Analysis of Green Closed-Loop Supply Chain Efficiency under Generalized Stochastic Petri Nets

Abstract

:1. Introduction

2. Literature Review

2.1. Optimal Decision Making in Green Closed-Loop Supply Chain

2.2. Overall Supply Chain System Performance Analysis

2.3. Application of Petri Net Modeling

3. Basic Theory

3.1. Generalized Stochastic Petri Net (GSPN)

3.2. Continuous Time Markov Chain

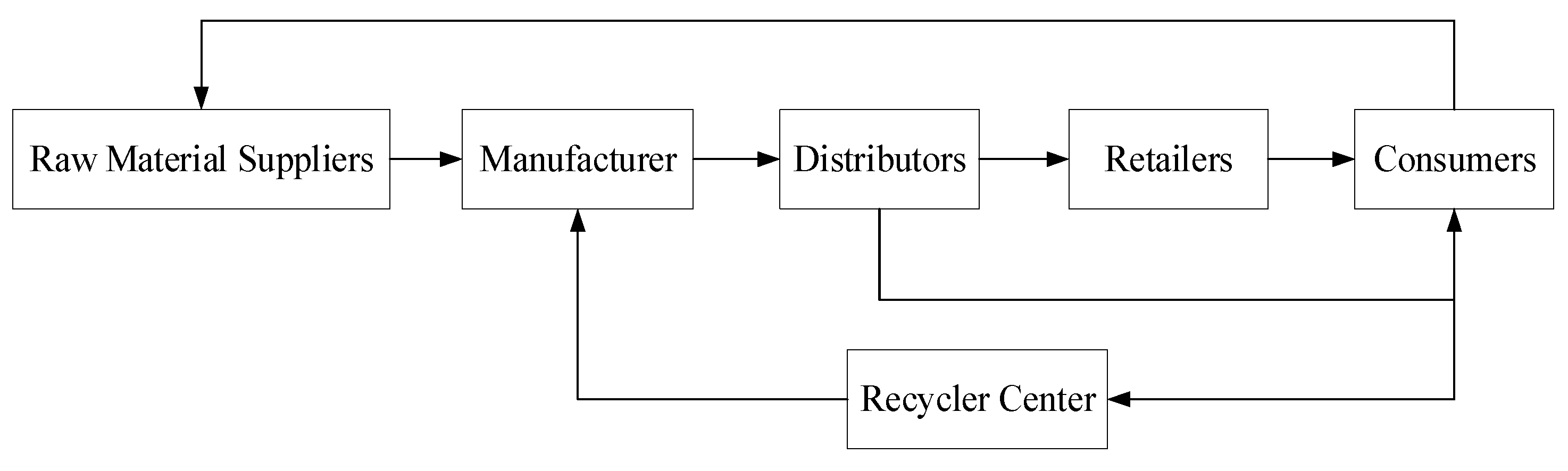

4. GSPN Model of Green Closed-Loop Supply Chain (GSPN of Green CLSC)

5. Performance Analysis of Green Closed-Loop Supply Chain

5.1. Time Performance Analysis

5.2. Utilization Analysis of Changes

5.3. Operational Efficiency Analysis

6. Discussion and Conclusions

6.1. Discussion

6.2. Research Conclusions

- (1)

- When the green closed-loop supply chain system as a whole is affected by the market random events, the required transfer rate between the links will constantly change, and at this time, the steady state probability of the system as a whole will also change.

- (2)

- When the green closed-loop supply chain system as a whole reaches a steady state, the time performance of the system as a whole can be obtained based on the steady state probability of each link, and the greater the number of tokens passing through the subsystems per unit of time, the shorter the average operation time required for the system as a whole.

- (3)

- From a manufacturer’s perspective, in a constant market environment, decision makers need to focus on monitoring the following segments: marketing, packaging and processing, market feedback, and market demand planning, which require a higher percentage of time. Since the third-party recycling center only begin operations when used goods are collected for disposal, the time required to run this segment is much less significant.

- (4)

- From the perspective of green products, the average execution time of the production and sales process of products is longer than the average execution time of the re-cycling and treatment process.

- (1)

- For each manufacturer in the green closed-loop supply chain, it is necessary to maintain the stability of the system as a whole, and each manufacturer pays attention to the market risk and takes the initiative to reduce the impact of non-systematic risks that may exist during the operation of green products, so as to ensure that the system as a whole can operate smoothly and efficiently.

- (2)

- From the perspective of the system as a whole, decision makers need to focus on the overall operational performance, as well as the utilization level of each member and each link, and make constant adjustments to the green closed-loop supply chain system, so as to make it run smoothly and shorten the time period required for the system operation as much as possible, so as to realize a good and high-yield cycle.

6.3. Limitations and Challenges

6.4. Future Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Su, Y.; Yu, Y. Spatial agglomeration of new energy industries on the performance of regional pollution control through spatial econometric analysis. Sci. Total Environ. 2020, 704, 135261. [Google Scholar] [CrossRef]

- Song, H.; Gao, X. Green supply chain game model and analysis under revenue-sharing contract. J. Clean. Prod. 2018, 170, 183–192. [Google Scholar] [CrossRef]

- Fu, Y.; Jiang, X.; Jiang, Z.; Jhang, S. Fast algorithms for finding the solution of CUPL-Toeplitz linear system from Markov chain. Appl. Math. Comput. 2021, 396, 125859. [Google Scholar] [CrossRef]

- Pan, X.; Xu, C.; Cheng, H.; Shi, Y.; Dong, J.; Chen, Z. Urban Logistics Services Supply Chain Process Modelling Based on the Underground Logistics System via the Hierarchical Colored Petri Net. Math. Probl. Eng. 2022, 2022, 2556405. [Google Scholar] [CrossRef]

- Krikke, H.; Blanc, l.; Velde, S. Product Modularity and the Design of Closed-Loop Supply Chains. Calif. Manag. Rev. 2004, 46, 23–39. [Google Scholar] [CrossRef]

- Neto, Q.; Walther, G.; Bloemhof, J.; Spengler, J.A.E.E. A methodology for assessing eco-efficiency in logistics networks. Eur. J. Oper. Res. 2007, 193, 670–682. [Google Scholar] [CrossRef]

- Yang, H.; Chen, X.; Li, L.; Sun, Y. Supply chain decision-making of green products considering a retailer’s fairness concerns under a pre-sale model. J. Clean. Prod. 2023, 414, 137457. [Google Scholar] [CrossRef]

- Shi, J.; Jiao, W.; Jing, K.; Yang, Q.; Lai, K. Joint Economic–Environmental Benefit Optimization by Carbon-Abatement Cost Sharing in a Capital-Constrained Green Supply Chain. Processes 2023, 11, 226. [Google Scholar] [CrossRef]

- Ma, C. Comparison of Cooperation Modes in a Two-Period Closed-Loop Supply Chain System considering Green Manufacturing. Math. Probl. Eng. 2020, 2020, 9202370. [Google Scholar] [CrossRef]

- Zhou, Y.; Lin, X.; Fan, Z.; Wong, K. Remanufacturing Strategy Choice of a Closed-Loop Supply Chain Network Considering Carbon Emission Trading, Green Innovation, and Green Consumers. Int. J. Environ. Res. Public Health 2022, 19, 6782. [Google Scholar] [CrossRef]

- Zhang, Z.; Gong, B.; Tang, J.; Liu, Z.; Zheng, X. The joint dynamic green innovation and pricing strategies for a hybrid system of manufacturing and remanufacturing with carbon emission constraints. Kybernetes 2019, 48, 1699–1730. [Google Scholar] [CrossRef]

- Lu, C.; Huang, W.; Cheng, H. Comparative Analysis of Government Subsidy Policies in a Dynamic Green Supply Chain Considering Consumers Preference. Sustainability 2021, 13, 11601. [Google Scholar] [CrossRef]

- Liu, X.; Zhou, W.; Xie, L. Dynamic competitive game study of a green supply chain with R&D level. Comput. Ind. Eng. 2022, 163, 107785. [Google Scholar] [CrossRef]

- Kuchesfehani, E.K.; Parilina, E.M.; Georges, Z. Revenue and cost sharing contract in a dynamic closed-loop supply chain with uncertain parameters. Ann. Oper. Res. 2022, 322, 851–877. [Google Scholar] [CrossRef]

- Zeballos, L.J.; Méndez, C.A.; Barbosa-Povoa, A.P. Integrating decisions of product and closed-loop supply chain design under uncertain return flows. Comput. Chem. Eng. 2018, 112, 211–238. [Google Scholar] [CrossRef]

- Yang, Y.; Xu, X. A differential game model for closed-loop supply chain participants under carbon emission permits. Comput. Ind. Eng. 2019, 135, 1077–1090. [Google Scholar] [CrossRef]

- Iryaning, D.H.; Ilyas, M.; Ahmad, R.; Judi, S. Production-Distribution Model Considering Traceability and Carbon Emission: A Case Study of the Indonesian Canned Fish Food Industry. Logistics 2021, 5, 59. [Google Scholar] [CrossRef]

- Govindan, K.; Salehian, F.; Kian, H.; Hosseini, S.T.; Mina, H. A location-inventory-routing problem to design a circular closed-loop supply chain network with carbon tax policy for achieving circular economy: An augmented epsilon-constraint approach. Int. J. Prod. Econ. 2023, 257, 108771. [Google Scholar] [CrossRef]

- Yuniarti, R.; Masudin, I.; Rusdiansyah, A.; Handayani, D.I. Model of multiperiod production-distribution for closed-loop supply chain considering carbon emission and traceability for agri-food products. Int. J. Ind. Eng. Oper. Manag. 2023, 5, 240–263. [Google Scholar] [CrossRef]

- Lehna, M.; Hoppmann, B.; Scholz, C.; Heinrich, R. A Reinforcement Learning approach for the continuous electricity market of Germany: Trading from the perspective of a wind park operator. Energy AI 2022, 8, 100139. [Google Scholar] [CrossRef]

- Beamon, B.M. Supply chain design and analysis: Models and methods. Int. J. Prod. Econ. 1998, 55, 281–294. [Google Scholar] [CrossRef]

- Zhang, Y.; Huang, S.; Dang, D.; Ruan, H. Evaluation of natural disaster emergency response procedure based on Petri net. Appl. Mech. Mater. 2013, 339, 236–241. [Google Scholar] [CrossRef]

- Li, J.; Wang, Z.; Sun, L.; Wang, W. Modeling and Analysis of Network Control System Based on Hierarchical Coloured Petri Net and Markov Chain. Discret. Dyn. Nat. Soc. 2021, 2021, 9948855. [Google Scholar] [CrossRef]

- Wang, W.; Da, Q. Remanufacturing Supply Chain Modeling and Analysis based on Generalized Stochastic Petri Nets. Syst. Eng.-Theory Pract. 2007, 2007, 56–61. [Google Scholar] [CrossRef]

- Ding, J.; Chen, X.; Sun, H.; Yang, W.; Fang, H. Hierarchical structure of a green supply chain. Comput. Ind. Eng. 2021, 157, 107303. [Google Scholar] [CrossRef]

- Molloy, M.K. Discrete Time Stochastic Petri Nets. IEEE Trans. Softw. Eng. 1985, 11, 417–423. [Google Scholar] [CrossRef]

- Iwankiewicz, R. Probability distribution and moments of the first-excursion time for dynamic systems under non-Poisson impulse processes: Markov approach based on integro-differential Chapman-Kolmogorov equations. Int. J. Dyn. Control 2016, 4, 168–179. [Google Scholar] [CrossRef]

| Author(s) | Green Closed Loop Supply Chain | Overall Supply Chain System Performance Analysis | Generalized Stochastic Petri Nets |

|---|---|---|---|

| Zhang et al. [11] | √ | — | — |

| Lu et al. [12] | √ | — | — |

| Iryaning et al. [17] | — | √ | — |

| Yuniarti et al. [19] | — | √ | — |

| Li et al. [23] | — | — | √ |

| Wang and Da [24] | — | √ | √ |

| Ding et al. [25] | √ | — | √ |

| This study | √ | √ | √ |

| Location | Meaning | Transition | Meaning | |

|---|---|---|---|---|

| Configure raw materials according to market demand | Raw material transportation process | 2 | ||

| Arrival of raw materials to manufacturers | Green product manufacturing process | 3 | ||

| Green product production is complete | Retailer contact and product marketing process | 2 | ||

| Green products arrive at distributors | Distribution process of distributors | 2 | ||

| Green products arrive at retailers | Retailers’ packaging processes | 1 | ||

| Green products are sold by distributors to consumers | Market sales process of green products | 4 | ||

| Green products sold by retailers to consumers | Marketing feedback process | 1 | ||

| Green product sales complete | The recycling process in the recycling center | 4 | ||

| Waste products to recycling centers for recycling | Develop demand plans for the market | 1 | ||

| Market attitude | Contact manufacturer for secondary process | 2 | ||

| Processing complete | Manufacturer secondary processing into raw material process | 3 | ||

| Treated product arrives at manufacturer |

| State | ||||||||||||

| 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 0 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | |

| 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | |

| 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | |

| 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | |

| 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | |

| 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, L.; Pu, Y.; Liu, Z.; Liu, J. Analysis of Green Closed-Loop Supply Chain Efficiency under Generalized Stochastic Petri Nets. Sustainability 2023, 15, 13181. https://doi.org/10.3390/su151713181

Liu L, Pu Y, Liu Z, Liu J. Analysis of Green Closed-Loop Supply Chain Efficiency under Generalized Stochastic Petri Nets. Sustainability. 2023; 15(17):13181. https://doi.org/10.3390/su151713181

Chicago/Turabian StyleLiu, Lang, Yutao Pu, Zhenwei Liu, and Junjie Liu. 2023. "Analysis of Green Closed-Loop Supply Chain Efficiency under Generalized Stochastic Petri Nets" Sustainability 15, no. 17: 13181. https://doi.org/10.3390/su151713181

APA StyleLiu, L., Pu, Y., Liu, Z., & Liu, J. (2023). Analysis of Green Closed-Loop Supply Chain Efficiency under Generalized Stochastic Petri Nets. Sustainability, 15(17), 13181. https://doi.org/10.3390/su151713181