Carbon-Based Solid Acid Catalyzed Esterification of Soybean Saponin-Acidified Oil with Methanol Vapor for Biodiesel Synthesis

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Catalyst Preparation

2.3. Pretreatment of Soybean Saponin-Acidified Oil

2.4. Esterification Experiments

2.5. Reuse of Catalysts

2.6. Analytical Methods

3. Results and Discussions

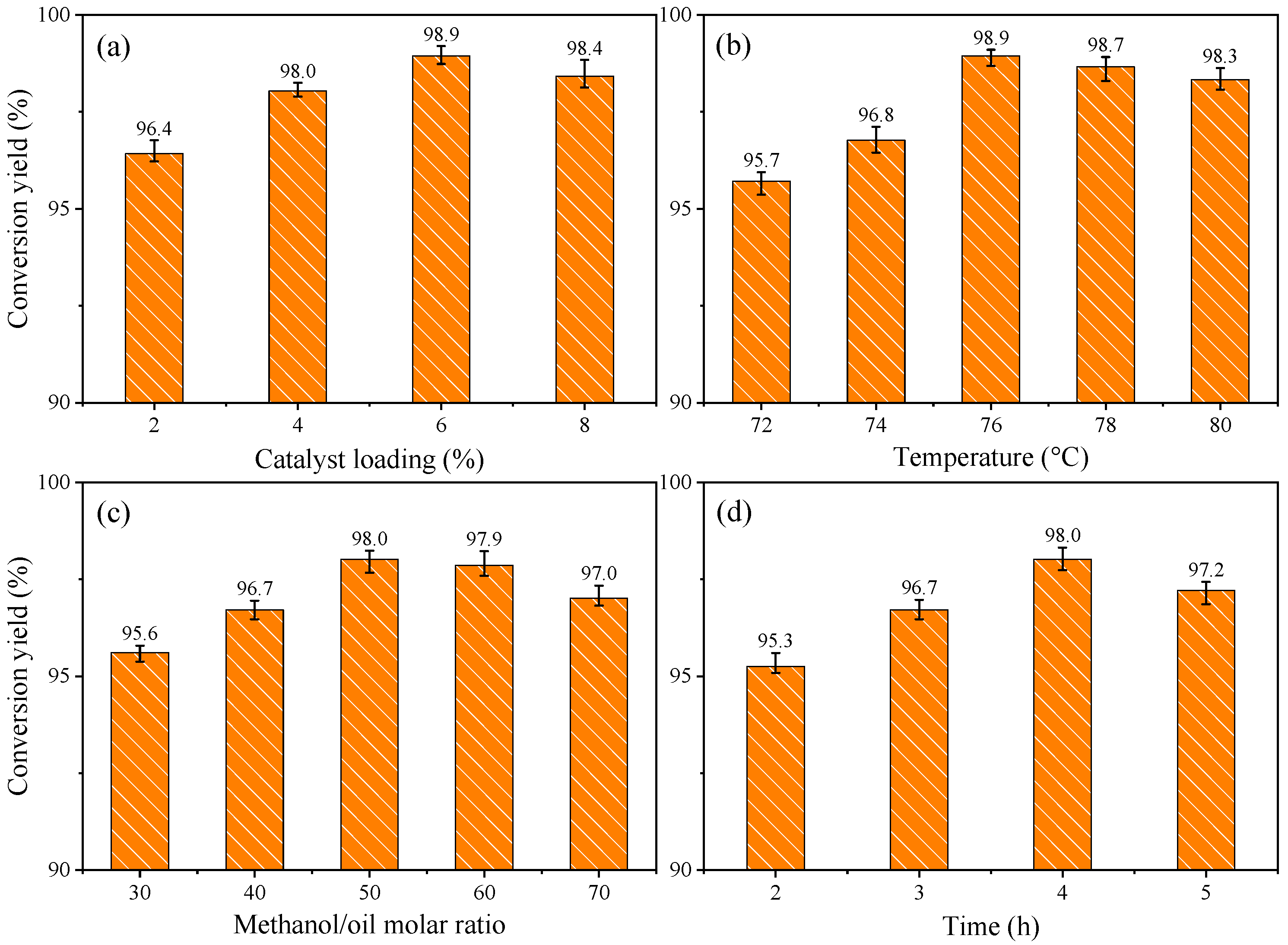

3.1. Optimization of Esterification Conditions of SSAO with Methanol Vapor

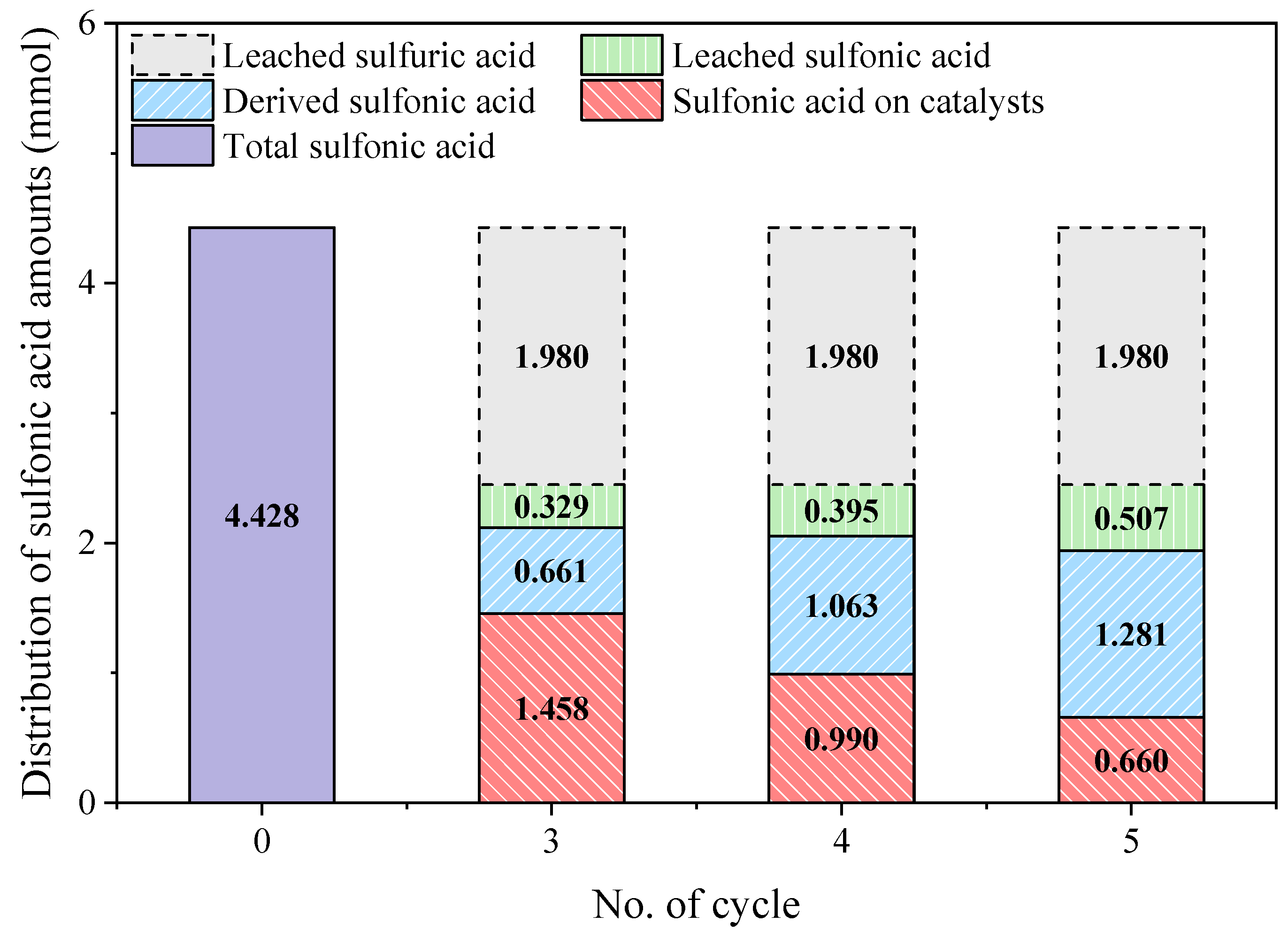

3.2. Catalyst Stability and Deactivation Mechanisms in Methanol Vapor Esterification

3.3. Effect of SSAO Pretreatment on Catalyst Activity

3.4. Comparison of Methanol Vapor Esterification with Other Liquid Methanol Esterification Studies

3.5. Costing of Biodiesel Synthesis from Soybean Saponin-Acidified Oil

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclatures

| CSAC | Carbon-based solid acid catalyst |

| FFA | Free fatty acid |

| SSAO | Soybean saponin-acidified oil |

| LME | Liquid methanol esterification |

| MVE | Methanol vapor esterification |

| USD | United States dollar |

| λ | Heat conductivity (kW/(m·°C)) |

| δ | The thickness of the reactor wall (m) |

| A | Total heated area of the reactor (m2) |

| Cp | Specific heat capacity (kJ/(kg·°C)) |

| D | Outer wall circumference of the reactor (m) |

| H | Height of reactor (m) |

| M | Mass (kg) |

| Q | Heating energy (kJ) |

| t | Temperature (°C) |

| T | Reaction time |

References

- Ma, Y.; Liu, Y. Turning Food Waste to Energy and Resources towards a Great Environmental and Economic Sustainability: An Innovative Integrated Biological Approach. Biotechnol. Adv. 2019, 37, 107414. [Google Scholar] [CrossRef]

- Talebian-Kiakalaieh, A.; Amin, N.A.S.; Mazaheri, H. A Review on Novel Processes of Biodiesel Production from Waste Cooking Oil. Appl. Energy 2013, 104, 683–710. [Google Scholar] [CrossRef]

- Sahar; Sadaf, S.; Iqbal, J.; Ullah, I.; Bhatti, H.N.; Nouren, S.; Habib-ur-Rehman; Nisar, J.; Iqbal, M. Biodiesel Production from Waste Cooking Oil: An Efficient Technique to Convert Waste into Biodiesel. Sustain. Cities Soc. 2018, 41, 220–226. [Google Scholar] [CrossRef]

- Pydimalla, M.; Husaini, S.; Kadire, A.; Kumar Verma, R. Sustainable Biodiesel: A Comprehensive Review on Feedstock, Production Methods, Applications, Challenges and Opportunities. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Akram, F.; Haq, I.L.; Raja, S.I.; Mir, A.S.; Qureshi, S.S.; Aqeel, A.; Shah, F.I. Current Trends in Biodiesel Production Technologies and Future Progressions: A Possible Displacement of the Petro-Diesel. J. Clean. Prod. 2022, 370, 133479. [Google Scholar] [CrossRef]

- Li, Y.; Wen, Y.; Chen, B.; Fu, X.; Wu, Y. The Dilemma and Potential Development of Biodiesel in China—In View of Production Capacity and Policy. Energy Sustain. Dev. 2023, 75, 60–71. [Google Scholar] [CrossRef]

- Gutiérrez-López, A.N.; Mena-Cervantes, V.Y.; González-Espinosa, M.A.; Sosa-Rodríguez, F.S.; Vazquez-Arenas, J.; Rodríguez-Ramírez, R.; Hernández-Altamirano, R. Green and Fast Biodiesel Production at Room Temperature Using Soybean and Jatropha curcas L. Oils Catalyzed by Potassium Ferrate. J. Clean. Prod. 2022, 372, 133739. [Google Scholar] [CrossRef]

- Sharma, K.; Kaur, R.; Kumar, S.; Saini, R.K.; Sharma, S.; Pawde, S.V.; Kumar, V. Saponins: A Concise Review on Food Related Aspects, Applications and Health Implications. Food Chem. Adv. 2023, 2, 100191. [Google Scholar] [CrossRef]

- Niu, S.; Ning, Y.; Lu, C.; Han, K.; Yu, H.; Zhou, Y. Esterification of Oleic Acid to Produce Biodiesel Catalyzed by Sulfonated Activated Carbon from Bamboo. Energy Convers. Manag. 2018, 163, 59–65. [Google Scholar] [CrossRef]

- Konwar, L.J.; Das, R.; Thakur, A.J.; Salminen, E.; Mäki-Arvela, P.; Kumar, N.; Mikkola, J.P.; Deka, D. Biodiesel Production from Acid Oils Using Sulfonated Carbon Catalyst Derived from Oil-Cake Waste. J. Mol. Catal. A Chem. 2014, 388–389, 167–176. [Google Scholar] [CrossRef]

- Singh, V.; Belova, L.; Singh, B.; Sharma, Y.C. Biodiesel Production Using a Novel Heterogeneous Catalyst, Magnesium Zirconate (Mg2Zr5O12): Process Optimization through Response Surface Methodology (RSM). Energy Convers. Manag. 2018, 174, 198–207. [Google Scholar] [CrossRef]

- Ibrahim, S.M.; Mustafa, A. Synthesis and Characterization of New Bifunctional SnZrSi Oxide Catalysts for Biodiesel Production. J. Mol. Liq. 2022, 354, 118811. [Google Scholar] [CrossRef]

- Sheikh, R.; Choi, M.S.; Im, J.S.; Park, Y.H. Study on the Solid Acid Catalysts in Biodiesel Production from High Acid Value Oil. J. Ind. Eng. Chem. 2013, 19, 1413–1419. [Google Scholar] [CrossRef]

- Guldhe, A.; Moura, C.V.R.; Singh, P.; Rawat, I.; Moura, E.M.; Sharma, Y.; Bux, F. Conversion of Microalgal Lipids to Biodiesel Using Chromium-Aluminum Mixed Oxide as a Heterogeneous Solid Acid Catalyst. Renew. Energy 2017, 105, 175–182. [Google Scholar] [CrossRef]

- Li, J.; Fu, Y.J.; Qu, X.J.; Wang, W.; Luo, M.; Zhao, C.J.; Zu, Y.G. Biodiesel Production from Yellow Horn (Xanthoceras sorbifolia Bunge.) Seed Oil Using Ion Exchange Resin as Heterogeneous Catalyst. Bioresour. Technol. 2012, 108, 112–118. [Google Scholar] [CrossRef]

- Mendaros, C.M.; Go, A.W.; Nietes, W.J.T.; Gollem, B.E.J.O.; Cabatingan, L.K. Direct Sulfonation of Cacao Shell to Synthesize a Solid Acid Catalyst for the Esterification of Oleic Acid with Methanol. Renew. Energy 2020, 152, 320–330. [Google Scholar] [CrossRef]

- Mahajan, A.; Gupta, P. Carbon-Based Solid Acids: A Review. Environ. Chem. Lett. 2020, 18, 299–314. [Google Scholar] [CrossRef]

- Konwar, L.J.; Mäki-Arvela, P.; Mikkola, J.P. SO3H-Containing Functional Carbon Materials: Synthesis, Structure, and Acid Catalysis. Chem. Rev. 2019, 119, 11576–11630. [Google Scholar] [CrossRef] [PubMed]

- Nakajima, K.; Hara, M. Amorphous Carbon with SO3H Groups as a Solid Brønsted Acid Catalyst. ACS Catal. 2012, 2, 1296–1304. [Google Scholar] [CrossRef]

- Daud, N.M.; Sheikh Abdullah, S.R.; Abu Hasan, H.; Yaakob, Z. Production of Biodiesel and Its Wastewater Treatment Technologies. Process Saf. Environ. Prot. 2015, 94, 487–508. [Google Scholar] [CrossRef]

- Fonseca, J.M.; Spessato, L.; Cazetta, A.L.; da Silva, C.; Almeida, V.d.C. Sulfonated Carbon: Synthesis, Properties and Production of Biodiesel. Chem. Eng. Process. Process Intensif. 2022, 170, 108668. [Google Scholar] [CrossRef]

- Fraile, J.M.; García-Bordejé, E.; Pires, E.; Roldán, L. New Insights into the Strength and Accessibility of Acid Sites of Sulfonated Hydrothermal Carbon. Carbon N. Y. 2014, 77, 1157–1167. [Google Scholar] [CrossRef]

- Zhang, B.; Gao, M.; Tang, W.; Wang, X.; Wu, C.; Wang, Q. Substitution of Liquid Methanol with Methanol Vapour Increases the Activity and Stability of Carbon-Based Solid Acid Catalysts in Biodiesel Production Process. Energy Convers. Manag. 2023, 278, 116708. [Google Scholar] [CrossRef]

- Tang, W.; Gao, M.; Zhang, B.; Wang, X.; Wu, C.; Wang, Q.; Liu, S. Performance and Deactivation Mechanism of a Carbon-Based Solid Acid Catalyst in the Esterification of Soybean Saponin Acid Oil. J. Environ. Chem. Eng. 2023, 11, 109797. [Google Scholar] [CrossRef]

- Yu, H.; Niu, S.; Bai, T.; Tang, X.; Lu, C. Microwave-Assisted Preparation of Coal-Based Heterogeneous Acid Catalyst and Its Catalytic Performance in Esterification. J. Clean. Prod. 2018, 183, 67–76. [Google Scholar] [CrossRef]

- Fraile, J.M.; García-Bordejé, E.; Pires, E.; Roldán, L. Catalytic Performance and Deactivation of Sulfonated Hydrothermal Carbon in the Esterification of Fatty Acids: Comparison with Sulfonic Solids of Different Nature. J. Catal. 2015, 324, 107–118. [Google Scholar] [CrossRef]

- Zhou, Y.; Niu, S.; Li, J. Activity of the Carbon-Based Heterogeneous Acid Catalyst Derived from Bamboo in Esterification of Oleic Acid with Ethanol. Energy Convers. Manag. 2016, 114, 188–196. [Google Scholar] [CrossRef]

- Dechakhumwat, S.; Hongmanorom, P.; Thunyaratchatanon, C.; Smith, S.M.; Boonyuen, S.; Luengnaruemitchai, A. Catalytic Activity of Heterogeneous Acid Catalysts Derived from Corncob in the Esterification of Oleic Acid with Methanol. Renew. Energy 2020, 148, 897–906. [Google Scholar] [CrossRef]

- Ni, Z.; Li, F.; Wang, H.; Wang, S.; Gao, S. Catalytic Esterification, Kinetics, and Cold Flow Properties of Isobutyl Palmitate. Fuel 2019, 254, 115368. [Google Scholar] [CrossRef]

- Javed, F.; Shamair, Z.; Hafeez, A.; Fazal, T.; Aslam, R.; Akram, S.; Rashid, N.; Zimmerman, W.B.; Rehman, F. Conversion of Poultry-Fat Waste to a Sustainable Feedstock for Biodiesel Production via Microbubble Injection of Reagent Vapor. J. Clean. Prod. 2021, 311, 127525. [Google Scholar] [CrossRef]

- Veillette, M.; Giroir-Fendler, A.; Faucheux, N.; Heitz, M. Esterification of Free Fatty Acids with Methanol to Biodiesel Using Heterogeneous Catalysts: From Model Acid Oil to Microalgae Lipids. Chem. Eng. J. 2017, 308, 101–109. [Google Scholar] [CrossRef]

- Zailan, Z.; Tahir, M.; Jusoh, M.; Zakaria, Z.Y. A Review of Sulfonic Group Bearing Porous Carbon Catalyst for Biodiesel Production. Renew. Energy 2021, 175, 430–452. [Google Scholar] [CrossRef]

- Tang, Z.E.; Lim, S.; Pang, Y.L.; Shuit, S.H.; Ong, H.C. Utilisation of Biomass Wastes Based Activated Carbon Supported Heterogeneous Acid Catalyst for Biodiesel Production. Renew. Energy 2020, 158, 91–102. [Google Scholar] [CrossRef]

- Hamza, M.; Ayoub, M.; Shamsuddin, R.B.; Mukhtar, A.; Saqib, S.; Zahid, I.; Ameen, M.; Ullah, S.; Al-Sehemi, A.G.; Ibrahim, M. A Review on the Waste Biomass Derived Catalysts for Biodiesel Production. Environ. Technol. Innov. 2021, 21, 101200. [Google Scholar] [CrossRef]

- Rosmeika; Yuwono, A.S.; Tambunan, A.H. Comparison of Biodiesel Production by Conventional and Superheated Methanol Vapor Technologies Using Life Cycle Assessment Method. Environ. Eng. Sci. 2014, 31, 107–116. [Google Scholar] [CrossRef]

- Liu, F.; Huang, K.; Zheng, A.; Xiao, F.S.; Dai, S. Hydrophobic Solid Acids and Their Catalytic Applications in Green and Sustainable Chemistry. ACS Catal. 2018, 8, 372–391. [Google Scholar] [CrossRef]

- Jiang, X.; Long, F.; Zhai, Q.; Zhao, J.; Liu, P.; Xu, J. Catalytic Cracking of Acidified Oil and Modification of Pyrolytic Oils from Soap Stock for the Production of a High-Quality Biofuel. New J. Chem. 2022, 46, 1770–1778. [Google Scholar] [CrossRef]

- Zhang, B.; Gao, M.; Tang, W.; Wang, X.; Wu, C.; Wang, Q.; Xie, H. Reduced Surface Sulphonic Acid Concentration Alleviates Carbon-Based Solid Acid Catalysts Deactivation in Biodiesel Production. Energy 2023, 271, 127079. [Google Scholar] [CrossRef]

- Zhang, B.; Gao, M.; Geng, J.; Cheng, Y.; Wang, X.; Wu, C.; Wang, Q.; Liu, S.; Cheung, S.M. Catalytic Performance and Deactivation Mechanism of a One-Step Sulfonated Carbon-Based Solid-Acid Catalyst in an Esterification Reaction. Renew. Energy 2021, 164, 824–832. [Google Scholar] [CrossRef]

- Liu, S.; Zhu, M.; Iqbal, M. Research Progress on Stability of Solid Acid Catalysts. Catal. Surv. Asia 2020, 24, 196–206. [Google Scholar] [CrossRef]

- Flores, K.P.; Omega, J.L.O.; Cabatingan, L.K.; Go, A.W.; Agapay, R.C.; Ju, Y.H. Simultaneously Carbonized and Sulfonated Sugarcane Bagasse as Solid Acid Catalyst for the Esterification of Oleic Acid with Methanol. Renew. Energy 2019, 130, 510–523. [Google Scholar] [CrossRef]

- Malins, K.; Brinks, J.; Kampars, V.; Malina, I. Esterification of Rapeseed Oil Fatty Acids Using a Carbon-Based Heterogeneous Acid Catalyst Derived from Cellulose. Appl. Catal. A Gen. 2016, 519, 99–106. [Google Scholar] [CrossRef]

- Shang, Y.; Jiang, Y.; Gao, J. One-Step Synthesis of Peanut Shell-Derived Solid Acid for Biodiesel Production. Energy Sources Part A Recover. Util. Environ. Eff. 2015, 37, 1039–1045. [Google Scholar] [CrossRef]

- Thushari, I.; Babel, S. Sustainable Utilization of Waste Palm Oil and Sulfonated Carbon Catalyst Derived from Coconut Meal Residue for Biodiesel Production. Bioresour. Technol. 2018, 248, 199–203. [Google Scholar] [CrossRef]

| The Batch of Esterification Reaction | Sulfonic Acid Density (mmol/g) | Sulfur Density (mmol/g) | Catalyst Mass (g) | Total Sulfonic Acid (mmol) | Total Sulfur (mmol) | |

|---|---|---|---|---|---|---|

| Fresh C150-4 catalyst | - | 1.476 | 1.146 | 3.00 | 4.428 | 3.438 |

| Liquid methanol esterification | 3rd batch | 0.167 | 0.706 | 3.11 | 0.519 | 2.198 |

| 4th batch | 0.143 | 0.681 | 3.14 | 0.449 | 2.142 | |

| Methanol vapor esterification | 3rd batch | 0.481 | 0.699 | 3.03 | 1.458 | 2.119 |

| 4th batch | 0.324 | 0.671 | 3.06 | 0.990 | 2.053 | |

| 5th batch | 0.214 | 0.630 | 3.08 | 0.660 | 1.941 | |

| Methanol vapor esterification (SSAO with adsorption treatment) | 6th batch | 0.377 | 0.704 | 3.02 | 1.140 | 2.127 |

| Metal Ions | SSAO | SSAO with Absorption Treatment | |||||

|---|---|---|---|---|---|---|---|

| Raw Oil | Fresh Catalyst | Catalyst Used 3 Batches | Catalyst Used 4 Batches | Catalyst Used 5 Batches | Raw Oil | Catalyst Used 6 Batches | |

| Na+ | 19.86 | 1.53 | 1.71 | 1.83 | 1.79 | 11.39 | 1.81 |

| Ca2+ | 6.97 | 0.58 | 0.65 | 0.68 | 0.73 | 5.36 | 0.82 |

| Al3+ | 7.41 | 0.34 | 0.43 | 0.50 | 0.50 | 1.96 | 0.55 |

| Mg2+ | 5.88 | 0.46 | 0.60 | 0.66 | 0.73 | 2.55 | 0.46 |

| K+ | 0.39 | 0.025 | 0.030 | 0.031 | 0.032 | 0.155 | 0.030 |

| Zn2+ | 0.26 | 0.017 | 0.020 | 0.022 | 0.025 | 0.079 | 0.039 |

| Mn2+ | 0.0037 | 0.0020 | 0.0023 | 0.0021 | 0.0033 | 0.0022 | 0.0026 |

| Ba2+ | 0.10 | 0.0063 | 0.0072 | 0.0087 | 0.0092 | 0.023 | 0.0010 |

| Sum | 40.87 | 2.96 | 3.45 | 3.74 | 3.82 | 21.52 | 3.72 |

| Catalyst Raw Materials | Feedstock Oil | Catalyst Loading (wt%) | Methanol/Oil Molar Ratio | Reaction Temperature (°C) | Reaction Time (h) | Conversion (%) | Number of Reuses | Ref. |

|---|---|---|---|---|---|---|---|---|

| Bagasse | Oleic acid | 10 | 20 | 45 | 24 | 85.1 | 4 | [41] |

| Cacao shell | Oleic acid | 7 | 7 | 65 | 24 | 77 | 4 | [16] |

| Cellulose | Rapeseed oil fatty acids | 20 | 6 | 65 | 6 | 87.5 | 4 | [42] |

| Peanut shell | Oleic acid | 4 | 10 | 85 | 3 | 98 | 6 | [43] |

| Coconut coir husk | Waste palm oil | 10 | 12 | 130 | 3 | 89.8 | 4 | [44] |

| Bamboo | Soybean Saponin acidified oil | 6 | 50 | 76 | 4 | 98.2 | 4 | This study |

| Esterification Method | LME | MVE | MVE (SSAO with Adsorption Treatment) |

|---|---|---|---|

| SSAO mass (kg) | 1000 | 1000 | 1000 |

| SSAO costs (USD) | 766 | 766 | 766 |

| Adsorbent costs (USD) | - | - | 23 |

| Catalyst costs (USD) | 40 | 30 | 20 |

| Methanol inflow mass (kg) | 1.25 × 103 | 5.71 × 103 | 5.71 × 103 |

| Methanol recovery mass (kg) | - | 5.18 × 103 | 5.18 × 103 |

| Methanol costs (USD) | 475 | 201.4 | 201.4 |

| Methanol heating energy consumption (kJ) | - | 8.03 × 105 | 8.03 × 105 |

| Esterification heating energy consumption (kJ) | 8.06 × 105 | 6.59 × 105 | 6.59 × 105 |

| Adsorption treatment energy (kJ) | - | - | 1.77 × 105 |

| Energy costs (USD) | 20.4 | 37.0 | 40.4 |

| The average mass of biodiesel produced per batch (kg) | 703.8 | 684.1 | 672.3 |

| The average production cost of biodiesel (USD/kg) | 1.85 | 1.51 | 1.56 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, B.; Wang, X.; Tang, W.; Wu, C.; Wang, Q.; Sun, X. Carbon-Based Solid Acid Catalyzed Esterification of Soybean Saponin-Acidified Oil with Methanol Vapor for Biodiesel Synthesis. Sustainability 2023, 15, 13670. https://doi.org/10.3390/su151813670

Zhang B, Wang X, Tang W, Wu C, Wang Q, Sun X. Carbon-Based Solid Acid Catalyzed Esterification of Soybean Saponin-Acidified Oil with Methanol Vapor for Biodiesel Synthesis. Sustainability. 2023; 15(18):13670. https://doi.org/10.3390/su151813670

Chicago/Turabian StyleZhang, Bingxin, Xiaona Wang, Weiqi Tang, Chuanfu Wu, Qunhui Wang, and Xiaohong Sun. 2023. "Carbon-Based Solid Acid Catalyzed Esterification of Soybean Saponin-Acidified Oil with Methanol Vapor for Biodiesel Synthesis" Sustainability 15, no. 18: 13670. https://doi.org/10.3390/su151813670

APA StyleZhang, B., Wang, X., Tang, W., Wu, C., Wang, Q., & Sun, X. (2023). Carbon-Based Solid Acid Catalyzed Esterification of Soybean Saponin-Acidified Oil with Methanol Vapor for Biodiesel Synthesis. Sustainability, 15(18), 13670. https://doi.org/10.3390/su151813670