Performance Evaluation of Asphalt Mixtures Containing Different Proportions of Alternative Materials

Abstract

:1. Introduction

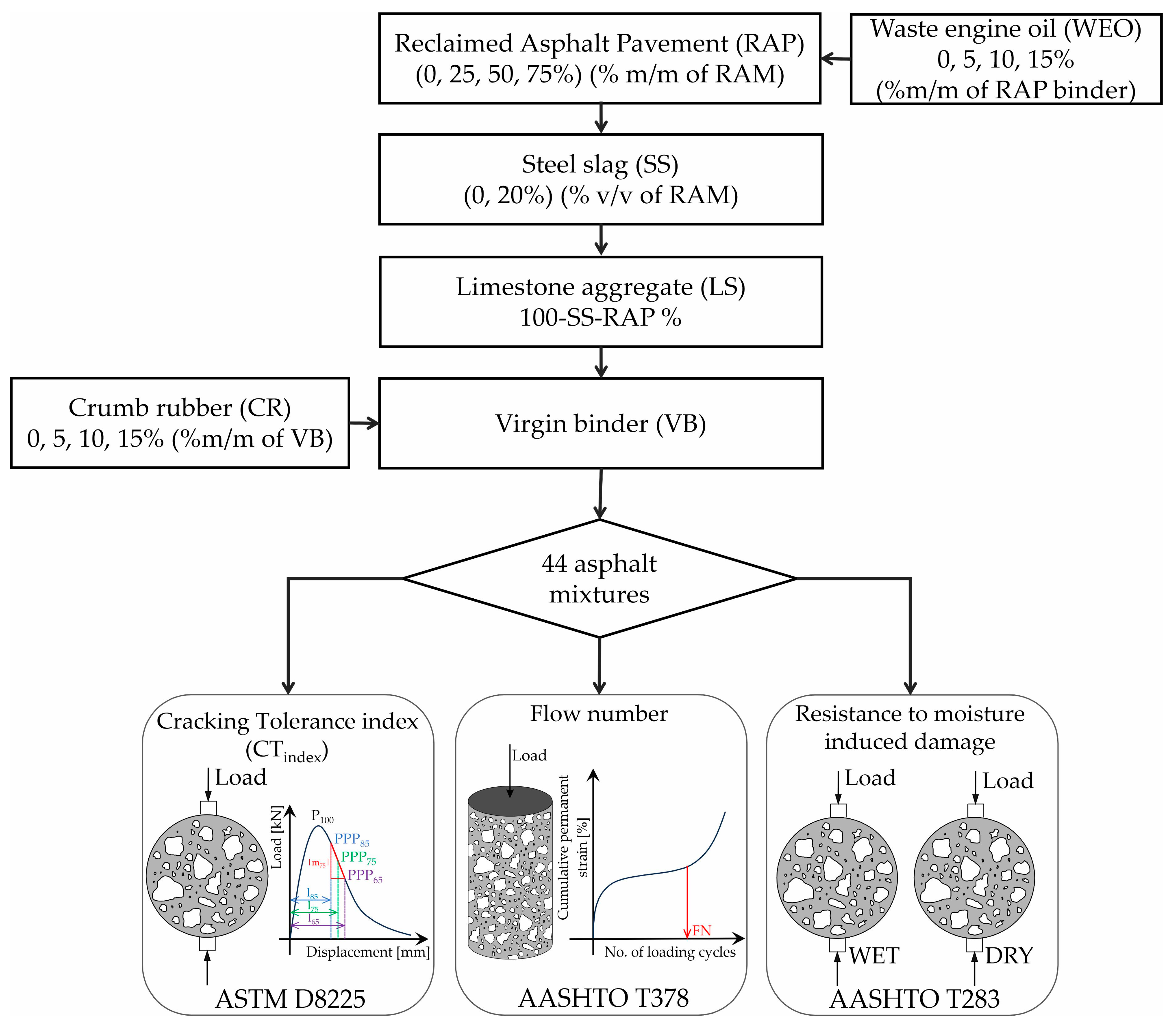

2. Materials and Methods

2.1. Materials

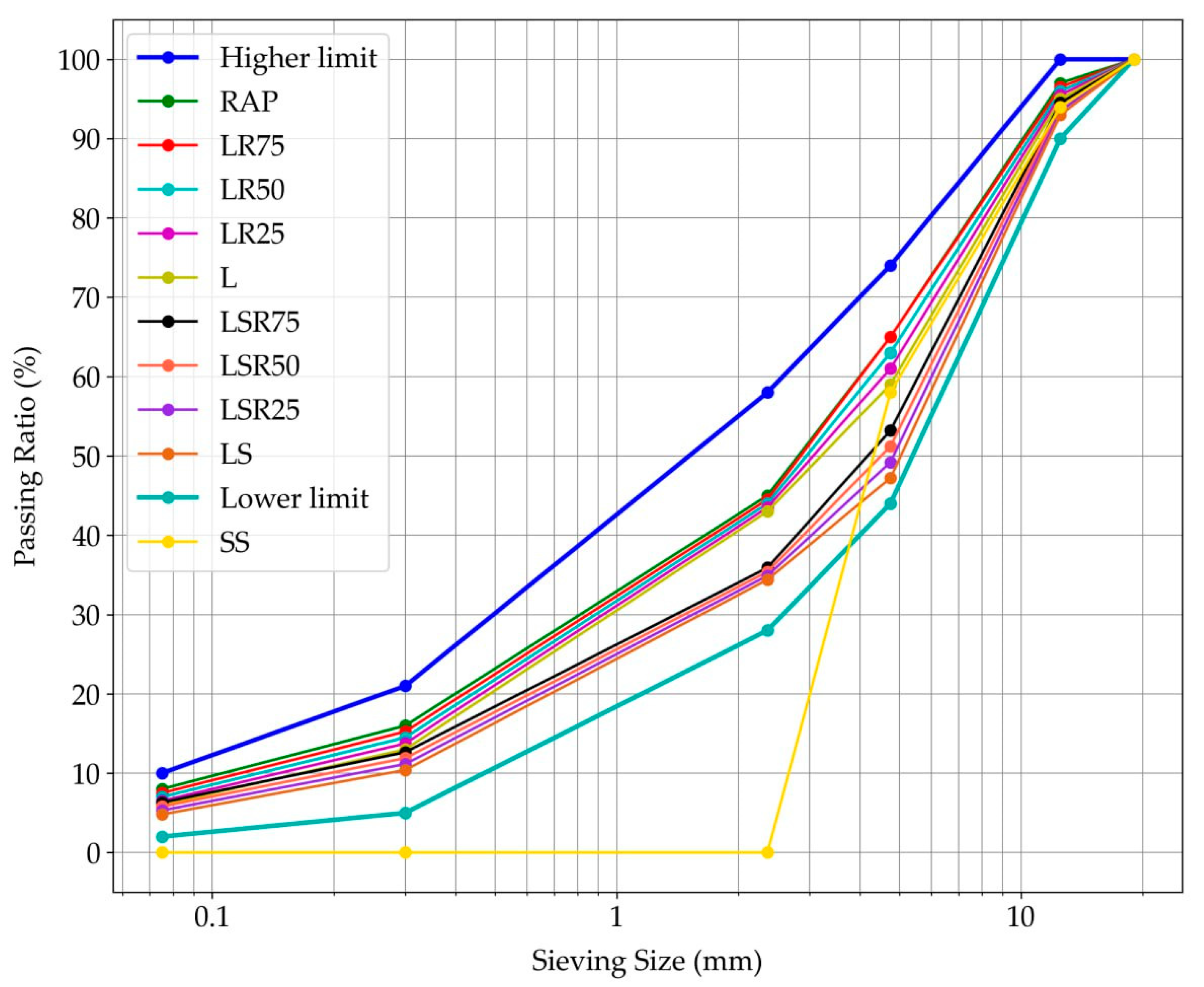

2.1.1. Limestone Aggregate

2.1.2. Steel Slag Aggregate

2.1.3. Reclaimed Asphalt Pavement

2.1.4. Waste Engine Oil

2.1.5. Crumb Rubber

2.1.6. Asphalt Binder

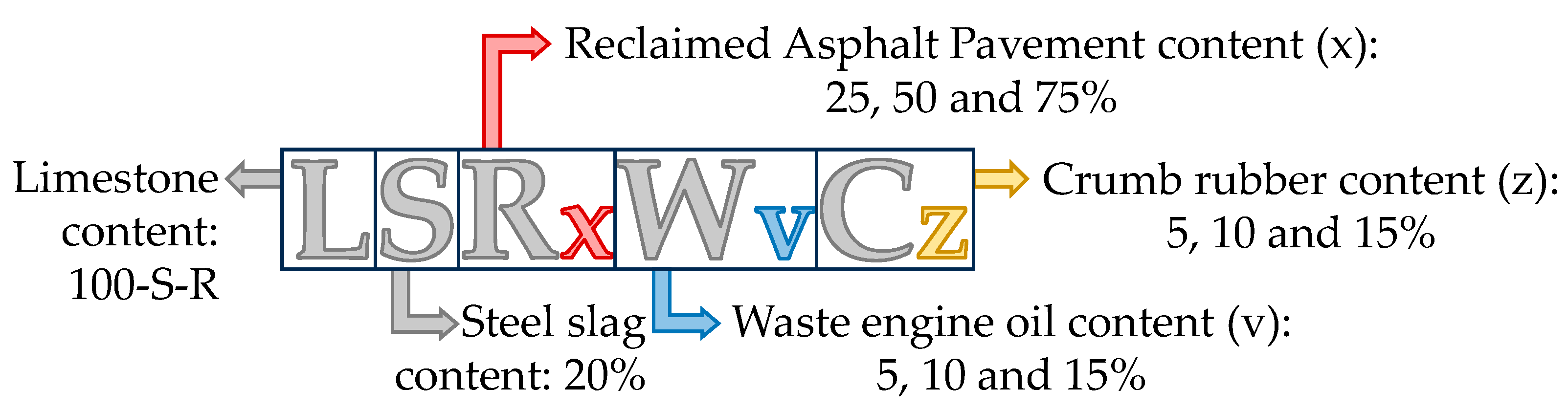

2.1.7. Asphalt Mixture

2.2. Methods

2.2.1. Specimen Preparation

2.2.2. Cracking Resistance

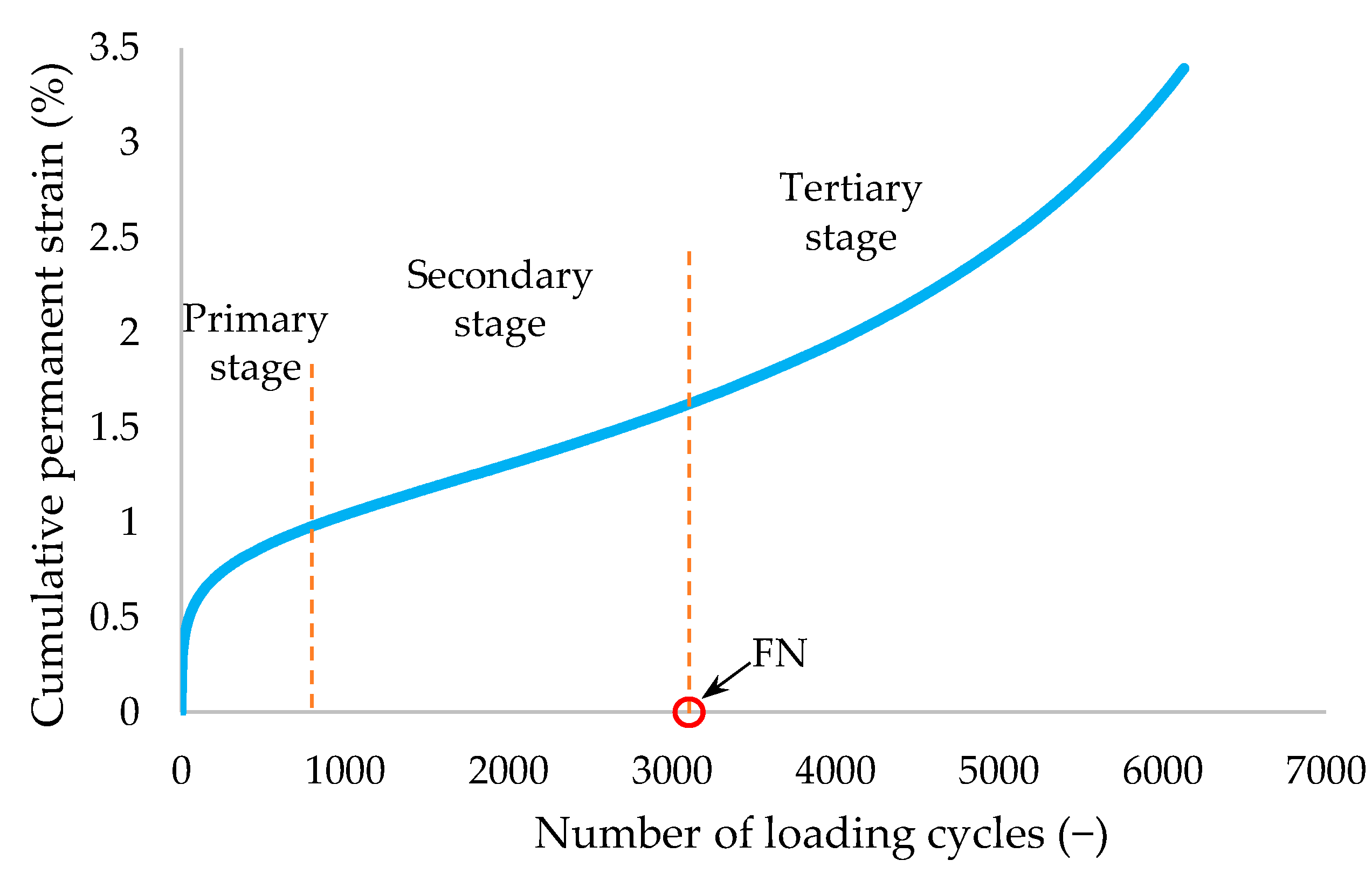

2.2.3. Rutting Resistance

2.2.4. Moisture Damage Resistance

2.2.5. Prediction Model’s Development

3. Results and Discussion

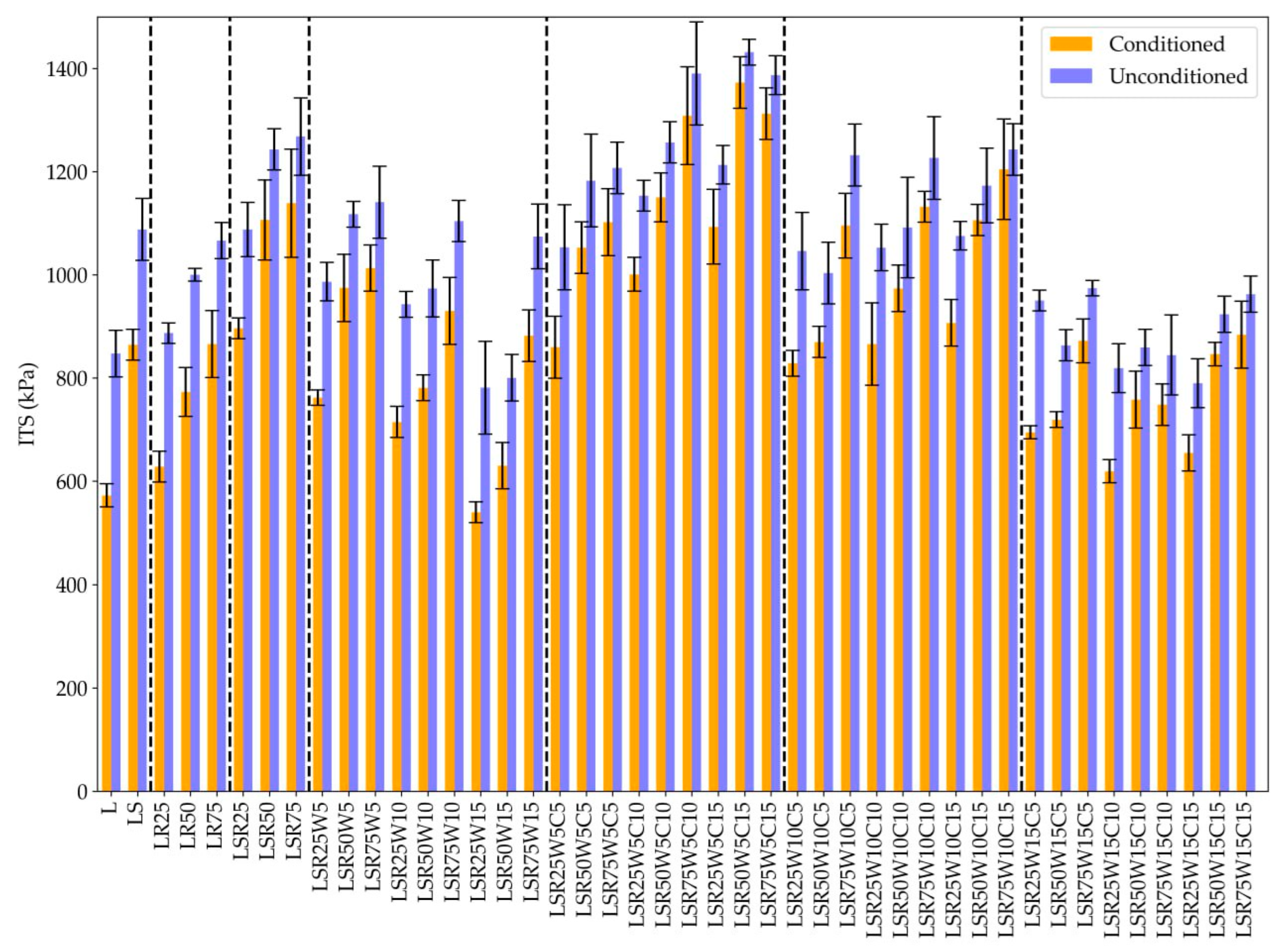

3.1. Moisture Damage Resistance and ITS Test

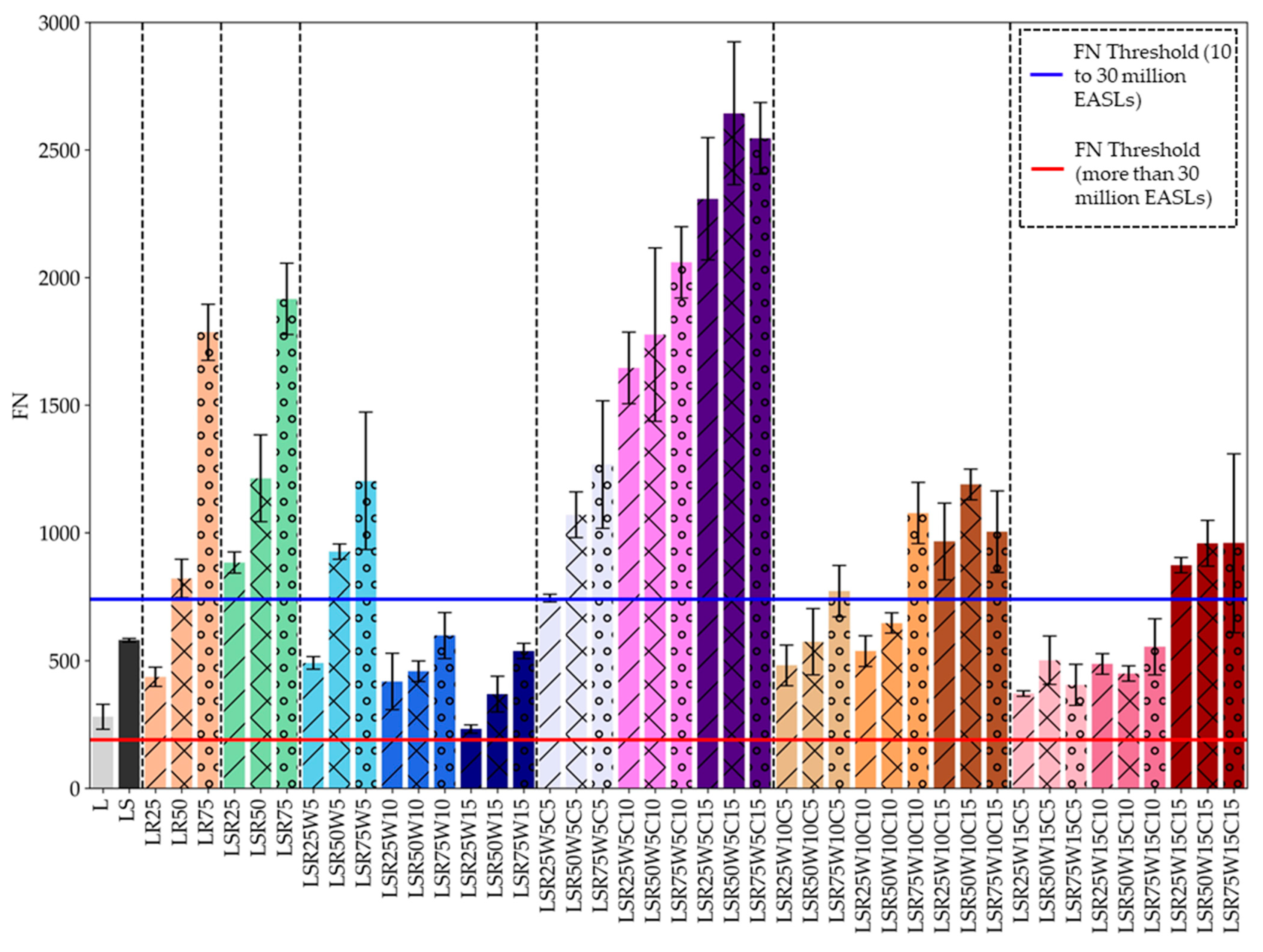

3.2. Dynamic Creep Test

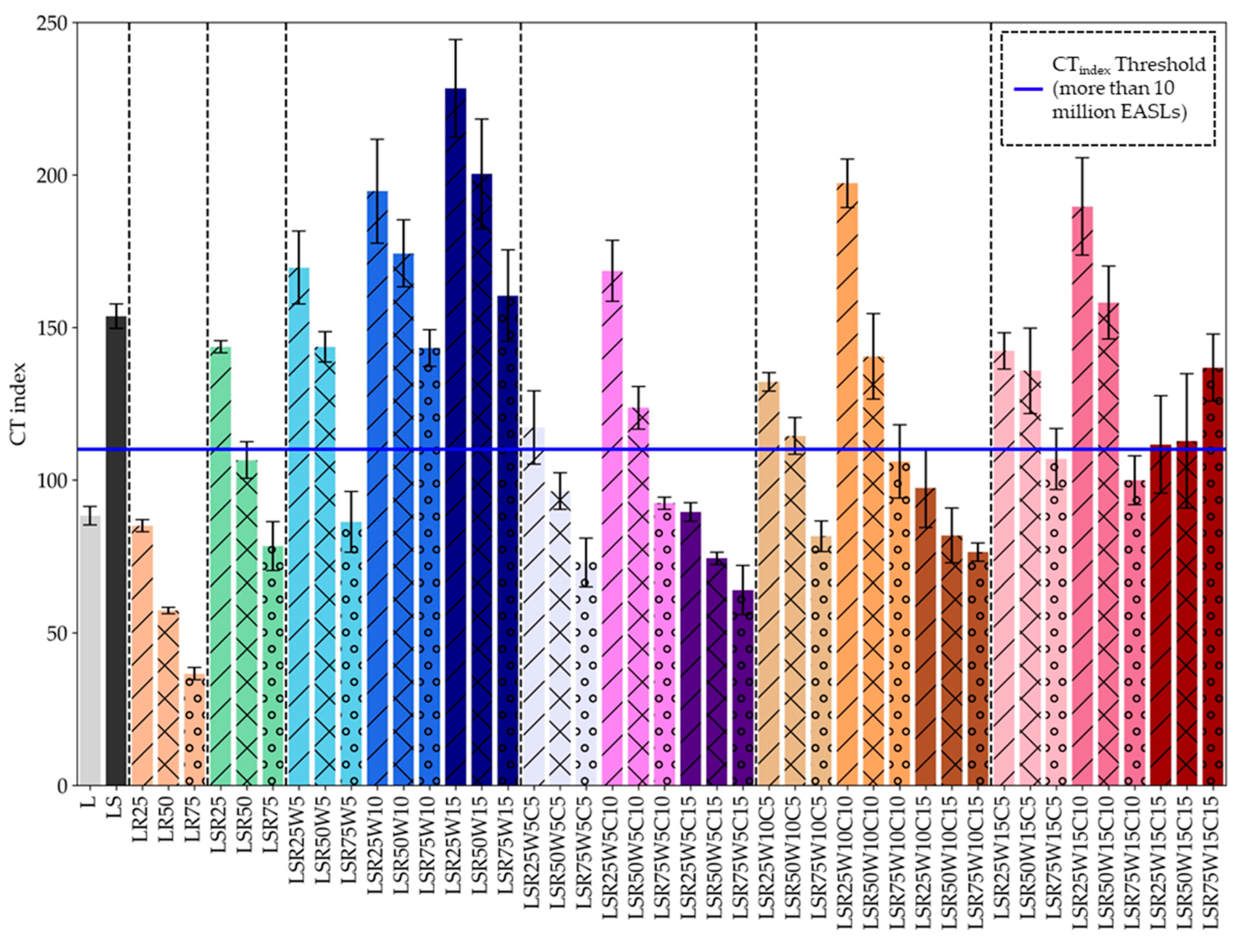

3.3. Indirect Tensile Cracking Test

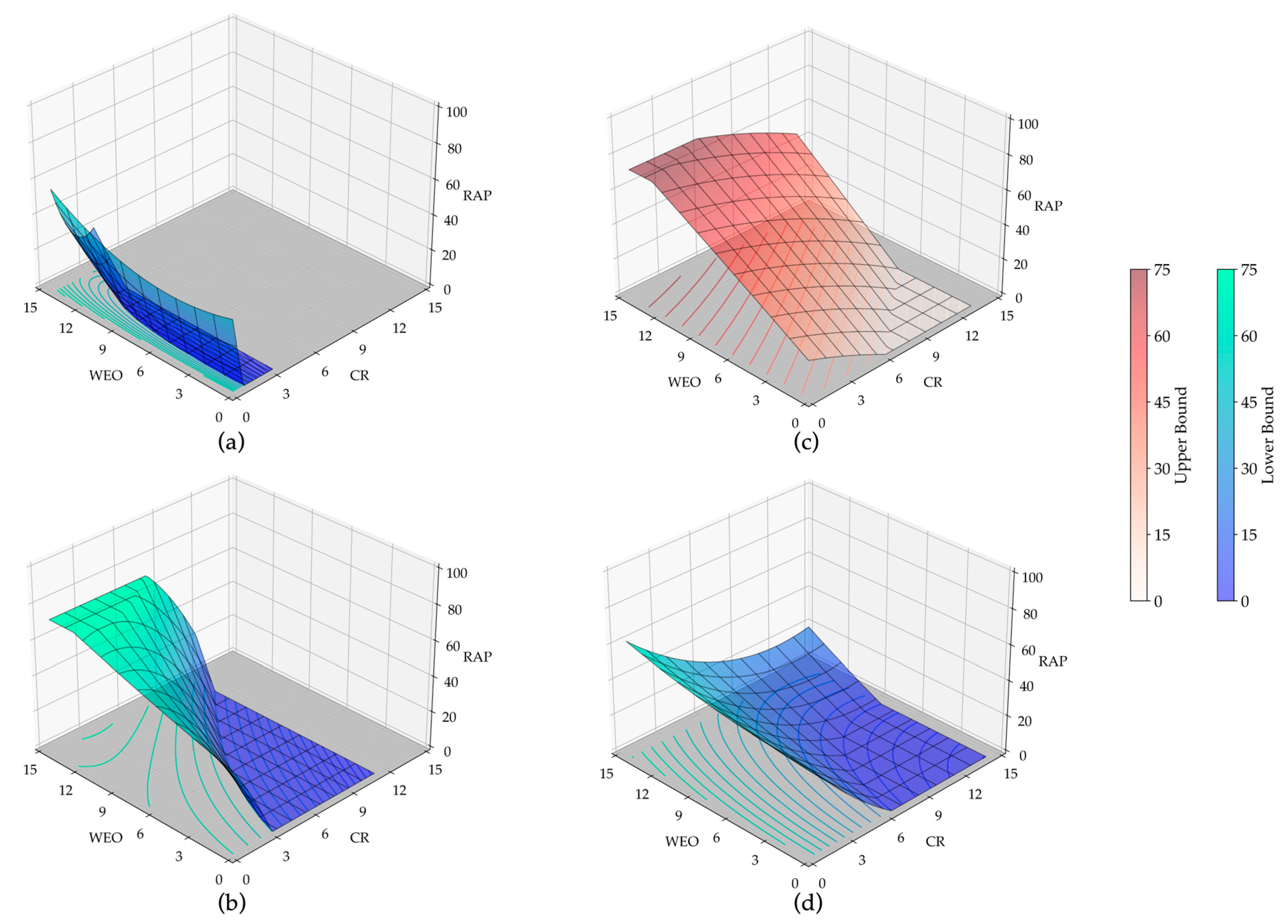

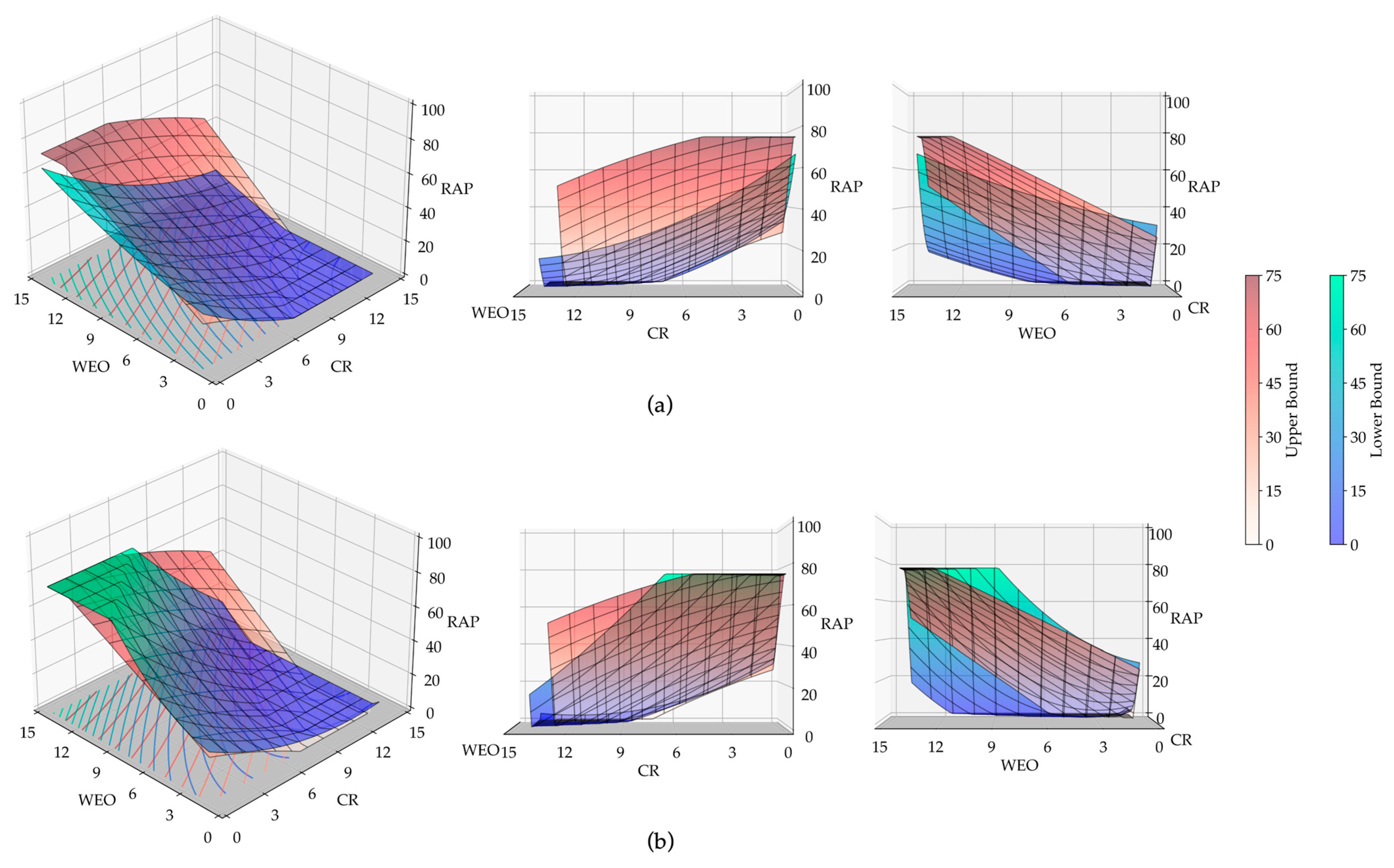

3.4. Determining the Appropriate Usage Percentages of Alternative Materials

4. Conclusions

- Overall, the use of 20% SS instead of virgin aggregate enhances all performance metrics of asphalt mixtures, especially when combined with a low RAP content (25%).

- The RAP content significantly affects the cracking resistance. When compared to the L mixture, the CTindex value dropped by up to 59% with an increase in RAP content of up to 75% in asphalt mixtures without other alternative materials. RAP presence generally improves the rutting and moisture damage resistance of all asphalt mixtures, regardless of the contents and combination of alternative materials.

- WEO significantly improves cracking resistance, where only 5% was enough to meet the proposed threshold value. At the same time, it reduces the rutting and moisture damage resistance, especially if more than 5% is used.

- Addition of 10% CR led to the highest cracking resistance of the mixtures containing RAP, SS and WEO. The use of CR simultaneously offsets the negative effect of WEO on the rutting resistance, especially when combined with 5% WEO, and has a positive impact on moisture damage resistance.

- The GPR model can successfully be used to determine the most beneficial ratio and combination of alternative materials, considering individual or overall performance of RAMs depending on the traffic level.

- The application of a paired t-test to the GPR models showed that rutting and cracking resistance are mostly influenced by WEO, whereas moisture damage resistance is mostly affected by CR.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Aurangzeb, Q.; Al-Qadi, I.L.; Ozer, H.; Yang, R. Hybrid Life Cycle Assessment for Asphalt Mixtures with High RAP Content. Resour. Conserv. Recycl. 2014, 83, 77–86. [Google Scholar] [CrossRef]

- Willis, J.R.; Turner, P.; Julian, G.; Taylor, A.J.; Tran, N.; Padula, F. Effects of Changing Virgin Binder Grade and Content on Rap Mixture Properties—NCAT Report 12-03. Natl. Cent. Ashalt Technol. 2012, 1–47. [Google Scholar]

- Jahanbakhsh, H.; Karimi, M.M.; Naseri, H. Sustainable Asphalt Concrete Containing High Reclaimed Asphalt Pavements and Recycling Agents: Performance Assessment, Cost Analysis, and Environmental Impact. J. Clean. Prod. 2020, 244, 118837. [Google Scholar] [CrossRef]

- Williams, B.A.; Willis, J.R.; Ross, T.C. Asphalt Pavement Industry Survey on Recycled Materials and Warm-Mix Asphalt Usage: 2018. Natl. Asph. Pavement Assoc. 2019, 1–46. [Google Scholar]

- Kim, S.; Sholar, G.A.; Byron, T.; Kim, J. Performance of Polymer-Modified Asphalt Mixture with Reclaimed Asphalt Pavement. Transp. Res. Rec. 2009, 2126, 109–114. [Google Scholar] [CrossRef]

- Majidifard, H.; Tabatabaee, N.; Buttlar, W. Investigating Short-Term and Long-Term Binder Performance of High-RAP Mixtures Containing Waste Cooking Oil. J. Traffic Transp. Eng. English Ed. 2019, 6, 396–406. [Google Scholar] [CrossRef]

- Taherkhani, H.; Noorian, F. Comparing the Effects of Waste Engine and Cooking Oil on the Properties of Asphalt Concrete Containing Reclaimed Asphalt Pavement (RAP). Road Mater. Pavement Des. 2020, 21, 1238–1257. [Google Scholar] [CrossRef]

- Hugener, M.; Wang, D.; Cannone Falchetto, A.; Porot, L.; Kara De Maeijer, P.; Orešković, M.; Sa-da-Costa, M.; Tabatabaee, H.; Bocci, E.; Kawakami, A. Recommendation of RILEM TC 264 RAP on the Evaluation of Asphalt Recycling Agents for Hot Mix Asphalt. Mater. Struct. 2022, 55, 31. [Google Scholar] [CrossRef]

- Daryaee, D.; Ameri, M.; Mansourkhaki, A. Utilizing of Waste Polymer Modified Bitumen in Combination with Rejuvenator in High Reclaimed Asphalt Pavement Mixtures. Constr. Build. Mater. 2020, 235, 117516. [Google Scholar] [CrossRef]

- Poulikakos, L.D.; Pasquini, E.; Tusar, M.; Hernando, D.; Wang, D.; Mikhailenko, P.; Pasetto, M.; Baliello, A.; Cannone Falchetto, A.; Miljković, M.; et al. RILEM Interlaboratory Study on the Mechanical Properties of Asphalt Mixtures Modified with Polyethylene Waste. J. Clean. Prod. 2022, 375, 134124. [Google Scholar] [CrossRef]

- Mohamed, A.S.; Cao, Z.; Xu, X.; Xiao, F.; Abdel-wahed, T. Bonding, Rheological, and Physiochemical Characteristics of Reclaimed Asphalt Rejuvenated by Crumb Rubber Modified Binder. J. Clean. Prod. 2022, 373, 133896. [Google Scholar] [CrossRef]

- Dhoble, Y.N.; Ahmed, S. Review on the Innovative Uses of Steel Slag for Waste Minimization. J. Mater. Cycles Waste Manag. 2018, 20, 1373–1382. [Google Scholar] [CrossRef]

- Orešković, M.; Santos, J.; Mladenović, G.; Rajaković-Ognjanović, V. The Feasibility of Using Copper Slag in Asphalt Mixtures for Base and Surface Layers Based on Laboratory Results. Constr. Build. Mater. 2023, 384, 131285. [Google Scholar] [CrossRef]

- Wen, H.; Wu, S.; Bhusal, S. Performance Evaluation of Asphalt Mixes Containing Steel Slag Aggregate as a Measure to Resist Studded Tire Wear. J. Mater. Civ. Eng. 2016, 28, 04015191. [Google Scholar] [CrossRef]

- Kavussi, A.; Qazizadeh, M.J. Fatigue Characterization of Asphalt Mixes Containing Electric Arc Furnace (EAF) Steel Slag Subjected to Long Term Aging. Constr. Build. Mater. 2014, 72, 158–166. [Google Scholar] [CrossRef]

- Ye, Y.; Wu, S.; Li, C.; Kong, D.; Shu, B. Morphological Discrepancy of Various Basic Oxygen Furnace Steel Slags and Road Performance of Corresponding Asphalt Mixtures. Materials Basel 2019, 12, 2322. [Google Scholar] [CrossRef]

- Zaumanis, M.; Poulikakos, L.D.; Partl, M.N. Performance-Based Design of Asphalt Mixtures and Review of Key Parameters. Mater. Des. 2018, 141, 185–201. [Google Scholar] [CrossRef]

- Sabouri, M. Evaluation of Performance-Based Mix Design for Asphalt Mixtures Containing Reclaimed Asphalt Pavement (RAP). Constr. Build. Mater. 2020, 235, 117545. [Google Scholar] [CrossRef]

- Asi, I.M.; Qasrawi, H.Y.; Shalabi, F.I. Use of Steel Slag Aggregate in Asphalt Concrete Mixes. Can. J. Civ. Eng. 2007, 34, 902–911. [Google Scholar] [CrossRef]

- Rahbar-Rastegar, R.; Zhang, R.; Sias, J.E.; Dave, E.V. Evaluation of Laboratory Ageing Procedures on Cracking Performance of Asphalt Mixtures. Road Mater. Pavement Des. 2019, 20, S647–S662. [Google Scholar] [CrossRef]

- Meroni, F.; Flintsch, G.W.; Habbouche, J.; Diefenderfer, B.K.; Giustozzi, F. Three-Level Performance Evaluation of High RAP Asphalt Surface Mixes. Constr. Build. Mater. 2021, 309, 125164. [Google Scholar] [CrossRef]

- Jia, X.; Huang, B.; Moore, J.A.; Zhao, S. Influence of Waste Engine Oil on Asphalt Mixtures Containing Reclaimed Asphalt Pavement. J. Mater. Civ. Eng. 2015, 27, 04015042. [Google Scholar] [CrossRef]

- Devulapalli, L.; Kothandaraman, S.; Sarang, G. Effect of Rejuvenating Agents on Stone Matrix Asphalt Mixtures Incorporating RAP. Constr. Build. Mater. 2020, 254, 119298. [Google Scholar] [CrossRef]

- Khan, M.Z.H.; Koting, S.; Katman, H.Y.B.; Ibrahim, M.R.; Babalghaith, A.M.; Asqool, O. Performance of High Content Reclaimed Asphalt Pavement (Rap) in Asphaltic Mix with Crumb Rubber Modifier and Waste Engine Oil as Rejuvenator. Appl. Sci. 2021, 11, 5226. [Google Scholar] [CrossRef]

- Sienkiewicz, M.; Borzędowska-Labuda, K.; Wojtkiewicz, A.; Janik, H. Development of Methods Improving Storage Stability of Bitumen Modified with Ground Tire Rubber: A Review. Fuel Process Technol. 2017, 159, 272–279. [Google Scholar] [CrossRef]

- Bressi, S.; Fiorentini, N.; Huang, J.; Losa, M. Crumb Rubber Modifier in Road Asphalt Pavements: State of the Art and Statistics. Coatings 2019, 9, 384. [Google Scholar] [CrossRef]

- Lo Presti, D. Recycled Tyre Rubber Modified Bitumens for Road Asphalt Mixtures: A Literature Review. Constr. Build. Mater. 2013, 49, 863–881. [Google Scholar] [CrossRef]

- Khalili, M.; Jadidi, K.; Karakouzian, M.; Amirkhanian, S. Rheological Properties of Modified Crumb Rubber Asphalt Binder and Selecting the Best Modified Binder Using AHP Method. Case Stud. Constr. Mater. 2019, 11, e00276. [Google Scholar] [CrossRef]

- Shen, J.; Amirkhanian, S.; Xiao, F.; Tang, B. Influence of Surface Area and Size of Crumb Rubber on High Temperature Properties of Crumb Rubber Modified Binders. Constr. Build. Mater. 2009, 23, 304–310. [Google Scholar] [CrossRef]

- Mohammadi, I.; Khabbaz, H. Challenges Associated with Optimisation of Blending, Mixing and Compaction Temperatures for Asphalt Mixture Modified with Crumb Rubber Modifier (CRM). Appl. Mech. Mater. 2013, 256–259, 1837–1844. [Google Scholar] [CrossRef]

- ASTM D8225 Standard; Test Method for Determination of Cracking Tolerance Index of Asphalt Mixture Using the Indirect Tensile Cracking Test at Intermediate Tempreture. ASTM International: West Conshohocken, PA, USA, 2019; pp. 1–6. [CrossRef]

- Zhou, F.; Im, S.; Sun, L.; Scullion, T. Development of an IDEAL Cracking Test for Asphalt Mix Design and QC/QA. Road Mater. Pavement Des. 2017, 18, 405–427. [Google Scholar] [CrossRef]

- Yin, F.; West, R. Balanced Mix Design Resource Guide; National Asphat Pavement Assiciation: Greenbelt, MD, USA, 2021. [Google Scholar]

- Zhang, R.; Sias, J.E.; Dave, E.V. Comparison and Correlation of Asphalt Binder and Mixture Cracking Parameters Incorporating the Aging Effect. Constr. Build. Mater. 2021, 301, 124075. [Google Scholar] [CrossRef]

- Khodaii, A.; Mehrara, A. Evaluation of Permanent Deformation of Unmodified and SBS Modified Asphalt Mixtures Using Dynamic Creep Test. Constr. Build. Mater. 2009, 23, 2586–2592. [Google Scholar] [CrossRef]

- Behnood, A.; Shah, A.; McDaniel, R.S.; Beeson, M.; Olek, J. High-Temperature Properties of Asphalt Binders: Comparison of Multiple Stress Creep Recovery and Performance Grading Systems. Transp. Res. Rec. 2016, 2574, 131–143. [Google Scholar] [CrossRef]

- National Academies of Sciences, Engineering, and Medicine. A Manual for Design of Hot-Mix Asphalt with Commentary; The National Academies Press: Washington, DC, USA, 2011. [Google Scholar]

- Goh, S.W.; You, Z. A Simple Stepwise Method to Determine and Evaluate the Initiation of Tertiary Flow for Asphalt Mixtures under Dynamic Creep Test. Constr. Build. Mater. 2009, 23, 3398–3405. [Google Scholar] [CrossRef]

- Khalifah, S. Use of Anova Asphalt Rejuvenator and Balanced Mix Design Principle to Improve the Performance of High-RAP Asphalt Mixtures. Auburn Univ. 2019, 126, 1–7. [Google Scholar]

- Khorshidi, M.; Ameri, M.; Goli, A. Cracking Performance Evaluation and Modelling of RAP Mixtures Containing Different Recycled Materials Using Deep Neural Network Model. Road Mater. Pavement Des. 2023, 1–20. [Google Scholar] [CrossRef]

- Taherkhani, A.H.; Mei, Q.; Han, F. A Deep Learning Model to Predict the Lateral Capacity of Monopiles. In Proceedings of the Geo-Congress 2023, Los Angeles, CA, USA, 26–29 March 2023; pp. 220–227. [Google Scholar]

- Lecun, Y.; Bengio, Y.; Hinton, G. Deep Learning. Nature 2015, 521, 436–444. [Google Scholar] [CrossRef]

- Nelder, J.A.; Wedderburn, R.W.M. Generalized Linear Models. J. R. Stat. Soc. Ser. A Stat. Soc. 1972, 135, 370–384. [Google Scholar] [CrossRef]

- Smola, A.J.; Schölkopf, B. A Tutorial on Support Vector Regression. Stat. Comput. 2004, 14, 199–222. [Google Scholar] [CrossRef]

- Williams, C. Gaussian processes for machine learning (Presentation). Inst. Adapt. Neural Comput. 2007, 2, 3. [Google Scholar]

- Motevalizadeh, S.M.; Sedghi, R.; Rooholamini, H. Fracture Properties of Asphalt Mixtures Containing Electric Arc Furnace Slag at Low and Intermediate Temperatures. Constr. Build. Mater. 2020, 240, 117965. [Google Scholar] [CrossRef]

- Liu, W.; Li, H.; Zhu, H.; Xu, P. The Interfacial Adhesion Performance and Mechanism of a Modified Asphalt-Steel Slag Aggregate. Materials Basel 2020, 13, 1180. [Google Scholar] [CrossRef]

- Fakhri, M.; Ahmadi, A. Evaluation of Fracture Resistance of Asphalt Mixes Involving Steel Slag and RAP: Susceptibility to Aging Level and Freeze and Thaw Cycles. Constr. Build. Mater. 2017, 157, 748–756. [Google Scholar] [CrossRef]

- Chen, Z.; Jiao, Y.; Wu, S.; Tu, F. Moisture-Induced Damage Resistance of Asphalt Mixture Entirely Composed of Gneiss and Steel Slag. Constr. Build. Mater. 2018, 177, 332–341. [Google Scholar] [CrossRef]

- Al-Qadi, I.L.; Qazi, A.; Carpenter, S.H. Impact of High RAP Content on Structural and Performance Properties of Asphalt Mixtures; Illinois Center for Transportation: Urbana, IL, USA, 2012; pp. 1–107. [Google Scholar]

- Ghabchi, R.; Singh, D.; Zaman, M.; Hossain, Z. Laboratory Characterisation of Asphalt Mixes Containing RAP and RAS. Int. J. Pavement Eng. 2016, 17, 829–846. [Google Scholar] [CrossRef]

- Kocak, S.; Kutay, M.E. Use of Crumb Rubber in Lieu of Binder Grade Bumping for Mixtures with High Percentage of Reclaimed Asphalt Pavement. Road Mater. Pavement Des. 2017, 18, 116–129. [Google Scholar] [CrossRef]

- Lee, E.J.; Park, H.M.; Suh, Y.C.; Lee, J. Performance Evaluation of Asphalt Mixtures with 100% EAF and BOF Steel Slag Aggregates Using Laboratory Tests and Mechanistic Analyses. KSCE J. Civ. Eng. 2022, 26, 4542–4551. [Google Scholar] [CrossRef]

- Duan, K.; Wang, C.; Liu, J.; Song, L.; Chen, Q.; Chen, Y. Research Progress and Performance Evaluation of Crumb-Rubber-Modified Asphalts and Their Mixtures. Constr. Build. Mater. 2022, 361, 129687. [Google Scholar] [CrossRef]

- Ren, S.; Liu, X.; Xu, J.; Lin, P. Investigating the Role of Swelling-Degradation Degree of Crumb Rubber on CR/SBS Modified Porous Asphalt Binder and Mixture. Constr. Build. Mater. 2021, 300, 124048. [Google Scholar] [CrossRef]

- Kavussi, A.; Qazizadeh, M.J.; Hassani, A. Fatigue Behavior Analysis of Asphalt Mixes Containing Electric Arc Furnace (EAF) Steel Slag. J. Rehabil. Civ. Eng. 2016, 1, 74–86. [Google Scholar]

- Pasetto, M.; Baldo, N. Mix Design and Performance Analysis of Asphalt Concretes with Electric Arc Furnace Slag. Constr. Build. Mater. 2011, 25, 3458–3468. [Google Scholar] [CrossRef]

- Pattanaik, M.L.; Choudhary, R.; Kumar, B.; Kumar, A. Mechanical Properties of Open Graded Friction Course Mixtures with Different Contents of Electric Arc Furnace Steel Slag as an Alternative Aggregate from Steel Industries. Road Mater. Pavement Des. 2021, 22, 268–292. [Google Scholar] [CrossRef]

- Ma, Y.; Zheng, K.; Ding, Y.; Polaczyk, P.; Jiang, X.; Huang, B. Binder Availability and Blending Efficiency of Reclaimed Asphalt: A State-of-the-Art Review. Constr. Build. Mater. 2022, 357, 129334. [Google Scholar] [CrossRef]

- Xing, C.; Li, M.; Liu, L.; Lu, R.; Liu, N.; Wu, W.; Yuan, D. A Comprehensive Review on the Blending Condition between Virgin and RAP Asphalt Binders in Hot Recycled Asphalt Mixtures: Mechanisms, Evaluation Methods, and Influencing Factors. J. Clean. Prod. 2023, 398, 136515. [Google Scholar] [CrossRef]

- Lo Presti, D.; Vasconcelos, K.; Orešković, M.; Pires, G.M.; Bressi, S. On the Degree of Binder Activity of Reclaimed Asphalt and Degree of Blending with Recycling Agents. Road Mater. Pavement Des. 2020, 21, 2071–2090. [Google Scholar] [CrossRef]

| Property | Standard | Requirement | Limestone | Steel Slag |

|---|---|---|---|---|

| Los Angeles abrasion (%) | ASTM-C131 | <30 | 23 | 18 |

| Water absorption of coarse aggregates (%) | ASTM-C127 | <2.5 | 0.9 | 1.28 |

| Water absorption of fine aggregates (%) | <2.8 | 1.1 | - | |

| Compressive strength (kg/cm2) | ASTM-C39 | - | 409 | 1823 |

| Specific gravity of coarse aggregates (g/cm3) | ASTM-C128 | - | 2.66 | 3.299 |

| Specific gravity of fine aggregates (g/cm3) | ASTM-C127 | - | 2.51 | - |

| Ingredient | Al2O3 | FeO | P2O5 | MgO | MnO | SiO2 | CaO |

|---|---|---|---|---|---|---|---|

| Percent | 3.95% | 33.68% | 0.68% | 11.44% | 2.24% | 17.72% | 29.96% |

| Sieve Size | No. 20 | No. 30 | No. 40 | No. 50 | No. 80 | No. 100 |

|---|---|---|---|---|---|---|

| Required passing percentages | 100 | 100 | 85–90 | 55–60 | 21–25 | 17–20 |

| Utilized passing percentages | 100 | 100 | 87 | 58 | 22 | 17 |

| Property | Test Standard | Value |

|---|---|---|

| Penetration at 25 °C | ASTM D5 | 65 |

| Softening point (°C) | ASTM D36 | 49 |

| Ductility (cm) | ASTM D113 | 100 |

| Flashpoint (°C) | ASTM D92 | 280 |

| Mass lost (%) | ASTM D6 | 0.1 |

| Viscosity at 135 °C (0.01 cSt) | ASTM D2170 | 490 |

| Viscosity at 160 °C (0.01 cSt) | ASTM D2170 | 120 |

| Examples | Components |

|---|---|

| LS | 80% limestone aggregate 20% SS aggregate |

| LR50 | 50% limestone aggregate 50% RAP |

| LSR50W10C15 | 30% limestone aggregate 20% SS aggregate 50% RAP 10% WEO 15% CR |

| Binder | Rotational Viscosity (mPa.s) | Temperature (°C) | ||

|---|---|---|---|---|

| 135 °C | 160 °C | Mixing | Compaction | |

| 0% CR | 490 | 120 | 154 | 145 |

| 5% CR | 670 | 150 | 158 | 150 |

| 10% CR | 1080 | 250 | 167 | 158 |

| 15% CR | 1930 | 580 | 185 | 174 |

| Parameter | GLM | SVR | GPR | FNN |

|---|---|---|---|---|

| FN | Alpha: 1 × 101 | Kernel: Linear | Variance: 1 × 100 | # Neurons: 32 |

| C: 1 | # Layers: 3 | |||

| Fit intercept: True | Epsilon: 1 × 10−1 | Length scale: 1 × 100 | Batch Size: 8 | |

| # Epochs: 500 | ||||

| CTindex | Alpha: 1 × 101 | Kernel: Linear | Variance: 1 × 101 | # Neurons: 4 |

| C: 1 | # Layers: 3 | |||

| Fit intercept: True | Epsilon: 1 × 10−1 | Length scale: 1 × 100 | Batch Size: 8 | |

| # Epochs: 500 | ||||

| TSR | Alpha: 1 × 10−1 | Kernel: RBF | Variance: 1 × 1010 | # Neurons: 32 |

| C: 1 | # Layers: 2 | |||

| Fit intercept: True | Epsilon: 1 × 10-3 | Length scale: 1 × 104 | Batch Size: 8 | |

| # Epochs: 500 |

| Parameter | GLM | SVR | GPR | FNN | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MAE | RMSE | MRE | MAE | RMSE | MRE | MAE | RMSE | MRE | MAE | RMSE | MRE | |

| (Rank) | (Rank) | (Rank) | (Rank) | (Rank) | (Rank) | (Rank) | (Rank) | (Rank) | (Rank) | (Rank) | (Rank) | |

| FN | 174.91 | 257.8 | 0.243 | 175.39 | 254.357 | 0.241 | 162.36 | 188.255 | 0.262 | 153.734 | 185.119 | 0.259 |

| (3) | (4) | (2) | (4) | (3) | (1) | (2) | (2) | (4) | (1) | (1) | (3) | |

| CTindex | 22.712 | 27.664 | 0.179 | 31.511 | 36.51 | 0.206 | 17.5 | 23.154 | 0.129 | 22.682 | 28.437 | 0.181 |

| (3) | (2) | (2) | (4) | (4) | (4) | (1) | (1) | (1) | (2) | (3) | (3) | |

| TSR | 0.027 | 0.034 | 0.035 | 0.019 | 0.025 | 0.019 | 0.024 | 0.023 | 0.029 | 0.02 | 0.026 | 0.021 |

| (4) | (4) | (4) | (1) | (2) | (1) | (3) | (1) | (3) | (2) | (3) | (2) | |

| Overall Rank | 3.111 | 2.667 | 2.000 | 2.222 | ||||||||

| Parameter | Threshold | Equation |

|---|---|---|

| FN (10 to 30 million ESALs) | Low Bound | 0.265(WEO)2 +6.383(CR)2 − 2.436(WEO) − 55.100(CR) + 1.788(WEO)(CR) + 40.064 − min (RAP, 75) = 0 |

| FN (more than 30 million ESALs) | Low Bound | 0.028(WEO)2 − 1.059(CR)2 + 2.112(WEO) − 12.301(CR) + 1.363(WEO)(CR) + 45.545 − min (RAP, 75) = 0 |

| CTindex | High Bound | −0.012(WEO)2 − 0.108(CR)2 + 4.571(WEO) − 2.959(CR) + 0.135(WEO)(CR) + 21.485 − min (RAP, 75) = 0 |

| TSR | Low Bound | 0.07(WEO)2 + 0.327(CR)2 + 0.158(WEO) − 9.923(CR) + 0.172(WEO)(CR) + 49.513 − min (RAP, 75) = 0 |

| All three (10 to 30 million ESALs) | Low Bound | 0.085(WEO)2 + 0.201(CR)2 + 1.376(WEO) − 5.863(CR) − 0.041(WEO)(CR) + 30.748 − min (RAP, 75) = 0 |

| High Bound | −0.012(WEO)2 − 0.108(CR)2 + 4.571(WEO) − 2.959(CR) + 0.135(WEO)(CR) + 21.485 − min (RAP, 75) = 0 | |

| All three (more than 30 million ESALs) | Low Bound | 0.553(WEO)2 + 0.197(CR)2 + 0.610(WEO) − 4.093(CR) − 0.562(WEO)(CR) + 28.403 − min (RAP, 75) = 0 |

| High Bound | −0.012(WEO)2 − 0.108(CR)2 + 4.571(WEO) − 2.959(CR) + 0.135(WEO)(CR) + 21.485 − min (RAP, 75) = 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khorshidi, M.; Goli, A.; Orešković, M.; Khayambashi, K.; Ameri, M. Performance Evaluation of Asphalt Mixtures Containing Different Proportions of Alternative Materials. Sustainability 2023, 15, 13314. https://doi.org/10.3390/su151813314

Khorshidi M, Goli A, Orešković M, Khayambashi K, Ameri M. Performance Evaluation of Asphalt Mixtures Containing Different Proportions of Alternative Materials. Sustainability. 2023; 15(18):13314. https://doi.org/10.3390/su151813314

Chicago/Turabian StyleKhorshidi, Meisam, Ahmad Goli, Marko Orešković, Kamiar Khayambashi, and Mahmoud Ameri. 2023. "Performance Evaluation of Asphalt Mixtures Containing Different Proportions of Alternative Materials" Sustainability 15, no. 18: 13314. https://doi.org/10.3390/su151813314

APA StyleKhorshidi, M., Goli, A., Orešković, M., Khayambashi, K., & Ameri, M. (2023). Performance Evaluation of Asphalt Mixtures Containing Different Proportions of Alternative Materials. Sustainability, 15(18), 13314. https://doi.org/10.3390/su151813314