Impact of Low-Reactivity Calcined Clay on the Performance of Fly Ash-Based Geopolymer Mortar

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Mix Proportion

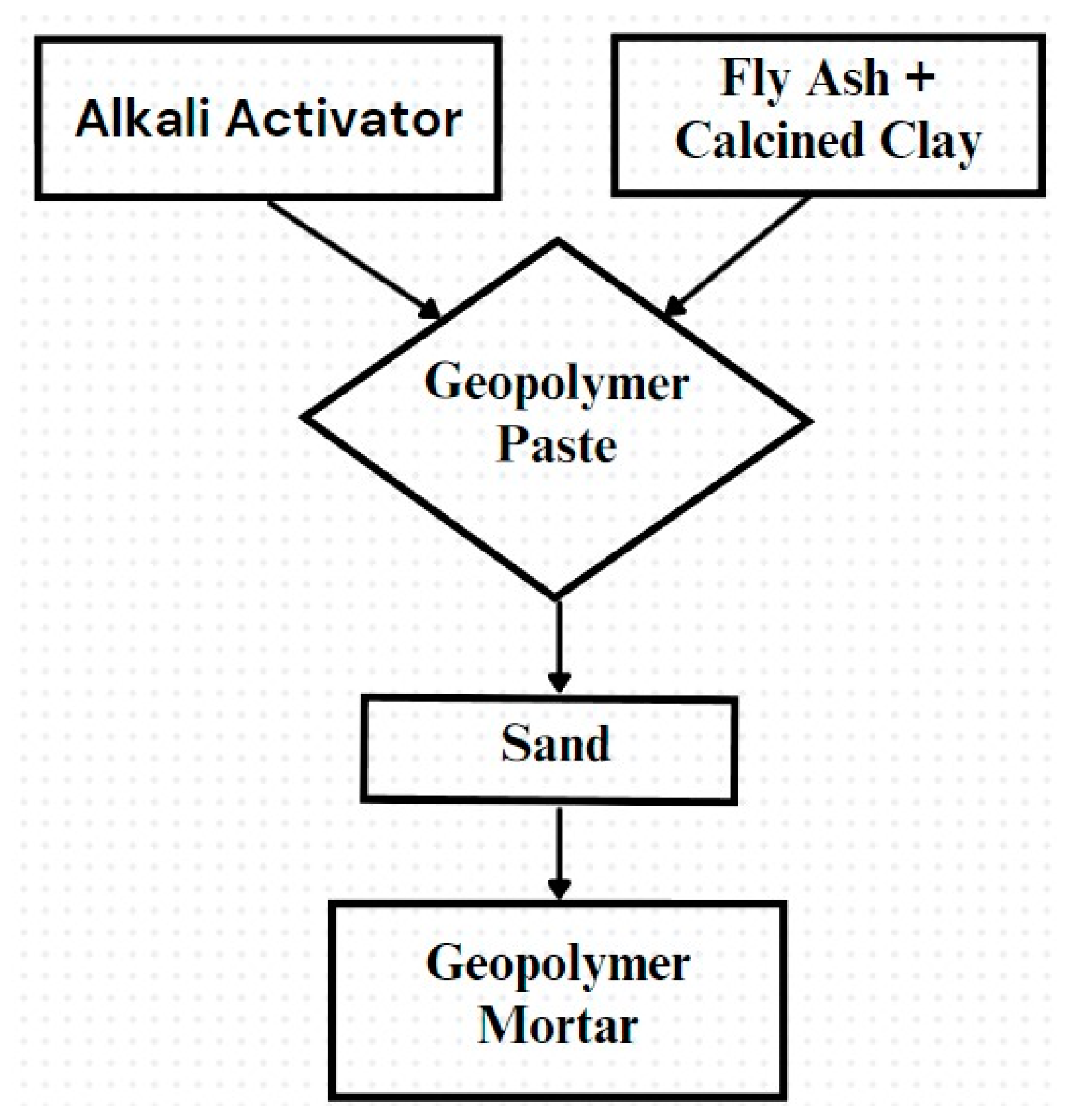

2.2.2. Geopolymer Mortar Preparation

2.2.3. Testing Methods

3. Results and Discussion

3.1. Raw Materials Characterization

3.2. Isothermal Calorimetry

3.3. Setting Times

3.4. Compressive Strength

3.5. Mercury Intrusion Porosimetry (MIP)

3.6. Autogenous Shrinkage

3.7. X-ray Diffraction Analysis

4. Conclusions

- As revealed by the isothermal conduction calorimetry results, heat evolution decreased with increasing calcined clay content. The addition of calcined clay reduced the surface interaction between the dissolved particles in the alkali solution, leading to slow initial reactivity.

- The incorporation of 20% calcined clay in the mix favored early and late compressive strength development, outperforming the reference geopolymer mortar (containing 100% fly ash) by 5.6%, 17%, and 18.5% at 7, 28, and 91 days, respectively. Geopolymer mixes containing 100% fly ash, however, obtained slightly improved compressive strength figures at all curing ages as compared to the ones prepared with 100% calcined clay. Setting times increased with increasing calcined clay content in the geopolymer mix. Optimum replacement was found to be 20%.

- The highest porosity (24%) was recorded for mixes containing only fly ash (CC0), whereas the calcined clay-based geopolymer mortar (CC100) obtained the least porosity (6.5%). All mixes that contained calcined clay, irrespective of the level of replacement, were found to be less porous than CC0. The calcined clay particles appeared to be denser and interlocking as compared to that of fly ash.

- Shrinkage was observed to be less severe in mixes containing calcined clay. The MIP analysis revealed that refinement of the pore structure of geopolymer specimens containing calcined clay resulted in the release of tensional forces within the pore fluid.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zafar, M.S.; Javed, U.; Khushnood, R.A.; Nawaz, A.; Zafar, T. Sustainable incorporation of waste granite dust as partial replacement of sand in autoclave aerated concrete. Constr. Build. Mater. 2020, 250, 118878. [Google Scholar] [CrossRef]

- Boakye, K.; Khorami, M.; Saidani, M.; Ganjian, E.; Dunster, A.; Ehsani, A.; Tyrer, M. Mechanochemical characterisation of calcined impure kaolinitic clay as a composite binder in cementitious mortars. J. Compos. Sci. 2022, 6, 134. [Google Scholar] [CrossRef]

- Wang, Y.; Dai, J. Use of magnesia sand for optimal design of high performance magnesium potassium phosphate cement mortar. Constr. Build. Mater. 2017, 153, 385–392. [Google Scholar] [CrossRef]

- van Deventer, J.S.; Provis, J.L.; Duxson, P.; Brice, D.G. Chemical research and climate change as drivers in the commercial adoption of alkali activated materials. Waste Biomass Valorization 2010, 1, 145–155. [Google Scholar] [CrossRef]

- Provis, J.L.; Bernal, S.A. Geopolymers and related alkali-activated materials. Annu. Rev. Mater. Res. 2014, 44, 299–327. [Google Scholar] [CrossRef]

- Krivenko, P.; Garcia-Lodeiro, I.; Kavalerova, E.; Maltseva, O.; Fernández-Jiménez, A. A review on alkaline activation: New analytical perspectives. Mater. Construcc. 2014, 64, e022. [Google Scholar]

- Davidovits, J. Global warming impact on the cement and aggregates industries. World Resour. Rev. 1994, 6, 263–278. [Google Scholar]

- Gomaa, E.; Sargon, S.; Kashosi, C.; Gheni, A.; ElGawady, M. Effect of different class C fly ash compositions on the properties of the alkali-activated concrete. In International Congress on Polymers in Concrete (ICPIC 2018) Polymers for Resilient and Sustainable Concrete Infrastructure 16; Springer International Publishing: Cham, Switzerland, 2018; pp. 541–547. [Google Scholar]

- Xie, J.; Wang, J.; Rao, R.; Wang, C.; Fang, C. Effects of combined usage of GGBS and fly ash on workability and mechanical properties of alkali activated geopolymer concrete with recycled aggregate. Compos. Part B Eng. 2019, 164, 179–190. [Google Scholar] [CrossRef]

- Stolz, J.; Boluk, Y.; Bindiganavile, V. Mechanical, thermal and acoustic properties of cellular alkali activated fly ash concrete. Cem. Concr. Compos. 2018, 94, 24–32. [Google Scholar] [CrossRef]

- Hadi, M.N.; Farhan, N.A.; Sheikh, M.N. Design of geopolymer concrete with GGBFS at ambient curing condition using Taguchi method. Constr. Build. Mater. 2017, 140, 424–431. [Google Scholar] [CrossRef]

- Anbarasan, I.; Soundarapandian, N. Investigation of mechanical and micro structural properties of geopolymer concrete blended by dredged marine sand and manufactured sand under ambient curing conditions. Struct. Concr. 2020, 21, 992–1003. [Google Scholar] [CrossRef]

- Aygörmez, Y.; Canpolat, O.; Al-mashhadani, M.M.; Uysal, M. Elevated temperature, freezing-thawing and wetting-drying effects on polypropylene fiber reinforced metakaolin based geopolymer composites. Constr. Build. Mater. 2020, 235, 117502. [Google Scholar] [CrossRef]

- Jaya, N.A.; Yun-Ming, L.; Cheng-Yong, H.; Abdullah, M.M.A.B.; Hussin, K. Correlation between pore structure, compressive strength and thermal conductivity of porous metakaolin geopolymer. Constr. Build. Mater. 2020, 247, 118641. [Google Scholar] [CrossRef]

- Nguyen, K.T.; Nguyen, Q.D.; Le, T.A.; Shin, J.; Lee, K. Analyzing the compressive strength of green fly ash based geopolymer concrete using experiment and machine learning approaches. Constr. Build. Mater. 2020, 247, 118581. [Google Scholar] [CrossRef]

- Nath, S.K.; Kumar, S. Role of particle fineness on engineering properties and microstructure of fly ash derived geopolymer. Constr. Build. Mater. 2020, 233, 117294. [Google Scholar] [CrossRef]

- McCarthy, M.J.; Robl, T.; Csetenyi, L.J. Recovery, Processing, and Usage of Wet-Stored Fly Ash. In Coal Combustion Products (CCP’s); Robl, T., Oberlink, A., Jones, R., Eds.; Woodhead Publishing: Duxford, UK, 2017. [Google Scholar]

- Juenger, M.C.G.; Snellings, R.; Bernal, S.A. Supplementary cementitious materials: New sources, characterization, and performance insights. Cem. Concr. Res. 2019, 122, 257–273. [Google Scholar] [CrossRef]

- Kuenzel, C.; Neville, T.P.; Donatello, S.; Vandeperre, L.; Boccaccini, A.R.; Cheeseman, C.R. Influence of metakaolin characteristics on the mechanical properties of geopolymers. Appl. Clay Sci. 2013, 83–84, 308–314. [Google Scholar] [CrossRef]

- Albidah, A.; Alqarni, A.S.; Abbas, H.; Almusallam, T.; Al-Salloum, Y. Behavior of Metakaolin-Based geopolymer concrete at ambient and elevated temperatures. Constr. Build. Mater. 2022, 317, 125910. [Google Scholar] [CrossRef]

- Shilar, F.A.; Ganachari, S.V.; Patil, V.B.; Nisar, K.S. Evaluation of structural performances of metakaolin based geopolymer concrete. J. Mater. Res. Technol. 2022, 20, 3208–3228. [Google Scholar] [CrossRef]

- Gopalakrishna, B.; Pasla, D. Development of metakaolin based high strength recycled aggregate geopolymer concrete. Constr. Build. Mater. 2023, 391, 131810. [Google Scholar] [CrossRef]

- Dhasmana, A.; Singh, S.P. Long-term mechanical characteristics of fibre reinforced metakaolin-based geopolymer concrete: A review. Mater. Today Proc. 2023; in press. [Google Scholar] [CrossRef]

- Murray, H.H. Traditional and new applications for kaolin, smectite, and palygorskite: A general overview. Appl. Clay Sci. 2000, 17, 207–221. [Google Scholar] [CrossRef]

- Tironi, A.; Trezza, M.A.; Scian, A.N.; Irassar, E.F. Assessment of pozzolanic activity of different calcined clays. Cem. Concr. Compos. 2013, 37, 319–327. [Google Scholar] [CrossRef]

- Sabir, B.B.; Wild, S.; Bai, J. Metakaolin and calcined clays as pozzolans for concrete: A review. Cem. Concr. Compos. 2001, 23, 441–454. [Google Scholar] [CrossRef]

- Boakye, K.; Khorami, M. Influence of Calcined Clay Pozzolan and Aggregate Size on the Mechanical and Durability Properties of Pervious Concrete. J. Compos. Sci. 2023, 7, 182. [Google Scholar] [CrossRef]

- Du, H.; Pang, S.D. Value-added utilization of marine clay as cement replacement for sustainable concrete production. J. Clean. Prod. 2018, 198, 867–873. [Google Scholar] [CrossRef]

- Sarfo-Ansah, J.; Atiemo, E.; Boakye, K.A.; Adjei, D.; Adjaottor, A.A. Calcined clay Pozzolan as an admixture to mitigate the alkali-silica reaction in concrete. J. Mater. Sci. Chem. Eng. 2014, 2014, 46116. [Google Scholar] [CrossRef]

- Zheng, D.; Liang, X.; Cui, H.; Tang, W.; Liu, W.; Zhou, D. Study of performances and microstructures of mortar with calcined low-grade clay. Constr. Build. Mater. 2022, 327, 126963. [Google Scholar] [CrossRef]

- Zolfagharnasab, A.; Ramezanianpour, A.A.; Bahman-Zadeh, F. Investigating the potential of low-grade calcined clays to produce durable LC3 binders against chloride ions attack. Constr. Build. Mater. 2021, 303, 124541. [Google Scholar] [CrossRef]

- Tchadjie, L.N.; Ekolu, S.O. Enhancing the reactivity of aluminosilicate materials toward geopolymer synthesis. J. Mater. Sci. 2018, 53, 4709–4733. [Google Scholar] [CrossRef]

- Hamdi, N.; Ben Messaoud, I.; Srasra, E. Production of geopolymer binders using clay minerals and industrial wastes. Comptes Rendus Chim. 2019, 22, 220–226. [Google Scholar] [CrossRef]

- Ogundiran, M.B.; Kumar, S. Synthesis and characterisation of geopolymer from Nigerian Clay. Appl. Clay Sci. 2015, 108, 173–181. [Google Scholar] [CrossRef]

- Bature, A.S.; Khorami, M.; Ganjian, E.; Tyrer, M. Influence of alkali activator type and proportion on strength performance of calcined clay geopolymer mortar. Constr. Build. Mater. 2021, 267, 120446. [Google Scholar] [CrossRef]

- Ferone, C.; Liguori, B.; Capasso, I.; Colangelo, F.; Cioffi, R.; Cappelletto, E.; Di Maggio, R. Thermally treated clay sediments as geopolymer source material. Appl. Clay Sci. 2015, 107, 195–204. [Google Scholar] [CrossRef]

- Rahman, M.M.; Law, D.; Patnaikuni, I. Factors affecting the performance of 100% clay based geopolymer concrete. In Proceedings of the 28th Biennial National Conference of the Concrete Institute of Australia (Concrete 2017), Adelaide, Australia, 22–27 October 2017; pp. 1–7. [Google Scholar]

- Tahmasebi Yamchelou, M.; Law, D.; Brkljača, R.; Gunasekara, C.; Li, J.; Patnaikuni, I. Geopolymer synthesis using low-grade clays. Constr. Build. Mater. 2021, 268, 121066. [Google Scholar] [CrossRef]

- ASTM C191–19; Standard test methods for time of setting of hydraulic cement by Vicat needle. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM C109/109M-20A; Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimen). ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM C490-07; Standard Practice for Use of Apparatus for the Determination of Length Change of Hardened Cement Paste, Mortar, and Concrete. ASTM International: West Conshohocken, PA, USA, 2007.

- Panias, D.; Giannopoulou, I.P.; Perraki, T. Effect of synthesis parameters on the mechanical properties of fly ash-based geopolymers. Colloids Surf. Physicochem. Eng. Asp. 2007, 301, 246–254. [Google Scholar] [CrossRef]

- Qin, Z.; Ma, C.; Zheng, Z.; Long, G.; Chen, B. Effects of metakaolin on properties and microstructure of magnesium phosphate cement. Constr. Build. Mater. 2020, 234, 117353. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, H.; Zhu, Y.; Reid, A.; Provis, J.L.; Bullen, F. Using fly ash to partially substitute metakaolin in geopolymer synthesis. Appl. Clay Sci. 2014, 88–89, 194–201. [Google Scholar] [CrossRef]

- Ogundiran, M.B.; Kumar, S. Synthesis of fly ash-calcined clay geopolymers: Reactivity, mechanical strength, structural and microstructural characteristics. Constr. Build. Mater. 2016, 125, 450–457. [Google Scholar] [CrossRef]

- Duan, P.; Yan, C.; Zhou, W. Influence of partial replacement of fly ash by metakaolin on mechanical properties and microstructure of fly ash geopolymer paste exposed to sulfate attack. Ceram. Int. 2016, 42, 3504–3517. [Google Scholar] [CrossRef]

- Parashar, A.K.; Gupta, N.; Singh, P.; Saxena, K.K.; Prakash, C.; Kumar, S. Investigation on the properties of GGBS based geopolymer mortar with the inclusion of calcined clay. Adv. Mater. Process. Technol. 2023, 1–12. [Google Scholar] [CrossRef]

- Li, J.; Mailhiot, S.; Sreenivasan, H.; Kantola, A.M.; Illikainen, M.; Adesanya, E.; Kriskova, L.; Telkki, V.-V.; Kinnunen, P. Curing process and pore structure of metakaolin-based geopolymers: Liquid-state 1H NMR investigation. Cem. Concr. Res. 2021, 143, 106394. [Google Scholar] [CrossRef]

- Cai, R.; Tian, Z.; Ye, H.; He, Z.; Tang, S. The role of metakaolin in pore structure evolution of Portland cement pastes revealed by an impedance approach. Cem. Concr. Compos. 2021, 119, 103999. [Google Scholar] [CrossRef]

- Melo Neto, A.A.; Cincotto, M.A.; Repette, W. Drying and autogenous shrinkage of pastes and mortars with activated slag cement. Cem. Concr. Res. 2008, 38, 565–574. [Google Scholar] [CrossRef]

- Yang, T.; Zhu, H.; Zhang, Z. Influence of fly ash on the pore structure and shrinkage characteristics of metakaolin-based geopolymer pastes and mortars. Constr. Build. Mater. 2017, 153, 284–293. [Google Scholar] [CrossRef]

- Ates, F.; Park, K.T.; Kim, K.W.; Woo, B.; Kim, H.G. Effects of treated biomass wood fly ash as a partial substitute for fly ash in a geopolymer mortar system. Constr. Build. Mater. 2023, 376, 131063. [Google Scholar] [CrossRef]

- Mijarsh, M.J.A.; Megat Johari, M.A.; Ahmad, Z.A. Effect of delay time and Na2SiO3 concentrations on compressive strength development of geopolymer mortar synthesized from TPOFA. Constr. Build. Mater. 2015, 86, 64–74. [Google Scholar] [CrossRef]

- Hajimohammadi, A.; Ngo, T.; Provis, J.L.; Kim, T.; Vongsvivut, J. High strength/density ratio in a syntactic foam made from one-part mix geopolymer and cenospheres. Compos. Part B Eng. 2019, 173, 106908. [Google Scholar] [CrossRef]

- García-Lodeiro, I.; Fernández-Jiménez, A.; Palomo, A.; Macphee, D.E. Effect of calcium additions on N–A–S–H cementitious gels. J. Am. Ceram. Soc. 2010, 93, 1934–1940. [Google Scholar] [CrossRef]

- García-Lodeiro, I.; Fernández-Jiménez, A.; Palomo, A. Variation in hybrid cements over time. Alkaline activation of fly ash–portland cement blends. Cem. Concr. Res. 2013, 52, 112–122. [Google Scholar] [CrossRef]

- García-Lodeiro, I.; Palomo, A.; Fernández-Jiménez, A.; Macphee, D.E. Compatibility studies between NASH and CASH gels. Study in the ternary diagram Na2O–CaO–Al2O3–SiO2–H2O. Cem. Concr. Res. 2011, 41, 923–931. [Google Scholar] [CrossRef]

- Cheah, C.B.; Part, W.K.; Ramli, M. The hybridizations of coal fly ash and wood ash for the fabrication of low alkalinity geopolymer load bearing block cured at ambient temperature. Constr. Build. Mater. 2015, 88, 41–55. [Google Scholar] [CrossRef]

| Composition, % | SiO2 | A12O3 | Fe2O3 | MgO | CaO | Na2O | K2O | MnO | TiO2 | P2O5 | SO3 | LOI |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Calcined clay | 62.77 | 18.71 | 11.68 | 1.89 | 0.25 | 0.03 | 2.12 | 0.46 | 0.41 | 0.03 | 0.19 | 1.46 |

| Fly ash | 58.1 | 25.82 | 4.25 | 0.25 | 2.28 | - | 1.13 | 1.1 | 0.22 | 0.12 | 6.73 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Boakye, K.; Khorami, M. Impact of Low-Reactivity Calcined Clay on the Performance of Fly Ash-Based Geopolymer Mortar. Sustainability 2023, 15, 13556. https://doi.org/10.3390/su151813556

Boakye K, Khorami M. Impact of Low-Reactivity Calcined Clay on the Performance of Fly Ash-Based Geopolymer Mortar. Sustainability. 2023; 15(18):13556. https://doi.org/10.3390/su151813556

Chicago/Turabian StyleBoakye, Kwabena, and Morteza Khorami. 2023. "Impact of Low-Reactivity Calcined Clay on the Performance of Fly Ash-Based Geopolymer Mortar" Sustainability 15, no. 18: 13556. https://doi.org/10.3390/su151813556