Experimental Study on the Mechanical Properties and Permeability of Cement-Stabilized Permeable Recycle Aggregate Materials

Abstract

:1. Introduction

2. Experimental Design

2.1. Materials and Methods

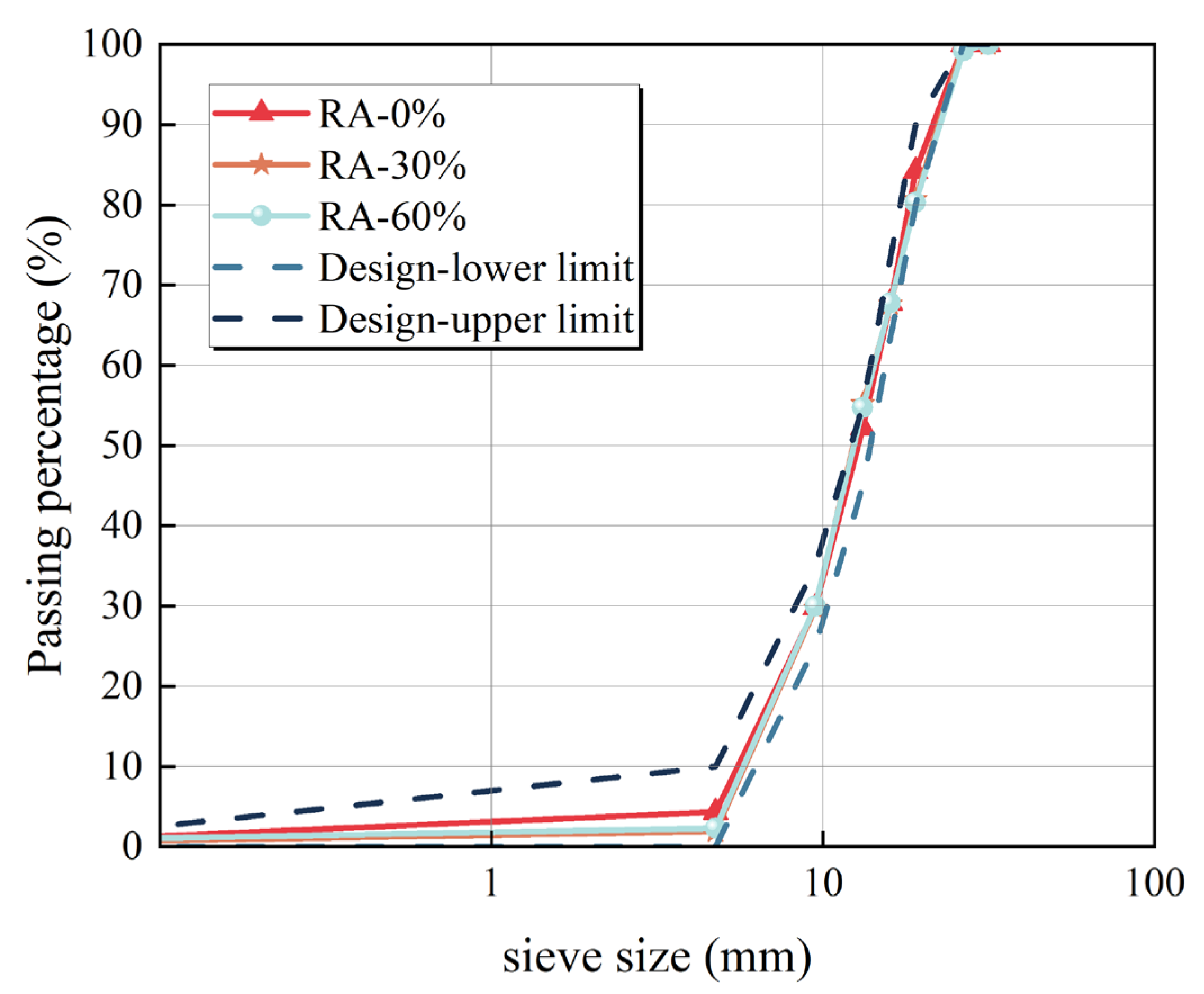

2.1.1. Aggregates

2.1.2. Cementitious Additives

2.2. CPRAM Design

2.3. Sample Preparation

2.4. Methods

2.4.1. Compressive Stress Test

2.4.2. Four-Point Bending (4PB) Stress Test

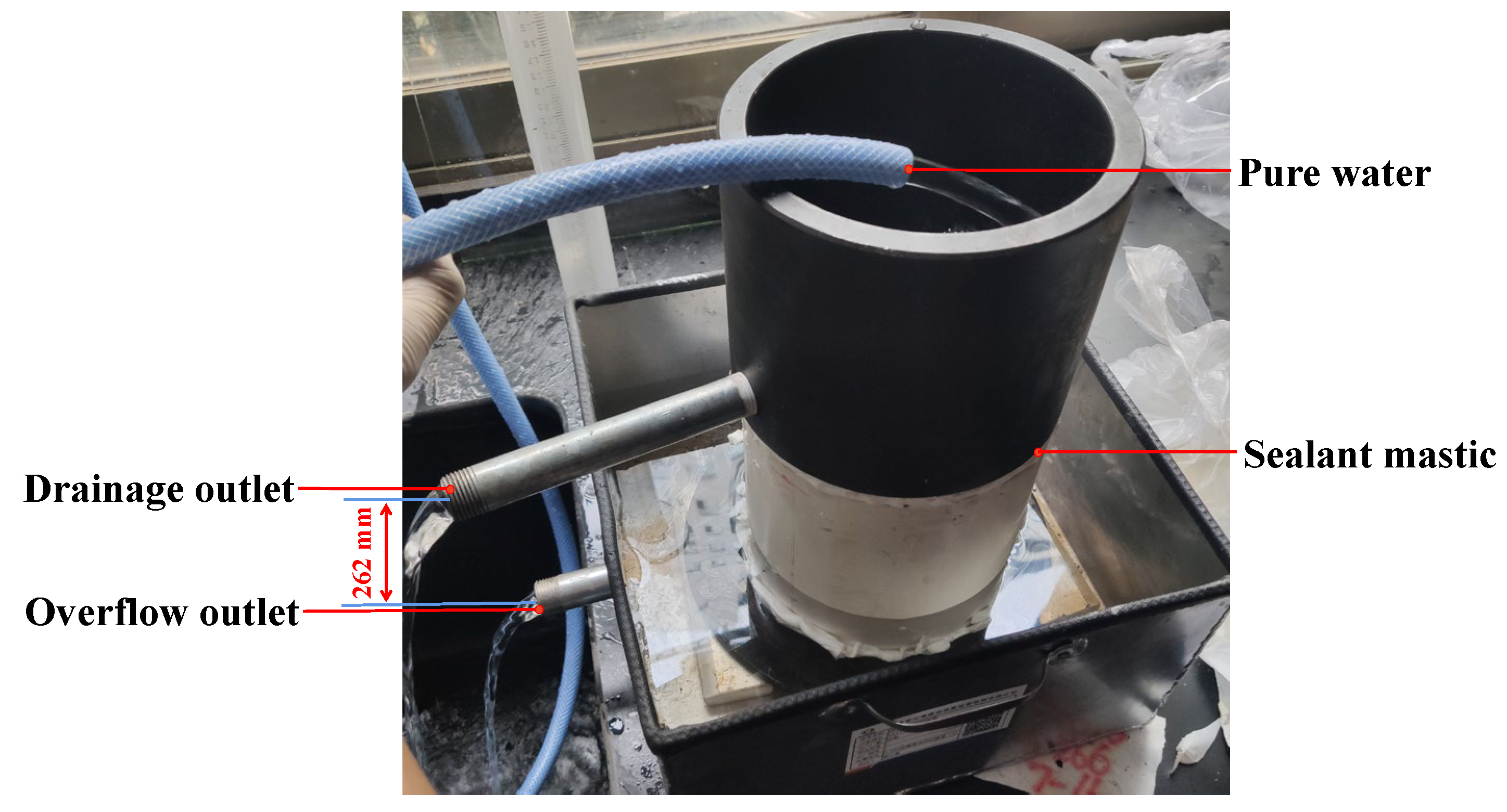

2.4.3. Water Permeability Test

2.4.4. Freeze-Thaw Cycle Test

2.4.5. Dry-Wet Cycle Test

2.4.6. Compressive Resilience Modulus Test

3. Test Results and Analysis

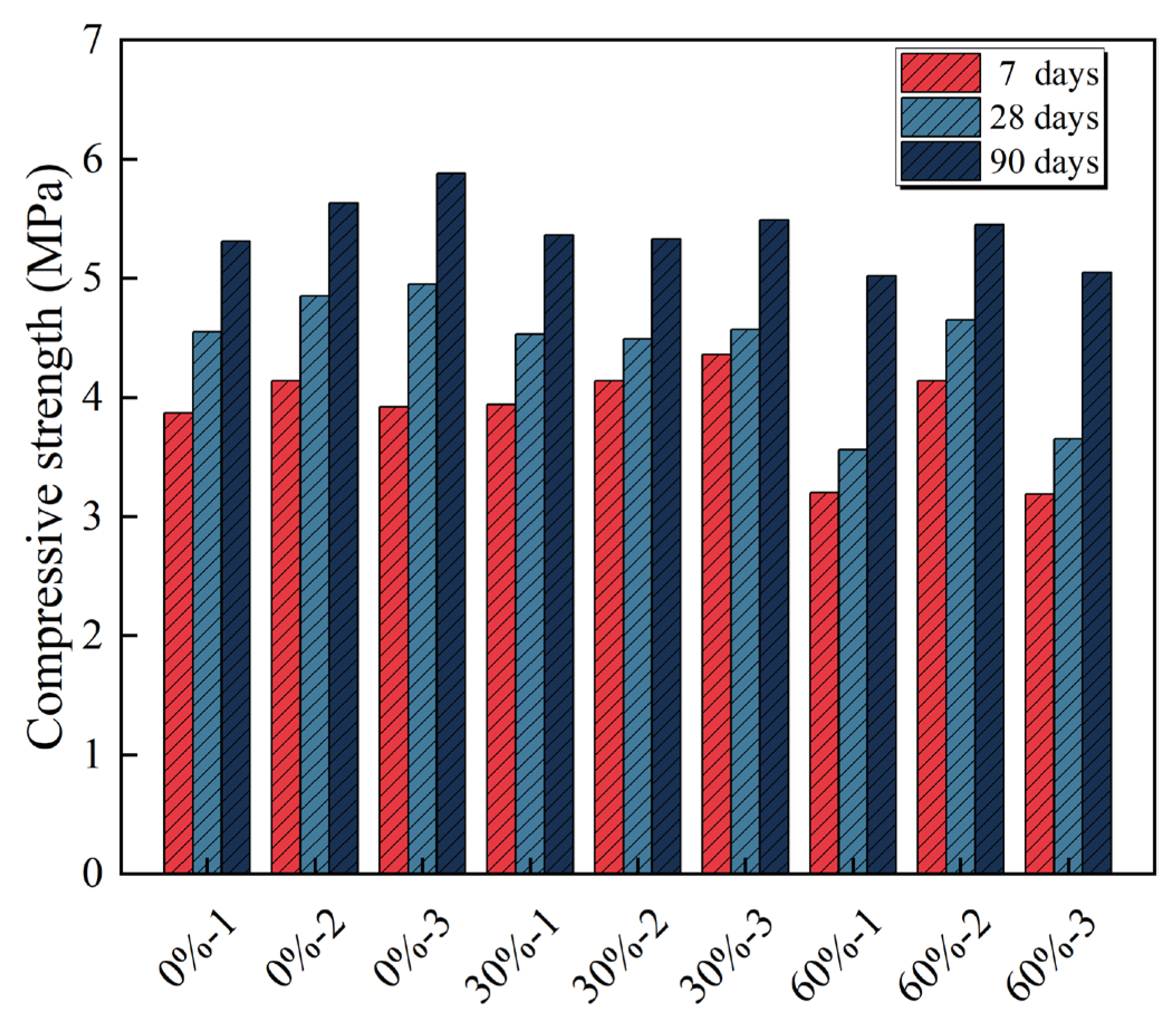

3.1. Unconfined Compressive Strength

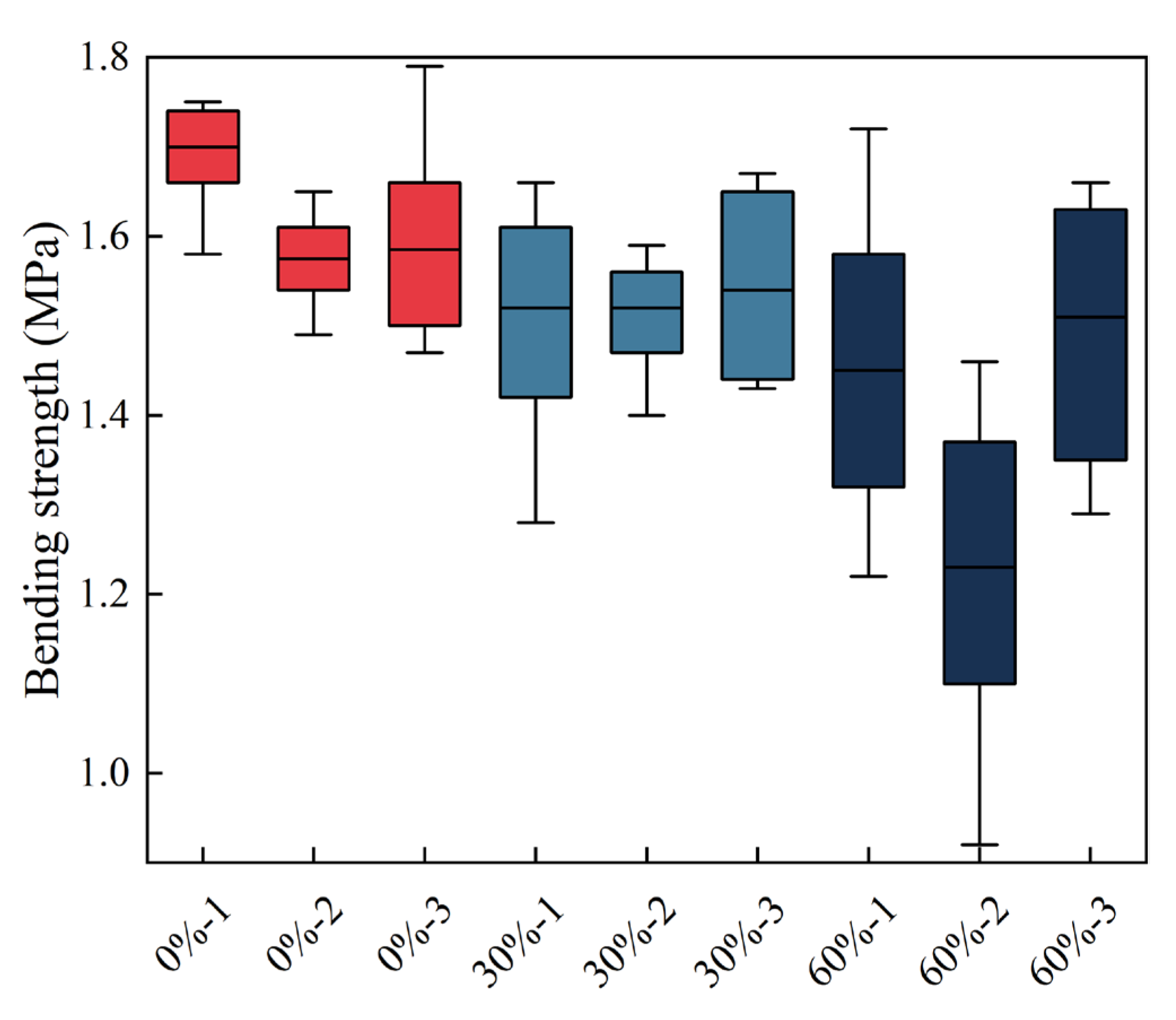

3.2. Bending Strength

3.3. Water Permeability

3.4. Compressive Strength after Freeze-Thaw Cycle Tests

3.5. Compressive Strength after Dry-Wet Cycle Tests

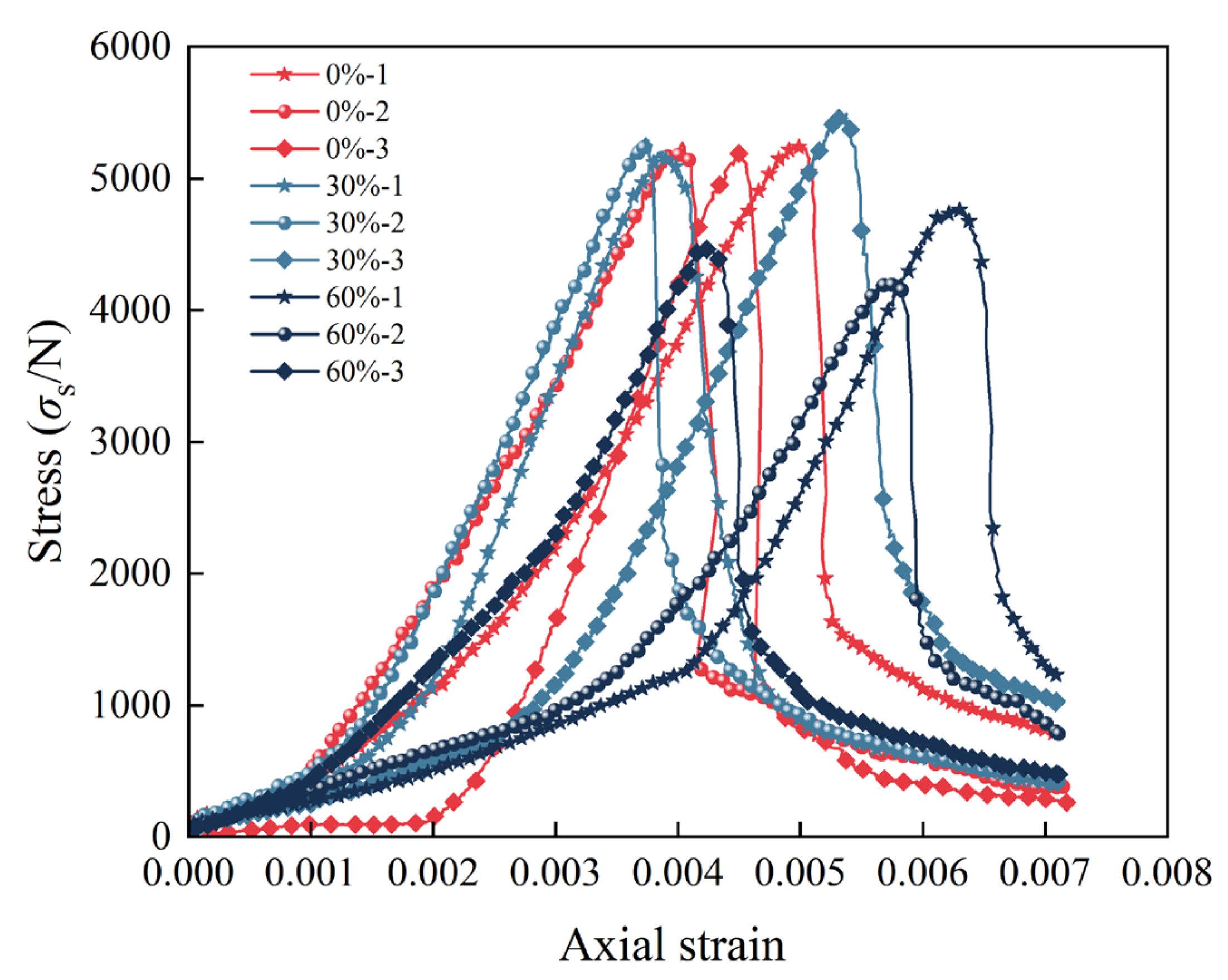

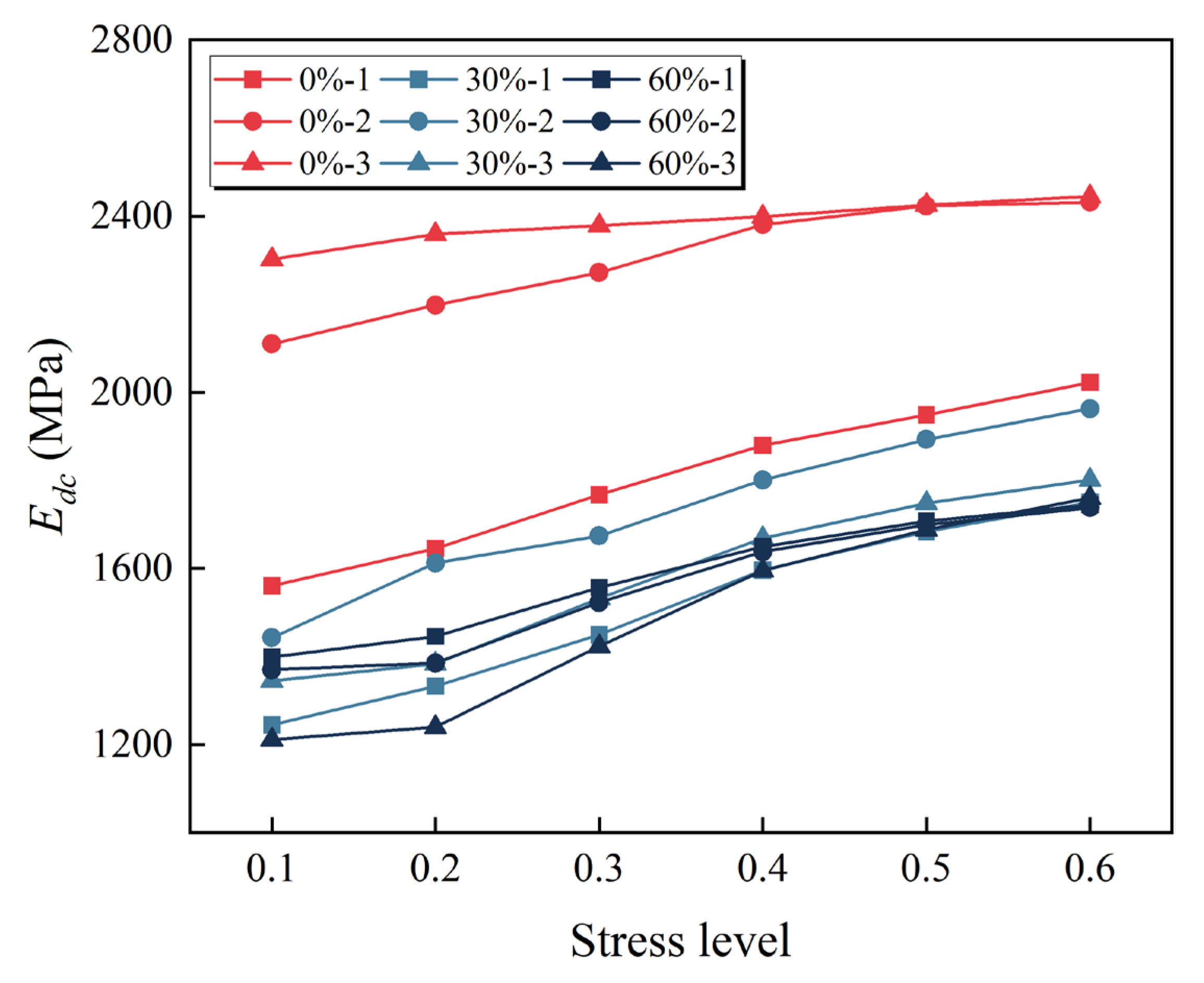

3.6. Dynamic Compressive Resilience Modulus

4. Discussion

5. Conclusions

- (1)

- The mechanical properties and water permeability of CPRAM mixed with large RA ratios can satisfy the road subgrade requirements of China. Incorporating RA weakened the mechanical properties and water permeability of CPRAM, and the weakening degree increased with the RA content.

- (2)

- The laboratory test results of CPRAM specimens with nine proportions of cementitious ratio show that the cementitious additives improve the mechanical properties of CPRAM. The effect of fly ash on the compressive strength of CPRAM is larger for low curing ages compared with silica fume and blast furnace slag, and the effect of silica fume on the compressive strength of CPRAM is larger for late curing ages compared with fly ash and silica fume.

- (3)

- CPRAM is poorly adaptable to low-temperature environments. The compressive strength of CPRAM specimens significantly reduces after freeze-thaw cycles, and the compressive strength reduction degree increases with the RA content. CPRAM is better adaptable to pure dry-wet environments as the compressive strength of CPRAM does not show a clear decreasing trend.

- (4)

- The incorporation of silica fume greatly strengthens the mechanical properties of CPRAM. That is, filling the micropores of the CPRAM interface transition zone improves the mechanical properties.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Guerin, T.F. Using integrated risk assessment to enable on-site repurposing of construction wastes from renewable energy projects to confirm highest value re-use. Environ. Sci. Pollut. Res. 2021, 29, 8909–8920. [Google Scholar] [CrossRef] [PubMed]

- Huang, B.; Wang, X.; Kua, H.; Geng, Y.; Bleischwitz, R.; Ren, J. Construction and demolition waste management in china through the 3r principle. Resour. Conserv. Recycl. 2018, 129, 36–44. [Google Scholar] [CrossRef]

- Yuanhui, C.; Shengjie, W.; Yong, W.; Zhu, Z.; Wang, S.; Cao, Y. The current situation and future development trend of comprehensive utilization of construction waste in China. China Build. Mater. 2021, 9, 118–121. [Google Scholar] [CrossRef]

- Yang, L.-X.; Song, X.-F.; Lu, M.-R.; Xia, Y.-H. The mixture proportioning design of sand-containing permeable concrete based on mortar thickness of recycled coarse aggregate. Mater. Rep. 2022, 36, 21020037. [Google Scholar] [CrossRef]

- Zhao, Y.; Gao, J.; Chen, F.; Liu, C.; Chen, X. Utilization of waste clay bricks as coarse and fine aggregates for the preparation of lightweight aggregate concrete. J. Clean. Prod. 2018, 201, 706–715. [Google Scholar] [CrossRef]

- Duan, Z.H.; Poon, C.S. Properties of recycled aggregate concrete made with recycled aggregates with different amounts of old adhered mortars. Mater. Des. 2014, 58, 19–29. [Google Scholar] [CrossRef]

- Su, H.; Yang, J.; Ling, T.-C.; Ghataora, G.S.; Dirar, S. Properties of concrete prepared with waste tyre rubber particles of uniform and varying sizes. J. Clean. Prod. 2015, 91, 288–296. [Google Scholar] [CrossRef]

- Bahrami, N.; Zohrabi, M.; Mahmoudy, S.A.; Akbari, M. Optimum recycled concrete aggregate and micro-silica content in self-compacting concrete: Rheological, mechanical and microstructural properties. J. Build. Eng. 2020, 31, 101361. [Google Scholar] [CrossRef]

- Huang, J.; Zhang, Y.; Sun, Y.; Ren, J.; Zhao, Z.; Zhang, J. Evaluation of pore size distribution and permeability reduction behavior in permeable concrete. Constr. Build. Mater. 2021, 290, 123228. [Google Scholar] [CrossRef]

- Güneyisi, E.; Gesoğlu, M.; Kareem, Q.; Ipek, S. Effect of different substitution of natural aggregate by recycled aggregate on performance characteristics of permeable concrete. Mater. Struct. 2016, 49, 521–536. [Google Scholar] [CrossRef]

- Zaetang, Y.; Sata, V.; Wongsa, A.; Chindaprasirt, P. Properties of permeable concrete containing recycled concrete block aggregate and recycled concrete aggregate. Constr. Build. Mater. 2016, 111, 15–21. [Google Scholar] [CrossRef]

- Bai, X.; Dawson, R.J.; Ürge-Vorsatz, D.; Delgado, G.C.; Barau, A.S.; Dhakal, S.; Dodman, D.; Leonardsen, L.; Masson-Delmotte, V.; Roberts, D.C.; et al. Six research priorities for cities and climate change. Nature 2018, 555, 23–25. [Google Scholar] [CrossRef]

- Yu, Y.-X. Application of Porous Concrete Sponge City Construction. Master’s Thesis, Anhui University of Science and Technology School, Hefei, China, 2016. [Google Scholar] [CrossRef]

- Yu, K.-J.; Li, D.-H.; Yuan, H.; Fu, W.; Qiao, Q.; Wang, S.-S. “Sopng City”: Theory and Practice. City Plann. Rev. 2015, 39, 26–36. [Google Scholar] [CrossRef]

- Chandrappa, A.K.; Biligiri, K.P. Permeable concrete as a sustainable pavement material—Research findings and future prospects: A state-of-the-art review. Constr. Build. Mater. 2016, 111, 262–274. [Google Scholar] [CrossRef]

- Ibrahim, A.; Mahmoud, E.; Yamin, M.; Patibandla, V.C. Experimental study on portland cement permeable concrete mechanical and hydrological properties. Constr. Build. Mater. 2014, 50, 524–529. [Google Scholar] [CrossRef]

- Xiang, D.; Youyuan, X.; Yongjun, W. Research on choice of engineering site and type of ueban pervious pavement. J. Hunan Univ. Technol. 2009, 5, 5–9. [Google Scholar] [CrossRef]

- Singh, R.; Goel, S. Permeable concrete—A review on its properties and applications. In Sustainable Engineering; Lecture Notes in Civil Engineering; Springer: Singapore, 2019; Volume 30, pp. 5–16. [Google Scholar] [CrossRef]

- Huang, L.; Lin, C.; Yudong, N.; Zhou, D.-Z.; Chen, F.; Li, Z. Study on Surface Runoff Characteristics of Initial Rainwater in a Typical Hily City. Admin. Tech. Environ. Monit. 2019, 31, 21–25. [Google Scholar] [CrossRef]

- Chanchai, N.; Satiennam, T.; Klungboonkrong, P.; Chindaprasirt, P. Mechanical properties, thermal conductivity, and sound absorption of pervious concrete containing recycled concrete and bottom ash aggregates. KSCE J. Civ. Eng. 2018, 22, 1369–1376. [Google Scholar] [CrossRef]

- Martellotta, F.; Crociata, S.D.; D’Alba, M. On site validation of sound absorption measurements of occupied pews. Appl. Acoust. 2011, 72, 923–933. [Google Scholar] [CrossRef]

- Ho, H.-L.; Huang, R.; Hwang, L.-C.; Lin, W.-T.; Hsu, H.-M. Waste-based permeable concrete for climate-resilient pavements. Materials 2018, 11, 900. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Yang, J.; Yu, X.; Zhang, Y.; Zhang, L. Permeability prediction of pervious concrete based on mix proportions and pore characteristics. Constr. Build. Mater. 2023, 395, 132247. [Google Scholar] [CrossRef]

- Xie, H.Z.; Li, L.G.; Ng, P.L.; Liu, F. Effects of Solid Waste Reutilization on Performance of Pervious Concrete: A Review. Sustainbility 2023, 15, 15076105. [Google Scholar] [CrossRef]

- Demet, Y.; Semsi, Y. Experimental study of aggregate size and gradation on pervious concretes′ mechanic, hydraulic, and surface properties. Struct. Concr. 2023, 24, 5451–5464. [Google Scholar] [CrossRef]

- Bechara, H.; Hamze, K.; Mohamed, B.; Boudart, B.; Sebaibi, N. Investigation Properties of Pervious and Water-Retaining Recycled Concrete to Mitigate Urban Heat Island Phenomena. Sustainbility 2023, 15, 5384. [Google Scholar]

- Chiranjeevi, K.; Kumar, D.H.; Srinivasa, A.S.; Shankar, A.U.R. Optimisation of recycled concrete aggregates for cement-treated bases by response surface method. Int. J. Pave Eng. 2023, 24, 2179051. [Google Scholar] [CrossRef]

- Ferrández, D.; Saiz, P.; Zaragoza-Benzal, A.; Zúñiga-Vicente, J.A. Towards a more sustainable environmentally production system for the treatment of recycled aggregates in the construction industry: An experimental study. Heiyon 2023, 9, e16641. [Google Scholar] [CrossRef] [PubMed]

- Maameri, N.E.; Bensaci, H.; Kenai, S. The effect of treated recycled steel fibers and slag on the properties of recycled self-compacting concrete. MRS Adv. 2023, 8, 613–617. [Google Scholar] [CrossRef]

- Lu, Y.; Qin, Y.; Huang, C.; Pang, X. Albedo of Pervious Concrete and Its Implications for Mitigating Urban Heat Island. Sustainability 2023, 15, 8222. [Google Scholar] [CrossRef]

- Ferić, K.; Kumar, V.S.; Romić, A.; Gotovac, H. Effect of Aggregate Size and Compaction on the Strength and Hydraulic Properties of Pervious Concrete. Sustainability 2023, 15, 1146. [Google Scholar] [CrossRef]

- Atta, I.; Bakhoum, E.S. Environmental feasibility of recycling construction and demolition waste. Int. J. Environ. Sci. Tech. 2023, 1–20. [Google Scholar] [CrossRef]

- Merino-Lechuga, A.M.; González-Caro, Á.; Fernández-Ledesma, E.; Jiménez, J.R.; Fernández-Rodríguez, J.M.; Suescum-Morales, D. Accelerated Carbonation of Vibro-Compacted Porous Concrete for Eco-Friendly Precast Elements. Materials 2023, 16, 2995. [Google Scholar] [CrossRef] [PubMed]

- Research Institute of Highway Ministry of Transport. Pavement Base Construction Technical Instructions: JTG/T F20-2015; China Communications Press: Beijing, China, 2015. [Google Scholar]

- Bajpai, R.; Choudhary, K.; Srivastava, A.; Sangwan, K.S.; Singh, M. Environmental impact assessment of fly ash and silica fume based geopolymer concrete. J. Clean. Prod. 2020, 254, 120147. [Google Scholar] [CrossRef]

- Ali, B.; El Ouni, M.H.; Kurda, R. Life cycle assessment (LCA) of precast concrete blocks utilizing ground granulated blast furnace slag. Environ. Sci. Pollut. Res. 2022, 29, 83580–83595. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Jin, M.; Wu, Y.; Zhou, Y.; Tang, S. Hydration, shrinkage, pore structure and fractal dimension of silica fume modified low heat portland cement-based materials. Constr. Build. Mater. 2021, 272, 121952. [Google Scholar] [CrossRef]

- Gao, S.; Liu, Q.; Han, F.; Fu, Y. Mix Design of Recycled Coarse Aggregate Self-Compacting Concrete Based on Orthogonal Test and Analysis of Mercury Intrusion Porosimetry. Adv. Mater. Sci. Eng. 2021, 2021, 4829673. [Google Scholar] [CrossRef]

- Yao, C.; Guo, Y.; Shen, A.; Cui, W.; He, Z. Recycling of fine-asphalt-pavement solid waste for low-shrinkage rapid hardening Portland cement concrete pavement. Constr. Build. Mater. 2021, 289, 123312. [Google Scholar] [CrossRef]

- JTG E51-2009; Test Methods of Materials Stabilized with Inorganic Binders for Highway Engineering. Ministry of Transportation Highway Research Institute: Beijing, China, 2009.

- Li, L.G.; Feng, J.-J.; Zhu, J.; Chu, S.-H.; Kwan, A.K.H. Pervious Concrete: Effects of porosity on permeability and strength. Mag. Concr. Rea. 2021, 73, 69–79. [Google Scholar] [CrossRef]

- Zhu, H.; Wen, C.; Wang, Z.; Li, L. Study on the permeability of recycled aggregate pervious concrete with fibers. Materials 2020, 13, 321. [Google Scholar] [CrossRef]

- Qin, Y.; Yang, H.; Deng, Z.; He, J. Water permeability of pervious concrete is dependent on the applied pressure and testing methods. Adv. Mater. Sci. Eng. 2015, 2015, 404136. [Google Scholar] [CrossRef]

- Zhang, X.; Qian, C.-X.; Chen, H.-C.; Liang, C.-Y.; Kang, W.-C. Calculation of expansion stresses and strains in concrete under sulfate crystallization attack in dry-wet cycles environments. J. Mater. Civ. Eng. 2021, 33, 4020479. [Google Scholar] [CrossRef]

- Hoong, J.D.L.H.; Hou, Y.; Turcry, P.; Mahieux, P.-Y.; Hamdoun, H.; Amiri, O.; Lux, J.; Aït-Mokhtar, A. Reactivity of recycled aggregates used for pavement base: From field to laboratory. J. Mater. Civ. Eng. 2021, 33, 4021129. [Google Scholar] [CrossRef]

- Xie, J.; Wang, J.; Rao, R.; Wang, C.; Fang, C. Effects of combined usage of GGBS and fly ash on workability and mechanical properties of alkali activated geopolymer concrete with recycled aggregate. Compos. Part B 2019, 164, 179–190. [Google Scholar] [CrossRef]

- Ministry of Housing and Urban-Rural Development. Technical Specification for Pervious Cement Concrete Pavement: CJJ/T 135-2009; China Architecture & Building Press: Beijing, China, 2009. [Google Scholar]

- Wang, S.; Gainey, L.; Marinelli, J.; Deer, B.; Wang, X.; Mackinnon, I.D.; Xi, Y. Effects of vermiculite on in-situ thermal behaviour, microstructure, physical and mechanical properties of fired clay bricks. Constr. Build. Mater. 2022, 316, 125828. [Google Scholar] [CrossRef]

- Wang, S.; Gainey, L.; Mackinnon, I.D.R.; Xi, Y. High- and low-defect kaolinite for brick making: Comparisons of technological properties, phase evolution and microstructure. Constr. Build. Mater. 2023, 366, 130250. [Google Scholar] [CrossRef]

- Freyburg, A.S.; Schwarz, S. Influence of the clay type on the pore structure of structural ceramics. J. Eur. Ceram. Soc. 2007, 27, 1727–1733. [Google Scholar] [CrossRef]

- Luo, S.; Bai, T.; Guo, M.; Wei, Y.; Ma, W. Impact of freeze–thaw cycles on the long-term performance of concrete pavement and related improvement measures: A review. Materials 2022, 15, 4568. [Google Scholar] [CrossRef] [PubMed]

- Haoxiang, L.; Jin, W.; Jiayu, P. Freeze–thaw durability of recycled aggregate concrete: An overview. J. Wuhan Univ. Technol. (Mater. Sci. Ed.) 2021, 36, 58–69. [Google Scholar] [CrossRef]

- Liu, D.; Tu, Y.; Sas, G.; Elfgren, L. Freeze–thaw damage evaluation and model creation for concrete exposed to freeze–thaw cycles at early-age. Constr. Build. Mater. 2021, 312, 125352. [Google Scholar] [CrossRef]

| Size (mm) | Crushing Stone (%) | Red Bricks (%) | Old Concrete (%) | Other (Wood Blocks, Glass, and Mortar, etc.) (%) |

|---|---|---|---|---|

| 19–26.5 | 42.52 | 13.97 | 34.62 | 8.90 |

| 9.5–19 | 28.01 | 19.19 | 44.90 | 7.90 |

| 0–9.5 | 62.43 | 2.74 | 29.68 | 5.14 |

| Aggregates | Size (mm) | Apparent Specific Density (g/cm3) | Crushing Value (%) | Water Absorption (%) | Flakiness Content (%) |

|---|---|---|---|---|---|

| RA | 19–26.5 | 2.55 | 26.4 | 7.59 | 8.9 |

| 9.5–19 | 2.63 | 25.7 | 6.72 | 9.5 | |

| 4.75–9.5 | 2.66 | 23.9 | 6.01 | 12.5 | |

| NA | 19–26.5 | 2.72 | 21.8 | 0.35 | 9.4 |

| 9.5–19 | 2.72 | 20.2 | 0.75 | 12.1 | |

| 4.75–9.5 | 2.76 | 23.7 | 0.41 | 6.2 |

| Type | Cement (%) | Fly Ash (%) | Blast Furnace Slag (%) | Silica Fume (%) |

|---|---|---|---|---|

| Density (g/cm3) | 3.1 | 2.9 | 2.3 | 2.7 |

| SiO2 | 20.53 | 55.37 | 34.74 | 97.1 |

| Al2O3 | 4.44 | 30.11 | 13.65 | 0.20 |

| CaO | 4.20 | 4.38 | 0.78 | 0.08 |

| Fe2O3 | 58.40 | 3.54 | 33.16 | 0.57 |

| SO3 | 2.03 | 1.27 | 7.27 | 0.80 |

| MgO | 3.28 | 1.11 | 2.17 | 0.32 |

| Type | RA (%) | NA (%) | Total Percentage of Cementitious Materials (%) | Cement (%) | Fly Ash (%) | Blast Furnace Slag (%) | Silica Fume (%) |

|---|---|---|---|---|---|---|---|

| 0%–1 | 0 | 100 | 10 | 10 | 0 | 0 | 0 |

| 0%–2 | 0 | 100 | 10 | 8.10 | 1 | 0.5 | 0.40 |

| 0%–3 | 0 | 100 | 10 | 6.80 | 2 | 1 | 0.20 |

| 30%–1 | 30 | 70 | 10 | 8.80 | 0 | 0.5 | 0.20 |

| 30%–2 | 30 | 70 | 10 | 7.50 | 1 | 1 | 0 |

| 30%–3 | 30 | 70 | 10 | 8.60 | 2 | 0 | 0.40 |

| 60%–1 | 60 | 40 | 10 | 7.60 | 0 | 1 | 0.40 |

| 60%–2 | 60 | 40 | 10 | 9.30 | 1 | 0 | 0.20 |

| 60%–3 | 60 | 40 | 10 | 8 | 2 | 0.5 | 0 |

| Type | RA (%) | Blast Furnace Slag (%) | Fly Ash (%) | Silica Fume (%) | 7-d Compressive Strength (MPa) |

|---|---|---|---|---|---|

| 0%-1 | 0 | 0 | 0 | 0 | 3.87 |

| 0%-2 | 0 | 0.5 | 1 | 0.40 | 4.14 |

| 0%-3 | 0 | 1 | 2 | 0.20 | 3.92 |

| 30%-1 | 30 | 0 | 1 | 0.20 | 3.94 |

| 30%-2 | 30 | 0.5 | 2 | 0 | 4.14 |

| 30%-3 | 30 | 1 | 0 | 0.40 | 4.36 |

| 60%-1 | 60 | 0 | 2 | 0.40 | 3.20 |

| 60%-2 | 60 | 0.5 | 0 | 0.20 | 4.14 |

| 60%-3 | 60 | 1 | 1 | 0 | 3.19 |

| K1 | 11.93 | 11.01 | 12.37 | 11.20 | |

| K2 | 12.44 | 12.42 | 11.27 | 12.00 | |

| K3 | 10.53 | 11.47 | 11.26 | 11.70 | |

| k1 | 3.98 | 3.67 | 4.12 | 3.73 | |

| k2 | 4.15 | 4.14 | 3.76 | 4.00 | |

| k3 | 3.51 | 3.82 | 3.75 | 3.90 | |

| Range | 0.64 | 0.47 | 0.37 | 0.27 |

| Type | RA (%) | Blast Furnace Slag (%) | Fly Ash (%) | Silica Fume (%) | 28-d Compressive Strength (MPa) |

|---|---|---|---|---|---|

| 0%-1 | 0 | 0 | 0 | 0 | 4.55 |

| 0%-2 | 0 | 0.5 | 1 | 0.40 | 4.85 |

| 0%-3 | 0 | 1 | 2 | 0.20 | 4.95 |

| 30%-1 | 30 | 0 | 1 | 0.20 | 4.53 |

| 30%-2 | 30 | 0.5 | 2 | 0 | 4.49 |

| 30%-3 | 30 | 1 | 0 | 0.40 | 4.57 |

| 60%-1 | 60 | 0 | 2 | 0.40 | 3.56 |

| 60%-2 | 60 | 0.5 | 0 | 0.20 | 4.56 |

| 60%-3 | 60 | 1 | 1 | 0 | 3.65 |

| K1 | 14.35 | 12.64 | 13.77 | 12.69 | |

| K2 | 13.59 | 13.99 | 13.03 | 14.13 | |

| K3 | 11.86 | 13.17 | 13.00 | 12.98 | |

| k1 | 4.78 | 4.21 | 4.59 | 4.22 | |

| k2 | 4.53 | 4.66 | 4.34 | 4.71 | |

| k3 | 3.95 | 4.39 | 4.33 | 4.33 | |

| Range | 0.83 | 0.45 | 0.26 | 0.48 |

| Type | RA (%) | Blast Furnace Slag (%) | Fly Ash (%) | Silica Fume (%) | 90-d Compressive Strength (MPa) |

|---|---|---|---|---|---|

| 0%-1 | 0 | 0 | 0 | 0 | 5.31 |

| 0%-2 | 0 | 0.5 | 1 | 0.40 | 5.63 |

| 0%-3 | 0 | 1 | 2 | 0.20 | 5.88 |

| 30%-1 | 30 | 0 | 1 | 0.20 | 5.36 |

| 30%-2 | 30 | 0.5 | 2 | 0 | 5.33 |

| 30%-3 | 30 | 1 | 0 | 0.40 | 5.49 |

| 60%-1 | 60 | 0 | 2 | 0.40 | 5.02 |

| 60%-2 | 60 | 0.5 | 0 | 0.20 | 5.45 |

| 60%-3 | 60 | 1 | 1 | 0 | 5.05 |

| K1 | 16.82 | 15.69 | 16.25 | 15.69 | |

| K2 | 16.18 | 16.41 | 16.04 | 16.69 | |

| K3 | 15.52 | 16.42 | 16.23 | 16.14 | |

| k1 | 5.61 | 5.23 | 5.42 | 5.23 | |

| k2 | 5.39 | 5.47 | 5.35 | 5.56 | |

| k3 | 5.17 | 5.47 | 5.41 | 5.38 | |

| Range | 0.44 | 0.24 | 0.07 | 0.33 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhi, X.; Yang, T.; Zhang, X.; Ren, Y.; Deng, P.; Chen, Y.; Xiao, Y. Experimental Study on the Mechanical Properties and Permeability of Cement-Stabilized Permeable Recycle Aggregate Materials. Sustainability 2023, 15, 14063. https://doi.org/10.3390/su151914063

Zhi X, Yang T, Zhang X, Ren Y, Deng P, Chen Y, Xiao Y. Experimental Study on the Mechanical Properties and Permeability of Cement-Stabilized Permeable Recycle Aggregate Materials. Sustainability. 2023; 15(19):14063. https://doi.org/10.3390/su151914063

Chicago/Turabian StyleZhi, Xiao, Tao Yang, Xun Zhang, Yi Ren, Pin Deng, Yuliang Chen, and Yuanjie Xiao. 2023. "Experimental Study on the Mechanical Properties and Permeability of Cement-Stabilized Permeable Recycle Aggregate Materials" Sustainability 15, no. 19: 14063. https://doi.org/10.3390/su151914063

APA StyleZhi, X., Yang, T., Zhang, X., Ren, Y., Deng, P., Chen, Y., & Xiao, Y. (2023). Experimental Study on the Mechanical Properties and Permeability of Cement-Stabilized Permeable Recycle Aggregate Materials. Sustainability, 15(19), 14063. https://doi.org/10.3390/su151914063