Abstract

The continuous growth of interior decoration activities has caused a massive consumption of energy and materials, which has contributed to a large amount of carbon emissions in the construction sector. The carbon emissions of building decoration were overlooked in previous studies. Hence, the life cycle assessment (LCA) approach was employed to build a life cycle carbon emissions model for building decoration. An office building was selected to verify the availability. The results show that the carbon emissions intensity of the decoration project was 254.5 kg CO2 eq/m2. The operation stage was the most crucial carbon emissions contributor in the life cycle of building decoration, accounting for 49.8%; followed by the materials embodied impact stage, which contributed 36.3%; while the remaining three stages, namely, the decoration, transportation, and end-of-life stage, had less carbon emissions, accounting for 6.8%, 5.3%, and 1.8%. Improving the performance of inorganic materials, optimizing transportation routes and energy structure, and dismantling plan optimization can reduce carbon emissions. The findings of this study provide a theoretical basis and fundamental data for carbon emissions reduction and sustainable development strategies for building decoration.

1. Introduction

Continuing urbanization has brought large-scale construction activities, which consume materials and energy and generate massive carbon emissions during the life cycle stage. According to statistics announced by the Professional Committee of Building Energy and Emissions, the life cycle carbon emissions of buildings in China amounted to about 5 billion t CO2 eq in 2020. It accounts for more than 50% of the total carbon emissions in the whole society [1]. To achieve the goal of China’s independent contribution to climate change by 2030, the 14th Five-Year Plan proposes to promote low-carbon transformation in the construction sector. It requires forming a green, low-carbon, and recyclable construction development pathway, and laying a solid foundation for achieving the peak carbon emissions in 2030 [2].

Building decoration is one of the main construction processes in the life cycle of buildings, but the present form of architectural decoration in China is simple and rough [3], which has a significant influence on the low-carbon transformation of the construction sector. In 2020, the building decoration industry’s gross product reached approximately CNY 1264.8 billion, with an increase of 45.6% from 2015 to 2020 [4], and the decoration of public buildings contributed 48.9% to the industry. The continuous growth of completed floor space will provide an abundant stock demand for building decoration. A public building will be decorated several times throughout its lifespan, and the market increment transformed into stock expansion. It provides a significant market for decoration enterprises and further increases the scale of building decoration.

However, with the fast development of the industry, there would be a massive consumption of materials and energy and significant carbon emissions during the decoration process. For instance, the average CO2 emissions of cement was 806 kg/t clinker [5]. Meanwhile, the decoration components, such as an air-conditioner, will consume large amounts of electricity during the operation stage. It overwhelmingly increases the contribution of carbon emissions from building decoration to climate change. Before conducting low-carbon actions in the building decoration sector, it is necessary to identify the key carbon emissions generation factors.

There were some studies focused on the carbon emissions of buildings. For instance, Wang et al. (2021) developed an improved STIRPAT model, concluding that energy saving in the operational stage of civil buildings is crucial to carbon emissions reduction [6]. Liu et al. (2020) adopted the emissions factor calculation method and life cycle assessment (LCA) approach to establish a carbon emissions model of buildings, promoting the precise calculation of carbon emissions in the building life cycle [7]. Yang et al. (2021) quantified the decarbonization potential of seven timber buildings from a life cycle perspective, which indicated that carbon emissions in the operation stage of buildings accounted for an average of 87.7% of carbon emissions in the total life cycle of buildings, where all of these projects took place from 2010–2018 and covered cold climate regions and those with hot summers and cold winters in China [8]. Zhang et al. (2016) developed a quantitative carbon emissions life cycle model and adopted a residential building in Tianjin to reveal the main contributing stages of carbon emissions, which are the material production stage and the operation stage [9]. Meanwhile, the characteristics of life cycle carbon emissions in different structures were also studied based on each sub-stage in the life cycle [10]. Furthermore, some studies focused on the environmental impacts of decoration waste, which was mainly described by the quantitative index of CO2. Yu et al. (2014) calculated carbon emissions regarding nine typical decoration materials [11]. Wang et al. (2021) employed the waste-generation-per-area method and LCA approach to explore the carbon emissions of building decoration wastes in commercial buildings in the Greater Bay Area [12].

From the previous studies, the life cycle assessment (LCA) approach was used to calculate the carbon emissions of buildings. However, only a few studies focused on the carbon emissions of building decoration and included the carbon emissions of materials and the disposal of decoration waste. There is a lack of a specific carbon emissions assessment method and database for building decoration. Therefore, this study employed the LCA approach to develop a carbon emissions assessment model for building decoration. Based on a case study, the carbon emissions intensity of office building decoration was assessed, and carbon reduction strategies were proposed. The findings of this study can provide a reasonable reference for researchers related to carbon emissions reduction of building decoration.

2. Literature Review

2.1. The Environmental Impacts of Building Decoration

As a critical part of the building, interior decoration has inevitable impacts on the environment and public health [13]. The environmental impacts from construction are mainly characterized by global warming potential (GWP), eutrophication potential (EP), acidification potential (AP), human toxicity potential (HTP), etc. (Zhang, 2019) [14] showed that the acidification potential of steel bar exceeds approximately that of pottery and stainless steel. Ceramics contribute the most eutrophication potential; it also produces ecotoxic effects similar to those of recovering steel bars, stainless steel, and ceramic tiles, damaging the ecological environment seriously [14]. Among these impacts, GWP is the most significant, with 64 kg CO2 eq per square meter of building decoration.

Wang et al. (2021) assessed the environmental impacts caused by decoration waste. CO2 eq was used as an indicator to verify the environmental benefits of the separate recycling of decoration waste and the environmental impacts of disposal; if the decoration waste recycling rate rises to 70%, there will be a 70% reduction in carbon emissions [12]. Among environmental impact factors caused by decoration, global warming is the most significant.

2.2. Life Cycle Carbon Emissions of Building Decoration

There are relatively few studies on the carbon emissions from building decoration, and the current studies focused on the material production stage and the decoration waste disposal stage. Yu et al. (2014) calculated the energy consumption and carbon emissions regarding nine typical decoration materials, considering the process from primary energy extraction to transportation to primary dealers [11]. Cui et al. (2022) explored the features of energy-efficient and environmentally friendly decoration materials, such as coated glass and soft film ceilings [15]. Meanwhile, some studies showed that the hollow carbon nanospheres decoration material, which is made with either carbon nanotube or metal oxide nanowire decoration, will become the most selected material for building decoration. It will promote the low-carbon development of building decoration in the production and construction process [16]. Li et al. (2022) analyzed the current management status of building decoration waste, which intersected the generation, composition, transportation, and disposal stages [17]. They made effective recommendations for building decoration waste management and disposal in Shenzhen. Sun et al. (2020) analyzed the life cycle process of building decoration waste and considered the generation and flow of waste [18]. The fuel consumption during transportation, the energy consumption of landfill mechanical equipment, and the landfill itself will emit a certain amount of CO2. It is not conducive to the carbon emissions reduction of building decoration. Wu (2017) took 16 buildings in Fujian province in China as an example to investigate the characteristics and patterns of carbon emissions in the whole construction process; they showed that the carbon emissions from building decoration accounted for 24.99%, ranking second in terms of the carbon emissions contribution [19].

As discussed above, previous studies mainly focused on the environmental impacts of building decoration in the material production stage and decoration waste generation stage. However, the building decoration would also emit numerous carbon emissions in other stages because of the materials transportation and electricity usage in the construction stage, among others. At present, the carbon emissions intensity during the life cycle of building decoration is not comprehensively considered. The problems such as inconsistent life cycle stages, insufficient data, and lack of comprehensiveness existed in previous studies. Hence, this study employed the LCA approach to develop a carbon emissions assessment model for building decoration.

3. Methods

The LCA is a method used to assess the potential impacts caused by various products and technologies during the entire life cycle of a product. It also provides comprehensive design-related environmental data for products and systems from multiple dimensions [20,21,22]. The LCA approach has been widely used in studies related to carbon footprint in various fields, including construction, agriculture, and transportation [23,24,25,26]. The LCA approach is mainly classified into three categories according to the inventory analysis: (1) process-based LCA, (2) input–output LCA, and (3) hybrid LCA. Among them, the process-based LCA obtains the basic information data of each part in detail from the bottom-up, and the data reliability is higher. An LCA study is mainly composed of four stages, namely, (1) goal and scope definition, which confirms the research goal and the boundary of a system; (2) life cycle inventory analysis, which is a quantification of the correlation between matter and energy input and output within the boundary of a system; (3) life cycle impact assessment, which is a determination to the negative externalities to the environment resulting from the exchange of matter and energy within the product system; and (4) life cycle interpretation, which is an adequate interpretation of the study results.

Through comparing the applicability of the LCA, combined with the difficulty and accuracy of data acquisition, this study adopted the process-based LCA, where the material data was from the bill of quantities and construction organization design documents obtained through field research and the carbon footprint method was in accordance with the ISO standard. Meanwhile, this study follows the ISO standards, in accordance with the steps of life cycle assessment (LCA). We took the building decoration as the object and the building decoration input and output into account adequately. kg CO2 eq was regarded as the undesirable output and it was used as the environmental impacts assessment index. An actual case was used to quantify the carbon emissions during its life cycle at each stage and to reveal the carbon emissions change characteristics of building decoration.

3.1. Goal and Scope Definition

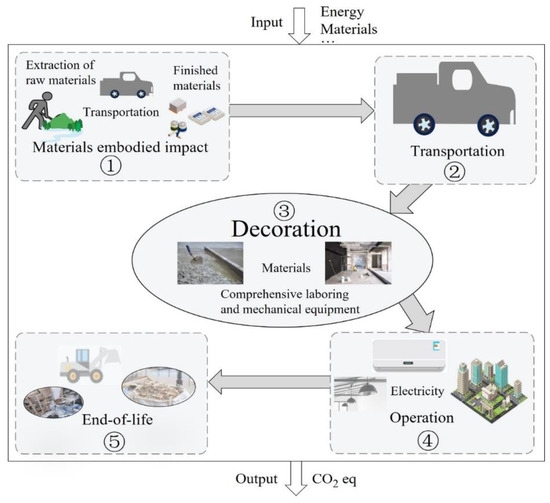

Based on the principles of “Environmental Management Life Cycle Assessment Principles and Framework” (GB/T 24040-2008) [27], this study defined the boundary of the system of building decoration as the following five stages, as shown in Figure 1: (1) the materials embodied impact stage, which reflects the carbon emissions and pollutant emissions due to the resources use, energy consumption from raw materials extraction, transportation, and production; (2) the transportation stage, which mirrors the vehicles’ carbon emissions of energy consumption during transportation of building materials from production sites or distributors to construction sites; (3) the decoration stage, which reveals the carbon emissions generated by the decoration process due to the comprehensive laboring and the energy consumption of decoration machine; (4) the operation stage, which reflects the carbon emissions of the building due to the energy consumption from lights, air-conditioner, electrically operated gate, etc.; (5) the end-of-life stage, which refers to the carbon emissions of energy consumption of comprehensive laboring and dismantling mechanical equipment and the carbon emissions of electricity consumption during the decoration materials demolition, which excludes the waste transportation, landfill and recycling.

Figure 1.

Life cycle stages of building decoration.

3.2. Life Cycle Carbon Emissions Assessment

The total carbon emissions of building decoration are the summation of the carbon emissions from the materials embodied impact, transportation, decoration, operation, and end-of-life stages. The formula is shown as Equation (1). The per-area-carbon emissions () is calculated using Equation (2).

where is the total carbon emissions of building decoration; , , , , and are the carbon emissions in materials embodied impact stage, transportation stage, decoration stage, operation stage, and end-of-life stage, respectively (unit: kg CO2 eq); (unit: kg CO2 eq/m2) is the per-area-carbon emissions of the decoration engineering; and (unit: m2) is the decoration area of the office building.

3.2.1. Materials Embodied Impact Stage

Building decoration adopts materials to treat and beatify the internal and external surfaces and spaces of buildings. Consequently, there has been a large demand for decoration materials in building decoration. The carbon emissions in this stage, mainly the materials’ implicit carbon emission, come from various types of material inputs and energy consumption in the production process. The carbon emissions formula is shown in Equation (3):

where is the amount of material consumption (unit: m3, t), refers to the carbon emissions factor of material (unit: kg CO2 eq/m3, kg CO2 eq/t), and represents the quantity of material.

3.2.2. Transportation Stage

The carbon emissions in the transportation stage are mainly caused by the vehicle’s fuel consumption, which is used to transport the decoration materials to the construction sites. The carbon emissions formula is shown in Equation (4):

where (unit: t) means the amount of material transported, (unit: km) is the transportation distance of material, and refers to the carbon emissions factor for transporting 1 kg material per km under the transportation mode of material (unit: kg CO2 eq/(t·km)).

3.2.3. Decoration Stage

Decoration is a critical stage in realizing a building’s use and decoration function. The carbon emissions of this stage mainly includes comprehensive laboring and decoration machine’s energy consumption carbon emissions. The formula is shown in Equation (5):

where (unit: man-day) is the comprehensive laboring man-days, where its formula is shown in Equation (6), and in this office building case, the is known; is the decoration quantity; is the time rating; (kg CO2 eq/(man-day)) is the carbon emissions factor related to comprehensive laboring man-day, (kWh, kg) and (kg CO2 eq/kWh, kg CO2 eq/kg) refer to the total energy consumption of decoration machine and the carbon emissions factor of the energy consumption of decoration machine , respectively. The formula for is shown in Equation (7):

where (unit: shift) refers to the shift consumption of decoration machine and (unit: kWh/shift, kg/shift) means the energy consumption per unit shift of the decoration machine.

3.2.4. Operation Stage

The operation stage provides the largest contribution of carbon emissions in the building’s entire life cycle process [28,29,30]. It contributes almost 90% and includes the carbon emissions from the replacement of materials during building maintenance [31], which is the key stage of energy saving and carbon emissions reduction [32]. This stage mainly includes the daily use activities during the operation of the building. In order to maintain the operation of the building and people’s comfortable living, decoration parts, such as lights, air conditioners, and electrically operated gate systems, need to be operated. Regarding the engineering building decoration, the installed decoration parts have their corresponding energy consumption. They will generate carbon emissions in the operation stage. Since the carbon emissions from the maintenance of decoration parts are less significant in the entire life cycle, they can be ignored. Hence, they were not taken into consideration. On the basis of the design documents and the standard carbon emissions calculation of building decoration in Shenzhen [33], the interior decoration lifespan was calculated as 10 years. The formula is shown in Equation (8):

where (unit: kWh/(m2·a)) refers to the annual average energy consumption per unit area of the decoration parts with used function. (m2) and (y) refers to the building decoration area and the building decoration using lifespan, respectively.

3.2.5. End-of-Life Stage

The end-of-life stage is the last stage of the entire life cycle process. After considering the availability of decoration waste disposal data into account, this study excluded waste disposal from the calculation. The carbon emissions in this stage mainly include the carbon emissions of comprehensive laboring and the carbon emissions of energy consumption of dismantling mechanical equipment. The formula is shown in Equation (9):

where (unit: man-day) means the comprehensive laboring man-day; (kg CO2 eq/(man-day)) is the carbon emissions factor related to comprehensive laboring man-day; (kWh) and (kg CO2 eq/kWh) refer to the total energy consumption of mechanical equipment , and the carbon emissions factor of the energy consumption of mechanical equipment , respectively. The calculation formula of is equal to Equation (7).

3.3. Life Cycle Inventory Analysis

In order to better understand the characteristics of carbon emissions of building decoration at each stage during its life cycle and to improve the accuracy and credibility of the work, this study selected an office building decoration project in Shenzhen for the empirical analysis. We carried out an analysis of the environmental impacts generated by interior decoration with a view to reveal the changing characteristics of the carbon emissions of building decoration.

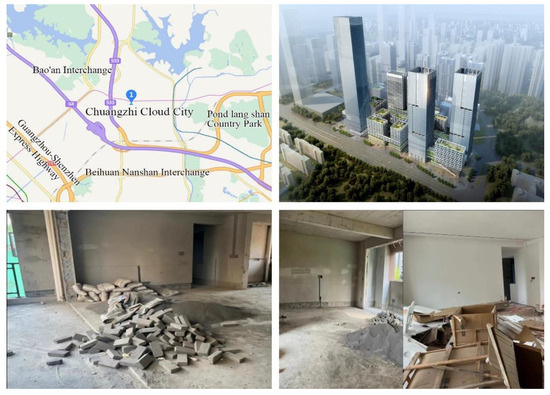

3.3.1. Case Description

The project was located at the intersection of Liuxian Avenue and Chuangke Road in Xili District, Nanshan District, Shenzhen, with a construction area of 20,172.14 m2 and a decoration area of 6500 m2. The decoration area involved 5 towers, 5 podiums, and 5 basements. Blocks 4A, 4B, 5A, and 5B are R&D office towers, where 4A and 4B have 43 floors above the ground and a building height of 166.35 m. Both 5A and 5B have 13 floors above the ground and a building height of 56.4 m. Block 4C is a 2-story R&D office tower (elevated at the bottom) with a building height of 33.4 m. Additionally, there is a 3-story basement with a burial depth of 13.0 m, mainly for basement parking, equipment, and civil air defense. It does not belong to the important activity area; thus, the basement decoration was not considered. The project decoration process, location, and effect pictures are shown in Figure 2.

Figure 2.

The basic information of selected project.

3.3.2. Data Acquisition for Inventory Analysis

The main sources of data acquisition for inventory analysis were a field investigation, semi-structured interviews, and desk research. Among them, the building decoration material types and consumption were obtained through the decoration material manual of the project, construction organization design, and the bill of quantities. As for the selection criteria for materials, it was described as follows: Due to the comprehensive consideration of the safety, aesthetics, and cost of the material, a flame retardant plate with a high flame retardant rate and wear-resistant stone were selected as the decorative panel. The decorative brick was mainly based on ceramic products, mainly because of its corrosion resistance, small water absorption rate, anti-aging, and cost. For the coating and plastering works, the main consideration was water resistance, health, and beauty, and thus, white latex paint and other materials were chosen. The light steel keel, square steel, and so on were mainly chosen based on their cost and strength. After comprehensive consideration, the decorative materials used in office buildings are shown in Table S1.

The carbon emissions factor data was obtained through the carbon emissions calculation standard of building decoration in Shenzhen [33], as shown in Table S1.

The material carbon emissions factor in the transportation stage was related to the cargo transportation mode and the energy consumed type. This study employed a light gasoline truck (2t) and assumed that materials were transported to the site with full loads. The transportation distance of ceramic tiles was 150 km. Both the transportation distances of the stone and flame-retardant plate were 200 km, while those of the white latex paint and light-gage steel joist were 120 km and 270 km, respectively. The transportation distances of the remaining seven materials were 500 km. The carbon emissions factor () of energy consumption and fuel of vehicles in the transportation stage was obtained through the building carbon emissions calculation standard [34], as shown in Table S3a.

The comprehensive laboring man-day data and decoration quantity data of the decoration stage and end-of-life stage were derived from the design documents, construction organization design, operation scheme, and registration of the actual construction team. The time rating data were acquired from the labor productivity standards for construction works [35]. The shift consumption, energy consumption per shift, and the carbon emissions factor were obtained from the building carbon emissions calculation standard [34], the establishment rules of construction equipment shift costs for construction were based on projects in Guangdong Province [36] and the special scheme of the building. The decoration machines included a mortar mixer, concrete vibrator, woodworking circular sawing machine, rotary hammer, cutting machine, grinder, AC spot welder, and electric air compressor, as shown in Tables S3a and S4. The average annual energy consumption per unit area of the decoration parts in the operation stage is shown in Table S3b and was calculated based on the engineering design documents and existing studies [37]. This study took a 1 m2 decoration area as a functional unit. A large amount of statistical and survey data was collected to characterize the carbon emissions generation of the office building (shown in Table 1).

Table 1.

Data sources and definitions of decoration carbon emissions generation.

3.3.3. Data Limitations

In the LCA of office building decoration, the actual project conditions were variable, data were complicated and of many types, and the calculation process involved a wide range of data with limited collectability and lack of underlying statistical basis. The uncertainty of data quality in the study mainly included the following points: (1) Most of the data in the study came from field research data; some of the input–output and carbon emission factors data referred to the existing research results; and the error was caused by the inconsistency of the system boundary, time boundary, and so on of the study. Due to the late development of the LCA database, the dynamics of the emissions factor data could not be reflected in real time; the study assumed that it obeyed a normal distribution; and Monte Carlo simulation was used for the uncertainty analysis, with 10,000 calculations of the results and a 95% confidence level. (2) Regarding case characterization, a typical, standardized office building decoration case was used for the prediction analysis; not all the decoration projects were investigated and calculated in detail; and due to the lack of transportation information, it was assumed that the vehicle used for transporting the materials was only a light-duty gasoline truck (2t), and the materials were transported to the site with a full load. Monte Carlo simulation was used to take uncertainty into account, assuming that the transportation distance followed a uniform distribution, and 10,000 calculations were performed with a 95% confidence level.

4. Results

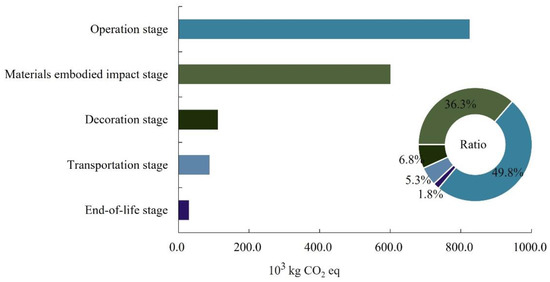

4.1. Building Decoration Life Cycle Carbon Emissions Intensity

Based on Equation (1) in Section 3.2, Figure 3 shows the carbon emissions during the building decoration life cycle. The carbon emissions of the selected case’s interior decoration were 1654.0 tons CO2 eq in the life cycle process. Since area discrepancies between different building decoration engineering existed, it was difficult to compare the carbon emissions of the office building decoration and to standardize the carbon emissions level of the office building’s interior decoration. This study adopted the kg CO2 eq/m2 as a functional unit to eliminate the impacts caused by the area discrepancies of office building decoration. Its carbon emissions intensity was 254.5 kg CO2 eq/m2. From the perspective of the formation path of carbon, the largest contributor of carbon emissions in the life cycle of the building decoration was the operation stage because there was a large electricity consumption. It accounted for 49.8% of the total carbon emissions; 39.9% of the carbon emissions were caused by the electrically operated gate, 33.5% of the carbon emissions were generated by the electricity consumption of air conditioner, and the rest of the carbon emissions were due to the electricity consumption of lights demand.

Figure 3.

The carbon emissions during building decoration life cycle.

The second stage was the materials embodied impact stage, which accounted for 36.3%. The decoration materials production was related to exploitation and machining, which consumed large amounts of energy and manual resources. According to the decoration structural parts, the carbon emissions of the flame-retardant plate, square steel, and ceramic tiles in the ceiling engineering of material production and tapestry plate engineering accounted for 58.3% because the decoration was a wet operation, and thus, it consumed many high-resource-density materials. The cement mortar used in the plastering engineering accounted for 15.8%. It is important to pay attention to the decoration materials production. The decoration stage, transportation stage, and end-of-life stage had less carbon emissions, with the sum of the three accounting for only 13.9%. The result is consistent with the results of the entire life cycle assessment of the building [31]. Compared with residential buildings, the decoration style of office buildings is more uniform, and will generally not be demolished and renovated frequently. Hence, the carbon emissions in the end-of-life stage are less impressive.

4.2. Building Decoration Carbon Emissions Intensity of Each Sub-Stage

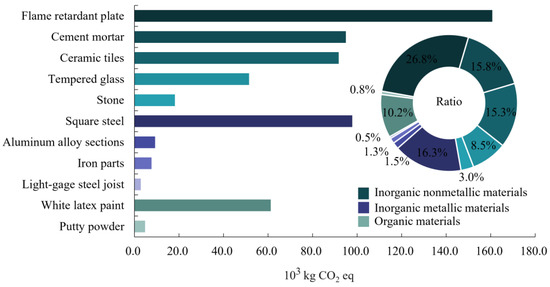

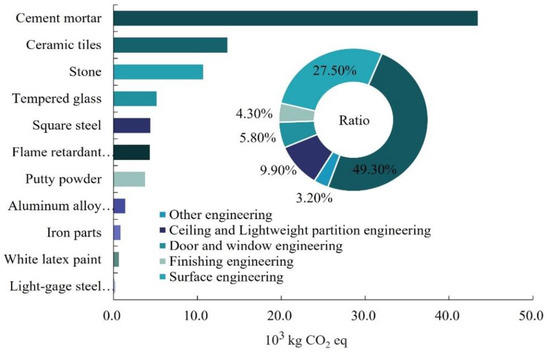

4.2.1. The Carbon Emissions Intensity of Materials Embodied Impact Stage

Based on Equation (3) in Section 3.2.1 and the inventory data in Table S1, the calculation results of the carbon emissions and ratio of building decoration materials embodied impact stage are shown in Figure 4. The total carbon emissions from the materials embodied impact stage of the building decoration materials were 600.3 tons CO2 eq. The flame-retardant plate caused 160.7 tons CO2 eq, accounting for 26.8% of the materials embodied impact stage. It was the largest component of carbon emissions, followed by the square steel, cement mortar, and ceramic tiles, which accounted for 16.3%, 15.8%, and 15.3%, respectively. The carbon emissions of the light-gage steel joist and putty powder accounted for less than 1%.

Figure 4.

The carbon emissions of materials embodied impact stage and ratio of decoration materials.

According to the composition of material elements, this study classified materials into inorganic materials and organic materials, where inorganic materials were subdivided into inorganic nonmetallic materials and inorganic metallic materials. It can be seen that the inorganic nonmetallic materials caused more carbon emissions because they have a complex crystal structure; hence, they consumed more energy during the finished process. At the same time, in accordance with the decoration structural parts, the carbon emissions of materials embodied impact stage of the flame-retardant plate, square steel, and ceramic tiles in ceiling engineering and tapestry plate engineering accounted for 58.3%, whereas the cement mortar in the plaster engineering accounted for only 15.8%. In view of the materials of the decoration part and their carbon emissions ratio, it is important to focus on three aspects: the improvement in the decoration materials production process, increasing the usage rate of recycled materials, and achieving the carbon emissions reduction of building decoration engineering.

4.2.2. The Carbon Emissions Intensity of Transportation Stage

Transportation was divided into four different modes: highway transportation, air transportation, railway transportation, and waterway transportation. In general, the consumed energy sources of the road, air, and waterway transportation modes were assumed to be diesel and gasoline, while railway transportation may use other energy sources, such as coal, diesel, or electricity [39]. Due to the sources of various materials being different, the transport distances were also different. For the energy consumption of the transportation stage, this study selected a light gasoline truck (2t) as the vehicle based on the most economic principles. Based on Equation (4) in Section 3.2.2 and the data inventory in Tables S3a and S4, Figure 5 shows the carbon emissions in the transportation stage.

Figure 5.

The carbon emissions and ratios of transportation stage.

The total carbon emissions derived from the transportation stage of the building decoration materials were 88.1 tons CO2 eq. According to the decoration structural parts of the material used, the cement mortar used in plastering engineering was the most important source of carbon emissions during the transportation stage, where it emitted 43.4 tons CO2 eq and contributed 49.3% of the carbon emissions. This was mainly caused by the long transportation distance, the large amount of fuel consumed, and the high amount of cement mortar compared with other materials, which can be considered when optimizing the shipping structure to reduce carbon emissions. The next was the ceramic tiles and stone used in surface engineering; they emitted 24.3 tons CO2 eq, accounting for 27.5% of the total emissions of this stage. The main reason that caused this phenomenon was the large amount of materials consumed. The carbon emissions of the ceiling and lightweight partition engineering were 8.7 tons CO2 eq; it accounted for 9.9% and was mainly caused by the long distance traveled. Selecting nearby square steel suppliers could mitigate carbon emissions. The remaining door and window engineering, finishing engineering, and other engineering emitted lower carbon emissions; their carbon emissions could be reduced by increasing the use of environmentally friendly materials. Thus, the carbon emissions of the cement mortar, ceramic tiles, and stone used in plastering engineering and surface engineering in the transportation stage should be given priority attention.

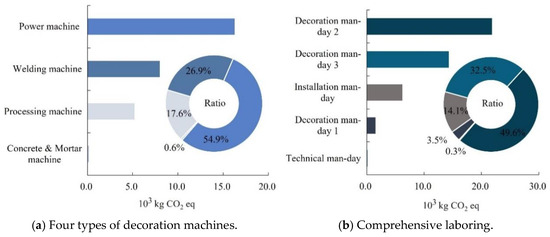

4.2.3. The Carbon Emissions Intensity of Decoration Stage

The implementation of building decoration and beautification functions mainly depended on the decoration process. The bill of quantities, special scheme of the building decoration, comprehensive laboring, decoration machinery types, and shift quantities are illustrated in Table S4. Based on Equations (5) and (7) in Section 3.2.3, Figure 6a,b show the carbon emissions and ratios of the decoration stage. The machines were divided into five kinds: concrete and mortar machines, processing machines, welding machines, power machines, and other machines. Among them, the carbon dioxide emitted by the concrete and mortar machines and other machines was small, and it had little impact on the environment. Therefore, they are not discussed, and the processing machine, welding machine, and power machine equipment are given priority attention.

Figure 6.

The carbon emissions and ratios of decoration machines and comprehensive laboring.

There were 111.8 tons CO2 eq in the decoration stage. It was generated by the electricity consumption of the decoration machines and comprehensive laboring. In terms of the emissions categories, the carbon emissions generated by the decoration machines were 67.8 tons CO2 eq, accounting for 60.6% of total emissions in the decoration stage. The power machines had the most carbon emissions, where they emitted 16.3 tons CO2 eq and accounted for 54.9% of the decoration machine emissions; this was followed by the welding machines, which emitted 8.0 tons CO2 eq and accounted for 26.9% of the decoration machine emissions.

The carbon emissions of the decoration machine used in the decoration process are shown in Figure S1, among which, the cumulative contribution of AC spot welders was 56.3%, emitting 38.6 tons CO2 eq; they were the most important source of carbon emissions. The electric air compressors’ share was 24.0%, emitting 16.3 tons CO2 eq; and the cutting machines’ share was 11.0%, emitting 7.5 tons CO2 eq. This shows that power machines, welding machines, and processing machines have a huge potential for emissions reduction, and their main energy consumption originates from electricity. Hence, it is important to focus on changing the energy structure by using photovoltaic generation, wind power generation, geothermal power generation, and other clean energy instead of thermal power generation.

The carbon emissions generated by comprehensive laboring were 44.0 tons CO2 eq, which accounted for 39.4% of the total emissions in the decoration stage. As shown in Figure 6b, the decoration man-days emitted 85.6% of the carbon emissions and installation man-days emitted 14.1% of the carbon emissions; meanwhile, technical man-days accounted for less than 1% of the carbon emissions, and thus, they were a non-substantial emissions source and was ignored. Therefore, it is important to focus on decoration man-days emissions.

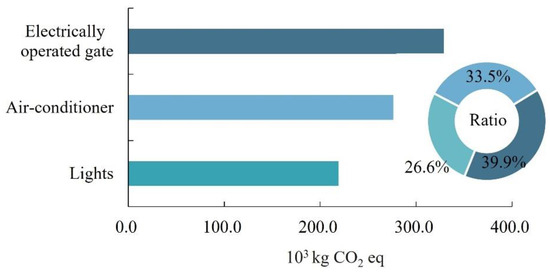

4.2.4. The Carbon Emissions Intensity of the Operation Stage

The operation stage is the longest in a building life cycle process. It consumes a significant amount of energy and is also an important carbon emissions contribution source. The building operation is closely related to the decoration parts. For example, lights, air conditioners, and electrically operated gates consume more energy. In light of the decoration area data and interior decoration lifespan data provided by the study case, by combining Equation (8) in Section 3.2.4 and the inventory data from Table S3a,b, the results are shown in Figure 7. The lifespan of the office building was stated as 10 years.

Figure 7.

The carbon emissions and ratios of operation stage.

As shown in Figure 7, the carbon emissions in the operation stage were 824.3 tons CO2 eq. There were 39.9% of the carbon emissions caused by the electrically operated gate, with a cumulative contribution of 328.8 tons CO2 eq. A total of 33.5% (276.3 tons CO2 eq) of the carbon emissions were generated by the energy consumption of the air conditioner usage. The remaining 26.6% was due to the energy consumption of the lighting demand, with carbon emissions of 219.27 tons CO2 eq. As shown above, the carbon emissions generated by the decoration parts in the operation stage had a small difference. Hence, attention should be paid to lights, air conditioners, and electrically operated gates. Clean electricity and energy-saving equipment can be used to reduce energy consumption and reduce carbon emissions accordingly.

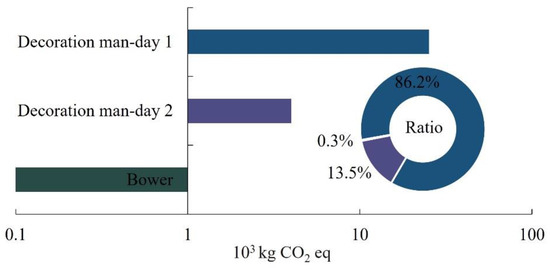

4.2.5. The Carbon Emissions Intensity of End-of-Life Stage

Based on Equations (7) and (9) in Section 3.2.3 and Section 3.2.5 and the data in Tables S3a and S4, the carbon emissions results of the end-of-life stage are shown in Figure 8. The carbon emissions in the end-of-life stage of building decoration were calculated to be 29.4 tons CO2 eq. A total of 99.7% of the carbon emissions were contributed by the decoration man-day. The building decoration in the end-of-life stage generally belonged to the building for decoration function transformation. Many pieces of mechanical equipment cannot be used to dismantle the area violently because of the change in the space usage layout and other factors. This prevents damage to the bearing capacity of the building structure, and hence, a significant amount of manual demolition is required. The cumulative contribution value of the decoration man-day 1 was 25.3 tons CO2 eq, accounting for 86.2%. The decoration man-day 2 was only 4.0 tons CO2 eq, accounting for 13.5%. A few non-load-bearing structures were dismantled by mechanical equipment. This led to carbon emissions from energy consumption. The carbon emissions caused by the energy consumption of the dismantled mechanical equipment were 77.5 kg CO2 eq, which only accounted for 0.3%.

Figure 8.

The carbon emissions and ratios of end-of-life stage.

5. Discussion

5.1. Building Decoration Life Cycle Carbon Emissions

The carbon emissions intensity of office building decoration was 254.5 kg CO2 eq/m2, where the decoration style of office buildings is more functional and uniform compared with residential decoration, and thus, supporting facilities are correspondingly less. Residential buildings are designed for maximum comfort, which will consume more materials and energy. Therefore, maybe the carbon emissions intensity of office building decoration is less than residential buildings, which we hope to further validate in future studies.

The carbon emissions of the materials embodied impact stage were 600.3 tons CO2 eq, accounting for 36.3% of the carbon emissions in the building decoration life cycle. Due to the complex production process of materials, the processing of raw materials consumed a large amount of energy. This resulted in the carbon emissions during this stage of the building decoration life cycle becoming the second-highest source. The carbon emissions caused by the flame-retardant plate’s production accounted for 26.8%, while the square steel and cement mortar accounted for 16.3% and 15.8%, respectively. With the three accounting for more than 50%, they should therefore be taken as a key path to regulating the production process of inorganic materials. The materials and technical performances should be improved and the process route also replaced. There are some alternative natural materials for building decoration to reduce energy consumption, and thus, they could cause low carbon emissions. For example, bamboo has strong renewable properties and consumes relatively low energy during production and processing, thus making it highly sustainable. Bamboo fiber board and moss walls have low volatile compound (VOC) emissions, and thus, they can be used as environmentally friendly interior wall decoration materials. Solar panels and solar window materials can fully harness solar energy, and thus, could reduce the reliance on traditional energy sources and decrease energy consumption and carbon emissions. Previous studies showed that replacing HRB 335 steel with HRB 400 steel can achieve a steel reduction of 10–14% [37]. Assuming all the HRB 335 square steel used in this building decoration was replaced with HRB 400 square steel, the carbon intensity due to the production of this material could be reduced to 13.54 kg CO2 eq/m2 from 20.56 kg CO2 eq/m2.

The carbon emissions in the transportation stage were 88.1 tons CO2 eq, which accounted for 5.3% of the total emissions. In this stage, the synergism effect of material transportation can be achieved by optimizing the transportation route. Both the shipping structure and vehicles can be improved, and thus, a reduction in the carbon emissions generated by material transportation can be achieved. For example, the distance of transportation could be reduced by using local materials. Assuming that the transportation distance of all materials is reduced by 10%, the carbon emissions of the transportation stage can be reduced by 8.8 tons CO2 eq with the same material weight and vehicle type. In addition, for short-distance transportation, one can choose an automobile that uses a new energy type, namely, one that has low energy consumption and less pollution. Traditional vehicles are prioritized for medium and long distances, forming the shipping structure of both complementary alternate transportation methods.

The carbon emissions in the decoration stage were 111.8 tons CO2 eq, accounting for 6.8%. Since the decoration machines consumed large amounts of electricity, AC spot welders and electric air compressors should be used as key methods to reduce carbon emissions in building decoration. At the same time, through site and technology management strengthening, a reasonable green construction plan can be formulated that can reduce extra manual work. Moreover, the usage of recycling materials, such as steel, can effectively reduce the additional carbon emissions generated by the extraction and production of materials. Steel is a material that is highly recyclable and offers advantages for structures (flexible layout and great seismic performance). Its recycling rate following disassembly is relatively high, which can decrease carbon emissions from virgin materials year over year and reduce the net material loss to some extent [40]. A higher prefabricated penetration rate of building decoration is another efficient strategy besides the ones listed above. Based on the scale and industrialized production of components, assembled decoration merely requires the transportation of prefabricated components to the assembly location. Hence, the residual waste generated by site cutting is reduced. It also avoids a certain amount of the generation of decoration waste and facilitates a greater replacement of accessories.

The carbon emissions in the operation stage were 824.3 tons CO2 eq, accounting for 49.8% of the building decoration life cycle. This stage involved the operation of building decoration parts, such as lights, air conditioners, and electrically operated gates, which consumed a large amount of electricity. Optimization of the building energy structure by using clean electricity instead of traditional energy generation is an effective way to reduce carbon emissions at this stage. At present, China’s energy mix is still dominated by fossil energy. Data show that the proportion of fossil (coal, oil, and natural gas) consumption in China’s energy consumption has declined from 90.3% in 2012 to 82.5% in 2022. Concurrently, the share of energy consumption, such as primary electricity (referring to electricity generated from nuclear power, hydropower, wind power, and solar power) has been gradually increasing from 9.7% in 2012 to 17.5% in 2022 [41]. With the steady development of renewable energy and the restructuring of the energy mix, carbon emissions from energy consumption during the construction, operation, and dismantling stages will gradually decrease.

Concurrently, the improved performance of decoration components can reduce the equipment’s energy consumption during daily operation. In addition, intelligent energy-saving systems can realize fine control and optimal operation to reduce energy consumption and carbon emissions. Furthermore, the lifespan of decoration parts can also be extended by improving the project quality management system. The public building lifespan is 50 years, while that of the interior decoration is 6–8 years. The renewing interior decoration parts dismantling speed is much faster than the lifespan of the building, which has more room for improvement.

The carbon emissions in the end-of-life stage were 29.4 tons CO2 eq, which accounted for 1.8%. A sound dismantling plan is the best means to achieve the optimal efficiency of carbon emissions at this stage. The best collaboration of personnel and mechanical equipment at a work site can be achieved through the rational deployment of operators. Meanwhile, the diminishing of night work could decrease the energy consumption of equipment indirectly caused by manual work, such as lights. Furthermore, the building’s interior layout can be optimized at the early design stage. This reduces the dismantling amount and frequency and reduces the carbon emissions that result from unnecessary dismantling. The unrecyclable decoration materials waste can be effectively avoided to achieve a carbon emissions reduction.

In summary, the carbon emissions of each of the building decoration’s sub-stages during its life cycle varied widely. The most significant source of carbon emissions contribution of buildings was the operation stage, followed by the building decoration materials embodied impact stage. The ratio of CO2 eq emitted by the two stages exceeded 85% of the carbon emissions in the life cycle of the building decoration, and therefore, they are the key targets of carbon reduction.

5.2. Limitations

Building decoration processes are complex and diverse and include public buildings and residential buildings. Different types of building decoration approaches have discrepancies, and it is difficult for this assessment model to unify the carbon emissions generated by various types of building decoration. They are only measured and analyzed for the defined range of the building’s carbon emissions intensity. It was inevitable that this study was biased to represent the carbon emissions intensity of office buildings, which was due to the characterization of a certain office building case.

Meanwhile, for carbon emissions of building decoration, there is no unified measurement and evaluation standard in China. A carbon emissions assessment model of building decoration was constructed based on the building carbon emissions calculation standard [34]. It also integrated characteristics of actual engineering and the standard carbon emissions calculation of building decoration in Shenzhen [33]. In this study, the calculation process involved a wide range of data with limited collectability.

6. Conclusions

This study developed a life-cycle carbon emissions assessment model for building decoration. The model was applied to a case of office building decoration. Additionally, it provided quantitative data that demonstrated the building decoration carbon emissions of each stage, including the decoration materials embodied impact, transportation, decoration, operation, and end-of-life processes. At the same time, the key stages and factors of the building decoration were also identified. The main conclusions of this case study were the following:

- (1)

- The carbon emissions intensity of the case was 254.5 kg CO2 eq/m2 during the entire life cycle.

- (2)

- The materials embodied impact stage and the operation stage were the main carbon emissions contributors. The carbon emissions from these two stages accounted for 36.3% and 49.8% of the total carbon emissions, respectively; therefore, the carbon emissions reduction of building decoration should focus on the above two stages.

- (3)

- By replacing the HRB 335 square steel with HRB 400 square steel, the carbon intensity due to the production of this material could be reduced to 13.54 kg CO2 eq/m2 from 20.56 kg CO2 eq/m2; hence, improving the production process of building materials or replacing lower performance materials with high-performance materials can efficiently reduce the carbon emissions in the materials embodied impact stage.

- (4)

- In the operation stage, the optimization of the building energy structure is a suitable way to reduce carbon emissions. And the improvement of the performance of decoration parts, such as lights and air conditioners, can reduce carbon emissions.

- (5)

- In the transportation stage, a carbon emissions reduction can be attained through optimizing the transportation route.

- (6)

- In the decoration stage, a synergism effect can be achieved via regular maintenance of decoration machines and increasing the recyclable materials used. Lastly, during the end-of-life stage, a sound demolition plan formulation and reasonable deployment of operators are better ways to increase efficiency and reduce carbon emissions.

Supplementary Materials

The following supporting information can be downloaded from https://www.mdpi.com/article/10.3390/su151914055/s1: Figure S1. Carbon emissions and ratio of decoration machine; Figure S2. Carbon emissions and ratios of decoration machine and comprehensive laboring. Table S1. Materials consumption list for the materials embodied impact stage of main decoration materials; Table S2. Materials amount and transportation distance for the transportation stage; Table S3. The carbon emission factor and the consumption list of some life cycle stages. Table S4. Integrated labor days and construction machinery energy consumption list for the decoration and end-of-life stage. References [33,34,36,37,38] are cited in Supplementary Materials.

Author Contributions

H.W.: supervision, project administration, and writing—review and editing. W.Z.: conceptualization, data curation, methodology, and writing—original draft. K.C.: resources, writing—review and editing, and validation. L.Z.: data curation and visualization. Z.Z.: validation and investigation. Y.L.: supervision and data curation. Z.H.: supervision, project administration, and funding acquisition. All authors have read and agreed to the published version of the manuscript.

Funding

This work was financially supported by the Shenzhen Science and Technology Plan (JCYJ20190808123013260, JCYJ20220811111306001) and The Fifth Construction Co., Ltd., of the China Construction First Group Research project (89202306).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- China Association of Building Energy Efficiency (CABEE). Research Report of China Building Energy Consumption and Carbon Emissions in 2022. 2023. Available online: https://www.cabee.org/upload/file/20230104/1672820934145324.pdf (accessed on 16 August 2023).

- The State Council People’s Republic of China. The Fourteenth Five-Year Plan. Available online: https://www.gov.cn/xinwen/2021-03/13/content_5592681.htm?gov (accessed on 16 August 2023).

- Zhang, G.C.; Chi, F.G. The technology of cement-based building facade decoration materials. Agro Food Ind. Hi-Tech 2017, 28, 1900–1903. [Google Scholar]

- National Bureau of Statistics of China (NBSC). China Statistical Yearbook in 2021. Available online: http://www.stats.gov.cn/sj/ndsj/2021/indexeh.htm (accessed on 16 August 2023).

- Shen, L.; Zhong, S.; Ayman, E.; Zhang, H.L.; Zhao, J.A. Energy-Cement-Carbon Emission Nexus and its Implications for Future Urbanization in China. J. Sustain. Dev. Energy Water Environ. Syst. 2021, 9, 1080354. [Google Scholar] [CrossRef]

- Wang, J.; Du, G.J.; Liu, M.H. Spatiotemporal characteristics and influencing factors of carbon emissions from civil buildings: Evidence from urban China. PLoS ONE 2022, 17, e027229. [Google Scholar] [CrossRef]

- Liu, H.W.; Li, J.; Sun, Y.F.; Wang, Y.S.; Zhao, H.C. Estimation Method of Carbon Emissions in the Embodied Phase of Low Carbon Building. Adv. Civ. Eng. 2020, 2020, 8853536. [Google Scholar] [CrossRef]

- Yang, X.Y.; Zhang, S.C.; Wang, K. Quantitative study of life cycle carbon emissions from 7 timber buildings in China. Int. J. Life Cycle Assess. 2021, 26, 1721–1734. [Google Scholar] [CrossRef]

- Zhang, Y.; Zheng, X.J.; Zhang, H.; Chen, G.F.; Wang, X. Carbon emission analysis of a residential building in China through life cycle assessment. Front. Environ. Sci. Eng. 2016, 10, 150–158. [Google Scholar] [CrossRef]

- Sim, J.; Sim, J. The air emission assessment of a South Korean traditional building during its life cycle. Build. Environ. 2016, 105, 283–294. [Google Scholar] [CrossRef]

- Yu, H.Y.; Zeng, J.; Zhao, M. The typical decoration materials life cycle energy consumption and carbon emissions. Build. Sci. 2014, 30, 21–25. (In Chinese) [Google Scholar]

- Wang, J.J.; Teng, Y.; Chen, Z.; Bai, J.; Niu, Y.N.; Duan, H.B. Assessment of carbon emissions of building interior decoration and renovation waste disposal in the fast growing Greater Bay Area, China. Sci. Total Environ. 2021, 798, 149158. [Google Scholar] [CrossRef]

- Wu, Z.Z.; Li, H.; Feng, Y.; Luo, X.C.; Chen, Q.H. Developing a green building evaluation standard for interior decoration: A case study of China. Build. Environ. 2019, 152, 50–58. [Google Scholar] [CrossRef]

- Zhang, T.N. The Building Decoration Environmental Impact Measurement Method and Application Research Based on LCA. Master’s Thesis, Shenzhen University, Shenzhen, China, 2019. (In Chinese). [Google Scholar]

- Cui, W.; Liu, H.; Xu, B.; Zhong, C. Impact of Industry 4.0 on Green Decoration Materials in Public Architectural Engineering for Application of Energy Conservation and Environmental Protection. Wirel. Commun. Mob. Comput. 2022, 2022, 1360739. [Google Scholar] [CrossRef]

- Poyraz, S.; Cook, J.; Liu, Z.; Zhang, L.; Nautiyal, A.; Hohmann, B.; Klamt, S.; Zhang, X.Y. Microwave energy-based manufacturing of hollow carbon nanospheres decorated with carbon nanotubes or metal oxide nanowires. J. Mater. Sci. 2018, 53, 12178–12189. [Google Scholar] [CrossRef]

- Li, Z.H.; Deng, Q.X.; Bai, J.; Li, Y.; Wang, Y.Z.; Liu, N.X.; Gong, Y.X. Management system for engineering and decoration waste: An exploratory study in Shenzhen. J. Environ. Manag. 2022, 314, 115085. [Google Scholar] [CrossRef] [PubMed]

- Sun, P.W.; Zhang, N.; Zuo, J.; Mao, R.C.; Gao, X.F.; Duan, H.B. Characterizing the generation and flows of building interior decoration and renovation waste: A case study in Shenzhen City. J. Clean. Prod. 2020, 260, 121077. [Google Scholar] [CrossRef]

- Wu, S.Y. Research on Constructional Engineering Carbon Emission Based on Bill of Quantities. Master’s Thesis, Fujian Agriculture and Forestry University, Fuzhou, China, 2017. (In Chinese). [Google Scholar]

- Geng, H.C. Research on Carbon Emission Calculation and Emission Reduction Measures for Urban Residential Bulidings Based on LCA. Master’s Thesis, Xi’an University of Science and Technology, Xi’an, China, 2021. (In Chinese). [Google Scholar]

- Steele, N.L.C.; Allen, D.T. An abridged Life-Cycle Assessment of Electric Vehicle Batteries. Environ. Sci. Technol. 1998, 32, 40A–46A. [Google Scholar] [CrossRef]

- Xiao, X.D. Study on Life Cycle Carbon Emissions and Costs of Green Buildings. Master’s Thesis, Beijing Jiaotong University, Beijing, China, 2021. (In Chinese). [Google Scholar]

- Duan, H.Y.; Chen, S.Y.; Liu, Y.Y.; Zhang, S.P.; Wang, X.E.; Wang, S.; Song, J.N. A study of regional energy consumption characteristics of China’s construction industry based on a life cycle perspective. China Popul. Resour. Environ. 2020, 30, 57–65. (In Chinese) [Google Scholar]

- Guo, C.; Guo, Y.L.; Chen, Z. Analysis of carbon emission accounting and research progress of traffic tunnel engineering. Mod. Tunn. Technol. 2023, 60, 1–10. (In Chinese) [Google Scholar]

- Sovacool, B.K.; Brown, M.A. Twelve metropolitan carbon footprints: A preliminary comparative global assessment. Energy Policy 2010, 38, 4856–4869. [Google Scholar] [CrossRef]

- Wang, Y.Q.; Pu, C.; Zhao, X.; Wang, X.; Liu, S.L.; Zhang, H.L. Historical dynamics and future trends of the carbon footprint of wheat and corn in China. Resour. Sci. 2018, 40, 1800–1811. (In Chinese) [Google Scholar]

- GB/T 24040-2008; Environmental Management-Life Cycle Assessment—Principles and Frameworks. Standard Press of China: Beijing, China, 2008. (In Chinese)

- Bonamente, E.; Merico, M.C.; Rinaldi, S.; Pignatta, G.; Pisello, A.L.; Cotana, F.; Nicolini, A. Environmental Impact of Industrial Prefabricated Buildings: Carbon and Energy Footprint Analysis Based on an LCA Approach. Energy Procedia 2014, 61, 2841–2844. [Google Scholar] [CrossRef]

- Cao, J. A Study on the Whole Life Cycle of Residential Building Carbon Footprint. Master’s Thesis, Chongqing University, Chongqing, China, 2017. (In Chinese). [Google Scholar]

- Thormark, C. A low energy building in a life cycle—Its embodied energy, energy need for operation and recycling potential. Build. Environ. 2002, 37, 429–435. [Google Scholar] [CrossRef]

- Bai, L.H. A Study on Whole Life Cycle Carbon Emission Prediction Model for Public Buildings. Master’s Thesis, Tianjin University, Tianjin, China, 2019. (In Chinese). [Google Scholar]

- Chen, L. Research on the Whole Life Cycle Carbon Emission Measurement and Reduction Strategy of Residential Buildings. Master’s Thesis, Shenyang Jianzhu University, Shenyang, China, 2020. (In Chinese). [Google Scholar]

- T/CBDA X-2022; Standard for Building Decoration Carbon Emission Calculation. China Architecture and Building Press: Beijing, China, 2022. (In Chinese)

- GB/T51366-2019; The building Carbon Emissions Calculation Standard. China Architecture and Building Press: Beijing, China, 2019. (In Chinese)

- National Public Service Platform for Standards Information (NPSPSI). Labour Productivity Standards for Construction Works (LD/T 73.1-4-2008). Available online: https://ebook.chinabuilding.com.cn/zbooklib/bookpdf/probation?SiteID=1&bookID=129617 (accessed on 16 August 2023).

- The Establishment Rules of Construction Equipment Shift Costs for Construction Projects in Guangdong Province. 2018. Available online: http://www.gd.gov.cn/attachment/0/381/381883/2721956.pdf (accessed on 14 July 2023).

- Luo, Z.X. Research on the Calculation Method and Emission Reduction Strategy of Building Life Cycle Carbon Dioxide Emission. Ph.D. Thesis, Xi‘an University of Architecture and Technology, Xi’an, China, 2016. (In Chinese). [Google Scholar]

- China Climate Change Info-Net (CCCHINA). The Average CO2 Emission Factor of China’s Regional Power Grid (2011–2012). Available online: https://www.ccchina.org.cn/archiver/ccchinacn/UpFile/Files/Default/20140923163205362312.pdf (accessed on 16 August 2023).

- Zhao, X.X. Green Building Whole Life Cycle Carbon Emission Calculation and Carbon Reduction Benefit Evaluation. Master’s Thesis, Dalian University of Technology, Dalian, China, 2017. (In Chinese). [Google Scholar]

- Bai, J.; Kang, P.; Zhang, W.B.; Chen, K.Y.; Zhang, Y.; Zhou, D.; Duan, H.B. Feasibility study on using excavated soil and rock to sintering utilization. Circ. Econ. 2022, 1, 100007. [Google Scholar] [CrossRef]

- National Energy Administration (NEA). Record-Breaking Electricity Consumption in Many Places: Energy for Change, the Rise of Wind and Solar Installations in Progress. Available online: http://www.nea.gov.cn/2023-07/31/c_1310734804.htm (accessed on 17 August 2023).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).