Product Traceability and Supply Chain Sustainability of Black Soybeans as Raw Materials for Soy Sauce in Maintaining Quality and Safety

Abstract

1. Introduction

2. Materials and Methods

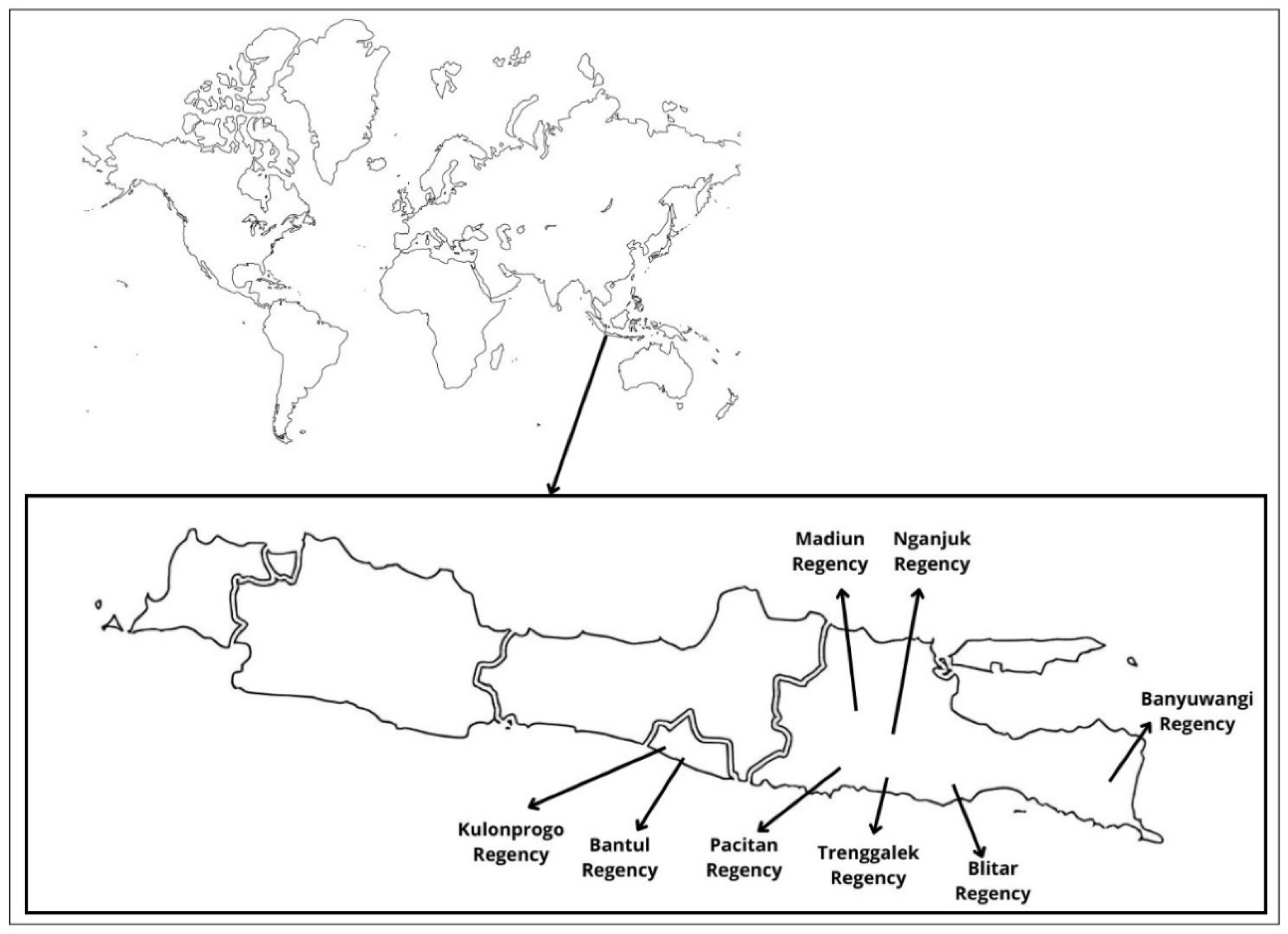

2.1. Study Area

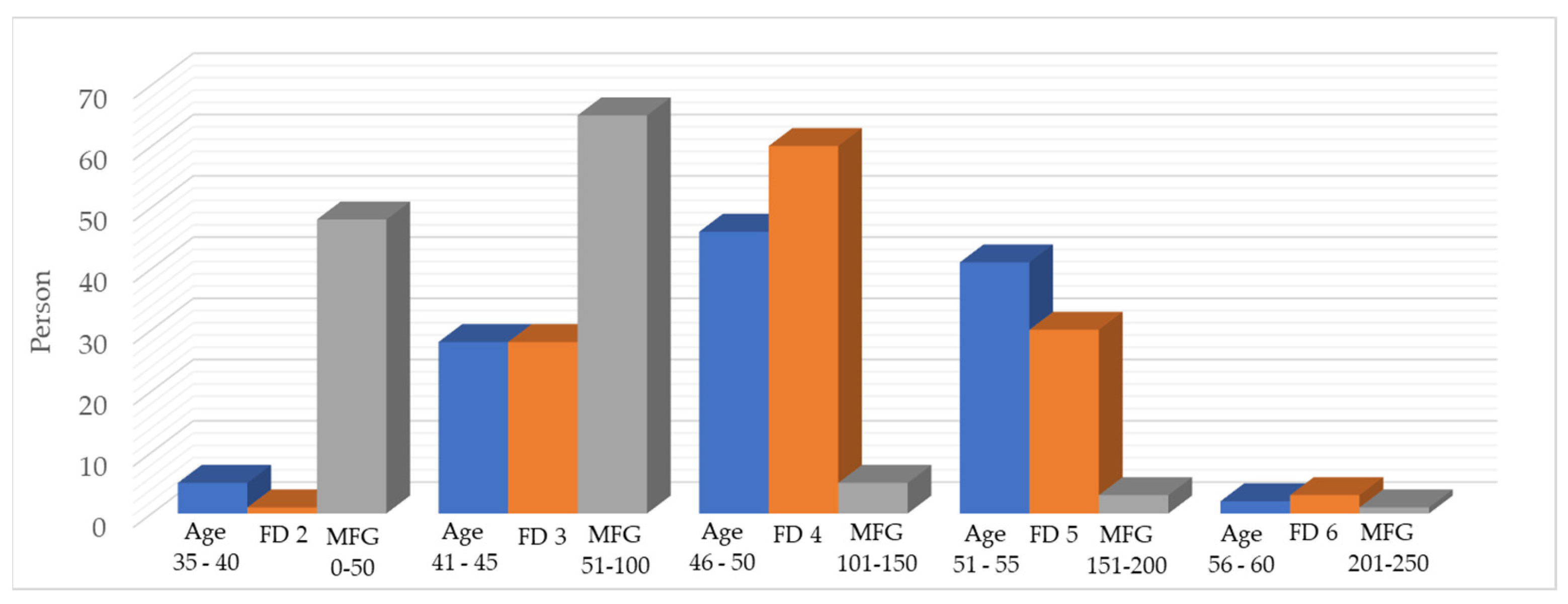

2.2. Participants

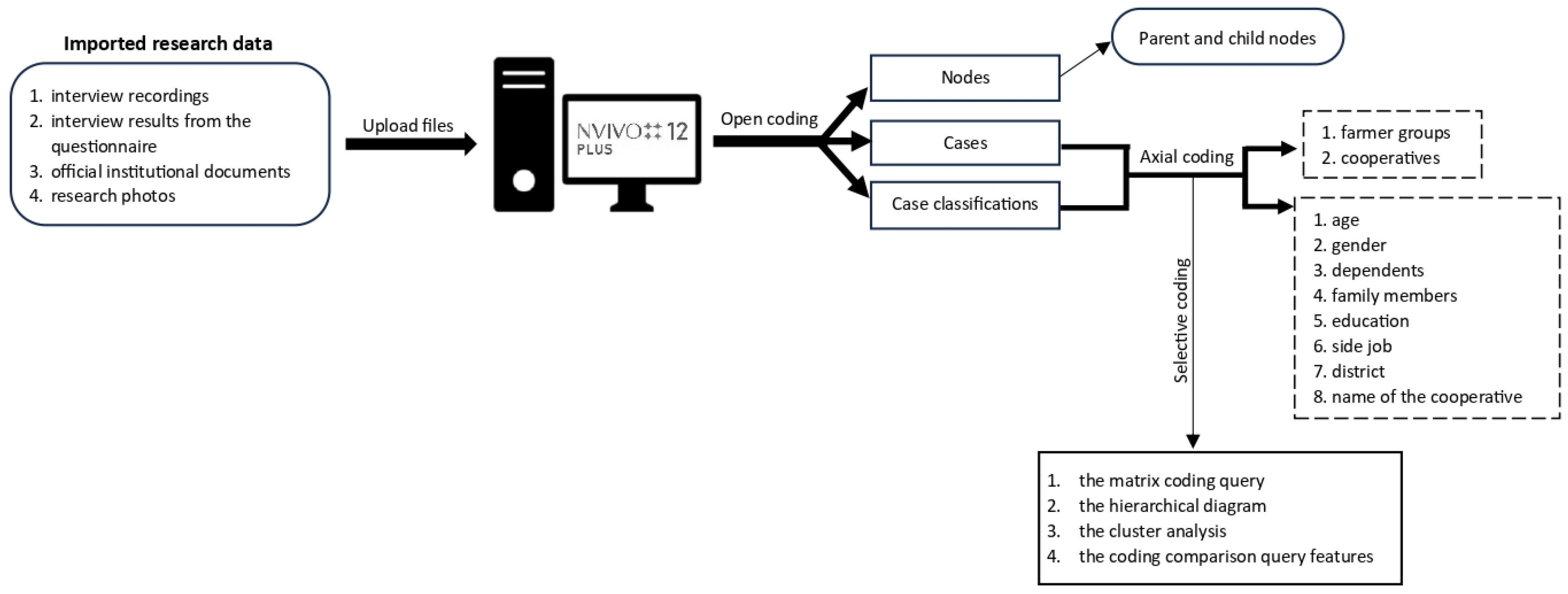

2.3. Data Analysis

3. Result

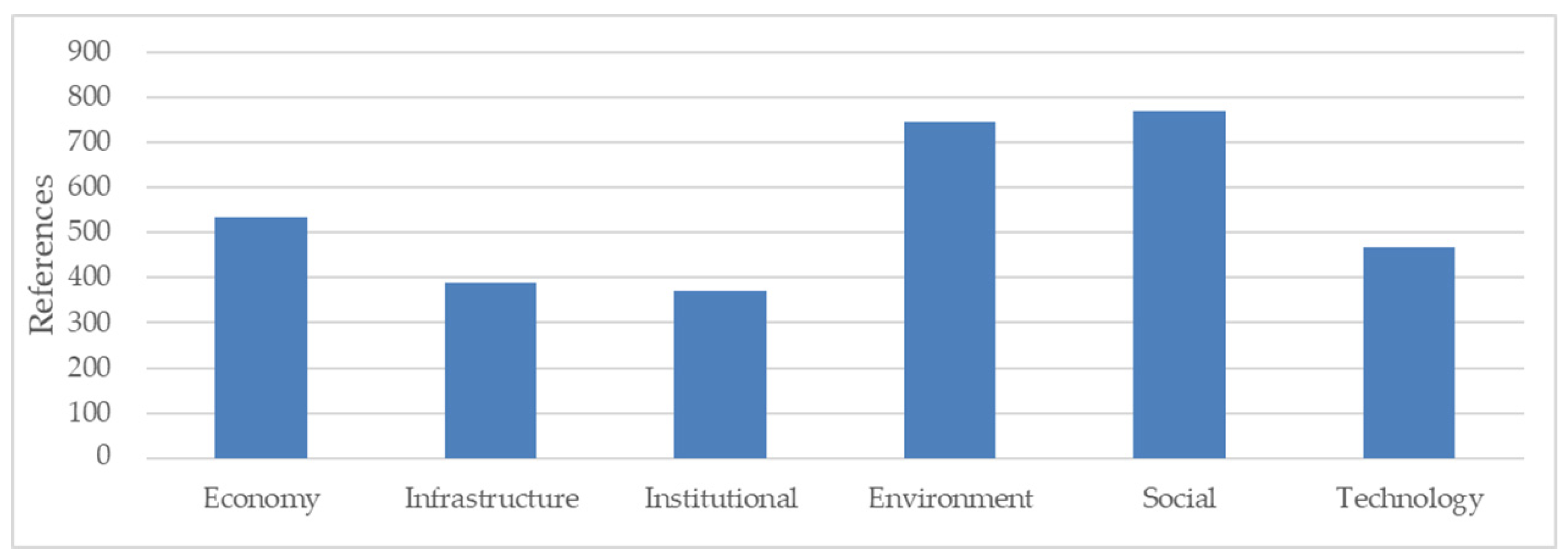

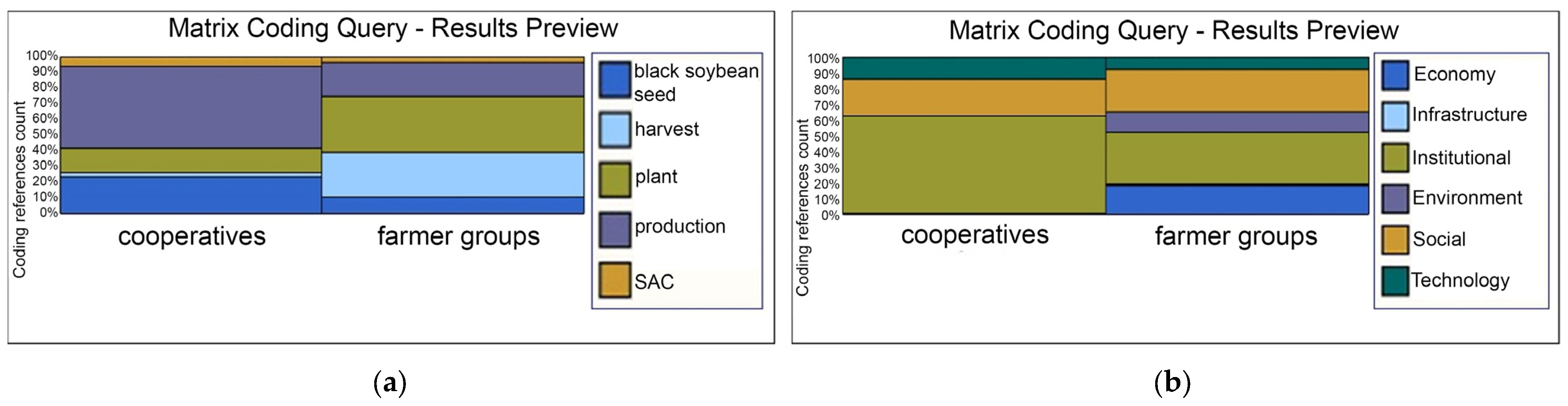

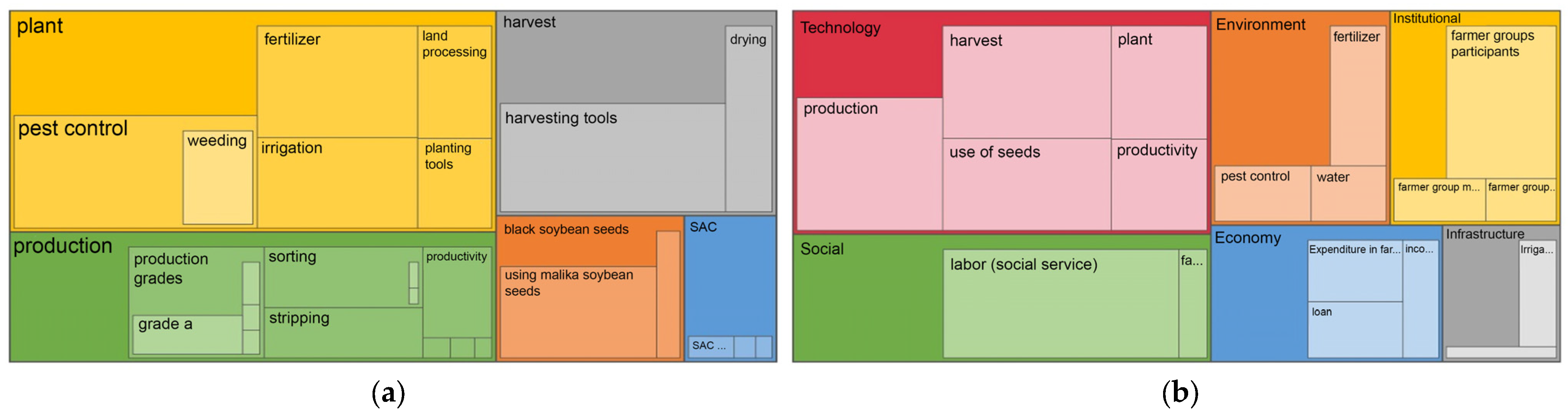

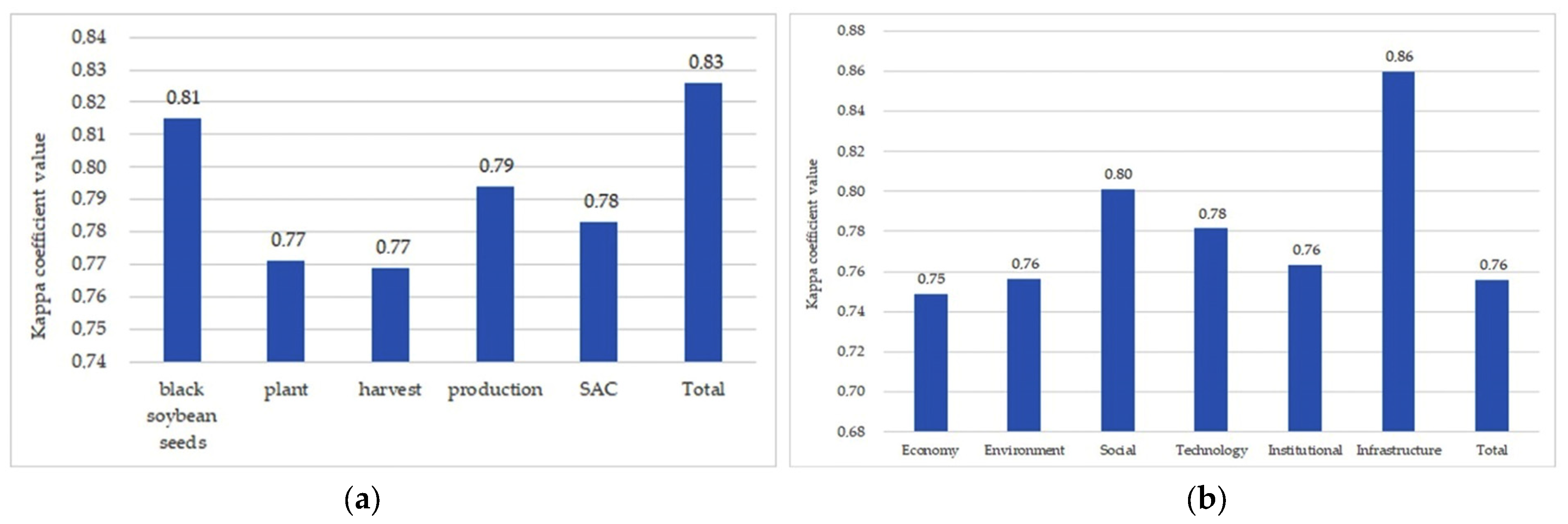

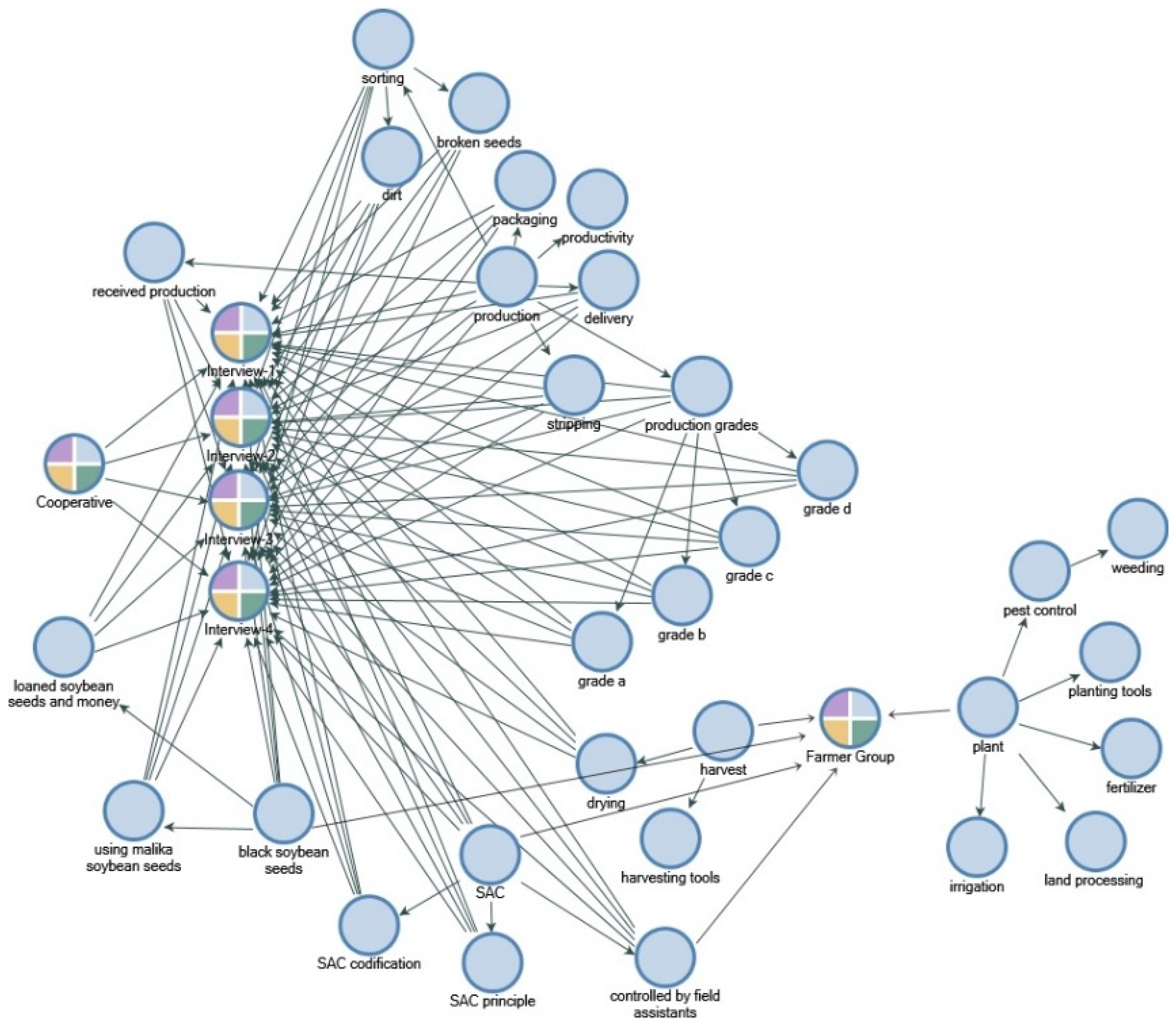

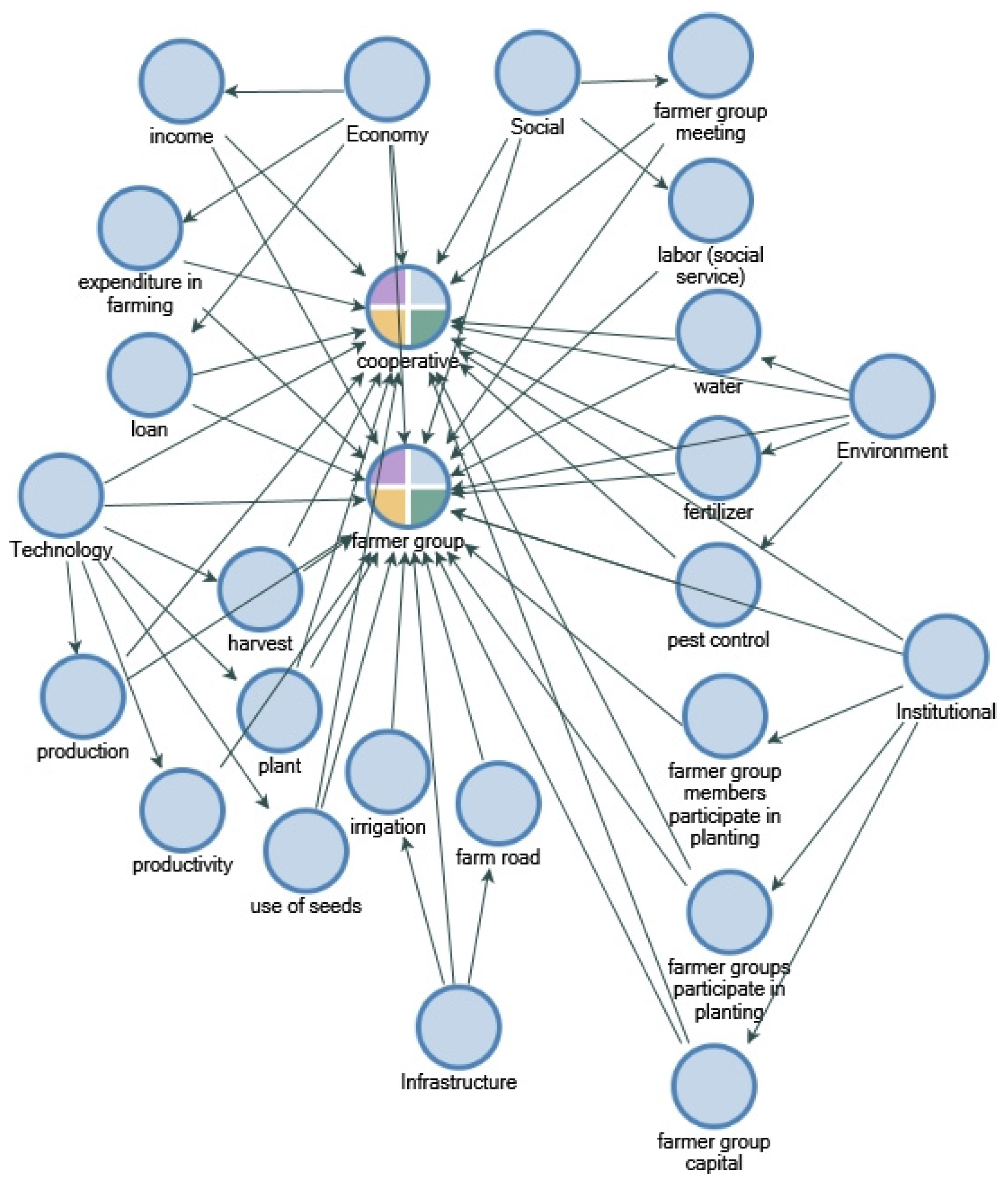

3.1. Results of Analysis with QSR NVivo Version 12 Plus

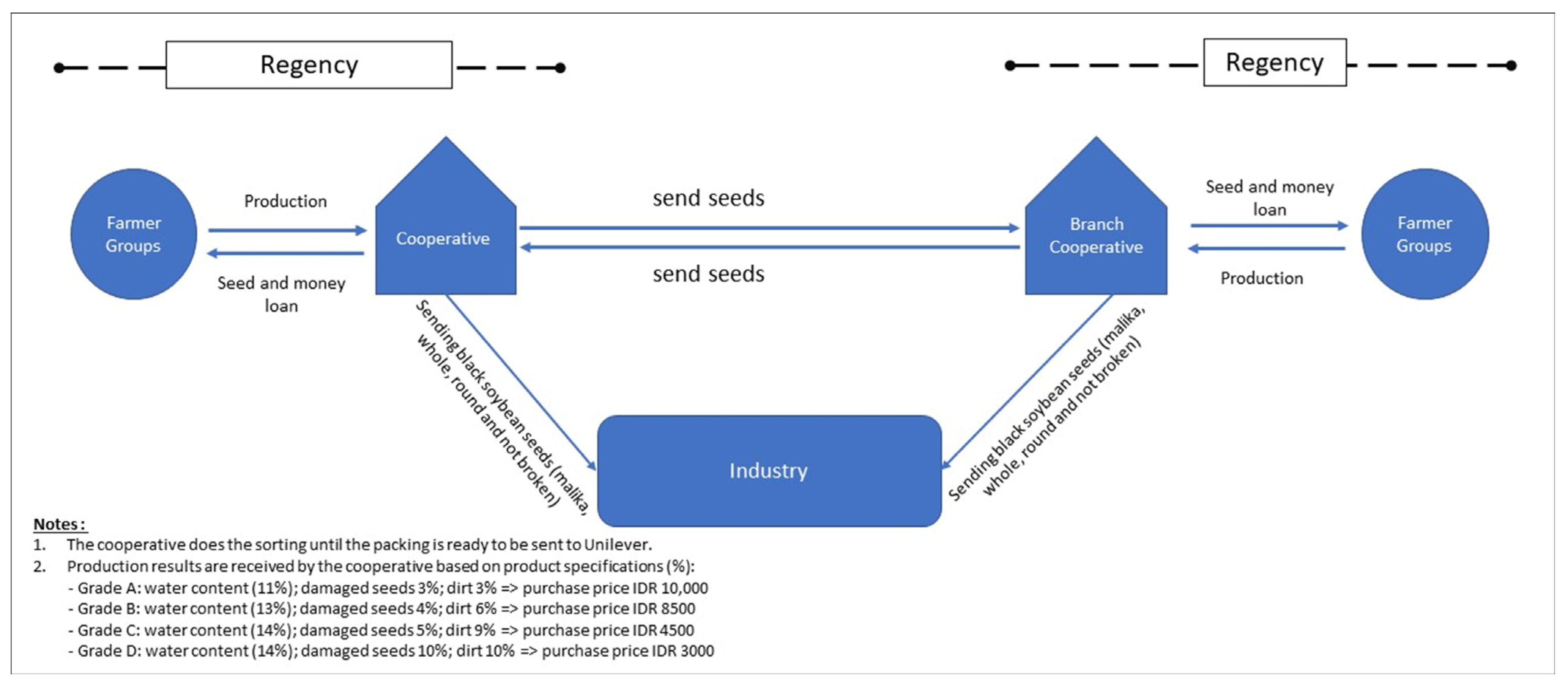

3.2. Traceability of Black Soybeans

3.3. Sustainability for the Black Soybean Supply Chain

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Teuscher, P.; Grüninger, B.; Ferdinand, N. Risk Management in Sustainable Supply Chain Management (SSCM): Lessons Learnt from the Case of GMO-Free Soybeans. Corp. Soc. Responsib. Environ. Manag. 2006, 13, 1–10. [Google Scholar] [CrossRef]

- Jia, F.; Peng, S.; Green, J.; Koh, L.; Chen, X. Soybean Supply Chain Management and Sustainability: A Systematic Literature Review. J. Clean. Prod. 2020, 255, 120254. [Google Scholar] [CrossRef]

- Oliveira, G.D.L.T.; Schneider, M. The politics of flexing soybeans: China, Brazil, and global agroindustrial restructuring. J. Peasant. Stud. 2015, 43, 167–194. [Google Scholar] [CrossRef]

- Fearnside, P.M. Soybean cultivation as a threat to the environment in Brazil. Environ. Conserv. 2001, 28, 23–38. [Google Scholar] [CrossRef]

- Ercin, A.E.; Aldaya, M.M.; Hoekstra, A.Y. The water footprint of soy milk and soy burger and equivalent animal products. Ecol. Indic. 2012, 18, 392–402. [Google Scholar] [CrossRef]

- Susilowati, I.; Kirana, M. Re-evaluation of value-chain and the strategy to secure soybeans as the main input for Javanese indigenous dish of “Tahu-Tempe-Kecap” (With a pilot project in Central Java Province). Rev. Espac. 2018, 39, 27–31. [Google Scholar]

- Wiloso, E.I.; Sinke, P.; Muryanto; Setiawan, A.A.R.; Sari, A.A.; Waluyo, J.; Putri, A.M.H.; Guinee, J. Hotspot identification in the Indonesian tempeh supply chain using life cycle assessment. Int. J. Life Cycle Assess. 2019, 24, 1948–1961. [Google Scholar] [CrossRef]

- Ginting, E.; Yulifianti, R.; Mulyana, H.I.; Tarmizi, d. Varietas Unggul Kedelai Hitam Sebagai Bahan Baku Kecap. In Proceedings of the Seminar Agroindustri dan Lokakarya Nasional FKPT—TPI; Trunojoyo University: Madura Regency, Indonesia, 2015; ISBN 978-602-7998-92-6. [Google Scholar]

- Sjauw-Koen-Fa, A.R.; Blok, V.; Omta, O.S.W.F. Exploring the applicability of a sustainable smallholder sourcing model in the black soybean case in Java. Int. Food Agribus. Manag. Rev. 2017, 20, 709–728. [Google Scholar] [CrossRef]

- Sjauw-Koen-Fa, A.R.; Blok, V.; Omta, O.S.W.F. Exploring the integration of business and CSR perspectives in smallholder souring: Black soybean in Indonesia and tomato in India. J. Agribus. Dev. Emerg. Econ. 2018, 8, 656–677. [Google Scholar] [CrossRef]

- Storøy, J.; Thakur, M.; Olsen, P. The TraceFood Framework—Principles and guidelines for implementing traceability in food value chains. J. Food Eng. 2013, 115, 41–48. [Google Scholar] [CrossRef]

- Wang, X.; Wang, C.; Wang, X.; Zhuang, W. Study for organic soybean production information traceability system based on the web. In Computer and Computing Technologies in Agriculture IV, CCTA 2010; IFIP Advances in Information and Communication Technology; Li, D., Liu, Y., Chen, Y., Eds.; Springer: Berlin/Heidelberg, Germany, 2011; Volume 345, pp. 567–572. [Google Scholar]

- Folinas, D.; Manikas, I.; Manos, B. Traceability data management for food chains. Br. Food J. 2006, 108, 622–633. [Google Scholar] [CrossRef]

- Regattieri, A.; Gamberi, M.; Manzini, R. Traceability of food products: General framework and experimental evidence. J. Food Eng. 2007, 81, 347–356. [Google Scholar] [CrossRef]

- Wang, X.; Li, D.; Li, L. Adding value of food traceability to the business: A supply chain management approach. Int. J. Serv. Oper. Inform. 2009, 4, 232–257. [Google Scholar] [CrossRef]

- Thakur, M.; Donnelly, K.A.-M. Modeling traceability information in soybean value chains. J. Food Eng. 2010, 99, 98–105. [Google Scholar] [CrossRef]

- Aung, M.M.; Chang, Y.S. Traceability in a food supply chain: Safety and quality perspectives. Food Control 2014, 39, 172–184. [Google Scholar] [CrossRef]

- Godar, J.; Persson, U.M.; Tizado, E.J.; Meyfroidt, P. Towards more accurate and policy relevant footprint analyses: Tracing fine-scale socio-environmental impacts of production to consumption. Ecol. Econ. 2015, 112, 25–35. [Google Scholar] [CrossRef]

- Morales, V.; Vendrametto, O.; Rois, J.G.M.D.; Toloi, R.G.; Canuto, S.A. Information Systems in the Soybean Brazilian Supply Chain: An Analysis from the Trading Companies Perspective. In Proceedings of the ILS Conference, Bordeaux, France, 1–4 June 2016; pp. 1–7. [Google Scholar]

- Gardner, T.A.; Benzie, M.; Börner, J.; Dawkins, E.; Fick, S.; Garrett, R.; Godar, J.; Grimard, A.; Lake, S.; Larsen, R.K.; et al. Transparency and sustainability in global commodity supply chains. World Dev. 2018, 121, 163–177. [Google Scholar] [CrossRef]

- Mao, D.; Hao, Z.; Wang, F.; Li, H. Innovative Blockchain-Based Approach for Sustainable and Credible Environment in Food Trade: A Case Study in Shandong Province, China. Sustainability 2018, 10, 3149. [Google Scholar] [CrossRef]

- Salah, K.; Nizamuddin, N.; Jayaraman, R.; Omar, M. Blockchain-Based Soybean Traceability in Agricultural Supply Chain. IEEE Access 2019, 7, 73295–73305. [Google Scholar] [CrossRef]

- Creydt, M.; Fischer, M. Blockchain and more-Algorithm driven food traceability. Food Control 2019, 105, 45–51. [Google Scholar] [CrossRef]

- Haleem, A.; Khan, S.; Khan, M.I. Traceability implementation in food supply chain: A grey-DEMATEL approach. Inf. Process. Agric. 2019, 6, 335–348. [Google Scholar] [CrossRef]

- You, N.; Dong, J. Examining earliest identifiable timing of crops using all available Sentinel 1/2 imagery and Google Earth Engine. ISPRS J. Photogramm. Remote Sens. 2020, 161, 109–123. [Google Scholar] [CrossRef]

- Demestichas, K.; Peppes, N.; Alexakis, T.; Adamopoulu, E. Blockchain in Agriculture Traceability Systems: A Review. Appl. Sci. 2020, 10, 4113. [Google Scholar] [CrossRef]

- Paliwal, V.; Chandra, S.; Sharma, S. Blockchain Technology for Sustainable Supply Chain Management: A Systematic Literature Review and a Classification Framework. Sustainability 2020, 12, 7638. [Google Scholar] [CrossRef]

- Sanjaya, S.; Perdana, T. Logistics system model development on supply chain management of tomato commodities for structured market. Procedia Manuf. 2015, 4, 513–520. [Google Scholar] [CrossRef][Green Version]

- Utami, H.N.; Sadeli, A.H.; Perdana, T. Customer Value Creation of Fresh Tomatoes Through Branding and Packaging as Customer Perceived Quality. J. ISSAAS 2016, 22, 123–136. [Google Scholar]

- Li, L.; Li, T. Traceability model based on improved witness mechanism. CAAI Trans. Intell. Technol. 2022, 7, 331–339. [Google Scholar] [CrossRef]

- Verma, R.; Kumari, A.; Anand, A.; Yadavalli, V.S.S. Revisiting Shift Cipher Technique for Amplified Data Security. J. Comput. Cogn. Eng. 2022, 1–7. [Google Scholar] [CrossRef]

- Agrawal, D.; Minocha, S.; Namasudra, S.; Gandomi, A.H. A robust drug recall supply chain management system using hyperledger blockchain ecosystem. Comput. Biol. Med. 2022, 140, 105100. [Google Scholar] [CrossRef]

- Gutub, A. Boosting image watermarking authenticity spreading secrecy from counting-based secret-sharing. CAAI Trans. Intell. Technol. 2023, 8, 440–452. [Google Scholar] [CrossRef]

- Namasudra, S.; Nath, S.; Majumder, A. Profile based access control model in cloud computing environment. In Proceedings of the International Conference on Green Computing Communication and Electrical Engineering (ICGCCEE), Coimbatore, India, 6–8 March 2014; pp. 1–5. [Google Scholar]

- Das, S.; Namasudra, S. Multiauthority CP-ABE-based Access Control Model for IoT-enabled Healthcare Infrastructure. IEEE Trans. Ind. Inform. 2023, 19, 821–829. [Google Scholar] [CrossRef]

- Zhang, M.; Fan, Y.; Chen, C.; Cao, J.; Pu, H. Consumer perception, mandatory labeling, and traceability of GM soybean oil: Evidence from Chinese urban consumers. GM Crops Food 2021, 12, 36–46. [Google Scholar] [CrossRef]

- Medina, G.; Thomé, K. Transparency in Global Agribusiness: Transforming Brazil’s Soybean Supply Chain Based on Companies’ Accountability. Logistics 2021, 5, 58. [Google Scholar] [CrossRef]

- Nurgazina, J.; Pakdeetrakulwong, U.; Moser, T.; Reiner, G. Distributed Ledger Technology Applications in Food Supply Chains: A Review of Challenges and Future Research Directions. Sustainability 2021, 13, 4206. [Google Scholar] [CrossRef]

- Dasaklis, T.K.; Voutsinas, T.G.; Tsoulfas, G.T.; Casino, F.A. A Systematic Literature Review of Blockchain-Enabled Supply Chain Traceability Implementations. Sustainability 2022, 14, 2439. [Google Scholar] [CrossRef]

- Anwar, S.; Perdana, T.; Rachmadi, M.; Noor, T.I. Traceability Information Model for Sustainability of Black Soybean Supply Chain: A Systematic Literature Review. Sustainability 2022, 14, 9498. [Google Scholar] [CrossRef]

- Moe, T. Perspectives on traceability in food manufacture. Trend Food Sci. Technol. 1998, 9, 211–214. [Google Scholar] [CrossRef]

- Kurniawan, M.; Pramono, D.; Amalia, F. Design of a website-based traceability information system on subsidized fertilizer supply chain. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Malang, Indonesia, 6–7 July 2021; Volume 924, p. 012050. [Google Scholar]

- Hinkes, C.; Peter, G. Traceability matters: A conceptual framework for deforestation-free supply chains applied to soy certification. Sustain. Account. Manag. Policy J. 2020, 11, 1159–1187. [Google Scholar] [CrossRef]

- Ding, Q.; Gao, S.; Zhu, J.; Yuan, C. Permissioned Blockchain-Based Double-Layer Framework for Product Traceability System. IEEE Access 2020, 8, 6209–6225. [Google Scholar] [CrossRef]

- Duan, Y.; Miao, M.; Wang, R.; Fu, Z.; Xu, M. A framework for the successful implementation of food traceability systems in China. Inf. Soc. 2017, 33, 226–242. [Google Scholar] [CrossRef]

- Ekawati, R.; Arkeman, Y.; Suprihatin, S.; Sunarti, T.C. Proposed Design of White Sugar Industrial Supply Chain System based on Blockchain Technology. Int. J. Adv. Comput. Sci. Appl. 2021, 12, 459–465. [Google Scholar] [CrossRef]

- Ng, H.; Ker, A.P. On the Changing Nature of Canadian Crop Yield Distributions. J. Agric. Resour. Econ. 2021, 46, 101–125. [Google Scholar]

- Monteiro, E.S.; Righi, R.D.R.; Barbosa, J.L.V.; Alberti, A.M. APTM: A Model for Pervasive Traceability of Agrochemicals. Appl. Sci. 2021, 11, 8149. [Google Scholar] [CrossRef]

- Anders, S.; Cowling, W.; Pareek, A.; Gupta, K.J.; Singla-Pareek, S.L.; Foyer, C.H. Gaining Acceptance of Novel Plant Breeding Technologies. Trends Plant Sci. 2021, 26, 575–587. [Google Scholar] [CrossRef]

- Barma, M.; Modibbo, U.M. Multiobjective Mathematical Optimization Model for Municipal Solid Waste Management with Economic Analysis of Reuse/Recycling Recovered Waste Materials. J. Comput. Cogn. Eng. 2022, 1, 122–137. [Google Scholar] [CrossRef]

- Pranto, T.H.; Noman, A.A.; Mahmud, A.; Haque, A.B. Blockchain and smart contract for IoT enabled smart agriculture. PeerJ Comput. Sci. 2021, 7, e407. [Google Scholar] [CrossRef]

- Hizbi, M.S.; Ghulamahdi, M. Pertumbuhan dan Produksi Kedelai Hitam dengan Pemberian Jenis Biomassa dan Dosis Pemupukan Kalsium pada Budidaya Jenuh Air di Lahan Pasang Surut. Bul. Agrohorti 2019, 7, 153–161. [Google Scholar] [CrossRef]

- Sampurna, A.; Tandian, M.; Huang, V.; Simanjuntak, R.F.; Marta, R.F. Implementasi Total Branding Dalam Perspektif Semiotika Pemasaran. J. Strateg. Commun. 2020, 10, 59–73. [Google Scholar] [CrossRef]

- Fitry, N.; Herdiansah, D.; Hardiyanto, T. Analisis Nilai Tambah Agroindustri Kecap (Studi Kasus pada Pengusaha Kecap Cap Jago di Desa Cibenda Kecamatan Parigi Kabupaten Pangandaran). J. Ilm. Mhs. Agroinfo Galuh 2017, 4, 352–359. [Google Scholar]

- Badan Pusat Statistik. Analisis Profil Penduduk Indonesia: Mendeskripsikan Peran Penduduk dalam Pembangunan; Badan Pusat Statistik: Jakarta, Indonesia, 2022. [Google Scholar]

- Rungkat, J.S.; Kindangen, P.; Walewangko, E.N. Pengaruh Pendidikan, Jumlah Anggota Keluarga dan Pengalaman Kerja Terhadap Pendapatan Rumah Tangga di Kabupaten Minahasa. J. Pembang. Ekon. Dan. Keuang. Drh. 2020, 21, 1–15. [Google Scholar]

- Falo, M.; Nubatonis, A. Partisipasi Anggota Kelompok Tani dalam Berusahatani Bawang Putih di Desa Sallu Kecamatan Miomaffo Barat Kabupaten Timor Tengah Utara. Agrimor J. Agribisnis Lahan Kering 2017, 2, 17–22. [Google Scholar] [CrossRef][Green Version]

- Bandur, A. Penelitian Kualitatif: Studi Multi-Displin Keilmuan Dengan NVivo 12 Plus; Mitra Wacana Media: Jawa, Indonesia, 2019. [Google Scholar]

- Spartano, S.; Grasso, S. Consumers’ Perspectives on Eggs from Insect-Fed Hens: A UK Focus Group Study. Foods 2021, 10, 420. [Google Scholar] [CrossRef] [PubMed]

- Sohel, M.S.; Shi, G.; Zaman, N.T.; Hossain, B.; Halimuzzaman, M.; Akintunde, T.Y.; Liu, H. Understanding the Food Insecurity and Coping Strategies of Indigenous Households during COVID-19 Crisis in Chittagong Hill Tracts, Bangladesh: A Qualitative Study. Foods 2022, 11, 3103. [Google Scholar] [CrossRef] [PubMed]

- Bazeley, P.; Jackson, K. Qualitative Data Analysis with Nvivo; Sage Publications: Los Angeles, CA, USA, 2013. [Google Scholar]

- Andajani, W.; Sidhi, E.Y. Efisiensi Usahatani Kedelai Hitam melalui Pola Kemitraan dengan Koperasi (Studi Kasus di Desa Sumberagung Kecamatan Gondang Kabupaten Nganjuk). J. Agrinika 2019, 3, 120–133. [Google Scholar] [CrossRef]

- Perdana, T.; Renaldy, E.; Utami, H.N.; Sadeli, A.H.; Heryanto, M.A.; Ginanjar, T.; Ajeng, S.N.P.; Hermiatin, F.R.; Sanjaya, S. Farmers Behavior on Using Fertilizer in West Java. AIP Conf. Proc. 2018, 1927, 030011. [Google Scholar]

- Bashiri, M.; Tjahjono, B.; Lazell, J.; Ferreira, J.; Perdana, T. The Dynamics of Sustainability Risks in the Global Coffee Supply Chain: A Case of Indonesia–UK. Sustainability 2021, 13, 589. [Google Scholar] [CrossRef]

- Gayialis, S.P.; Kechagias, E.P.; Papadopoulos, G.A.; Masouras, D. A Review and Classification Framework of Traceability Approaches for Identifying Product Supply Chain Counterfeiting. Sustainability 2022, 14, 6666. [Google Scholar] [CrossRef]

- Boström, M.; Jönsson, A.M.; Lockie, S.; Mol, A.P.; Oosterveer, P. Sustainable and responsible supply chain governance: Challenges and opportunities. J. Clean. Prod. 2015, 107, 1–7. [Google Scholar] [CrossRef]

- Garrett, R.D.; Lambin, E.F.; Naylor, R.L. The new economic geography of land use change: Supply chain configurations and land use in the Brazilian Amazon. Land. Use Policy 2013, 34, 265–275. [Google Scholar] [CrossRef]

- Delai, I.; Takahashi, S. Sustainability measurement system: A reference model proposal. Soc. Responsib. J. 2011, 7, 438–471. [Google Scholar] [CrossRef]

- Allaoui, H.; Guo, Y.; Sarkis, J. Decision support for collaboration planning in sustainable supply chains. J. Clean. Prod. 2019, 229, 761–774. [Google Scholar] [CrossRef]

- Jia, F.; Zuluaga-Cardona, L.; Bailey, A.; Rueda, X. Sustainable supply chain management in developing countries: An analysis of the literature. J. Clean. Prod. 2018, 189, 263–278. [Google Scholar] [CrossRef]

- Hossan Chowdhury, M.M.; Quaddus, M.A. Supply chain sustainability practices and governance for mitigating sustainability risk and improving market performance: A Dynamic capability Perspective. J. Clean. Prod. 2020, 278, 123521. [Google Scholar] [CrossRef]

- Hong, J.; Guo, P.; Chen, M.; Li, Y. The adoption of sustainable supply chain management and the role of organisational culture: A Chinese perspective. Int. J. Logist. Res. Appl. 2020, 25, 52–76. [Google Scholar] [CrossRef]

- Humphrey, J.; Schmitz, H. How does insertion in global value chains affect upgrading in industrial clusters? Reg. Stud. 2002, 36, 1017–1027. [Google Scholar] [CrossRef]

- Newton, P.; Agrawal, A.; Wollenberg, L. Enhancing the sustainability of commodity supply chains in tropical forest and agricultural landscapes. Glob. Environ. Chang. 2013, 23, 1761–1772. [Google Scholar] [CrossRef]

- Seuring, S.; Müller, M. From a literature review to a conceptual framework for sustainable supply chain management. J. Clean. Prod. 2008, 16, 1699–1710. [Google Scholar] [CrossRef]

- Unilever. Building a Sustainable Future Every Day; PT Unilever Indonesia Tbk: Jakarta, Indonesia, 2017. [Google Scholar]

- Unilever. Sustainability Report: Purpose-Led, Future-Fit; PT Unilever Indonesia Tbk: Jakarta, Indonesia, 2019. [Google Scholar]

- Fleiss, J.; Levin, B.; Paik, M. Statistical Methods for Rates and Proportions; Wiley: New York, NY, USA, 2003. [Google Scholar]

- QSR International. NVivo 12 for Windows Help; QSR International: Burlington, MA, USA, 2022. [Google Scholar]

- Rajesh, R. Sustainable supply chains in the Indian context: An integrative decision-making model. Technol. Soc. 2020, 61, 101230. [Google Scholar] [CrossRef]

- Flores, H.; Villalobos, J.R. A stochastic planning framework for the discovery of complementary, agricultural systems. Eur. J. Oper. Res. 2020, 280, 707–729. [Google Scholar] [CrossRef]

- Saberi, S.; Kouhizadeh, M.; Sarkis, J. Blockchain technology: A panacea or pariah for resources conservation and recycling? Resour. Conserv. Recycl. 2018, 130, 80–81. [Google Scholar] [CrossRef]

- He, L.; Wu, Z.; Xiang, W.; Goh, M.; Xu, Z.; Song, W.; Ming, X.; Wu, X. A novel Kano-QFD-DEMATEL approach to optimise the risk resilience solution for sustainable supply chain. Int. J. Prod. Res. 2020, 59, 1714–1735. [Google Scholar] [CrossRef]

- Pancino, B.; Blasi, E.; Rappoldt, A.; Pascucci, S.; Ruini, L.; Ronchi, C. Partnering for sustainability in agri-food supply chains: The case of Barilla Sustainable Farming in the Po Valley. Agric. Food Econ. 2019, 7, 13. [Google Scholar] [CrossRef]

- Horton, P.; Bruce, R.; Reynolds, C.; Milligan, G. Food Chain Inefficiency (FCI): Accounting Conversion Efficiencies Across Entire Food Supply Chains to Re-define Food Loss and Waste. Front. Sustain. Food Syst. 2019, 3, 79. [Google Scholar] [CrossRef]

- Sadeli, A.H.; Perdana, T.; Deliana, Y.; Onggo, B.S. Consumers’ purchase behavior in short food supply chains using social commerce in Indonesia. J. Clean. Prod. 2022, 2023, 135812. [Google Scholar] [CrossRef]

- Perdana, T.; Onggo, B.S.; Sadeli, A.H.; Chaerani, D.; Achmad, A.L.H.; Hermiatin, F.R.; Gong, Y. Food supply chain management in disaster events: A systematic literature review. Inter. J. Disaster Risk Reduct. 2022, 79, 103183. [Google Scholar] [CrossRef]

- Unilever. Sustainable Agriculture Code 2017; PT Unilever Indonesia Tbk: Jakarta, Indonesia, 2017. [Google Scholar]

- Unilever. Transformasi Untuk Masa Depan Berkelanjutan; PT Unilever Indonesia Tbk: Jakarta, Indonesia, 2018. [Google Scholar]

- Hamrouni, A.D.; Akkari, I. The Entrepreneurial Failure: Exploring Links between the Main Causes of Failure and the Company life Cycle Qualitative Analysis using NVivo 7 Software. Int. J. Bus. Soc. Sci. 2012, 3, 4. [Google Scholar]

| Source | Article Period (Year) | Product Traceability | Discussion of Product Traceability | Sustainability | Approach | Model | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Food (Y/N) | Soy (Y/N) | Seed (Y/N) | Plant (Y/N) | Harvest (Y/N) | Pest and Diseases (Y/N) | Eco (Y/N) | Soc (Y/N) | Env (Y/N) | Tech (Y/N) | Inst (Y/N) | Infra (Y/N) | ||||

| [11] | 1998–2009 | Y | N | N | N | N | N | N | N | N | N | N | N | Quan | XML |

| [12] | 2001–2007 | N | Y | N | Y | Y | Y | N | N | N | Y | N | N | Quan | Website |

| [13] | 1995–2005 | Y | N | N | N | N | N | N | N | N | N | N | N | Qual | XML-PML |

| [14] | 1973–2003 | Y | N | N | N | N | N | N | N | N | N | N | N | Quan | RFID |

| [15] | 1989–2009 | Y | N | N | N | N | N | N | N | N | N | N | N | Quan | Website |

| [16] | 1998–2009 | N | Y | Y | Y | N | N | N | N | N | N | N | N | Quan | UML |

| [17] | 1994–2013 | Y | N | N | N | N | N | N | N | N | N | N | N | Quan | RFID TQM |

| [18] | 2007–2014 | N | Y | N | N | N | N | Y | Y | Y | N | N | N | Quan | SEI-PCS |

| [19] | 2008–2016 | N | Y | N | Y | Y | N | N | N | N | N | N | N | Quan | ERP |

| [20] | 1998–2017 | Y | Y | N | Y | Y | N | Y | Y | Y | N | N | N | Qual | N |

| [21] | 2005–2018 | Y | N | N | N | N | N | N | N | Y | N | N | N | Quan | Blockchain |

| [22] | 2001–2018 | N | Y | Y | Y | Y | N | N | N | N | N | N | N | Quan | Blockchain |

| [23] | 2009–2018 | Y | N | N | N | N | N | N | N | Y | Y | N | N | Qual | Blockchain |

| [24] | 2009–2018 | Y | N | N | N | N | N | N | Y | N | N | N | N | Quan | Dematel |

| [25] | 2000–2019 | Y | Y | N | Y | Y | N | N | N | N | N | N | N | Quan | GEE |

| [26] | 2002–2020 | Y | N | N | N | N | N | Y | N | N | N | N | N | Quan | Blockchain |

| [27] | 1967–2020 | Y | N | N | N | N | N | Y | Y | Y | Y | N | N | Quan | Blockchain |

| [36] | 2005–2019 | N | Y | N | N | N | N | Y | N | N | N | Y | N | Qual | Logit |

| [37] | 1989–2021 | N | Y | N | N | N | N | Y | Y | Y | N | Y | Y | Quan | N |

| [38] | 2003–2021 | Y | N | N | N | N | N | Y | N | N | N | N | N | Quan | Blockchain-IoT |

| [39] | 1992–2022 | Y | N | N | N | N | N | Y | Y | Y | Y | N | N | Quan | Blockchain |

| This Article | 1998–2023 | N | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Qual | NVivo 12 Plus |

| Coding | Theme | Reference Code from NVivo Version 12 Plus | Descriptive Coding |

|---|---|---|---|

| Nodes | black soybean seeds | 89 | We use black soybean seeds that were recognized by the Ministry of Agriculture |

| Parent Nodes | loaned soybean seeds and money | 47 | Farmer groups were given black soybean seed loans and money to buy agricultural production facilities |

| Parent Nodes | using Mallika soybean seeds | 231 | We use the Mallika variety of black soybean seeds |

| Nodes | Plant | 323 | We empower local farmers to plant black soybeans |

| Parent Nodes | land processing | 124 | Before planting, we cultivate the land for black soybeans |

| Parent Nodes | Fertilizer | 266 | Farmer groups use fertilizers that do not damage the environment |

| Parent Nodes | Irrigation | 215 | Black soybeans are irrigated using pumps due to erratic rainfall |

| Parent Nodes | pest control | 286 | Pest control does not use chemicals because it is not allowed by the industry |

| Child Nodes | carry out weed | 122 | To reduce weeds, we carry out weed clearing so that the black soybean plants grow well |

| Parent Nodes | planting tools | 99 | We use planting tools |

| Nodes | Harvest | 263 | The farmer group harvests black soybeans |

| Parent Nodes | Drying | 132 | The farmer group is drying the black soybean yields to reduce the water content |

| Parent Nodes | harvesting tools | 371 | We use harvesting tools |

| Nodes | Production | 203 | We use Mallika black soybean production from local farmer groups |

| Parent Nodes | production grades | 119 | Black soybean production has a grade that will be accepted |

| Child Nodes | grade A | 89 | Grade A has a moisture content of 11%, 3% damaged seeds, and 3% dirt for IDR 10,000/kg. The production of Mallika soybeans with grade A is used as seeds |

| Child Nodes | grade B | 15 | Grade B has a moisture content of 13%, 4% damaged seeds, and 6% dirt for IDR 8500/kg |

| Child Nodes | grade C | 8 | Grade C has a moisture content of 14%, 5% damaged seeds, and 9% dirt for IDR 4500/kg |

| Child Nodes | grade D | 9 | Grade D has a moisture content of 14%, 10% damaged seeds, and 10% dirt for IDR 3000/kg |

| Parent Nodes | Productivity | 100 | Black soybean productivity according to planting treatment |

| Parent Nodes | Sorting | 144 | For black soybean production from farmer groups, we do the sorting and cleaning with a blower machine |

| Child Nodes | broken seeds | 4 | Damaged seeds from the sorting results are collected to be used as animal feed in the surrounding environment or sold to feed traders or others |

| Child Nodes | Dirt | 6 | The dirt is collected and used as fertilizer or feed |

| Parent Nodes | Stripping | 128 | We separate the pods and seeds by machine |

| Parent Nodes | Packaging | 5 | We pack the black soybeans that are sent to the industry. The sacks must be good, with no traces of fertilizer or anything else |

| Parent Nodes | received production | 8 | Soybean production received by industry is black, Mallika, whole/round seeds, and unbroken/damaged seeds |

| Parent Nodes | Delivery | 9 | Delivery of black soybeans using a truck with a load of sixteen tons, and costs one thousand rupiahs per kilo |

| Nodes | SAC | 149 | The SAC must be followed by black soybean suppliers |

| Parent Nodes | controlled by field assistants | 8 | Black soybean suppliers are controlled by field assistants |

| Parent Nodes | SAC codification | 16 | There are 3 groups of SAC codification in agriculture, namely planting and fertilizing management; control of pests, diseases, and weeds; and land management |

| Parent Nodes | SAC principle | 6 | The SAC principles as sustainability standards handled by the soy sauce industry |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Anwar, S.; Perdana, T.; Rachmadi, M.; Noor, T.I. Product Traceability and Supply Chain Sustainability of Black Soybeans as Raw Materials for Soy Sauce in Maintaining Quality and Safety. Sustainability 2023, 15, 13453. https://doi.org/10.3390/su151813453

Anwar S, Perdana T, Rachmadi M, Noor TI. Product Traceability and Supply Chain Sustainability of Black Soybeans as Raw Materials for Soy Sauce in Maintaining Quality and Safety. Sustainability. 2023; 15(18):13453. https://doi.org/10.3390/su151813453

Chicago/Turabian StyleAnwar, Syaiful, Tomy Perdana, Meddy Rachmadi, and Trisna Insan Noor. 2023. "Product Traceability and Supply Chain Sustainability of Black Soybeans as Raw Materials for Soy Sauce in Maintaining Quality and Safety" Sustainability 15, no. 18: 13453. https://doi.org/10.3390/su151813453

APA StyleAnwar, S., Perdana, T., Rachmadi, M., & Noor, T. I. (2023). Product Traceability and Supply Chain Sustainability of Black Soybeans as Raw Materials for Soy Sauce in Maintaining Quality and Safety. Sustainability, 15(18), 13453. https://doi.org/10.3390/su151813453