Performance and Mechanism of High-Viscosity and High-Elasticity Bitumen (HVE-MB) Modified with Five Additives

Abstract

:1. Introduction

2. Materials and Experimental Methods

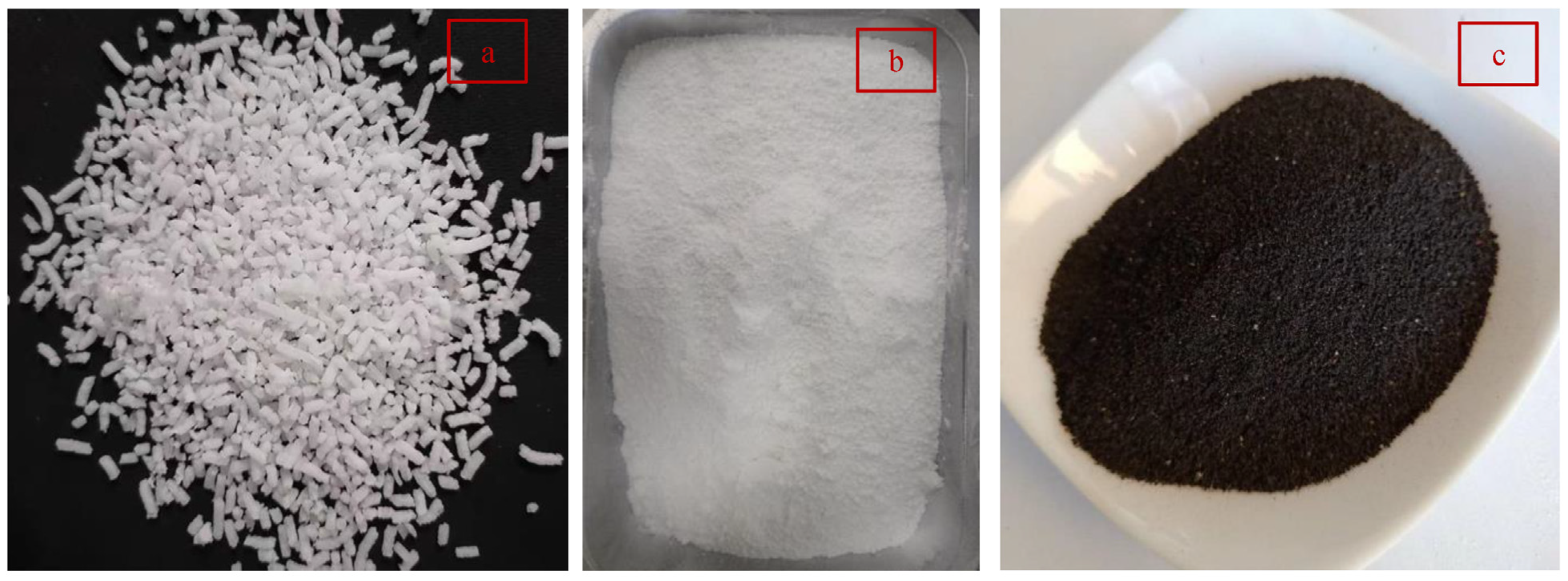

2.1. Materials

- (1)

- Original bitumen

- (2)

- Modified additives

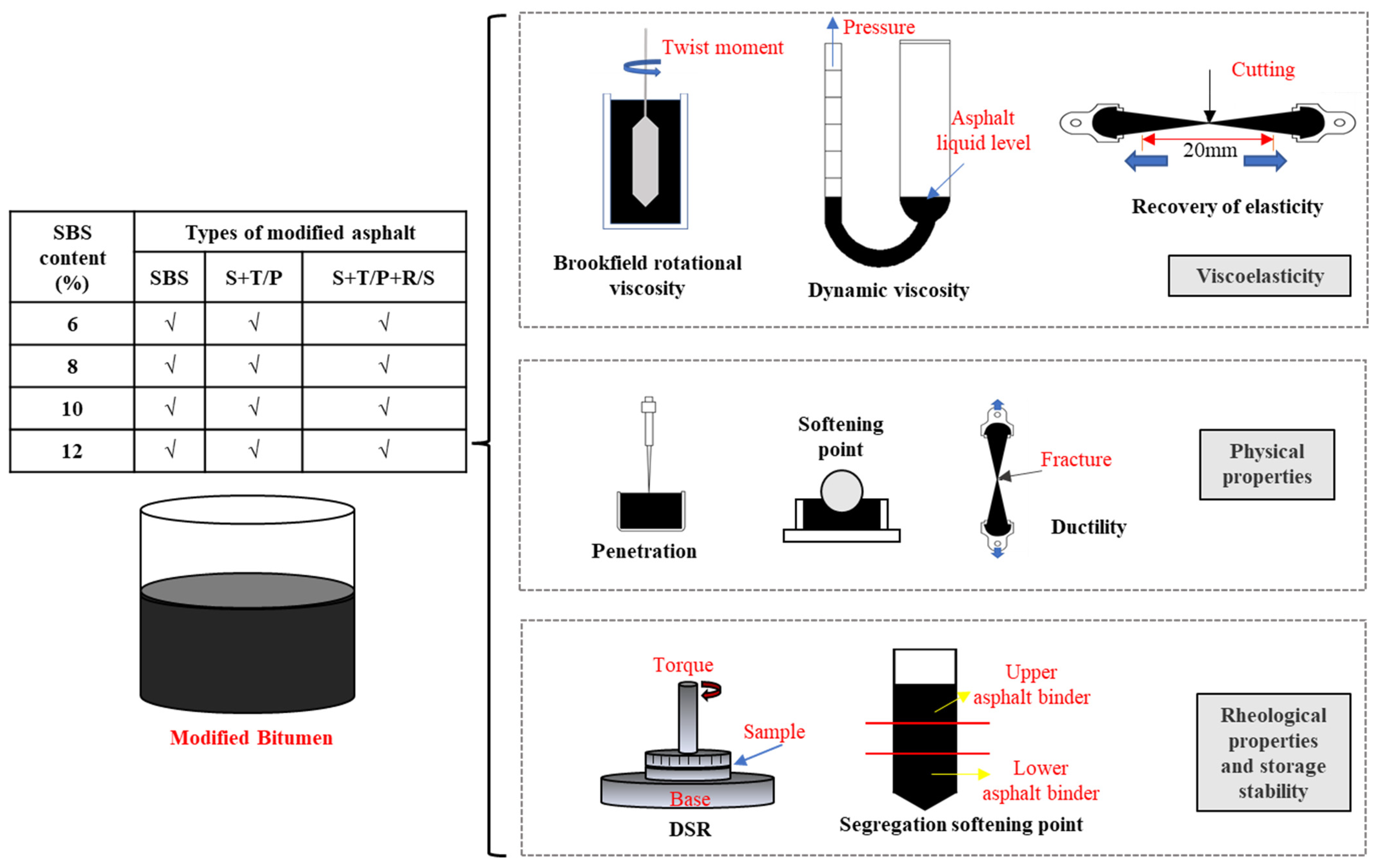

2.2. Manufacture of the Modified Bitumen

2.3. Performance Test of HVE-MB

2.3.1. Physical Performance Test

2.3.2. Viscosity Test

- (1)

- Dynamic viscosity

- (2)

- Rotational viscosity

2.3.3. Elastic Recovery Test

2.3.4. Rheological Property Test

2.3.5. Segregation Test (Storage Stability of HVE-MB)

3. Results and Discussions

3.1. High-Viscosity and High-Elasticity Properties of HVE-MB

3.1.1. Dynamic Viscosity

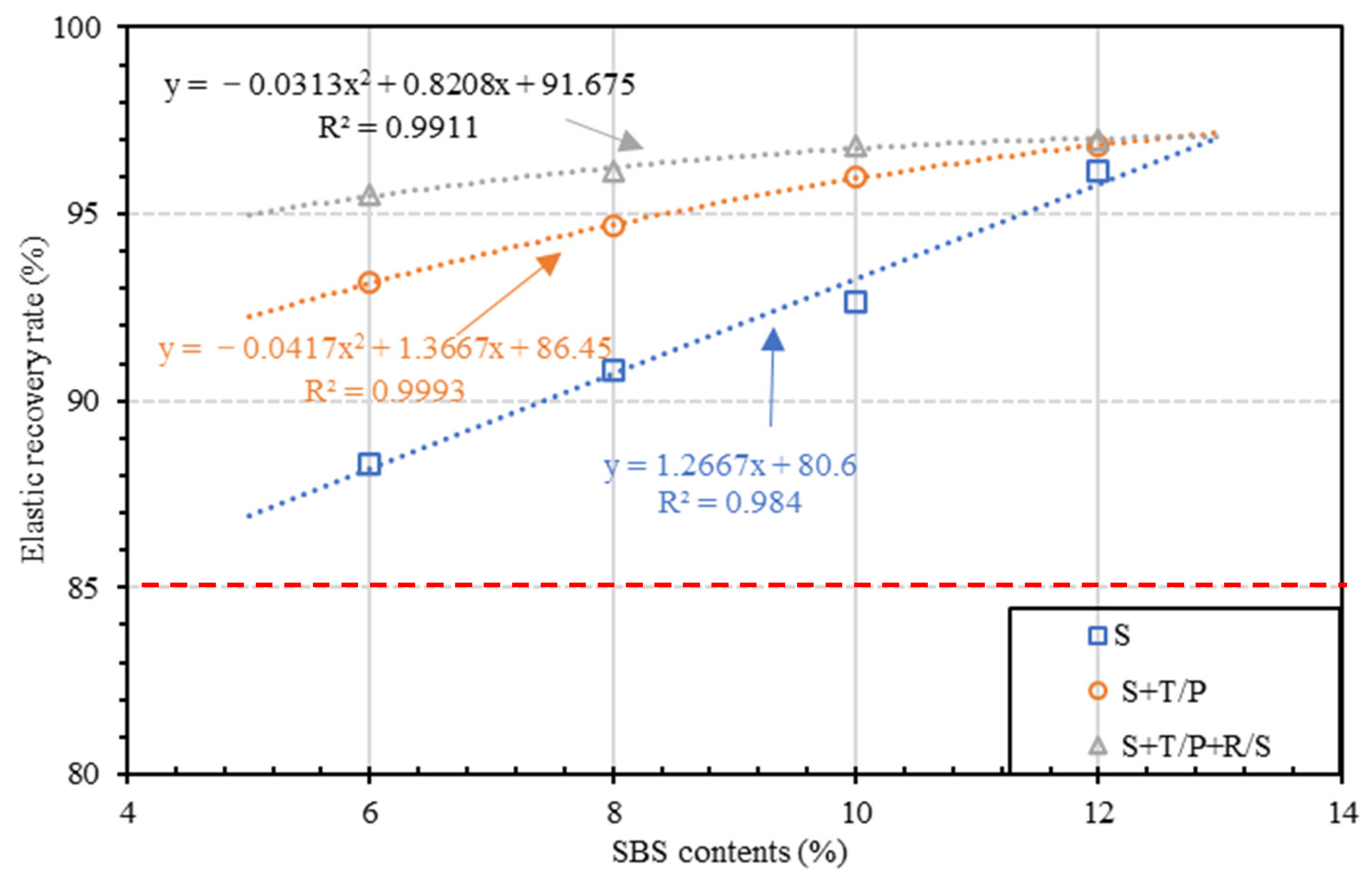

3.1.2. Properties of Elastic Recovery

3.2. Physical Properties of HVE-MB

3.2.1. Penetration

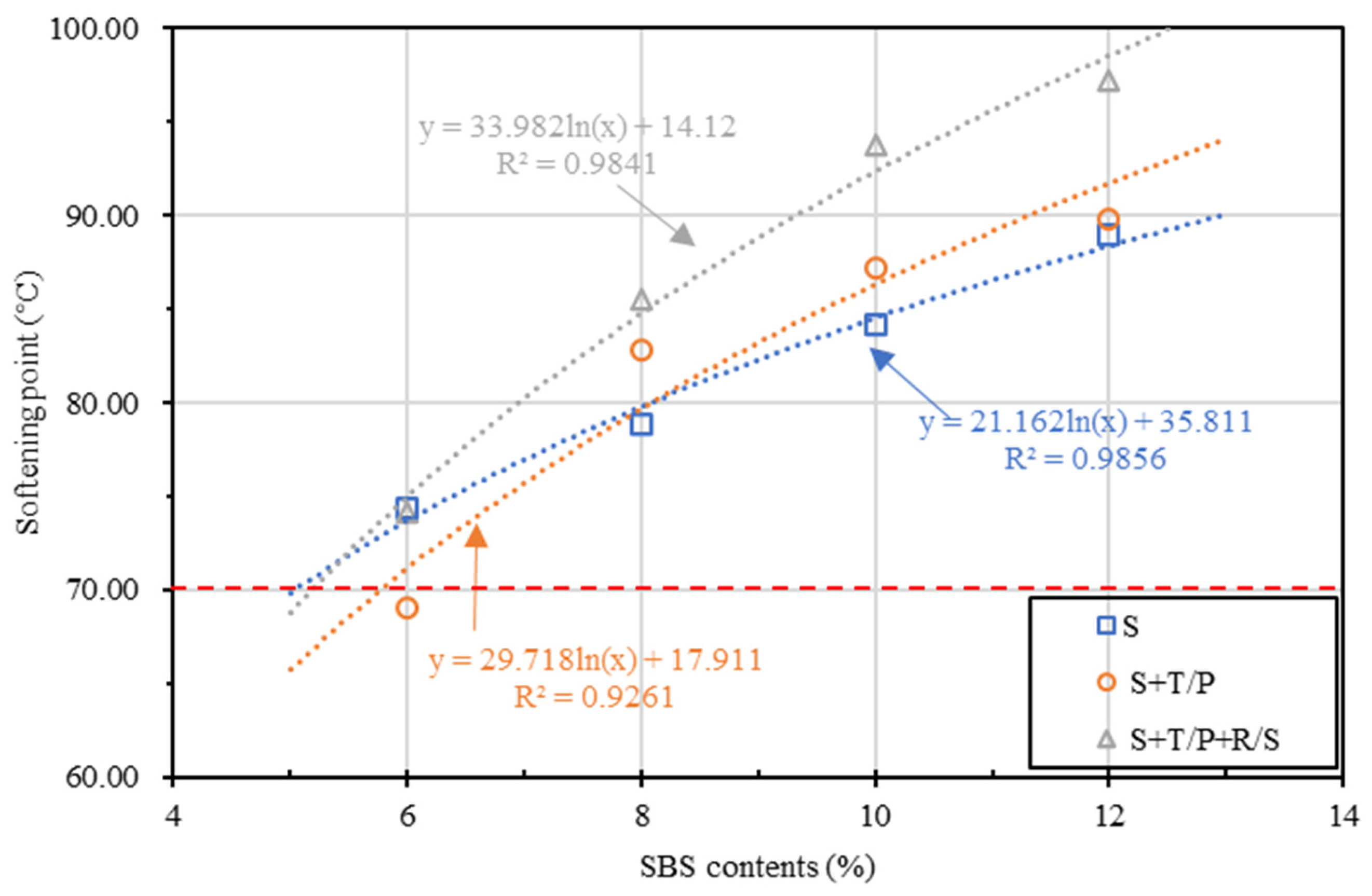

3.2.2. Softening Point

3.2.3. Ductility

3.3. Rheological Property of HVE-MB

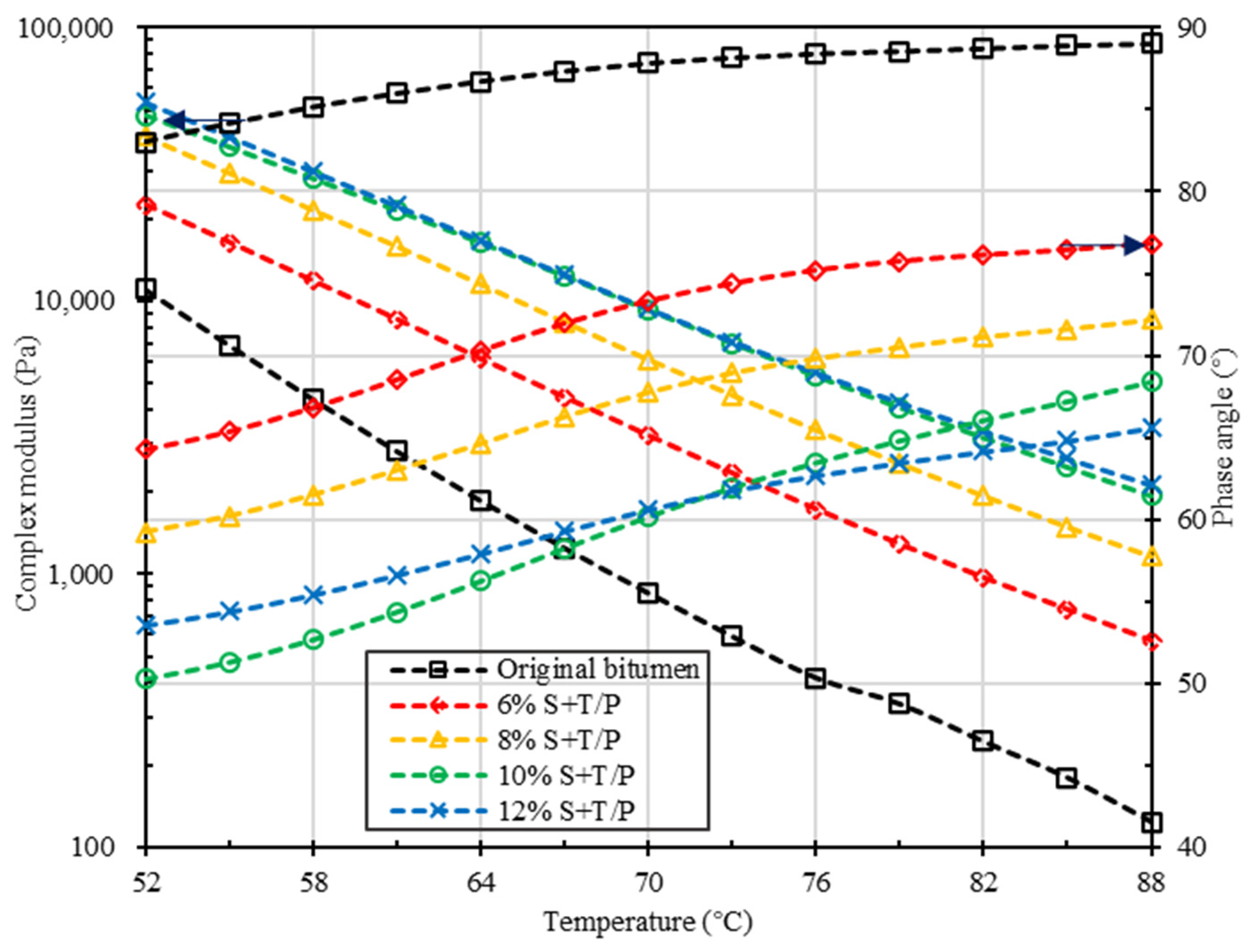

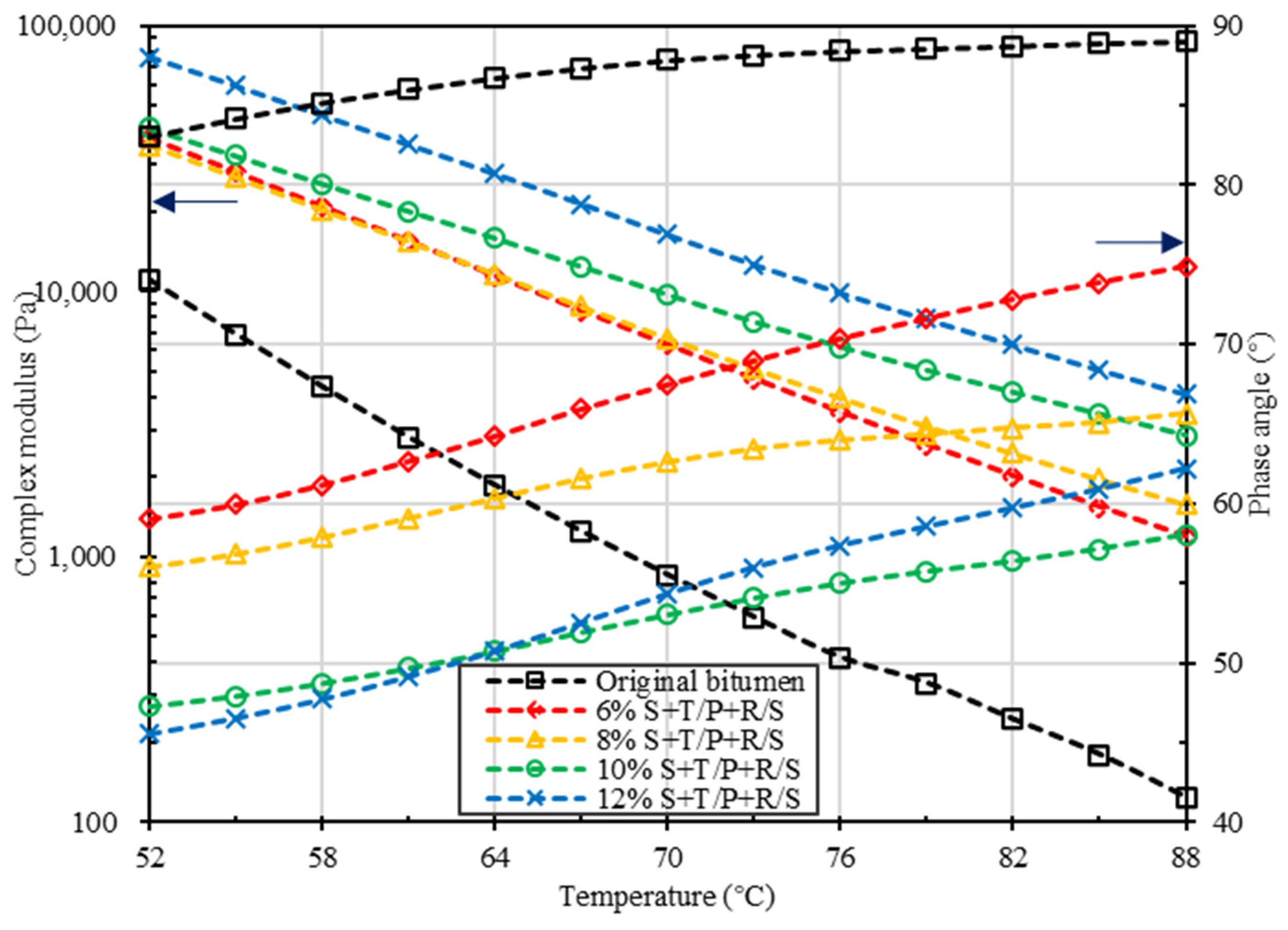

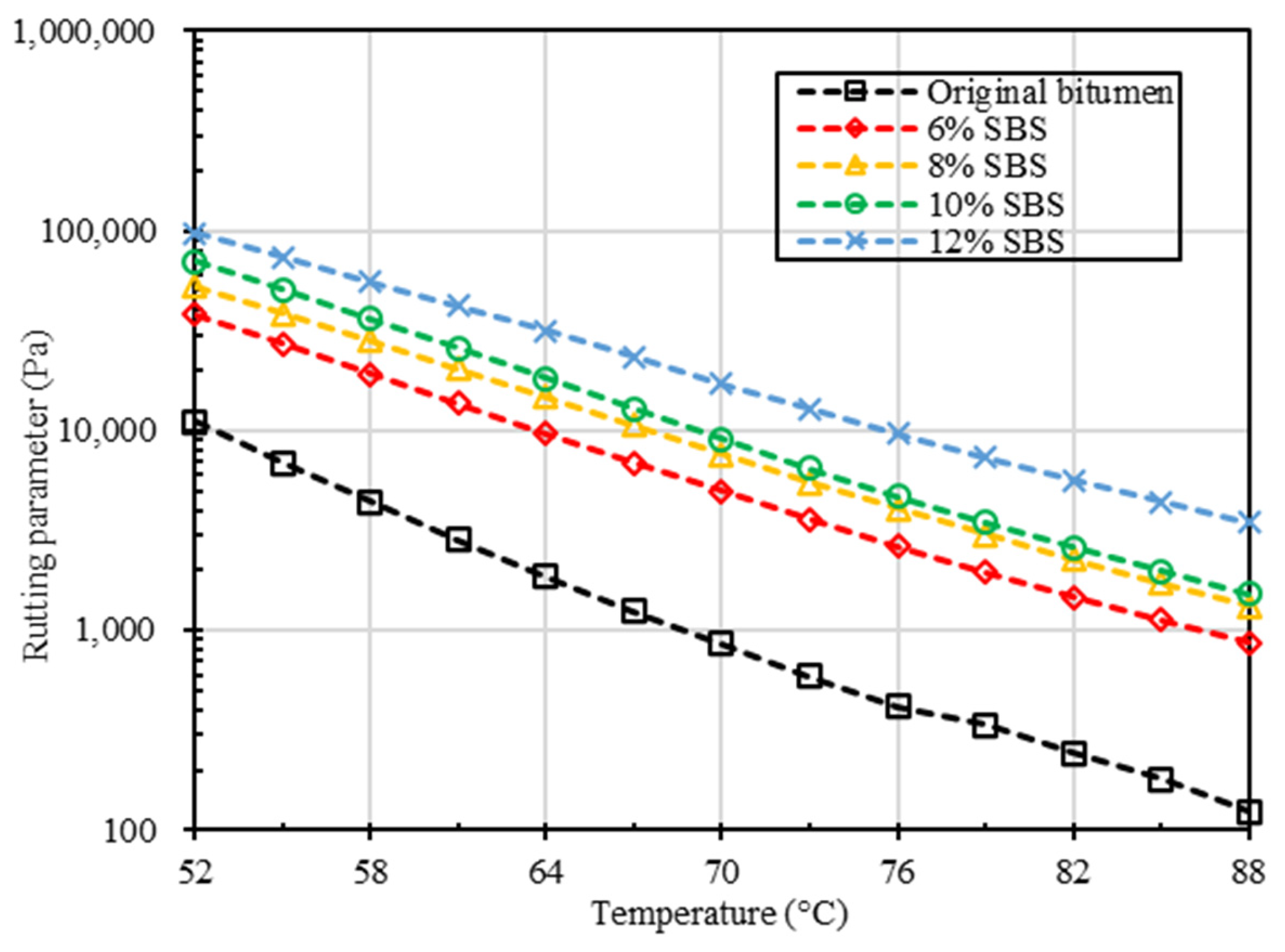

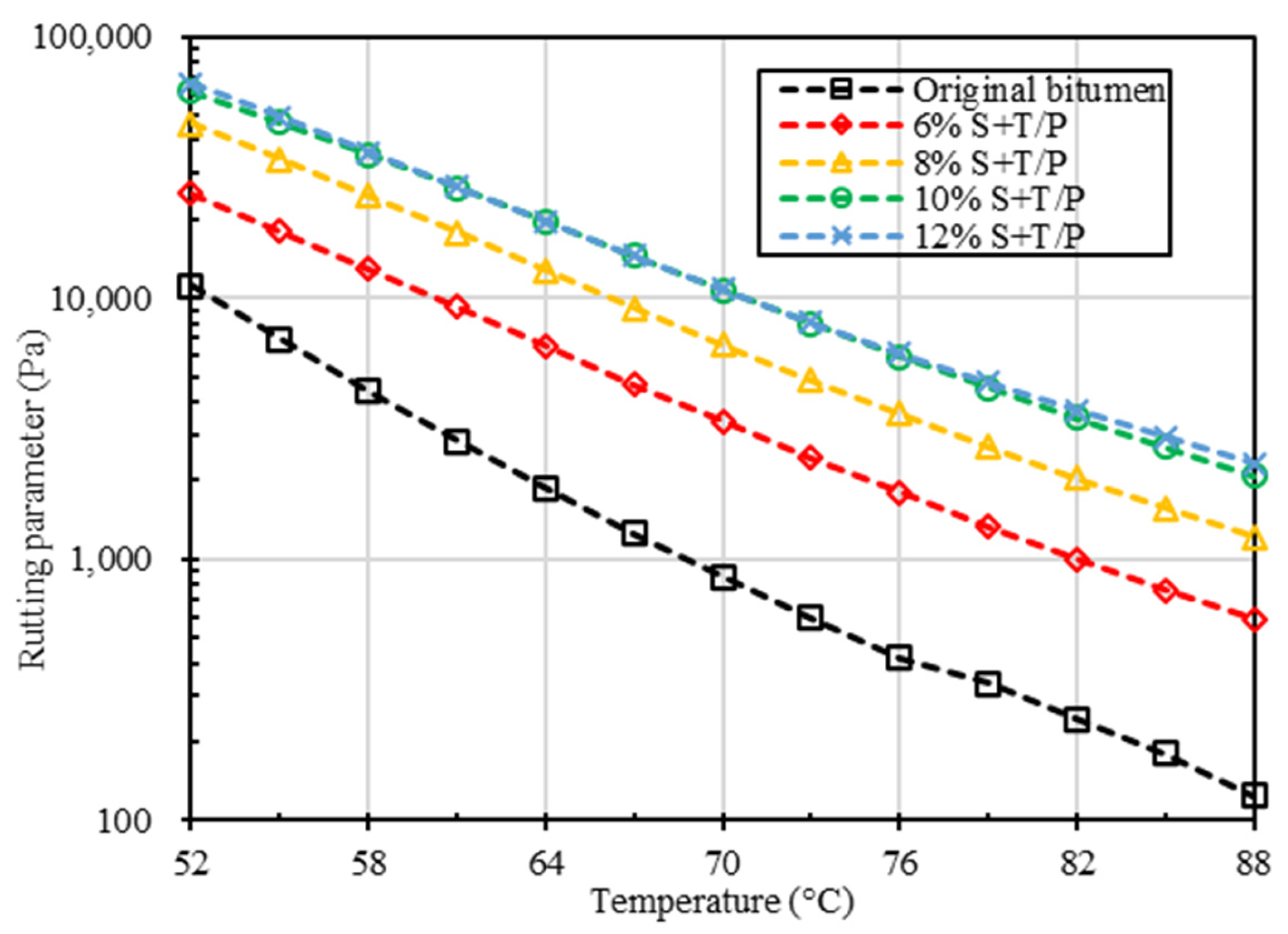

3.3.1. Complex Modulus and Phase Angle

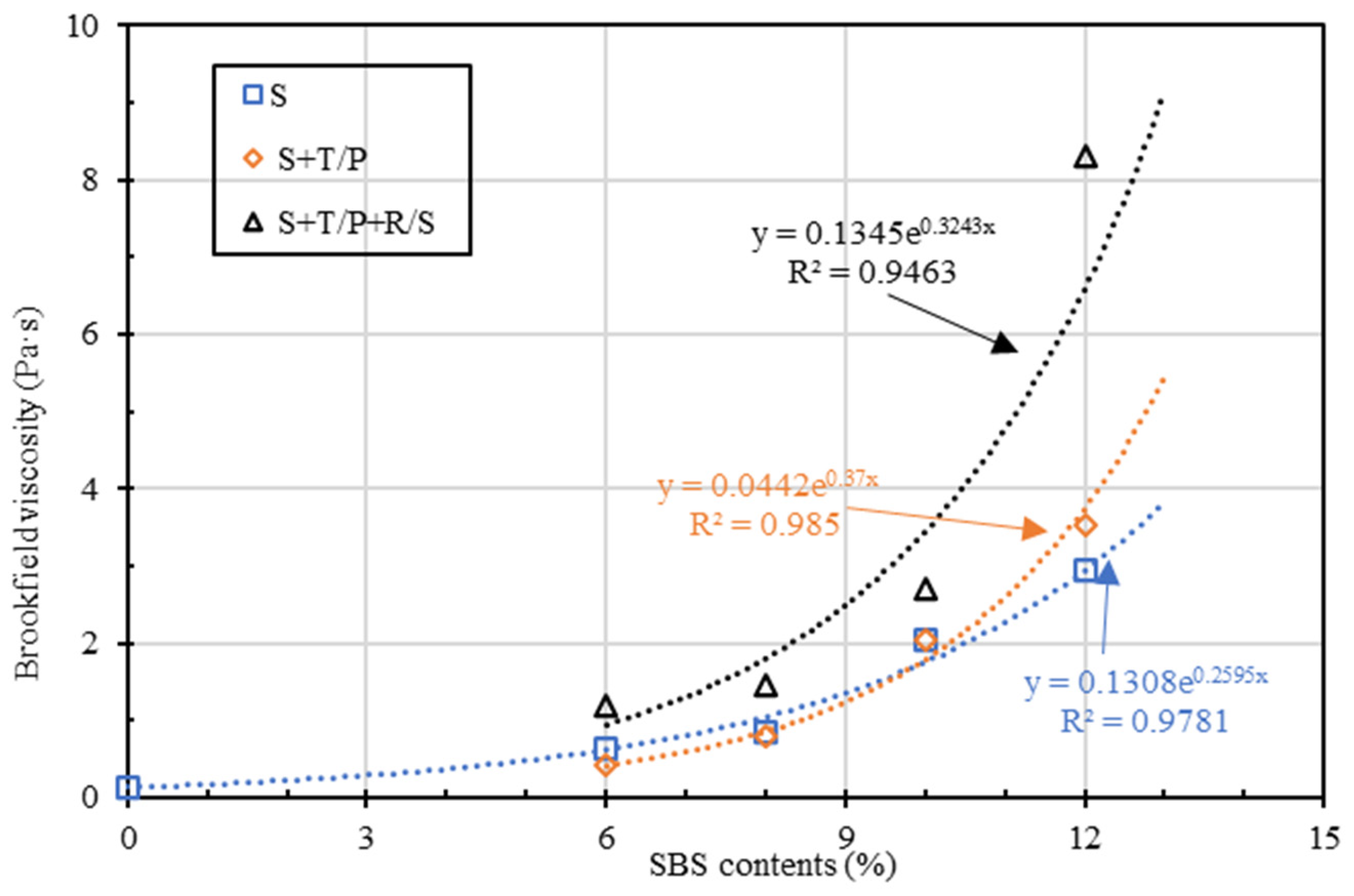

3.3.2. Brookfield Viscosity

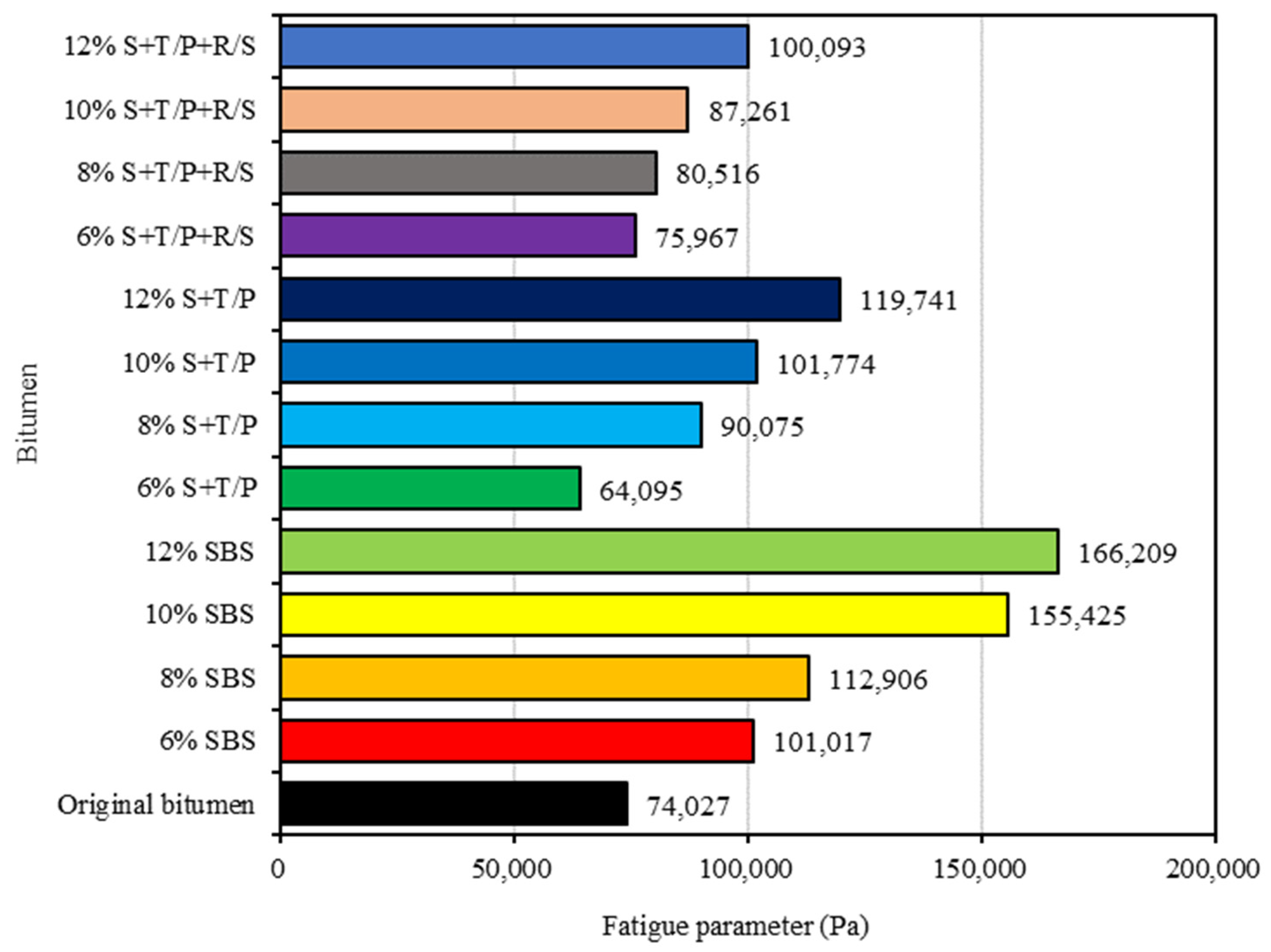

3.3.3. Fatigue Factor

3.3.4. Viscoelasticity

- (1)

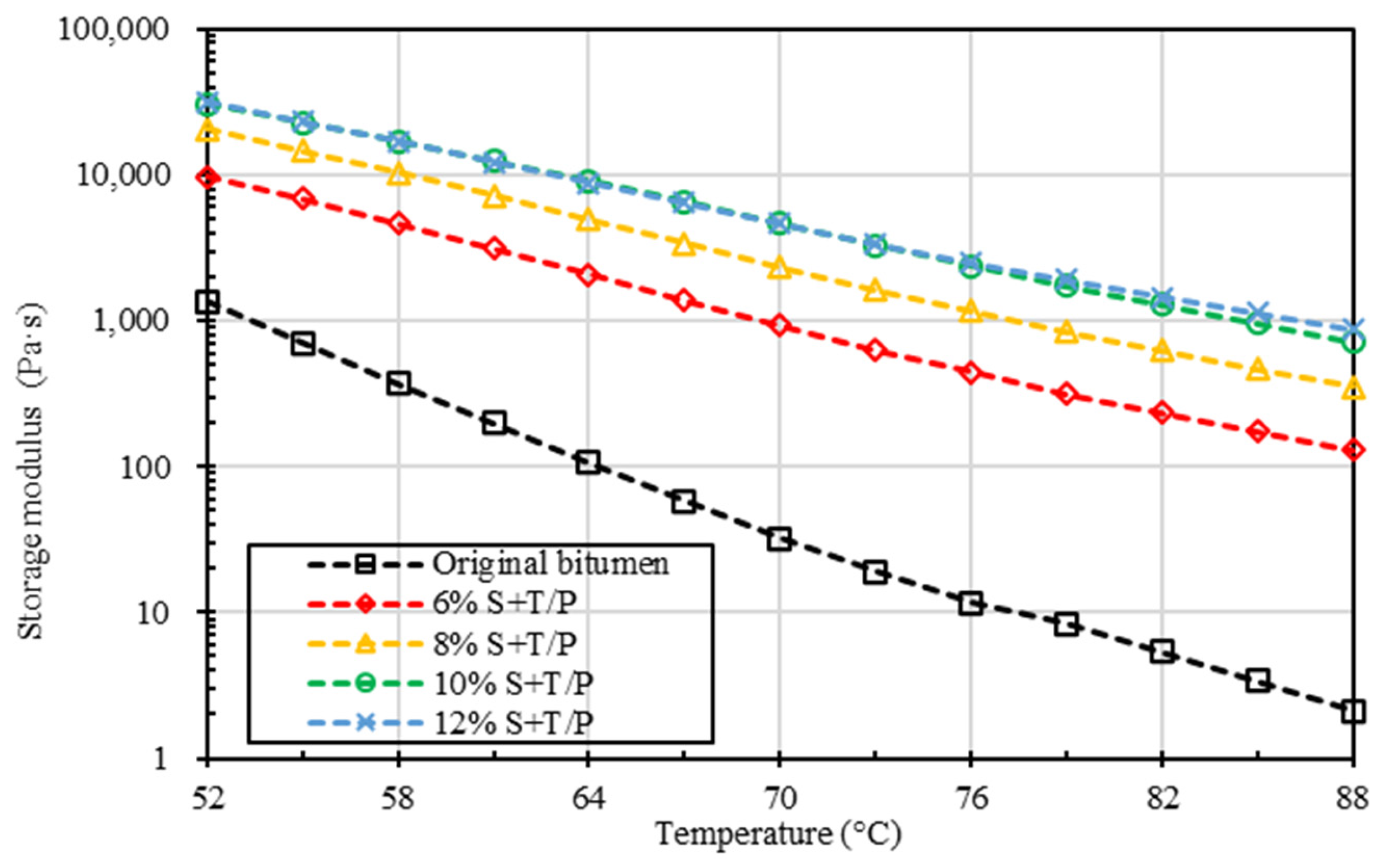

- Storage modulus and loss modulus

- (2)

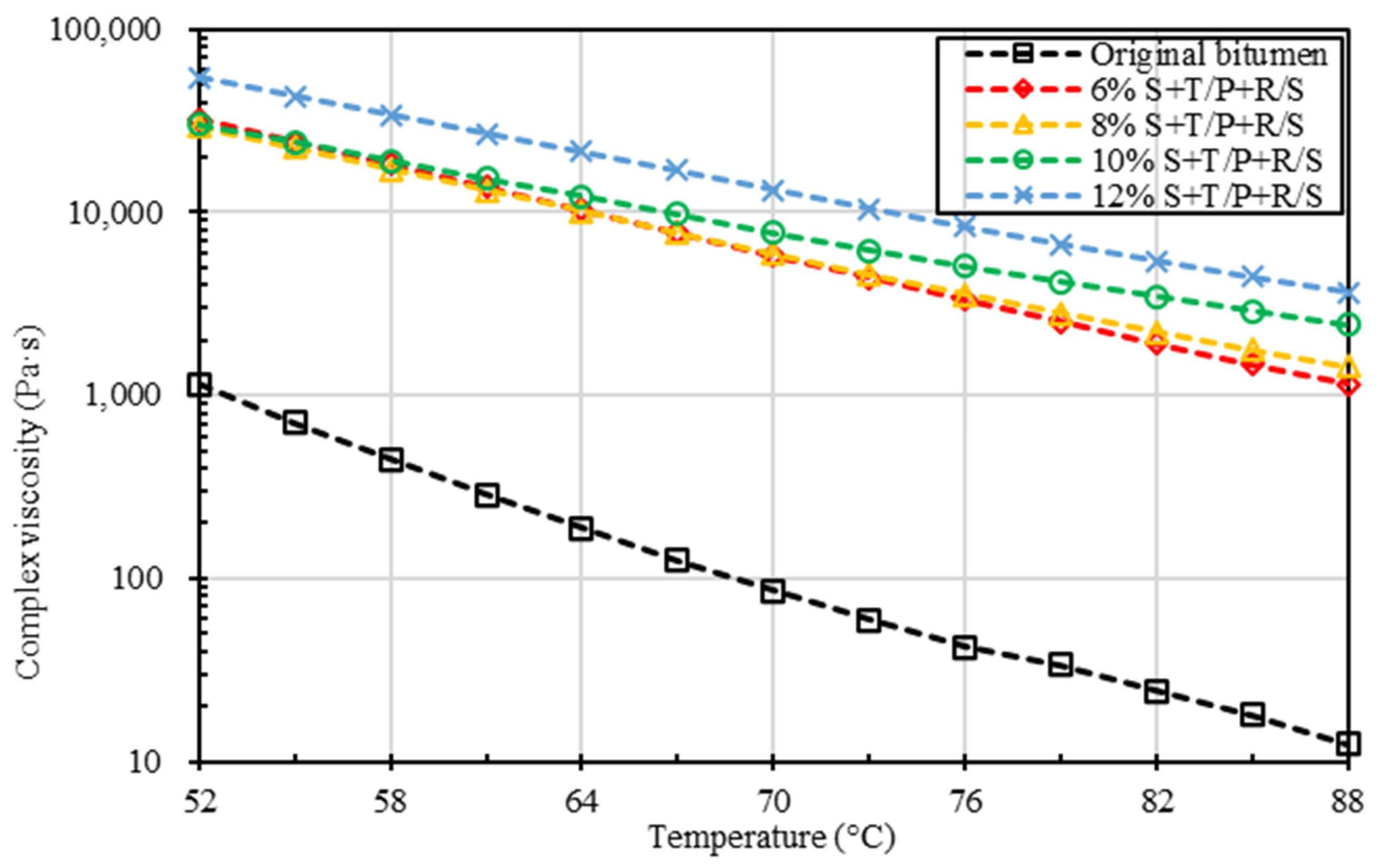

- Complex viscosity

3.4. Workability of HVE-MB

3.4.1. Storage Stability of HVE-MB

3.4.2. Construction Temperatures of HVE-MB

4. Conclusions

- (1)

- The dynamic viscosity of HVE-MB (SBS alone at a content of 6%) is greater than 110 times that of the original bitumen, and the elastic recovery rate is more than two times higher. The addition of modifiers also increases the softening point and ductility of the bitumen, while decreasing its penetration. These changes demonstrate the significant improvement of the bitumen’s viscoelasticity due to the addition of modifiers. Furthermore, the effect is more pronounced as the content of SBS is increased.

- (2)

- Twelve HVE-MB fulfill the requirements that the dynamic viscosity is no less than 20,000 Pa·s and the elastic recovery rate is no less than 85%. The softening point and ductility of HVE-MB are almost up to standard requirements. To achieve the requirement of penetration greater than 40 dmm, the SBS content should not be higher than 6% of the bitumen when SBS is added solely.

- (3)

- The effect of styrene-butadiene-styrene (SBS) on the rheological properties of bitumen is consistent when added solely or in combination with other substances (S+T/P and S+T/P+R/S). When the temperature is between 52 °C and 88 °C, the complex modulus and complex viscosity of the bitumen increase gradually with an increase in SBS content, and the phase angle decreases gradually. The temperature sensitivity of HVE-MB decreases with an increase in SBS content, with the bitumen containing S+T/P+R/S at 12% showing the best results. The fatigue parameter (Pa) is significantly reduced with the composite addition of other additives with SBS modifier, especially for the bitumen with rubber powder.

- (4)

- The viscoelasticity of HVE-MB is greatly improved compared to the original bitumen, but the storage stability decreases as the SBS content increases. For bitumen with added SBS solely and S+T/P, the SBS content should not exceed 10% and 8%, respectively. However, for the bitumen with S+T/P+R/S, SBS contents ranging from 6% to 12% can satisfy requirements, with a maximum difference in softening point of 1.73 °C. Additionally, the increase in mixing and rolling temperature for HVE-MB with 6–12% SBS is 29.67–47.47 °C and 25.28–36.69 °C, respectively.

- (5)

- Based on our research, the best type of high-viscosity and high-elasticity modified bitumen (HVE-MB) is S+T/P+R/S. The addition of a stabilizer ensures that all technical indicators meet the necessary requirements for this type of bitumen. The content of SBS can be selected based on the specific construction requirements.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Munder, B.; Mohamad, Y.A.; Norhidayah, A.H.; Zaid, A.; Nuha, S.; Mashaan, Z.A.M.; Abdalrhman, M.; Nur, I.M.Y. Effects of Waste Frying Oil and Crumb Rubber on the Characteristics of a Reclaimed Asphalt Pavement Binder. Materials 2021, 14, 3482. [Google Scholar]

- Guo, R.; Nian, T.; Zhou, F. Analysis of Factors That Influence Anti-rutting Performance of Asphalt Pavement. Constr. Build. Mater. 2020, 254, 119237. [Google Scholar] [CrossRef]

- Yao, L.; Dong, Q.; Jiang, J.; Ni, F. Establishment of Prediction Models of Asphalt Pavement Performance Based on a Novel Data Calibration Method and Neural Network. Transp. Res. Rec. J. Transp. Res. Board 2019, 2673, 66–82. [Google Scholar] [CrossRef]

- Yang, L.; Hu, Y.; Zhang, H. Comparative Study on Asphalt Pavement Rut Based on Analytical Models and Test Data. Int. J. Pavement Eng. 2018, 21, 1–15. [Google Scholar] [CrossRef]

- Shi, X.; Cai, L. Effects of Nano-silica and Rock Asphalt on Rheological Properties of Modified Bitumen. Constr. Build. Mater. 2018, 161, 705–714. [Google Scholar] [CrossRef]

- Nhat, T.T.; Takahashi, O. Investigation on Indices of Workability and Rutting Resistance for Wearing Course Mixtures. Balt. J. Road Bridge Eng. 2017, 12, 37. [Google Scholar] [CrossRef]

- Li, S.; Gu, X.; Xu, X.; Xu, D.; Dong, Q. Detection of Concealed Cracks From Ground Penetrating Radar Images Based on Deep Learning Algorithm. Constr. Build. Mater. 2021, 273, 121949. [Google Scholar] [CrossRef]

- Oliveira, J.R.M.; Silva, H.M.R.D.; Abreu, L.P.F.; Fernandes, S.R.M. Use of a Warm Mix Asphalt Additive to Reduce the Production Temperatures and to Improve the Performance of Asphalt Rubber Mixtures. J. Clean. Prod. 2013, 41, 15–22. [Google Scholar] [CrossRef]

- Li, D.; Leng, Z.; Zou, F.; Yu, H. Effects of Rubber Absorption on the Aging Resistance of Hot and Warm Asphalt Rubber Binders Prepared with Waste Tire Rubber. J. Clean. Prod. 2021, 303, 127082. [Google Scholar] [CrossRef]

- Xu, J.; Li, R.; Liu, T.; Pei, J.; Li, Y.; Luo, Q. Study on the Effect of Microwave Processing on Asphalt-rubber. Materials 2020, 13, 411. [Google Scholar] [CrossRef]

- Shirini, B.; Imaninasab, R. Performance Evaluation of Rubberized and SBS Modified Porous Asphalt Mixtures. Constr. Build. Mater. 2016, 107, 165–171. [Google Scholar] [CrossRef]

- Xu, B.; Li, M.; Liu, S.; Fang, J.; Ding, R.; Cao, D. Performance Analysis of Different Type Preventive Maintenance Materials for Porous Asphalt Based on High Viscosity Modified Asphalt. Constr. Build. Mater. 2018, 191, 320–329. [Google Scholar] [CrossRef]

- Wang, H.; You, Z.; Mills-Beale, J.; Hao, P. Laboratory Evaluation on High Temperature Viscosity and Low Temperature Stiffness of Asphalt Binder with High Percent Scrap Tire Rubber. Constr. Build. Mater. 2012, 26, 583–590. [Google Scholar] [CrossRef]

- Zhang, F. The Research for Low-temperature Rheological Properties and Structural Characteristics of High-viscosity Modified Asphalt. J. Therm. Anal. Calorim. 2017, 131, 1025–1034. [Google Scholar] [CrossRef]

- Wang, T.; Jiang, W.; Ruan, C.; Xiao, J.; Yuan, D.; Wu, W.; Xing, C. The rheological properties of high-viscosity modified reclaimed asphalt binder at multiple application temperatures. Constr. Build. Mater. 2023, 372, 130758. [Google Scholar] [CrossRef]

- Rasool, R.T.; Wang, S.; Zhang, Y.; Li, Y.; Zhang, G. Improving the Aging Resistance of SBS Modified Asphalt with the Addition of Highly Reclaimed Rubber. Constr. Build. Mater. 2017, 145, 126–134. [Google Scholar] [CrossRef]

- Geng, L.T.; Xu, Q.; Ren, R.B.; Wang, L.Z.; Yang, X.L.; Wang, X.Y. Performance Research of High-viscosity Asphalt Mixture as Deck-paving Materials for Steel Bridges. Road Mater. Pavement Des. 2016, 18, 208–220. [Google Scholar] [CrossRef]

- Nahas, N.C.; Bardet, J.; Eckman, B.; Siano, D.B. Polymer modified asphalts for high performance hot mix asphalt pavement binders. Assoc. Asph. Paving Technol. 1990, 59. [Google Scholar]

- Cheng, G.; Shen, B.; Zhang, J. A Study on the Performance and Storage Stability of Crumb Rubber-modified Asphalts. Liq. Fuels Technol. 2011, 29, 192–200. [Google Scholar] [CrossRef]

- Luo, Y.; Zhang, K.; Li, P.; Yang, J.; Xie, X. Performance Evaluation of Stone Mastic Asphalt Mixture with Different High Viscosity Modified Asphalt Based on Laboratory Tests. Constr. Build. Mater. 2019, 225, 214–222. [Google Scholar] [CrossRef]

- Luo, Y.; Zhang, Z.; Zhang, H.; Zhang, M.; Zhang, K.; Zhao, Y. Performance Optimization of High Viscosity Modified Asphalt with SBS Composite Modifier and Comparison of Different High Viscosity Modified Asphalts. Int. J. Pavement Res. Technol. 2021, 15, 1386–1398. [Google Scholar] [CrossRef]

- Zhang, F.; Hu, C. Preparation and Properties of High Viscosity Modified Asphalt. Polym. Compos. 2017, 38, 936–946. [Google Scholar] [CrossRef]

- Zhou, C.; Chen, G. Preparation, Performance, and Modification Mechanism of High Viscosity Modified Asphalt. Constr. Build. Mater. 2021, 310, 125007. [Google Scholar] [CrossRef]

- Li, J.; Li, Y.; Li, M.; Lu, H.; Cao, D. Dynamic Viscosity Standard of High Viscosity Modified Asphalt Considering Temperature and Load Coupling Effect. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1075, 12013. [Google Scholar] [CrossRef]

- Zhang, F.; Hu, C.; Zhang, Y. The Effect of PPA on Performances and Structures of High-viscosity Modified Asphalt. J. Therm. Anal. Calorim. 2018, 134, 1729–1738. [Google Scholar] [CrossRef]

- Shi, J.; Zhao, P.; Fan, W.; Yang, Z.; Ouyang, J. Facile Preparation and Application Performance Evaluation of SBS/C9 Petroleum Resin Blends as Modifier for High Viscosity Asphalt. Constr. Build. Mater. 2020, 262, 120073. [Google Scholar] [CrossRef]

- Zhang, W.; Jia, Z.; Wang, F. Effect and Prediction of Aromatic Oil on Swelling Degree of Direct-to-plant SBS Modifier in Bitumen. Pet. Sci. Technol. 2019, 37, 1033–1040. [Google Scholar] [CrossRef]

- Hong, W.; Mo, L.; Pan, C.; Riara, M.; Wei, M.; Zhang, J. Investigation of Rejuvenation and Modification of Aged Asphalt Binders By Using Aromatic Oil-SBS Polymer Blend. Constr. Build. Mater. 2020, 231, 117154. [Google Scholar] [CrossRef]

- Yu, H.; Leng, Z.; Zhang, Z.; Li, D.; Zhang, J. Selective absorption of swelling rubber in hot and warm asphalt binder fractions. Constr. Build. Mater. 2020, 238, 117727. [Google Scholar] [CrossRef]

- Zhu, Y.; Xu, G.; Ma, T.; Fan, J.; Li, S. Performances of rubber asphalt with middle/high content of waste tire crumb rubber. Constr. Build. Mater. 2022, 335, 127488. [Google Scholar] [CrossRef]

- Airey, G.; Rahman, M.; Collop, A.C. Crumb Rubber and Bitumen Interaction as a Function of Crude Source and Bitumen Viscosity. Road Mater. Pavement Des. 2004, 5, 453–475. [Google Scholar] [CrossRef]

- Mashaan, N.; Ali, A.; Karim, M.R. Effect of Crumb Rubber Concentration on the Physical and Rheological Properties of Rubberized Bitumen Binders. Int. J. Phys. Sci. 2011, 6, 684–690. [Google Scholar]

- Zhu, H. Swelled Mechanism of Crumb Rubber and Technical Properties of Crumb Rubber Modified Bitumen. Materials 2022, 15, 7987. [Google Scholar] [CrossRef]

- Zhu, Y. Study on Storage Stability of Activated Reclaimed Rubber Powder Modified Asphalt. Materials 2021, 14, 4684. [Google Scholar]

- Wen, G.; Zhang, Y.; Zhang, Y.; Sun, K.; Fan, Y. Rheological Characterization of Storage-stable SBS-modified Asphalts. Polym. Test. 2002, 21, 295–302. [Google Scholar] [CrossRef]

- Feng, Z.; Yu, J.; Wu, S. Effect of Ageing on Rheological Properties of Storage-stable SBS/sulfur-modified Asphalts. J. Hazard. Mater. 2010, 182, 507–517. [Google Scholar]

- GB/T 30516-2014; Bitumen with High Viscosity and Elastic Recovery for Pavement. Standards Press of China: Beijing, China, 2014.

- D 422–63; ASTM Standard, American Society for Testing and Materials. ASTM International: West Conshohocken, PA, USA, 2003.

- JTG E20-2011; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. China Communications Press: Beijing, China, 2011.

- Júnior, A.; Battistelle, R.A.; Bezerra, B.S. Use of Scrap Tire Rubber in Place of SBS in Modified Asphalt as an Environmentally Correct Alternative for Brazil. J. Clean. Prod. 2012, 33, 236–238. [Google Scholar] [CrossRef]

- Xu, X.; Leng, Z.; Lan, J.; Wang, W.; Yu, J.; Bai, Y.; Hu, J. Sustainable practice in pavement engineering through value-added collective recycling of waste plastic and waste tyre rubber. Engineering 2021, 7, 857–867. [Google Scholar] [CrossRef]

- Xu, X.; Luo, Y.; Sreeram, A.; Wu, Q.; Chen, G.; Cheng, S.; Chen, X. Potential use of recycled concrete aggregate (RCA) for sustainable asphalt pavements of the future: A state-of-the-art review. J. Clean. Prod. 2022, 344, 130893. [Google Scholar] [CrossRef]

- Bai, T.; Mao, B.; Chen, A.; Li, Y.; Wu, S.; Hu, Z.; Lin, Z. Investigation of Low-temperature Construction Additives (LCAS) Effects on the Technical Properties of Asphalt Binder. Constr. Build. Mater. 2021, 304, 124634. [Google Scholar] [CrossRef]

- Cong, P.; Wang, J.; Li, K.; Chen, S. Physical and Rheological Properties of Asphalt Binders Containing Various Antiaging Agents. Fuel 2012, 97, 678–684. [Google Scholar] [CrossRef]

- Li, Y.; Feng, J.; Yang, F.; Wu, S.; Liu, Q.; Liu, Z.; Jin, Y. Gradient Aging Behaviors of Asphalt Aged By Ultraviolet Lights with Various Intensities. Constr. Build. Mater. 2021, 295, 123618. [Google Scholar] [CrossRef]

- Wu, S. Carbon Nanomaterials for Enhancing the Thermal, Physical and Rheological Properties of Asphalt Binders. Materials 2021, 14, 2585. [Google Scholar]

- Fang, C.; Jiao, L.; Hu, J.; Yu, Q.; Guo, D.; Zhou, X.; Yu, R. Viscoelasticity of Asphalt Modified with Packaging Waste Expended Polystyrene. J. Mater. Sci. Technol. 2014, 30, 939–943. [Google Scholar] [CrossRef]

- Zhang, H.; Chen, Z.; Xu, G.; Shi, C. Evaluation of Aging Behaviors of Asphalt Binders Through Different Rheological Indices. Fuel 2018, 221, 78–88. [Google Scholar] [CrossRef]

- Tan, Y.; Lei, Z.; Gong, W.; Meng, G. Investigation of the Effects of Wax Additive on the Properties of Asphalt Binder. Constr. Build. Mater. 2012, 36, 578–584. [Google Scholar]

- Sengoz, B.; Oylumluoglu, J. Utilization of Recycled Asphalt Concrete with Different Warm Mix Asphalt Additives Prepared with Different Penetration Grades Bitumen. Constr. Build. Mater. 2013, 45, 173–183. [Google Scholar] [CrossRef]

- Hadiwardoyo, S.P.; Sinaga, E.S.; Fikri, H. The Influence of Buton Asphalt Additive on Skid Resistance Based on Penetration Index and Temperature. Constr. Build. Mater. 2013, 42, 5–10. [Google Scholar] [CrossRef]

- JTG F40-2004; Technical Specifications for Construction of Highway Asphalt Pavements. China Communications Press: Beijing, China, 2004.

- Li, Y.; Li, J.; Li, C.; Chen, A.; Bai, T.; Tang, S.; Wu, S.; Gao, Y.; Zhu, H.; Feng, J. Strength formation mechanism and performance of steel slag self-compacting epoxy resin concrete. Constr. Build. Mater. 2022, 359, 129525. [Google Scholar]

- Yu, H.; Wu, S.; Chen, A.; Li, Y. Modification Mechanism and Technical Performance of Recycled PE-Modified Asphalt. Sustainability 2023, 15, 12273. [Google Scholar]

- Zhu, W.; Yu, Z.; Yang, C. Spatial Distribution of Corrosion Products Influenced by the Initial Defects and Corrosion-Induced Cracking of the Concrete. J. Test. Eval. 2023, 51, 2582–2597. [Google Scholar] [CrossRef]

- Zhu, W.; Yang, C.; Yu, Z.; Xiao, J.; Xu, Y. Impact of Defects in Steel-Concrete Interface on the Corrosion-Induced Cracking Propagation of the Reinforced Concrete. KSCE J. Civ. Eng. 2023, 27, 2621–2628. [Google Scholar] [CrossRef]

| Parameters | Unit | Testing Result | Specification | Test Methods | |

|---|---|---|---|---|---|

| Needle penetration (25 °C, 5 s, 100 g) | 0.1 mm | 69.0 | 60–80 | ASTM D5 | |

| Softening point (R&B) | °C | 48.2 | ≥46 | ASTM D36 | |

| Ductility (15 °C) | Cm | >100 | ≥100 | ASTM D113 | |

| Ductility (10 °C) | cm | 46.5 | ≥20 | ASTM D113 | |

| Density (15 °C) | g/cm3 | 1.035 | NA | JTG E20 T0603 | |

| Dynamic viscosity (60 °C) | Pa·s | 265.0 | ≥180 | JTG E20 T0620 | |

| Solubility (Trichloroethylene) | % | 99.8 | ≥99.5 | JTG E20 T0607 | |

| RTFOT | Mass change | % | −0.12 | ±0.8 | JTG E20 T0609 |

| Needle penetration ratio | % | 69 | ≥61 | JTG E20 T0604 | |

| Ductility (10 °C) | cm | 27.1 | ≥6 | JTG E20 T0605 | |

| Technical Parameters | Result | Technical Parameters | Result |

|---|---|---|---|

| Relative density | 1.039 | Elongation at break (%) | 750 |

| S/B ratio | 30/70 | 300% fixed elongation | 2.4 |

| Tensile strength (MPa) | 24 | Appearance | White solid |

| Shore hardness A | 72 |

| Technical Parameters | Result |

|---|---|

| Relative density | 0.963 |

| Softening point (°C) | 108 |

| Acid value (mgKOH/g) | ≤1 |

| Toluene insoluble matter (%) | 0.05 |

| Appearance | Transparent and brittle solid |

| Technical Parameters | Result |

|---|---|

| Relative density | 1.21 |

| Rubber hydrocarbon content (%) | 56 |

| Grain size (mesh) | 40 |

| Softening temperature (°C) | 136 |

| Appearance | Black powder particles |

| Technical Parameters | Result |

|---|---|

| Density (g/cm3) | 0.985 |

| Boiling point (°C) | 416.36 |

| Flashing point (°C) | 222.29 |

| Ester content (%) | ≤1 |

| Appearance | Colorless transparent oily liquid |

| Technical Parameters | Result | Standard |

|---|---|---|

| Density (g/cm3) | 1.126 | ASTM D4052 |

| Flashing point (°C) | >230 | ASTM D92 |

| Aromatic content (%) | 91 | ASTM D2007 |

| Viscosity index | 106 | ASTM D2270 |

| Sulfur content (%) | <0.3 | ASTM D2622 |

| Appearance | Light yellow oily liquid | Visual analysis |

| Code | Modifiers and Contents (%) | ||||

|---|---|---|---|---|---|

| SBS | Tackifier | Plasticizer | Reclaimed Rubber Powder | Stabilizer | |

| 6% S | 6 | 0 | 0 | 0 | 0 |

| 8% S | 8 | 0 | 0 | 0 | 0 |

| 10% S | 10 | 0 | 0 | 0 | 0 |

| 12% S | 12 | 0 | 0 | 0 | 0 |

| 6% S+T/P | 6 | 2.5 | 1 | 0 | 0 |

| 8% S+T/P | 8 | 2.5 | 1 | 0 | 0 |

| 10% S+T/P | 10 | 2.5 | 1 | 0 | 0 |

| 12% S+T/P | 12 | 2.5 | 1 | 0 | 0 |

| 6% S+T/P+R/S | 6 | 2.5 | 1 | 5 | 1 |

| 8% S+T/P+R/S | 8 | 2.5 | 1 | 5 | 1 |

| 10% S+T/P+R/S | 10 | 2.5 | 1 | 5 | 1 |

| 12% S+T/P+R/S | 12 | 2.5 | 1 | 5 | 1 |

| Parameters | Unit | Specification | Test Methods |

|---|---|---|---|

| Needle penetration (25 °C, 5 s, 100 g) | 0.1 mm | 40–80 | ASTM D5 |

| Softening point (Ring and ball method) | °C | ≥70 | ASTM D36 |

| Ductility (5 °C) | cm | ≥30 | ASTM D113 |

| Dynamic viscosity (60 °C) | Pa·s | ≥20,000 | JTG E20 T0620 |

| Recovery of elasticity (25 °C) | % | ≥85 | ASTM D6084 |

| Segregation (softening point differences) | °C | ≤2.5 | JTG E20 T0661 |

| Model | Capillary Radius (mm) | Calibration Coefficient, 40 kPa Vacuum (Pa·s/s) | Viscosity Range (Pa·s) | ||

|---|---|---|---|---|---|

| B | C | D | |||

| 100 | 0.5 | 3.445 | 1.721 | 1.148 | 60–1280 |

| 400R | 2.0 | 47.74 | 24.65 | 16.21 | 960–140,000 |

| 800R | 4.0 | 195.73 | 98.26 | 64.96 | 3800–580,000 |

| Bitumen | Residual Length of Specimen Cut after 1 h (cm) | Average of Residual Lengths (cm) | Elastic Recovery Rate (%) | ||

|---|---|---|---|---|---|

| 1 | 2 | 3 | |||

| Original bitumen | 12.5 | 9.4 | 11.2 | 11.03 | 44.83 |

| 6% S | 2.5 | 2.4 | 2.1 | 2.33 | 88.33 |

| 8% S | 1.8 | 1.7 | 2.0 | 1.83 | 90.83 |

| 10% S | 1.5 | 1.7 | 1.2 | 1.47 | 92.67 |

| 12% S | 0.9 | 0.6 | 0.8 | 0.77 | 96.17 |

| 6% S+T/P | 1.4 | 1.2 | 1.5 | 1.37 | 93.17 |

| 8% S+T/P | 1.1 | 1.0 | 1.1 | 1.07 | 94.67 |

| 10% S+T/P | 1.0 | 0.8 | 0.6 | 0.80 | 96.00 |

| 12% S+T/P | 0.7 | 0.4 | 0.8 | 0.63 | 96.83 |

| 6% S+T/P+R/S | 0.8 | 0.9 | 1.0 | 0.90 | 95.50 |

| 8% S+T/P+R/S | 0.7 | 0.9 | 0.7 | 0.77 | 96.17 |

| 10% S+T/P+R/S | 0.5 | 0.8 | 0.6 | 0.63 | 96.83 |

| 12% S+T/P+R/S | 0.6 | 0.4 | 0.8 | 0.60 | 97.00 |

| HVE-MB | Ductility (cm) | ||

|---|---|---|---|

| 5 °C | 10 °C | 15 °C | |

| 6% S | 30.5 | 55.1 | >100 |

| 8% S | 48.0 | 71.3 | |

| 10% S | 65.8 | 92.3 | |

| 12% S | 81.2 | >100 | |

| 6% S+T/P | 40.9 | 58.5 | |

| 8% S+T/P | 59.2 | 86.6 | |

| 10% S+T/P | 72.2 | >100 | |

| 12% S+T/P | 89.2 | >100 | |

| 6% S+T/P+R/S | 48.4 | 71.3 | |

| 8% S+T/P+R/S | 68.7 | >100 | |

| 10% S+T/P+R/S | 77.5 | >100 | |

| 12% S+T/P+R/S | 92.3 | >100 | |

| Increment of Viscosity | Additive | Effect of Different Content of SBS on the Rotational Viscosity Indicator of Bitumen | |||

|---|---|---|---|---|---|

| 6% | 8% | 10% | 12% | ||

| Brookfield rotational viscosity at 135 °C (Pa·s) | S | 211.34 | 435.05 | 1389.69 | 1832.99 |

| S+T/P | 236.08 | 463.92 | 1601.03 | 2549.48 | |

| S+T/P+R/S | 570.10 | 825.36 | 1776.29 | 5209.28 | |

| Brookfield rotational viscosity at 165 °C (Pa·s) | S | 374.07 | 522.22 | 1411.11 | 2085.19 |

| S+T/P | 201.48 | 494.07 | 1403.70 | 2507.41 | |

| S+T/P+R/S | 774.07 | 970.37 | 1911.11 | 6055.56 | |

| Bitumen’s Type | Viscosity–Temperature Fitting Equation | R2 | VTS |

|---|---|---|---|

| Original bitumen | lg(lgη) = 22.54355 − 8.78361 × lgTK | 0.99139 | −8.78361 |

| 6% S | lg(lgη) = 10.33174 − 3.85472 × lgTK | 0.99462 | −3.85472 |

| 8% S | lg(lgη) = 9.45276 − 3.58084 × lgTK | 0.99214 | −3.58084 |

| 10% S | lg(lgη) = 9.73265 − 3.54076 × lgTK | 0.99386 | −3.54076 |

| 12% S | lg(lgη) = 8.87776 − 3.25315 × lgTK | 0.99551 | −3.25315 |

| 6% S+T/P | lg(lgη) = 10.65706 − 3.99121 × lgTK | 0.99252 | −3.99121 |

| 8% S+T/P | lg(lgη) = 9.59651 − 3.55993 × lgTK | 0.99354 | −3.55993 |

| 10% S+T/P | lg(lgη) = 8.50414 − 3.12125 × lgTK | 0.99648 | −3.12125 |

| 12% S+T/P | lg(lgη) = 8.15574 − 2.98505 × lgTK | 0.99246 | −2.98505 |

| 6% S+T/P+R/S | lg(lgη) = 9.31772 − 3.44966 × lgTK | 0.99393 | −3.44966 |

| 8% S+T/P+R/S | lg(lgη) = 8.56435 − 3.15133 × lgTK | 0.99631 | −3.15133 |

| 10% S+T/P+R/S | lg(lgη) = 7.12689 − 2.60676 × lgTK | 0.99699 | −2.60676 |

| 12% S+T/P+R/S | lg(lgη) = 6.99446 − 2.52031 × lgTK | 0.99451 | −2.52031 |

| Bitumen | Softening Point on Upper Part of Segregation Tube (°C) | Softening Point on Lower Part of Segregation Tube (°C) | Segregation Softening Point Difference (°C) |

|---|---|---|---|

| Original bitumen | 48.27 | 48.19 | 0.08 |

| 6% S | 74.62 | 74.03 | 0.59 |

| 8% S | 79.68 | 78.34 | 1.34 |

| 10% S | 86.21 | 84.23 | 1.98 |

| 12% S | 91.44 | 88.73 | 2.71 |

| 6% S+T/P | 70.28 | 69.03 | 1.25 |

| 8% S+T/P | 84.32 | 82.68 | 1.64 |

| 10% S+T/P | 89.63 | 86.82 | 2.81 |

| 12% S+T/P | 92.12 | 89.26 | 2.86 |

| 6% S+T/P+R/S | 74.26 | 73.86 | 0.40 |

| 8% S+T/P+R/S | 86.12 | 85.76 | 0.36 |

| 10% S+T/P+R/S | 94.62 | 93.35 | 1.27 |

| 12% S+T/P+R/S | 98.94 | 97.21 | 1.73 |

| Rheological Performance Indicator | Additive | Effect of Different Content of SBS on the Rheological Performance Indicator of Original Bitumen | |||

|---|---|---|---|---|---|

| 6% | 8% | 10% | 12% | ||

| Increase in Complex Modulus (%) | S | 385.56 | 624.09 | 773.15 | 1267.07 |

| S+T/P | 230.96 | 520.46 | 777.01 | 797.07 | |

| S+T/P+R/S | 515.19 | 525.30 | 751.16 | 1388.55 | |

| Reduction in Phase Angle (◦) | S | 17.78 | 21.50 | 23.95 | 32.84 |

| S+T/P | 16.40 | 22.11 | 30.48 | 28.81 | |

| S+T/P+R/S | 22.48 | 26.39 | 36.00 | 35.98 | |

| Increase in Rutting Parameter (%) | S | 419.51 | 496.26 | 880.38 | 1589.63 |

| S+T/P | 250.93 | 585.72 | 953.22 | 957.16 | |

| S+T/P+R/S | 582.00 | 618.51 | 998.04 | 1819.34 | |

| Bitumen | Mixing Temperature (°C) | Increment of Mixing Temperature (°C) | Rolling Temperature (°C) | Increment of Rolling Temperature (°C) |

|---|---|---|---|---|

| Original bitumen | 151.54 | – | 142.14 | – |

| 6% S | 181.21 | 29.67 | 167.41 | 25.28 |

| 8% S | 186.46 | 34.92 | 170.58 | 28.44 |

| 10% S | 195.86 | 44.32 | 175.22 | 33.08 |

| 12% S | 197.96 | 46.42 | 177.44 | 35.30 |

| 6% S+T/P | 180.67 | 29.14 | 167.98 | 25.84 |

| 8% S+T/P | 184.91 | 33.37 | 170.20 | 28.06 |

| 10% S+T/P | 194.00 | 42.46 | 173.47 | 31.33 |

| 12% S+T/P | 195.77 | 44.23 | 175.42 | 33.28 |

| 6% S+T/P+R/S | 189.64 | 38.10 | 170.04 | 27.91 |

| 8% S+T/P+R/S | 187.63 | 36.09 | 176.55 | 34.41 |

| 10% S+T/P+R/S | 196.99 | 45.45 | 176.47 | 34.33 |

| 12% S+T/P+R/S | 199.01 | 47.47 | 178.82 | 36.69 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Jiang, G.; Yan, S.; Feng, J.; Li, D. Performance and Mechanism of High-Viscosity and High-Elasticity Bitumen (HVE-MB) Modified with Five Additives. Sustainability 2023, 15, 14089. https://doi.org/10.3390/su151914089

Li Y, Jiang G, Yan S, Feng J, Li D. Performance and Mechanism of High-Viscosity and High-Elasticity Bitumen (HVE-MB) Modified with Five Additives. Sustainability. 2023; 15(19):14089. https://doi.org/10.3390/su151914089

Chicago/Turabian StyleLi, Yuanyuan, Gangping Jiang, Shuting Yan, Jianlin Feng, and Da Li. 2023. "Performance and Mechanism of High-Viscosity and High-Elasticity Bitumen (HVE-MB) Modified with Five Additives" Sustainability 15, no. 19: 14089. https://doi.org/10.3390/su151914089

APA StyleLi, Y., Jiang, G., Yan, S., Feng, J., & Li, D. (2023). Performance and Mechanism of High-Viscosity and High-Elasticity Bitumen (HVE-MB) Modified with Five Additives. Sustainability, 15(19), 14089. https://doi.org/10.3390/su151914089