1. Introduction

Since 2004, the manufacturing sector, the driving force of China’s economic development, has maintained a long-term contribution rate of over 26% to GDP [

1] and has always been at the heart of China’s economic development. As economic trade between countries becomes more frequent, China has relied on its lower factor cost to actively participate in GVC activities and has rapidly developed into a major manufacturing country by its two-headed production model. However, in the GVC division of labour system dominated by developed countries, most of China’s manufacturing industries are engaged in highly polluting, low value-added processing. This trade pattern has let China become a “refuge” for the pollution-intensive industries of developed countries. In 2019, China’s total carbon emissions were 10.2 billion tonnes, of which the manufacturing industry’s CO

2 emissions accounted for about 35.80% of society’s total emissions [

2]. The manufacturing industry has become the second largest carbon emission sector after the electricity and heat supply sectors. In 2020, the Chinese government set a clear target of “carbon peaking” and “carbon neutrality” (hereinafter referred to as the “double carbon” target). The 20th Party Congress report reiterates that “achieving carbon neutrality involves a comprehensive and fundamental economic and social structural transformation. Based on China’s energy resource endowment, we will adhere to the principle of first establishing and then breaking, and implement carbon peaking actions in a systematic and step-by-step manner”. “We should collaborate to promote carbon reduction, pollution reduction, green expansion, and growth, and create conditions to accelerate the shift from a ‘double control’ system of energy consumption to a ‘double control’ system of carbon emissions”. This has put forward higher requirements for the low-carbon transformation of the manufacturing industry. The industrial chain and value chain will be upgraded comprehensively. The production model of China’s manufacturing industry participating in the GVC division of labour will be reshaped. Enhancing carbon productivity is a key strategy for achieving a win–win scenario for low carbon emission reduction and economic growth [

3]. Carbon productivity refers to the level of GDP produced per unit of CO

2. In this regard, a positive relationship between GVC embedding and carbon productivity will be conducive to the low-carbon transformation of China’s manufacturing industry.

Existing research in the literature on GVC has focused on structural measures of GVC embedding [

4,

5,

6,

7], productivity effects [

8], and technological innovation effects [

9]. With regard to carbon productivity, scholars have analysed the impact of factors such as consumption structure [

10], technological progress [

11], environmental regulation [

12], energy efficiency, and industry structure [

13] on carbon productivity. As the GVC division of labour continues to deepen and low-carbon emission reduction continues to advance, more and more scholars have explored the intrinsic links between GVC and carbon emissions.

Among the studies about the direct impact of GVC on carbon emissions, Li et al. [

14] found that raising GVC participation can reduce carbon emissions. They discovered that GVC embedded status has an inverted U-shape relationship with the intensity of carbon emissions by including the squared term of GVC embedding position. However, when the GVC embedding position is low, the inhibitory effect of GVC participation on carbon emissions is constrained. In recent years, China’s manufacturing GVC participation has deepened, but the embedded position has been low, and it is still at the downstream stage with low added value [

15]. When the division of labour status is low, there may be environmental risks of GVC embedding, resulting in a negative relationship between GVC participation and carbon productivity. The environmental risks faced by GVC embedding are inversely proportional to the level of technology in the industry [

16]. However, Cai et al. [

17] further divided GVC participation into forward and backward GVC participation. The study found that forward GVC participation has a U-shaped relationship with carbon emissions, while backward GVC participation significantly increases the intensity of carbon emissions. Therefore, the effect of GVC participation and GVC embedding location on the direct impact of carbon productivity is still controversial and requires further analysis.

Among the studies about the mechanism of GVC embedding on carbon emissions, Xie et al. [

18] found that the degree of GVC embedding positively contributes to carbon productivity through R&D investment, low-end lock-in, and environmental regulation. On this basis, Sun and Du [

19] innovatively introduced an interaction term for the structural upgrading effect. The study found that both the degree of GVC embeddedness and position can have an impact on carbon productivity through industrial structural upgrading. These articles have two drawbacks. First, the correlation analysis is only based on a single dimension of GVC participation or GVC embedding position, and they fail to comprehensively explore the differential impacts on carbon productivity under the same mechanism of action. Second, neither paper made the digital economy a key component of the framework for analysis. In recent years, the digital economy has flourished and has become an accelerator of China’s high-quality economic growth. According to the China Digital Economy Development Report, the scale of the country’s digital economy reached RMB 45.50 trillion in 2021, accounting for 39.80% of GDP. Industrial digitisation’s contribution to the digital economy reached 81.80%, accounting for 32.50% of GDP. The digital economy not only facilitates the upgrading of the GVC division of labour but also mitigates the contribution of GVC participation to the implied carbon emissions of trade [

20]. The digital economy is also conducive to enhancing the technological progress effect and industrial upgrading effect of GVC embedding [

21,

22]. Therefore, it is necessary to include the digital economy in the analytical framework to explore the impact of the embedding of GVC on carbon productivity.

The analysis of the heterogeneity of GVC embeddedness on carbon emissions focuses on the following three aspects. First, the effect of GVC on carbon emissions varies across regions with different levels of economic development. Bai et al. [

23] divided the sample into two groups of developed and developing economies based on the per capita income level of each region. It is found that GVC embedding has a positive but insignificant impact on the carbon intensity of industries in developed economies, but it has a considerable negative impact on industries in developing economies. Second, the effect of GVC embeddedness on carbon emissions is different in industries with different factor intensities. Li et al. [

24] classified the manufacturing industries of the countries along the Belt and Road into labour-intensive, capital-intensive, and technology-intensive industries according to factor intensity. According to the study, GVC embedding is more conducive to enhancing the carbon emission efficiency of technology-intensive industries, whereas it significantly reduces the efficiency of carbon emissions in labour- and capital-intensive industries. Third, different GVC embedding methods have different effects on carbon emissions. Shi et al. [

25] analysed the impact of GVC participation on the carbon emission intensity of countries along the Belt and Road based on a multi-regional input–output model. The study found that forward GVC participation could effectively reduce carbon emission intensity, while backward GVC participation was negatively related to carbon emission intensity. The impact of forward and backward GVC participation on the carbon emission intensity of developing countries was greater than that of developed countries. However, with the deepening division of labour in GVC, GVC can be further classified into simple and complex GVC based on how frequently it crosses international boundaries. The GVC division of labour is accompanied by rich flows of factors such as capital, technology, resources, and management experience. Theoretically, the more the GVC crosses borders, i.e., the deeper the involvement of complex GVC, the richer the factor resources that enterprises obtain from them, and the more conducive they are in reducing the intensity of carbon emissions. But deeper GVC embedding is also likely to lead to an increase in implied carbon from export trade [

26]. Does this mean that more GVC across national borders will exacerbate the rise in carbon intensity? To this end, it is necessary to explore the effects of simple and complex GVC on carbon emissions. However, there is very little literature exploring the heterogeneous effects of GVC activity complexity on carbon productivity. Therefore, this field of study urgently needs to be expanded.

In summary, existing research in the literature on GVC embedding and carbon productivity has produced a wealth of findings; however, the following gaps still exist. Firstly, existing studies tend to examine the non-linear relationship between GVC embedding and carbon productivity using the introduction of a quadratic term [

17,

18,

19]. When the quadratic term coefficients are statistically significant, the studies claim that there is an (inverted) U-shaped relationship between the variables. In specific studies, the economic meaning and range of values of the variables must be considered. Once the range of values of the variables is taken into account, together with the location of the turning point of the quadratic curve, it becomes clear that within the sample interval, the relationship between the variables may simply be the left or right half branch of the (inverted) U-shaped curve [

21]. In other words, the relationship between the variables is still monotonic, and only the marginal impact is changing (increasing or decreasing). Secondly, existing studies struggle to fully reflect the mechanism of GVC embedding on carbon productivity [

18,

19]. On the one hand, the majority of the currently available literature only examines the mechanism of GVC’s impact on carbon productivity based on a single aspect of GVC participation or GVC embedding position. On the other hand, barely any research has concentrated on the moderating effect of industry digitisation on GVC’s impact on carbon productivity. Third, most of the studies only examined the effects of different GVC embedding methods (forward versus backward embedding) [

17,

21,

25] and the impact of GVC on carbon productivity in regions with different levels of economic development [

23,

24]. They did not take into account the diversity of the effects of various GVC activities’ complexity on carbon productivity.

Based on the above analysis, the contributions are as follows: First, setting up a threshold regression model to investigate the variations in the marginal impact of GVC embedding position on carbon productivity in manufacturing in more detail and rigorously, as well as improve the “pseudo-(inverted) U-shaped” results that may result from the introduction of only quadratic terms. Second, a thorough examination of the moderating impact of GVC embedding on carbon productivity in three dimensions: forward GVC participation, backward GVC participation, and GVC embedding position. Third, the innovative inclusion of industry digitisation in the analytical framework explores the impact of GVC embedding on carbon productivity in the context of the digital economy. Fourth, the GVC participation is divided into forward and backward GVC participation according to the different embedding methods, simple GVC and complex GVC according to the degree of complexity, and the manufacturing industry is divided into the high-technology industry and low- and medium-technology industries according to the different technology levels to develop a three-dimensional heterogeneity analysis of GVC embedding and carbon productivity so as to form a comprehensive research result on GVC embedding and carbon productivity.

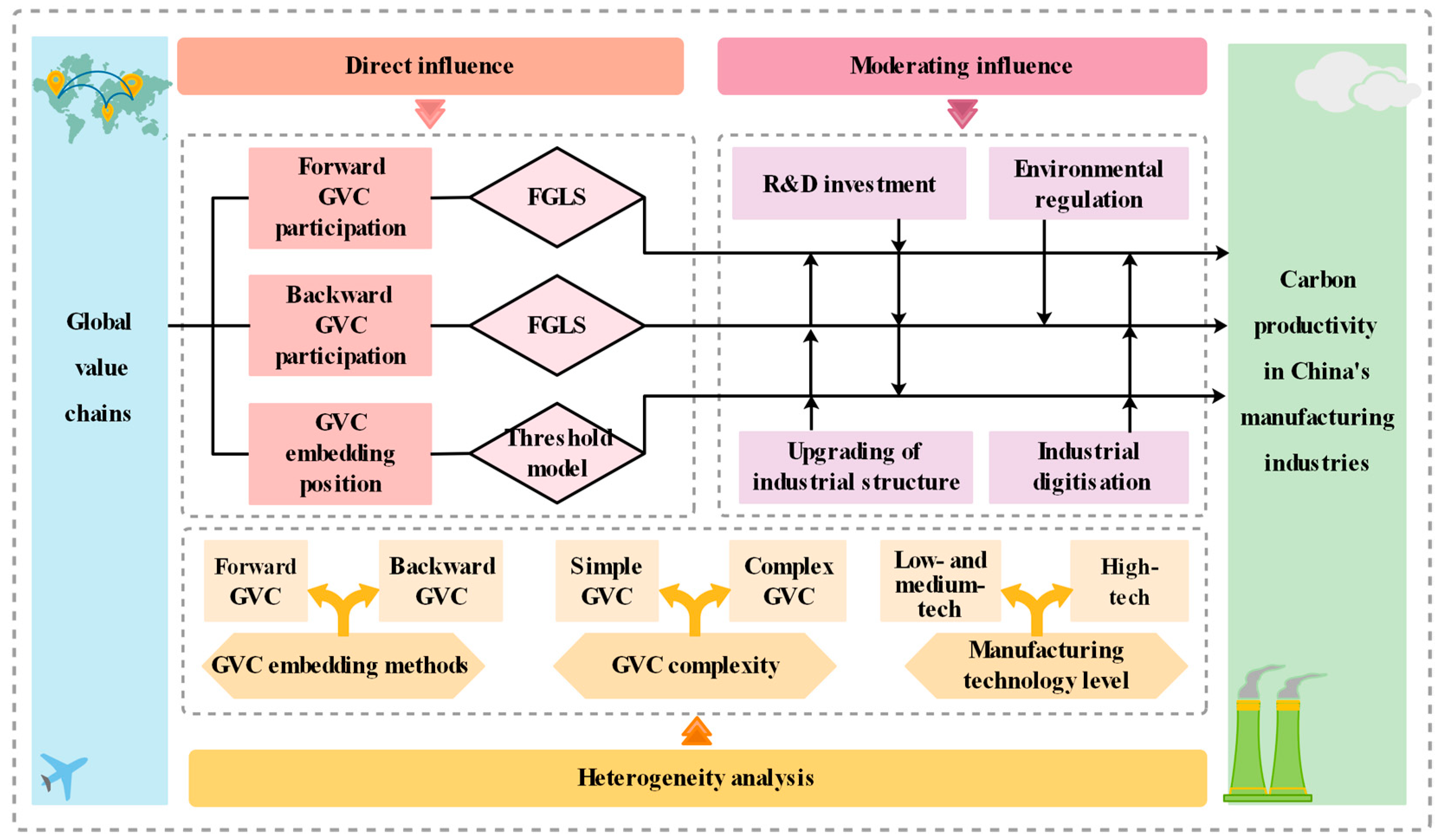

Based on this, this paper takes the GVC embeddedness and carbon productivity of China’s manufacturing industries from 2006 to 2018. First, the estimation method of FGLS is used to explore the direct linear effect of forward and backward GVC participation on carbon productivity. The panel threshold regression model is built to analyse the marginal effect of the GVC embedding position on carbon productivity. Then, the mechanism of GVC embeddedness on carbon productivity is analysed by combining the moderating effects of R&D investment, environmental regulation, industrial structure upgrading, and industrial digitisation in the three dimensions of forward GVC participation, backward GVC participation, and GVC embeddedness position. Finally, the heterogeneous impact of GVC embedding on carbon productivity is analysed in terms of the different GVC embedding methods, the different technology levels in the manufacturing industry, and the degree of participation in simple and complex GVC activities. Our research framework is presented in

Figure 1.

The paper is structured as follows:

Section 2 conducts the theoretical analysis and develops the research hypothesis.

Section 3 describes the model and data.

Section 4 conducts an empirical analysis and performs robustness tests.

Section 5 explores the moderating effect of GVC embedding on carbon productivity and conducts a heterogeneity analysis.

Section 6 concludes and provides policy recommendations based on the findings.

Section 7 presents perspectives for future studies.

6. Conclusions and Policy Recommendations

This article explores the impact of GVC participation and GVC embedding position on carbon productivity in China’s manufacturing industries using panel data from 2006–2018, combining the moderating effects of industry digitisation, R&D investment, environmental regulation, and industrial structure upgrading, and further examines the heterogeneity of the impact of GVC embedding on carbon productivity. This article mainly draws the following conclusions and makes relevant recommendations.

First, in terms of the direct effect of forward and backward GVC participation on carbon productivity in China’s manufacturing industries, increasing forward and backward GVC participation will have a dampening effect on carbon productivity. At present, China’s manufacturing enterprises embedded in GVC based on the forward approach are limited by their technology level and are vulnerable to technology blockade from other countries. The intermediate products they provide to other countries are mainly energy-intensive products; thus, they have not yet achieved the carbon reduction effect. The backward approach to embedding GVC enterprises mainly relies on the processing of intermediate products from other countries to participate in trade activities. The “pollution sanctuary” effect is prominent. The trade model will easily lead to the capture of enterprises by developed countries, resulting in China’s manufacturing industry in the “low-end locking” dilemma. Therefore, the first step for China’s manufacturing industries to break through the technological blockade of other countries and break the low-end locking dilemma is still to enhance the ability of independent innovation, then promote enterprises to upgrade their processes and products, and accelerate the transformation of intermediate trade goods to green and clean products. It should give full play to the advantages of the domestic market, expand domestic market demand, and pull endogenous innovation represented by independent, collaborative, and integrated innovation. It can also promote the development of high-quality and diversified intermediate products, thereby enhancing product competitiveness, broadening domestic and international markets, and reducing the effect of technological blockade and capture.

Second, in terms of the direct effect of the GVC embedding position on carbon productivity in China’s manufacturing industries, raising the GVC embedding position can significantly increase the level of carbon productivity, and this marginal effect tends to increase and then decrease. Therefore, the GVC embedding position of the manufacturing industry should be raised, and the industries should be accelerated to the upstream end of low-pollution and high value-added. Currently, China’s manufacturing industry is actively taking advantage of low factor costs and has successfully integrated into the GVC production network, forming a global manufacturing base. Subsequently, the country’s non-core businesses and technologies should be gradually outsourced to enhance the attractiveness of the high-end segments of the manufacturing industry based on local high-end elements. The investment should be shifted to R&D design and marketing channel construction, becoming a self-designed developer and self-distributed seller, and realising the transformation of the value chain from process upgrading to product and function upgrading. When the overall capital and technology accumulation reaches a certain level, then the chain will be upgraded by its strength, thus completing the GVC upgrading process and realising the value chain climbing up to the top end.

Third, although the boosting impact of GVC embedding position on carbon productivity is strengthened by R&D investment, it cannot be effectively converted into technological progress, which leads to insufficient technological innovation capacity of enterprises, thus enhancing the inhibitory effect of forward and backward GVC participation on carbon productivity. Therefore, the allocation of technology R&D funds should be increased, and incentive policies such as funding subsidies and tax exemptions. Rewards for achievements should be implemented for green, clean, and high-tech R&D activities of enterprises so as to fully motivate enterprises to take the initiative to carry out independent R&D activities on green technologies. The utilisation rate of R&D funding to achieve an effective conversion from R&D investment to technological progress should also be improved, thereby reducing the moderating effect of R&D investment on forward and backward GVC participation in inhibiting carbon productivity.

Fourth, environmental regulation weakens the negative impact of backward GVC participation on carbon productivity. Therefore, environmental regulation policies should be strengthened to mitigate the “pollution shelter” effect caused by foreign investment and, at the same time, force domestic enterprises to upgrade their green technologies. On the one hand, green investments should be vigorously developed. The following should all be prioritized: the development of green technologies; the prioritization of investments in energy-saving, environmental protection, and green businesses; the promotion of the application and enforcement of green concepts throughout the design, production, and marketing of products; and obtaining carbon labelling green certification. On the other hand, an environmental regulation tool that integrates government and market is used through the power of the government to issue administrative directives for carbon reduction and pollution reduction. At the same time, we should give full play to the decisive role of the market in the allocation of green resources, increase public participation in environmental protection; strengthen communication between the government, enterprises, and the public; and achieve a positive interaction between the three.

Fifth, industrial structure upgrading strengthens the promotion effect of GVC embedding position on carbon productivity, but since the foundation of China’s manufacturing industry is relatively weak, blindly carrying out industrial structure upgrading may lead to unbalanced development of the industries, which makes the inhibitory effect of both forward and backward GVC participation on carbon productivity stronger. Therefore, to accelerate the optimisation and upgrading of industrial structure, on the one hand, we should identify the comparative advantages and work focus, increase reform and innovation, optimise industrial layout, coordinate the development of the three industries, and continue to grow the economy of the urban areas, the county economy, and the town and village economy. On the other hand, we should do better in industry, be stronger in agriculture, and be more active in the service industry, highlighting hydrogen energy, big data, new materials, and other emerging industries and cultivating new kinetic energy for high-quality economic development.

Sixth, industry digitisation attenuates the inhibitory effect of forward and backward GVC participation on carbon productivity in China’s manufacturing industries, but since the development of the digital economy requires a large amount of capital, blindly promoting the development of industry digitisation when the total amount of capital is certain may have some crowding-out effect on technological progress, thus attenuating the promotional effect of GVC embedding position enhancement on carbon productivity. Therefore, the digitisation of industry and digital industrialization should be further promoted, and the application of artificial intelligence, 5G, Internet, blockchain, and data mining in the manufacturing industry should be continuously strengthened so as to reduce the dependence of China’s manufacturing industry on traditional factors of production. The government should invest more in digitalisation, actively carry out research and development activities on high-end digital technologies, accelerate the diffusion of technology between industries, improve the efficiency of resource allocation, thereby promoting a more rationalised and advanced industrial structure, and actively exploit the carbon reduction effect brought about by the upgrading of the industrial structure and the digitalisation of industries in the process of CVC embedding.

Finally, heterogeneity analysis shows that the contribution of forward and backward GVC participation to carbon productivity is significant in low- and medium-tech manufacturing industries. Increasing forward simple GVC participation can raise carbon productivity levels. Complex GVC production activities are negatively correlated with carbon productivity because they involve multiple border crossings of value added and exacerbate negative impacts such as technological blockages, resulting in both forward and backward complex GVC participation being negatively correlated with carbon productivity. Therefore, the forward simple GVC participation of China’s manufacturing industries should be actively increased. The enterprises in low- and medium-technology industries should also be actively embedded in the GVC division of labour to increase their GVC participation so as to give full play to the GVC import learning effect. This can help enterprises acquire advanced technology and management experience from other countries, enhance the independent innovation capacity of enterprises, promote the progress of green technology in enterprises, and ultimately improve the efficiency of carbon production.

7. Future Study

This study explores the mechanisms by which forward and backward GVC participation, as well as GVC embedding position, affect carbon productivity in China’s manufacturing industries at both theoretical and empirical levels. To provide a different understanding and develop more comprehensive policy support for the coordinated development of global climate change governance and international trade, more explorations can be made in the following aspects.

First, due to the scarcity of input–output datasets, the study period for this work is limited to 2006–2018 in order to give a micro-understanding of the issue at the manufacturing industry level. With the update of relevant data in the future, more up-to-date or country-level macro analyses can be conducted.

Second, to measure the GVC embedded position, this research uses the GVC position index established by Wang et al. [

51]. Although the procedure is reasonably mature and excellent, there are still many differences between it and the upstream and downstream locations in our real economy. There is still a need to collect and count the data of intermediate goods transactions between firms to recognise the position of firms in the production chain.

Finally, this article chooses carbon productivity as the subject of investigation so that it may fully weigh both economic benefits and environmental costs. Future research can try to study different aspects such as absolute carbon emissions, carbon total factor productivity, and so on.