Comparative Study on Dyed Fabrics of Tea and Tea Stem Based on Kansei Engineering

Abstract

:1. Introduction

2. Methods

2.1. Making Samples

2.1.1. Making Materials

2.1.2. The Instrument

2.1.3. Production Methods

2.1.4. Production Process

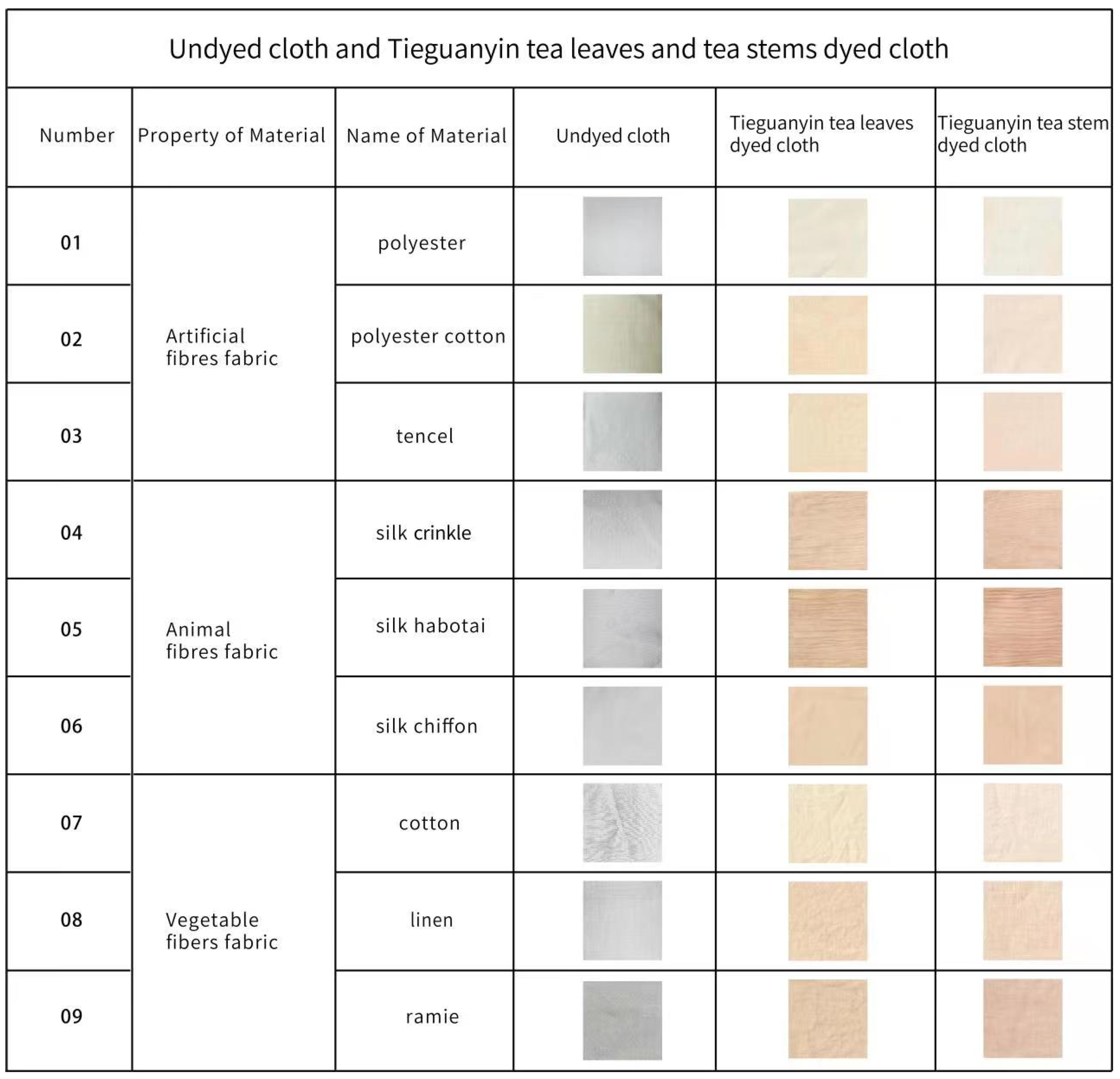

2.1.5. Samples

2.2. Material Perceptual Experience Test

2.2.1. Subjects and Experiment Site

2.2.2. Choosing Perceptual Evaluation Vocabulary

2.2.3. Experiment Method

3. Results and Analysis

3.1. Factor Analysis

3.1.1. Perceptual Evaluation Results of Synthetic Fabric

3.1.2. Perceptual Evaluation Results of Animal Fiber Fabric

3.1.3. Perceptual Evaluation Results of Plant Fiber Fabric

3.2. Factor Analysis

3.2.1. T-Test

3.2.2. Cluster Analysis

4. Discussion

5. Design Practice

5.1. Product Positioning

5.2. Product Design

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yang, L.; Yong, H.; Yinna, L. Study on nutrient components and extraction technology of tea polyphenols from tea stem. Fujian Tea 2019, 41, 12–14. [Google Scholar]

- Ma, X.M.; Pan, T. A Natural Tea Polyphenol Dye from Tieguanyin Tea Stalk and Its Extraction Method and Application. Patent CN110256865A, 20 September 2019. [Google Scholar]

- Cheng, T.H. Dyeing and Functional Modification of Natural Fiber by Tea Stem Extract. Master’s Thesis, Suzhou University, Suzhou, China, 2020. [Google Scholar]

- Amarasinghe, B.; Williams, R.A. Tea waste as a low cost adsorbent for the removal of Cu and Pb from wastewater. Chem. Eng. J. 2007, 132, 299–309. [Google Scholar] [CrossRef]

- Debnath, B.; Haldar, D.; Purkait, M.K. Potential and sustainable utilization of tea waste: A review on present status and future trends. J. Environ. Chem. Eng. 2021, 9, 106179. [Google Scholar] [CrossRef]

- Guo, S.; Awasthi, M.K.; Wang, Y.; Xu, P. Current understanding in conversion and application of tea waste biomass: A review. Bioresour. Technol. 2021, 338, 125530. [Google Scholar] [CrossRef] [PubMed]

- Karana, E.; Barati, B.; Rognoli, V.; Zeeuw Van Der Laan, A. Material driven design (MDD): A method to design for material experiences. Int. J. Des. 2015, 9, 35–54. [Google Scholar]

- Junhua, Z. Investigation analysis in Planning and Design 16—SD Method. Chin. Landsc. Archit. 2004, 10, 57–61. [Google Scholar]

- Ma, X.M.; Pan, T. Extraction of tea polyphenols from Tieguanyin Tea Stem and dyeing on cotton and linen Fabric. Knitt. Ind. 2021, 08, 58–62. [Google Scholar]

- Osgood, C.E. The Measurement of Meaning; University of Illinois Press: Chicago, IL, USA, 1957. [Google Scholar]

- Wenting, D. Tea Dye Application in the Clothing Design Research. Master’s Thesis, Suzhou University, Suzhou, China, 2019. [Google Scholar]

- Gang, T.; Jun, B. Study on the development and mode of Chinese tea dyeing art. Tea Commun. 2020, 47, 164–169. [Google Scholar]

- Yuyan, Z. Innovative Application of “Tea dyeing” Technique in Silk Women’s Dress Design. Master’s Thesis, Beijing Institute of Fashion Technology, Beijing, China, 2013. [Google Scholar]

| Item | Factor 1 | Factor 2 |

|---|---|---|

| Bright–Dark | 0.792 | |

| Soft–Stiff | 0.935 | |

| Light–Thick | 0.906 | |

| Smooth–Rough | 0.916 | |

| Elegant–Vulgar | 0.693 | |

| Costly–Cheap | 0.792 | |

| Classical–Modern | 0.895 | |

| Natural–Artificial | 0.923 | |

| Eigenvalue | 4.320 | 2.319 |

| Contribution rate | 53.994 | 28.988 |

| Cumulative contribution rate | 53.994 | 82.982 |

| Cloth/Sense | Tencel | Polyester | Polyester–Cotton | Silk Habotai | Silk Crinkle | Silk Chiffon | Cotton | Linen | Ramie |

|---|---|---|---|---|---|---|---|---|---|

| Comfort, value | *** | ||||||||

| Naturalness, age | *** |

| Type | The Name of the Fabric | The Factor Score |

|---|---|---|

| Synthetic fiber fabric | Tencel (tea leaves dyeing) | 1.13 |

| entry 2 | Tencel (tea stems dyeing) | 0.9 |

| Polyester (tea leaves dyeing) | 0.4 | |

| Polyester (tea stems dyeing) | 0.4 | |

| Polyester–cotton (tea leaves dyeing) | 0.33 | |

| Polyester–cotton (tea stems dyeing) | 0.27 | |

| Animal fiber fabric | Silk Chiffon (tea leaves dyeing) | 0.4 |

| Silk Chiffon (tea stems dyeing) | 1.42 | |

| Silk Habotai (tea leaves dyeing) | −0.14 | |

| Silk Habotai (tea stems dyeing) | −0.43 | |

| Silk Crinkle (tea leaves dyeing) | −0.51 | |

| Silk Crinkle (tea stems dyeing) | −0.46 | |

| Plant fiber fabric | Cotton (tea leaves dyeing) | 0.33 |

| Cotton (tea stems dyeing) | 0.22 | |

| Linen (tea leaves dyeing) | −0.94 | |

| Linen (tea stems dyeing) | −1.19 | |

| Ramie (tea leaves dyeing) | −0.76 | |

| Ramie (tea stems dyeing) | −1.04 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, L.; Dai, X.; Meng, Y.; Zhou, L.; Yue, X. Comparative Study on Dyed Fabrics of Tea and Tea Stem Based on Kansei Engineering. Sustainability 2023, 15, 1134. https://doi.org/10.3390/su15021134

Yang L, Dai X, Meng Y, Zhou L, Yue X. Comparative Study on Dyed Fabrics of Tea and Tea Stem Based on Kansei Engineering. Sustainability. 2023; 15(2):1134. https://doi.org/10.3390/su15021134

Chicago/Turabian StyleYang, Li, Xudong Dai, Yuke Meng, Lin Zhou, and Xinyu Yue. 2023. "Comparative Study on Dyed Fabrics of Tea and Tea Stem Based on Kansei Engineering" Sustainability 15, no. 2: 1134. https://doi.org/10.3390/su15021134