Advancements in Liquid Desiccant Technologies: A Comprehensive Review of Materials, Systems, and Applications

Abstract

:1. Recent Developments in Desiccant Materials and Their Applications

1.1. Innovative Liquid Desiccants

1.2. Solar-Powered Desiccant Cooling System

1.3. Energy Use of Liquid Desiccant Systems

2. Liquid Desiccant Agents (LDAs)

- Lithium Bromide (LiBr): This is one of the most commonly used liquid desiccants and is frequently used in industrial and commercial applications. LiBr has a strong affinity for water vapor and is effective at dehydrating the air.

- Calcium Chloride (CaCl2): This is another popular liquid desiccant widely used in residential and small commercial applications. CaCl2 is inexpensive and can absorb a substantial quantity of water vapor [67].

- Sodium Chloride (NaCl): NaCl can also be used as a liquid desiccant, although less frequently than LiBr or CaCl2. Typically, it is less efficacious than LiBr or CaCl2 but more affordable.

- Potassium Formate (KCOOH): This is a relatively new liquid desiccant that garners favor due to its low toxicity and biodegradability. It has a lower corrosion potential than other liquid desiccants and effectively removes moisture from the air, which makes it suitable for natural gas purification. In addition, there is a growing interest in developing novel desiccant materials and improving existing ones [1,68].

3. Liquid Desiccant Characteristics

4. Liquid Desiccant Systems

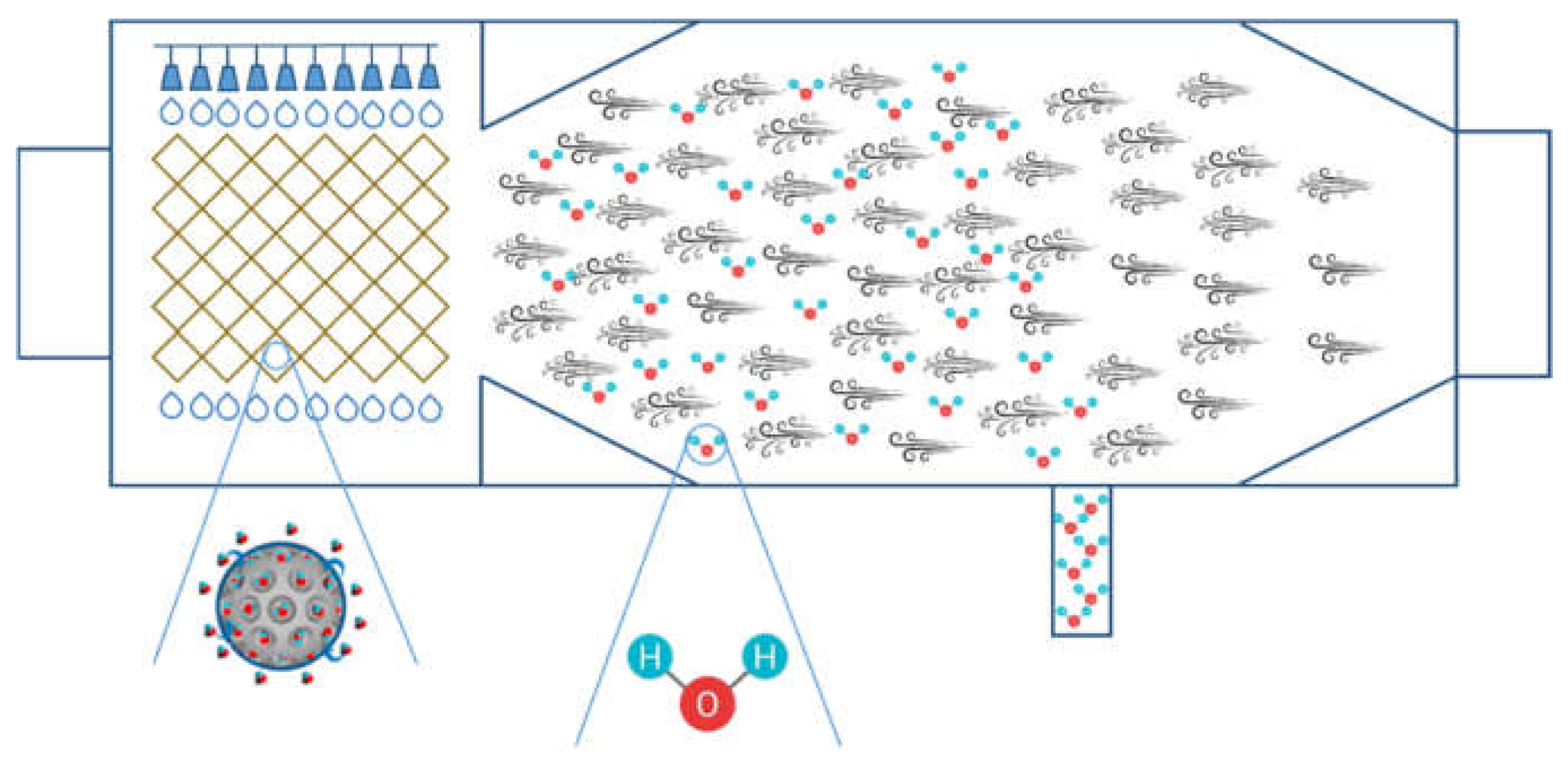

5. Liquid Desiccant Dehumidifiers

- Capable of rapid mass and thermal transfer.

- The minimum decrease in pressure.

- Offer minimal resistance to moisture diffusion in liquids.

- Have a large surface contact area per unit volume.

- Corrosion prevention requires compatibility with liquid desiccant.

- The air should not transport the liquid desiccant.

6. Liquid Desiccant Cooling (LDC)

7. Solid Desiccants (SDs)

8. Mixed and Composite Desiccant

9. LD Applications

- LDs are used in air conditioning systems to eliminate moisture from the air. Consequently, mold and mildew prevention, humidity reduction, and air quality enhancement can maintain a comfortable and healthy indoor environment.

- LDs are also utilized for dehumidification. This is especially essential in humid climates, where excess moisture can cause damage to structures, equipment, and goods.

- LDs may also be used in industrial drying procedures to remove moisture from paper, textiles, and food products.

- LDs have been utilized in energy recovery systems to remove moisture from the air and transfer it to a distinct air stream for reuse. Consequently, energy consumption and the efficiency of air conditioning and dehumidification systems are decreased.

10. Conclusions

- Single salts such as LiCl, LiBr, and CaCl2 are frequently used in dehumidification. Due to its superior dehumidification ability, LiCl has become the preferred option in approximately 85 percent of reported studies. However, LiBr and CaCl2, despite being less expensive, exhibit inferior stability and dehumidification performance. Exploring the potential of potassium formate solution (KCOOH) and blended solvents requires additional research.

- Packaging material selection, arrangement, and flow pattern within a desiccant dehumidifier substantially affect system performance. These factors must be optimized for optimal dehumidification efficacy.

- Additional fieldwork is necessary to design liquid desiccant (LD) systems that supplant conventional air conditioning (AC) systems. Applications in the real world and performance evaluations are required to validate theoretical findings.

- Composite-based desiccants have the potential to optimize absorption capacity and reduce regeneration temperature compared with single-component desiccants. However, potential limitations associated with scalability and compatibility with different operating conditions must be addressed.

- The core component of LD cooling systems is the desiccant dehumidifier. There has been extensive research on adiabatic and inner-cooled configurations. Inner-cooled dehumidifiers are advantageous because they do not require desiccant conveyance or high flow rates for complete surface saturation. Desiccant carryover can be prevented by rotary LD dehumidifiers constructed from porous materials, such as dense cloth.

- The combination of liquid desiccant systems with solar collectors, heat exchangers, and hybrid heat and power systems has the potential to improve performance. However, more experimental research is required to validate theoretical findings in this field.

- Due to varying solar radiation, liquid desiccant systems powered by solar energy have advantages but encounter practical limitations. Incorporating energy storage systems into solar-powered liquid desiccant systems will improve their efficacy.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, X.; Riffat, S.; Bai, H.; Zheng, X.; Reay, D. Recent progress in liquid desiccant dehumidification and air-conditioning: A review. Energy Built Environ. 2020, 1, 106–130. [Google Scholar] [CrossRef]

- Li, R.; Shi, Y.; Shi, L.; Alsaedi, M.; Wang, P. Harvesting water from air: Using anhydrous salt with sunlight. Environ. Sci. Technol. 2018, 52, 5398–5406. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Liu, X.; Qu, M.; Liu, X.; Bahar, B. An experimental study on dehumidification and regeneration performance of a new nonporous membrane-based heat and mass exchanger using an ionic liquid desiccant. Energy Build. 2022, 254, 111592. [Google Scholar] [CrossRef]

- Ho, K.; Kim, K.M.; Oh, H.T.; Lim, S.J.; Park, Y.; Lee, C.H. Adsorption equilibria of water vapor on zeolite 3A, zeolite 13X, and dealuminated Y zeolite. J. Chem. 2016, 61, 1547–1554. [Google Scholar]

- Kavasoğulları, B.; Cihan, E.; Demir, H. Novel packing materials for open liquid desiccant system. Energy Procedia 2016, 91, 785–791. [Google Scholar] [CrossRef]

- Mohamed, A.S.A.; Ahmed, M.S.; Hassan, A.A.M.; Hassan, M.S. Performance evaluation of gauze packing for liquid desiccant dehumidification system. Case Stud. Therm. Eng. 2016, 8, 260–276. [Google Scholar] [CrossRef]

- Li, G.; Wang, J.; Zhang, F.; Liu, J. Comprehensive operational parameter analysis of cross-flow hollow fiber membrane humidifier for humidification dehumidification desalination. Desalination 2022, 542, 116066. [Google Scholar] [CrossRef]

- Giampieri, A.; Ma, Z.; Ling-Chin, J.; Bao, H.; Smallbone, A.J.; Roskilly, A.P. Liquid desiccant dehumidification and regeneration process: Advancing correlations for moisture and enthalpy effectiveness. Appl. Energy 2022, 314, 118962. [Google Scholar] [CrossRef]

- Wasti, T.Z.; Sultan, M.; Aleem, M.; Sajjad, U.; Farooq, M.; Raza, H.M.; Noor, S. An overview of solid and liquid materials for adsorption-based atmospheric water harvesting. Adv. Mech. Eng. 2022, 14, 1–27. [Google Scholar] [CrossRef]

- Shakouri, M.; Krishnan, E.N.; Karoyo, A.H.; Dehabadi, L.; Wilson, L.D.; Simonson, C.J. Water vapor adsorption–desorption behavior of surfactant-coated starch particles for commercial energy wheels. ACS Omega 2019, 4, 14378–14389. [Google Scholar] [CrossRef]

- Sleiti, A.K.; Al-Khawaja, H.; Al-Khawaja, H.; Al-Ali, M. Harvesting water from air using adsorption material–Prototype and experimental results. Sep. Purif. Technol. 2021, 257, 117921. [Google Scholar] [CrossRef]

- Jarimi, H.; Powell, R.; Riffat, S. Review of sustainable methods for atmospheric water harvesting. Int. J. Low-Carbon Technol. 2020, 15, 253–276. [Google Scholar] [CrossRef]

- Salarian, H.; Taherian, H.; Ghadamian, H.; Khalaji Assadi, M. A study of liquid desiccant system performance. In Proceedings of the 6TII International Symposium on Heating, Ventilating and Air Conditioning, ISHVAC09, Tianjin, China, 12–15 July 2009; pp. 565–572. [Google Scholar]

- Wu, X.N.; Ge, T.S.; Dai, Y.J.; Wang, R.Z. Review on substrate of solid desiccant dehumidification system. Renew. Sustain. Energy Rev. 2018, 82, 3236–3249. [Google Scholar] [CrossRef]

- Shamim, J.A.; Hsu, W.-L.; Paul, S.; Yu, L.; Daiguji, H. A review of solid desiccant dehumidifiers: Current status and near-term development goals in the context of net zero energy buildings. Renew. Sustain. Energy Rev. 2021, 137, 110456. [Google Scholar] [CrossRef]

- Ghoulem, M.; El Moueddeb, K.; Nehdi, E.; Boukhanouf, R.; Calautit, J.K. Greenhouse design and cooling technologies for sustainable food cultivation in hot climates: Review of current practice and future status. Biosyst. Eng. 2019, 183, 121–150. [Google Scholar] [CrossRef]

- Wang, Y.; Danook, S.H.; Al-Bonsrulah, H.A.Z.; Veeman, D.; Wang, F. A recent and systematic review on water extraction from the atmosphere for arid zones. Energies 2022, 15, 421. [Google Scholar] [CrossRef]

- Taresh, H.M.; Abdul-Zahra, A.S.; Saleh, A.A. Study the Performance of a Novel Desiccant Heat Exchanger. Eng. Technol. J. 2023, 41, 45–59. [Google Scholar] [CrossRef]

- Eslami, M.; Tajeddini, F.; Etaati, N. Thermodynamic analysis and optimization of water harvesting from air using thermoelectric coolers. J. Energy Convers. Manag. 2018, 174, 417–429. [Google Scholar] [CrossRef]

- Maleki, M.; Eslamian, S.; Hamouda, B. Principles and applications of atmospheric water harvesting. In Handbook of Water Harvesting and Conservation: Basic Concepts and Fundamentals; Wiley: Hoboken, NJ, USA, 2021; pp. 243–259. [Google Scholar]

- Liu, L.; Wu, R.; Li, J.; Kubota, M.; Bai, Y.; Huang, H.; Kobayashi, N. Experimental and theoretical study on water vapor isothermal adsorption-desorption characteristics of desiccant coated adsorber. Int. J. Heat Mass Transf. 2022, 187, 122529. [Google Scholar] [CrossRef]

- Leila, D.; Farhad, F. Study of Dehumidification and Regeneration in a Starch Coated Energy Wheel. ACS Sustain. Chem. Eng. 2017, 5, 221–231. [Google Scholar]

- Ge, T.S.; Cao, W.; Pan, X.; Dai, Y.J.; Wang, R.Z. Experimental investigation on performance of desiccant coated heat exchanger and sensible heat exchanger operating in series. Int. J. Refrig. 2017, 83, 88–98. [Google Scholar] [CrossRef]

- Shehadi, M. Review of humidity control technologies in buildings. J. Build. Eng. 2018, 19, 539–551. [Google Scholar] [CrossRef]

- Bahraminia, S.; Anbia, M.; Koohsaryan, E. Dehydration of natural gas and biogas streams using solid desiccants: A review. Front. Chem. Sci. Eng. 2021, 15, 1050–1074. [Google Scholar] [CrossRef]

- Amged, T.; Laith, I.; Mohammed, A.F.; Alaa, A.J.; Ayad, M.; Thaer, A.; Hayder, A.D.; Hongbin, M.; Talal, Y. Experimental investigation of dehumidification and regeneration of zeolite coated energy exchanger. Int. J. Thermofluids 2022, 15, 100164. [Google Scholar]

- Zhang, L.; Hihara, E.; Matsuoka, F.; Dang, C. Experimental analysis of mass transfer in adiabatic structured packing dehumidifier/regenerator with liquid desiccant. Int. J. Heat Mass Transf. 2010, 53, 2856–2863. [Google Scholar] [CrossRef]

- Gao, W.Z.; Liu, J.H.; Cheng, Y.P.; Zhang, X.L. Experimental investigation on the heat and mass transfer between air and liquid desiccant in a cross-flow dehumidifier. Renew. Energy 2012, 37, 117–123. [Google Scholar] [CrossRef]

- Fu, H.X.; Liu, X.H. Review of the impact of liquid desiccant dehumidification on indoor air quality. Build. Environ. 2017, 116, 158–172. [Google Scholar] [CrossRef]

- Sanaye, S.; Taheri, M. Modeling and multi-objective optimization of a modified hybrid liquid desiccant heat pump (LD-HP) system for hot and humid regions. Appl. Therm. Eng. 2018, 129, 212–229. [Google Scholar] [CrossRef]

- Sahlot, M.; Saffa, B.R. Desiccant cooling systems: A review. Int. J. Low-Carbon Technol. 2016, 11, 489–505. [Google Scholar] [CrossRef]

- Khraisheh, M.; Inamdar, M.; AlMomani, F.; Adham, S. Humidification–Dehumidification (HDH) Desalination and Other Volume Reduction Techniques for Produced Water Treatment. Water 2022, 14, 60. [Google Scholar] [CrossRef]

- Liu, X.; Qu, M.; Liu, X.; Wang, L. Membrane-based liquid desiccant air dehumidification: A comprehensive review on materials, components, systems and performances. Renew. Sustain. Energy Rev. 2019, 110, 444–466. [Google Scholar] [CrossRef]

- Chemtech, S. Structured Packings for Distillation, Absorption and Reactive Distillation; Sulzer Chemtech Ltd.: Winterthur, Switzerland, 2010; pp. 1–28. [Google Scholar]

- Gandhidasan, P. Prediction of pressure drop in a packed bed dehumidifier operating with liquid desiccant. Appl. Therm. Eng. 2002, 22, 1117–1127. [Google Scholar] [CrossRef]

- Tu, Y.; Wang, R.; Zhang, Y.; Wang, J. Progress and expectation of atmospheric water harvesting. Joule 2018, 2, 1452–1475. [Google Scholar] [CrossRef]

- Ismael, L.; Al Ezzi, A.; Ma, H. Experimental Study of Combined Compact Evaporative Cooler with Desiccant Dehumidification; American Society of Thermal and Fluids Engineers (ASTFE): College Park, MD, USA, 2021; pp. 2020–36893. [Google Scholar]

- Dehabadi, L.; Lee, D.W. NMR Investigation of the Fractionation of Water–Ethanol Mixtures with Starch and Its Cross-Linked Forms. Energy Fuels 2016, 30, 5684–5692. [Google Scholar] [CrossRef]

- Fathieh, F.; Nasr, M.R.; Sadeh, S.; Besant, R.W.; Evitts, R.W.; Müller, J.; Simonson, C.J. Determination of air-to-air energy wheels latent effectiveness using humidity step test data. Int. J. Heat Mass Transf. 2016, 103, 501–515. [Google Scholar] [CrossRef]

- Fathieh, F.; Nezakat, M.; Evitts, R.W.; Simonson, C.J. Effects of physical and sorption properties of desiccant coating on performance of energy wheels. J. Heat Transf. 2017, 139, 062601. [Google Scholar] [CrossRef]

- Riaz, F.; Qyyum, M.A.; Bokhari, A.; Klemeš, J.J.; Usman, M.; Asim, M.; Lee, M. Design and energy analysis of a solar desiccant evaporative cooling system with built-in daily energy storage. Energies 2021, 14, 2429. [Google Scholar] [CrossRef]

- Kim, H.; Rao, S.R.; Kapustin, E.A.; Zhao, L.; Yang, S.; Yaghi, O.M.; Wang, E.N. Adsorption-based atmospheric water harvesting device for arid climates. Nat. Commun. 2018, 9, 1191. [Google Scholar] [CrossRef]

- Dezfouli, M.; Sopian, K.; Kadir, K. Energy and performance analysis of solar solid desiccant cooling systems for energy efficient buildings in tropical regions. Energy Convers. Manag. X 2022, 14, 100186. [Google Scholar] [CrossRef]

- Tafesse, G.H.; Ahmed, G.M.S.; Badruddin, I.A.; Kamangar, S.; Hussien, M. Estimation of Evaporation of Water from a Liquid Desiccant Solar Collector and Regenerator by Using Conservation of Mass and Energy Principles. Sustainability 2023, 15, 6520. [Google Scholar] [CrossRef]

- Djaeni, M.; A’yuni, D.Q.; Alhanif, M.; Hii, C.L.; Kumoro, A.C. Air dehumidification with advance adsorptive materials for food drying: A critical assessment for future prospective. Dry. Technol. 2021, 39, 1648–1666. [Google Scholar] [CrossRef]

- Son, K.N.; Richardson, T.M.J.; Cmarik, G.E. Equilibrium adsorption isotherms for H2O on Zeolite 13X. J. Chem. Eng. Data 2019, 64, 1063–1071. [Google Scholar] [CrossRef]

- Park, B.; Lee, S. Investigation on heat and mass transfer characteristics for a zeolite-coated heat exchanger using comparatively low-temperature energy: Heating humidification mode and cooling dehumidification mode. Indoor Built Environ. 2021, 30, 1486–1502. [Google Scholar] [CrossRef]

- Xu, S.Z.; Wang, R.Z.; Wang, L.W.; Zhu, J. A zeolite 13X/magnesium sulfate–water sorption thermal energy storage device for domestic heating. Energy Convers. Manag. 2018, 171, 98–109. [Google Scholar] [CrossRef]

- Charidi, M. Investigation of a Liquid Desiccant Enhanced Evaporative Cooling System for Building Application. Master’s Thesis, Eastern Mediterranean University (EMU)-Doğu Akdeniz Üniversitesi (DAÜ)), Famagusta, Cyprus, 2018. [Google Scholar]

- Crofoot, L. Experimental Evaluation and Modeling of a Solar Liquid Desiccant Air Conditioner. Master’s Thesis, Queen’s University, Kingston, BC, Canada, 2012. [Google Scholar]

- Wu, Q. Modeling and Control of Dehumidifier in Distributed Operating Liquid Desiccant Dehumidification System. Ph.D. Thesis, Nanyang Technological University, Singapore, 2017. [Google Scholar]

- Zhang, Q.; Liu, X.; Zhang, T.; Xie, Y. Performance optimization of a heat pump driven liquid desiccant dehumidification system using exergy analysis. Energy 2020, 204, 117891. [Google Scholar] [CrossRef]

- Kadhim, B.J.; Mahdy, O.S.; Alsaedi, S.S.; Majdi, H.S.; Shnain, Z.Y.; Alwaiti, A.A.; AbdulRazak, A.A. Effect of Rigid Xanthan Gums (RXGs) on Flow and Pressure Drops to Improve Drag Reduction Rates in Horizontal Pipe Flow. Chem. Eng. 2023, 7, 36. [Google Scholar] [CrossRef]

- Jani, D.B.; Vadera, N.J.; Patel, M.R. A Progressive Review on Solid Desiccant Cooling Systems. Int. J. Adv. Res. Sci. Commun. Technol. 2022, 2, 702–708. [Google Scholar]

- Jani, D.B.; Rathod, D.P.; Kureshi, F. A Review on Recent Development in Liquid Desiccant Dehumidification Assisted Cooling Systems. Int. J. Adv. Res. Sci. Commun. Technol. 2022, 2, 683–689. [Google Scholar]

- Kumar, K.; Singh, A.; Chaurasiya, P.K.; Pathak, K.K.; Pandey, V. Progressive development in hybrid liquid desiccant-vapour compression cooling system: A review. Sustain. Energy Technol. Assess. 2023, 55, 102960. [Google Scholar] [CrossRef]

- Cho, H.J.; Cheon, S.Y.; Jeong, J.W. Experimental analysis of dehumidification performance of counter and cross-flow liquid desiccant dehumidifiers. Appl. Therm. Eng. 2019, 150, 210–223. [Google Scholar] [CrossRef]

- Ani, F.; Badawi, E.; Kannan, K. The effect of absorber packing height on the performance of a hybrid liquid desiccant system. Renew. Energy 2005, 30, 2247–2256. [Google Scholar] [CrossRef]

- Fekadu, G.; Subudhi, S. Renewable energy for liquid desiccants air conditioning system: A review. Renew. Sustain. Energy Rev. 2018, 93, 364–379. [Google Scholar] [CrossRef]

- Kumar, K.; Singh, A. Economic and Experimental Assessment of KCOOH Hybrid Liquid Desiccant-Vapor Compression System. Sustainability 2022, 14, 15917. [Google Scholar] [CrossRef]

- Indrawan, W.; Lubis, A.; Alhamid, M. The experimental study of dehumidification and regeneration processes in a fin and tube liquid desiccant system. Case Stud. Therm. Eng. 2022, 39, 102440. [Google Scholar] [CrossRef]

- Sanjeev, J.; Mithilesh, K.; Asati, A.; Dhar, P. Drift and Wetting Characteristics of Falling Film Absorber and Regenerator; Allied Publishers: New Delhi, India, 2003; pp. 16–25. [Google Scholar]

- Su, W.; Li, W.; Sun, B.; Zhang, X. Experimental study and correlations for heat and mass transfer coefficients in the dehumidifier of a frost-free heat pump system. Int. J. Heat Mass Transf. 2019, 131, 450–462. [Google Scholar] [CrossRef]

- Guo, Y.; Ma, Z.; Al-Jubainawi, A.; Cooper, P.; Nghiem, L.D. Using electrodialysis for regeneration of aqueous lithium chloride solution in liquid desiccant air conditioning systems. Energy Build. 2016, 116, 285–295. [Google Scholar] [CrossRef]

- LePree, J. Just Cool It! Chem. Eng. 2010, 117, 17. [Google Scholar]

- Pietruschka, D.; Eicker, U.; Huber, M.; Schumacher, J. Experimental performance analysis and modelling of liquid desiccant cooling systems for air conditioning in residential buildings. Int. J. Refrig. 2006, 29, 110–124. [Google Scholar] [CrossRef]

- Naik, B.K.; Joshi, M.; Muthukumar, P.; Sultan, M.; Miyazaki, T.; Shamshiri, R.R.; Ashraf, H. Investigating solid and liquid desiccant dehumidification options for room air-conditioning and drying applications. Sustainability 2020, 12, 10582. [Google Scholar] [CrossRef]

- Qi, R.; Dong, C.; Zhang, L.-Z. A review of liquid desiccant air dehumidification: From system to material manipulations. Energy Build. 2020, 215, 109897. [Google Scholar] [CrossRef]

- El-sarrag, E. Dehumidification of air by chemical liquid desiccant in a packed column and its heat and mass transfer effectiveness. HVAC&R Res. 2006, 12, 3–16. [Google Scholar]

- Gandhidasan, P.; Mohandes, M.A. Predictions of vapor pressures of aqueous desiccants for cooling applications by using artificial neural networks. Appl. Therm. Eng. 2008, 28, 126–135. [Google Scholar] [CrossRef]

- Giampieri, A.; Ma, Z.; Smallbone, A.; Roskilly, A.P. Thermodynamics and economics of liquid desiccants for heating, ventilation and air-conditioning—An overview. Appl. Energy 2018, 220, 455–479. [Google Scholar] [CrossRef]

- Lide, D.R. CRC Handbook of Chemistry and Physics; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Shin, J.-H.; Park, J.-Y.; Jo, M.-S.; Jeong, J.-W. Impact of heat pump-driven liquid desiccant dehumidification on the energy performance of an evaporative cooling-assisted air conditioning system. Energies 2018, 11, 345. [Google Scholar] [CrossRef]

- Su, W.; Lu, Z.; She, X.; Zhou, J.; Wang, F.; Sun, B.; Zhang, X. Liquid desiccant regeneration for advanced air conditioning: A comprehensive review on desiccant materials, regenerators, systems and improvement technologies. Appl. Energy 2022, 308, 118394. [Google Scholar] [CrossRef]

- Rafique, M.M.; Gandhidasan, P.; Al-Hadhrami, M.; Rehman, S. Energy, exergy and energy analysis of a solar desiccant cooling system. J. Clean Energy Technol. 2016, 4, 78–83. [Google Scholar] [CrossRef]

- Sonowal, J.; Mahajan, M.; Muthukumar, P.; Anandalakshmi, R. Performance analysis of liquid desiccant dehumidifier system for various packing density. Therm. Sci. Eng. Prog. 2023, 38, 101663. [Google Scholar] [CrossRef]

- Ge, G.; Xiao, F.; Niu, X. Control strategies for a liquid desiccant air-conditioning system. Energy Build. 2011, 43, 1499–1507. [Google Scholar] [CrossRef]

- Kalpana; Subudhi, S. Developments in liquid desiccant dehumidification system integrated with evaporative cooling technology. Int. J. Energy Res. 2022, 46, 61–88. [Google Scholar] [CrossRef]

- Lott, P.; Deutschmann, O. Heterogeneous chemical reactions—A cornerstone in emission reduction of local pollutants and greenhouse gases. Proc. Combust. Inst. 2023, 39, 3183–3215. [Google Scholar] [CrossRef]

- Mahmud, R.; Erguvan, M.; MacPhee, D.W. Performance of closed loop venturi aspirated aeration system: Experimental study and numerical analysis with discrete bubble model. Water 2020, 12, 1637. [Google Scholar] [CrossRef]

- Goldsworthy, M.; White, S.D. Limiting performance mechanisms in desiccant wheel dehumidification. Appl. Therm. Eng. 2012, 44, 21–28. [Google Scholar] [CrossRef]

- Santos, A.F.; Gaspar, P.D.; de Souza, H.J.; Caldeira, J.M.; Soares, V.N. An Eco-Energetic Performance Comparison of Dehumidification Systems in High-Moisture Indoor Environments. Appl. Sci. 2023, 13, 6824. [Google Scholar] [CrossRef]

- Liang, C.H. Research on a refrigeration dehumidification system with membrane-based total heat recovery. Heat Transf. Eng. 2014, 35, 1043–1049. [Google Scholar] [CrossRef]

- Zhao, Y.; Ge, T.S.; Dai, Y.J. Experimental investigation on a desiccant dehumidification unit using fin-tube heat exchanger with silica gel coating. Appl. Therm. Eng. 2014, 63, 52–58. [Google Scholar] [CrossRef]

- Ng, E.P.; Mintova, S. Nano porous materials with enhanced hydrophilicity and high water sorption capacity. Microporous Mesoporous Mater. 2008, 114, 1–26. [Google Scholar] [CrossRef]

- Lin, J.; Huang, S.M.; Wang, R.; Chua, K.J. Thermodynamic analysis of a hybrid membrane liquid desiccant de- humidification and dew point evaporative cooling system. Energy Conv. Manag. 2018, 156, 440–458. [Google Scholar] [CrossRef]

- Salikandi, M.; Ranjbar, B.; Shirkhan, E.; Priya, S.S.; Thirunavukkarasu, I.; Sudhakar, K. Recent trends in liquid desiccant materials and cooling systems: Application, performance and regeneration characteristics. J. Build. Eng. 2021, 33, 101579. [Google Scholar] [CrossRef]

- Al-Farayedhi, A.A.; Gandhidasan, P.; Al-Mutairi, M.A. Evaluation of heat and mass transfer coefficients in a gauze-type structured packing air dehumidifier operating with liquid desiccant. Int. J. Refrig. 2002, 25, 330–339. [Google Scholar] [CrossRef]

- Bouzenada, S.; Kaabi, A.; Frainkin, L.; Salmon, T.; Léonard, A. Experimental comparative study on lithium chloride and calcium chloride desiccants. Procedia Comput. Sci. 2016, 83, 718–725. [Google Scholar] [CrossRef]

- Chen, L.F.; Soriano, A.N.; Li, M.H. Vapour pressures and densities of the mixed–solvent desiccants (glycols + water + salts). J. Chem. Thermodyn. 2009, 41, 724–730. [Google Scholar] [CrossRef]

- Tsai, C.Y.; Soriano, A.N.; Li, M.H. Vapour pressures, densities, and viscosities of the aqueous solutions containing (triethylene glycol or propylene glycol) and (LiCl or LiBr). J. Chem. Thermodyn. 2009, 41, 623–631. [Google Scholar] [CrossRef]

- González, J.C.; Molina-Sabio, M.; Rodríguez-Reinoso, F. Sepiolite-based adsorbents as humidity controller. Appl. Clay. Sci. 2001, 20, 111–118. [Google Scholar] [CrossRef]

- Baniyounes, A.M.; Ghadi, Y.Y.; Rasul, M.G. An overview of solar assisted air conditioning in Queensland’s subtropical regions, Australia. Renew Sustain. Energy Rev. 2013, 26, 781–804. [Google Scholar] [CrossRef]

- Capozzoli, A.; Mazzei, P.; Minichiello, F.; Palma, D. Hybrid HVAC systems with chemical dehumidification for supermarket applications. Appl. Therm. Eng. 2006, 26, 795–805. [Google Scholar] [CrossRef]

- Jiang, Y.; Li, Z.; Chen, X.L.; Liu, X.H. Liquid desiccant air conditioning system and its applications. Heat Vent. Air Cond. 2004, 34, 88–98. [Google Scholar]

- Lowenstein, A.; Slyzak, K.E. A zero carry over liquid desiccant air conditioner for solar applications. In Proceedings of the ASME International Solar Energy Conference (ISEC), Denver, CO, USA, 8–13 July 2006. [Google Scholar]

| Desiccant | Air | L/G | Remarks | Reference | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Type | Temp. (°C) | Conc. (%) | Flow rate/flux (l/min) | Flow rate/flux (m3/min) | Temp. (°C) | Humidity (g/kg) | ΔT (°C) | ΔW (g/kg) | |||

| LiCI | 25–27 | 35–40 | 3.76–5.01 | 4.9–6.4 | n/a | n/a | n/a | n/a | n/a | SP, CF, COPhyb: 2.6–4.9 | Ani et al. [58] |

| LiCI | n/a | 40 | n/a | 40–96 | 30 | 18.9 | −4.0 | −7.2 | n/a | SP, CF, COPhyb: 2.7–3.0 | Fekadu and Subudhi [59] |

| TEG | 29–35 | 92 | 1.7–2.2 a | 0.94–2 a | n/a | 17–26 | n/a | −5.5 to −1.1 | 1.9–2.3 | SP, CF, DP: 35–140 Pa/m | Kumar, K., and Singh, A. [60] |

| LiBr | n/a | n/a | n/a | n/a | n/a | n/a | −2 to −11 | −2 to −8 | n/a | Cooled FF, ST, PF | Indrawan, W. et. al. [61] |

| TEG | 22.9 | 96.8 | 0.057 b | 0.07 b | 20.6 | 12.48 | 2.5 | −8.1 | 0.81 | Cooled FF, ST, CF, DP: 1736 Pa, drift: 5.6–9 g/min | Sanjeev, J. [62] |

| 20.5 | 95.2 | 0.058 b | 0.07 b | 19.4 | 8.71 | 2.1 | −4.54 | 0.83 | |||

| 20.2 | 95.5 | 0.057 b | 0.07 b | 28.6 | 16.93 | −4 | −12.46 | 0.81 | |||

| 21.8 | 92.2 | 0.052 b | 0.051 b | 21 | 8.95 | 1.2 | −4.21 | 1.02 | |||

| LiBr | 20.1–29.5 | 42.6–54.8 | 0.3–0.64 b | 0.31–0.47 b | 24.7–33.9 | 10–21 | n/a | n/a | n/a | SP, cross flow | Su, W., et al. [63] |

| LiCI | 27–30 | 35 | 0.35–0.51 b | 0.6–0.7 b | 26–29 | 11.6–13.9 | n/a | −2 to −4 | n/a | RP, CF | Guo, Y. [64] |

| PG | n/a | n/a | n/a | n/a | 4.4 | 3.12 | −2.77 | −1.4 | n/a | Cooled spray type | LePree [65] |

| LiCI | 27 | 43 | 1.67 | 3.3 | 26 | 11.6 | 5 | −4.2 | n/a | SP, cross flow | Pietruschka et al. [66] |

| CaCl2 | 27 | 43 | 1.67 | 3.3 | 26 | 11.6 | −1 | −5.7 | n/a | Cross-flow PHE, cooled | Pietruschka et al. [66] |

| Characteristics | Properties |

|---|---|

| Dehumidification ability |

|

| Thermo-physical properties |

|

| Heat and mass transfer |

|

| Other properties |

|

| Salt | RH [%] | Saturation Concentration at 25 °C |

|---|---|---|

| Caesium Fluoride (CsF) | 3.39 ± 0.94 | 0.851 |

| Lithium Bromide (LiBr) | 6.37 ± 0.52 | 0.644 |

| Zinc Bromide (ZnBr) | 7.75 ± 0.39 | 0.830 |

| Potassium Hydroxide (KOH) | 8.23 ± 0.72 | 0.547 |

| Sodium Hydroxide (NaOH) | 8.24 ± 2.1 | 0.500 |

| Lithium Chloride (LiCl) | 11.3 ± 0.27 | 0.458 |

| Calcium Bromide (CaBr2) | 16.5 ± 0.2 | 0.610 |

| Lithium Iodide (LiI) | 17.56 ± 0.13 | 0.623 |

| Potassium Acetate (CH3CO2K) | 22.51 ± 0.32 | 0.722 |

| Potassium Fluoride (KF) | 30.85 ± 1.3 | 0.501 |

| Magnesium Chloride (MgCl2) | 32.78 ± 0.16 | 0.359 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fahad, F.G.; Al-Humairi, S.T.; Al-Ezzi, A.T.; Majdi, H.S.; Sultan, A.J.; Alhuzaymi, T.M.; Aljuwaya, T.M. Advancements in Liquid Desiccant Technologies: A Comprehensive Review of Materials, Systems, and Applications. Sustainability 2023, 15, 14021. https://doi.org/10.3390/su151814021

Fahad FG, Al-Humairi ST, Al-Ezzi AT, Majdi HS, Sultan AJ, Alhuzaymi TM, Aljuwaya TM. Advancements in Liquid Desiccant Technologies: A Comprehensive Review of Materials, Systems, and Applications. Sustainability. 2023; 15(18):14021. https://doi.org/10.3390/su151814021

Chicago/Turabian StyleFahad, Farah G., Shurooq T. Al-Humairi, Amged T. Al-Ezzi, Hasan Sh. Majdi, Abbas J. Sultan, Thaqal M. Alhuzaymi, and Thaar M. Aljuwaya. 2023. "Advancements in Liquid Desiccant Technologies: A Comprehensive Review of Materials, Systems, and Applications" Sustainability 15, no. 18: 14021. https://doi.org/10.3390/su151814021

APA StyleFahad, F. G., Al-Humairi, S. T., Al-Ezzi, A. T., Majdi, H. S., Sultan, A. J., Alhuzaymi, T. M., & Aljuwaya, T. M. (2023). Advancements in Liquid Desiccant Technologies: A Comprehensive Review of Materials, Systems, and Applications. Sustainability, 15(18), 14021. https://doi.org/10.3390/su151814021