A Review of Rubberised Asphalt for Flexible Pavement Applications: Production, Content, Performance, Motivations and Future Directions

Abstract

:1. Introduction

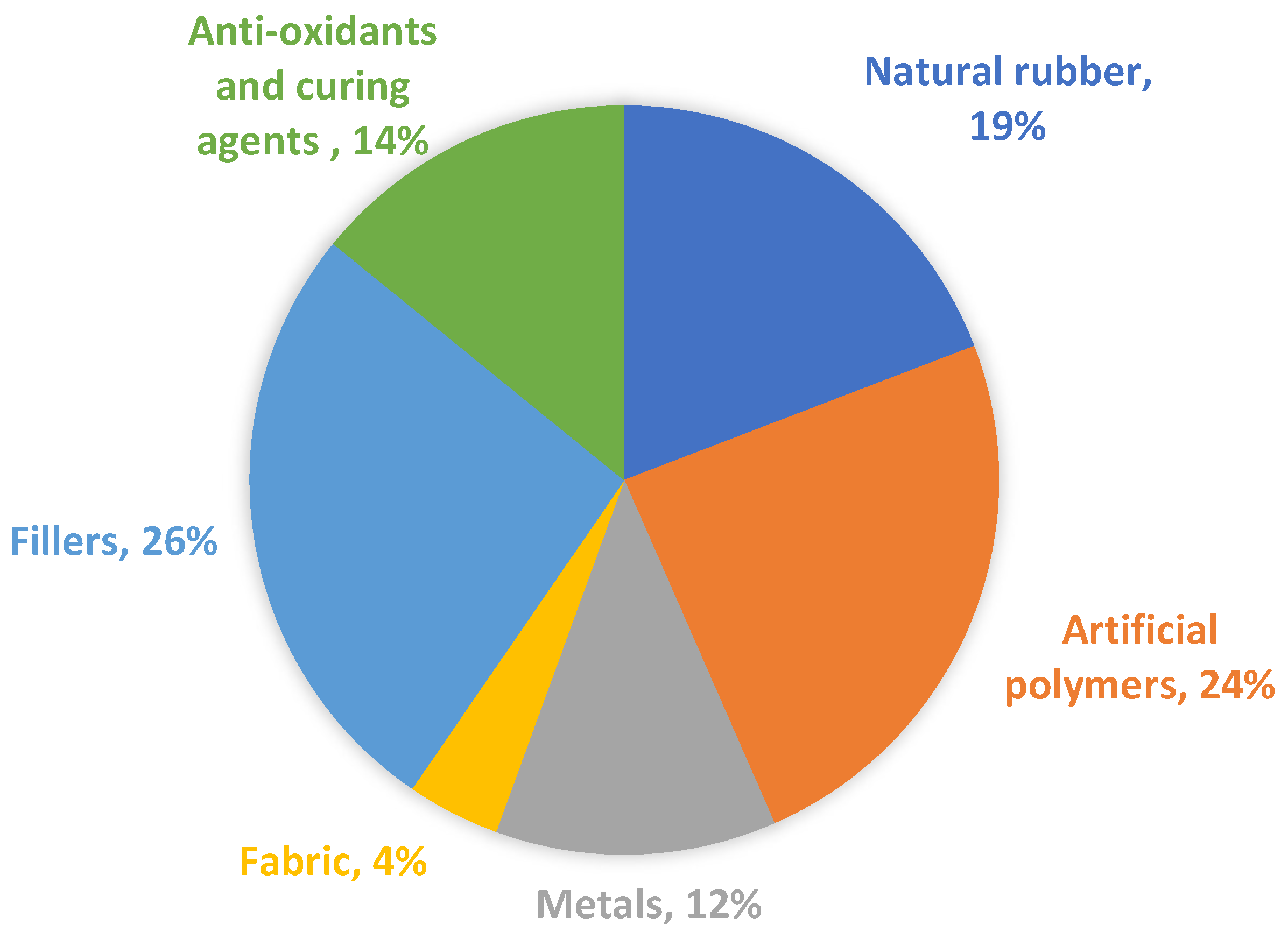

2. Crumb Rubber

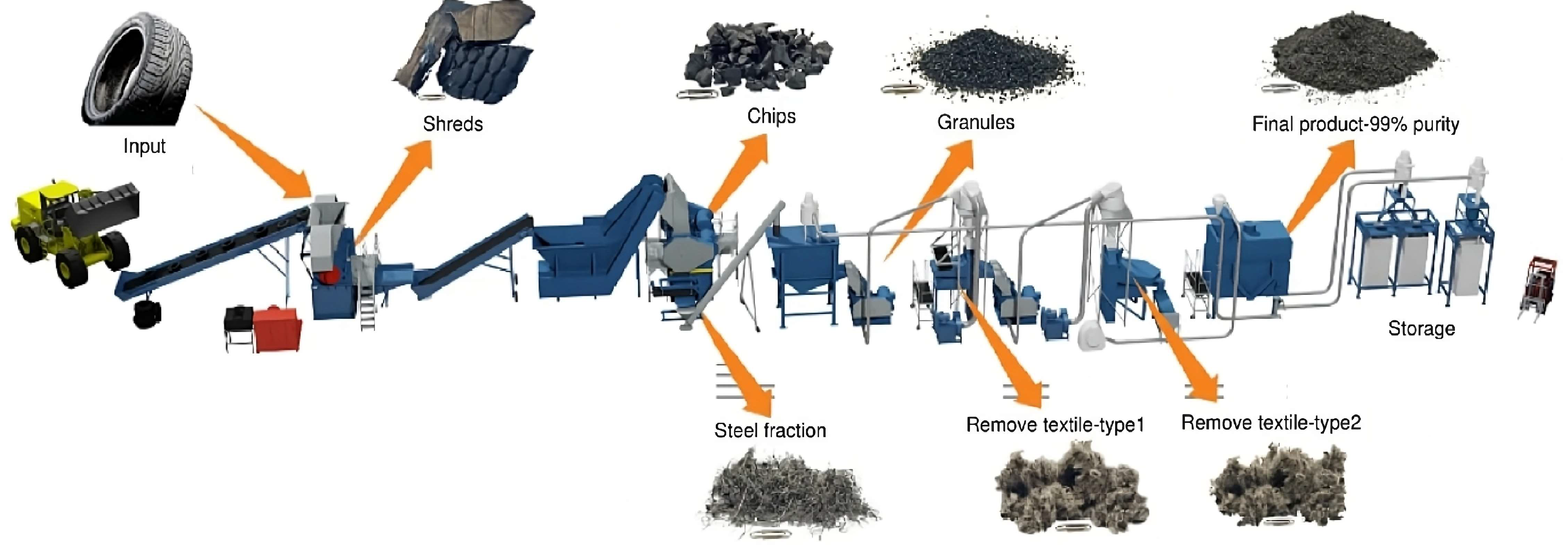

2.1. Production Methods

2.2. Physical and Chemical Properties

| Property | Ambient | Cryogenic |

|---|---|---|

| Specific gravity | 1.15 | 1.15 |

| Shape | Irregular | Regular |

| Steel content | 0.1% | - |

| Fiber content | 0.5% | - |

| Surface area | High | Low |

| Chemical Composition | Percentage (%) | |

|---|---|---|

| Acetone extract % | 15.5 | 9.21 |

| Ash content % | 6 | 6 |

| Carbon black % | 29.5 | 32 |

| Rubber hydrocarbon % | 49 | 52.79 |

| Property | Ambient | Cryogenic |

|---|---|---|

| Specific gravity (wt%) | 1.042 | 1.053 |

| Moisture content (wt%) | 0.76 | 0.77 |

| Ash content (wt%) | 6.01 | 4.66 |

| Carbon black content (wt%) | 32.98 | 30.41 |

| Sulfur content (wt%) | 2.02 | 1.24 |

| Acetone and chloroform content (wt%) | 9.86 | 11.69 |

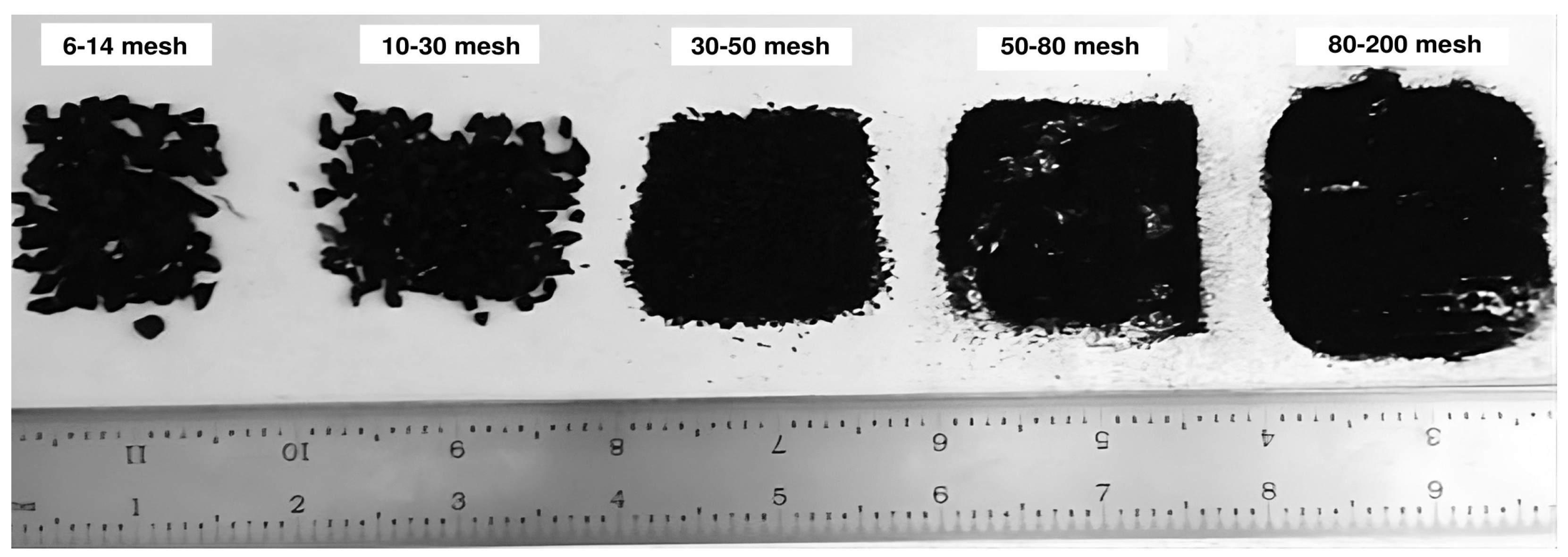

2.3. Size and Contents

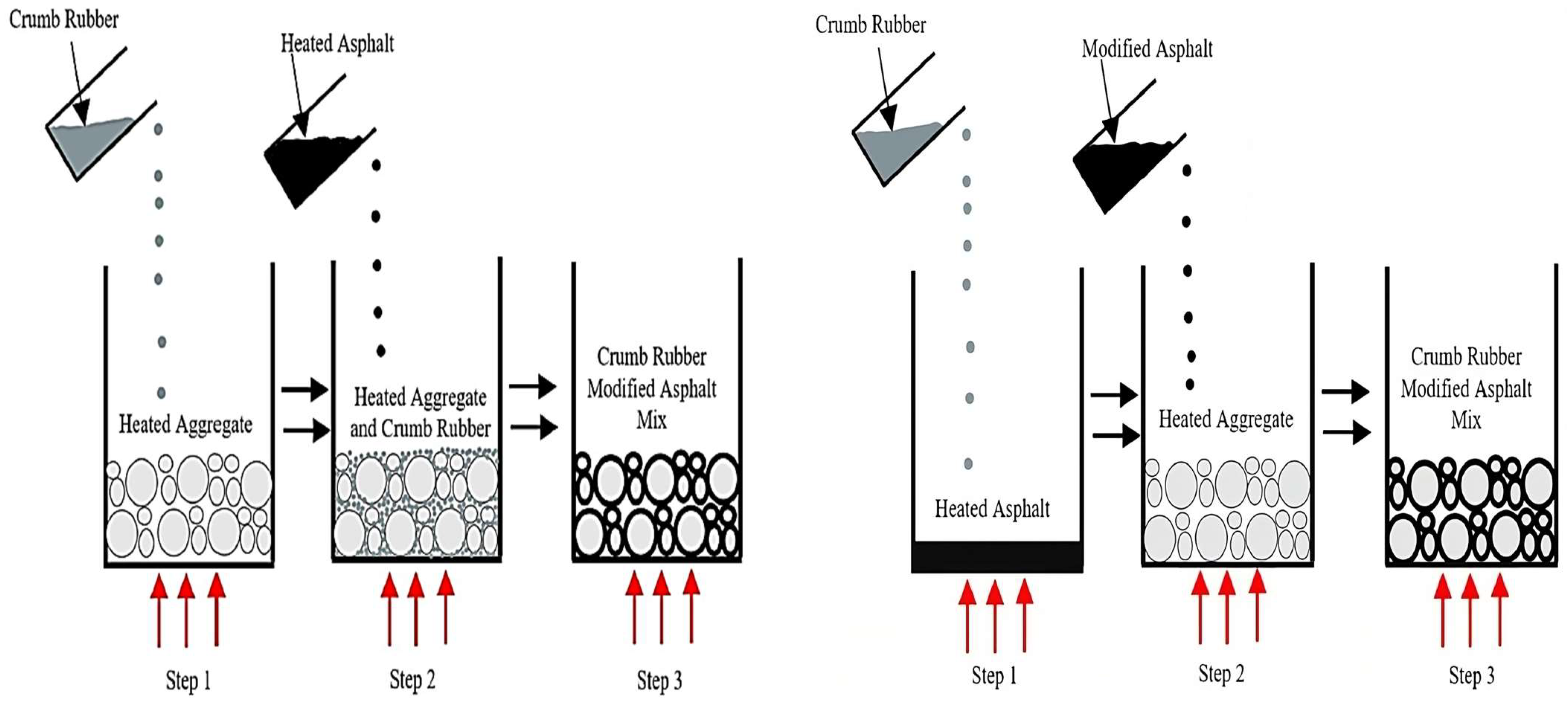

2.4. Blending Methods

- The optimal shearing temperature for ductility at 5 °C ranged from 170 to 180 °C [43], where low shearing temperatures reduced the asphalt’s fluidity (higher consistency), making it unsuitable for CR adsorption and swelling, while too high shearing temperatures caused ageing.

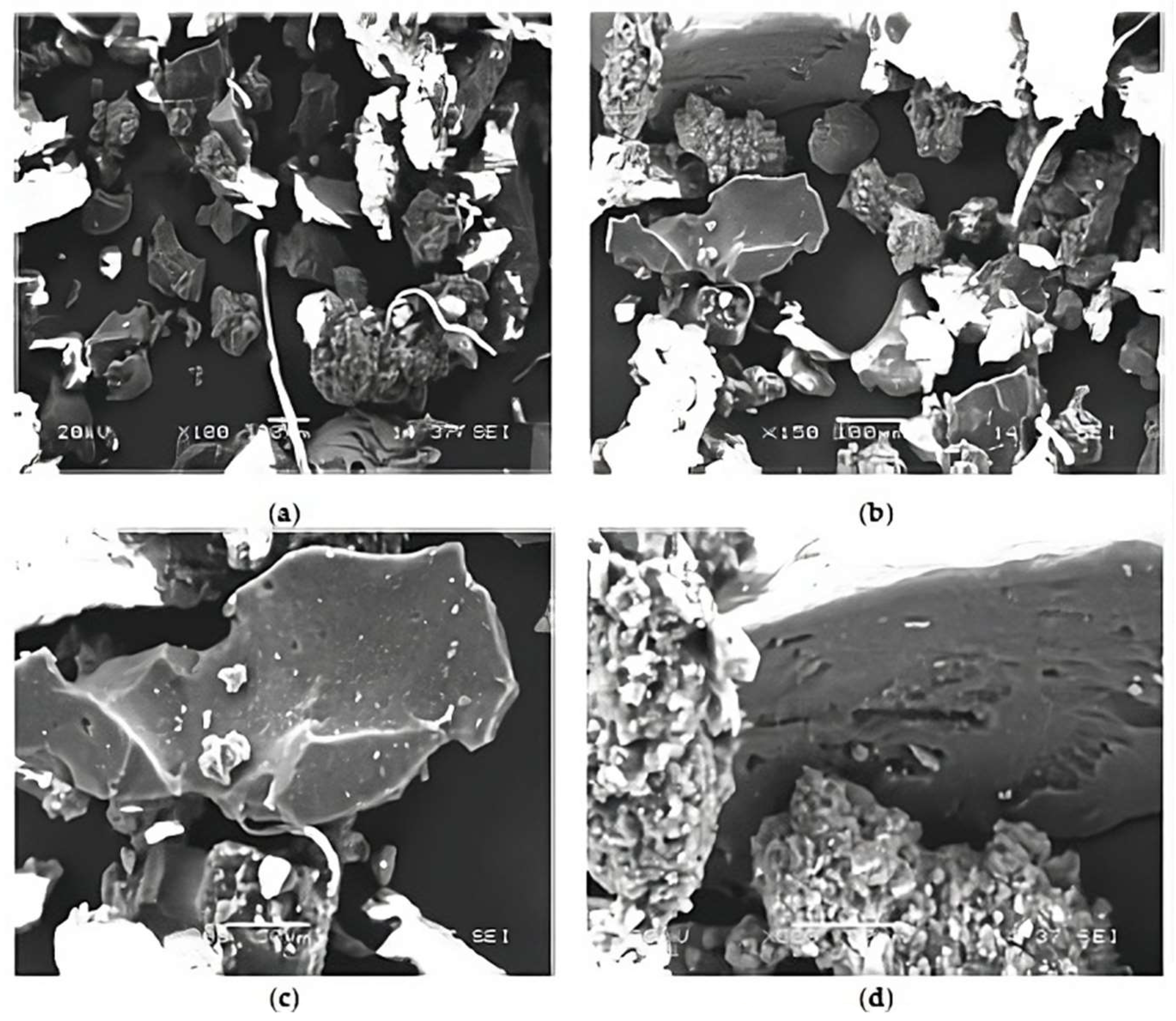

2.5. Morphology

3. The Effects of Crumb Rubbers on Asphalt

3.1. Physical Properties

| Reference | Bitumen | CR Size | CR (%) | Blending Method | Penetration | Softening Point | Ductility | Viscosity |

|---|---|---|---|---|---|---|---|---|

| Asgharzadeh et al. [64] | PG 64-22 | 50–100-mesh | 20 |

| ↓ | ↑ | - | ↑ |

| Li et al. [65] | 80/100 PEN | 40-mesh | 24, 28 and 32 |

| ↓ | - | - | ↑ |

| Bilema et al. [66] | 60/70 PEN | 20-mesh | 5 |

| ↓ | ↑ | ↓ | ↑ |

| Yu et al. [67] | 60/70 PEN | 40-mesh | 10 and 20 |

| ↓ | ↑ | - | ↑ |

| Geng et al. [68] | 70 SK base binder | 60-mesh | 20 |

| ↓ | ↑ | ↓ | ↑ |

| Poovaneshvaran et al. [2] | 60/70 PEN | 0.425–0.075 mm | 5, 10 and 15 |

| ↓ | ↑ | - | ↑ |

| Leng et al. [69] | 60/70 PEN | 40-mesh | 18 |

| ↓ | ↑ | - | ↑ |

| Yu et al. [70] | 60/70 PEN | - | - |

| ↓ | ↑ | - | ↑ |

| Yu et al. [71] | 60/70 PEN | 40-mesh | 18 |

| ↓ | ↑ | - | ↑ |

| Pouranian et al. [72] | PG 67-22 | 0.6 mm | 10, 15, 20 and 25 |

| ↓ | ↑ | - | ↑ |

| Zumrawi et al. [73] | 60/70 PEN | ˂4.75 | 5, 10, 15, 20 and 30 |

| ↓ | ↑ | ↓ | ↑ |

| Mashaan et al. [74] | 80/100 PEN | 30-mesh | 4, 8, 12, 16 and 20 |

| ↓ | ↑ | ↓ | ↑ |

| Kedarisetty et al. [75] | VG-30 and VG-40 | ˂0.6 mm | 5, 10, 15, 20 and 25 |

| ↓ | ↑ | - | ↑ |

| Kök et al. [76] | 160-220 PEN | - | 3, 6, 9, 12 and 15 |

| ↓ | ↑ | - | - |

| Wulandari and Tjandra [77] | 60/70 PEN | 40- and 80-mesh | 1 and 2 |

| ↓ | ↑ | ↓ | - |

| Xie et al. [78] | 70/90 PEN | 60–80-mesh | 10, 15 and 20 |

| - | ↑ | - | ↑ |

| Palit et al. [59] | 80/100 PEN | 0.6 mm | 5, 10 and 15 |

| ↓ | ↑ | ↓ | - |

3.2. Rheological Properties

3.3. Mechanical Performance

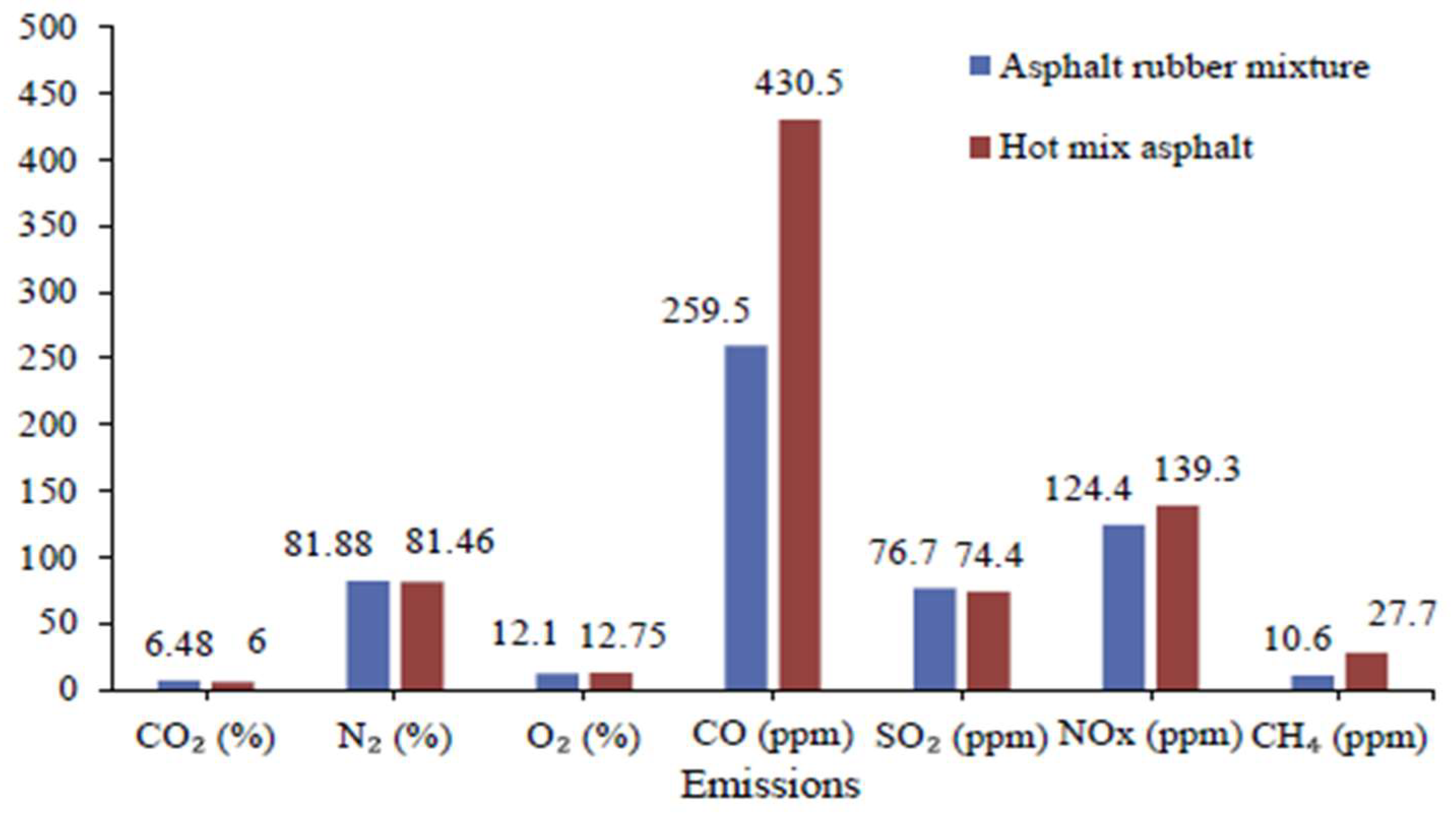

3.4. Emissions and Their Effects on Health

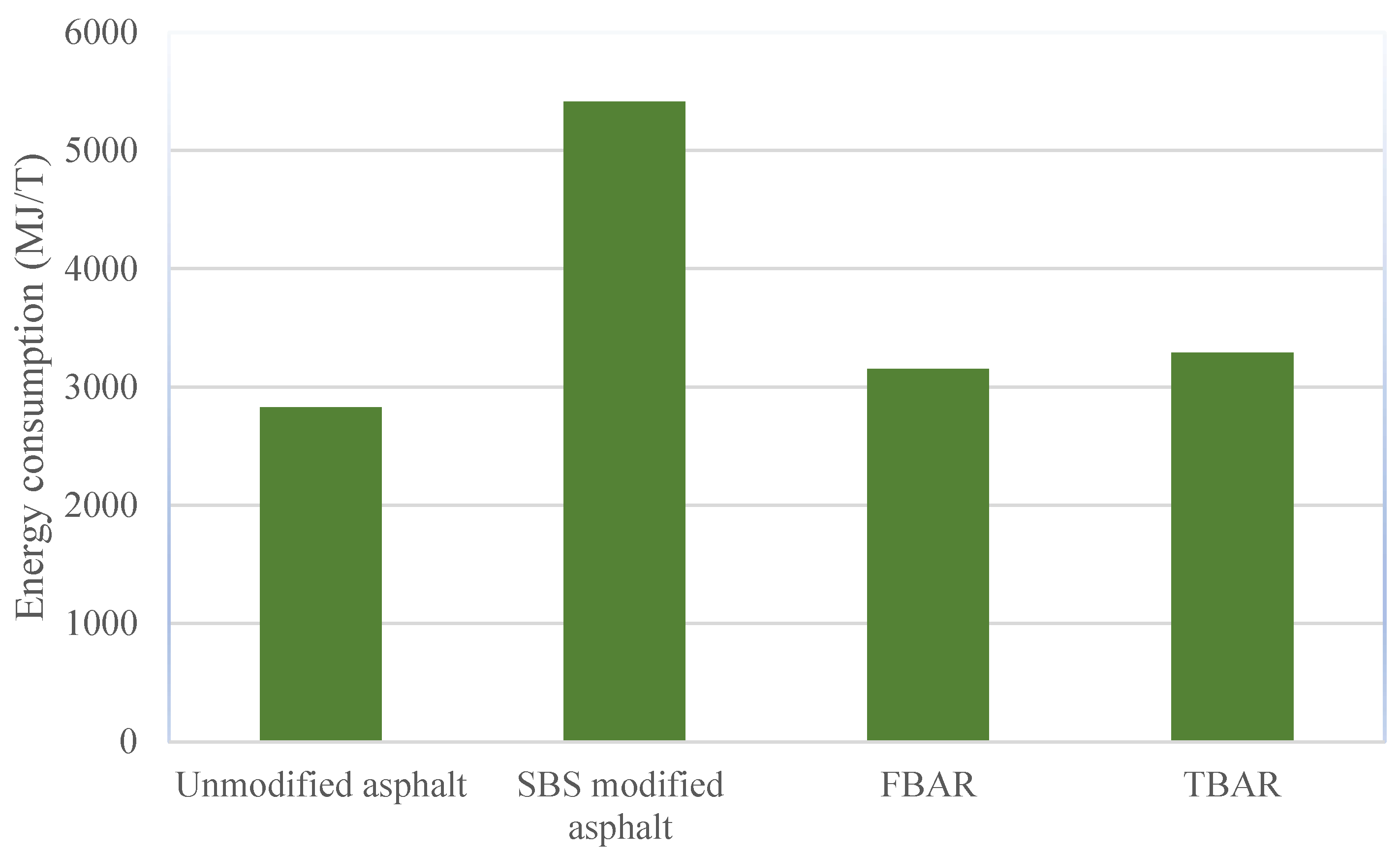

3.5. Energy Consumption

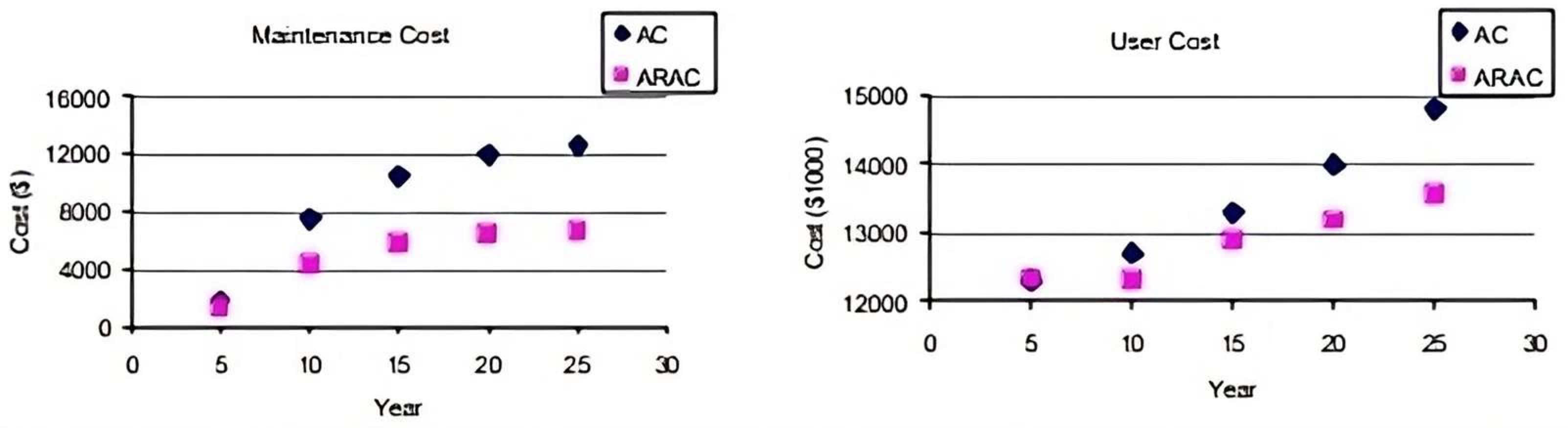

3.6. Life Cycle Costs

4. Conclusions and Future Research

4.1. Conclusions

- -

- CR is produced through ambient mechanical grinding or cryogenic grinding, where ambient mechanical grinding is more cost-effective and widely used.

- -

- The recommended CR content for the wet method is 10% of the binder weight without additives and up to 30% with additives. For the dry method, the recommended CR content is 1.5% of the mixture weight without additives and up to 3% with additives.

- -

- Adding CR may increase the optimal bitumen content slightly because the CR particles absorb some bitumen constituents.

- -

- Even though CR increases asphalt viscosity, it can be mitigated with additives, such as warm mix asphalt (WMA) additives or rejuvenators.

- -

- CR improves the physical properties of asphalt mixtures, for example, by reducing the penetration and viscosity values and increasing the softening values. It enhances the rheological properties by increasing stiffness and rutting resistance and reducing the phase angle.

- -

- Rubberised asphalt production emits similar levels of O2, N2, CO2, NOx and SO2 as unmodified asphalt but less CO and CH4. Rubberised asphalt ensures superior functional and structural performance during rehabilitation and less adverse environmental impacts.

- -

- Asphalt rubber has energy-saving benefits throughout its lifecycle through lower energy consumption during construction and maintenance.

- -

- Considering the costs for manufacturing materials, construction, maintenance and rehabilitation, CR asphalt pavement is more economical than traditional pavement.

4.2. Future Research

- Comprehensive investigations and quantitative analyses to determine the energy consumption patterns of asphalt rubber during construction, recycling and service life.

- An in-depth examination and quantitative evaluation of the costs associated with rubberised asphalt construction, service life and recycling.

- A quantitative appraisal of the environmental implications of recycling rubberised asphalt materials.

- Case studies and analyses to explore various asphalt mixtures, including rubberised asphalt containing SBS-modified components, WMA additives, rejuvenating agents and nano and waste constituents.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shafabakhsh, G.; Sadeghnejad, M.; Sajed, Y. Case study of rutting performance of HMA modified with waste rubber powder. Case Stud. Constr. Mater. 2014, 1, 69–76. [Google Scholar] [CrossRef]

- Poovaneshvaran, S.; Hasan, M.R.M.; Jaya, R.P. Impacts of recycled crumb rubber powder and natural rubber latex on the modified asphalt rheological behaviour, bonding, and resistance to shear. Constr. Build. Mater. 2020, 234, 117357. [Google Scholar] [CrossRef]

- Zafar, S. Production and Application of Crumb Rubber; Industrial Waste Management Recycling. EcoMena 2014, 2014. [Google Scholar]

- Mashaan, N.S.; Karim, M.R. Waste tyre rubber in asphalt pavement modification. Mater. Res. Innov. 2014, 18, S6-6–S6-9. [Google Scholar] [CrossRef]

- Mashaan, N.S.; Karim, M.R. Investigating the rheological properties of crumb rubber modified bitumen and its correlation with temperature susceptibility. Mater. Res. 2013, 16, 116–127. [Google Scholar] [CrossRef]

- Isayev, A.I. Recycling of Rubbers. In Science and Technology of Rubber; Academic Press: Cambridge, MA, USA, 2005; pp. 663–701. [Google Scholar] [CrossRef]

- Mashaan, N.S.; Ali, A.H.; Karim, M.R.; Abdelaziz, M. A Review on Using Crumb Rubber in Reinforcement of Asphalt Pavement. Sci. World J. 2014, 2014, 214612. [Google Scholar] [CrossRef]

- Bilema, M.A.; Aman, M.Y.; Hassan, N.A.; Al-Saffar, Z.; Rogo, K.; Abdullah, N.F.A. Influence of Crumb Rubber Incorporated with Different Warm Mix Asphalt Additives on the Mechanical Performance of WMA Mixture. J. Rehabil. Civ. Eng. 2021, 9, 1–11. [Google Scholar] [CrossRef]

- Xiao, Z.; Pramanik, A.; Basak, A.K.; Prakash, C.; Shankar, S. Material recovery and recycling of waste tyres-A review. Clean. Mater. 2022, 5, 100115. [Google Scholar] [CrossRef]

- Bilema, M.; Aman, M.Y.; Hassan, N.A.; Al-Saffar, Z.; Mashaan, N.S.; Memon, Z.A.; Yusoff, N.I.M. Effects of Waste Frying Oil and Crumb Rubber on the Characteristics of a Reclaimed Asphalt Pavement Binder. Materials 2021, 14, 3482. [Google Scholar] [CrossRef]

- Shatanawi, K.M.; Biro, S.; Geiger, A.; Amirkhanian, S.N. Effects of furfural activated crumb rubber on the properties of rubberized asphalt. Constr. Build. Mater. 2012, 28, 96–103. [Google Scholar] [CrossRef]

- Hoiberg, A. Bituminous Materials: Asphalts, Tars and Pitches; Interscience Publusher: New York, NY, USA, 1964. [Google Scholar]

- Jon, A. Epps, Uses of Recycled Rubber Tires in Highways; National Academy Press: Washington, DC, USA, 1994. [Google Scholar]

- Presti, D.L.; Memon, N.; Grenfell, J.; Airey, G. Alternative methodologies to evaluate storage stability of rubberised bitumens. In Proceedings of the International Conference on Asphalt Pavements, ISAP 2014, Raleigh, NC, USA, 1–5 June 2014; Volume 2, pp. 1481–1489. [Google Scholar] [CrossRef]

- Visser, A.T.; Verhaeghe, B. Bitumen–rubber: Lessons learned in South Africa. In Proceedings of the Asphalt Rubber 2000 Conference, Vilamoura, Portugal, 15–30 November 2000; pp. 33–52. [Google Scholar]

- Widyatmoko, I.; Elliot, R. A Review of the Use of Crumb Rubber Modified Asphalt Worldwide; Waste & Resources Action Programme (WRAP): Banbury, UK, 2007. [Google Scholar]

- Milad, A.; Ahmeda, A.G.F.; Taib, A.M.; Rahmad, S.; Solla, M.; Yusoff, N.I.M. A review of the feasibility of using crumb rubber derived from end-of-life tire as asphalt binder modifier. J. Rubber Res. 2020, 23, 203–216. [Google Scholar] [CrossRef]

- Lo Presti, D. Recycled Tyre Rubber Modified Bitumens for road asphalt mixtures: A literature review. Constr. Build. Mater. 2013, 49, 863–881. [Google Scholar] [CrossRef]

- Othman, Z.; Hainin, M.R.; Warid, M.N.M.; Idham, M.K.; Kamarudin, S.N.N. Cup lump modified asphalt mixture along jalan Kuala Lumpur-Kuantan, daerah Temerloh, Pahang. MATEC Web Conf. 2018, 250, 02007. [Google Scholar] [CrossRef]

- Azahar, N.F.B.M.; Hassan, N.A.; Jaya, R.P.; Kadir, M.A.B.A.; Yunus, N.Z.B.M.; Mahmud, M.Z.H. An overview on natural rubber application for asphalt modification. Int. J. Agric. For. Plant. 2016, 2, 212–218. [Google Scholar]

- ELDAN Recycling. Tyre Recycling. Available online: https://eldan-recycling.com/tyre-recycling/ (accessed on 8 March 2023).

- U.S. Tire Manufacturers Association. What’s In a Tire. Available online: https://www.ustires.org/whats-tire-0 (accessed on 8 March 2023).

- Hosseinnezhad, S.; Bocoum, A.; Martinez, F.M.; Fini, E.H. Biomodification of Rubberized Asphalt and Its High Temperature Properties. Transp. Res. Rec. 2015, 2506, 81–89. [Google Scholar] [CrossRef]

- Xiao, F.; Putman, B.J.; Amirkhanian, S.N. Laboratory investigation of dimensional changes of crumb rubber reacting with asphalt binder. Road Mater. Pavement Des. 2006, 82, 71. [Google Scholar]

- Li, B.; Huang, W.; Tang, N.; Hu, J.; Lin, P.; Guan, W.; Xiao, F.; Shan, Z. Evolution of components distribution and its effect on low temperature properties of terminal blend rubberized asphalt binder. Constr. Build. Mater. 2017, 136, 598–608. [Google Scholar] [CrossRef]

- Wang, G.; Wang, X.; Lv, S.; Qin, L.; Peng, X. Laboratory Investigation of Rubberized Asphalt Using High-Content Rubber Powder. Materials 2020, 13, 4437. [Google Scholar] [CrossRef]

- Turbay, E.; Martinez-Arguelles, G.; Navarro-Donado, T.; Sánchez-Cotte, E.; Polo-Mendoza, R.; Covilla-Valera, E. Rheological Behaviour of WMA-Modified Asphalt Binders with Crumb Rubber. Polymers 2022, 14, 4148. [Google Scholar] [CrossRef]

- Thodesen, C.; Shatanawi, K.; Amirkhanian, S. Effect of crumb rubber characteristics on crumb rubber modified (CRM) binder viscosity. Constr. Build. Mater. 2009, 23, 295–303. [Google Scholar] [CrossRef]

- Siddique, R.; Naik, T.R. Properties of concrete containing scrap-tire rubber—An overview. Waste Manag. 2004, 24, 563–569. [Google Scholar] [CrossRef] [PubMed]

- Han, L.; Zheng, M.; Wang, C. Current status and development of terminal blend tyre rubber modified asphalt. Constr. Build. Mater. 2016, 128, 399–409. [Google Scholar] [CrossRef]

- Cetin, A. Effects of Crumb Rubber Size and Concentration on Performance of Porous Asphalt Mixtures. Int. J. Polym. Sci. 2013, 2013, 789612. [Google Scholar] [CrossRef]

- Cao, W.D.; Liu, S.T.; Cui, X.Z.; Yu, X.Q. Effect of Crumb Rubber Particle Size and Content on Properties of Crumb Rubber Modified (CRM) Asphalt. Appl. Mech. Mater. 2011, 99, 955–959. [Google Scholar] [CrossRef]

- Wong, C.C.; Wong, W.-G. Effect of crumb rubber modifiers on high temperature susceptibility of wearing course mixtures. Constr. Build. Mater. 2007, 21, 1741–1745. [Google Scholar] [CrossRef]

- Bilema, M.; Aman, M.; Hassan, N.; Haloul, M.; Modibbo, S. Influence of crumb rubber size particles on moisture damage and strength of the hot mix asphalt. Mater. Today Proc. 2021, 42, 2387–2391. [Google Scholar] [CrossRef]

- Xiao, F.; Amirkhanian, S.; Juang, C.H. Rutting Resistance of Rubberized Asphalt Concrete Pavements Containing Reclaimed Asphalt Pavement Mixtures. J. Mater. Civ. Eng. 2007, 19, 475–483. [Google Scholar] [CrossRef]

- Ziari, H.; Goli, A.; Amini, A. Effect of Crumb Rubber Modifier on the Performance Properties of Rubberized Binders. J. Mater. Civ. Eng. 2016, 28, 04016156. [Google Scholar] [CrossRef]

- Liu, S.; Cao, W.; Fang, J.; Shang, S. Variance analysis and performance evaluation of different crumb rubber modified (CRM) asphalt. Constr. Build. Mater. 2009, 23, 2701–2708. [Google Scholar] [CrossRef]

- Ajmera, B.; Tiwari, B.; Koirala, J.; Obaid, Z. Compaction Characteristics, Unconfined Compressive Strengths, and Coefficients of Permeability of Fine-Grained Soils Mixed with Crumb-Rubber Tire. J. Mater. Civ. Eng. 2017, 29, 04017148. [Google Scholar] [CrossRef]

- Huang, W.; Lin, P.; Tang, N.; Hu, J.; Xiao, F. Effect of crumb rubber degradation on components distribution and rheological properties of Terminal Blend rubberized asphalt binder. Constr. Build. Mater. 2017, 151, 897–906. [Google Scholar] [CrossRef]

- Mashaan, N.S.; Ali, A.H.; Karim, M.R.; Abdelaziz, M. Effect of blending time and crumb rubber content on properties of crumb rubber modified asphalt binder. Int. J. Phys. Sci. 2011, 6, 2189–2193. [Google Scholar] [CrossRef]

- Moreno, F.; Sol, M.; Martín, J.; Pérez, M.; Rubio, M. The effect of crumb rubber modifier on the resistance of asphalt mixes to plastic deformation. Mater. Des. 2013, 47, 274–280. [Google Scholar] [CrossRef]

- Losa, M.; Leandri, P.; Cerchiai, M. Improvement of pavement sustainability by the use of crumb rubber modified asphalt concrete for wearing courses. Int. J. Pavement Res. Technol. 2012, 5. [Google Scholar] [CrossRef]

- Dong, F.; Zhao, W.; Zhang, Y.; Wei, J.; Fan, W.; Yu, Y.; Wang, Z. Influence of SBS and asphalt on SBS dispersion and the performance of modified asphalt. Constr. Build. Mater. 2014, 62, 1–7. [Google Scholar] [CrossRef]

- Lee, S.-J.; Akisetty, C.K.; Amirkhanian, S.N. The effect of crumb rubber modifier (CRM) on the performance properties of rubberized binders in HMA pavements. Constr. Build. Mater. 2008, 22, 1368–1376. [Google Scholar] [CrossRef]

- Liu, H.; Luo, G.; Wang, X.; Jiao, Y. Effects of preparation process on performance of rubber modified asphalt. IOP Conf. Ser. Mater. Sci. Eng. 2015, 87, 012008. [Google Scholar] [CrossRef]

- Bakar, S.K.A.; Abdullah, M.E.; Kamal, M.M.; Abd Rahman, R.; Buhari, R.; Jaya, R.P.; Ahmad, K.A. The effect of crumb rubber on the physical and rheological properties of modified binder. J. Phys. Conf. Ser. 2018, 1049, 012099. [Google Scholar] [CrossRef]

- Shu, X.; Huang, B. Recycling of waste tire rubber in asphalt and portland cement concrete: An overview. Constr. Build. Mater. 2014, 67, 217–224. [Google Scholar] [CrossRef]

- Jeong, K.-D.; Lee, S.-J.; Amirkhanian, S.N.; Kim, K.W. Interaction effects of crumb rubber modified asphalt binders. Constr. Build. Mater. 2010, 24, 824–831. [Google Scholar] [CrossRef]

- Bilema, M.; Aman, M.Y.; Hassan, N.A.; Memon, Z.A.; Omar, H.A.; Yusoff, N.I.M.; Milad, A. Mechanical Performance of Reclaimed Asphalt Pavement Modified with Waste Frying Oil and Crumb Rubber. Materials 2021, 14, 2781. [Google Scholar] [CrossRef] [PubMed]

- Cao, W. Study on properties of recycled tire rubber modified asphalt mixtures using dry process. Constr. Build. Mater. 2007, 21, 1011–1015. [Google Scholar] [CrossRef]

- Akisetty, C.K.; Lee, S.-J.; Amirkhanian, S.N. Laboratory investigation of the influence of warm asphalt additives on long-term performance properties of CRM binders. Int. J. Pavement Eng. 2010, 11, 153–160. [Google Scholar] [CrossRef]

- Khiong, L.M.; Safiuddin; Mannan, M. A. Resdiansyah Material Properties and Environmental Benefits of Hot-Mix Asphalt Mixes Including Local Crumb Rubber Obtained from Scrap Tires. Environments 2021, 8, 47. [Google Scholar] [CrossRef]

- Farouk, A.I.B.; Hassan, N.A.; Mahmud, M.Z.H.; Mirza, J.; Jaya, R.P.; Hainin, M.R.; Yaacob, H.; Yusoff, N.I.M. Effects of mixture design variables on rubber–bitumen interaction: Properties of dry mixed rubberized asphalt mixture. Mater Struct. 2017, 50, 12. [Google Scholar] [CrossRef]

- Bilema, M.A.; Aman, M.Y.; Hassan, N.A.; Ahmad, K.A.; Elghatas, H.M.; Radwan, A.A.; Shyaa, A.S. Moisture Sensitivity of Crumb Rubber Modified Modifier Warm Mix Asphalt Additive for Two Different Compaction Temperatures. IOP Conf. Ser. Earth Environ. Sci. 2018, 140, 012072. [Google Scholar] [CrossRef]

- Wang, X.; Liu, J.; Wang, Z.; Jing, H.; Yang, B. Investigations on Adhesion Characteristics between High-Content Rubberized Asphalt and Aggregates. Polymers 2022, 14, 5474. [Google Scholar] [CrossRef]

- Xu, M.; Liu, J.; Li, W.; Duan, W. Novel Method to Prepare Activated Crumb Rubber Used for Synthesis of Activated Crumb Rubber Modified Asphalt. J. Mater. Civ. Eng. 2014, 27, 04014173. [Google Scholar] [CrossRef]

- Cong, P.; Xun, P.; Xing, M.; Chen, S. Investigation of asphalt binder containing various crumb rubbers and asphalts. Constr. Build. Mater. 2013, 40, 632–641. [Google Scholar] [CrossRef]

- Zhang, F.; Hu, C. The research for crumb rubber/waste plastic compound modified asphalt. J. Therm. Anal. Calorim. 2016, 124, 729–741. [Google Scholar] [CrossRef]

- Palit, S.K.; Reddy, K.S.; Pandey, B.B. Laboratory Evaluation of Crumb Rubber Modified Asphalt Mixes. J. Mater. Civ. Eng. 2004, 16, 45–53. [Google Scholar] [CrossRef]

- López-Moro, F.J.; Moro, M.C.; Hernández-Olivares, F.; Witoszek-Schultz, B.; Alonso-Fernández, M. Microscopic analysis of the interaction between crumb rubber and bitumen in asphalt mixtures using the dry process. Constr. Build. Mater. 2013, 48, 691–699. [Google Scholar] [CrossRef]

- Zhao, Z.; Wang, L.; Wang, W.; Shangguan, X. Experimental Investigation of the High-Temperature Rheological and Aging Resistance Properties of Activated Crumb Rubber Powder/SBS Composite-Modified Asphalt. Polymers 2022, 14, 1905. [Google Scholar] [CrossRef] [PubMed]

- Gaweł, I.; Piłat, J.; Radziszewski, P.; Kowalski, K.J.; Król, J.B. Rubber modified bitumen. In Polymer Modified Bitumen; Woodhead Publishing: Sawston, UK, 2011. [Google Scholar] [CrossRef]

- Dong, D.; Huang, X.; Li, X.; Zhang, L. Swelling process of rubber in asphalt and its effect on the structure and properties of rubber and asphalt. Constr. Build. Mater. 2012, 29, 316–322. [Google Scholar] [CrossRef]

- Asgharzadeh, S.M.; Sadeghi, J.; Peivast, P.; Pedram, M. Fatigue properties of crumb rubber asphalt mixtures used in railways. Constr. Build. Mater. 2018, 184, 248–257. [Google Scholar] [CrossRef]

- Li, W.; Han, S.; Fu, X.; Huang, K. Evaluation of Micro-Mechanism and High- and Low-Temperature Rheological Properties of Disintegrated High Volume Crumb Rubber Asphalt (DHVRA). Materials 2021, 14, 1145. [Google Scholar] [CrossRef] [PubMed]

- Bilema, M.; Yuen, C.W.; Alharthai, M.; Al-Saffar, Z.H.; Aletba, S.R.O.; Yusoff, N.I.M. Influence of Warm Mix Asphalt Additives on the Physical Characteristics of Crumb Rubber Asphalt Binders. Appl. Sci. 2023, 13, 10337. [Google Scholar] [CrossRef]

- Yu, J.; Ren, Z.; Yu, H.; Wang, D.; Svetlana, S.; Korolev, E.; Gao, Z.; Guo, F. Modification of Asphalt Rubber with Nanoclay towards Enhanced Storage Stability. Materials 2018, 11, 2093. [Google Scholar] [CrossRef]

- Geng, J.G.; Zheng, M.N.; Jin, M.Q. Feasibility of Recycling Technology of Crumb Rubber Modified Asphalt. Adv. Mater. Res. 2015, 1073, 960–964. [Google Scholar] [CrossRef]

- Leng, Z.; Yu, H.; Zhang, Z.; Tan, Z. Optimizing the mixing procedure of warm asphalt rubber with wax-based additives through mechanism investigation and performance characterization. Constr. Build. Mater. 2017, 144, 291–299. [Google Scholar] [CrossRef]

- Yu, H.; Leng, Z.; Dong, Z.; Tan, Z.; Guo, F.; Yan, J. Workability and mechanical property characterization of asphalt rubber mixtures modified with various warm mix asphalt additives. Constr. Build. Mater. 2018, 175, 392–401. [Google Scholar] [CrossRef]

- Yu, J.; Ren, Z.; Gao, Z.; Wu, Q.; Zhu, Z.; Yu, H. Recycled Heavy Bio Oil as Performance Enhancer for Rubberized Bituminous Binders. Polymers 2019, 11, 800. [Google Scholar] [CrossRef] [PubMed]

- Pouranian, M.R.; Notani, M.A.; Tabesh, M.T.; Nazeri, B.; Shishehbor, M. Rheological and environmental characteristics of crumb rubber asphalt binders containing non-foaming warm mix asphalt additives. Constr. Build. Mater. 2020, 238, 117707. [Google Scholar] [CrossRef]

- Zumrawi, M.M.E. Effect of Crumb Rubber Modifiers (CRM) on Characteristics of Asphalt Binders in Sudan. Int. J. Mater. Sci. Appl. 2017, 6, 1–6. [Google Scholar] [CrossRef]

- Mashaan, N.S.; Ali, A.H.; Karim, M.R.; Abdelaziz, M. Effect of crumb rubber concentration on the physical and rheological properties of rubberised bitumen binders. Int. J. Phys. Sci. 2011, 6, 684–690. [Google Scholar]

- Kedarisetty, S.; Biligiri, K.P.; Sousa, J.B. Advanced rheological characterization of Reacted and Activated Rubber (RAR) modified asphalt binders. Constr. Build. Mater. 2016, 122, 12–22. [Google Scholar] [CrossRef]

- Kök, B.V.; Çolak, H. Laboratory comparison of the crumb-rubber and SBS modified bitumen and hot mix asphalt. Constr. Build. Mater. 2011, 25, 3204–3212. [Google Scholar] [CrossRef]

- Wulandari, P.S.; Tjandra, D. Use of Crumb Rubber as an Additive in Asphalt Concrete Mixture. Procedia Eng. 2017, 171, 1384–1389. [Google Scholar] [CrossRef]

- Xie, J.; Yang, Y.; Lv, S.; Peng, X.; Zhang, Y. Investigation on Preparation Process and Storage Stability of Modified Asphalt Binder by Grafting Activated Crumb Rubber. Materials 2019, 12, 2014. [Google Scholar] [CrossRef]

- Li, Y.; Abdelmagid, A.A.A.; Qiu, Y.; Yang, E.; Chen, Y. Study on the Aging Mechanism and Microstructure Analysis of Rice-Husk-Ash- and Crumb-Rubber-Powder-Modified Asphalt. Polymers 2022, 14, 1969. [Google Scholar] [CrossRef]

- Gong, Y.; Wu, S.; Zhang, Y.; Pang, Y.; Ma, Y. Investigation of the High-Temperature and Rheological Properties for Asphalt Sealant Modified by SBS and Rubber Crumb. Polymers 2022, 14, 2558. [Google Scholar] [CrossRef] [PubMed]

- Sol-Sánchez, M.; Carrión, A.J.d.B.; Hidalgo-Arroyo, A.; Moreno-Navarro, F.; Saiz, L.; Rubio-Gámez, M.d.C. Viability of producing sustainable asphalt mixtures with crumb rubber bitumen at reduced temperatures. Constr. Build. Mater. 2020, 265, 120154. [Google Scholar] [CrossRef]

- Wang, H.; Dang, Z.; You, Z.; Cao, D. Effect of warm mixture asphalt (WMA) additives on high failure temperature properties for crumb rubber modified (CRM) binders. Constr. Build. Mater. 2012, 35, 281–288. [Google Scholar] [CrossRef]

- Shen, J.; Amirkhanian, S.; Xiao, F.; Tang, B. Influence of surface area and size of crumb rubber on high temperature properties of crumb rubber modified binders. Constr. Build. Mater. 2009, 23, 304–310. [Google Scholar] [CrossRef]

- Bilema, M.A.M.; Aman, M.Y.; Ahmad, K.A. Investigating the Rheological and Physical Properties for Unaged of Crumb Rubber-Modified Binders Containing Warm Mix Asphalt Additive. In GCEC 2017: Proceedings of the 1st Global Civil Engineering Conference, Kuala Lumpur, Malaysia, 25–28 July 2017; Springer: Singapore, 2019; Volume 9, pp. 1389–1400. [Google Scholar] [CrossRef]

- Yu, J.; Yu, X.; Gao, Z.; Guo, F.; Wang, D.; Yu, H. Fatigue Resistance Characterization of Warm Asphalt Rubber by Multiple Approaches. Appl. Sci. 2018, 8, 1495. [Google Scholar] [CrossRef]

- Xiaoming, H.; Eldouma, I.B. Experimental Study to Determine the Most Preferred Additive for Improving Asphalt Performance Using Polypropylene, Crumb Rubber, and Tafpack Super in Medium and High-Temperature Range. Appl. Sci. 2019, 9, 1567. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, Z.; Peng, J. Silane Modification of Crumb Rubber on the Rheological Properties of Rubberized Asphalt. Appl. Sci. 2019, 9, 4831. [Google Scholar] [CrossRef]

- Zong, Y.; Xiong, R.; Tian, Y.; Chang, M.; Wang, X.; Yu, J.; Zhang, Y.; Feng, B.; Wang, H.; Li, C. Preparation and Temperature Susceptibility Evaluation of Crumb Rubber Modified Asphalt Applied in Alpine Regions. Coatings 2022, 12, 496. [Google Scholar] [CrossRef]

- Khan, M.I.; Sutanto, M.H.; Sunarjono, S.; Room, S.; Yusoff, N.I.M. Effect of Crumb Rubber, Epolene (EE-2), and Date Palm Ash as Modifiers on the Performance of Binders and Mixtures: A Sustainable Approach. Sustainability 2019, 11, 6484. [Google Scholar] [CrossRef]

- Khan, I.M.; Kabir, S.; Alhussain, M.A.; Almansoor, F.F. Asphalt Design Using Recycled Plastic and Crumb-rubber Waste for Sustainable Pavement Construction. Procedia Eng. 2016, 145, 1557–1564. [Google Scholar] [CrossRef]

- Yun, J.; Hemmati, N.; Lee, M.-S.; Lee, S.-J. Laboratory Evaluation of Storage Stability for CRM Asphalt Binders. Sustainability 2022, 14, 7542. [Google Scholar] [CrossRef]

- Hassan, N.A.; Hainin, M.R.; Yaacob, H.; Ismail, C.R.; Yunus, N.Z.M. Evaluation on Mix Design and Rutting Resistance of Dry Mixed Rubberised Asphalt Mixtures. J. Teknol. 2013, 65, 115–120. [Google Scholar] [CrossRef]

- Gardziejczyk, W.; Plewa, A.; Pakholak, R. Effect of Addition of Rubber Granulate and Type of Modified Binder on the Viscoelastic Properties of Stone Mastic Asphalt Reducing Tire/Road Noise (SMA LA). Materials 2020, 13, 3446. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, H.T.; Tran, T.N. Effects of crumb rubber content and curing time on the properties of asphalt concrete and stone mastic asphalt using dry process. Int. J. Pavement Res. Technol. 2018, 11, 236–244. [Google Scholar] [CrossRef]

- Rodríguez-Fernández, I.; Baheri, F.T.; Cavalli, M.C.; Poulikakos, L.D.; Bueno, M. Microstructure analysis and mechanical performance of crumb rubber modified asphalt concrete using the dry process. Constr. Build. Mater. 2020, 259, 119662. [Google Scholar] [CrossRef]

- Dias, J.F.; Picado-Santos, L.; Capitão, S. Mechanical performance of dry process fine crumb rubber asphalt mixtures placed on the Portuguese road network. Constr. Build. Mater. 2014, 73, 247–254. [Google Scholar] [CrossRef]

- Rodríguez-Fernández, I.; Cavalli, M.C.; Poulikakos, L.; Bueno, M. Recyclability of Asphalt Mixtures with Crumb Rubber Incorporated by Dry Process: A Laboratory Investigation. Materials 2020, 13, 2870. [Google Scholar] [CrossRef]

- Kamarudin, S.N.N.; Hainin, M.R.; Warid, M.N.M.; Satar, M.K.I.M.; A Hassan, N. Performance of Asphalt Mixture Incorporating Activated Crumb Rubber as Additive. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1144, 012081. [Google Scholar] [CrossRef]

- Fontes, L.P.; Trichês, G.; Pais, J.C.; Pereira, P.A. Evaluating permanent deformation in asphalt rubber mixtures. Constr. Build. Mater. 2010, 24, 1193–1200. [Google Scholar] [CrossRef]

- Kucukvar, M.; Tatari, O. Ecologically based hybrid life cycle analysis of continuously reinforced concrete and hot-mix asphalt pavements. Transp. Res. Part D Transp. Environ. 2012, 17, 86–90. [Google Scholar] [CrossRef]

- Thives, L.P.; Ghisi, E. Asphalt mixtures emission and energy consumption: A review. Renew. Sustain. Energy Rev. 2017, 72, 473–484. [Google Scholar] [CrossRef]

- Yang, X.; You, Z.; Perram, D.; Hand, D.; Ahmed, Z.; Wei, W.; Luo, S. Emission analysis of recycled tire rubber modified asphalt in hot and warm mix conditions. J. Hazard. Mater. 2019, 365, 942–951. [Google Scholar] [CrossRef] [PubMed]

- Khattak, S.; Syme, B. City of Colorado Springs Tests Terminal Blend Tire Rubber Asphalt. APWA Rep. 2009, 76, 66–69. [Google Scholar]

- Burr, G.; Tepper, A.; Feng, A.; Olsen, L.; Miller, A. Crumb-Rubber Modified Asphalt Paving: Occupational Exposures and Acute Health Effects; National Institute for Occupational Safety and Health (NIOSH): Cincinnati, OH, USA, 2001. [Google Scholar]

- Caltrans. CIWMB Partnered Research. In Asphalt Rubber Usage Guide; State of California Department of Transportation: Sacramento, CA, USA, 2006. [Google Scholar]

- Zanetti, M.C.; Fiore, S.; Ruffino, B.; Santagata, E.; Lanotte, M. Assessment of gaseous emissions produced on site by bituminous mixtures containing crumb rubber. Constr. Build. Mater. 2014, 67, 291–296. [Google Scholar] [CrossRef]

- Sousa, J.; Way, G.B.; Carlson, D. Energy and CO2 savings using asphalt rubber mixes. 2007. Available online: https://www.rubberpavements.org/Library_Information/SpecificationsHandbook/Section_02_Overview_of_AR_Technology/2F_Energy_and_CO2_Savings_with_AR.pdf (accessed on 8 March 2023).

- Carlson, D. Stack Emissions with Asphalt Rubber. 2003. Available online: https://www.semanticscholar.org/paper/Stack-Emissions-With-Asphalt-Rubber-Carlson/e804b56251f9b601a7aecdd28edfe0cc6453e5fa (accessed on 8 March 2023).

- Wang, T.; Xiao, F.; Amirkhanian, S.; Huang, W.; Zheng, M. A review on low temperature performances of rubberized asphalt materials. Constr. Build. Mater. 2017, 145, 483–505. [Google Scholar] [CrossRef]

- Stout, D.; Carlson, D.D. Stack Emissions with Asphalt Rubber A Synthesis of Studies. In Proceedings of the Asphalt Rubber Conference, Brasilia, Brazil, 2–4 December 2003. [Google Scholar]

- Jones, D.; Wu, R.; Barros, C.; Peterson, J. Research findings on the use of Rubberized Warm-Mix Asphalt in California. Mater. Sci. 2012. Available online: http://www.ra-foundation.org/wp-content/uploads/2013/02/040-PAP_060.pdf (accessed on 8 March 2023).

- Cheng, D.; Hicks, R.G.; Teesdale, T. Assessment of Warm Mix Technologies for Use with Asphalt Rubber Paving Applications. Mater. Sci. 2011. Available online: https://trid.trb.org/view/1093133 (accessed on 8 March 2023).

- Farina, A.; Zanetti, M.C.; Santagata, E.; Blengini, G.A. Life cycle assessment applied to bituminous mixtures containing recycled materials: Crumb rubber and reclaimed asphalt pavement. Resour. Conserv. Recycl. 2017, 117, 204–212. [Google Scholar] [CrossRef]

- Antunes, I.; Murachelli, A. Analysis of environmental sustainability in the rehabilitation of existing pavements using Asphalt Rubber hot mixes. In Proceedings of the Asphalt Rubber 2009 Conference, Nanjing, China, 2–4 November 2009; pp. 2–4. [Google Scholar]

- Bartolozzi, I.; Antunes, I.; Rizzi, F. The environmental impact assessment of Asphalt Rubber: Life Cycle Assessment. In Proceedings of the 5th Asphalt Rubber” Roads of the Future” International Conference, Munich, Germany, 23–26 October 2012; pp. 23–26. [Google Scholar]

- Zhu, H.; Cai, H.; Yan, J.; Lu, Y. Life cycle assessment on different types of asphalt rubber pavement in China. In Proceedings of the International Symposium on Pavement LCA, Davis, CA, USA, 14–16 October 2014. [Google Scholar]

- Wang, T.; Xiao, F.; Zhu, X.; Huang, B.; Wang, J.; Amirkhanian, S. Energy consumption and environmental impact of rubberized asphalt pavement. J. Clean. Prod. 2018, 180, 139–158. [Google Scholar] [CrossRef]

- Butt, A.A. Life Cycle Assessment of Asphalt Pavements including the Feedstock Energy and Asphalt Additives. Doctoral Dissertation, KTH Royal Institute of Technology, Stockholm, Sweden, 2012. [Google Scholar]

- Mitchell, M.R.; Link, R.E.; Xiao, F.; Amirkhanian, S.N.; Shen, J. Effects of Various Long-Term Aging Procedures on the Rheological Properties of Laboratory Prepared Rubberized Asphalt Binders. J. Test. Eval. 2009, 37, 329–336. [Google Scholar] [CrossRef]

- Behl, A.; Kumar, G.; Sharma, G. Performance of Low Energy Crumb Rubber Modified Bituminous Mixes. Procedia Soc. Behav. Sci. 2013, 104, 49–58. [Google Scholar] [CrossRef]

- Rodríguez-Alloza, A.M.; Malik, A.; Lenzen, M.; Gallego, J. Hybrid input–output life cycle assessment of warm mix asphalt mixtures. J. Clean. Prod. 2015, 90, 171–182. [Google Scholar] [CrossRef]

- Praticò, F.G.; Perri, G.; De Rose, M.; Vaiana, R. Comparing bio-binders, rubberised asphalts, and traditional pavement technologies. Constr. Build. Mater. 2023, 400, 132813. [Google Scholar] [CrossRef]

- Dias, J. Misturas Betuminosas Incorporando por via seca Borracha de Pneus Usados: Caracterização e Validação Tecnológica. Doctoral Dissertation, Universidade de Coimbra, Coimbra, Portugal, 2011. [Google Scholar]

- Hicks, R.; Epps, J.A. Life cycle cost analysis of asphalt-rubber paving materials. In World of Asphalt Pavements, International Conference, 1st ed.; Australian Asphalt Pavement Association: Sydney, NSW, Australia, 2000. [Google Scholar]

- Volle, T.H. Performance of Rubberized Asphalt Pavements in ILLINOIS; Illinois Department of Transportation: Springfield, IL, USA, 2000. [Google Scholar]

- Buttlar, W.G.; Meister, J.F.; Jahangiri, B.; Majidifard, H. Performance Characteristics of Modern Recycled Asphalt Mixes in Missouri, Including Ground Tire Rubber, Recycled Roofing Shingles, and Rejuvenators; United States Department of Transportation: Washington, DC, USA, 2019. [Google Scholar] [CrossRef]

- Harvey, J.; Bejarano, M.; Fantoni, A. Performance of Caltrans Asphalt Concrete and Asphalt-Rubber Hot Mix Overlays at Moderate Temperatures–Accelerated Pavement Testing Evaluation; California Department of Transportation: Sacramento, CA, USA, 2000. [Google Scholar]

- Howard, I.L.; Baumgardner, G.L.; Jordan, W.S.; Hemsley, J.M.; Hopkins, C. Comparing Ground Tire Rubber, Styrene-Butadyene-Styrene, and GTR-SBS Hybrids as Asphalt Binder Modifiers. J. Mater. Civ. Eng. 2021, 33, 04021091. [Google Scholar] [CrossRef]

- Buttlar, W.G.; Rath, P. State of Knowledge Report on Rubber Modified Asphalt; University of Missouri-Columbia: Columbia, MO, USA, 2021. [Google Scholar]

- Jung, J.-S.; Kamil, K.; Way, G. Life Cycle Cost Analysis: Conventional versus Asphalt-Rubber Pavements; Rubber Pavements Association: Phoenix, AZ, USA, 2002. [Google Scholar]

- Cheng, D.; Hicks, R.G. Life-Cycle Cost Analysis Comparison of Rubberized and Conventional Hot-Mix Asphalt in California. In Proceedings of the Transportation Research Board 91st Annual Meeting, Washington, DC, USA, 22–26 January 2012. [Google Scholar]

- Riekstins, A.; Haritonovs, V.; Straupe, V. Economic and environmental analysis of crumb rubber modified asphalt. Constr. Build. Mater. 2022, 335, 127468. [Google Scholar] [CrossRef]

- Gamboa, C.J.O.; Ruiz, P.A.C.; Kaloush, K.E.; Linares, J.P.L. Life cycle assessment including traffic noise: Conventional vs. rubberized asphalt. Int. J. Life Cycle Assess. 2021, 26, 2375–2390. [Google Scholar] [CrossRef]

- Wang, Q.-Z.; Chen, Z.-D.; Lin, K.-P.; Wang, C.-H. Estimation and Analysis of Energy Conservation and Emissions Reduction Effects of Warm-Mix Crumb Rubber-Modified Asphalts during Construction Period. Sustainability 2018, 10, 4521. [Google Scholar] [CrossRef]

| Property | Cryogenic 1 | Cryogenic 2 | Ambient 1 | Ambient 2 |

|---|---|---|---|---|

| Specific gravity (wt%) | 1.04 | 1.04 | 1.05 | 1.06 |

| Moisture content (wt%) | 0.76 | 0.67 | 0.77 | 0.67 |

| Ash content (wt%) | 6.01 | 5.36 | 4.66 | 5.61 |

| Carbon black content (wt%) | 32.98 | 29.75 | 30.41 | 32.74 |

| Sulfur content (wt%) | 9.86 | 11.80 | 11.69 | 8.52 |

| Acetone and chloroform content (wt%) | 2.02 | 1.32 | 1.24 | 1.47 |

| Reference | Bitumen | CR Size | CR (%) | Blending Method | Complex Modulus | Phase Angle | Rutting Resistance | Fatigue Life |

|---|---|---|---|---|---|---|---|---|

| Sol-Sánchez et al. [81] | 70/100 PEN grade | 0.6–0.063 mm | 20 |

| ↑ | ↓ | - | - |

| Wang et al. [82] | PG 64-22 | 40-mesh 0.425 mm | 10, 15, 20 and 25 |

| ↑ | ↓ | - | - |

| Leng et al. [69] | 60/70 PEN | 40-mesh | 18 |

| - | - | ↑ | ↓ |

| Yu et al. [70] | 60/70 PEN | - | - |

| - | - | ↑ | ↓ |

| Mashaan et al. [74] | 80/100 PEN | 30-mesh | 4, 8, 12, 16 and 20 |

| ↑ | ↓ | ↑ | - |

| Shen et al. [83] | PG 64-22 and PG 52–28 | 1.35, 0.6 and 0.425 mm | 10 and 15 |

| ↑ | ↓ | - | - |

| Shatanawi et al. [11] | PG 64-22 | - | 15 |

| ↑ | - | ↑ | - |

| Ziari et al. [36] | 85/100 PEN | 14- and 50-mesh | 10, 15 and 20 |

| - | - | ↑ | ↓ |

| Poovaneshvaran et al. [2] | 60/70 PEN | 0.425–0.075 mm | 5, 10 and 15 |

| ↑ | ↓ | ↑ | - |

| Bilema et al. [84] | 80/100 PEN | 20-mesh | 5, 10 and 15 |

| ↑ | ↓ | ↑ | - |

| Wang et al. [55] | 90/100 PEN | 80-mesh | 15, 20 and 25 |

| ↑ | ↓ | ↑ | - |

| Yu et al. [67] | 60/70 PEN | - | 10 and 20 |

| ↑ | ↓ | ↑ | ↓ |

| Wang et al. [26] | 60/80 PEN | <0.6 mm | 20, 25, 30, 35, 40, 45 and 50 |

| ↑ | ↓ | ↑ | ↓ |

| Yu et al. [85] | 60/70 PEN | 40-mesh | 18 |

| - | - | - | ↑ |

| Xiaoming et al. [86] | 60/70 PEN | 0.125 mm | 2, 3, 3.5 and 4 |

| ↑ | ↓ | ↑ | - |

| Zhang et al. [87] | 70/80 PEN | 40-mesh | 25 |

| ↑ | ↓ | ↑ | - |

| Zong et al. [88] | 80/100 PEN | 25-, 30-, 40- and 60-mesh | 12, 16, 20 and 24 |

| ↑ | ↓ | ↑ | - |

| Khan et al. [89] | PG 64-10 | 0.15–0.075 mm | 4, 8, 12 and 16 |

| ↑ | ↓ | ↑ | - |

| Khan et al. [90] | PG 64-10 | 0.15–0.075 mm | 2, 4, 8 and 10 |

| ↑ | ↓ | ↑ | - |

| Yun et al. [91] | PG 64-22 | 0.425–0.075mm | 5, 10, 15 and 20 |

| - | - | ↑ | - |

| CR (%) | CR Size | Blending Method | Result | Authors |

|---|---|---|---|---|

| 1 and 2 | 40- and 80-mesh |

| Improved the stiffness and durability of the asphalt mixtures. | Wulandari and Tjandra [77] |

| 1, 2 and 3 | 2.36–0.075 mm |

| Adding CR increased the Marshall stability and rutting resistance considerably. The recommended CR dosage in asphalt mixture is 1.5–2%. | Nguyen and Tran [94] |

| 10 | 2–0.075 mm |

| Waste CR powder reduced the rut depth of asphalt mixes at varying temperatures and pressures. | Shafabakhsh et al. [1] |

| 5, 10 and 15 | 20-mesh |

| The tensile strength ratio (TSR) of the WMA mixtures modified with CR decreased at lower test temperatures and higher CR contents. | Bilema et al. [54] |

| 1 | 0.8 mm |

| The CR-modified bitumen had a higher viscosity than the virgin bitumen. The CR had a significant impact on the mixture’s performance. The conditioning time determined the asphalt morphology. | Fernández et al. [95] |

| 20 | 0.6–0.063 mm |

| The CR with WMA additives reduced the manufacturing temperature by 45 °C without adversely affecting mechanical performance, energy consumption, costs and GHG emissions. | Sánchez et al. [81] |

| 1.5 and 1.9 | 0.6–0.063 mm |

| CR mixtures were less sensitive to high temperatures than the virgin asphalt mixture. CR improved fatigue cracking performance. The temperatures of over 190 °C at plants producing CR asphalt mixture had adverse effects on rubber performance (reduced stiffness at intermediate temperatures and lower fatigue resistance). | Dias et al. [96] |

| 10 | 0.15, 0.3 and 0.6 mm |

| CR increased the rutting resistance. | Wong and Wong [33] |

| 0.5 1 and 1.5 | 0.6 mm |

| CR enhanced the asphalt mixture’s stiffness modulus and rutting resistance. | Moreno et al. [41] |

| 20 | 50–100-mesh |

| The fatigue life of the CR-modified mixture was 3.6 times the unmodified asphalt mixtures for highway applications. | Asgharzadeh et al. [64] |

| 1 | 0.8 mm |

| The CR-modified asphalt mixtures showed satisfactory performance and were less susceptible to ageing than the conventional polymer-modified mixture. | Fernández et al. [97] |

| 5 | 0.075, 0.15 and 0.3 mm |

| Larger CR particles increased the ITS and reduced the moisture resistance. The 0.15 mm CR was suitable for improving the asphalt mixture’s strength and moisture damage resistance. | Bilema et al. [34] |

| 6, 12, 16 and 20 | 0.45 mm |

| CR improved the stability of stone mix asphalt by providing better adhesion. The stiffness modulus of SMA samples containing varying CR percentages was significantly higher than the virgin asphalt mixture. The optimal CR percentage was 12% by weight of the bitumen. | Mashaan et al. [7] |

| 5, 10 and 15 | 0.6 mm |

| Reduced the asphalt mixture’s permanent deformation and increased its resilient modulus. | Palit et al. [59] |

| 0.25, 0.5, 0.75, 1, 2, 3, 4 and 5 | 0.425 mm |

| Adding the 0.75 mm CR enhanced the fatigue cracking and rutting resistance. | Kamarudin et al. [98] |

| 15, 17, 20 and 21 | 2–0.075 mm |

| The CR asphalt mixtures showed improved resistance to permanent deformation. | Fontes et al. [99] |

| 5, 10, 15 and 19 | 0.3–0.6 mm |

| The fatigue resistance decreased with higher CR contents in the asphalt mixture. | Yun et al. [91] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bilema, M.; Yuen, C.W.; Alharthai, M.; Al-Saffar, Z.H.; Al-Sabaeei, A.; Yusoff, N.I.M. A Review of Rubberised Asphalt for Flexible Pavement Applications: Production, Content, Performance, Motivations and Future Directions. Sustainability 2023, 15, 14481. https://doi.org/10.3390/su151914481

Bilema M, Yuen CW, Alharthai M, Al-Saffar ZH, Al-Sabaeei A, Yusoff NIM. A Review of Rubberised Asphalt for Flexible Pavement Applications: Production, Content, Performance, Motivations and Future Directions. Sustainability. 2023; 15(19):14481. https://doi.org/10.3390/su151914481

Chicago/Turabian StyleBilema, Munder, Choon Wah Yuen, Mohammad Alharthai, Zaid Hazim Al-Saffar, Abdulnaser Al-Sabaeei, and Nur Izzi Md Yusoff. 2023. "A Review of Rubberised Asphalt for Flexible Pavement Applications: Production, Content, Performance, Motivations and Future Directions" Sustainability 15, no. 19: 14481. https://doi.org/10.3390/su151914481