Identifying Members of Common Structures Utilizing Three-Dimensional Detecting Information for 3D Point Cloud Model Application

Abstract

:1. Introduction

2. Literature Review

2.1. Estabilishment of BIM

2.2. Utilization of 3D Point Cloud Model

3. Previous Research

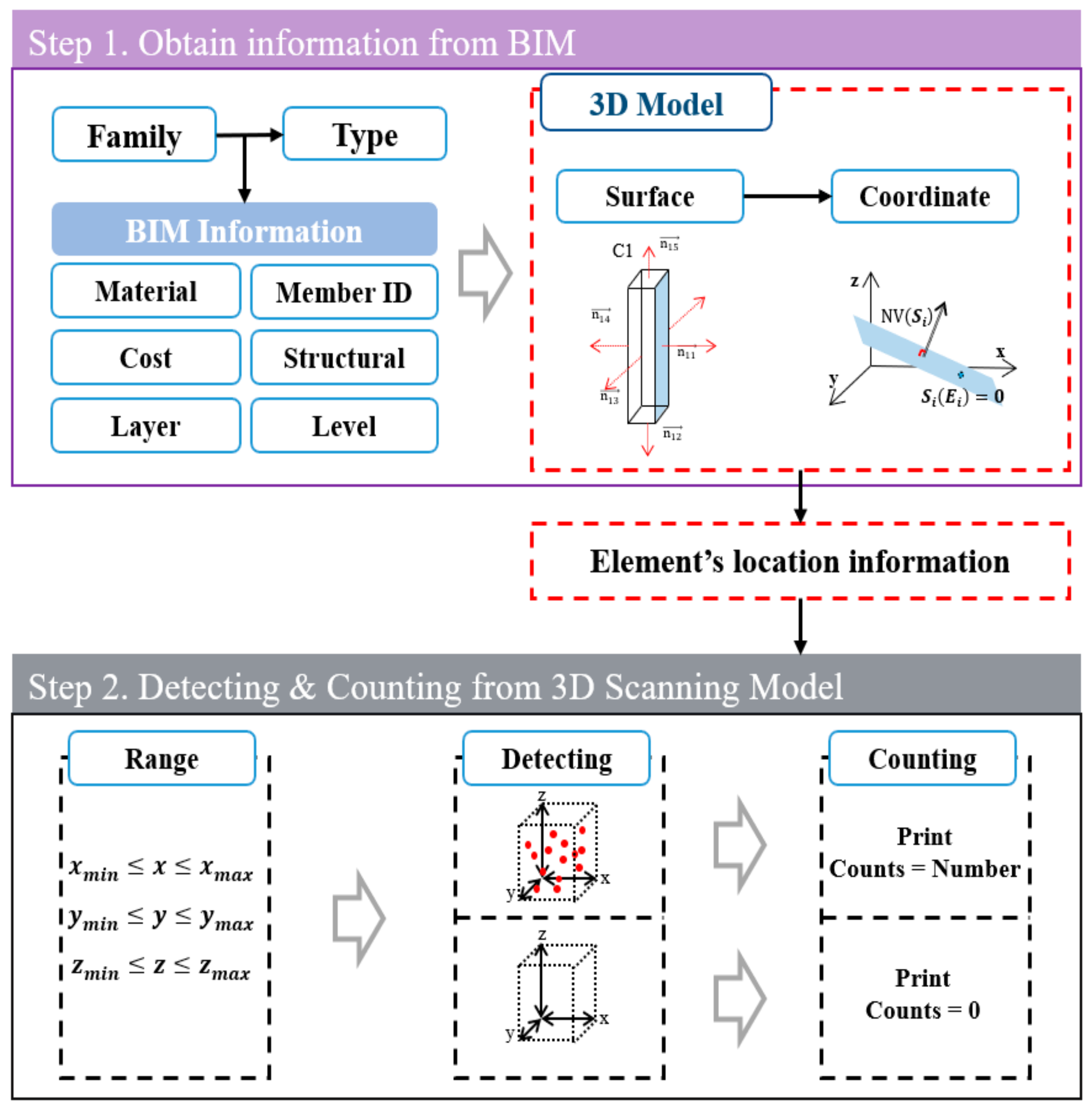

4. Identifying Member from 3D Point Cloud Model

4.1. Acquiring Property Information and Location from 3D Model

4.2. Identification of Data from 3D Point Cloud Model Based on Acquired Information

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kang, S.H.; Jung, Y.S. Data acquisition technology (DAT) selection algorithm for automated progress measurement and management. Korea J. Constr. Eng. Manag. 2012, 13, 77–86. [Google Scholar] [CrossRef]

- Kang, S.H. Utilizing Data Acquisition Technology (DAT) for Automated Construction Progress Management. Master’s Thesis, Myungji University, Seoul, Republic of Korea, 2008. [Google Scholar]

- Kim, S.H. The Construction Project EV Tracking Process based on the 3D Point Cloud and 4D BIM. Ph.D. Thesis, Yeungnam University, Gyeongsan, Republic of Korea, 2019. [Google Scholar]

- Lee, K.H.; Park, C.J.; Choi, I.S. A study on the improvement of construction progress management for EVMS. Korea J. Constr. Eng. Manag. 2002, 2, 155–162. [Google Scholar]

- Park, J.S. A Study on the Schedule Process for Forecasting Progress Rate for Construction Project. Master’s Thesis, Gyeongsang National University, Jinju-si, Republic of Korea, 2011. [Google Scholar]

- Jung, Y.S.; Woo, S.K. Flexible work breakdown structure for integrated cost and schedule control. J. Constr. Eng. Manag. 2004, 130, 616–625. [Google Scholar] [CrossRef]

- Sepasgozar, S.M.E.; Hui, F.K.P.; Shirowzhan, S.; Foroozanfar, M.; Yang, L.; Aye, L. Lean practices using building information modeling (BIM) and digital twinning for sustainable construction. Sustainability 2021, 13, 161. [Google Scholar] [CrossRef]

- Ammad, S.; Wesam, S.A.; Saad, S.; Abdul, H.Q. Personal protective equipment (PPE) usage in construction projects: A systematic review and smart PLS approach. Ain Shams Eng. J. 2021, 12, 3495–3507. [Google Scholar] [CrossRef]

- Kim, J.Y.; Kim, G.H. Application of 3D laser scanning technology to the measurement of construction precision in building structural frame construction. J. Archit. Inst. Korea 2022, 38, 245–253. [Google Scholar] [CrossRef]

- Medina, A.L.; Herrera-Pérez, V.; Cantal, L.R.P.; Rojas, M.M. Internet of Things for Construction Project Management: A Systematic Literature Review. In IoT and Data Science in Engineering Management. CIO 2022. Lecture Notes on Data Engineering and Communications Technologies; García Márquez, F.P., Segovia Ramiterat, I., Bernalte Sánchez, P.J., Muñoz del Río, A., Eds.; Springer: Berlin/Heidelberg, Germany, 2023; Volume 160, pp. 286–291. [Google Scholar] [CrossRef]

- Arayici, Y. An approach for real world data modelling with the 3D terrestrial laser scanner for built environment. Autom. Constr. 2007, 16, 816–829. [Google Scholar] [CrossRef]

- Wang, J.; Yi, T.; Liang, X.; Ueda, T. Application of 3D laser scanning technology using laser radar system to error analysis in the curtain wall construction. Remote Sens. 2023, 15, 64. [Google Scholar] [CrossRef]

- Maalek, R.; Lichti, D.D.; Ruwanpura, J.Y. Automatic recognition of common structural elements from point clouds for automated progress monitoring and dimensional quality control in reinforced concrete construction. Remote Sens. 2019, 11, 1102. [Google Scholar] [CrossRef]

- Turkan, Y.; Bosche, F.; Hass, C.T.; Hass, R. Automated progress tracking using 4D schedule and 3D sensing technology. Autom. Constr. 2012, 22, 414–421. [Google Scholar] [CrossRef]

- Su, S.; Wang, Q.; Han, L.; Hong, J.; Liu, Z. BIM-DLCA: An integrated dynamic environmental impact assessment model for buildings. Build. Environ. 2020, 183, 107218. [Google Scholar] [CrossRef]

- Ho, S.P.; Liu, L.Y. Analytical model for analyzing construction claims and opportunistic bidding. J. Constr. Eng. Manag. 2004, 130, 94–104. [Google Scholar] [CrossRef]

- Koseoglu, O.; Keskin, B.; Ozorhon, B. Challenges and enablers in BIM-enabled digital transformation in mega projects: The Istanbul new airport project case study. Buildings 2019, 9, 115. [Google Scholar] [CrossRef]

- Autodesk. Autodesk BIM Report; 2021.10; Autodesk: San Francisco, CA, USA, 2021. [Google Scholar]

- Ministry of Infrastructure and Transport. BIM Basic Guidelines for the Construction Industry; 2020.12; Ministry of Infrastructure and Transport: Sejong-Si, Republic of Korea, 2020.

- ISO 29481-1:2010; Building Information Modelling—Information Delivery Manual—Part 1: Methodology and Format. ISO: Geneva, Switzerland, 2010.

- BS 8541-1:2012; Library Objects for Architecture, Engineering and Construction. Identification and Classification. BSI: London, UK, 2012.

- Shin, J.H.; Choi, J.S.; Kim, I.H.; Yoon, D.Y. A Study on Development of Integrated Management System for BIM Property Information. Korean J. Comput. Des. Eng. 2016, 21, 130–142. [Google Scholar] [CrossRef]

- Jung, B.C. Manufacturer BIM library construction example. KARSE 2010, 1, 87–94. [Google Scholar]

- Kwom, S.O. Application of Shape Information Acquisition Technology using Laser Scanning Technology and BIM Technology to the Construction Industry. Architecture 2009, 52, 31–38. [Google Scholar]

- Liu, P.; Chen, A.Y.; Huang, Y.-N.; Han, J.-Y.; Lai, J.-S.; Kang, S.-C.; Wu, T.-H.; Wen, M.C.; Tsai, M.-H. A review of rotorcraft Unmanned Aerial Vehicle (UAV) developments and applications in civil engineering. Smart Struct. Syst. 2014, 13, 1065–1094. [Google Scholar] [CrossRef]

- Weinmann, M. Point Cloud Registration. Reconstruction and Analysis of 3D Scenes; Springer: Berlin/Heidelberg, Germany, 2016; pp. 55–110. [Google Scholar] [CrossRef]

- Cheng, L.; Chen, S.; Liu, X.; Xu, H.; Wu, Y.; Li, M.; Chen, Y. Registration of laser scanning point clouds: A review. Sensors 2018, 18, 1641. [Google Scholar] [CrossRef]

- Bernat, M.; Janowski, A.; Rzepa, S.; Sobieraj, A.; Szulwic, J. Studies on the use of terrestrial laser scanning in the maintenance of buildings belonging to the cultural heritage. In Proceedings of the 14th Geoconference on Informatics, Geoinformatics and Remote Sensing, SGEM, ORG, Albena, Bulgaria, 17–26 June 2014; pp. 307–318. [Google Scholar]

- Park, J.W.; Kim, S. Productivity analysis for the 3D digitization of earthwork sites based on scanning conditions. Inter. J. Railw. 2018, 11, 1–9. [Google Scholar]

- Jang, A.; Ju, Y.K.; Park, M.J. Structural stability evaluation of existing buildings by reverse engineering with 3D laser scanner. Remote Sens. 2022, 14, 2325. [Google Scholar] [CrossRef]

- Moyano, J.; Ángel, J.-E.; Juan, E.N.-J.; Barrera, A.O.; Maria, F.A. Evaluation of records using terrestrial laser scanner in architectural heritage for information modeling in HBIM construction: The case study of the La Anunciación church (Seville). J. Build. Eng. 2022, 62, 105190. [Google Scholar] [CrossRef]

- Hosamo, H.H.; Hosamo, M.H. Digital twin technology for bridge maintenance using 3D laser Scanning: A review. Adv. Civ. Eng. 2022, 2022, 2194949. [Google Scholar] [CrossRef]

- Singh, K.S.; Banerjee, B.P.; Raval, S. A review of laser scanning for geological and geotechnical applications in underground mining. Int. J. Min. Sci. Technol. 2023, 33, 133–154. [Google Scholar] [CrossRef]

- Kim, C.M.; Son, H.J.; Kim, C.W. Automated construciton progress measurment using a 4D building information model and 3D data. Autom. Constr. 2013, 31, 75–83. [Google Scholar] [CrossRef]

- Zhang, C.; Arditi, D. Automated progress control using laser scanning technology. Autom. Constr. 2013, 36, 108–116. [Google Scholar] [CrossRef]

- Samir, E.O.; Osama, M. Integrating 3D laser scanning and photogrammetry for progress measurement of construction work. Autom. Constr. 2008, 18, 1–9. [Google Scholar] [CrossRef]

- Kavaliauskas, P.; Fernandez, J.B.; McGuinness, K.; Jurelionis, A. Automation of construction progress monitoring by integrating 3D point cloud data with an IFC-based BIM model. Buildings 2022, 12, 1754. [Google Scholar] [CrossRef]

- Maalek, R.; Lichti, D.D.; Walker, R.; Bhavnani, A.; Ruwanpura, J.Y. Extraction of pipes and flanges from point clouds for automated verification of prefabricated modules in oil and gas refinery projects. Autom. Constr. 2019, 103, 150–167. [Google Scholar] [CrossRef]

| Type | Definition | Utilization | Information |

|---|---|---|---|

| Sample object | Provide guide and property information for a created object | Schematic Design | Shape Identification |

| General object | Provide information for detailed expression and analysis | Design Development | Shape Identification Performance |

| Product object | Provide information for products to be installed in building | Construction Document Construction Administration | Shape Identification Performance Product |

| Type | Data Structure | Library | Example |

|---|---|---|---|

| Revit | Model elements Annotation elements View elements | Category Family Type | Column, Wall, Beam ··· C1, C2, C3, W1, W2, B1 ··· 150 × 150, 200 × 200 ··· |

| Archi Cad | Object elements Layer elements | Object property Layer combination Layer Layer extension | Column, Wall, Beam ··· Drafting, Plans, Site ··· Interior, Finish, Annotation |

| Bentley | Parts Component Compound | Object information Object property | Column, Wall, Beam Definition, Cost, Type |

| Recognize Type | Feature Type |

|---|---|

| Point-based | Point feature/Point domain feature/Rotated image feature |

| Line-based | ALS, MLS Combination of building contours and road networks |

| Surface-based | Least squares surface/Conjugate surface |

| Subject | Author(s) | Research Title |

|---|---|---|

| Architecture | Bernat et al. [28] | Research on reverse engineering method for building maintenance using 3D laser scanning |

| Jang et al. [30] | Utilize 3D laser scanning to obtain inverse design data for existing buildings and conduct structural safety assessments | |

| Moyano et al. [31] | Presentation of data collection and recording methods for architectural heritage using 3D laser scanning | |

| Engineering | Park and Kim [29] | Research on calculating the amount of earthwork and the process control method in the civil engineering work stage |

| Hosamo and Hosamo [32] | Research on digital twin technology for bridge maintenance management using 3D laser scanning | |

| Singh et al. [33] | Research on geotechnical analysis of underground mines using 3D laser scanning | |

| Construction | Turkan et al. [14] | Research on 4D management method by automatic object recognition method from models by applying 3D laser scanning |

| Kim and Kim [9] | Study quality confirmation methods of framework during building construction using 3D laser scanning technology | |

| Wang et al. [12] | Study error analysis based on atypical curtain wall construction data obtained using 3D laser scanning |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.-Y.; Kim, G.-H. Identifying Members of Common Structures Utilizing Three-Dimensional Detecting Information for 3D Point Cloud Model Application. Sustainability 2023, 15, 14073. https://doi.org/10.3390/su151914073

Kim J-Y, Kim G-H. Identifying Members of Common Structures Utilizing Three-Dimensional Detecting Information for 3D Point Cloud Model Application. Sustainability. 2023; 15(19):14073. https://doi.org/10.3390/su151914073

Chicago/Turabian StyleKim, Ju-Yong, and Gwang-Hee Kim. 2023. "Identifying Members of Common Structures Utilizing Three-Dimensional Detecting Information for 3D Point Cloud Model Application" Sustainability 15, no. 19: 14073. https://doi.org/10.3390/su151914073

APA StyleKim, J.-Y., & Kim, G.-H. (2023). Identifying Members of Common Structures Utilizing Three-Dimensional Detecting Information for 3D Point Cloud Model Application. Sustainability, 15(19), 14073. https://doi.org/10.3390/su151914073