The Effects of Non-Uniformly-Aged Photovoltaic Array on Mismatch Power Loss: A Practical Investigation towards Novel Hybrid Array Configurations

Abstract

:1. Introduction

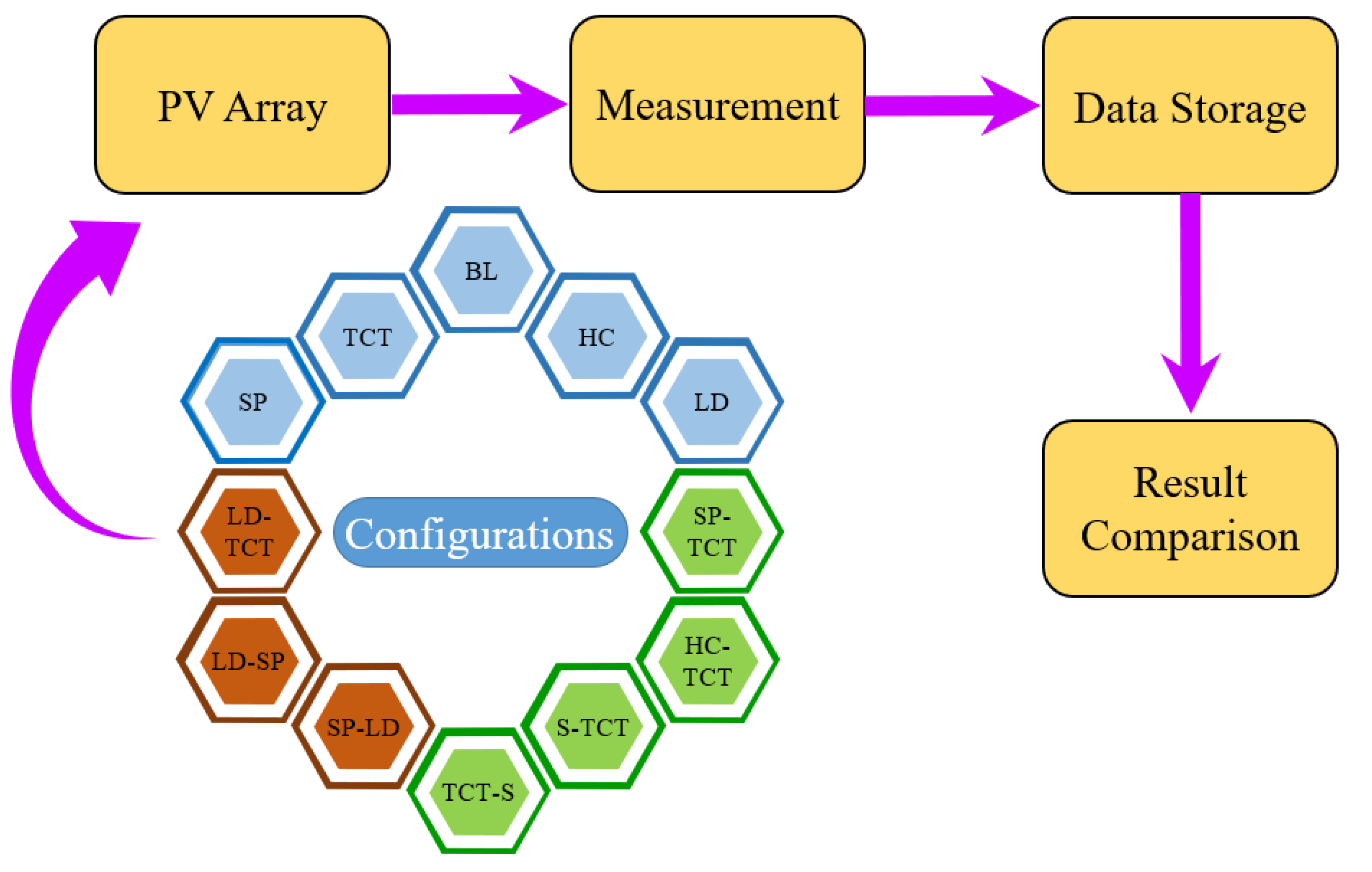

2. Methodology

2.1. Conventional and Proposed Configurations of PV Array Module

2.2. Dataset of the Tested PV Modules under Non-Uniform Aging Conditions

2.3. Calculation of Degradation Rate and Identification of Aging Factors

2.4. PV Module Arrangement Process Based on SCC Technique

3. Experimental Work

3.1. Experimental Procedure of PV Array Power Measurement in Outdoor Conditions

3.2. Analysis of Experimental Results

3.3. Validation of Experimental Results

- A professional PV system analyzer (PROVA 1011) built on IEC standards was used to convert data from the I–V curve under normal operating conditions (OPC) to data under standard test conditions (STC).

- IEC 60904-1 specifies that for outdoor I–V curve measurements, the irradiance must be at least 800 W/m2. As a result, the experimental data were collected between irradiance ranges from 800 to 950 W/m2.

- The practical array module rearrangement was accomplished using the SCC-based technique, wherein Electro Solar Limited Bangladesh, a commercial PV module producer, tested the module datasheet.

- The performance comparison was carried out for the novel hybrid array configurations with series–parallel configurations in terms of mismatch power losses. This comparison demonstrates the effectiveness of the proposed hybrid configurations and their practical relevance.

4. Discussion

- The non-uniform aging of PV modules can lead to significant mismatch power losses in PV arrays, which can reduce the overall system efficiency.

- When compared to standard PV array configurations, hybrid PV array topologies that integrate PV modules with various interconnections can dramatically reduce mismatch power losses.

- In hybrid array topologies, the positioning of PV modules with varying degrees of degradation can have an impact on the performance of the entire system, with some configurations resulting in higher output power increases than others.

- Utilizing a module rearrangement technique based on SSC, which can lessen the effects of mismatch power losses, these output power improvements are further boosted.

- The novelty of the work is some new hybrid PV is introduced, and two of them (SP-LD, LD-SP) performed with higher output power by reducing the %MPL considering all other configurations.

- One of the main differences of this research work compared to others is that here the different standard and hybrid array configurations are compared experimentally considering non-uniform aging conditions, while in other research the application was for a different scenario of partial shading conditions. To the best of the author’s knowledge, 12 different array configurations were not tested before in the literature.

- It is important to note that the trends observed in Figure 12 and Figure 13 may not be universally applicable to all aged photovoltaic arrays due to variations in aging characteristics and conditions. The generalizability of the trends depends on several factors, including the specific aging mechanisms, the degree of non-uniformity, and the operating conditions. These figures reflect the performance of the proposed hybrid array configurations in mitigating mismatch power losses in the context of non-uniformly-aged arrays. While they provide valuable insights and guidance for similar scenarios, their applicability to different aging results needs to be assessed on a case-by-case basis.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Abdalla, A.A.; El Moursi, M.S.; El-Fouly, T.H.; Al Hosani, K.H. A Novel Adaptive Power Smoothing Approach for PV Power Plant with Hybrid Energy Storage System. IEEE Trans. Sustain. Energy 2023, 14, 1457–1473. [Google Scholar] [CrossRef]

- Islam, I.; Maruf, H.; Al Mansur, A.; Ashique, R.H.; Haq, M.A.U.; Shihavuddin, A.; Jadin, M.S. Feasibility analysis of floating photovoltaic power plant in Bangladesh: A case study in Hatirjheel Lake, Dhaka. Sustain. Energy Technol. Assess. 2023, 55, 102994. [Google Scholar] [CrossRef]

- Islam, I.; Jadin, M.S.; Al Mansur, A.; Kamari, N.A.M.; Jamal, T.; Lipu, M.S.H.; Azlan, M.N.M.; Sarker, M.R.; Shihavuddin, A.S.M. Techno-Economic and Carbon Emission Assessment of a Large-Scale Floating Solar PV System for Sustainable Energy Generation in Support of Malaysia’s Renewable Energy Roadmap. Energies 2023, 16, 4034. [Google Scholar] [CrossRef]

- Sharma, M.; Pareek, S.; Singh, K. Robust reconfiguration strategies for maximum output power from large-scale photovoltaic arrays under partial shading conditions. Phys. Scr. 2023, 98, 035215. [Google Scholar] [CrossRef]

- Ali, T.; Al Mansur, A.; Shams, Z.B.; Ferdous, S.M.; Hoque, M.A. An overview of smart grid technology in Bangladesh: Development and opportunities. In Proceedings of the 2011 International Conference and Utility Exhibition on Power and Energy Systems: Issues and Prospects for Asia, ICUE, Pattaya, Thailand, 28–30 September 2011. [Google Scholar] [CrossRef]

- Rezazadeh, S.; Moradzadeh, A.; Pourhossein, K.; Akrami, M.; Mohammadi-Ivatloo, B.; Anvari-Moghaddam, A. Photovoltaic array reconfiguration under partial shading conditions for maximum power extraction: A state-of-the-art review and new solution method. Energy Convers. Manag. 2022, 258, 115468. [Google Scholar] [CrossRef]

- Rahman, T.; Al Mansur, A.; Lipu, M.S.H.; Rahman, S.; Ashique, R.H.; Houran, M.A.; Elavarasan, R.M.; Hossain, E. Investigation of Degradation of Solar Photovoltaics: A Review of Aging Factors, Impacts, and Future Directions toward Sustainable Energy Management. Energies 2023, 16, 3706. [Google Scholar] [CrossRef]

- Wu, Z.; Zhang, C.; Alkahtani, M.; Hu, Y.; Zhang, J. Cost Effective Offline Reconfiguration for Large-Scale Non-Uniformly Aging Photovoltaic Arrays Efficiency Enhancement. IEEE Access 2020, 8, 80572–80581. [Google Scholar] [CrossRef]

- Raj, R.D.A.; Naik, K.A. A novel scan pattern for reconfiguration of partially shaded photovoltaic arrays for maximum power extraction. Int. J. Circuit Theory Appl. 2022, 51, 668–701. [Google Scholar] [CrossRef]

- Chadge, R.B.; Sunheriya, N.; Giri, J.P.; Shrivastava, N. Experimental investigation of different electrical configurations and topologies for Photovoltaic system. Mater. Today Proc. 2022, 57, 316–320. [Google Scholar] [CrossRef]

- León, L.; Romero-Quete, D.; Merchán, N.; Cortés, C. Optimal design of PV and hybrid storage based microgrids for healthcare and government facilities connected to highly intermittent utility grids. Appl. Energy 2023, 335, 120709. [Google Scholar] [CrossRef]

- Malathy, S.; Ramaprabha, R. Reconfiguration strategies to extract maximum power from photovoltaic array under partially shaded conditions. Renew. Sustain. Energy Rev. 2018, 81, 2922–2934. [Google Scholar] [CrossRef]

- Al Mansur, A.; Amin, R.; Haq, M.A.U.; Maruf, H.; Mottalib, M.; Ashique, R.H.; Shihavuddin, A. Mitigation of mismatch power loss in aged photovoltaic arrays following a comparative investigation into module rearrangement techniques. Energy Rep. 2022, 8, 1896–1906. [Google Scholar] [CrossRef]

- Jagadeesh, K.; Chengaiah, C. A comprehensive review—Partial shading issues in PV system. In Proceedings of the AIP Conference Proceedings, Kolkata, India, 26–28 November 2021. [Google Scholar] [CrossRef]

- Jha, V. Generalized modelling of PV module and different PV array configurations under partial shading condition. Sustain. Energy Technol. Assess. 2023, 56, 103021. [Google Scholar] [CrossRef]

- Alkahtani, M.; Hu, Y.; Alghaseb, M.A.; Elkhayat, K.; Kuka, C.S.; Abdelhafez, M.H.; Mesloub, A. Investigating Fourteen Countries to Maximum the Economy Benefit by Using Offline Reconfiguration for Medium Scale PV Array Arrangements. Energies 2020, 14, 59. [Google Scholar] [CrossRef]

- Mohammadnejad, S.; Khalafi, A.; Ahmadi, S.M. Mathematical analysis of total-cross-tied photovoltaic array under partial shading condition and its comparison with other configurations. Sol. Energy 2016, 133, 501–511. [Google Scholar] [CrossRef]

- Karatepe, E.; Boztepe, M.; Çolak, M. Development of a suitable model for characterizing photovoltaic arrays with shaded solar cells. Sol. Energy 2007, 81, 977–992. [Google Scholar] [CrossRef]

- Narne, D.K.; Kumar, T.A.R.; Alla, R.R. Traditional and hybrid solar photovoltaic array configurations for partial shading conditions: Perspectives and challenges. Bull. Electr. Eng. Inform. 2023, 12, 642–649. [Google Scholar] [CrossRef]

- Satpathy, P.R.; Babu, T.S.; Mahmoud, A.H.; Sharma, R.; Nastasi, B. A TCT-SC Hybridized Voltage Equalizer for Partial Shading Mitigation in PV Arrays. IEEE Trans. Sustain. Energy 2021, 12, 2268–2281. [Google Scholar] [CrossRef]

- Aljafari, B.; Satpathy, P.R.; Thanikanti, S.B. Partial shading mitigation in PV arrays through dragonfly algorithm based dynamic reconfiguration. Energy 2022, 257, 124795. [Google Scholar] [CrossRef]

- Satpathy, P.R.; Aljafari, B.; Thanikanti, S.B. Power losses mitigation through electrical reconfiguration in partial shading prone solar PV arrays. Optik 2022, 259, 168973. [Google Scholar] [CrossRef]

- Krishna, G.S.; Moger, T. Improved SuDoKu reconfiguration technique for total-cross-tied PV array to enhance maximum power under partial shading conditions. Renew. Sustain. Energy Rev. 2019, 109, 333–348. [Google Scholar] [CrossRef]

- La Manna, D.; Vigni, V.L.; Sanseverino, E.R.; Di Dio, V.; Romano, P. Reconfigurable electrical interconnection strategies for photovoltaic arrays: A review. Renew. Sustain. Energy Rev. 2014, 33, 412–426. [Google Scholar] [CrossRef]

- Yang, B.; Ye, H.; Wang, J.; Li, J.; Wu, S.; Li, Y.; Shu, H.; Ren, Y.; Ye, H. PV arrays reconfiguration for partial shading mitigation: Recent advances, challenges and perspectives. Energy Convers. Manag. 2021, 247, 114738. [Google Scholar] [CrossRef]

- Yousri, D.; Allam, D.; Eteiba, M.B. Optimal photovoltaic array reconfiguration for alleviating the partial shading influence based on a modified harris hawks optimizer. Energy Convers. Manag. 2020, 206, 112470. [Google Scholar] [CrossRef]

- Pendem, S.R.; Mikkili, S. Modelling and performance assessment of PV array topologies under partial shading conditions to mitigate the mismatching power losses. Sol. Energy 2018, 160, 303–321. [Google Scholar] [CrossRef]

- Bana, S.; Saini, R. Experimental investigation on power output of different photovoltaic array configurations under uniform and partial shading scenarios. Energy 2017, 127, 438–453. [Google Scholar] [CrossRef]

- Yadav, A.S.; Pachauri, R.K.; Chauhan, Y.K.; Choudhury, S.; Singh, R. Performance enhancement of partially shaded PV array using novel shade dispersion effect on magic-square puzzle configuration. Sol. Energy 2017, 144, 780–797. [Google Scholar] [CrossRef]

- Satpathy, P.R.; Sharma, R. Power and mismatch losses mitigation by a fixed electrical reconfiguration technique for partially shaded photovoltaic arrays. Energy Convers. Manag. 2019, 192, 52–70. [Google Scholar] [CrossRef]

- Mishra, N.; Yadav, A.S.; Pachauri, R.; Chauhan, Y.K.; Yadav, V.K. Performance enhancement of PV system using proposed array topologies under various shadow patterns. Sol. Energy 2017, 157, 641–656. [Google Scholar] [CrossRef]

- Rezk, H.; Fathy, A.; Aly, M. A robust photovoltaic array reconfiguration strategy based on coyote optimization algorithm for enhancing the extracted power under partial shadow condition. Energy Rep. 2020, 7, 109–124. [Google Scholar] [CrossRef]

- Krishna, G.S.; Moger, T. Reconfiguration strategies for reducing partial shading effects in photovoltaic arrays: State of the art. Sol. Energy 2019, 182, 429–452. [Google Scholar] [CrossRef]

- Al Mansur, A.; Amin, M.R. Performance investigation of different PV array configurations at partial shading condition for maximum power output. In Proceedings of the 2019 International Conference on Sustainable Technologies for Industry 4.0, STI, Dhaka, Bangladesh, 24–25 December 2019. [Google Scholar] [CrossRef]

- Dhanalakshmi, B.; Rajasekar, N. A novel Competence Square based PV array reconfiguration technique for solar PV maximum power extraction. Energy Convers. Manag. 2018, 174, 897–912. [Google Scholar] [CrossRef]

- Rahman, T.; Al Mansur, A.; Islam, S.; Islam, I.; Sahin; Awal, R.; Shihavuddin, A.; Haq, M.A.U. Effects of Aging Factors on PV Modules Output Power: An Experimental Investigation. In Proceedings of the 2022 4th International Conference on Sustainable Technologies for Industry 4.0 (STI), Dhaka, Bangladesh, 17–18 December 2022; pp. 1–5. [Google Scholar] [CrossRef]

- Al Mansur, A.; Amin, R.; Islam, K.K. Performance Comparison of Mismatch Power Loss Minimization Techniques in Series-Parallel PV Array Configurations. Energies 2019, 12, 874. [Google Scholar] [CrossRef]

- Mansur, A.; Haq, M.; Maruf, H.; Shihavuddin, A.; Amin, R.; Islam, K. Experimental Investigation of PV Array Interconnection Topologies at Nonuniform Aging Condition for Power Maximization. GUB J. Sci. Eng. 2020, 6, 39–45. [Google Scholar] [CrossRef]

- Hu, Y.; Zhang, J.; Li, P.; Yu, D.; Jiang, L. Non-Uniform Aged Modules Reconfiguration for Large-Scale PV Array. IEEE Trans. Device Mater. Reliab. 2017, 17, 560–569. [Google Scholar] [CrossRef]

- Udenze, P.; Hu, Y.; Wen, H.; Ye, X.; Ni, K. A Reconfiguration Method for Extracting Maximum Power from Non-Uniform Aging Solar Panels. Energies 2018, 11, 2743. [Google Scholar] [CrossRef]

- Al Mansur, A.; Amin, M.R.; Islam, K.K. Determination of Module Rearrangement Techniques for Non-uniformly Aged PV Arrays with SP, TCT, BL and HC Configurations for Maximum Power Output. In Proceedings of the 2nd International Conference on Electrical, Computer and Communication Engineering, ECCE, Cox’s Bazar, Bangladesh, 7–9 February 2019. [Google Scholar] [CrossRef]

- Al Mansur, A.; Islam, I.; Kiron, M.K.; Haq, M.A.U.; Maruf, H.; Shihavuddin, A.; Ashique, R.H.; Amin, R. Electrical experimental data collection of polycrystalline and monocrystalline photovoltaic modules in an indoor environment using artificial sun simulator. Data Brief 2022, 43, 108389. [Google Scholar] [CrossRef]

- IEC 60904-1; Photovoltaic Devices—Part 1: Measurement of Photovoltaic Current-voltage Characteristics. International Electrotechnical Commission: London, UK, 2006.

- Al Mansur, A.; Ferdous, S.M.; Shams, Z.B.; Islam, M.R.; Rokonuzzaman, M.; Hoque, M.A. An experimental investigation of the real time electrical characteristics of a PV panel for different atmospheric conditions in Islamic University of Technology (OIC), Gazipur, Bangladesh. In Proceedings of the 2011 International Conference and Utility Exhibition on Power and Energy Systems: Issues and Prospects for Asia, ICUE, Pattaya, Thailand, 28–30 September 2012. [Google Scholar] [CrossRef]

- Al Mansur, A. Replication Data for: Tested Dataset of 10W, 40W, 80W and 250W Photovoltaic Modules under Aging Condition. Harv. Dataverse 2023, 47, 108989. [Google Scholar] [CrossRef]

- Al Mansur, A.; Islam, I.; Haq, M.A.U.; Maruf, H.; Shihavuddin, A.; Amin, R. Investigation of PV Modules Electrical Characteristics for Laboratory Experiments using Halogen Solar Simulator. In Proceedings of the 2020 2nd International Conference on Sustainable Technologies for Industry 4.0, STI, Dhaka, Bangladesh, 19–20 December 2020. [Google Scholar] [CrossRef]

| Refs. | Array Configurations | Key Findings | Application |

|---|---|---|---|

| [27] | SP, TCT, HC, BL, and a novel hybrid | A 6 × 6 array is used to perform the simulation. The novel hybrid configuration performed better considering output power. | partial shading |

| [17] | SP, TCT, BL, and HC | Mathematical model-based simulation is performed and TCT shows the highest output power. | partial shading |

| [18] | SP, BL, and TCT | Different array dimensions 2 × 6, 6 × 2, 4 × 3, and 3 × 4 is investigated via simulation. TCT performed maximum output in all cases. | partial shading |

| [28] | TCT, BL, SP, HC, and HC-TCT) | Experimental comparisons are conducted and TCT performed the lowest mismatch loss. | partial shading |

| [29] | TCT, SP-TCT, BL-TCT, and BL-HC | A 4 × 4 array is used to perform the simulation in the MATLAB Simulink platform. | partial shading |

| [30] | Conventional (SP, TCT, BL, HC) and hybrid (SP-TCT, BL-TCT, HC-TCT) | Simulation is carried out, where hybrid configurations performed better than the conventional interconnection in terms of MPL reduction. | moving shading |

| [31] | SP-TCT, BL-TCT, BL-HC, and NS hybrid | Simulink-based work is carried out, and hybrid NS configuration yielded the highest output power for this shading scenario. | diagonal shading |

| Si No | Panel Model No | Data Parameters of Photovoltaic Module | |||||

|---|---|---|---|---|---|---|---|

| Pmpp (watt) | Isc (amp) | Voc (volt) | Vmpp (volt) | Impp (amp) | FF | ||

| 1 | 1612E020001 | 9.821 | 1.314 | 10.430 | 8.364 | 1.174 | 0.716 |

| 2 | 1612E020002 | 9.743 | 1.300 | 10.365 | 8.349 | 1.167 | 0.723 |

| 3 | 1612E020003 | 9.285 | 1.318 | 10.426 | 8.044 | 1.154 | 0.675 |

| 4 | 1612E020004 | 9.983 | 1.311 | 10.426 | 8.442 | 1.183 | 0.730 |

| 5 | 1612E020005 | 10.177 | 1.331 | 10.456 | 8.508 | 1.196 | 0.731 |

| 6 | 1612E020006 | 9.756 | 1.294 | 10.385 | 8.395 | 1.162 | 0.725 |

| 7 | 1612E020007 | 9.769 | 1.311 | 10.451 | 8.388 | 1.164 | 0.713 |

| 8 | 1612E020008 | 9.988 | 1.318 | 10.389 | 8.402 | 1.189 | 0.729 |

| 9 | 1612E020009 | 9.936 | 1.289 | 10.332 | 8.462 | 1.173 | 0.745 |

| 10 | 1612E020010 | 10.015 | 1.314 | 10.485 | 8.478 | 1.181 | 0.726 |

| 40 | 1612E020046 | 10.111 | 1.335 | 10.417 | 8.472 | 1.193 | 0.726 |

| Average | 9.917 | 1.305 | 10.390 | 8.407 | 1.179 | 0.731 | |

| Parameter | Limit (Max) | Precision (%) |

|---|---|---|

| Voltage | 1000 V | ±1 |

| Current | 12 A | ±1 |

| Light intensity | 2000 W/m2 | ±3 |

| Temperature | 85 °C | ±1 |

| SI | Configuration | Output Variable for the Array | MPL (%) | RE (%) | ||

|---|---|---|---|---|---|---|

| Voltage (V) | Current (A) | Power (W) | ||||

| 1 | SP | 72.54 | 4.113 | 298.36 | 17.96 | 0.00 |

| 2 | TCT | 73.12 | 4.088 | 298.91 | 17.81 | 0.18 |

| 3 | BL | 81.36 | 3.708 | 301.68 | 17.05 | 1.11 |

| 4 | S-TCT | 75.45 | 4.205 | 317.29 | 12.75 | 6.34 |

| 5 | LD-TCT | 74.77 | 4.366 | 326.46 | 10.23 | 9.41 |

| 6 | HC-TCT | 75.04 | 4.388 | 329.26 | 9.46 | 10.35 |

| 7 | LD | 76.39 | 4.336 | 331.24 | 8.92 | 11.02 |

| 8 | TCT-S | 75.73 | 4.457 | 337.56 | 7.18 | 13.13 |

| 9 | SP-TCT | 76.32 | 4.435 | 338.46 | 6.93 | 13.44 |

| 10 | HC | 78.18 | 4.377 | 342.18 | 5.91 | 14.68 |

| 11 | SP-LD | 78.6 | 4.396 | 345.53 | 4.99 | 15.80 |

| 12 | LD-SP | 78.74 | 4.393 | 345.91 | 4.88 | 15.94 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mansur, A.A.; Amin, M.R.; Lipu, M.S.H.; Islam, M.I.; Ashique, R.H.; Shams, Z.B.; Haq, M.A.u.; Maruf, M.H.; Shihavuddin, A. The Effects of Non-Uniformly-Aged Photovoltaic Array on Mismatch Power Loss: A Practical Investigation towards Novel Hybrid Array Configurations. Sustainability 2023, 15, 13153. https://doi.org/10.3390/su151713153

Mansur AA, Amin MR, Lipu MSH, Islam MI, Ashique RH, Shams ZB, Haq MAu, Maruf MH, Shihavuddin A. The Effects of Non-Uniformly-Aged Photovoltaic Array on Mismatch Power Loss: A Practical Investigation towards Novel Hybrid Array Configurations. Sustainability. 2023; 15(17):13153. https://doi.org/10.3390/su151713153

Chicago/Turabian StyleMansur, Ahmed Al, Md. Ruhul Amin, Molla Shahadat Hossain Lipu, Md. Imamul Islam, Ratil H. Ashique, Zubaeer Bin Shams, Mohammad Asif ul Haq, Md. Hasan Maruf, and ASM Shihavuddin. 2023. "The Effects of Non-Uniformly-Aged Photovoltaic Array on Mismatch Power Loss: A Practical Investigation towards Novel Hybrid Array Configurations" Sustainability 15, no. 17: 13153. https://doi.org/10.3390/su151713153

APA StyleMansur, A. A., Amin, M. R., Lipu, M. S. H., Islam, M. I., Ashique, R. H., Shams, Z. B., Haq, M. A. u., Maruf, M. H., & Shihavuddin, A. (2023). The Effects of Non-Uniformly-Aged Photovoltaic Array on Mismatch Power Loss: A Practical Investigation towards Novel Hybrid Array Configurations. Sustainability, 15(17), 13153. https://doi.org/10.3390/su151713153