Adsorption of Pyraclostrobin in Water by Bamboo-Derived and Pecan Shell-Derived Biochars

Abstract

:1. Introduction

2. Materials and Methods

2.1. Reagents and Chemicals

2.2. Biochars

2.3. Characterization

2.4. Sorption Experiments

2.4.1. The Sorption Kinetic Experiment

2.4.2. The Sorption Isotherm Experiment

2.4.3. The Adsorption Thermodynamics Experiment

2.4.4. The Equilibrium Adsorption Experiment

2.4.5. Adsorbent Regeneration

2.4.6. Testing Conditions

2.5. Data Calculation

2.5.1. Adsorption Capacity and Removal Efficiency

2.5.2. Kinetic Models

2.5.3. Isothermal Models

2.5.4. Thermodynamics Models

2.6. Data Processing

3. Results

3.1. Biochars Characterization

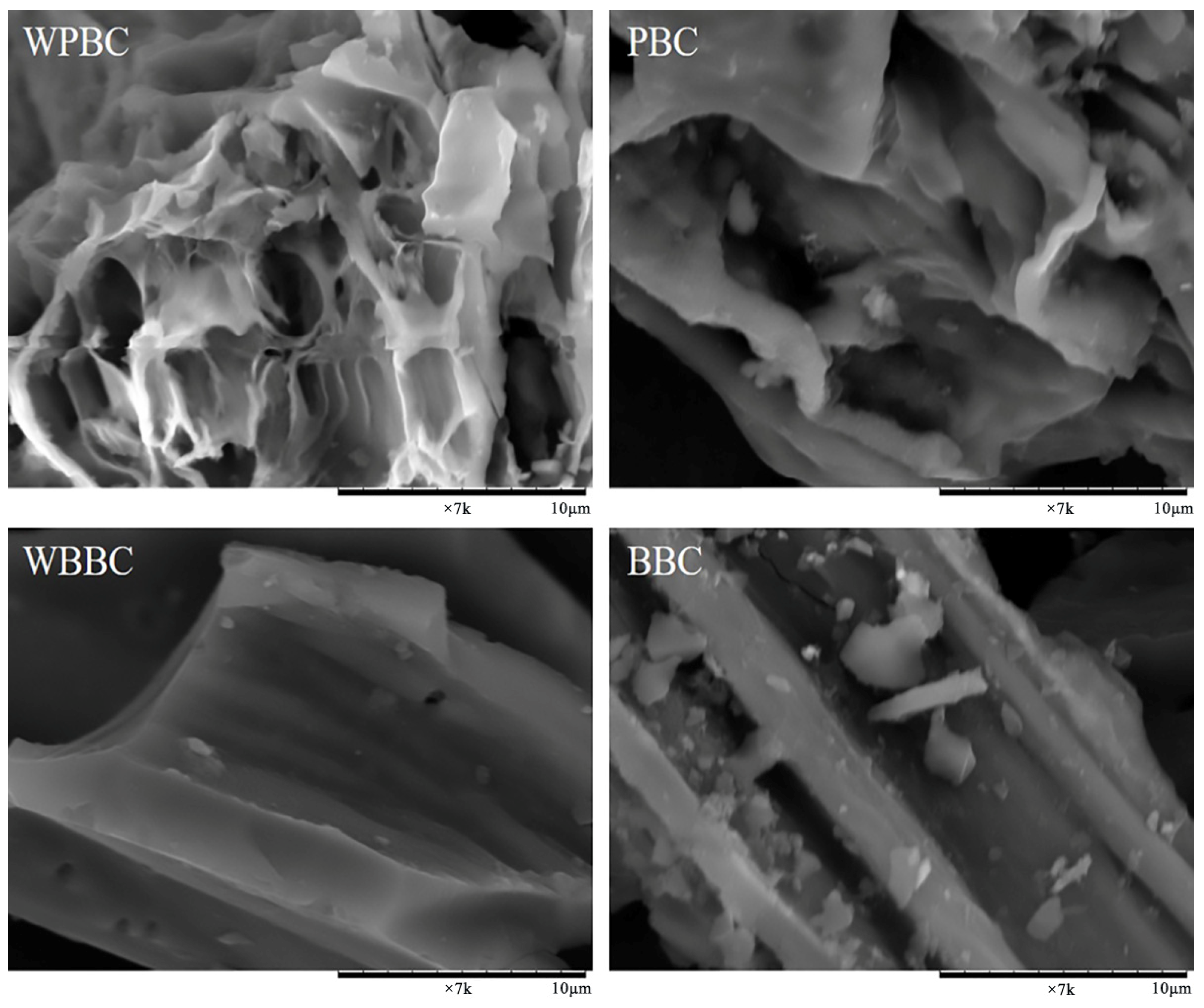

3.1.1. SEM

3.1.2. Physical Properties

3.1.3. Fourier-Transform Infrared Spectroscopic Analysis

3.1.4. X-ray Photoelectron Spectroscopy

3.2. Adsorption Kinetics

3.3. Adsorption Isotherms

3.4. Adsorption Thermodynamics

3.5. Influencing Factors

3.5.1. Effect of Particle Size

3.5.2. Effect of Initial Adsorbent Dosage

3.5.3. Effect of Inorganic Ions Strength

3.5.4. Effect of Solution pH

3.6. Adsorption Mechanism

3.7. Regeneration Analysis of Adsorbents

3.8. Comparison with Other Adsorbents

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hartman, E.A.H.; Belden, J.B.; Smith, L.M.; McMurry, S.T. Chronic effects of strobilurin fungicides on development, growth, and mortality of larval Great Plains toads (Bufo cognatus). Ecotoxicology 2014, 23, 396–403. [Google Scholar] [CrossRef]

- Patel, J.S.; Gudmestad, N.C.; Meinhardt, S.; Adhikari, T.B. Pyraclostrobin sensitivity of baseline and fungicide exposed isolates of Pyrenophora tritici-repentis. Crop Prot. 2012, 34, 37–41. [Google Scholar] [CrossRef]

- Mimbs, W.H.T.; Cusaac, J.P.W.; Smith, L.M.; McMurry, S.T.; Belden, J.B. Occurrence of current-use fungicides and bifenthrin in Rainwater Basin wetlands. Chemosphere 2016, 159, 275–281. [Google Scholar] [CrossRef] [PubMed]

- Wightwick, A.M.; Bui, A.D.; Zhang, P.; Rose, G.; Allinson, M.; Myers, J.H.; Reichman, S.M.; Menzies, N.W.; Pettigrove, V.; Allinson, G. Environmental fate of fungicides in surface waters of a horticultural-production catchment in southeastern Australia. Arch. Environ. Contam. Toxicol. 2012, 62, 380–390. [Google Scholar] [CrossRef] [PubMed]

- Smalling, K.L.; Kuivila, K.M.; Orlando, J.L.; Phillips, B.M.; Anderson, B.S.; Siegler, K.; Hunt, J.W.; Hamilton, M. Environmental fate of fungicides and other current-use pesticides in a central California estuary. Mar. Pollut. Bull. 2013, 73, 144–153. [Google Scholar] [CrossRef]

- Li, H.; Zhao, F.; Cao, F.J.; Teng, M.M.; Yang, Y.; Qiu, L.H. Mitochondrial dysfunction-based cardiotoxicity and neurotoxicity induced by pyraclostrobin in zebrafish larvae. Environ. Pollut. 2019, 251, 203–211. [Google Scholar] [CrossRef]

- Huang, X.P.; Yang, S.; Li, B.X.; Wang, A.P.; Li, H.; Li, X.H.; Luo, J.; Liu, F.; Mu, W. Comparative toxicity of multiple exposure routes of pyraclostrobin in adult zebrafish (Danio rerio). Sci. Total Environ. 2021, 777, 145957. [Google Scholar] [CrossRef]

- Ignatowicz, K.; Lozowicki, J.; Lozowicka, B.; Piekarski, J. Treatment of Agricultural Wastewater Containing Pesticides by Hydrophytic Method as a Preliminary Method of Water Recovery. Energies 2023, 16, 660. [Google Scholar] [CrossRef]

- Haleem, A.; Pan, J.-M.; Shah, A.; Hussain, H.; He, W.-D. A systematic review on new advancement and assessment of emerging polymeric cryogels for environmental sustainability and energy production. Sep. Purif. Technol. 2023, 316, 123678. [Google Scholar] [CrossRef]

- Haleem, A.; Shafiq, A.; Chen, S.-Q.; Nazar, M. A Comprehensive Review on Adsorption, Photocatalytic and Chemical Degradation of Dyes and Nitro-Compounds over Different Kinds of Porous and Composite Materials. Molecules 2023, 28, 1081. [Google Scholar] [CrossRef]

- Filipinas, J.Q.; Rivera, K.K.P.; Ong, D.C.; Pingul-Ong, S.M.B.; Abarca, R.R.M.; de Luna, M.D.G. Removal of sodium diclofenac from aqueous solutions by rice hull biochar. Biochar 2021, 3, 189–200. [Google Scholar] [CrossRef]

- Bamdad, H.; Hawboldt, K.; MacQuarrie, S. A review on common adsorbents for acid gases removal: Focus on biochar. Renew. Sustain. Energy Rev. 2018, 81, 1705–1720. [Google Scholar] [CrossRef]

- Wang, P.; Liu, X.; Yu, B.; Wu, X.; Xu, J.; Dong, F.; Zheng, Y. Characterization of peanut-shell biochar and the mechanisms underlying its sorption for atrazine and nicosulfuron in aqueous solution. Sci. Total Environ. 2020, 702, 134767. [Google Scholar] [CrossRef]

- Yuan, J.H.; Xu, R.K.; Zhang, H. The forms of alkalis in the biochar produced from crop residues at different temperatures. Bioresour. Technol. 2011, 102, 3488–3497. [Google Scholar] [CrossRef]

- Luo, S.X.; Qin, J.; Wu, Y.H.; Feng, F. Tetracycline adsorption on magnetic sludge biochar: Size effect of the Fe3O4 nanoparticles. R. Soc. Open Sci. 2022, 9, 210805. [Google Scholar] [CrossRef]

- Kohzadi, S.; Marzban, N.; Libra, J.A.; Bundschuh, M.; Maleki, A. Removal of RhB from water by Fe-modified hydrochar and biochar—An experimental evaluation supported by genetic programming. J. Mol. Liq. 2023, 369, 120971. [Google Scholar] [CrossRef]

- Zou, C.; Xu, Z.; Nie, F.; Guan, K.; Li, J. Application of hydroxyapatite-modified carbonized rice husk for the adsorption of Cr(VI) from aqueous solution. J. Mol. Liq. 2023, 371, 121137. [Google Scholar] [CrossRef]

- Intani, K.; Latif, S.; Islam, M.S.; Mueller, J. Phytotoxicity of Corncob Biochar before and after Heat Treatment and Washing. Sustainability 2019, 11, 30. [Google Scholar] [CrossRef]

- Qiu, Y.; Zheng, Z.; Zhou, Z.; Sheng, G.D. Effectiveness and mechanisms of dye adsorption on a straw-based biochar. Bioresour. Technol. 2009, 100, 5348–5351. [Google Scholar] [CrossRef]

- Ma, S.; Jing, F.; Sohi, S.P.; Chen, J. New insights into contrasting mechanisms for PAE adsorption on millimeter, micron- and nano-scale biochar. Environ. Sci. Pollut. Res. Int. 2019, 26, 18636–18650. [Google Scholar] [CrossRef]

- Suo, F.Y.; Liu, X.; Li, C.S.; Yuan, M.; Zhang, B.J.; Wang, J.L.; Ma, Y.Q.; Lai, Z.M.; Ji, M.S. Mesoporous activated carbon from starch for superior rapid pesticides removal. Int. J. Biol. Macromol. 2019, 121, 806–813. [Google Scholar] [CrossRef] [PubMed]

- Xiao, F.; Pignatello, J.J. pi(+)-pi Interactions between (Hetero)aromatic Amine Cations and the Graphitic Surfaces of Pyrogenic Carbonaceous Materials. Environ. Sci. Technol. 2015, 49, 906–914. [Google Scholar] [CrossRef] [PubMed]

- Xiao, X.; Chen, B.; Zhu, L. Transformation, Morphology, and Dissolution of Silicon and Carbon in Rice Straw-Derived Biochars under Different Pyrolytic Temperatures. Environ. Sci. Technol. 2014, 48, 3411–3419. [Google Scholar] [CrossRef] [PubMed]

- Fang, Q.; Chen, B.; Lin, Y.; Guan, Y. Aromatic and Hydrophobic Surfaces of Wood-derived Biochar Enhance Perchlorate Adsorption via Hydrogen Bonding to Oxygen-containing Organic Groups. Environ. Sci. Technol. 2014, 48, 279–288. [Google Scholar] [CrossRef] [PubMed]

- Chen, W.F.; Zhang, H.Y.; Wang, C.T.; Yang, L.M.; Ni, J.Z.; Wei, R. Differential roles of ash in sorption of triclosan to wood-derived biochars produced at different temperatures. J. Environ. Qual. 2020, 49, 335–345. [Google Scholar] [CrossRef] [PubMed]

- Zhang, P.; Sun, H.W.; Ren, C.; Min, L.J.; Zhang, H.M. Sorption mechanisms of neonicotinoids on biochars and the impact of deashing treatments on biochar structure and neonicotinoids sorption. Environ. Pollut. 2018, 234, 812–820. [Google Scholar] [CrossRef]

- Ihsanullah, I.; Khan, M.T.; Zubair, M.; Bilal, M.; Sajid, M. Removal of pharmaceuticals from water using sewage sludge-derived biochar: A review. Chemosphere 2022, 289, 133196. [Google Scholar] [CrossRef]

- Ioannidou, O.; Zabaniotou, A. Agricultural residues as precursors for activated carbon production—A review. Renew. Sustain. Energy Rev. 2007, 11, 1966–2005. [Google Scholar] [CrossRef]

- Kalderis, D.; Seifi, A.; Kieu Trang, T.; Tsubota, T.; Anastopoulos, I.; Manariotis, I.; Pashalidis, I.; Khataee, A. Bamboo-derived adsorbents for environmental remediation: A review of recent progress. Environ. Res. 2023, 224, 115533. [Google Scholar] [CrossRef]

- Keiluweit, M.; Nico, P.S.; Johnson, M.G.; Kleber, M. Dynamic Molecular Structure of Plant Biomass-Derived Black Carbon (Biochar). Environ. Sci. Technol. 2010, 44, 1247–1253. [Google Scholar] [CrossRef]

- Shao, X.; Liu, L.; Li, H.; Luo, Y.; Zhao, J.; Liu, S.; Yan, B.; Wang, D.; Luo, K.; Liu, M.; et al. The effects of polyethersulfone and Nylon 6 micromembrane filters on the pyraclostrobin detection: Adsorption performance and mechanism. Environ. Sci. Pollut. Res. 2022, 29, 74051–74061. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Shang, H.; Cao, Y.; Yang, C.; Feng, Y.; Yu, Y. High performance removal of sulfamethoxazole using large specific area of biochar derived from corncob xylose residue. Biochar 2022, 4, 11. [Google Scholar] [CrossRef]

- Hamadeen, H.M.; Elkhatib, E.A. Nanostructured modified biochar for effective elimination of chlorpyrifos from wastewater: Enhancement, mechanisms and performance. J. Water Process Eng. 2022, 47, 102703. [Google Scholar] [CrossRef]

- Zheng, H.; Zhang, Q.; Liu, G.C.; Luo, X.X.; Li, F.M.; Zhang, Y.P.; Wang, Z.Y. Characteristics and mechanisms of chlorpyrifos and chlorpyrifos-methyl adsorption onto biochars: Influence of deashing and low molecular weight organic acid (LMWOA) aging and co-existence. Sci. Total Environ. 2019, 657, 953–962. [Google Scholar] [CrossRef] [PubMed]

- Sun, K.; Kang, M.; Ro, K.S.; Libra, J.A.; Zhao, Y.; Xing, B. Variation in sorption of propiconazole with biochars: The effect of temperature, mineral, molecular structure, and nano-porosity. Chemosphere 2016, 142, 56–63. [Google Scholar] [CrossRef]

- Ma, Y.F.; Chen, S.Y.; Qi, Y.; Yang, L.; Wu, L.; He, L.Y.; Li, P.; Qi, X.B.; Gao, F.; Ding, Y.Z.; et al. An efficient, green and sustainable potassium hydroxide activated magnetic corn cob biochar for imidacloprid removal. Chemosphere 2022, 291, 132707. [Google Scholar] [CrossRef]

- Dominguez, A.N.; Emmert, G.E.; Gil, D.M.; Alvarez, R.M.S. Experimental and theoretical vibrational study of the fungicide pyraclostrobin. Spectrochim. Acta A Mol. Biomol. Spectrosc. 2021, 259, 119888. [Google Scholar] [CrossRef]

- Suo, F.Y.; You, X.W.; Ma, Y.Q.; Li, Y.Q. Rapid removal of triazine pesticides by P doped biochar and the adsorption mechanism. Chemosphere 2019, 235, 918–925. [Google Scholar] [CrossRef]

- Ma, Y.; Qi, Y.; Yang, L.; Wu, L.; Li, P.; Gao, F.; Qi, X.; Zhang, Z. Adsorptive removal of imidacloprid by potassium hydroxide activated magnetic sugarcane bagasse biochar: Adsorption efficiency, mechanism and regeneration. J. Clean. Prod. 2021, 292, 126005. [Google Scholar] [CrossRef]

- Ma, Y.; Li, P.; Yang, L.; Wu, L.; He, L.; Gao, F.; Qi, X.; Zhang, Z. Iron/zinc and phosphoric acid modified sludge biochar as an efficient adsorbent for fluoroquinolones antibiotics removal. Ecotoxicol. Environ. Saf. 2020, 196, 110550. [Google Scholar] [CrossRef]

- Li, Y.; Taggart, M.A.; McKenzie, C.; Zhang, Z.; Lu, Y.; Pap, S.; Gibb, S. Utilizing low-cost natural waste for the removal of pharmaceuticals from water: Mechanisms, isotherms and kinetics at low concentrations. J. Clean. Prod. 2019, 227, 88–97. [Google Scholar] [CrossRef]

- Wang, S.; Zhu, Z.H. Effects of acidic treatment of activated carbons on dye adsorption. Dye. Pigment. 2007, 75, 306–314. [Google Scholar] [CrossRef]

- Cho, E.-J.; Kang, J.-K.; Moon, J.-K.; Um, B.-H.; Lee, C.-G.; Jeong, S.; Park, S.-J. Removal of triclosan from aqueous solution via adsorption by kenaf-derived biochar: Its adsorption mechanism study via spectroscopic and experimental approaches. J. Environ. Chem. Eng. 2021, 9, 106343. [Google Scholar] [CrossRef]

- Azzam, A.B.; Tokhy, Y.A.; El Dars, F.M.; Younes, A.A. Construction of porous biochar decorated with NiS for the removal of ciprofloxacin antibiotic from pharmaceutical wastewaters. J. Water Process Eng. 2022, 49, 103006. [Google Scholar] [CrossRef]

- Jin, Z.; Xiao, S.; Dong, H.; Xiao, J.; Tian, R.; Chen, J.; Li, Y.; Li, L. Adsorption and catalytic degradation of organic contaminants by biochar: Overlooked role of biochar’s particle size. J. Hazard. Mater. 2022, 422, 126928. [Google Scholar] [CrossRef]

- Jacob, M.M.; Ponnuchamy, M.; Kapoor, A.; Sivaraman, P. Bagasse based biochar for the adsorptive removal of chlorpyrifos from contaminated water. J. Environ. Chem. Eng. 2020, 8, 103904. [Google Scholar] [CrossRef]

- Tremblay, L.; Kohl, S.D.; Rice, J.A.; Gagné, J.-P. Effects of temperature, salinity, and dissolved humic substances on the sorption of polycyclic aromatic hydrocarbons to estuarine particles. Mar. Chem. 2005, 96, 21–34. [Google Scholar] [CrossRef]

- Liu, P.; Liu, W.-J.; Jiang, H.; Chen, J.-J.; Li, W.-W.; Yu, H.-Q. Modification of bio-char derived from fast pyrolysis of biomass and its application in removal of tetracycline from aqueous solution. Bioresour. Technol. 2012, 121, 235–240. [Google Scholar] [CrossRef]

- Hai, N.; Liu, X.; Li, Y.; Kong, F.; Zhang, Y.; Fang, S. Effects of Microplastics on the Adsorption and Bioavailability of Three Strobilurin Fungicides. ACS Omega 2020, 5, 30679–30686. [Google Scholar] [CrossRef]

- An, C.; Huang, G. Stepwise adsorption of phenanthrene at the fly ash-water interface as affected by solution chemistry: Experimental and modeling studies. Environ. Sci. Technol. 2012, 46, 12742–12750. [Google Scholar] [CrossRef]

- Han, L.; Qian, L.; Yan, J.; Chen, M. Effects of the biochar aromaticity and molecular structures of the chlorinated organic compounds on the adsorption characteristics. Environ. Sci. Pollut. Res. Int. 2017, 24, 5554–5565. [Google Scholar] [CrossRef] [PubMed]

- Xu, X.; Zhao, Y.; Sima, J.; Zhao, L.; Masek, O.; Cao, X. Indispensable role of biochar-inherent mineral constituents in its environmental applications: A review. Bioresour. Technol. 2017, 241, 887–899. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Song, J.; He, Q.; Wang, H.; Lyu, W.; Feng, H.; Xiong, W.; Guo, W.; Wu, J.; Chen, L. Novel pectin based composite hydrogel derived from grapefruit peel for enhanced Cu(II) removal. J. Hazard. Mater. 2020, 384, 121445. [Google Scholar] [CrossRef] [PubMed]

| Biochar | Element (%) | H/C | O/C | (O + N)/C | SSA (m2/g) | PV (cm3/g) | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| N | C | H | O | Ash | ||||||

| WPBC a | 1.2663 | 63.8716 | 3.5504 | 23.5617 | 7.7500 | 0.0556 | 0.3689 | 0.3887 | 23.5818 | 0.0128 |

| WPBC b | 1.4184 | 62.3588 | 3.6246 | 24.3082 | 8.2900 | 0.0581 | 0.3898 | 0.4126 | 44.1823 | 0.0243 |

| WPBC c | 1.3860 | 60.7584 | 3.6486 | 24.7470 | 9.4600 | 0.0601 | 0.4073 | 0.4301 | 206.2498 | 0.1138 |

| PBC a | 1.2573 | 60.1070 | 3.6555 | 23.0003 | 11.9800 | 0.0608 | 0.3827 | 0.4036 | 9.4055 | 0.0084 |

| PBC b | 1.4398 | 57.4393 | 3.6323 | 26.2088 | 11.2800 | 0.0632 | 0.4563 | 0.4814 | 32.2835 | 0.0207 |

| PBC c | 1.4350 | 56.4132 | 3.5334 | 26.7684 | 11.8500 | 0.0626 | 0.4745 | 0.4999 | 178.0873 | 0.0986 |

| WBBC a | 0.5798 | 80.8845 | 3.1038 | 13.3120 | 2.1200 | 0.0384 | 0.1646 | 0.1717 | 1.6633 | 0.0005 |

| WBBC b | 0.7120 | 82.1940 | 3.0897 | 11.9543 | 2.0500 | 0.0376 | 0.1454 | 0.1541 | 4.0082 | 0.0040 |

| WBBC c | 0.7874 | 82.9020 | 2.4460 | 11.4546 | 2.4100 | 0.0295 | 0.1382 | 0.1477 | 127.2908 | 0.0731 |

| BBC a | 0.8178 | 79.1178 | 3.1213 | 12.8133 | 4.1300 | 0.0395 | 0.1620 | 0.1723 | 1.3871 | 0.0000 |

| BBC b | 0.6540 | 79.8697 | 2.7820 | 13.5443 | 3.1500 | 0.0348 | 0.1696 | 0.1778 | 1.7842 | 0.0012 |

| BBC c | 0.8413 | 81.0618 | 2.3288 | 11.2282 | 4.5400 | 0.0287 | 0.1385 | 0.1489 | 112.4005 | 0.0658 |

| WPBC | PBC | WBBC | BBC | ||

|---|---|---|---|---|---|

| Actual adsorption capacity | 0.4762 | 0.4758 | 0.4161 | 0.4197 | |

| Pseudo-first-order | R2 | 0.9735 | 0.9408 | 0.9943 | 0.9963 |

| qe | 0.4488 | 0.4329 | 0.4074 | 0.4123 | |

| k1 | 0.7536 | 0.4275 | 1.2467 | 1.3348 | |

| Pseudo-second-order | R2 | 0.9929 | 0.9816 | 0.9985 | 0.9991 |

| qe | 0.4601 | 0.4485 | 0.4121 | 0.4162 | |

| k2 | 3.3642 | 1.6083 | 10.4746 | 12.6860 | |

| Intra-particle diffusion model | R2 | 0.9816 | 0.9897 | 0.9319 | 0.8902 |

| ki1 | 0.0321 | 0.0507 | 0.0071 | 0.0060 | |

| C1 | 0.3181 | 0.2187 | 0.3684 | 0.3796 | |

| R2 | 0.9299 | 0.9381 | 0.9857 | 0.9994 | |

| ki2 | 0.0050 | 0.0072 | 0.0016 | 0.0013 | |

| C2 | 0.4058 | 0.3600 | 0.3971 | 0.4035 | |

| R2 | 0.9587 | 0.8749 | 0.8458 | 0.7995 | |

| ki3 | 6.2732 × 10−4 | 0.0014 | 7.0506 × 10−5 | 8.1833 × 10−5 | |

| C3 | 0.4537 | 0.4261 | 0.4137 | 0.4170 | |

| Adsorbates | T (K) | Linear | Freundlich | Langmuir | |||||

|---|---|---|---|---|---|---|---|---|---|

| Kd | R2 | KF | 1/n | R2 | KL | qm | R2 | ||

| WPBC | 298 | 11.4491 | 0.9892 | 7.3812 | 0.8085 | 0.9933 | N.A | N.A | <0.800 |

| 308 | 14.9383 | 0.9973 | 11.3170 | 0.8916 | 0.9982 | N.A | N.A | <0.800 | |

| 318 | 19.6723 | 0.9966 | 14.3411 | 0.8879 | 0.9975 | N.A | N.A | <0.800 | |

| PBC | 298 | 7.6697 | 0.9816 | 4.5369 | 0.7256 | 0.9975 | N.A | N.A | <0.800 |

| 308 | 10.5302 | 0.9981 | 8.3304 | 0.8955 | 0.9995 | N.A | N.A | <0.800 | |

| 318 | 14.7769 | 0.9898 | 9.4655 | 0.8239 | 0.9919 | N.A | N.A | <0.800 | |

| WBBC | 298 | 2.8789 | 0.9842 | 2.3647 | 0.7445 | 0.9980 | N.A | N.A | <0.800 |

| 308 | 3.9101 | 0.9842 | 2.9256 | 0.8128 | 0.9956 | N.A | N.A | <0.800 | |

| 318 | 3.9791 | 0.9915 | 3.0900 | 0.8186 | 0.9920 | N.A | N.A | <0.800 | |

| BBC | 298 | 2.9359 | 0.9706 | 2.3441 | 0.7104 | 0.9933 | N.A | N.A | <0.800 |

| 308 | 4.4135 | 0.9814 | 3.1408 | 0.7656 | 0.9879 | N.A | N.A | <0.800 | |

| 318 | 5.4385 | 0.9931 | 4.0589 | 0.8220 | 0.9975 | N.A | N.A | <0.800 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, K.; Wang, X.; Wu, H.; Fang, N.; Liu, Y.; Zhang, C.; Yu, X.; Wang, X. Adsorption of Pyraclostrobin in Water by Bamboo-Derived and Pecan Shell-Derived Biochars. Sustainability 2023, 15, 14585. https://doi.org/10.3390/su151914585

Yang K, Wang X, Wu H, Fang N, Liu Y, Zhang C, Yu X, Wang X. Adsorption of Pyraclostrobin in Water by Bamboo-Derived and Pecan Shell-Derived Biochars. Sustainability. 2023; 15(19):14585. https://doi.org/10.3390/su151914585

Chicago/Turabian StyleYang, Kongtan, Xumi Wang, Huanqi Wu, Nan Fang, Yuxue Liu, Changpeng Zhang, Xiaobin Yu, and Xiangyun Wang. 2023. "Adsorption of Pyraclostrobin in Water by Bamboo-Derived and Pecan Shell-Derived Biochars" Sustainability 15, no. 19: 14585. https://doi.org/10.3390/su151914585