Sustainability Impacts of Wood- and Concrete-Based Frame Buildings

Abstract

:1. Introduction

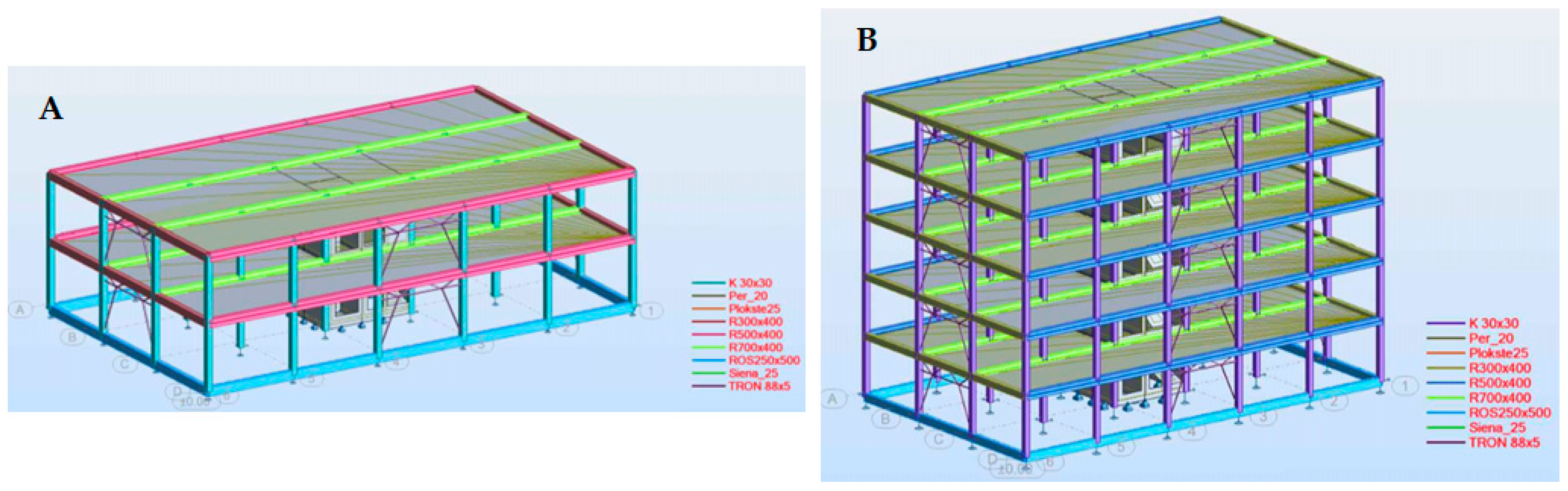

2. Materials and Methods

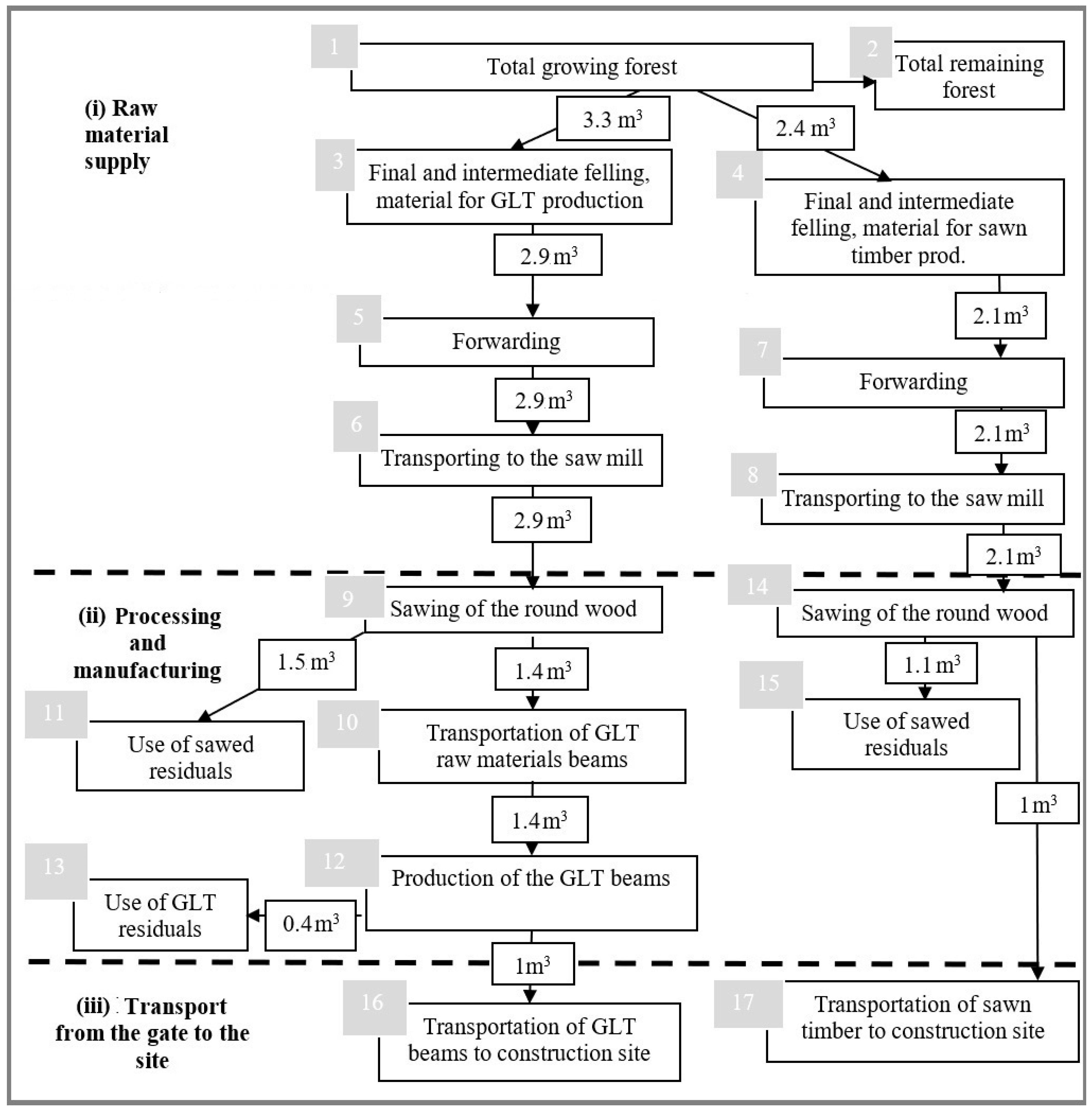

2.1. Value Chain Topology, Assumptions and Sources of Data

2.2. The Indicators Used

2.3. Study Description

2.4. ToSIA Approach and Result Processing

3. Results

3.1. The Main Differences between Wood- and Concrete-Based Frame Buildings

3.2. Environmental Impacts of Wood- and Concrete-Based Frame Buildings

3.3. Social Impacts of Wood- and Concrete-Based Frame Buildings

3.4. Economic Impacts of Wood- and Concrete-Based Frame Buildings

3.5. CO2 Emissions of Wood- and Concrete-Based Frame Buildings

4. Discussion

4.1. Sustainability Impacts of Wood- and Concrete-Based Frame Buildings

4.2. Benefits at the National Level

4.3. Policy Recommendations Based on Our Study and Stakeholders’ View

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Scarlat, N.; Dallemand, J.F.; Monforti-Ferrario, F.; Nita, V. The role of biomass and bioenergy in a future bioeconomy: Policies and facts. Environ. Dev. 2015, 15, 3–34. [Google Scholar] [CrossRef]

- Gustafsson, L.; Haus, S.; Lundblad, M.; Lundström, A.; Ortiz, C.A.; Sathre, R.; Truong, N.L.; Wikberg, P.-E. Climate change effects of forestry and substitution of carbon-intensive materials and fossil fuels. Renew. Sustain. Energy Rev. 2017, 67, 612–624. [Google Scholar] [CrossRef]

- Gustavsson, L.; Nguyen, T.; Sathre, R.; Tettey, U. Climate effects of forestry and substitution of concrete buildings and fossil energy. Renew. Sustain. Energy Rev. 2021, 136, 110435. [Google Scholar] [CrossRef]

- Nabuurs, G.-J.; Delacote, P.; Ellison, D.; Hanewinkel, M.; Lindner, M.; Nesbit, M.; Ollikainen, M.; Savaresi, A. A New Role for Forests and the Forest Sector in the EU Post-2020 Climate Targets. From Science to Policy 2; European Forest Institute: Joensuu, Finland, 2015. [Google Scholar] [CrossRef]

- Pilli, R.; Fiorese, G.; Grassi, G. EU mitigation potential of harvested wood products. Carbon Balance Manag. 2015, 10, 6. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jensen, L. EU Climate Target Plan Raising the Level of Ambition for 2030. Briefing—Towards Climate Neutrality. European Parliament. 2020. Available online: https://www.europarl.europa.eu/RegData/etudes/BRIE/2020/659370/EPRS_BRI(2020)659370_EN.pdf (accessed on 5 January 2022).

- Cabinet of Ministers. National Energy and Climate Action Plan of the Republic of Lithuania for 2021–2030. 2020. Available online: https://am.lrv.lt/uploads/am/documents/files/KLIMATO%20KAITA/Integruotas%20planas/Final%20NECP.pdf (accessed on 5 January 2022).

- Ministry of Environment of Lithuania, State Forest Service. Lithuanian Statistical Yearbook of Forestry. 2021, p. 184. Available online: http://www.amvmt.lt/images/veikla/stat/miskustatistika/2021/01%20Misku%20ukio%20statistika%202021_m.pdf (accessed on 5 January 2022).

- Vitunskienė, V.; Miceikienė, A.; Aleknevičienė, V.; Čaplikas, J.; Miškinis, V.; Pilverte, I.; Makutėnienė, D.; Dabkienė, V.; Lekavičius, V.; Øistad, K.; et al. Lithuanian Bioeconomy Development Feasibility Study; Aleksandras Stulginskis University: Kaunas, Lithuania, 2017; p. 179. [Google Scholar]

- Ministry of Environment of Lithuania, State Forest Service. Lithuanian Statistical Yearbook of Forestry. 2020, p. 184. Available online: http://www.amvmt.lt/images/veikla/stat/miskustatistika/2020/01%20Misku%20ukio%20statistika%202020_m.pdf (accessed on 5 January 2022).

- Lehne, J.; Preston, F. Making Concrete Change Innovation in Low-Carbon Cement and Concrete; Chatham House: London, UK, 2018; p. 122. Available online: https://www.chathamhouse.org/sites/default/files/publications/2018-06-13-making-concrete-change-cement-lehne-preston-final.pdf (accessed on 5 January 2022).

- Mahapatra, K.; Gustavsson, L.; Hemström, K. Multi-storey wood-frame buildings in Germany, Sweden and the UK. Constr. Innov. 2012, 12, 62–85. [Google Scholar] [CrossRef]

- Ramage, M.H.; Burridge, H.; Busse-Wicher, M.; Fereday, G.; Reynolds, T.; Shah, D.S.; Wu, G.; Yu, L.; Fleming, P.; Densley-Tingley, D.; et al. The wood from the trees: The use of timber in construction. Renew. Sustain. Energy Rev. 2017, 68, 333–359. [Google Scholar] [CrossRef]

- Markström, E.; Kuzman, M.K.; Bystedt, A.; Sandberg, D.; Fredriksson, M. Swedish architects view of engineered wood products in buildings. J. Clean. Prod. 2018, 181, 33–41. [Google Scholar] [CrossRef]

- Bruno, R.; Bevilacqua, P.; Cuconati, T.; Arcuri, N. Energy evaluations of an innovative multi-storey wooden near Zero Energy Building designed for Mediterranean areas. Appl. Energy 2019, 238, 929–941. [Google Scholar] [CrossRef]

- Lazarevic, D.; Kautto, P.; Antikainen, R. Finland’s wood-frame multi-storey construction innovation system: Analysing motors of creative destruction. Policy Econ. 2020, 110, 101861. [Google Scholar] [CrossRef]

- Petruch, M.; Walcher, D. Timber for future? Attitudes towards timber construction by young millennials in Austria—Marketing implications from a representative study. J. Clean. Prod. 2021, 294, 126324. [Google Scholar] [CrossRef]

- Lu, H.R.; El Hanandeh, A.; Gilbert, B.P. A comparative life cycle study of alternative materials for Australian multi-storey apartment building frame constructions: Environmental and economic perspective. J. Clean. Prod. 2017, 166, 458–473. [Google Scholar] [CrossRef]

- Hurmekoski, E.; Jonsson, R.; Nord, T. Context, drivers, and future potential for wood-frame multi-story construction in Europe. Technol. Forecast. Soc. Chang. 2015, 99, 181–196. [Google Scholar] [CrossRef]

- Mallo, M.F.L.; Espinoza, O. Awareness, perceptions and willingness to adopt Cross-Laminated Timber by the architecture community in the United States. J. Clean. Prod. 2015, 94, 198–210. [Google Scholar] [CrossRef]

- Hurmekoski, E. Long-term outlook for wood construction in Europe. Diss. For. 2016, 211, 57. [Google Scholar] [CrossRef] [Green Version]

- Toivonen, R.; Lilja, A.; Vihemäki, H.; Toppinen, A. Future export markets of industrial wood construction—A qualitative backcasting study. For. Policy Econ. 2021, 128, 102480. [Google Scholar] [CrossRef]

- Minunno, R.; O’Grady, T.; Morrison, G.M.; Gruner, R.L. Investigating the embodied energy and carbon of buildings: A systematic literature review and meta-nanlyses of life cycle assessments. Renew. Sustain. Energy Rev. 2021, 143, 110935. [Google Scholar] [CrossRef]

- Hildebrandt, J.; Hagemann, N.; Thrän, D. The contribution of wood-based construction materials for leveraging a low carbon building sector in europe. Sustain. Cities Soc. 2017, 34, 405–418. [Google Scholar] [CrossRef]

- Sikkema, R.; Styles, D.; Jonsson, R.; Tobin, B.; Byrne, K. A market inventory of construction wood for residential building in Europe—In the light of the Green Deal and new circular economy ambitions. Sustain. Cities Soc. 2023, 90, 104370. [Google Scholar] [CrossRef]

- Žemaitis, P.; Linkevičius, E.; Aleinikovas, M.; Tuomasjukka, D. Sustainability impact assessment of glue laminated timber and concrete-based building materials production chains—A Lithuanian case study. J. Clean. Prod. 2021, 321, 129005. [Google Scholar] [CrossRef]

- Pajchrowski, G.; Noskowiak, A.; Lewandowska, A.; Strykowski, W. Wood as a building material in the light of environmental assessment of full life cycle of four buildings. Constr. Build. Mater. 2014, 52, 428–436. [Google Scholar] [CrossRef]

- Cordier, S.; Robichaud, F.; Blanchet, P.; Amor, B. Regional environmental life cycle consequences of material substitutions: The case of increasing wood structures for non-residential buildings. J. Clean. Prod. 2021, 328, 129671. [Google Scholar] [CrossRef]

- Hafner, A.; Schäfer, S. Comparative LCA study of different timber and mineral buildings and calculation method for substitution factors on building level. J. Clean. Prod. 2017, 167, 630–642. [Google Scholar] [CrossRef]

- Younis, A.; Dodoo, A. Cross-laminated timber for building construction: A life-cycle-assessment overview. J. Build. Eng. 2022, 52, 104482. [Google Scholar] [CrossRef]

- Sathre, R.; González-García, S. Life Cycle Assessment (LCA) of Wood-Based Building Materials. In Eco-Efficient Construction and Building Materials; Pacheco-Torgal, F., Cabeza, L.F., Labrincha, J., de Magalhaes, A., Eds.; Woodhead Publishing: Soston, UK, 2014; pp. 311–337. [Google Scholar]

- Balasbaneh, A.T.; Sher, W.; Yeoh, D.; Koushfar, K. LCA & LCC analysis of hybrid glued laminated Timber–Concrete composite floor slab system. J. Build. Eng. 2022, 49, 104005. [Google Scholar] [CrossRef]

- Estévez-Cimadevila, J.; Martín-Gutiérrez, E.; Suárez-Riestra, F.; Otero-Chans, D.; Vázquez-Rodríguez, J. Timber-concrete composite structural flooring system. J. Build. Eng. 2022, 49, 104078. [Google Scholar] [CrossRef]

- D’Amico, B.; Pomponi, F.; Hart, J. Global potential for material substitution in building construction: The case of cross laminated timber. J. Clean. Prod. 2021, 279, 123487. [Google Scholar] [CrossRef]

- Saade, M.R.M.; Guest, G.; Amor, B. Comparative whole building LCAs: How far are our expectations from the documented evidence? Build Env. 2020, 167, 106449. [Google Scholar] [CrossRef]

- Nässén, J.; Hedenus, F.; Karlsson, S.; Holmberg, J. Concrete vs. wood in buildings–An energy system approach. Build Environ. 2012, 51, 361–369. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Rincón, L.; Vilariño, V.; Pérez, G.; Castell, A. Life cycle assessment (LCA) and life cycle energy analysis (LCEA) of buildings and the building sector: A review. Renew. Sustain. Energy Rev. 2014, 29, 394–416. [Google Scholar] [CrossRef]

- Amiri, A.; Ottelin, J.; Sorvari, J.; Junnila, S. Cities as carbon sinks—Classification of wooden buildings. Environ. Res. Lett. 2020, 15, 094076. [Google Scholar] [CrossRef]

- Börjesson, P.; Gustavsson, L. Greenhouse gas balances in building construction: Wood versus concrete from life-cycle and forest land-use perspectives. Energy Policy 2000, 28, 575–588. [Google Scholar] [CrossRef]

- Balasbaneh, A.T.; Sher, W. Comparative sustainability evaluation of two engineered wood-based construction materials: Life cycle analysis of CLT versus GLT. Build. Environ. 2021, 204, 108112. [Google Scholar] [CrossRef]

- Gerilla, G.; Teknomo, K.; Hokao, K. An environmental assessment of wood and steel reinforced concrete housing construction. Build. Environ. 2007, 42, 2778–2784. [Google Scholar] [CrossRef]

- Balasbaneh, A.T.; Sher, W.; Yeoh, D.; Yasin, M.N. Economic and environmental life cycle perspectives on two engineered wood products: Comparison of LVL and GLT construction materials. Environ. Sci. Pollut. Res. 2022. [Google Scholar] [CrossRef] [PubMed]

- Lolli, N.; Fufa, S.M.; Wiik, M.K. An assessment of greenhouse gas emissions from CLT and glulam in two residential nearly zero energy buildings. Wood Mater. Sci. Eng. 2019, 14, 342–354. [Google Scholar] [CrossRef] [Green Version]

- Hassan, O.A.B.; Emad, A.A.N.; Abdulahad, G. A comparative study between glulam and concrete columns in view of design, economy and environment. Case Stud. Constr. Mater. 2022, 16, e00966. [Google Scholar] [CrossRef]

- Knauf, M.; Köhl, M.; Mues, V.; Olschofsky, K.; Frühwald, A. Modeling the CO2 effects of forest management and wood usage on a regional basis. Carbon Balance Manag. 2015, 10, 13. [Google Scholar]

- Lindner, M.; Suominen, T.; Palosuo, T.; Garcia-Gonzalo, J.; Verweij, P.; Zudin, S.; Päivinen, R. ToSIA—A tool for sustainability impact assessment of forest-wood-chains. Ecol. Model. 2010, 221, 2197–2205. [Google Scholar] [CrossRef]

- Bates, J.S. Ketso: A New Tool for Extension Professionals; Ohio State University: Columbus, OH, USA, 2016. [Google Scholar]

- McIntosh, A.J.; Cockburn-Wootten, C. Using Ketso for engaged tourism scholarship. Ann. Tour. Res. 2016, 56, 148–151. [Google Scholar] [CrossRef]

- Climate Change Connection. CO2 Equivalents. Official Climate Change Connection Portal. Available online: https://climatechangeconnection.org/emissions/co2-equivalents/ (accessed on 12 July 2019).

- Deep Resource. Energy Related Conversion Factors. 2019. Available online: https://deepresource.wordpress.com/2012/04/23/energy-related-conversion-factors/ (accessed on 1 January 2021).

- Sathre, R.; O’Connor, J. Meta-analysis of greenhouse gas displacement factors of wood product substitution. Environ. Sci. Policy 2010, 13, 104–114. [Google Scholar] [CrossRef]

- Hiraishi, T.; Krug, T.; Tanabe, K.; Srivastava, N.; Baasansuren, J.; Fukuda, M.; Troxler, T. Revised Supplementary Methods and Good Practice Guidance Arising from the Kyoto Protocol; Intergovernmenntal Panel on Climate Change: Geneva, Switzerland, 2013; Available online: https://www.ipcc-nggip.iges.or.jp/public/kpsg/pdf/KP_Supplement_Entire_Report.pdf (accessed on 1 January 2021).

- Sandanayake, M.Y.; Lokuge, W.; Zhang, G.; Setunge, S.; Thushar, Q. Greenhouse gas emissions during timber and concrete building construction—A scenario based comparative case study. Sustain. Cities Soc. 2018, 38, 91–97. [Google Scholar] [CrossRef] [Green Version]

- Leskinen, P.; Cardellini, G.; González-García, S.; Hurmekoski, E.; Sathre, R.; Seppälä, J.; Smyth, C.; Stern, T.; Verkerk, P.J. Substitution Effects of Wood-Based Products in Climate Change Mitigation: From Science to Policy 7; European Forest Institute: Joensuu, Finland, 2018. [Google Scholar]

- Myllyviita, T.; Soimakallio, S.; Judl, J.; Seppälä, J. Wood substitution potential in greenhouse gas emission reduction–review on current state and application of displacement factors. For. Ecosyst. 2021, 8, 42. [Google Scholar] [CrossRef]

- Hurmekoski, E.; Myllyviita, T.; Seppälä, J.; Heinonen, T.; Kilpeläinen, A.; Pukkala, T.; Mattila, T.; Hetemäki, L.; Asikainen, A.; Peltola, H. Impact of structural changes in wood-using industries on net carbon emissions in Finland. J. Ind. Ecol. 2020, 24, 899–912. [Google Scholar] [CrossRef]

- Härtl, F.H.; Höllerl, S.; Knoke, T. A new way of carbon accounting emphasises the crucial role of sustainable timber use for successful carbon mitigation strategies. Mitig. Adapt. Strat. Glob. Chang. 2017, 22, 1163–1192. [Google Scholar] [CrossRef]

- Petersen, A.K.; Solberg, B. Greenhouse gas emissions, life-cycle inventory and cost-efficiency of using laminated wood instead of steel construction.: Case: Beams at Gardermoen airport. Environ. Sci. Policy 2002, 5, 169–182. [Google Scholar] [CrossRef]

- Petersen, A.K.; Solberg, B. Substitution between floor constructions in wood and natural stone: Comparison of energy consumption, greenhouse gas emissions, and costs over the life cycle. Can. J. For. Res. 2003, 33, 1061–1075. [Google Scholar] [CrossRef]

- Gustavsson, L.; Pingoud, K.; Sathre, R. Carbon Dioxide Balance of Wood Substitution: Comparing Concrete- and Wood-Framed Buildings. Mitig. Adapt. Strat. Glob. Chang. 2006, 11, 667–691. [Google Scholar] [CrossRef]

- Dodoo, A.; Gustavsson, L.; Sathre, R. Carbon implications of end-of-life management of building materials. Resour. Conserv. Recycl. 2009, 53, 276–286. [Google Scholar] [CrossRef]

- Yadav, A.; Yadav, A.; Jamwal, A.; Agrawal, R. Life cycle assessment and Life cycle energy analysis of buildings: A review. Manuf. Technol. Res. 2021, 14, 9. [Google Scholar]

- Soust-Verdaguer, B.; Llatas, C.; Moya, L. Comparative BIM-based Life Cycle Assessment of Uruguayan timber and concrete-masonry single-family houses in design stage. J. Clean. Prod. 2020, 277, 121958. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Barreneche, C.; Miró, L.; Morera, J.M.; Bartolí, E.; Fernández, A.I. Low carbon and low embodied energy materials in buildings: A review. Renew. Sustain. Energy Rev. 2013, 23, 536–542. [Google Scholar] [CrossRef]

- Eckelman, M.J.; Brown, C.; Troup, L.N.; Wang, L.; Webster, M.D.; Hajjar, J.F. Life cycle energy and environmental benefits of novel design-for-deconstruction structural systems in steel buildings. Build. Environ. 2018, 143, 421–430. [Google Scholar] [CrossRef]

- Jensen, L.; Seppälä, V. Climate Action in Lithuania Latest State of Play. Briefing—EU Progress on Climate Action—How Are the Member States Doing? European Parliament: Strasbourg, France. 2021. Available online: https://www.europarl.europa.eu/RegData/etudes/BRIE/2021/690683/EPRS_BRI(2021)690683_EN.pdf (accessed on 5 January 2022).

| No. | Indicator | Unit | Definition |

|---|---|---|---|

| Environmental | |||

| 1. | GHG emissions | t CO2eq./m2 | Emissions expressed as GWP for 100 years. Values for CO2eq. were selected as presented in [49]. CO2, CH4, N2O emissions are converted to the CO2eq. by using GWP factors: CO2 = 1, CH4 = 25, N2O = 298. All emissions throughout value chain processes were included in calculation. |

| 2. | Energy consumption | MJ/m2 | All energy used in processes. This includes diesel, CNG, electricity from grid and heat. Conversion factors were used as presented in [50]. |

| 3. | Water consumption | m3/m2 | Total freshwater intake by industry throughout value chain processes. |

| 4. | Generation of waste | t/m2 | Generation of hazardous and non-hazardous waste in tons per reporting unit. |

| 5. | Volume of non-renewable materials | t/m2 | Total volume of extracted non-renewable material throughout value chain processes. |

| 6. | Carbon inflow into the pool | tC/m2 | Biogenetic carbon storage in the wood [definition presented in 49]. Carbon capture and storage in cement were not calculated. |

| 7. | WDF (GLT) | tC/tC | WDF definition used as presented in Sathre and O’Connor [51]. The indicator is a measure of tC emission reduction per tC contained in wood products. |

| Social | |||

| 8. | Employment | Full time equivalent (FTE)/unit | Number of persons (expressed as FTE) employed in total throughout value chain processes per production unit. |

| 9. | Occupational accidents | Cases/m2 | Total number of fatal and non-fatal occupational accidents. In this study indicator was calculated per 1000 employees per reporting unit (m2). |

| 10. | Wages and salaries | EUR/m2 | Total wages and salaries (EUR) per reporting unit. |

| Economic | |||

| 11. | Product price | EUR/m2 | Average production price (EUR). |

| Construction Elements | Material | |||||||

|---|---|---|---|---|---|---|---|---|

| C8-10 (m3) | C20/25 XC2 (m3) | C25-30 XC2 (m3) | C30-37 X0 (m3) | Rebar S500 (t) | Joints Steel S355 (t) | GLT GL28h (m3) | ST C24 (m3) | |

| Drilled piles foundation | - | 16.03 | - | - | 2.56 | - | - | - |

| Basis for pile caps | 3.26 | - | - | - | - | - | - | - |

| Pile caps | - | 12.22 | - | - | 1.22 | 0.30 | - | - |

| Plinth beam | - | - | 9.71 | - | 1.16 | 0.96 | - | - |

| First floor columns | - | - | - | - | - | 2.67 | 4.32 | - |

| Walls shaft for lift and stairs | - | - | - | 41.47 | 4.15 | 0.20 | - | - |

| First floor beams | - | - | - | - | - | 0.50 | 17.35 | - |

| First floor joist beams and decking beams | - | - | - | - | - | - | - | 13.94 |

| Second floor columns | - | - | - | - | - | 1.58 | 4.12 | - |

| Steel (S355) joints | - | - | - | - | - | 0.79 | - | - |

| Second floor beams | - | - | - | - | - | 0.50 | 15.48 | - |

| Second floor ceiling beams and decking beams | - | - | - | - | - | - | - | 14.99 |

| Total material | 3.26 | 28.25 | 9.71 | 41.47 | 9.10 | 7.50 | 41.27 | 28.93 |

| Construction Elements | Material | |||||||

|---|---|---|---|---|---|---|---|---|

| C8-10 (m3) | C20/25 XC2 (m3) | C25-30 XC2 (m3) | C30-37 X0 (m3) | Rebar S500 (t) | Joints Steel S355 (t) | GLT GL28h (m3) | ST C24 (m3) | |

| Drilled piles foundation | - | 48.06 | - | - | 7.45 | - | - | - |

| Basis for pile caps | - | - | 4.56 | - | - | - | - | - |

| Pile caps | - | - | 23.94 | - | 2.39 | 0.40 | - | - |

| Plinth beam | - | - | 9.33 | - | 1.12 | 0.96 | - | - |

| First floor columns | - | - | - | - | - | 3.59 | 7.38 | - |

| Walls shaft for lift and stairs | - | - | - | 121.88 | 12.19 | 1.00 | - | - |

| First-fifth floor beams | - | - | - | - | - | 2.12 | 72.46 | - |

| First-fifth floor joist beams and decking beams | - | - | - | - | - | - | - | 55.77 |

| Second-fifth floor columns | - | - | - | - | - | 9.60 | 27.52 | - |

| Steel (S355) joints | - | - | - | - | - | 3.15 | - | - |

| Fifth floor beams | - | - | - | - | - | 0.50 | 15.48 | - |

| Fifth floor ceiling beams and decking beams | - | - | - | - | - | - | - | 14.99 |

| Total material | 0.00 | 48.06 | 37.82 | 121.88 | 23.15 | 21.32 | 122.84 | 70.75 |

| Construction Elements | Material | |||||

|---|---|---|---|---|---|---|

| C8-10 (m3) | C20/25 XC2 (m3) | C25-30 XC2 (m3) | C30-37 X0 (m3) | Rebar S500 (t) | Joints Steel S355 (t) | |

| Precast Reinforced Concrete Material | ||||||

| First floor columns | - | - | - | 8.83 | 0.88 | 1.44 |

| First floor beam header | - | - | - | 19.76 | 2.37 | 1.26 |

| First floor supported slab | - | - | - | 39.90 | 1.99 | - |

| Second floor columns | - | - | - | 7.58 | 0.76 | 1.44 |

| Second floor beam header | - | - | - | 20.13 | 2.42 | 1.26 |

| Second floor joist slab | - | - | - | 43.05 | 2.15 | - |

| Subtotal material | - | - | - | 139.26 | 10.58 | 5.40 |

| Site-cast concrete material | ||||||

| Drilled piles foundation | - | 25.64 | - | - | 4.10 | - |

| Basis for pile caps | 3.66 | - | - | - | - | - |

| Pile caps | - | - | 13.66 | - | 1.37 | 0.36 |

| Plinth beam | - | - | 10.09 | - | 1.21 | 0.96 |

| First floor columns monolitization | - | - | - | 0.44 | - | - |

| First floor steel joints | - | - | - | - | - | 0.68 |

| Walls shaft for lift and stairs | - | - | - | 28.90 | 2.89 | 1.20 |

| Monolitization of supported slab | - | - | - | 4.50 | 0.45 | - |

| First floor topping of supported slab | - | - | 21.60 | - | 0.53 | - |

| Monolitization of the columns | - | - | - | 0.44 | - | - |

| Steel joints | - | - | - | - | - | 0.68 |

| Monolitization of joint slabs | - | - | - | 4.70 | 0.47 | - |

| Subtotal material | 3.66 | 25.64 | 45.35 | 38.98 | 11.02 | 3.88 |

| Total material | 3.66 | 25.64 | 45.35 | 178.24 | 21.60 | 9.28 |

| Construction Elements | Material | |||||

|---|---|---|---|---|---|---|

| C8-10 (m3) | C20/25 XC2 (m3) | C25-30 XC2 (m3) | C30-37 X0 (m3) | Rebar S500 (t) | Joints Steel S355 (t) | |

| Precast Reinforced Concrete Material | ||||||

| First floor columns | - | - | - | 8.83 | 0.88 | 1.44 |

| First-fourth floor beam header | - | - | - | 97.05 | 9.49 | 5.04 |

| First-fourth floor supported slab | - | - | - | 177.60 | 9.78 | - |

| Second-fourth floor columns | - | - | - | 22.32 | 2.23 | 4.32 |

| Fifth floor column | - | - | - | 7.58 | 0.76 | 1.44 |

| Beam header | - | - | - | 20.13 | 2.42 | 1.26 |

| Joist slab | - | - | - | 43.05 | 2.15 | - |

| Subtotal | - | - | - | 376.57 | 27.71 | 13.50 |

| Site-cast concrete material | ||||||

| Drilled piles foundation | - | 25.64 | - | - | 4.102 | - |

| Basis for pile caps | - | 9.97 | - | - | - | - |

| Pile caps | - | - | 55.82 | - | 5.582 | 0.48 |

| Plinth beam | - | - | 10.09 | - | 1.21 | 0.96 |

| First floor columns monolitization | - | - | - | 0.444 | - | - |

| First floor steel joints | - | - | - | - | - | 0.68 |

| Walls shaft for lift and stairs | - | - | - | 106.5 | 10.65 | 3.0 |

| Second-fourth floor supported slabs topping | - | - | 86.40 | - | 2.12 | - |

| Second-fifth floor columns monolitization | - | - | - | 1.824 | - | - |

| Steel joints | - | - | - | - | - | 2.72 |

| Monolitization of joint slabs | - | - | - | 4.7 | 0.47 | - |

| Subtotal | - | 35.61 | 152.31 | 113.47 | 24.13 | 7.84 |

| Total | - | 35.61 | 152.31 | 490.04 | 51.84 | 21.34 |

| Indicator | Units | Two-Floor GLT | Five-Floor GLT | Two-Floor PRC | Five-Floor PRC |

|---|---|---|---|---|---|

| Environmental | |||||

| GHG emissions | t CO2eq/m2 | 0.0874 | 0.0899 | 0.2080 | 0.2190 |

| Generation of waste | t/1000 m2 | 0.0009 | 0.0010 | 0.0026 | 0.0026 |

| Water consumption | m3/m2 | 0.23 | 0.24 | 0.85 | 0.84 |

| Energy consumption | MJ/m2 | 510.0 | 518.0 | 1482.0 | 1519.0 |

| Volume of non-renewable materials | t/m2 | 0.327 | 0.333 | 0.970 | 1.030 |

| Carbon inflow into the pool | tC/m2 | 0.0275 | 0.0304 | 0 | 0 |

| WDF (GLT and ST) | tC/tC | 1.43 | 1.34 | 0 | 0 |

| Social | |||||

| Employment | FTE/1000 m2 | 0.52 | 0.54 | 1.30 | 1.41 |

| Wages and salaries | EUR/m2 | 6.94 | 7.29 | 16.53 | 17.89 |

| Occupational accidents | Cases/1000 m2 | 0.012 | 0.011 | 0.788 | 0.855 |

| Economic | |||||

| Production price | EUR/m2 | 48.05 | 46.93 | 74.00 | 68.68 |

| Building Type | Concrete-Based Building, tC | Wood-Based Building, tC | C Contained in the Wood-Based Frame Building, tC | C Contained in Concrete-Based Frame Building, tC |

|---|---|---|---|---|

| Two-floor (765 m2) | 159.12 | 66.89 | 17.55 | 0.00 |

| Five-floor (1913 m2) | 418.18 | 171.98 | 48.39 | 0.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Linkevičius, E.; Žemaitis, P.; Aleinikovas, M. Sustainability Impacts of Wood- and Concrete-Based Frame Buildings. Sustainability 2023, 15, 1560. https://doi.org/10.3390/su15021560

Linkevičius E, Žemaitis P, Aleinikovas M. Sustainability Impacts of Wood- and Concrete-Based Frame Buildings. Sustainability. 2023; 15(2):1560. https://doi.org/10.3390/su15021560

Chicago/Turabian StyleLinkevičius, Edgaras, Povilas Žemaitis, and Marius Aleinikovas. 2023. "Sustainability Impacts of Wood- and Concrete-Based Frame Buildings" Sustainability 15, no. 2: 1560. https://doi.org/10.3390/su15021560

APA StyleLinkevičius, E., Žemaitis, P., & Aleinikovas, M. (2023). Sustainability Impacts of Wood- and Concrete-Based Frame Buildings. Sustainability, 15(2), 1560. https://doi.org/10.3390/su15021560