Investigation into the Water Exit Behavior of a Cavity

Abstract

:1. Introduction

2. Methods

2.1. Physical Model

2.2. Numerical Calculation

3. Results and Discussion

3.1. Air Pressure in Cavity before Water Exit

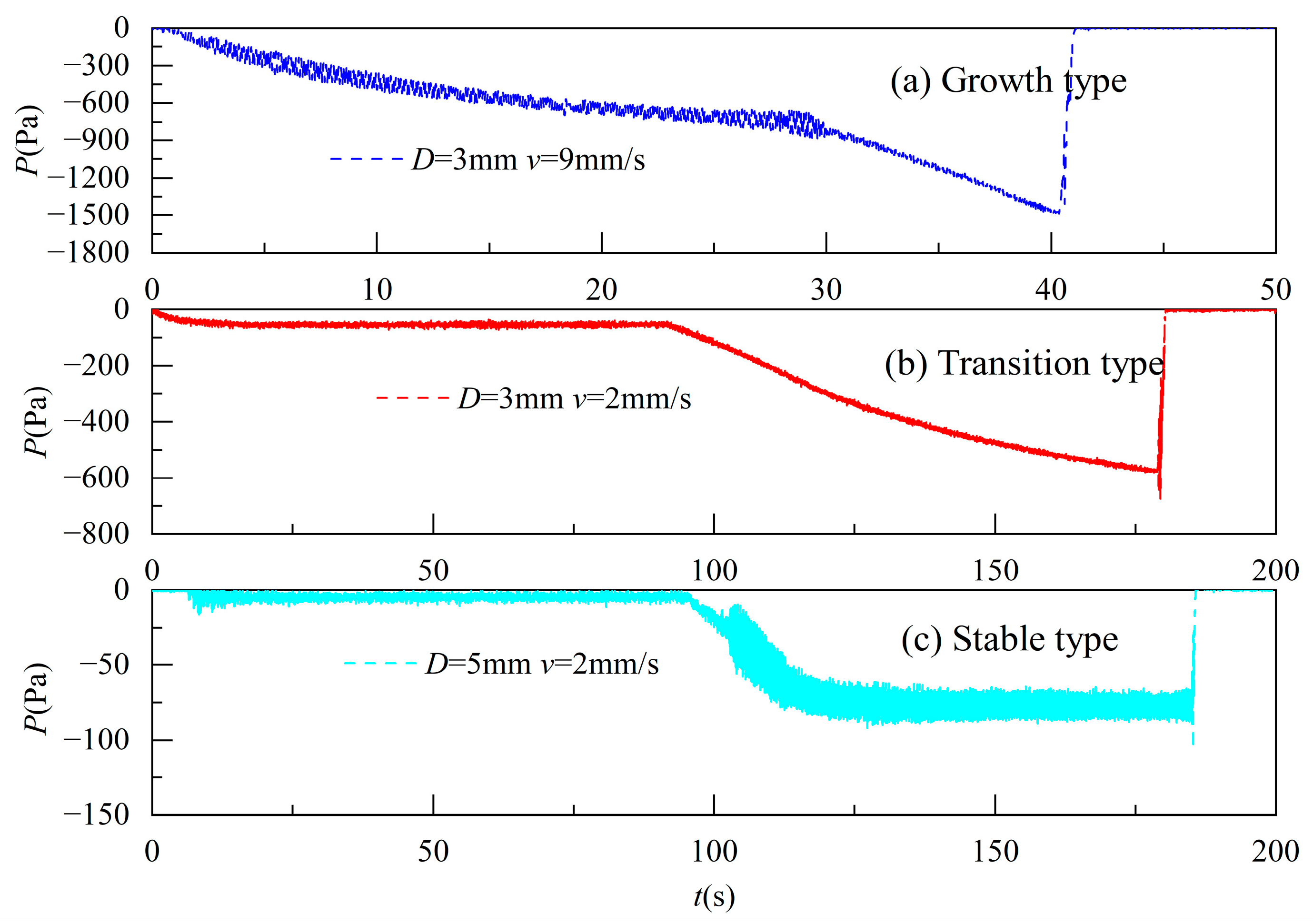

3.1.1. Pressure Type

- (1)

- Growth type. The air pressure in the cavity exhibited an increasing trend throughout the entire water exit process, with a relatively small increasing rate at its initial stage, as indicated in Figure 3a.

- (2)

- Transition type. This type is illustrated in Figure 3b. The air pressure in the cavity showed an increasing trend after the lifting of the beam and subsequently reached a stable process with an almost constant pressure. After that, the pressure increased again until the end of the water exit process.

- (3)

- Stable type. This type is illustrated in Figure 3c. The pressure exhibited similar behavior to that seen in the transition type earlier in the water exit process. In contrast, it underwent another stable process before the end of the water exit process.

3.1.2. Maximum Negative Pressure

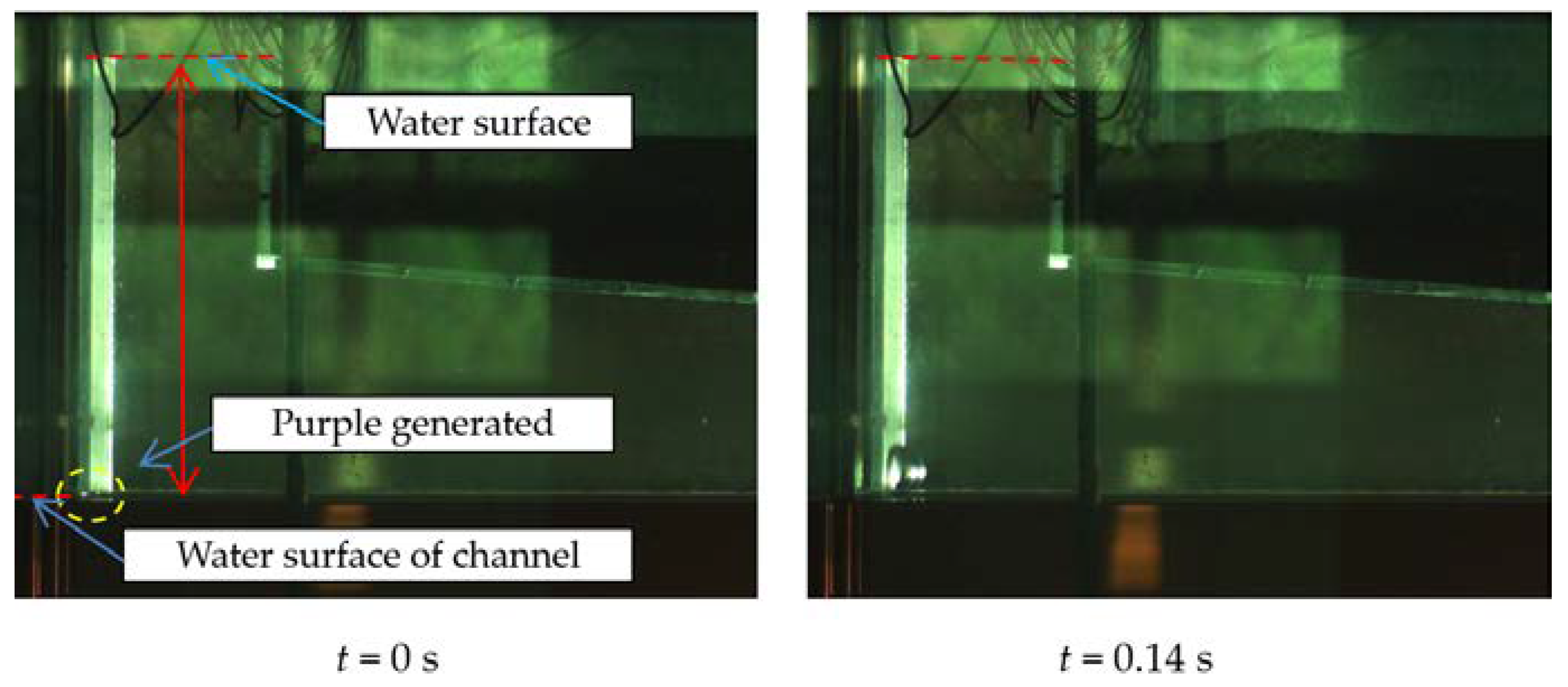

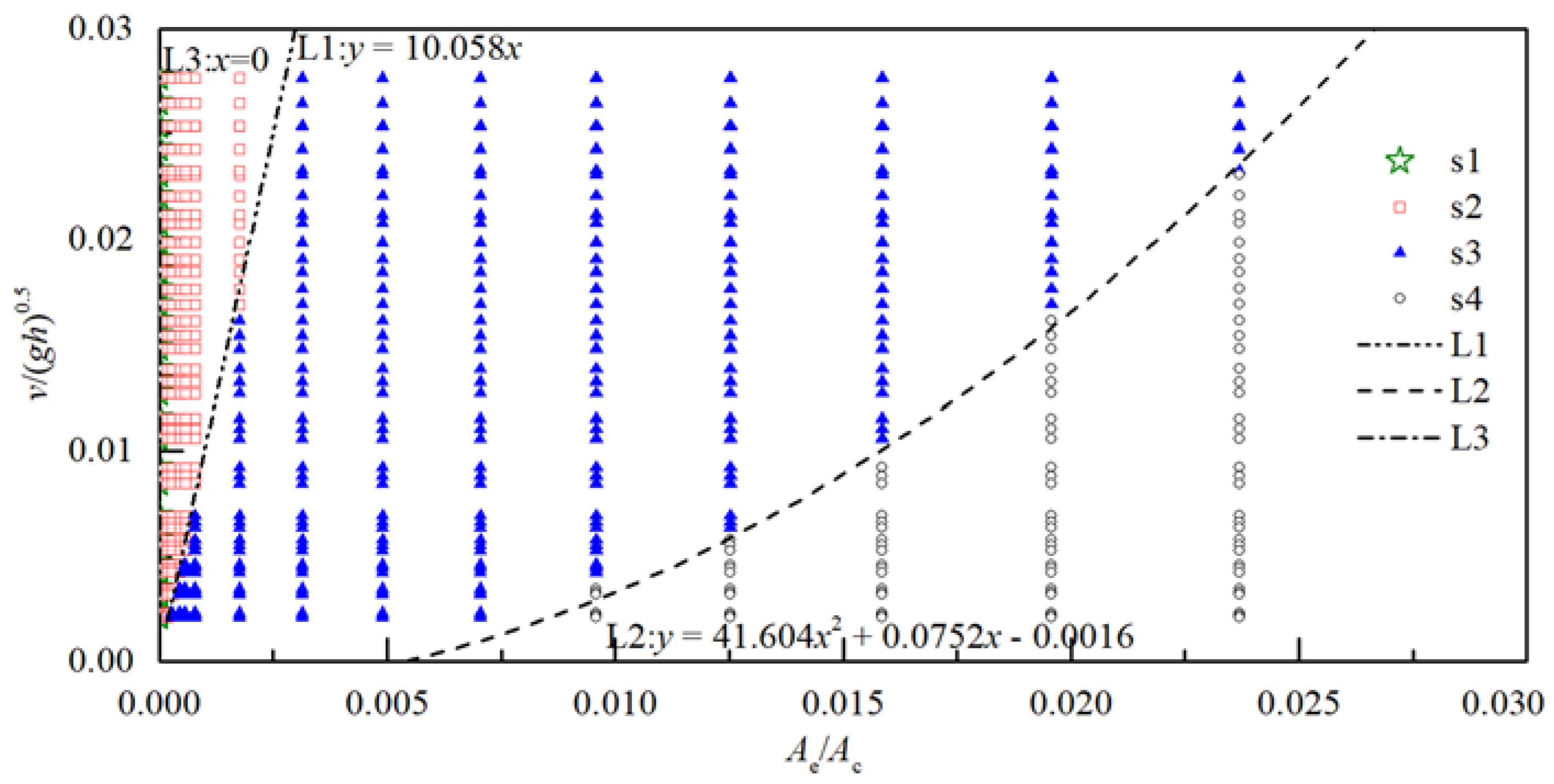

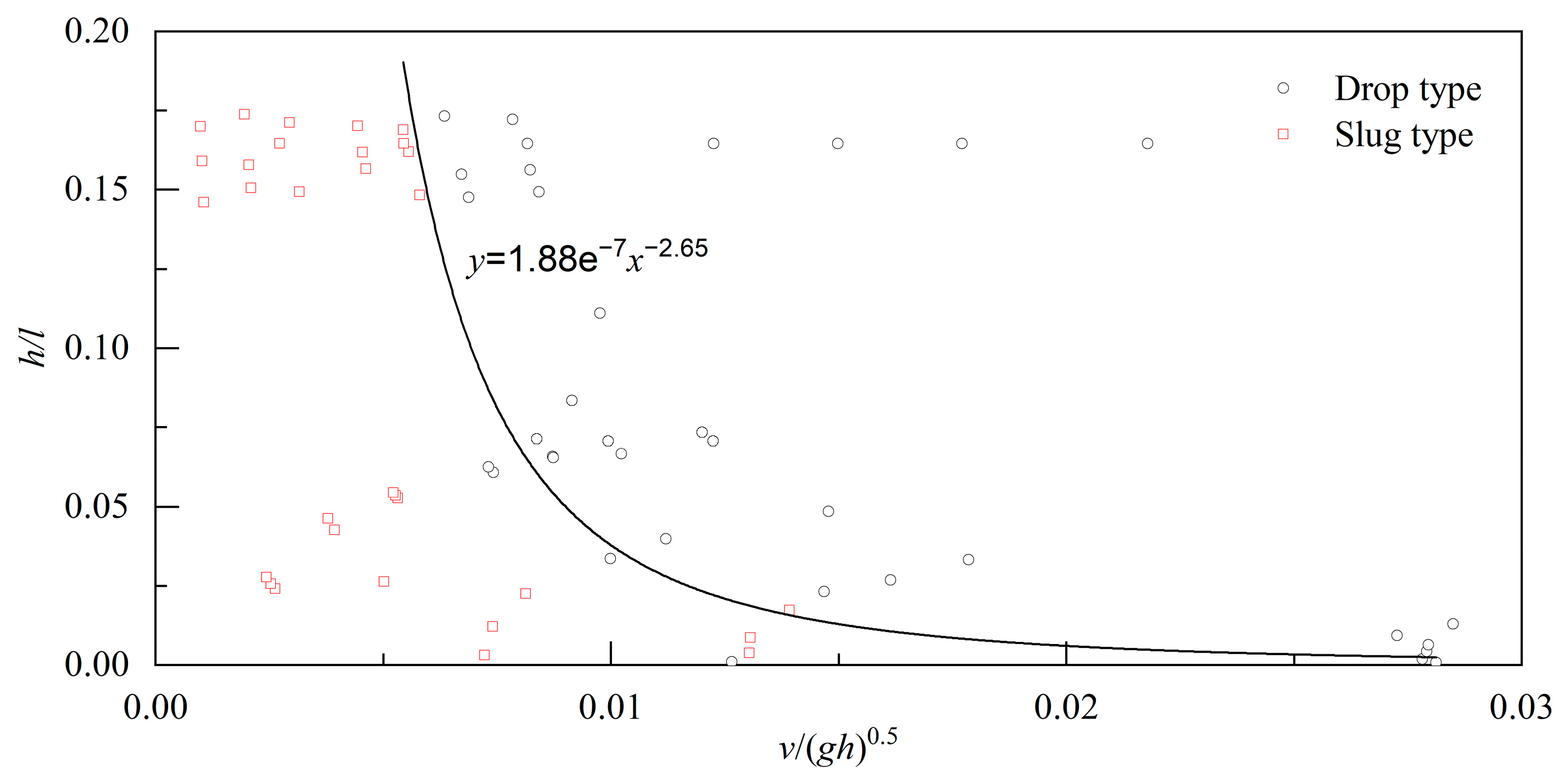

3.2. Hydraulic Characteristics inside the Cavity at Water Exit

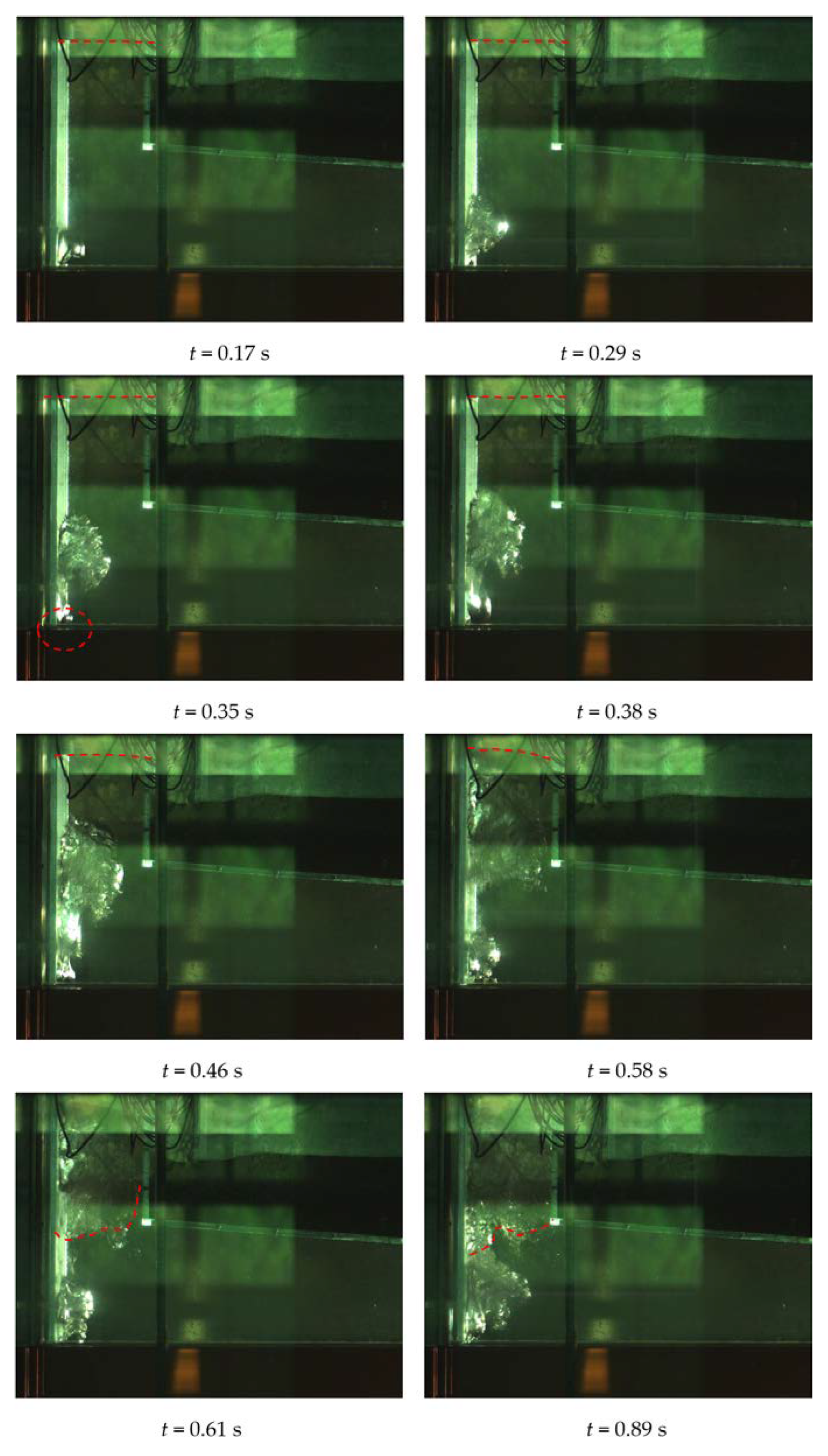

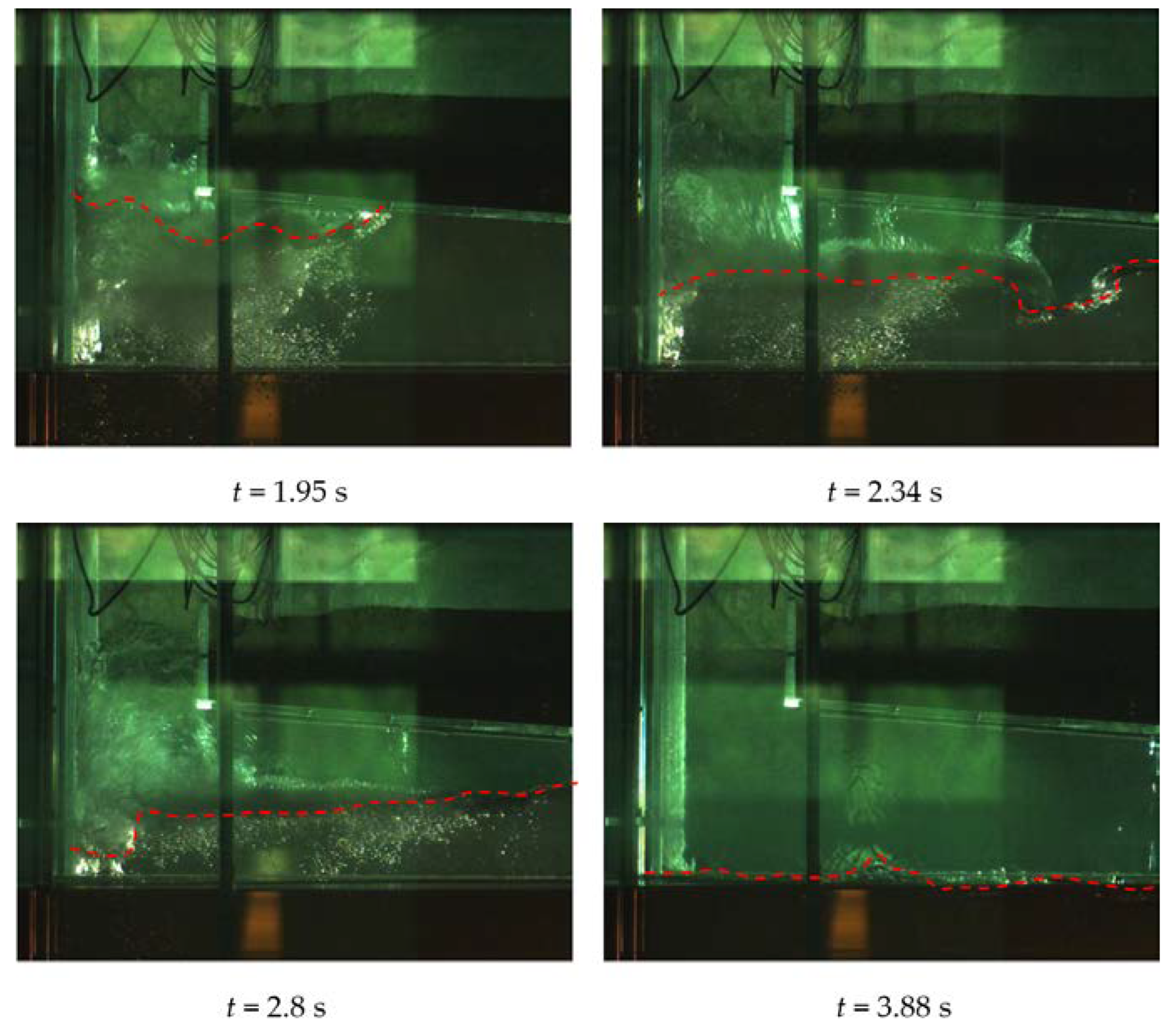

- (1)

- Slug flow. A photo sequence of this flow type is shown in Figure 5. Sudden bursts of air were periodically sucked in from the corner of the cavity. The entrained air formed a slug of air that propagated across the continuous water phase or a mix of water–air. The original volume of the entrained air bubble was occupied by water immediately after its runout, resulting in significant fluctuations in air pressure.

- (2)

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ukkola, A.M.; De Kauwe, M.G.; Roderick, M.L.; Abramowitz, G.; Pitman, A.J. Robust future changes in meteorological drought in CMIP6 projections despite uncertainty in precipitation. Geophys. Res. Lett. 2020, 47, e2020GL087820. [Google Scholar] [CrossRef]

- Yin, J.; Slater, L.; Gu, L.; Liao, Z.; Guo, S.; Gentine, P. Global Increases in Lethal Compound Heat Stress-Hydrological Drought Hazards under Climate Change. Geophys. Res. Lett. 2022, 49, e2022GL100880. [Google Scholar] [CrossRef]

- Wan, W.; Zhao, J.; Popat, E.; Herbert, C.; Döll, P. Analyzing the Impact of Streamflow Drought on Hydroelectricity Production: A Global-Scale Study. Water Resour. Res. 2021, 57, e2020WR028087. [Google Scholar] [CrossRef]

- Hongqi, M.; Xuexing, C. Research on the key technologies of hydraulic new type ship lift. J. Hydraul. Eng. 2018, 49, 446–455. [Google Scholar]

- Liu, J.; Hu, Y.; Li, Z.; Xue, S. Risk Analysis and Optimization of Water Surface Deviation from Shafts in the Filling–Emptying System of a Mega-Scale Hydro-Floating Ship Lift. Water 2021, 13, 1377. [Google Scholar] [CrossRef]

- Sun, Z.; Zheng, H.; Sun, L. Analysis on the Characteristics of Bed Materials in the Jinghong Reservoir on the Lancang River. Sustainability 2021, 13, 6874. [Google Scholar] [CrossRef]

- Cheng, X.; Shi, D.; Li, H.; Xia, R.; Zhang, Y.; Zhou, J. Influence of structural parameters on pitching stability of a vertical shiplift. SN Appl. Sci. 2020, 2, 1527. [Google Scholar] [CrossRef]

- Lang, S.; Yang, Z.; Hao, C.; Ji, Z.; Wei, S.; Re, X. Stability analysis of Hoist Vertical Shiplift chamber under pitching motion. IOP conference series. Mater. Sci. Eng. 2019, 631, 32028. [Google Scholar] [CrossRef]

- Wang, X.; Hu, Y.; Li, Z.; Yan, X. Prototype monitoring of mechanical characteristics of large ship lift chamber filling and outleting of water. Hydro-Sci. Eng. 2019, 3, 1–8. [Google Scholar]

- Li, X.; Zheng, F. Experimental and Numerical Investigation of the Water-Exit Behaviour of an Inverted T-Shaped Beam. Adv. Civ. Eng. 2022, 2022, 1–9. [Google Scholar] [CrossRef]

- De Rosis, A.; Tafuni, A. A phase-field lattice Boltzmann method for the solution of water-entry and water-exit problems. Comput.-Aided Civ. Inf. 2022, 37, 832–847. [Google Scholar] [CrossRef]

- Basic, J.; Degiuli, N.D.N.; Werner, A.W.A. Simulation of water entry and exit of a circular cylinder using the ISPH method. T. Famena 2014, 38, 45–62. [Google Scholar]

- Del Buono, A.; Bernardini, G.; Tassin, A.; Iafrati, A. Water entry and exit of 2D and axisymmetric bodies. J. Fluid. Struct. 2021, 103, 103269. [Google Scholar] [CrossRef]

- Breton, T.; Tassin, A.; Jacques, N. Experimental investigation of the water entry and/or exit of axisymmetric bodies. J. Fluid Mech. 2020, 901, 559. [Google Scholar] [CrossRef]

- Korobkin, A.A.; Khabakhpasheva, T.I.; Maki, K.J. Hydrodynamic forces in water exit problems. J. Fluid. Struct. 2017, 69, 16–33. [Google Scholar] [CrossRef] [Green Version]

- Greenhow, M. Water-entry and-exit of a horizontal circular cylinder. Appl. Ocean Res. 1988, 10, 191–198. [Google Scholar] [CrossRef]

- Rajavaheinthan, R.; Greenhow, M. Constant acceleration exit of two-dimensional free-surface-piercing bodies. Appl. Ocean Res. 2015, 50, 30–46. [Google Scholar] [CrossRef]

- Chanson, H. The Hydraulics of Open Channel Flows: An Introduction; Butterworth-Heinemann: Oxford, UK, 2004. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Zheng, F. Investigation into the Water Exit Behavior of a Cavity. Sustainability 2023, 15, 1007. https://doi.org/10.3390/su15021007

Li X, Zheng F. Investigation into the Water Exit Behavior of a Cavity. Sustainability. 2023; 15(2):1007. https://doi.org/10.3390/su15021007

Chicago/Turabian StyleLi, Xueyi, and Feidong Zheng. 2023. "Investigation into the Water Exit Behavior of a Cavity" Sustainability 15, no. 2: 1007. https://doi.org/10.3390/su15021007