1. Introduction

The economic environment of companies is subject to continuous change. Megatrends—long lasting trends that affect society globally—such as globalization and the increasing demand for personalized products result in a segmentation of markets. This forces producing companies into niches in which they specialize more and more [

1,

2]. This results in a significant increase of internal variety in the long term, followed by higher complexity costs. As a solution, the literature often refers to the development of modular product architectures, which enable offering a large external variety of products with fewer internal components [

1,

2,

3,

4].

However, the development of modular product architectures is only one solution. An alternative strategy is enabled by the transformation of the economy towards a service society [

5]. This transformation is known as servitization and is frequently discussed in the literature [

6,

7]. Rather than selling tangible products, these can, according to the idea of servitization, also be combined with product-related services [

8,

9,

10,

11,

12,

13] to form the so-called Product–Service Systems (PSS) [

10,

14]. PSS can increase customer loyalty, enable constant revenue, offer other advantages (see [

8,

15,

16,

17,

18]) and are an enabler for servitization. In addition, they allow addressing individual customer needs by customizing the physical product and providing individual service solutions [

19,

20,

21,

22,

23]. This condition increases the solution space in product development [

19].

In parallel, the relevance of sustainability is increasing worldwide. Manufacturing processes can be optimized to improve the sustainability or environmental footprint of products; however, new circular-based business models usually provide the greater leverage. PSS serve as the foundation for this and can significantly improve the sustainability of products [

9,

11,

17,

24,

25] or enable sustainable business models [

26,

27].

A significant challenge for the successful implementation of PSS is the increased complexity [

28,

29,

30]. This is caused by the added services and the interactions between services and products [

28] that are necessary for implementing PSS-based business models. The effect is amplified because PSS providers rarely transform their business model entirely, but offer different business models in parallel [

27] and develop individual solutions for customer-specific problems. This increases complexity even further by resulting in a high variety of PSS-based business model variants.

A solution proposed in the literature for this challenge is the development of modular PSS [

31,

32,

33,

34], as modular PSS allow the configuration of different PSS variants based on a small set of product and service modules. As PSS are often developed as customized solutions [

35], an initial approach for the development of modular PSS families has already been presented in a previous contribution [

36]. This contribution aims to present the method developed based on this initial approach and to show and critically discuss its application using an industrial example of a product family of pressure-reducing valves.

2. Research Methodology

The research design within this study is based on the Design Research Methodology (DRM) by Blessing and Chakrabati [

37]. Based on an initial literature search (Research Clarification) and discussions with project partners (mostly German machinery and plant engineering companies) and in-depth analysis of the literature found (Descriptive Study I), the need for research was identified (see

Section 3). Requirements for methodological support for the development of modular architectures for PSS are derived. Based on this, a methodological support was developed in a prescriptive study. An industrial context was used to apply certain parts of the method iteratively and to discuss it with experts during development. The initial description of the approach was published as a framework in [

33], with further refinements of the individual steps after that (see [

38,

39,

40]). To describe the method in

Section 4, a summary and enhancement of previous publications’ content is used. The last stage of the DRM comprises evaluating the method in Descriptive Study II regarding the three criteria comprising

usability,

applicability and

usefulness. For this purpose, the developed method is applied by an external method expert in a company on a product family of pressure-reducing valves, for which a mechatronic module kit will developed that already considers possible service-based business models (

Section 5). During the application, the interim results are frequently discussed with company representatives to collect their feedback and include it in the application of the following steps. This information is used to check the usefulness of the method. The results of the example application are analyzed and discussed afterwards (

Section 6). Therefore, a retrospective data collection, common in industrial settings, is performed with the help of a semi-structured interview, as proposed by Blessing and Chakrabati [

37] to validate the method regarding usability and applicability.

3. State of the Art

Product-centric servitization is the extension of existing products to include services, and is a topic that has become increasingly relevant in recent years [

6,

41]. To implement servitization, Product–Service Systems (PSS) are required as a foundation [

6]. PSS consist of a product and a service that share and represent an added value for the customer [

8,

9,

11,

14]. There are various description [

42] and classification systems for PSS in the literature [

36]. However, in this study, only the categorization according to Tukker [

9] with the three categories comprising

product-oriented,

use-oriented and

result-oriented classifications will be used, since this is the most established classification [

7].

3.1. Challenges in PSS Implementation

PSS enable numerous benefits for providers and customers, such as stronger customer loyalty, opportunities for differentiation against competitors or better adaptation of products to customer requirements [

8,

16,

19,

43]. However, there are also challenges in PSS. Several studies can be found on this topic in the literature. Matschewsky et al. [

15] have identified challenges in the context of PSS. Examples of this are the changing customer requirements compared to traditional products [

16], the development of a PSS itself [

16,

44,

45,

46] and also the increase in complexity for the PSS provider [

29].

Complexity in the context of PSS is also addressed in a study by Zou et al. [

28]. The authors analyzed 23 publications and assigned the identified complexity drivers into the following four categories:

multiplicity,

diversity,

interdependence and

variability. Notably, 19 of the 23 publications contain drivers from the diversity category. Drivers are counted in this category if traced back to the increasing number of elements, subsystems, activities and stakeholders. Examples of this comprise the

amount of service components [

20],

number of parts [

47] or

variety of service offerings [

48]. Complexity analysis is not limited to PSS since service processes are generally complex [

49], and complexity drivers have been specifically investigated in the context of services. Benedettini and Neely [

50] analyzed 76 complexity drivers and clustered them into a framework according to the

nature of complexity,

source of complexity,

complicatedness and

difficulty.

Some publications mention high complexity for the PSS provider as the main challenge for successfully implementing PSS [

28,

30,

31,

51]. However, as the authors use different categorizations, the literature results were re-evaluated. This analysis revealed that most complexity drivers can be traced back to the increase in the internal variety of products, services and processes (see [

33,

40]). This complexity can be referred to as

variety-induced complexity. In addition, complexity also arises from integrating customers into the PSS processes. However, this will not be considered in this article.

Companies usually do not completely transform their business model, but offer several business models in parallel [

16]; hence, the internal variety can increase further. Thus, one of the main challenges in PSS is the increase in variety-induced complexity. Therefore, a method for developing PSS should simultaneously reduce variety-induced complexity.

3.2. Development of Modular Product–Service Systems

Specific methods are required for the development of PSS [

8,

16,

17,

52]. Particular focus should be placed on the early phase of PSS development to design the dependencies between products and services as efficiently as possible [

10,

25]. Concerning the previously shown challenge of complexity increase, the methods dealing with modularization of PSS are especially interesting since modularization is mentioned in the literature as one approach to reduce complexity in PSS [

31,

32,

33]. For instance, a modular design of PSS allows to provide customer-specific solutions while reducing development times and costs [

17]. Various approaches exist to modularize, and are often based on the same four steps [

53]. Modular architectures are an established concept in the product [

1,

2] and service domain [

54].

Existing methods can be divided into two groups, with some methods focusing on the service during modularization [

20,

21,

55,

56,

57], while other methods modularize product and service together [

32,

58,

59,

60,

61]. For the modularization itself, these methods usually rely on matrix-based methods, e.g., [

20,

62], and do not consider all life phases [

39,

63]. However, to master variety-induced complexity in the long term, PSS strategic module drivers must also be considered for module creation in each life phase. The development of modular architectures from the perspective on individual life phases is an established approach in product development but is not yet sufficiently performed by existing methods in PSS design [

39]; however, it represents a significant lever in variant management.

3.3. Design of Mechatronic Systems

As information processing is an essential enabler for servitization and PSS, the development of mechatronic systems should be considered too. In mechatronic systems, electronics and information technology are integrated into mechatronic subsystems, enabling the information to be transmitted and processed [

64,

65].

Since new requirements for the product or data acquisition and processing arise during the development of PSS, mechatronic systems must be developed as an integrated part of the PSS.

During the development of mechanical systems, the main issue is the distribution of the requirements among the involved disciplines. This distribution generates discipline- and domain-specific designs, which can be re-integrated into the overall product. Here, it is essential to remember that the dependencies between the disciplines or domains should not be considered as entirely separate from each other. Therefore, interfaces between the designs must be explicitly integrated into the development of such mechatronic systems [

66,

67,

68].

Similar to the increase in complexity, due to the additional services described above, adding mechatronic components also increases the variety-induced complexity and thus should be handled systematically [

67]. Again, modularization can be applied to manage the increase in complexity.

Methods for modularizing mechatronic systems can be divided into technical–functional methods, as well as product-strategic approaches. For instance, Askhøj et al. [

69] create cross-disciplinary modules in which the interactions within the functionality and thus their technical–functional coupling are highlighted. Van Beek et al. [

70] use hierarchical functional structures to identify interfaces and categorize them into modules in terms of function. In addition, there are also product-strategic approaches, as by Zuefle et al. [

71], who juxtapose module drivers of different disciplines, or domains, and harmonize them accordingly to a previous technical–functional modularization.

Each of these approaches allows mechatronic systems to be designed as modular products and thus can be used to develop modular architectures for PSS.

3.4. Development Business Models for PSS

Different definitions exist for the concept of business models [

72]. A business model describes the mechanisms of a company to generate revenue [

73,

74]. According to Gassmann et al. [

75], a business model comprises the following four dimensions:

Who,

What,

How and

Value. In the context of this research, the

How is especially of interest, as it is the connection to the modular architectures that are needed to enable the

How.

As modularization of PSS is initiated late in the development process, variety-induced complexity needs to be addressed early in the development of business models. Since companies often offer different business models in parallel, these business models should be developed as a business model family [

36]. All business models should be realized based on the same elements with the smallest possible number of product and service elements. Existing approaches to identify PSS-based business models usually focus on the development of single business model variants (see, e.g., [

76,

77,

78]).

However, approaches that support the development of multiple business models [

79,

80,

81] neglect the aspect of variety.

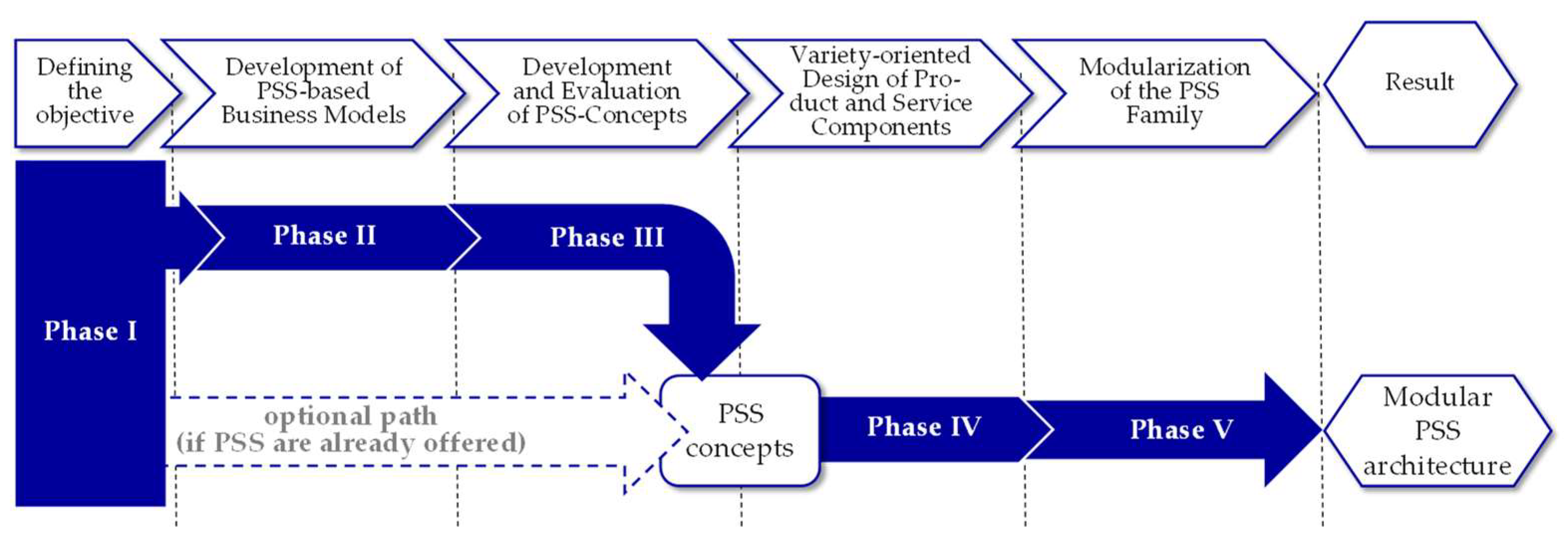

4. Method for the Development of Modular Architectures for PSS

In order to overcome the issues identified in

Section 3, the following method was designed. It aims at the reduction of the variety-induced complexity by focusing on the development of a PSS-based business model family and a sub-sequential life phases modularization of this business model family. A previous publication [

33] introduced this method’s general framework, which comprises five phases that run sequentially and have since been refined. The method targets small- and medium-sized companies that want to expand their market reach by creating PSS-based business models and offering product-related services. The structure of this method is shown in

Figure 1.

A sequential flow of the phases is shown, but, within the phases, an iterative and workshop-based development of the contents is foreseen so that new insights can be included and considered in the development at any time. The workshop-based approach enables the (external) method experts to collaborate efficiently with the company’s internal technical experts. The outcomes of this method’s applications are possible PSS-based business models with the corresponding modular product and service architectures that are required to offer business models.

4.1. Defining the Objective (Phase I)

The first phase begins with a review of the company’s strategy and objectives. The aim is to clarify whether the new PSS to be developed should offer new products to existing customers or to enter new market segments.

For this, unfulfilled customer requests are evaluated together with the sales department to decide whether these could have been fulfilled with a higher degree of servitization. Additionally, a

SWOT analysis [

82] can define the strategy regarding PSS. This allows a comparison of strengths and weaknesses along with opportunities and threats and uncovers the potential for PSS, and is already being used in the context of PSS (see [

77,

83]). Alternatively, compared to the

SWOT analysis, other methods and tools can be used for strategic planning. One example is the Impact Model of Modular Product Families (IMF) [

84], which links the characteristics of modular product architectures to the economic targets of

time,

cost,

quality and

flexibility via life-phases-specific impact chains. The generic model can be adapted to a specific company and used for an objective evaluation of alternative concepts [

84]. The result of this phase is the company’s objective regarding PSS.

4.2. Development of PSS-Based Business Models (Phase II)

Systematically identifying potential PSS-based business models that fit the company and its existing products is the objective of the second phase. For this purpose, the Business Model Graph (BMG) was developed [

38].

Figure 2 presents the solution space for PSS-based business models in the BMG (see

3 in

Figure 2) by plotting the Product–Customer Interaction (PCI) on the vertical axis (see

1 in

Figure 2) and the PSS continuum according to Oliva and Kallenberg [

5] with the PSS archetypes according to Tukker [

9] on the horizontal axis (see

2 in

Figure 2). The PCI describes the activities that the customer is performing in connection with the products in question, as these can be performed by the provider in the context of a PSS. The PCI is described from a customer’s perspective, with a focus on the use of the product. With the help of the solution space, possible new business model concepts can be identified by varying the two axes. A detailed description of the PCI and BMG is available in the literature [

38].

The business model concepts identified with the help of the BMG (see

4 in

Figure 2) are discussed in a workshop with company representatives from sales and product management. The business model concepts that are most promising for the company are then chosen. A business model concept primarily describes the activities that are performed by the provider and the billing mechanism, in other words, the mechanism used to generate revenue. The selected concepts are then detailed using the Business Model Canvas (BMC). The BMC describes the critical elements of a business model based on nine fields [

74] and is used in the literature as an established tool in various methods for the development of PSS (see e.g., [

76,

77,

85]).

The outcomes of the second phase are the documented business model concepts, which are elaborated to PSS concepts in the next phase.

4.3. Development and Evaluation of PSS-Concepts (Phase III)

Based on the previously selected business model concepts, possible PSS concepts and corresponding PSS architectures are developed in this phase. To do this, the process steps that are performed by the customer in relation to the considered product are initially collected based on the PCI. Examples of this are

machine monitoring,

process planning, but also the

procurement of raw materials or the

configuration of machines. In a second step, these customer processes are analyzed to determine which of them creates value for the customer, and the Value-Providing Mechanism (VPM) is properly defined. In the third step, the activities and/or functions required on the supplier’s side to fulfil the VPM are specified. This relationship is shown schematically in

Figure 3.

As the next step, potential principle solutions are developed for the provider activities/functions. These are arranged in a morphological matrix after consistent solution concepts are assembled. These solution concepts are called PSS architectures. A PSS architecture comprises the product and service elements, as well as the associated product and information flows, and thus represents the physical and functional structure of the PSS.

Different available tools are combined to create the visualization of the PSS architectures. The selected principle solutions, which are to be arranged to an architecture, form the basis. They are arranged according to their allocation in the product or service domain. In the product domain, the Module Interface Graph (MIG) [

1] can provide orientation as a simplified representation of the product. Around the MIG, the elements are arranged according to how they interact with the customer in a service blueprint adapted from Shostack [

49]. Finally, the flows and functional interdependencies are added, like in the MIG or as suggested by Maussang et al. [

86]. Optionally, the values of the elements could also be added, as shown by Bertoni et al. [

87].

Figure 4 shows the template of a PSS architecture (above in

Figure 4) and due PSS architecture for a mobile laser processing machine (below in

Figure 4).

The evaluation of the PSS architectures is performed regarding the following three dimensions:

technical feasibility,

economic efficiency and

attractiveness for the customer. Specific evaluation criteria which are to be evaluated depend on the company and cannot therefore be specified in a generally accurate manner. Regarding the technical feasibility, it must be considered that technical solutions, which do not yet exist, can be implemented subsequently by developing mechatronic systems and improving various factors, e.g., economic efficiency. Moreover, the aspect of sustainability can also be evaluated for concept selection. For this purpose, existing approaches from the literature [

24,

88] can be used.

4.4. Variety-Oriented Design of Product and Service Components (Phase IV)

The goal of this phase is to optimize the previously selected PSS architecture regarding the variety of the product and service domains. For this purpose, the tools of the Variety Allocation Model (VAM) (see [

1,

40]) for the product domain and the newly developed Resource Allocation Model (RAM) for the service domain are used. The two models are linked via the business models.

Figure 5 shows the structure of the VAM and RAM and their linkage.

The VAM comprises four levels. The top level lists the product properties relevant to the customer, while the bottom level lists the variant product components. The relationships between the outer levels are made via the levels of the functions and the operating principles. Further information about the VAM can be found in the literature (e.g., [

1]). For the service domain, the RAM connects the service characteristics (the individual services offered) via the corresponding activities in the second column, the types of fulfillments in the third column with the resources and competencies required for the service in the fourth column (see

Figure 5).

There are already design guidelines and ideals for the VAM, which support a reduction of the variety. For the RAM, these are redefined. For instance, resources and competencies should be bundled to increase their utilization. The same objective is pursued by the n-to-1 assignment, where the aim is to increase utilization by fulfilling the offered services (n) with the smallest possible number of resources (ideally 1 resource). This objective allows us to reduce the variety on the product and service domain. The final concept for the service domain, documented in the RAM, can additionally be converted into a service blueprint.

A more comprehensive reduction of variety is possible by linking the business model to the VAM and RAM. For this purpose, the business model is linked to the product and service characteristics that are relevant for the customers in the respective business model. The more service-based a business model is, the less relevant the customizability of the physical product is and the more diversified the service offering becomes [

38]. Therefore, for a result-oriented PSS, fewer product features will be relevant to the customer compared to the as-is situation. This often allows us to standardize the components linked to the feature that is no longer relevant and thus to further reduce the variety. Since several business models are covered by one architecture, the linkage of business models, the VAM and RAM, represents the whole PSS family and allows us to align the PSS architecture with the business model family and to develop a PSS family.

Figure 6 schematically shows the relationship between the different types of business models (BM1 and BM2) and the related product and service structures. It is evident that, for product-oriented business models, the focus lies on the product domain and only a few services are offered. In contrast, the service architecture becomes more complex with a results-oriented business model and variety and thus complexity can be reduced on the product domain.

Using this phase requires an existing product portfolio to be used as a starting point. If the existing products cannot technically realize all the elements specified in the PSS architecture, it is necessary to enhance these components to mechatronic systems in a parallel development project. The authors recommend an agile approach for the combination of the two development processes. Thereby, the differing requirements for the new PSS family can be iterated collaboratively and be synchronized with each other in the development within different domains. This step-by-step collaborative approach enables the necessary new mechatronic components to be developed at an early stage with a very high degree of coordination.

The outcome of the phase is a PSS family whose components have been optimized regarding variety and which can be clustered into modules in the following phase.

4.5. Modularization of the PSS Family (Phase V)

The last phase focuses on the modularization of the PSS family. This modularization is based on the Life Phases Modularization (LPM) [

1] developed for products. In this, technical–functional modularization approaches are combined with product-strategic modularization by using network diagrams and module drivers. The LPM is extended for the application in PSS by the dimension of the service perspective [

39], e.g., by using new module drivers in the context of PSS [

39]. PSS can increase sustainability by covering the entire life cycle of the product [

26,

89]. Then, the LPM considers each product life phase separately and harmonizes them afterwards which enables sustainability potential to be exploited effectively.

Figure 7 shows how technical–functional and PSS-strategic approaches are combined.

The first step is modularization from a technical–functional perspective. Here, for example, a matrix-based performance can be applied using functional dependencies between components. Examples of these methods are given in

Section 3. Alternatively, the heuristics, according to Stone et al. [

90], can be applied to the functional structure of the PSS family in order to develop modules from a technical–functional perspective. For the product- or PSS-strategic modularization, a network diagram is prepared for each life phase of the PSS family. This links so-called module drivers and the more specific module driver characteristics with the product and service components. Based on this connection, modules are defined for each life cycle phase, which are harmonized across all life phases afterwards. This enables a reduction in complexity within the processes, reduces development times and opens up further potential for modular (product) architectures. A detailed description of the approach to PSS strategic modularization can be found in [

39]. It should be emphasized that, because of the unique characteristics of services (e.g., simultaneous production and consumption), not all service components are present at every life phase. For example, service components are considered in modularization from a development perspective since the functional relationships are relevant there. Whereas, in the production life phase, services are not modularized because they cannot be created and stored alongside the physical product.

The result of the last phase is a consistent modular architecture for the PSS family, which can be transferred for further use, e.g., to design a configurator.

5. Application of the Developed Method

The developed method was applied to the example of a product family of pressure-reducing valves (see

Figure 8). The main function of the valves is to reduce a varying inlet pressure to a constant and lower outlet pressure. The outlet pressure can be adjusted during the usage. The starting point was a small German valve manufacturer with an existing product range of solely mechanical pressure-reducing valves. As a result of a growing diversity and very heterogeneous customer structure, a great external product variety had arisen over the years, which also led to a high internal variety, variety-induced complexity and finally to increasing (complexity) costs. For the following product generation, a module kit was to be developed that would enable a more efficient configuration of the valves but would also be capable of supporting future PSS-based business models. To achieve this goal, the previously presented method for the development of modular architectures for PSS was applied.

Excerpts of the results are presented in the following subsections. In parts, simplifications have been made for reasons of confidentiality.

5.1. Results of Phase I

The core competence of the valve manufacturer is the development and production of valves adapted to applications in a wide range of industries. A SWOT analysis showed how the company’s strengths (e.g., expertise in pressure-reducing valves) can exploit the identified opportunities, e.g., strengthening customer loyalty and increasing the company’s share of the value chain.

Weaknesses and, above all, risks of implementing PSS exist, but the opportunities outweigh them. Hence, the following objective was defined: Through the development of PSS, existing customer groups should be kept, and new customer groups should be acquired. The PSS should secure the market position and at the same time be used for advertising. In addition, the PSS should increase the amount of value added by the valve manufacturer without increasing the company’s internal variety and thus reduce the costs.

To enable a more objective evaluation of concepts, a company-specific IMF was created in collaboration with the company. Of the 68 impact chains included in the IMF, a total number of 17 chains were selected that particularly interest the company and that should be considered in the concept evaluation (see the last figure in

Section 6 for an excerpt). The selected impact chains primarily describe the effects of an increase in commonality on process times. One example is effect chain

No. 1210, which describes how an increase in commonality can reduce the number of components, resulting in less administration of parts and reduced part search times. This can reduce development times and thus reduce the costs.

5.2. Results of Phase II

As an excerpt of the results of the second phase,

Figure 9 shows the BMG for the considered product family of pressure-reducing valves. The left side of

Figure 9 shows the BMG for the existing, purely mechanically actuated pressure-reducing valves. The lack of sensors respectively to the lack of the ability to collect operational data limits the solution space to a large extent. The limits of the solution space can be expanded by developing technology so that customers can be offered additional benefits such as condition monitoring or suggestions for process optimization. To define the requirements for technology development, the business model concepts are first generated to derive specific requirements for the sensor technology in the third phase of the method. The BMG on the right shows that some use-oriented business models are not relevant. This refers to sharing and pooling, as these are not relevant for the valves as individual components of a more extensive system. Besides the consultancy service (1) and the leasing of the valves (2), the result-oriented PSS are interesting (3–5) since they cover a large part of the PCI and thus open up a high value-added potential.

The business model concepts were refined with the help of BMCs. It was decided by company representatives that all concepts should be pursued to minimize the risk of prematurely excluding possible solutions.

5.3. Results of Phase III

In the third phase, the customer processes associated with the business models and provider activities/functions required for these processes were identified. The results are shown in

Figure 10. In the level of customer processes, the entire workflow of the process steps is shown, including information on whether the customer or the provider assumes responsibility in each case. The level of the VPM in

Figure 10 describes the aspects the customer will pay for, in other words, the value proposition.

Figure 10 illustrates that many process steps are relevant for all or almost all business models and that the responsibility for these steps therefore lies with the provider of the PSS, e.g.,

maintain valve (see 1 in

Figure 10). In contrast, process steps such as

adjust plant setting or

propose plant settings are classified as relevant for only two business models (see 2 in

Figure 10). Eight VPMs were found for the process steps, for which the required supplier activities and functions were defined. During the development of the functions, it became apparent that sometimes several VPMs can be fulfilled by the same set of functions. An example of this is the installation and setting of valves (see 3 in

Figure 10).

Using the analysis as a basis, internally consistent PSS architectures are developed with the help of a morphological box. The premise that all five identified business model concepts should be covered remains valid.

Figure 11 shows two possible architecture alternatives. The scope covered is identical, only the realization varies. Concept I (on the left in

Figure 11) is structured in such a way that a technician of the customer is assigned a central role. This technician is involved in almost all VPMs and, for example, reads out sensor data on site or performs maintenance independently (under supervision). Concept II (on the right in

Figure 11), by contrast, is designed in such a way that data are automatically transmitted to the provider for evaluation and a technician from the provider travels to the customer, if necessary.

Assessing the two concepts revealed that Concept I has lower manufacturing costs and lower development costs. Additionally, by involving the customer’s technician, fewer resources are required for the operation from the supplier’s point of view. In contrast, the development costs and manufacturing costs, because of additional electronics, as well as the resources required, are higher for Concept II. Despite these drawbacks, Concept II is pursued further since the benefits and thus also the attractiveness to the customer are significantly higher in this case. With the PSS based on the architecture of Concept II, customers can order an “all-inclusive” package and no longer have to worry about the operation of the valves. From the valve manufacturer’s point of view, there is a significant hidden potential in this field, especially for safety-critical applications where the failure of a valve can lead to expensive downtimes for entire plants.

5.4. Results of Phase IV

The next phase is to establish the product and service structures for the selected PSS architecture using the VAM and RAM. The aim is to translate the BM, and the value proposition behind it, into specific product and service components, respectively.

Figure 12 shows an excerpt of the two models with the link to the business models.

In the product domain, the VAM was generated based on the existing products.

Figure 12 shows that the customer-relevant property

condition monitoring is relevant for Business Model 5, but not for Business Model 2. This mapping results from the customer processes (see

Figure 11). The goal of the fourth phase is to reduce the variety of the PSS architecture as much as possible. The VAM supports this. An example is the implementation of the outlet pressure control (see

1 in

Figure 12). The function

maintain constant pressure can be realized by two different principles, which are implemented by different components. In the process of variety reduction, the change of the effective diameter is removed as a working principle so that the variety caused by this for the

body is also eliminated. The combined approach of reducing the (mechanical) variety and simultaneously developing the innovative sensor technology is shown in

Figure 13. The development of the sensor technology was done in short development cycles, which were aligned with the primary process of variety reduction at defined points within the development cycle. This ensured an efficient development despite unclear requirements for the sensor technology at the beginning.

In

Figure 12, area

2 illustrates that the data transfer for condition monitoring can be carried out either manually via a flash drive, or wirelessly via an antenna. Since condition monitoring is not required for all business models, relatively lower quantities are expected here. Considering the pros and cons, it was decided to offer only the wireless solution as it offers more functionalities. The variety, due to the manual readout of the data, is eliminated.

In the service domain, an initial service design was performed, since only a few services were available so far. In some cases, different possible solutions were devised and added to the RAM. The area marked with

3 was identified for the subsequent variety reduction and increase in resource utilization (see

3 in

Figure 12). The

valve set-up can either be performed by a technician on site, or the customer can be enabled to do this by using augmented reality. Since the resource

AR glasses would only be used for this purpose, the alternative solution should be eliminated from a variety viewpoint. This simultaneously increases the utilization of the

technician resource, which is needed for all customer-relevant service features shown.

Logistics and

data analytics are also used only to a limited extent, such as the AR glasses, but cannot be replaced and thus they are kept.

The results of the phase are the product components and service resources optimized with regard to variety. By linking in the VAM and RAM, the previously described abstract PSS architectures are linked with specific product and service components. This describes the PSS family.

5.5. Results of Phase V

An important constraint for the modularization from the company’s perspective is the fact that the valves should also be available without additional services and sensors. For this reason, the modularization process attempts to distinguish the service and sensor components as independent and thus optional modules from the actual valve as far as possible. For the LPM, a technical–functional modularization was first performed using the PSS function structure (shown in

Figure 14). The service activities and processes were clustered according to the information flow between these and highlighted in different colors. This modular structure helps to identify the corresponding activities and processes if, for example, the customer orders maintenance or the business model is based on a monthly fee.

This was followed by modularization for the individual life phases by using network diagrams. An excerpt of the results for the module architecture of the product domain is shown in

Figure 15. It is evident that the module structures of the life phases differ from each other and contradict each other in some cases. For example, while the connector (CO) and body (BO) should be considered separately from the perspective of the development life phase, the two components should form a common module from the perspective of the usage life phase. These contradictions were resolved by harmonizing the various module structures and creating a homogeneous module architecture for all life phases of the company.

6. Discussion of the Results and Evaluation

This section is organized in two parts. First, the result of the method is discussed, followed by a detailed discussion of the application of the method.

6.1. Discussion of the Developed Concept

To evaluate whether the method has increased the service share in the business models, the

servitization index SI was developed. The index describes the degree of servitization based on the identified business model concepts in the BMG (see

Figure 16). The index ranges between the extreme values 0 (no service share) and 1 (max. possible service share).

For the initial situation before the development of the PSS family, the index is calculated as follows:

In Phase II, possible PSS-based business model concepts were identified with the help of the BMG. For these, the index is calculated as follows:

While comparing SI,1 and SI,2 it becomes clear that the service share in the business models increased significantly because of the application of the method.

In order to evaluate the effects on complexity, it was examined how the internal variety could be reduced by the developed concept.

Figure 17 illustrates that the internal variety could be significantly reduced. The modular product architecture developed enables a reduction in the number of components from 109 to 44, while at the same time 6 components can be standardized. If the additional sensor technology components required to provide the new business models are considered, the number of components increases slightly again, but even in this case the internal variety can be reduced by approx. 51%.

The effects of the variety on the economic target values, for example, costs, are visualized in the IMF for the valve manufacturer in

Figure 18. In the IMF, it is evident how the reduction of variety affects costs and process times, which can also be converted to costs. For information on how key figures can be used to calculate the impact chains see [

84]. For reasons of confidentiality, not all relevant impact chains and no quantitative data are mentioned. Instead, it is qualitatively shown how the concept affects the economic target values. This is performed by comparing the current reference (dashed circle) and the changes resulting from the developed modular architecture concept.

Figure 18 shows the effects of the developed concept that are primarily positive for the company. In the life phase of product development, the process times can be reduced noticeably. In procurement, the standardization enables improved purchase conditions and in the life phase production the potential for automation increases. Nevertheless, there are also negative effects, such as the increase in product volume and thus also in product costs due to oversizing.

Since no services have been offered to the extent developed so far, no reliable comparison could be made between the initial status and the concept in terms of service complexity. However, according to statements by the company, the variety-oriented design of the PSS family that has been achieved will enable the services to be implemented with a low level of complexity in the future. The modular product architecture developed, together with the planned services, provides the basis for offering a future-proof overall product.

6.2. Discussion of the Application of the Method

To evaluate the application of the developed method, an external method expert worked closely with the company to generate the results. During this process, the preliminary results were regularly reviewed and discussed (e.g., with the managing director, head of sales and the product manager). This allowed feedback on the results to be directly integrated into subsequent steps and to gather information regarding the usefulness of the method. As a final part of the method application, a semi-structured interview with the product manager of the company was conducted to record the company’s feedback on the method with a focus on usability and applicability. The one-hour interview was conducted digitally via Zoom after the last phase of the method was applied. Besides the interviewer, a third person was attending to protocol the answers. The interviewer asked a set of five higher-level questions regarding the application of the method. The focus was placed on questions concerning the comprehensibility and applicability of the method, as well as which parts of the method will be used for future development projects. The interviewee’s answers are the basis for the following discussion of method application and are given in quotation marks.

As the company had no previous knowledge about the development of PSS before, the method was described as very helpful with the following extract: “The method’s structured approach and the tools and visualizations provided enabled the company to develop a modular PSS family in a comprehensible and reproducible manner”. This closes one of the research gaps identified in

Section 3. The newly developed BMG was highlighted. This vividly visualized which aspects need to be considered in the development of new business model concepts. In the case of the pressure-reducing valve, the BMG showed “which business model options can be exploited through the development of technology” in a targeted manner. Since its introduction, the BMG has also been used internally in other projects to communicate within the company.

Phase IV’s approach, i.e., the development of the VAM and RAM and their linkage, was likewise highlighted with the following extract: “The VAM summarizes the relationships between components and product properties and allows specific components to be identified for redesign”. The RAM is a helpful tool for the initial planning of complex services as it shows which process steps and resources are required for which services. This enables a reduction of variety that existing methods cannot offer (see

Section 3). To summarize, the tools and visualizations of the

Phase IV document the implementation of the PSS concepts very well and can be used as a repository of information. Through visualizations, the relationships could be documented in a comprehensible way and therefore “still be used as a reference for the following product generation development or other development projects several years from now”.

From the company’s point of view, a criticism is the extent of specific visualizations. As an example, the PSS architecture was mentioned and described as follows: “It [the PSS architecture] requires more effort to familiarize oneself with, but once an understanding has been gained, it can reveal possible complications in the flow of information and customer communication”. The second visualization that is rated as too extensive at first glance is the representation of the customer processes and provider activities/functions. Again, this visualization requires additional effort for familiarization. However, the higher effort for familiarization enables the potential for monetarization to be shown via the VPM. The VPM “can be used as a basis for realigning the product portfolio with the sales department”.

In the example application, the implementation and preparation of the data using Microsoft PowerPoint 2021 were emphasized as an advantage, especially for SMEs, since no special software would have to be introduced. However, this type of implementation could be too time-consuming for more complex products. In such a case, it is advisable to support the method in a model-based manner with special software since even large amounts of data can be handled in this way. The model-based implementation has already been successfully realized for

Phase V of the method (see [

39]).

The considered valves are a particular application example because they are a relatively inexpensive component of larger plants and systems. In the past, rather high-priced capital goods were discussed in the context of PSS [

6]. The pressure-reducing valves represent an example of the increasing relevance of product-centric servitization, in which existing products are extended by services. Since the valves are only one component of larger systems, PSS-based business models for pressure-reducing valves will not be relevant for all customers. This is exacerbated because data sovereignty between manufacturer, system integrator and customer is often not clarified. Nevertheless, PSS can be relevant for particular applications of the valves. For example, PSS can be relevant when valves are installed in safety-critical systems and malfunction-free operation must be guaranteed. This is consistent with the findings from the literature which depict that companies in the context of PSS rarely undergo a complete transformation of the business model, but somewhat different business models are offered in parallel [

16]. In such cases, in which the existing product is offered in different configurations across different business models, the presented method represents an added value for manufacturing companies, which are supported by the five phases in developing modular PSS architectures for the above-described boundary conditions.

Regarding this study’s quality, it is noted that a single example of method application per se only permits claims to be made for comparable applications. For generalizable statements regarding validation, further validations must be carried out on other product examples.

7. Conclusions and Outlook

In this article, we introduced the topic of Product Service Systems (PSS) in general and discussed literature-based challenges in the implementation of PSS afterwards. It was shown that the most frequently named complexity driver is the increasing variety in the context of PSS. Therefore, variety-induced complexity can be seen as the main challenge in the development and implementation of PSS. Next, two possible levers to reduce the variety-induced complexity were analyzed, along with the respective research gaps.

To close these gaps, an approach has been outlined in earlier publications, which was described holistically for the first time in this paper and was refined into the Method for the Development of Modular PSS Architectures. The five phases of the method and the corresponding steps and tools were described using the example of a mobile laser processing machine. Afterwards, the method was applied to the example of a product family of pressure-reducing valves, for which a module kit was developed that already foresees potential future PSS-based business models and reduces the total number of components by 50%. By applying the method, it was possible to develop a business model family comprising five business models that fit the given company and product constraints. Among other tools, the newly developed Business Model Graph was used for this purpose. To implement the business model family, two alternative PSS architectures were designed, which were evaluated regarding the criteria of cost-effectiveness, technical feasibility and attractiveness for the customer. The chosen architecture was then refined, and the related product and service components were optimized in terms of variety. Finally, the PSS family was modularized to get a module kit that can be used as the basis for configuring PSS to meet individual customer requirements in the future.

The application of the method was evaluated through an analysis of the process, continuous exchange with the participating company and a final interview. The evaluation proved that the method is suitable for the development of modular PSS architectures and that the newly developed tools such as the Business Model Graph are used in the company for other projects as well. The mentioned points of criticism mainly refer to the partly complex visualizations, which can be eliminated by software support. Overall, the method can thus be considered validated within the restrictions of a single example application. From the practical application, it can be concluded that manufacturing companies, especially SMEs, are enabled by the method to develop PSS and the supporting architectures that match their existing products. The visualizations support the preliminary planning of the services, in particular, they enable an initial service concept to be developed quickly, which can be used as a starting point for further detailing in the company.

The restrictions of an example application are at the same time the limitation of this contribution. The results of a method application can only be transferred to similar application examples. This implies that further studies should be conducted for a comprehensive validation. Furthermore, the identified business models with the associated PSS were not yet offered on the market at the time of the data evaluation so that no reliable statements can yet be made regarding market success and the assessments, especially regarding attractiveness for the customer, which are still subject to uncertainties.

Future work should investigate not only the application of the method in further industry examples but also the software support. For one phase of the method, the model-based implementation using SysML could already be shown, but it remains to be investigated how the other phases can be supported.

Author Contributions

Conceptualization, C.R.; methodology, C.R.; validation, C.R., M.B. and D.B.; formal analysis, C.R.; investigation, C.R.; resources, C.R.; data curation, C.R.; writing—original draft preparation, C.R. and M.Z.; writing—review and editing, D.K., M.Z. and C.R.; visualization, C.R. and M.Z.; supervision, D.K. All authors have read and agreed to the published version of the manuscript.

Funding

Publishing fees supported by the Funding Programme Open Access Publishing of Hamburg University of Technology (TUHH). This research is funded by the German Federal Ministry of Education and Research within the project MODERATED (contract number 02K20K502) belonging to the program “KMU-innovativ: Produktionsforschung”. The authors wish to thank all those involved in the empirical study for their contribution to this research.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Krause, D.; Gebhardt, N. Methodical Development of Modular Product Families; Springer: Berlin/Heidelberg, Germany, 2023. [Google Scholar] [CrossRef]

- ElMaraghy, H.; Schuh, G.; ElMaraghy, W.; Piller, F.; Schönsleben, P.; Tseng, M.; Bernard, A. Product variety management. CIRP Annals 2013, 62, 629–652. [Google Scholar] [CrossRef]

- Baldwin, C.Y.; Clark, K.B. Design Rules: The Power of Modularity; MIT Press: Cambridge, UK, 2000. [Google Scholar]

- Fixson, S.K. Product architecture assessment: A tool to link product, process, and supply chain design decisions. J. Ops. Manag. 2005, 23, 345–369. [Google Scholar] [CrossRef]

- Oliva, R.; Kallenberg, R. Managing the transition from products to services. Int. J. Serv. Ind. Manag. 2003, 14, 160–172. [Google Scholar] [CrossRef]

- Rabetino, R.; Kohtamäki, M.; Brax, S.A.; Sihvonen, J. The tribes in the field of servitization: Discovering latent streams across 30 years of research. Ind. Mark. Manag. 2021, 95, 70–84. [Google Scholar] [CrossRef]

- Annarelli, A.; Battistella, C.; Nonino, F. The Road to Servitization: How Product Service Systems Can Disrupt Companies’ Business Models; Springer International Publishing: Cham, Switzerland, 2019. [Google Scholar] [CrossRef]

- Mont, O. Clarifying the concept of product–service system. J. Clean. Prod. 2002, 10, 237–245. [Google Scholar] [CrossRef]

- Tukker, A. Eight types of product–service system: Eight ways to sustainability? Experiences from SusProNet. Bus. Strat. Env. 2004, 13, 246–260. [Google Scholar] [CrossRef]

- Alonso-Rasgado, T.; Thompson, G. A rapid design process for Total Care Product creation. J. Eng. Des. 2006, 17, 509–531. [Google Scholar] [CrossRef]

- Baines, T.S.; Lightfoot, H.W.; Evans, S.; Neely, A.; Greenough, R.; Peppard, J.; Roy, R.; Shehab, E.; Braganza, A.; Tiwari, A.; et al. State-of-the-art in product-service systems. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2007, 221, 1543–1552. [Google Scholar] [CrossRef]

- Vasantha, G.V.A.; Roy, R.; Lelah, A.; Brissaud, D. A review of product–service systems design methodologies. J. Eng. Des. 2012, 23, 635–659. [Google Scholar] [CrossRef]

- Baines, T.; Lightfoot, H.; Peppard, J.; Johnson, M.; Tiwari, A.; Shehab, E.; Swink, M. Towards an operations strategy for product-centric servitization. Int. J. Oper. Prod. Manag. 2009, 29, 494–519. [Google Scholar] [CrossRef]

- Goedkoop, M.J.; van Halen, C.J.; Te Riele, H.R.; Rommens, P.J. Product Service systems, Ecological and Economic Basics; Dutch Ministries of Environment (VROM) and Economic Affairs (EZ): Amsterdam, The Netherlands, 1999; Volume 36, pp. 1–122. [Google Scholar]

- Matschewsky, J.; Kambanou, M.L.; Sakao, T. Designing and providing integrated product-service systems—Challenges, opportunities and solutions resulting from prescriptive approaches in two industrial companies. Int. J. Prod. Res. 2018, 56, 2150–2168. [Google Scholar] [CrossRef]

- Isaksson, O.; Larsson, T.C.; Rönnbäck, A.Ö. Development of product-service systems: Challenges and opportunities for the manufacturing firm. J. Eng. Des. 2009, 20, 329–348. [Google Scholar] [CrossRef]

- Tukker, A. Product services for a resource-efficient and circular economy—A review. J. Clean. Prod. 2015, 97, 76–91. [Google Scholar] [CrossRef]

- Annarelli, A.; Battistella, C.; Nonino, F. Product service system: A conceptual framework from a systematic review. J. Clean. Prod. 2016, 139, 1011–1032. [Google Scholar] [CrossRef]

- Sundin, E.; Lindahl, M.; Comstock, M.; Sakao, T.; Shimomura, Y. Achieving mass customisation through servicification. Int. J. Internet Manuf. Serv. 2009, 2, 56. [Google Scholar] [CrossRef]

- Sakao, T.; Song, W.; Matschewsky, J. Creating service modules for customising product/service systems by extending DSM. CIRP Ann. 2017, 66, 21–24. [Google Scholar] [CrossRef]

- Song, W.; Sakao, T. A customization-oriented framework for design of sustainable product/service system. J. Clean. Prod. 2017, 140, 1672–1685. [Google Scholar] [CrossRef]

- Pine, B.J. Mass Customization: The New Frontier in Business Competition; Harvard Business School Press: Boston, MA, USA, 1993. [Google Scholar]

- Tseng, M.M.; Jiao, R.J.; Wang, C. Design for mass personalization. CIRP Ann. 2010, 59, 175–178. [Google Scholar] [CrossRef]

- Bertoni, M. Multi-Criteria Decision Making for Sustainability and Value Assessment in Early PSS Design. Sustainability 2019, 11, 1952. [Google Scholar] [CrossRef]

- Vezzoli, C.; Ceschin, F.; Diehl, J.C.; Kohtala, C. New design challenges to widely implement ‘Sustainable Product–Service Systems’. J. Clean. Prod. 2015, 97, 1–12. [Google Scholar] [CrossRef]

- Evans, S.; Vladimirova, D.; Holgado, M.; van Fossen, K.; Yang, M.; Silva, E.A.; Barlow, C.Y. Business Model Innovation for Sustainability: Towards a Unified Perspective for Creation of Sustainable Business Models. Bus. Strat. Env. 2017, 26, 597–608. [Google Scholar] [CrossRef]

- Reim, W.; Parida, V.; Örtqvist, D. Product–Service Systems (PSS) business models and tactics—A systematic literature review. J. Clean. Prod. 2015, 97, 61–75. [Google Scholar] [CrossRef]

- Zou, W.; Brax, S.A.; Rajala, R. Complexity in Product-Service Systems: Review and Framework. Procedia CIRP 2018, 73, 3–8. [Google Scholar] [CrossRef]

- Martinez, V.; Bastl, M.; Kingston, J.; Evans, S. Challenges in transforming manufacturing organisations into product-service providers. J. Manuf. Technol. Manag. 2010, 21, 449–469. [Google Scholar] [CrossRef]

- Schuh, G.; Kuntz, J.; Stich, V.; Jussen, P. Managing Complexity in Product Service Systems and Smart Services. Procedia CIRP 2019, 83, 410–414. [Google Scholar] [CrossRef]

- Tuunanen, T.; Cassab, H. Service Process Modularization. J. Serv. Res. 2011, 14, 340–354. [Google Scholar] [CrossRef]

- Ezzat, O.; Medini, K.; Boucher, X.; Delorme, X. Product and service modularization for variety management. Procedia Manuf. 2019, 28, 148–153. [Google Scholar] [CrossRef]

- Rennpferdt, C.; Krause, D. Towards a Framework for the Design of Variety-Oriented Product-Service Systems. Proc. Des. Soc. Des. Conf. 2020, 1, 1345–1354. [Google Scholar] [CrossRef]

- Cenamor, J.; Rönnberg Sjödin, D.; Parida, V. Adopting a platform approach in servitization: Leveraging the value of digitalization. Int. J. Prod. Econ. 2017, 192, 54–65. [Google Scholar] [CrossRef]

- Meier, H.; Roy, R.; Seliger, G. Industrial Product-Service Systems—IPS 2. CIRP Ann. 2010, 59, 607–627. [Google Scholar] [CrossRef]

- Rennpferdt, C.; Bagusat, M.; Bender, D.; Krause, D. Development of Business Model Families for Product-Service Systems. In DS 119, Proceedings of the 33rd Symposium Design for X (DFX2022), Hamburg, Germany, 22–23 September 2022; Krause, D., Paetzold, K., Wartzack, S., Eds.; The Design Society: Glasgow, UK, 2022; p. 10. [Google Scholar] [CrossRef]

- Blessing, L.T.; Chakrabarti, A. DRM, a Design Research Methodology; Springer: London, UK, 2009. [Google Scholar] [CrossRef]

- Rennpferdt, C.; Dambietz, F.M.; Krause, D. Business Models and Product-Service System Design—Introducing the Business Model Graph. In Proceedings of the 2021 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), IEEE, Singapore, 13–16 December 2021; pp. 1102–1106. [Google Scholar] [CrossRef]

- Dambietz, F.M.; Rennpferdt, C.; Hanna, M.; Krause, D. Using MBSE for the Enhancement of Consistency and Continuity in Modular Product-Service-System Architectures. Systems 2021, 9, 63. [Google Scholar] [CrossRef]

- Rennpferdt, C.; Kuhl, J.; Krause, D. Tools for the Variety-Oriented Product-Service System Design. In Towards Sustainable Customization: Bridging Smart Products and Manufacturing Systems; Andersen, A.-L., Andersen, R., Brunoe, T.D., Larsen, M.S.S., Nielsen, K., Napoleone, A., Kjeldgaard, S., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 798–806. [Google Scholar] [CrossRef]

- Barravecchia, F.; Franceschini, F.; Mastrogiacomo, L.; Zaki, M. Research on product-service systems: Topic landscape and future trends. J. Manuf. Technol. Manag. 2021, 32, 208–238. [Google Scholar] [CrossRef]

- Boehm, M.; Thomas, O. Looking beyond the rim of one’s teacup: A multidisciplinary literature review of Product-Service Systems in Information Systems, Business Management, and Engineering & Design. J. Clean. Prod. 2013, 51, 245–260. [Google Scholar] [CrossRef]

- Alonso-Rasgado, T.; Thompson, G.; Elfström, B.-O. The design of functional (total care) products. J. Eng. Des. 2004, 15, 515–540. [Google Scholar] [CrossRef]

- Baines, T.S.; Lightfoot, H.W.; Kay, J.M. Servitized manufacture: Practical challenges of delivering integrated products and services. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2009, 223, 1207–1215. [Google Scholar] [CrossRef]

- Ulaga, W.; Reinartz, W.J. Hybrid Offerings: How Manufacturing Firms Combine Goods and Services Successfully. J. Mark. 2011, 75, 5–23. [Google Scholar] [CrossRef]

- Brax, S. A manufacturer becoming service provider—Challenges and a paradox. Manag. Serv. Qual. Int. J. 2005, 15, 142–155. [Google Scholar] [CrossRef]

- Nordin, F.; Lindahl, I.; Brege, S. The Applicability of Integrated Solutions Offerings: Differential Effects of Product Complexity. J. Relatsh. Mark. 2013, 12, 59–78. [Google Scholar] [CrossRef]

- Brax, S.A.; Visintin, F. Meta-model of servitization: The integrative profiling approach. Ind. Mark. Manag. 2017, 60, 17–32. [Google Scholar] [CrossRef]

- Shostack, G.L. How to Design a Service. Eur. J. Mark. 1982, 16, 49–63. [Google Scholar] [CrossRef]

- Benedettini, O.; Neely, A. Complexity in services: An interpretative framework. In Proceedings of the 23rd Annual Conference of the Production and Operations Management Society, Socially Responsible Operations, Chicago, IL, USA, 20–23 April 2012. [Google Scholar]

- Schuh, G.; Riesener, M.; Breunig, S.; Koch, J.; Kuntz, J. Evaluation of Variety-induced Costs in Product-Service Systems (PSS). Procedia CIRP 2017, 61, 673–678. [Google Scholar] [CrossRef]

- Qu, M.; Yu, S.; Chen, D.; Chu, J.; Tian, B. State-of-the-art of design, evaluation, and operation methodologies in product service systems. Comput. Ind. 2016, 77, 1–14. [Google Scholar] [CrossRef]

- Larsen, M.S.S.; Andersen, A.-L.; Nielsen, K.; Brunoe, T.D. Modularity in Product-Service Systems: Literature Review and Future Research Directions. In Advances in Production Management Systems. Production Management for Data-Driven, Intelligent, Collaborative, and Sustainable Manufacturing; Moon, I., Lee, G.M., Park, J., Kiritsis, D., von Cieminski, G., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 150–158. [Google Scholar] [CrossRef]

- Voss, C.A.; Hsuan, J. Service Architecture and Modularity. Decis. Sci. 2009, 40, 541–569. [Google Scholar] [CrossRef]

- Yu, M.; Zhang, W.; Meier, H. Modularization based design for innovative product-related industrial service. In Proceedings of the 2008 IEEE International Conference on Service Operations and Logistics, and Informatics (SOLI), IEEE, Beijing, China, 12–15 October 2008; pp. 48–53. [Google Scholar] [CrossRef]

- Fargnoli, M.; Haber, N.; Sakao, T. PSS modularisation: A customer-driven integrated approach. Int. J. Prod. Res. 2019, 57, 4061–4077. [Google Scholar] [CrossRef]

- Moon, S.K.; Shu, J.; Simpson, T.W.; Kumara, S.R. A module-based service model for mass customization: Service family design. IIE Trans. 2010, 43, 153–163. [Google Scholar] [CrossRef]

- Wang, P.P.; Ming, X.G.; Li, D.; Kong, F.B.; Wang, L.; Wu, Z.Y. Modular Development of Product Service Systems. Concurr. Eng. 2011, 19, 85–96. [Google Scholar] [CrossRef]

- Sun, J.; Chai, N.; Pi, G.; Zhang, Z.; Fan, B. Modularization of Product Service System Based on Functional Requirement. Procedia CIRP 2017, 64, 301–305. [Google Scholar] [CrossRef]

- Sheng, Z.; Liu, C.; Song, J.; Xie, H. Module division and configuration modeling of CNC product–service system. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2017, 231, 494–506. [Google Scholar] [CrossRef]

- Aurich, J.C.; Fuchs, C.; Wagenknecht, C. Modular design of technical product-service systems. In Innovation in Life Cycle Engineering and Sustainable Development; Brissaud, D., Tichkiewitch, S., Zwolinski, P., Eds.; Springer: Dordrecht, The Netherlands, 2006; pp. 303–320. [Google Scholar] [CrossRef]

- Riesener, M.; Dölle, C.; Kreß, J.; Boßmann, C.; Schuh, G. Methodology for Structuring and Bundling Product-Service Systems. In DS 112, Proceedings of the 23rd International DSM Conference (DSM 2021), Singapore, 12–14 October 2021; The Design Society: Glasgow, UK, 2021. [Google Scholar] [CrossRef]

- Rennpferdt, C.; Greve, E.; Krause, D. The Impact of Modular Product Architectures in PSS Design: A systematic Literature Review. Procedia CIRP 2019, 84, 290–295. [Google Scholar] [CrossRef]

- Eigner, M.; Dickopf, T.; Apostolov, H.; Schaefer, P.; Faißt, K.-G.; Keßler, A. System Lifecycle Management: Initial Approach for a Sustainable Product Development Process Based on Methods of Model Based Systems Engineering. In Product Lifecycle Management for a Global Market, Proceedings of the 11th IFIP WG 5.1 International Conference, PLM 2014, Yokohama, Japan, 7–9 July 2014; revised selected papers; Fukuda, S., Bernard, A., Gurumoorthy, B., Bouras, A., Eds.; Springer: Heidelberg, Germany, 2014; pp. 287–300. [Google Scholar] [CrossRef]

- Isermann, R. Mechatronic systems—Innovative products with embedded control. Control. Eng. Pract. 2008, 16, 14–29. [Google Scholar] [CrossRef]

- Graessler, I.; Hentze, J. The new V-Model of VDI 2206 and its validation. Automatisierungstechnik 2020, 68, 312–324. [Google Scholar] [CrossRef]

- Mcharek, M.; Azib, T.; Larouci, C.; Hammadi, M. Collaboration and multidisciplinary design optimization for mechatronic systems. In Proceedings of the IECON 2019—45th Annual Conference of the IEEE Industrial Electronics Society, IECON, IEEE, Lisbon, Portugal, 14–17 October 2019; pp. 624–629. [Google Scholar] [CrossRef]

- Zheng, C.; Hehenberger, P.; Le Duigou, J.; Bricogne, M.; Eynard, B. Multidisciplinary design methodology for mechatronic systems based on interface model. Res. Eng. Des. 2017, 28, 333–356. [Google Scholar] [CrossRef]

- Askhøj, C.; Christensen, C.K.F.; Mortensen, N.H. Cross domain modularization tool: Mechanics, electronics, and software. Concurr. Eng. 2021, 29, 221–235. [Google Scholar] [CrossRef]

- van Beek, T.J.; Erden, M.S.; Tomiyama, T. Modular design of mechatronic systems with function modeling. Mechatronics 2010, 20, 850–863. [Google Scholar] [CrossRef]

- Zuefle, M.; Küchenhof, J.; Hanna, M.; Krause, K. Assessing the Influence of Digital Innovations on the Organizational Design of Product Family Generations. In DS 121, Proceedings of the 24th International DSM Conference (DSM 2022), Eindhoven, The Netherlands, 11–13 October 2022; The Design Society: Glasgow, UK, 2022; pp. 58–67. [Google Scholar] [CrossRef]

- DaSilva, C.M.; Trkman, P. Business Model: What It Is and What It Is Not. Long Range Plan. 2014, 47, 379–389. [Google Scholar] [CrossRef]

- Teece, D.J. Business Models, Business Strategy and Innovation. Long Range Plan. 2010, 43, 172–194. [Google Scholar] [CrossRef]

- Osterwalder, A.; Pigneur, Y. Business Model Generation: A Handbook for Visionaries, Game Changers, and Challengers; Wiley&Sons: New York, NY, USA, 2010. [Google Scholar]

- Gassmann, O.; Frankenberger, K.; Csik, M. Revolutionizing the Business Model. In Management of the Fuzzy Front End of Innovation; Gassmann, O., Schweitzer, F., Eds.; Springer International Publishing: Cham, Switzerland, 2014; pp. 89–97. [Google Scholar] [CrossRef]

- Adrodegari, F.; Saccani, N.; Kowalkowski, C.; Vilo, J. PSS business model conceptualization and application. Prod. Plan. Control. 2017, 28, 1251–1263. [Google Scholar] [CrossRef]

- Frederiksen, T.B.; Pieroni, M.P.P.; Pigosso, D.C.A.; McAloone, T.C. Strategic Development of Product-Service Systems (PSS) through Archetype Assessment. Sustainability 2021, 13, 2592. [Google Scholar] [CrossRef]

- Reim, W.; Parida, V.; Sjödin, D. Digital Business Model Innovation for Product-Service Systems. In The Palgrave Handbook of Servitization; Kohtamäki, M., Baines, T., Rabetino, R., Bigdeli, A.Z., Kowalkowski, C., Oliva, R., Parida, V., Eds.; Springer International Publishing: Cham, Switzerland, 2021; pp. 89–101. [Google Scholar] [CrossRef]

- Pieroni, M.; Marques, C.; Campese, C.; Guzzo, D.; Mendes, G.; Costa, J.; Rosa, M.; de Oliveira, M.G.; Macul, V.; Rozenfeld, H. Transforming a Traditional Product Offer into PSS: A Practical Application. Procedia CIRP 2016, 47, 412–417. [Google Scholar] [CrossRef]

- Boßlau, M.; Gesing, J.; Meier, H.; Wieseke, J. Geschäftsmodelle für Industrielle Produkt-Service Systeme. In Industrielle Produkt-Service Systeme; Meier, H., Uhlmann, E., Eds.; Springer: Berlin/Heidelberg, Germany, 2017; pp. 299–324. [Google Scholar] [CrossRef]

- van Ostaeyen, J.; van Horenbeek, A.; Pintelon, L.; Duflou, J.R. A refined typology of product–service systems based on functional hierarchy modeling. J. Clean. Prod. 2013, 51, 261–276. [Google Scholar] [CrossRef]

- Leigh, D. SWOT Analysis. In Handbook of Improving Performance in the Workplace: Volumes 1–3; Silber, K.H., Foshay, W.R., Watkins, R., Leigh, D., Moseley, J.L., Dessinger, J.C., Eds.; John Wiley & Sons, Inc: Hoboken, NJ, USA, 2009; pp. 115–140. [Google Scholar] [CrossRef]

- Sholihah, M.; Maezono, T.; Mitake, Y.; Shimomura, Y. Towards development a PSS business evaluation: Proposal of internal and external analysis for sevitizing manufacturers. Procedia CIRP 2019, 83, 363–368. [Google Scholar] [CrossRef]

- Greve, E.; Fuchs, C.; Hamraz, B.; Windheim, M.; Rennpferdt, C.; Schwede, L.-N.; Krause, D. Knowledge-Based Decision Support for Concept Evaluation Using the Extended Impact Model of Modular Product Families. Appl. Sci. 2022, 12, 547. [Google Scholar] [CrossRef]

- Barquet, A.P.B.; de Oliveira, M.G.; Amigo, C.R.; Cunha, V.P.; Rozenfeld, H. Employing the business model concept to support the adoption of product–service systems (PSS). Ind. Mark. Manag. 2013, 42, 693–704. [Google Scholar] [CrossRef]

- Maussang, N.; Zwolinski, P.; Brissaud, D. Product-service system design methodology: From the PSS architecture design to the products specifications. J. Eng. Des. 2009, 20, 349–366. [Google Scholar] [CrossRef]

- Bertoni, A.; Bertoni, M.; Isaksson, O. Value visualization in Product Service Systems preliminary design. J. Clean. Prod. 2013, 53, 103–117. [Google Scholar] [CrossRef]

- Pieroni, M.P.P.; McAloone, T.C.; Pigosso, D.C.A. Configuring New Business Models for Circular Economy through Product–Service Systems. Sustainability 2019, 11, 3727. [Google Scholar] [CrossRef]

- Aurich, J.C.; Fuchs, C.; Wagenknecht, C. Life cycle oriented design of technical Product-Service Systems. J. Clean. Prod. 2006, 14, 1480–1494. [Google Scholar] [CrossRef]

- Stone, R.B.; Wood, K.L.; Crawford, R.H. A heuristic method for identifying modules for product architectures. Des. Stud. 2000, 21, 5–31. [Google Scholar] [CrossRef]

- Berluto Armaturen-GmbH. Product Portfolio. Available online: https://www.berluto.com/products/index.html (accessed on 24 July 2023).

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).