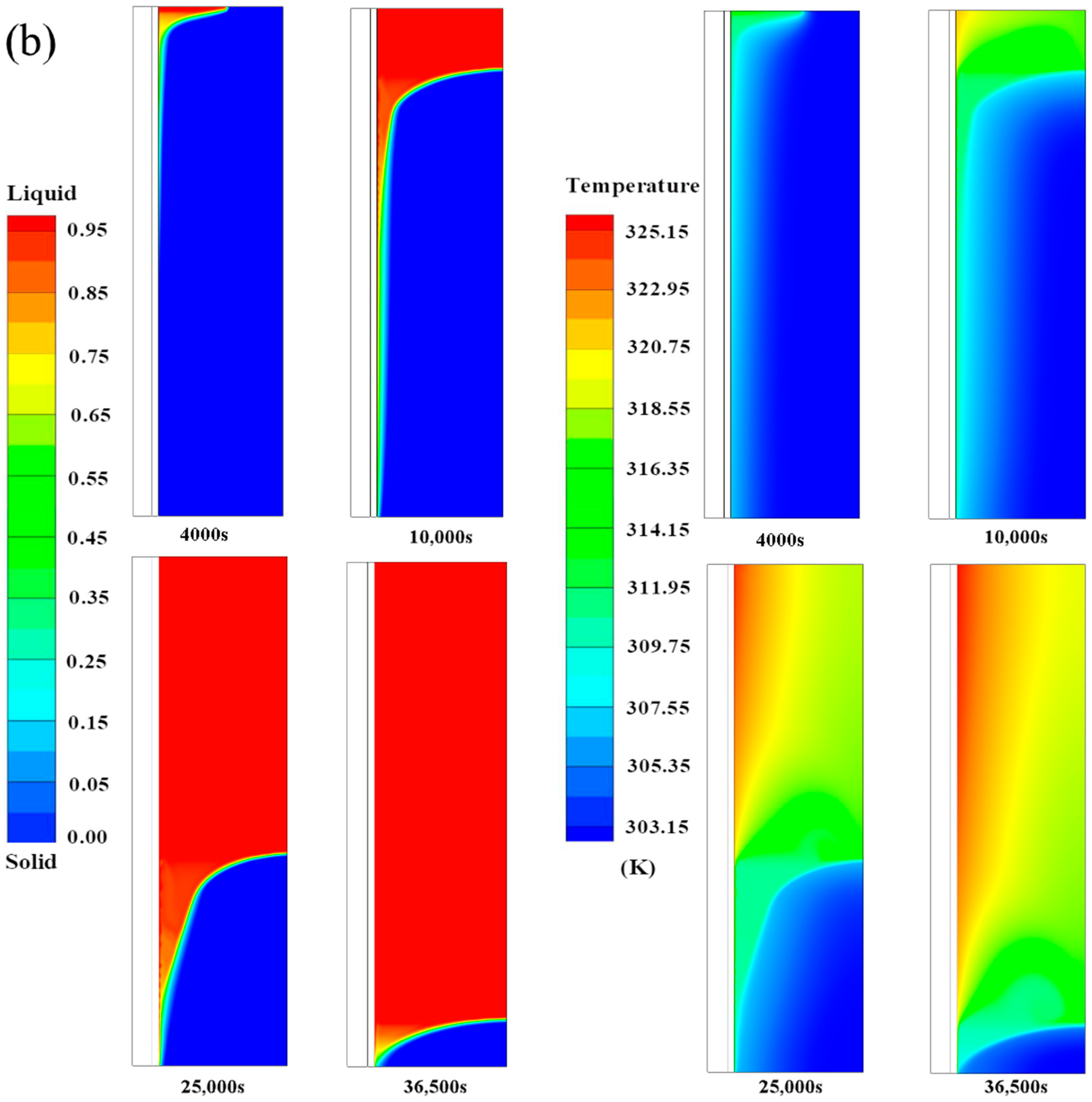

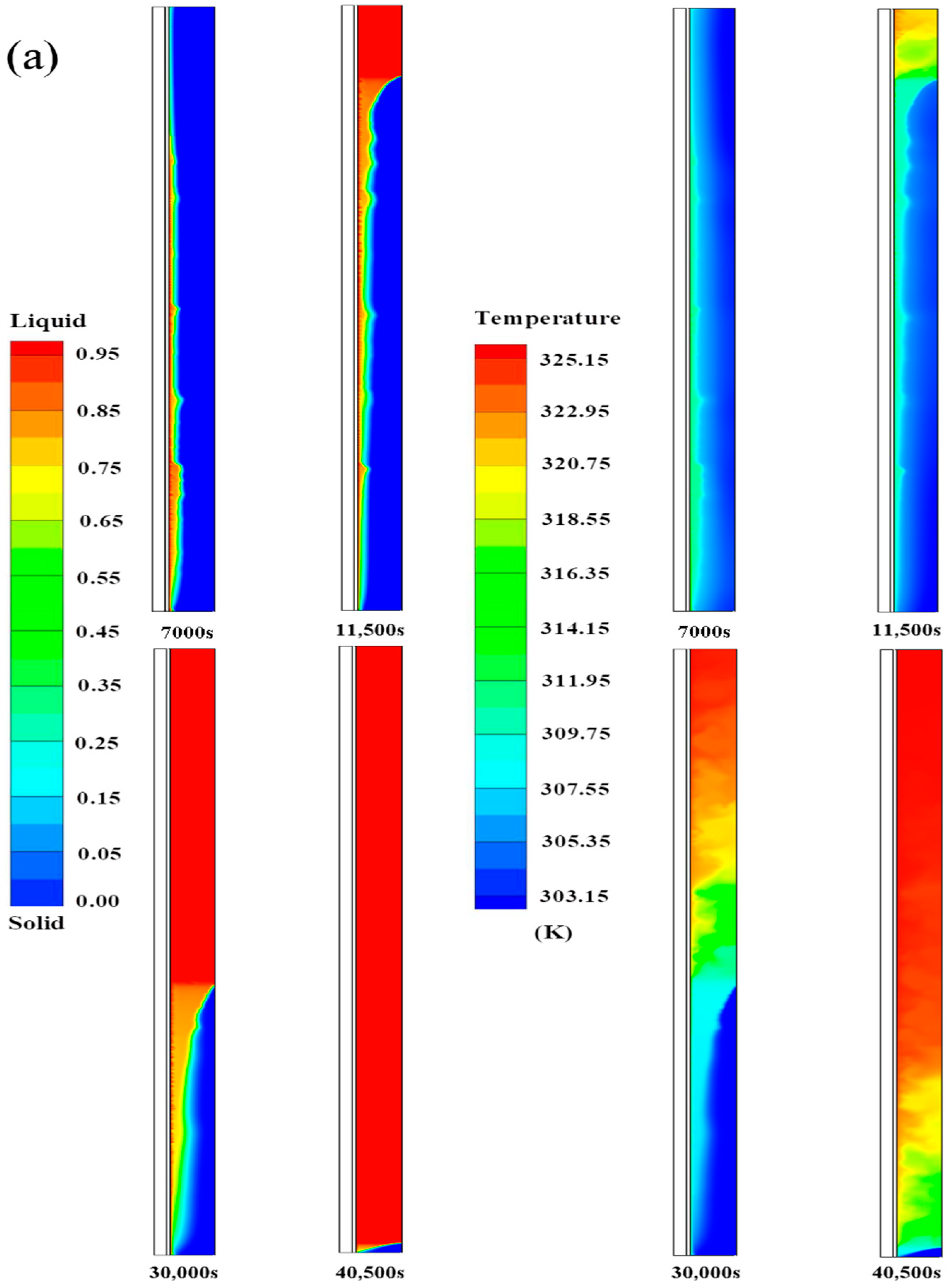

3.1.1. Evolution of Solid–Liquid Interface and Isotherm of PCM Injected at the Top of HTF

3.1.2. Evolution of Solid–Liquid Interface and Isotherm of PCM Injected at the Bottom of HTF

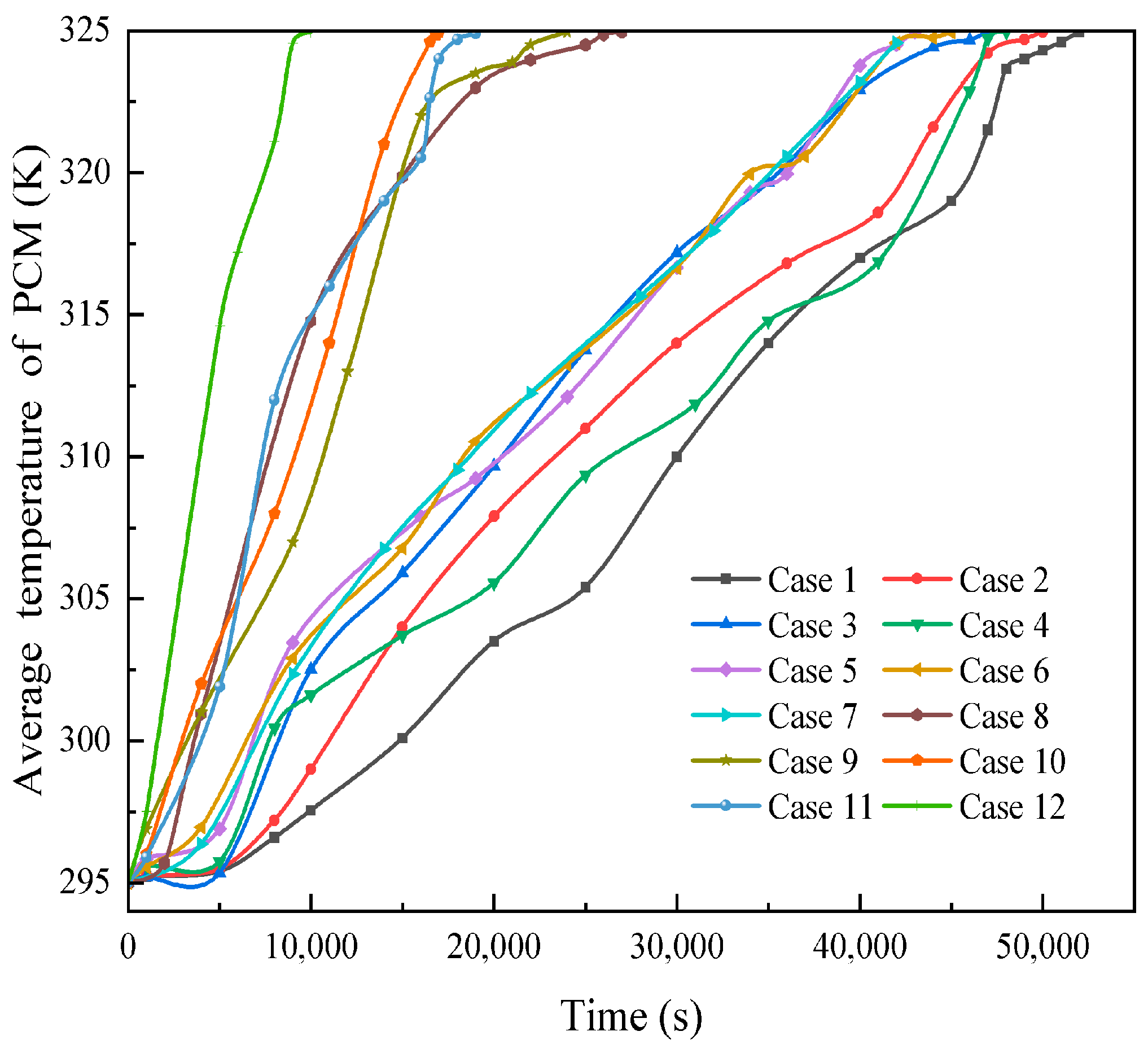

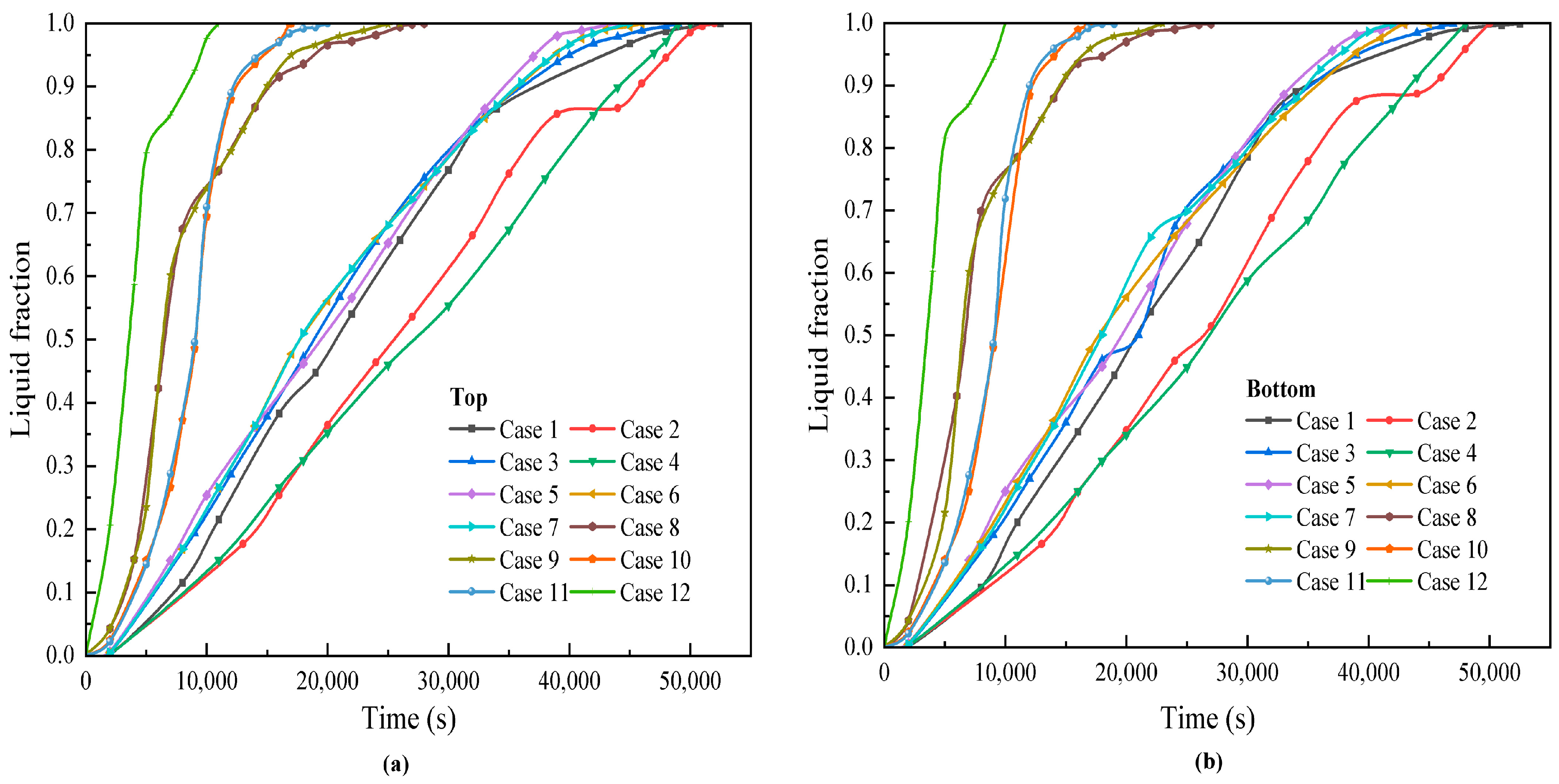

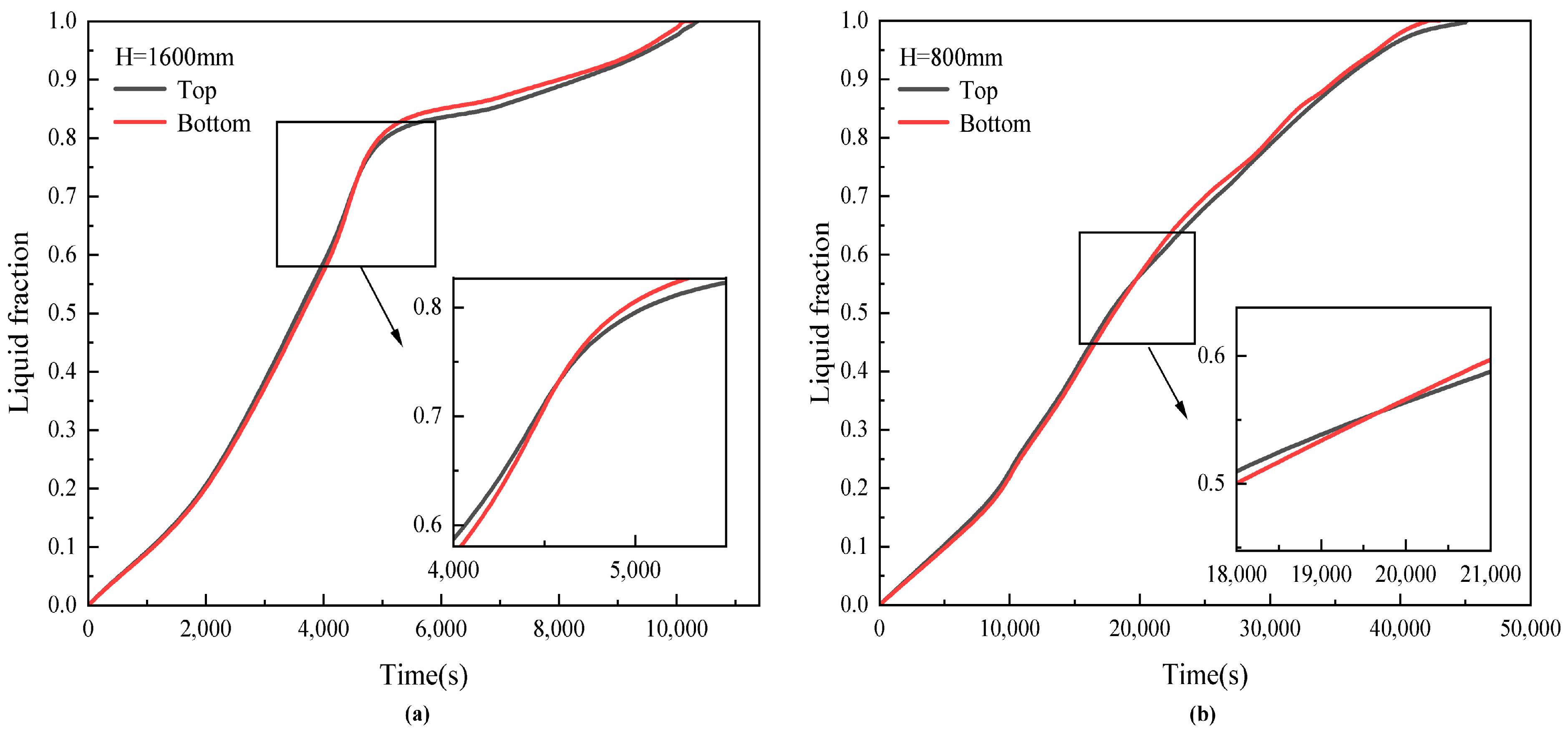

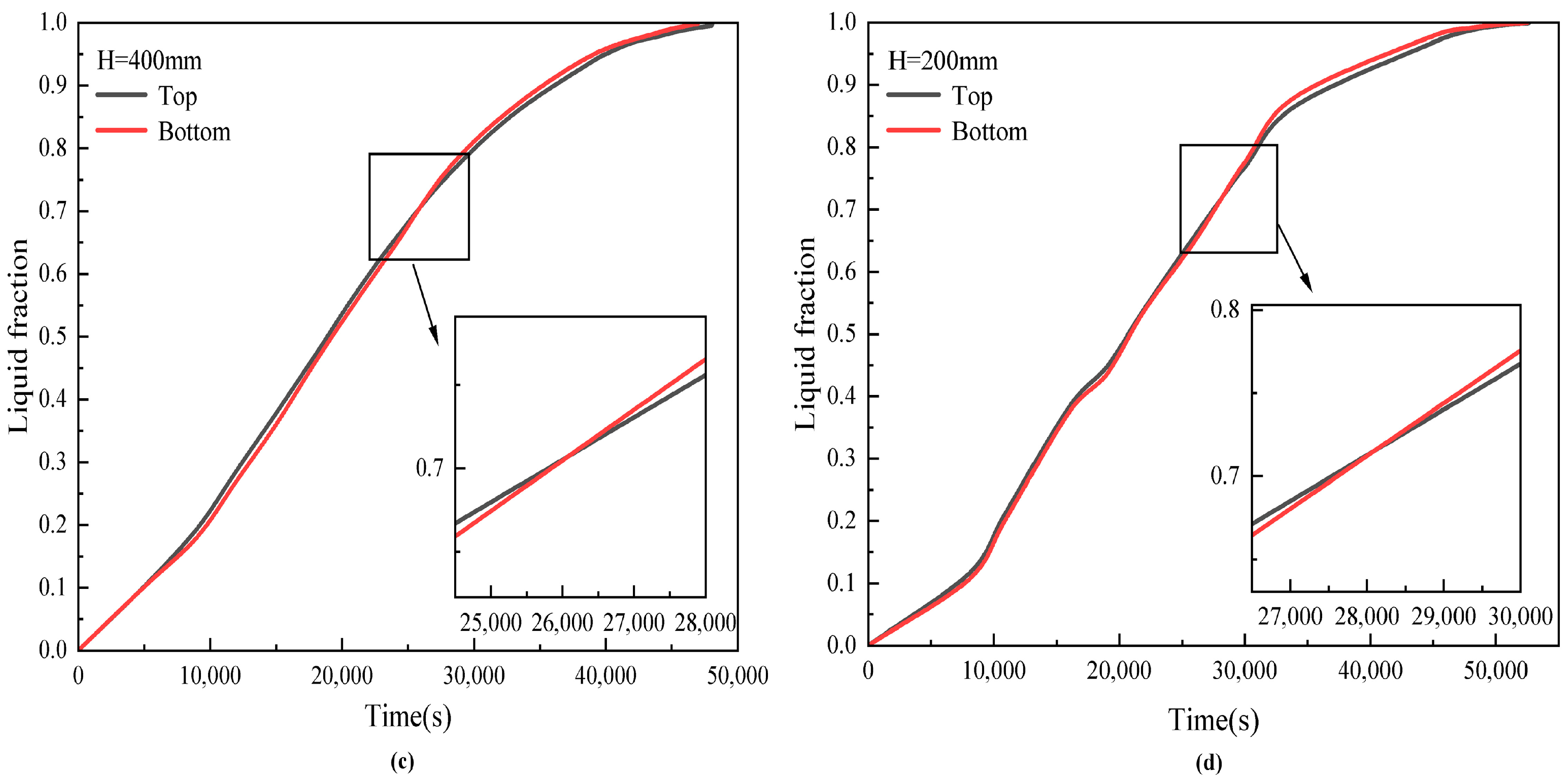

3.1.3. Change in PCM Melting Rate

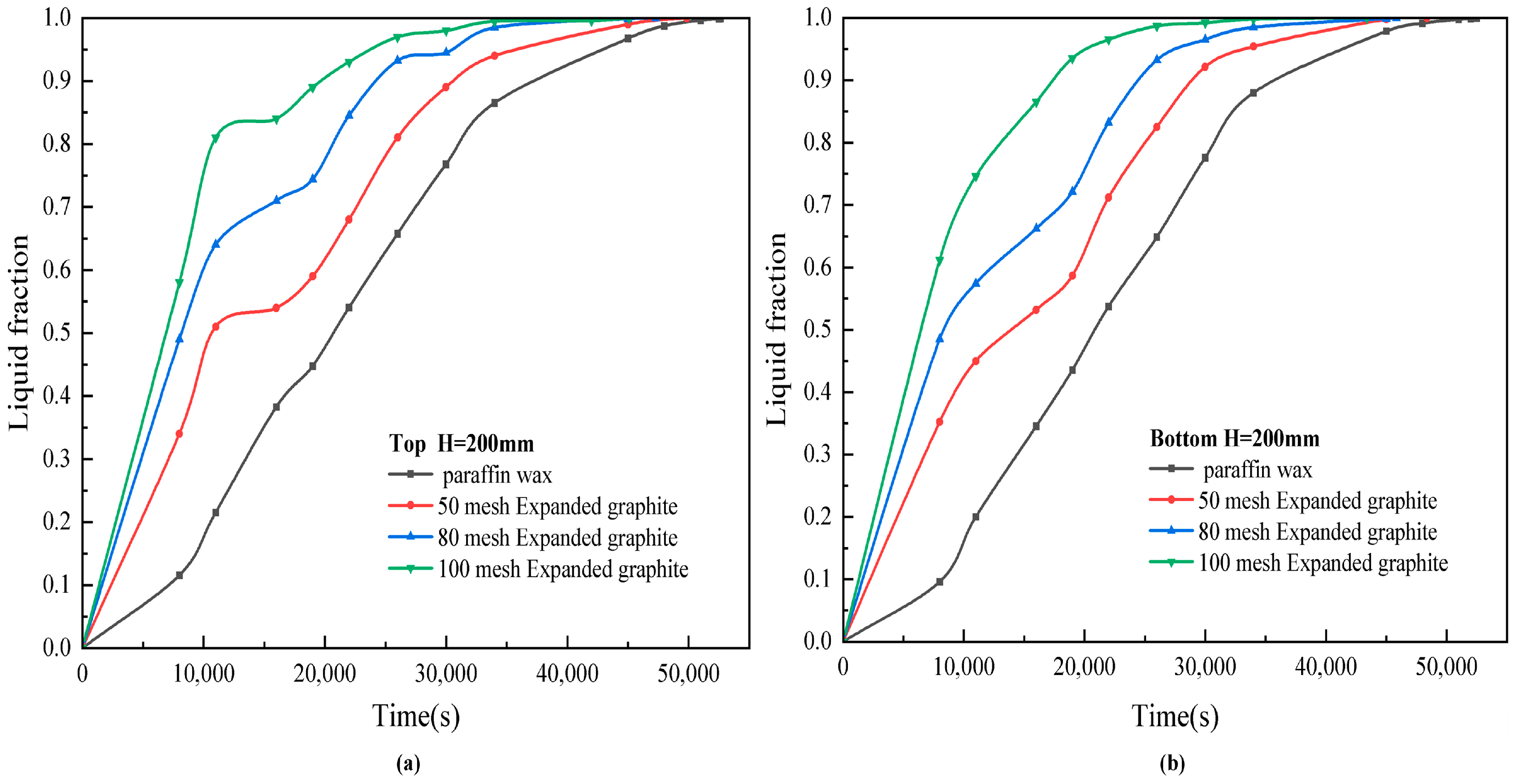

3.2. PCM Performance Improvement

4. Conclusions

- (1)

- During the initial phase of PCM melting, its predominant heat-transfer mechanism is conduction, thus the HTF injection direction has negligible impact on the melting rate. Nonetheless, as time progresses, natural convection starts to manifest, leading to noteworthy changes in the PCM’s melting rate.

- (2)

- In the range of tube length H between 1.6 m and 0.2 m, and PCM thickness D between 19.7 mm and 49 mm, an increase in tube length H results in a corresponding decrease in PCM thickness D. Consequently, this promotes more robust natural convection within the PCM. As a result, the melting time of PCM increases in tandem with the tube length H, demonstrating a positive correlation. Moreover, under the bottom-injection condition, the melting time of PCM is generally faster than that of the top injection.

- (3)

- Regardless of whether the heat-transfer fluid is injected at the top or bottom, when the tube length H exceeds 800 mm, the melting efficiency of the PCM undergoes a significant change, leading to a reduction in melting time of nearly 15,000 s.

- (4)

- For instance, when considering H = 200 mm and top injection, the three types of composite materials containing 10% expanded graphite with different mesh numbers can save 5.3%, 10.2%, and 14.3% of the melting time, respectively, compared to pure paraffin wax. On the other hand, in the case of bottom injection, these three composite materials save 7.7%, 12.5%, and 17.2% of the melting time, respectively, further emphasizing the more significant effect of improving the melting time with bottom injection.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chandran Govindaraju, V.G.R.; Tang, C.F. The dynamic links between CO2 emissions, economic growth and coal consumption in China and India. Appl. Energy 2013, 104, 310–318. [Google Scholar] [CrossRef]

- Zhao, D.L.; Li, Y.; Dai, Y.J.; Wang, R.Z. Optimal study of a solar air heating system with pebble bed energy storage. Energy Convers. Manag. 2011, 52, 2392–2400. [Google Scholar] [CrossRef]

- Cárdenas-Ramírez, C.; Jaramillo, F.; Gómez, M. Systematic review of encapsulation and shape-stabilization of phase change materials. J. Energy Storage 2020, 30, 101495. [Google Scholar] [CrossRef]

- Alam, M.T.; Raj, A.; Singh, L.K.; Gupta, A.K. Configurational assessment of solidification performance in a triplex-tube heat exchanger filled with composite phase change material. Appl. Therm. Eng. 2023, 230, 120814. [Google Scholar] [CrossRef]

- Dhaidan, N.S.; Khodadadi, J.M. Melting and convection of phase change materials in different shape containers: A review. Renew. Sustain. Energy Rev. 2015, 43, 449–477. [Google Scholar] [CrossRef]

- Kang, Z.; Zhou, W.; Qiu, K.; Wang, C.; Qin, Z.; Zhang, B.; Yao, Q. Numerical Simulation of an Indirect Contact Mobilized Thermal Energy Storage Container with Different Tube Bundle Layout and Fin Structure. Sustainability 2023, 15, 5511. [Google Scholar] [CrossRef]

- Agyenim, F.; Eames, P.; Smyth, M. Heat transfer enhancement in medium temperature thermal energy storage system using a multitube heat transfer array. Renew. Energy 2010, 35, 198–207. [Google Scholar] [CrossRef]

- Guo, S.; Zhao, J.; Wang, W.; Yan, J.; Jin, G.; Zhang, Z.; Gu, J.; Niu, Y. Numerical study of the improvement of an indirect contact mobilized thermal energy storage container. Appl. Energy 2016, 161, 476–486. [Google Scholar] [CrossRef]

- Memon, A.; Mishra, G.; Gupta, A.K. Buoyancy-driven melting and heat transfer around a horizontal cylinder in square enclosure filled with phase change material. Appl. Therm. Eng. 2020, 181, 115990. [Google Scholar] [CrossRef]

- Agyenim, F.; Hewitt, N. The development of a finned phase change material (PCM) storage system to take advantage of off-peak electricity tariff for improvement in cost of heat pump operation. Energy Build. 2010, 42, 1552–1560. [Google Scholar] [CrossRef]

- Joybari, M.M.; Seddegh, S.; Wang, X.; Haghighat, F. Experimental investigation of multiple tube heat transfer enhancement in a vertical cylindrical latent heat thermal energy storage system. Renew. Energy 2019, 140, 234–244. [Google Scholar] [CrossRef]

- Trp, A.; Lenic, K.; Frankovic, B. Analysis of the influence of operating conditions and geometric parameters on heat transfer in water-paraffin shell-and-tube latent thermal energy storage unit. Appl. Therm. Eng. 2006, 26, 1830–1839. [Google Scholar] [CrossRef]

- Yang, X.; Yu, J.; Xiao, T.; Hu, Z.; He, Y.-L. Design and operating evaluation of a finned shell-and-tube thermal energy storage unit filled with metal foam. Appl. Energy 2020, 261, 114385. [Google Scholar] [CrossRef]

- Han, G.-S.; Ding, H.-S.; Huang, Y.; Tong, L.-G.; Ding, Y.-L. A comparative study on the performances of different shell-and-tube type latent heat thermal energy storage units including the effects of natural convection. Int. Commun. Heat Mass Transf. 2017, 88, 228–235. [Google Scholar] [CrossRef]

- Kurnia, J.C.; Sasmito, A.P. Numerical investigation of heat transfer performance of a rotating latent heat thermal energy storage. Appl. Energy 2018, 227, 542–554. [Google Scholar] [CrossRef]

- Longeon, M.; Soupart, A.; Fourmigué, J.-F.; Bruch, A.; Marty, P. Experimental and numerical study of annular PCM storage in the presence of natural convection. Appl. Energy 2013, 112, 175–184. [Google Scholar] [CrossRef]

- Shahsavar, A.; Goodarzi, A.; Mohammed, H.I.; Shirneshan, A.; Talebizadehsardari, P. Thermal performance evaluation of non-uniform fin array in a finned double-pipe latent heat storage system. Energy 2020, 193, 116800. [Google Scholar] [CrossRef]

- Ismail, K.; Goncalves, M. Thermal performance of a PCM storage unit. Energy Convers. Manag. 1999, 40, 115–138. [Google Scholar] [CrossRef]

- Seddegh, S.; Wang, X.; Joybari, M.M.; Haghighat, F. Investigation of the effect of geometric and operating parameters on thermal behavior of vertical shell-and-tube latent heat energy storage systems. Energy 2017, 137, 69–82. [Google Scholar] [CrossRef]

- Nie, C.; Liu, J.; Deng, S. Effect of geometric parameter and nanoparticles on PCM melting in a vertical shell-tube system. Appl. Therm. Eng. 2021, 184, 116290. [Google Scholar] [CrossRef]

- Yang, X.; Lu, Z.; Bai, Q.; Zhang, Q.; Jin, L.; Yan, J. Thermal performance of a shell-and-tube latent heat thermal energy storage unit: Role of annular fins. Appl. Energy 2017, 202, 558–570. [Google Scholar] [CrossRef]

- Ettouney, H.; El-Dessouky, H.; Al-Kandari, E. Heat transfer characteristics during melting and solidification of phase change energy storage process. Ind. Eng. Chem. Res. 2004, 43, 5350–5357. [Google Scholar] [CrossRef]

- Martinelli, M.; Bentivoglio, F.; Caron-Soupart, A.; Couturier, R.; Fourmigue, J.-F.; Marty, P. Experimental study of a phase change thermal energy storage with copper foam. Appl. Therm. Eng. 2016, 101, 247–261. [Google Scholar] [CrossRef]

- Lacroix, M. Study of the heat transfer behavior of a latent heat thermal energy storage unit with a finned tube. Int. J. Heat Mass Transf. 1993, 36, 2083–2092. [Google Scholar] [CrossRef]

- Shudong, S. Microstructure adjustment of expanded graphite and its influence on thermal performance of composite paraffin/expanded graphite phasse-change material. Funct. Mater. 2018, 49, 1064–1070. (In Chinese) [Google Scholar]

| Parameters | PCM |

|---|---|

| Density (kg·m−3) | 880 (s), 760 (l) |

| Specific heat (J·kg−1·K−1) | 1800 (s), 2400 (l) |

| Latent heat (kJ·kg–1) | 157 |

| Melting temperature (K) | 308.0 |

| Viscosity (m2·s–1) | 3.3 × 10−6 |

| Thermal conductivity (W·m–1·K–1) | 0.2 |

| Case | R1 | R0 | H | D = R0 − R1 − 2.5 |

|---|---|---|---|---|

| 1 | 7.5 mm | 29.7 mm | 1600 mm | 19.7 mm |

| 2 | 7.5 mm | 30.7 mm | 1400 mm | 20.7 mm |

| 3 | 7.5 mm | 32.0 mm | 1200 mm | 22.0 mm |

| 4 | 7.5 mm | 33.7 mm | 1000 mm | 23.7 mm |

| 5 | 7.5 mm | 34.7 mm | 900 mm | 24.7 mm |

| 6 | 7.5 mm | 36.0 mm | 800 mm | 26.0 mm |

| 7 | 7.5 mm | 37.5 mm | 700 mm | 27.5 mm |

| 8 | 7.5 mm | 39.5 mm | 600 mm | 29.5 mm |

| 9 | 7.5 mm | 42.0 mm | 500 mm | 32.0 mm |

| 10 | 7.5 mm | 45.4 mm | 400 mm | 35.4 mm |

| 11 | 7.5 mm | 50.5 mm | 300 mm | 40.5 mm |

| 12 | 7.5 mm | 59.0 mm | 200 mm | 49.0 mm |

| Case | Time to Reach Complete Melting (s) | |

|---|---|---|

| Top | Bottom | |

| 1 | 52,640 | 52,400 |

| 2 | 51,250 | 50,952 |

| 3 | 48,260 | 47,824 |

| 4 | 49,321 | 48,685 |

| 5 | 44,115 | 43,082 |

| 6 | 46,137 | 45,582 |

| 7 | 45,124 | 43,010 |

| 8 | 27,325 | 27,240 |

| 9 | 25,274 | 23,120 |

| 10 | 16,885 | 16,544 |

| 11 | 19,521 | 19,412 |

| 12 | 11,325 | 10,250 |

| Added Materials | Mesh | |

|---|---|---|

| Expanded graphite | 50 | 0.82 |

| 80 | 0.95 | |

| 100 | 1.46 |

| Case | Time to Reach Complete Melting (s) | |||

|---|---|---|---|---|

| Top | Bottom | |||

| paraffin wax | 52,640 | Time saving (%) | 52,400 | Time saving (%) |

| 50 mesh | 49,850 | 5.3% | 48,365 | 7.7% |

| 80 mesh | 47,270 | 10.2% | 45,850 | 12.5% |

| 100 mesh | 45,112 | 14.3% | 43,387 | 17.2% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, Z.; Zhou, W.; Liu, S.; Kang, Z.; Tan, R. Effects of Geometric Parameters and Heat-Transfer Fluid Injection Direction on Enhanced Phase-Change Energy Storage in Vertical Shell-and-Tube System. Sustainability 2023, 15, 13062. https://doi.org/10.3390/su151713062

Guo Z, Zhou W, Liu S, Kang Z, Tan R. Effects of Geometric Parameters and Heat-Transfer Fluid Injection Direction on Enhanced Phase-Change Energy Storage in Vertical Shell-and-Tube System. Sustainability. 2023; 15(17):13062. https://doi.org/10.3390/su151713062

Chicago/Turabian StyleGuo, Zhanjun, Wu Zhou, Sen Liu, Zhangyang Kang, and Rufei Tan. 2023. "Effects of Geometric Parameters and Heat-Transfer Fluid Injection Direction on Enhanced Phase-Change Energy Storage in Vertical Shell-and-Tube System" Sustainability 15, no. 17: 13062. https://doi.org/10.3390/su151713062

APA StyleGuo, Z., Zhou, W., Liu, S., Kang, Z., & Tan, R. (2023). Effects of Geometric Parameters and Heat-Transfer Fluid Injection Direction on Enhanced Phase-Change Energy Storage in Vertical Shell-and-Tube System. Sustainability, 15(17), 13062. https://doi.org/10.3390/su151713062