RoboDoc: Smart Robot Design Dealing with Contagious Patients for Essential Vitals Amid COVID-19 Pandemic

Abstract

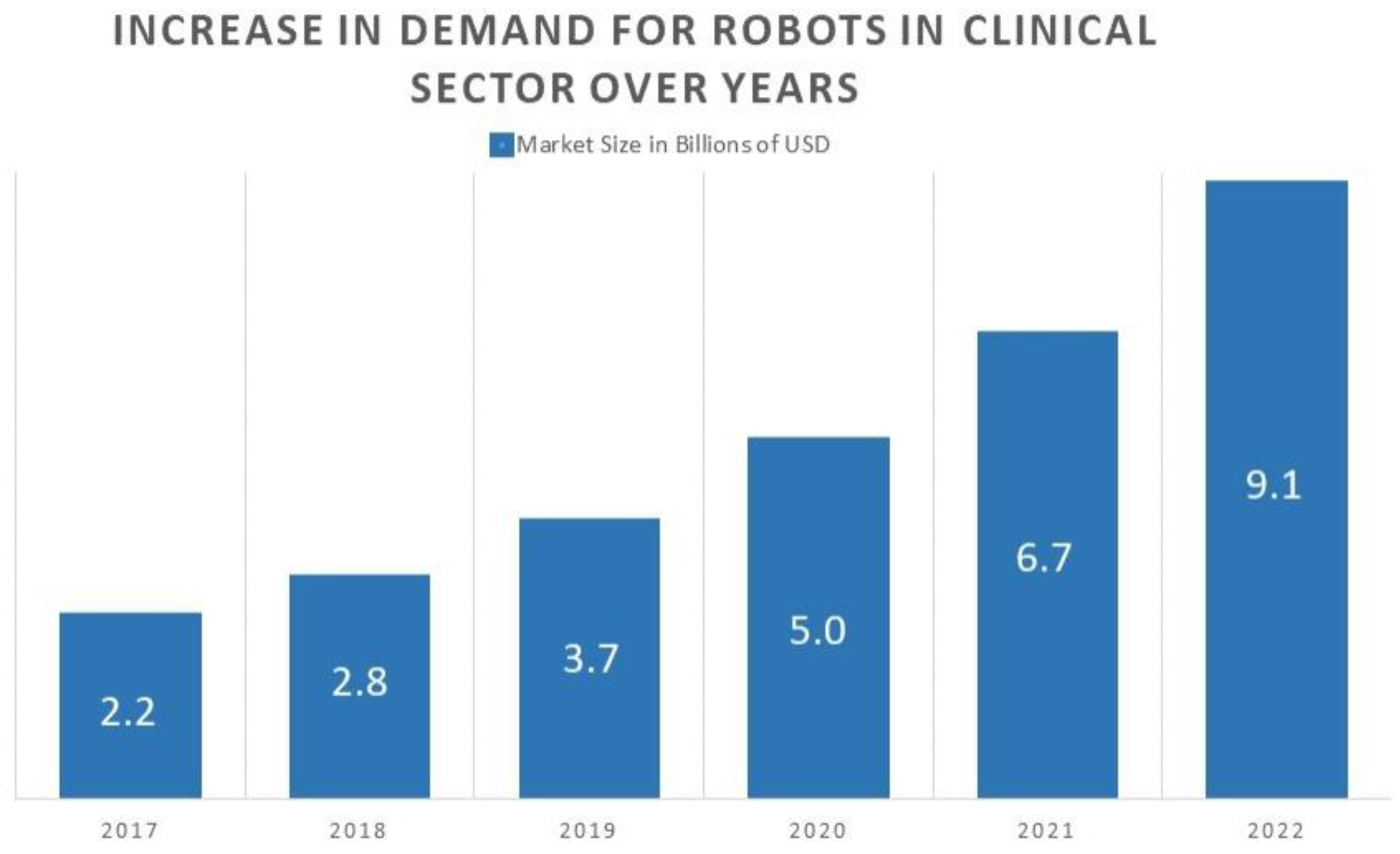

:1. Introduction

2. Modeling and Design of Mechanical Hardware

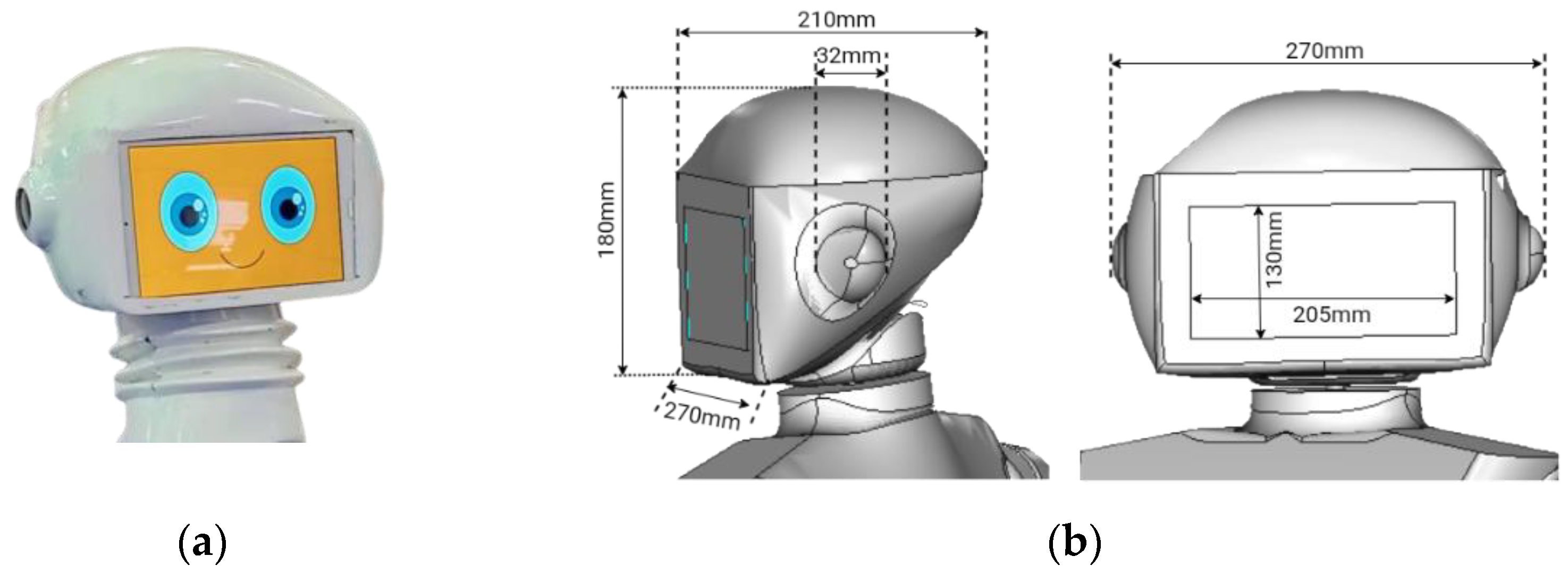

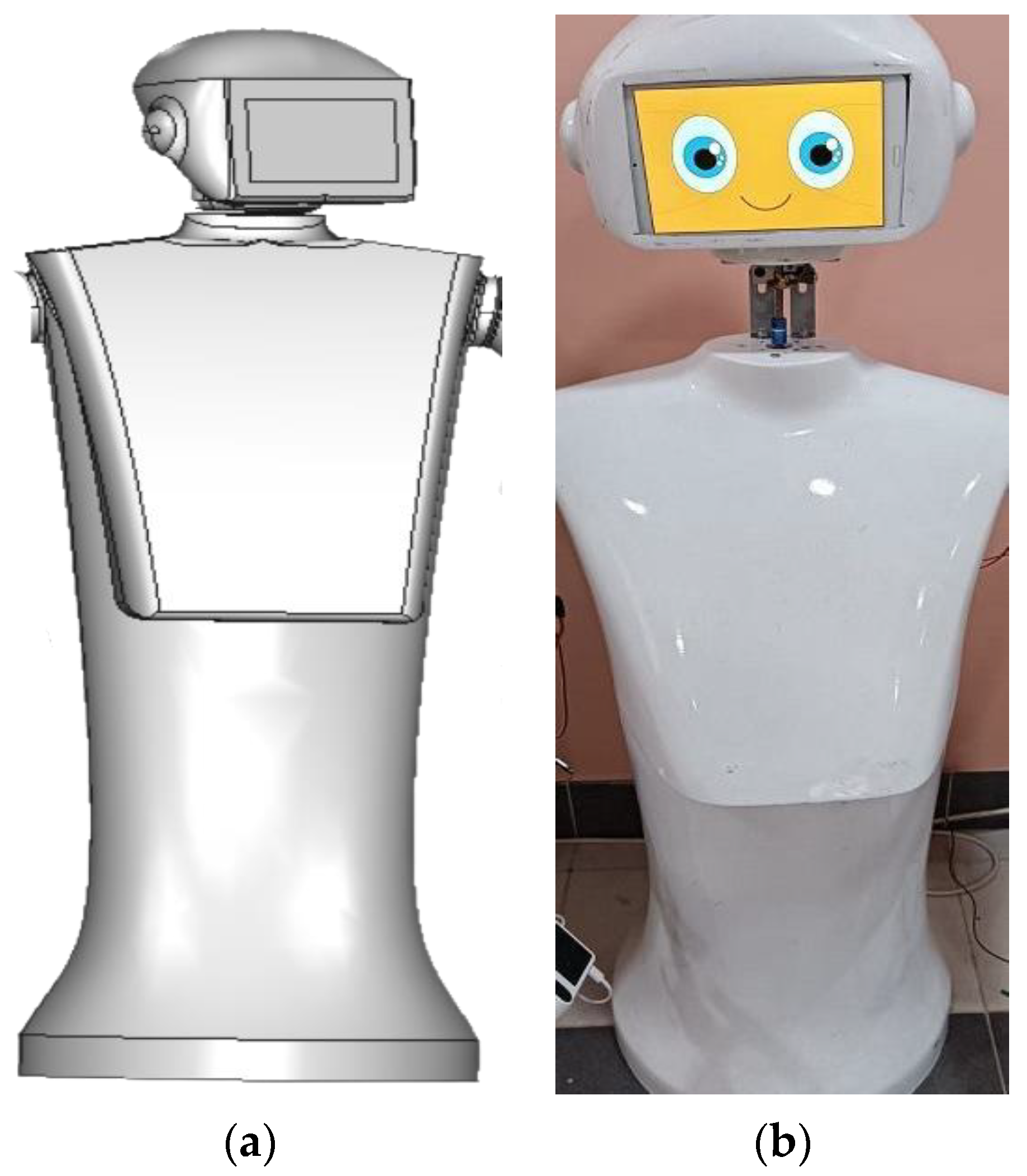

2.1. Head Design

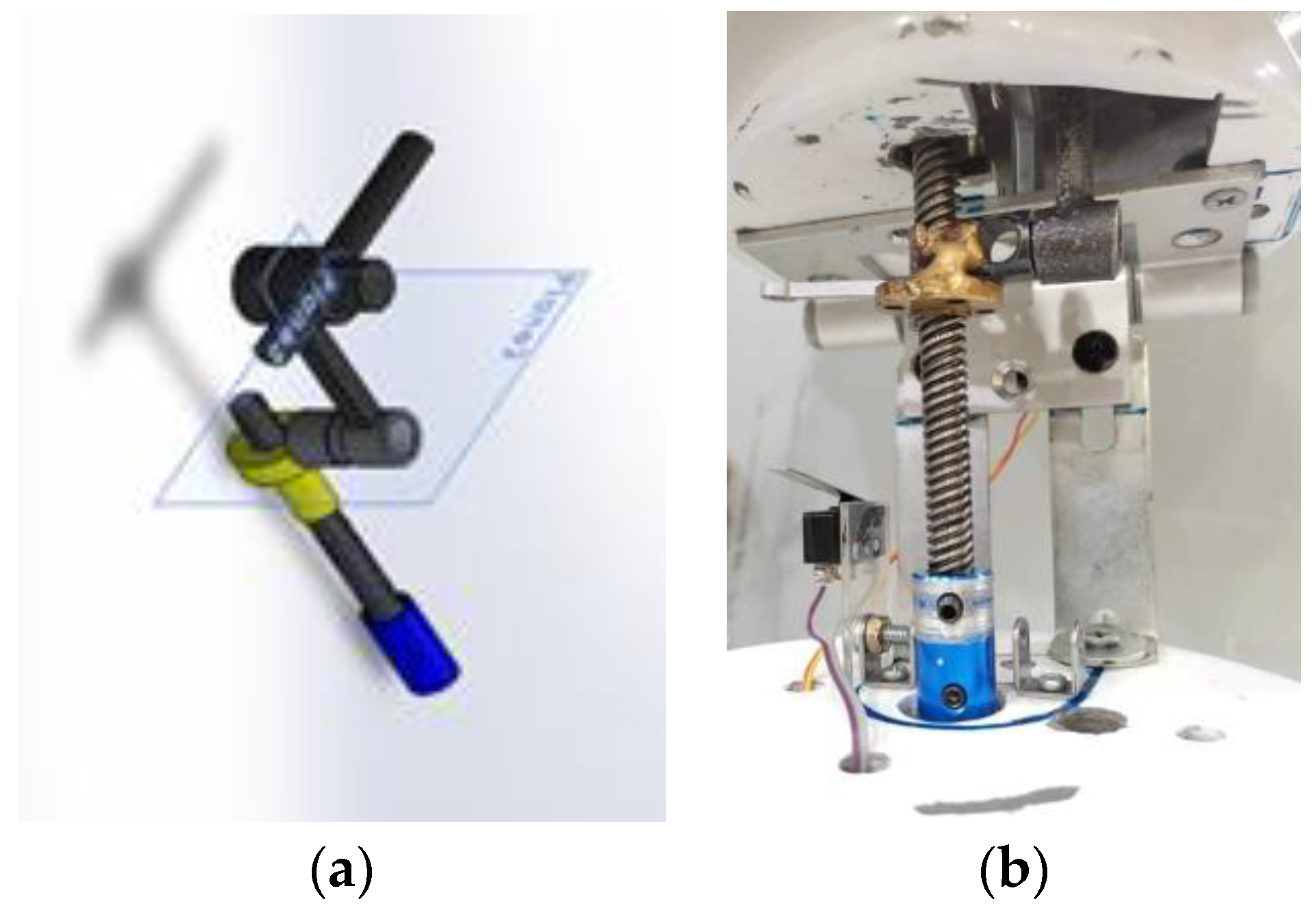

2.2. Single-DoF Neck Design

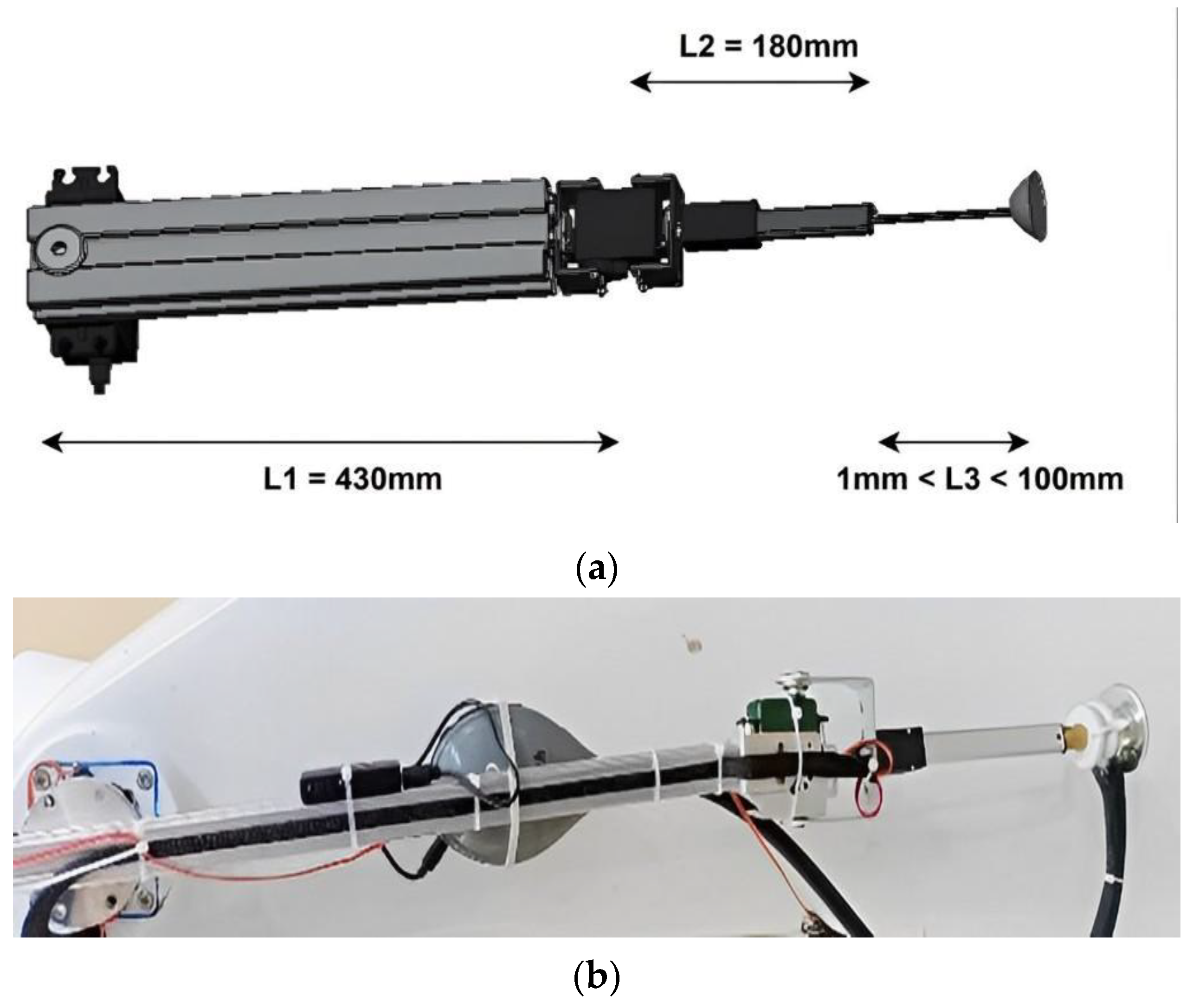

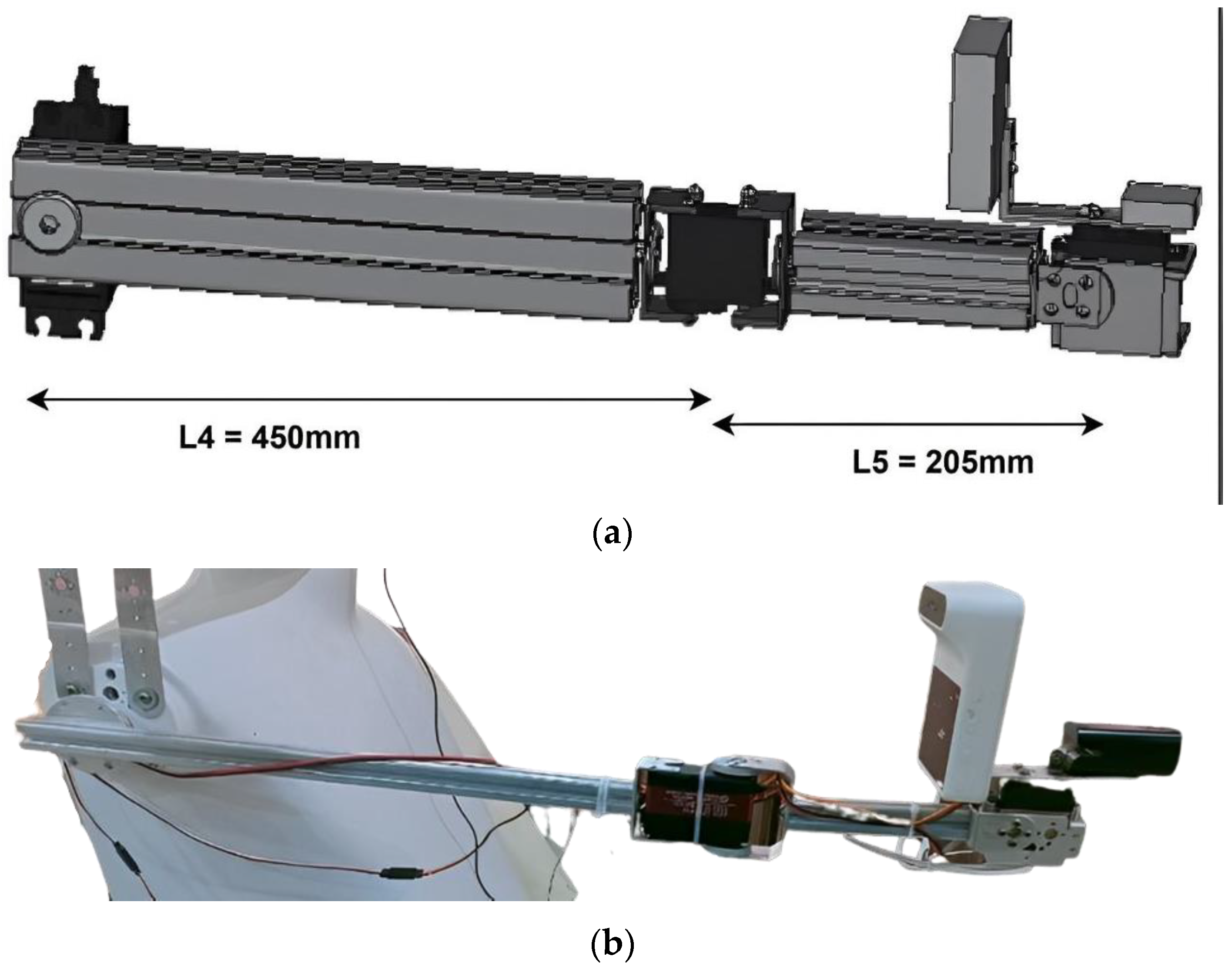

2.3. Arm Design and Prototyping

2.4. Body Design

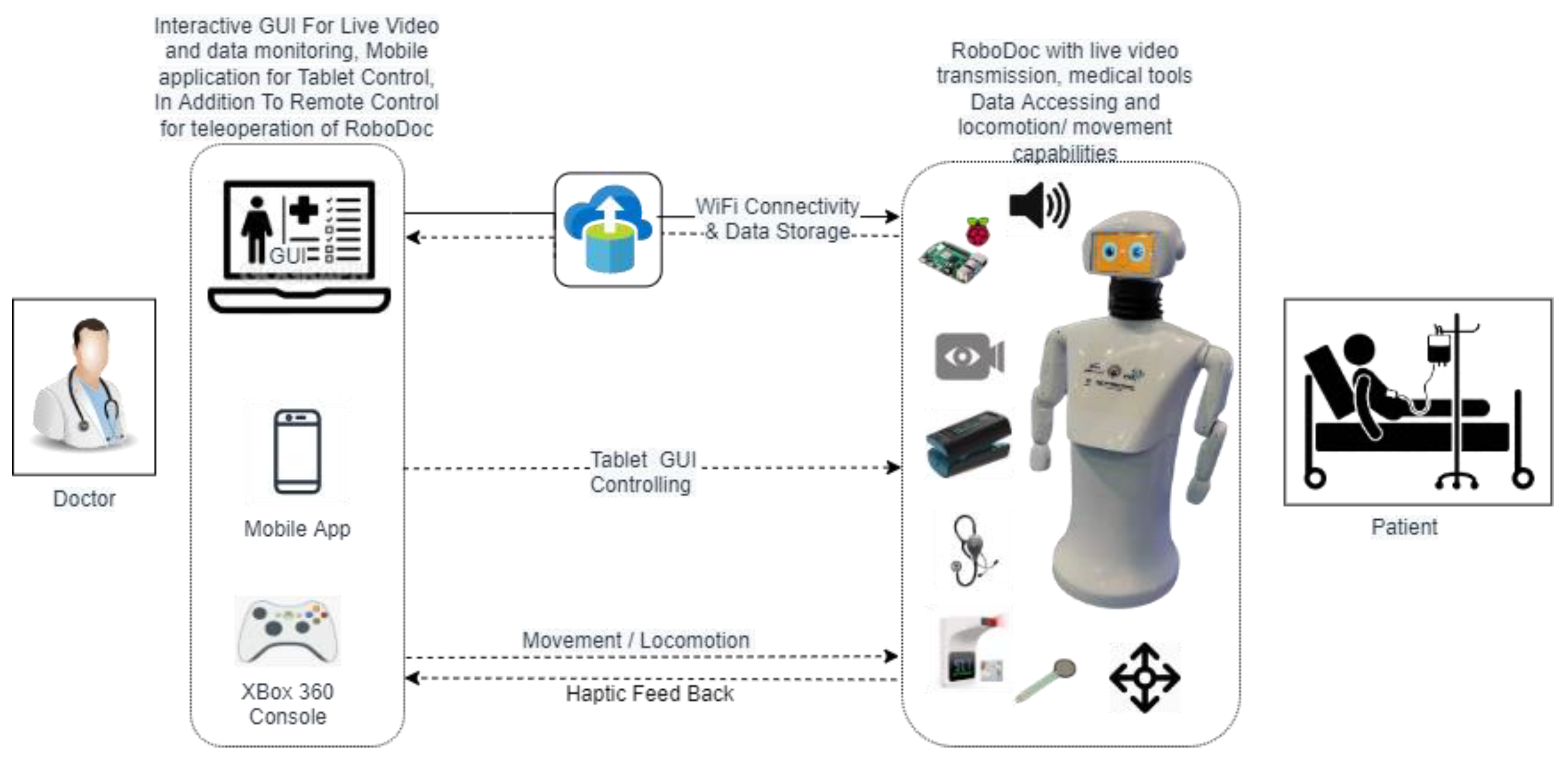

2.5. Rover Design

3. Electrical and Electronic Design

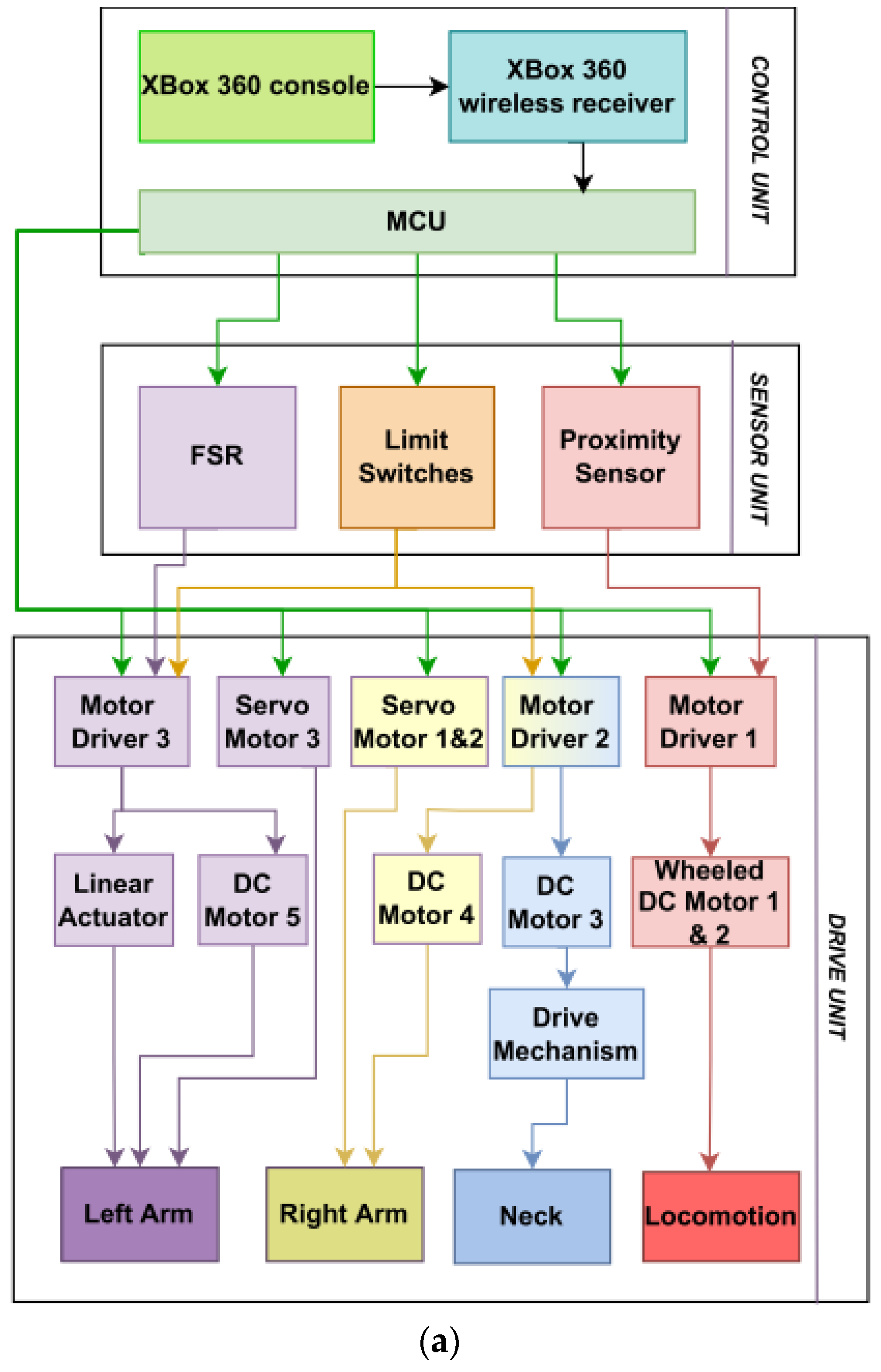

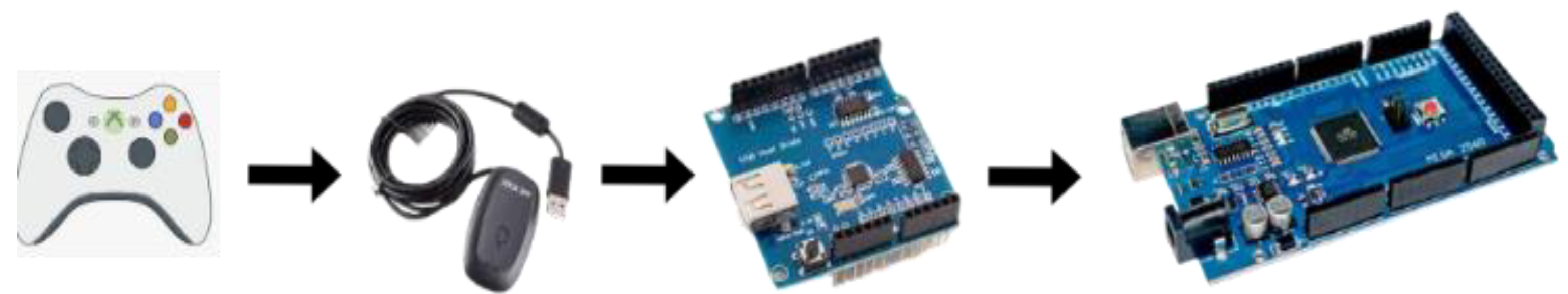

3.1. Control Unit

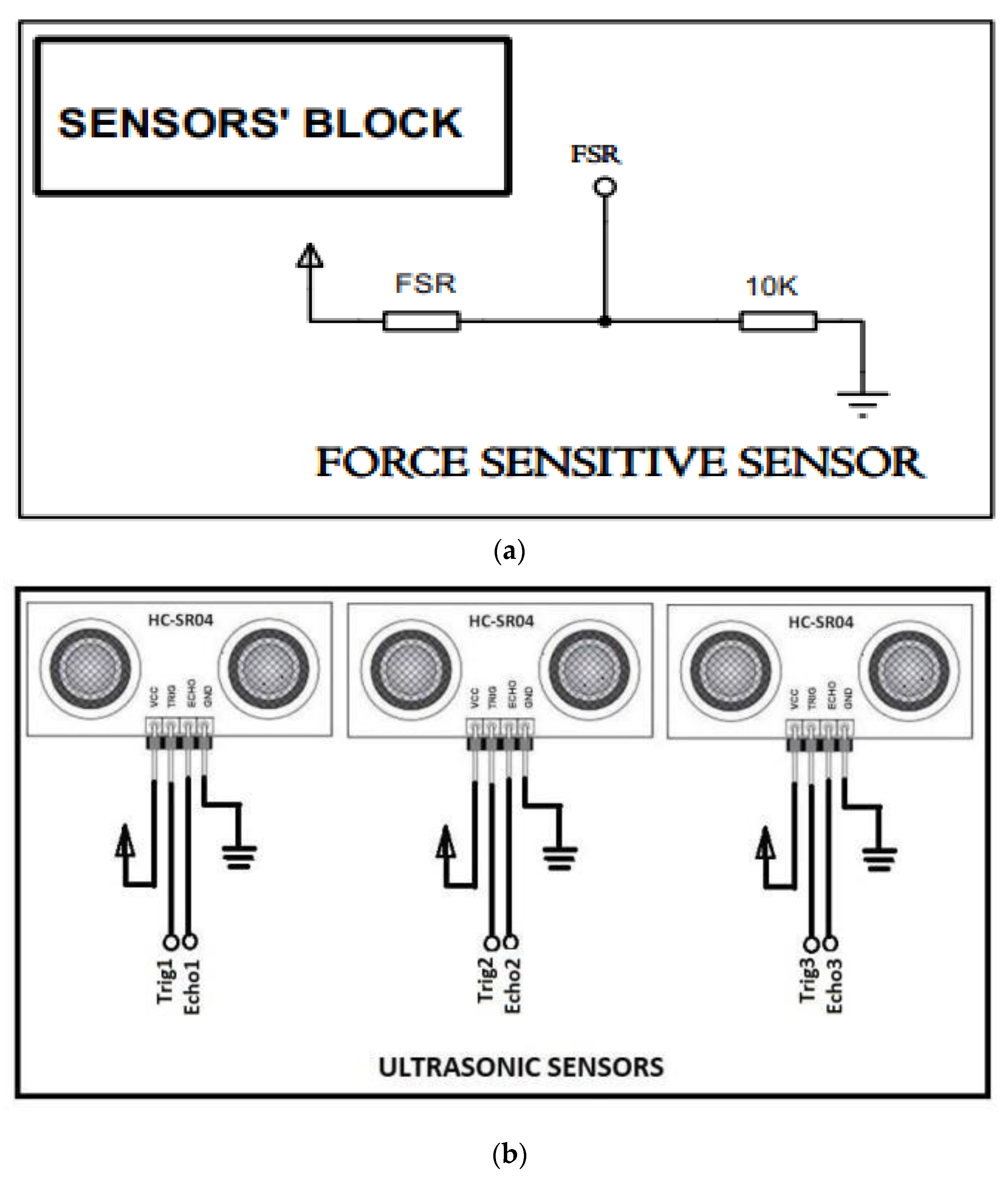

3.2. Sensing Unit

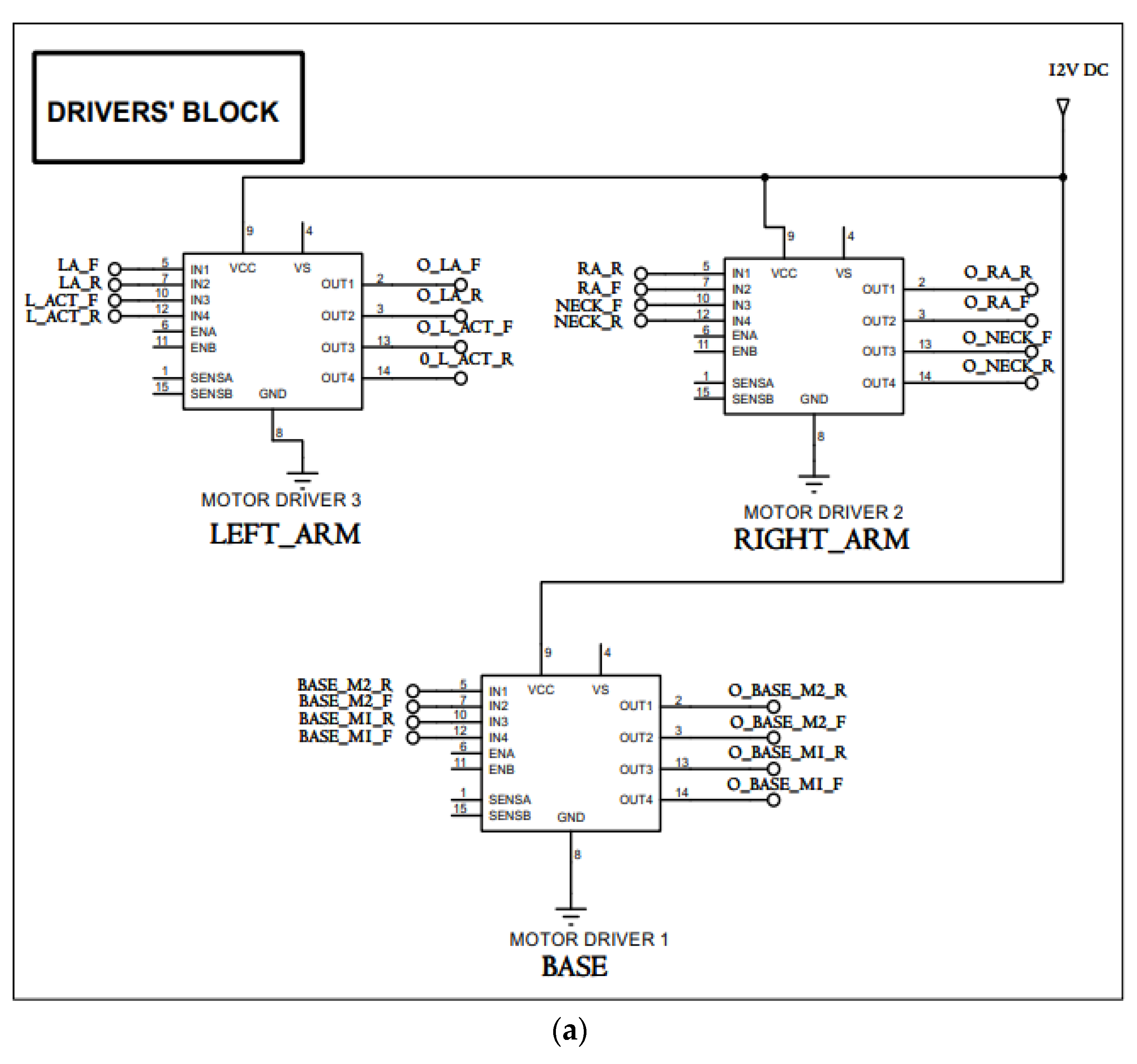

3.3. Driver Unit

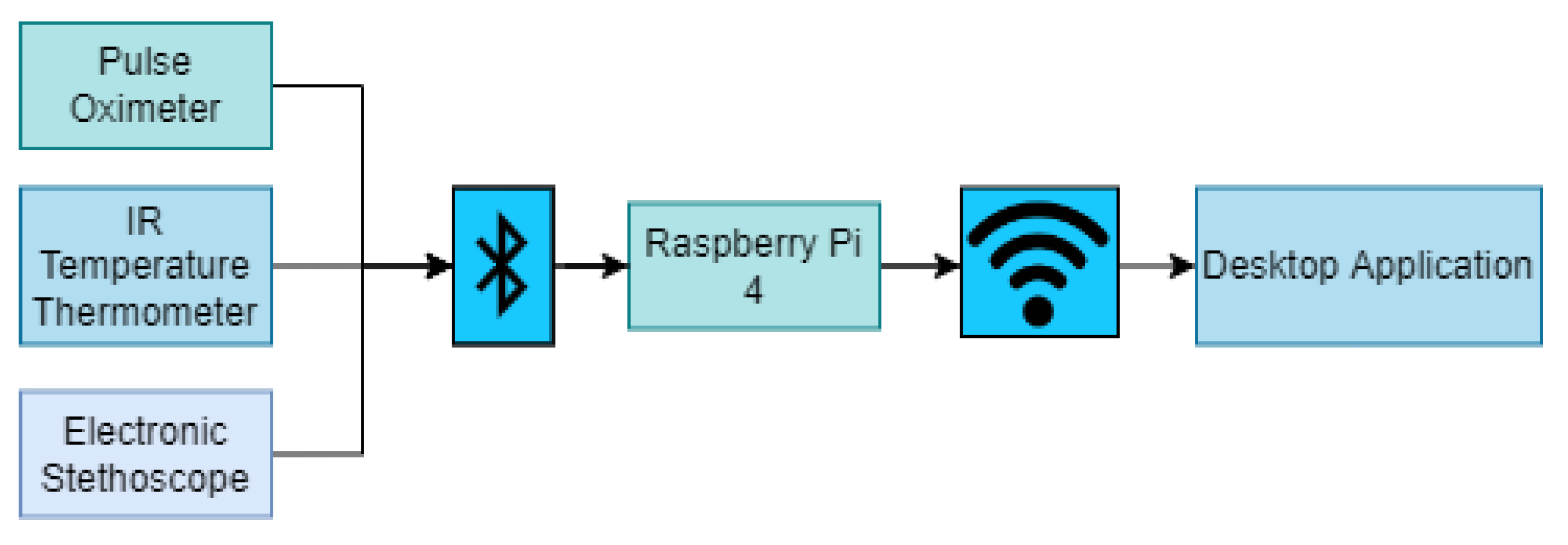

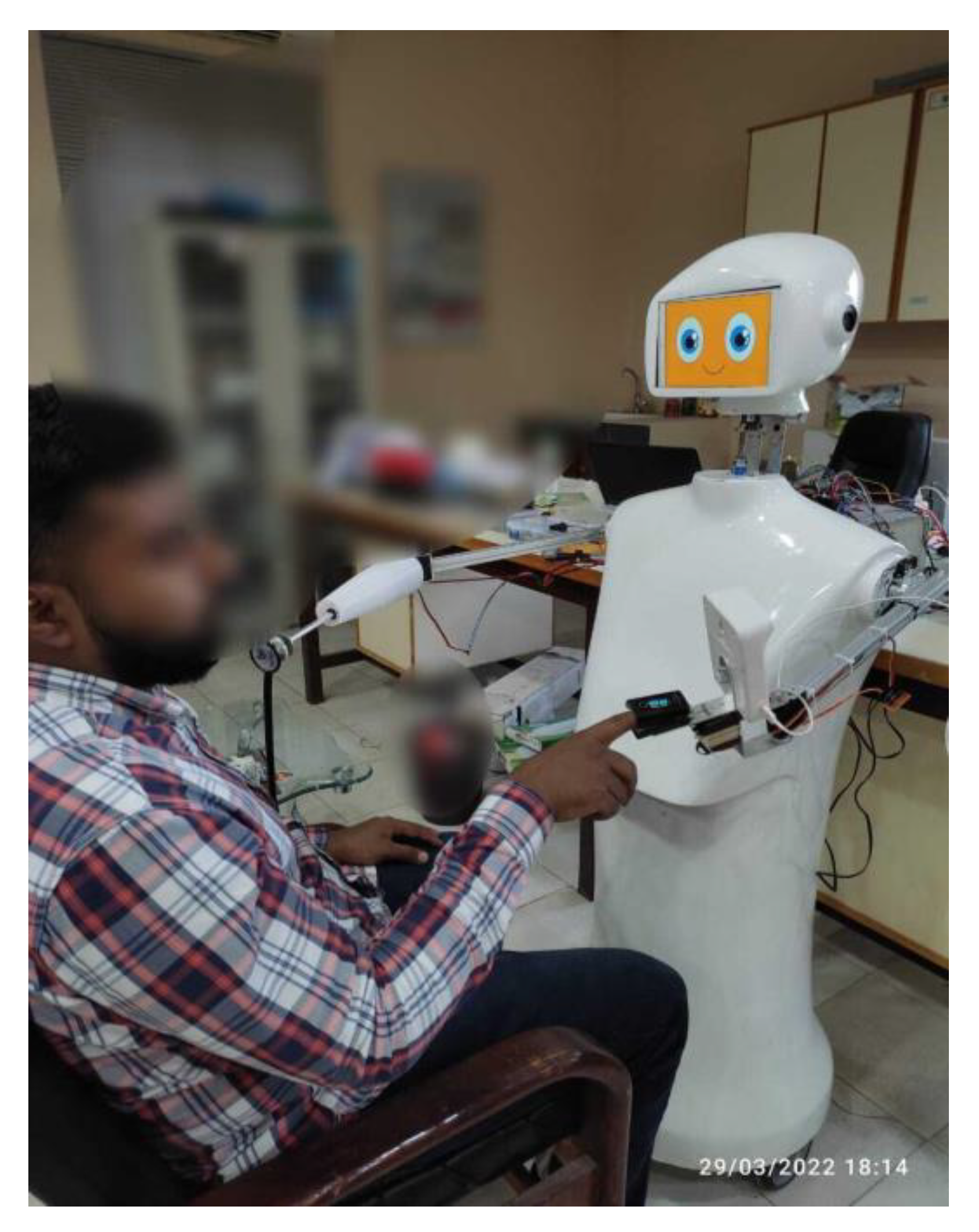

4. Interfacing of Vital Taking Devices

5. Haptics Feedback Interface Design for Stethoscope

6. Interactive Graphical User Interface

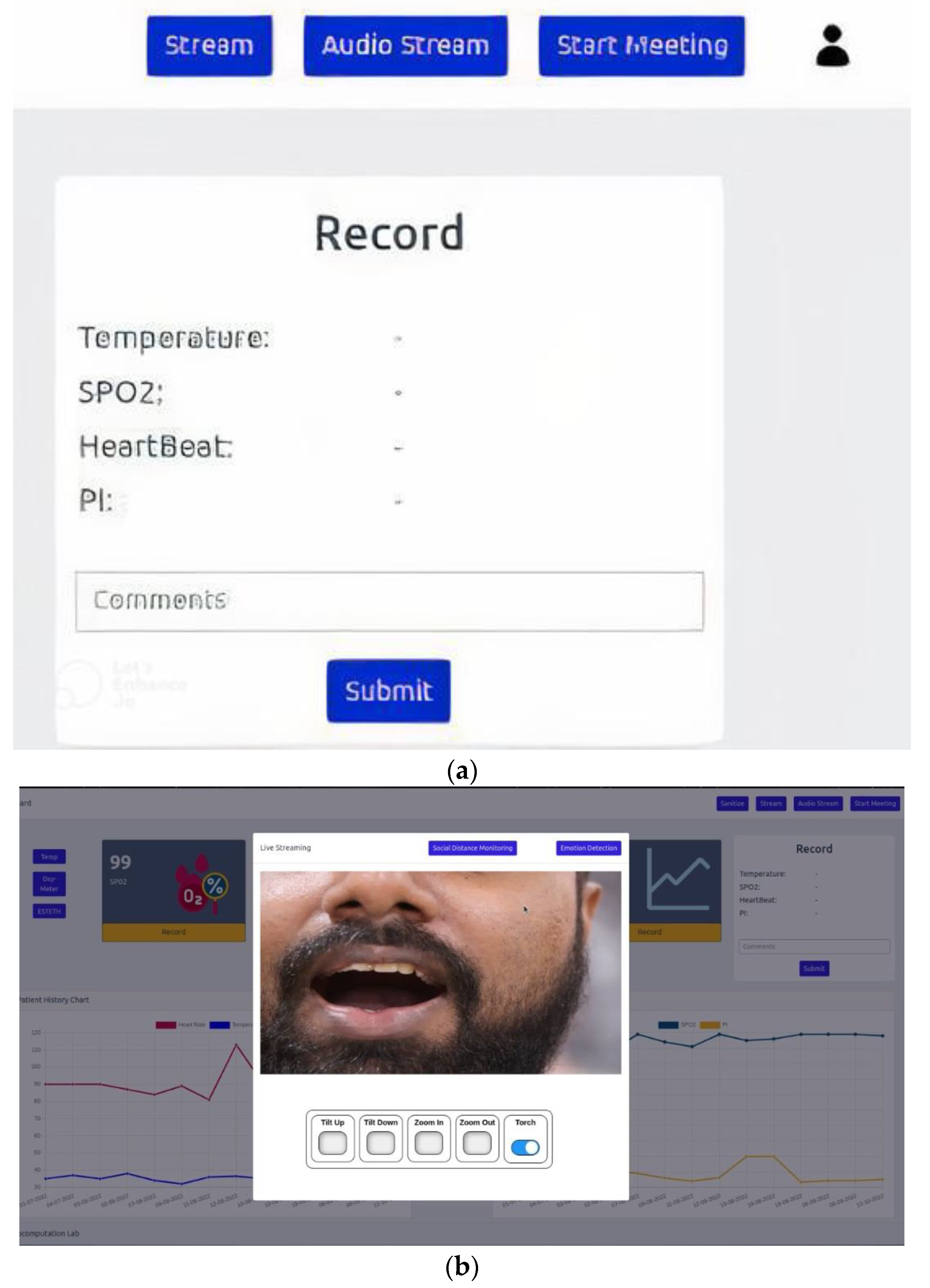

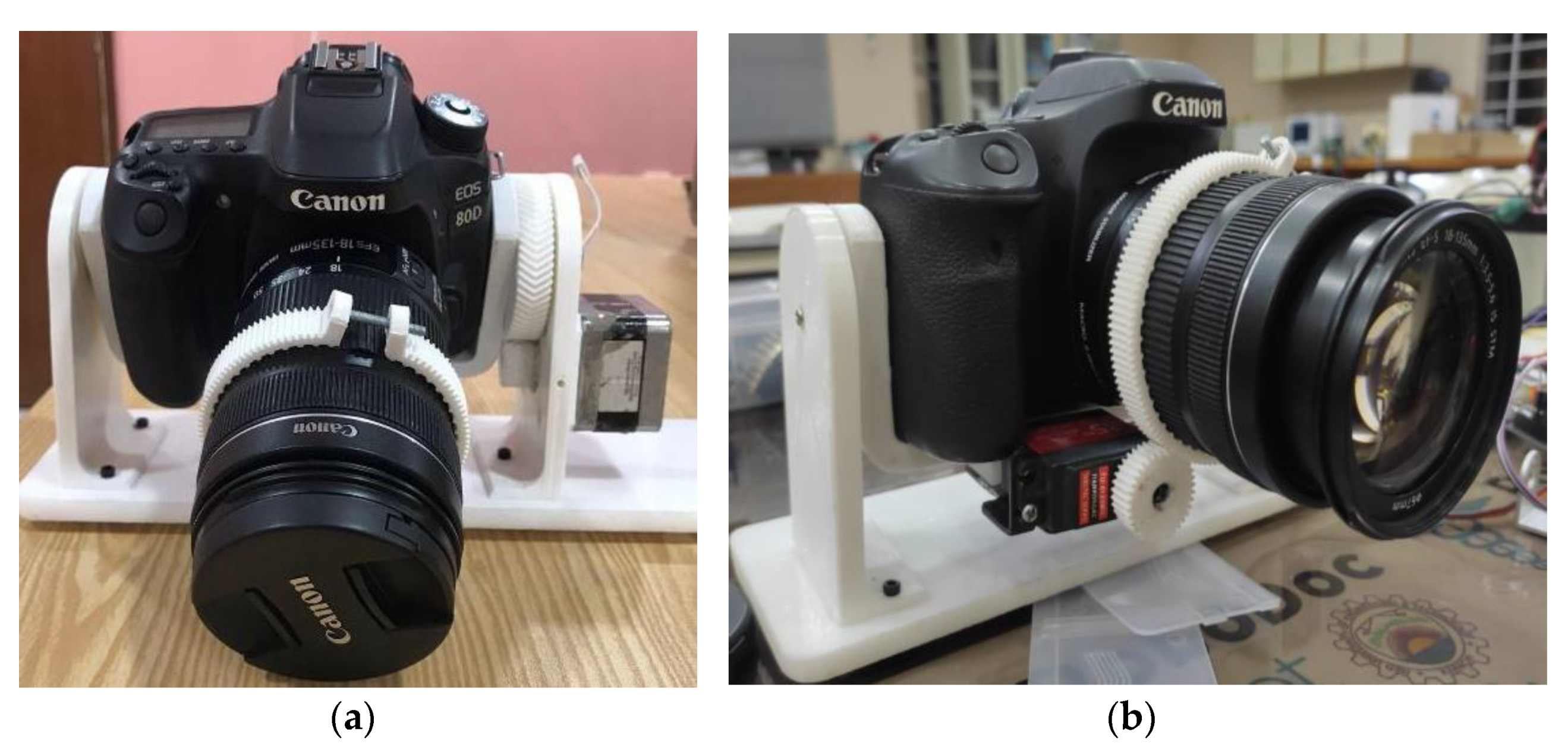

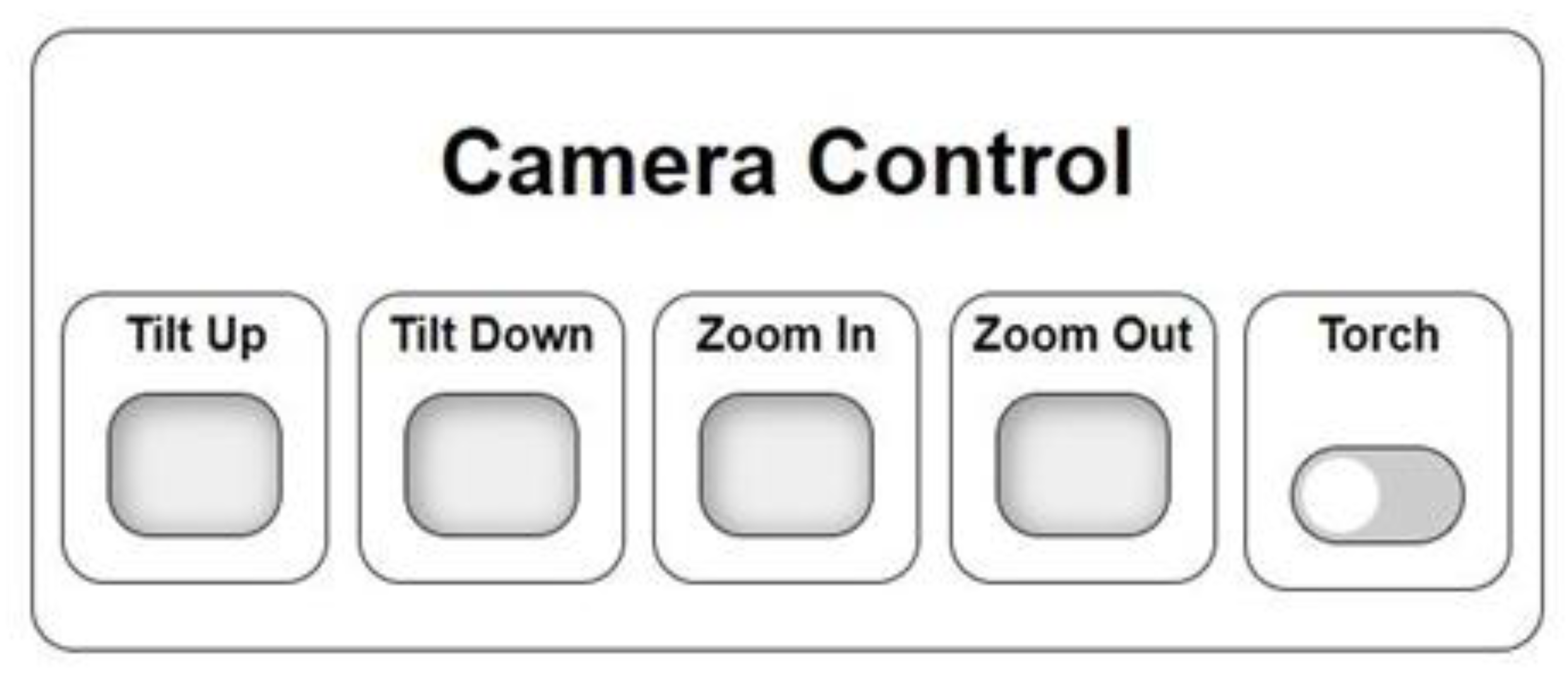

7. DSLR Camera Interface

8. Complete Overview of Robodoc

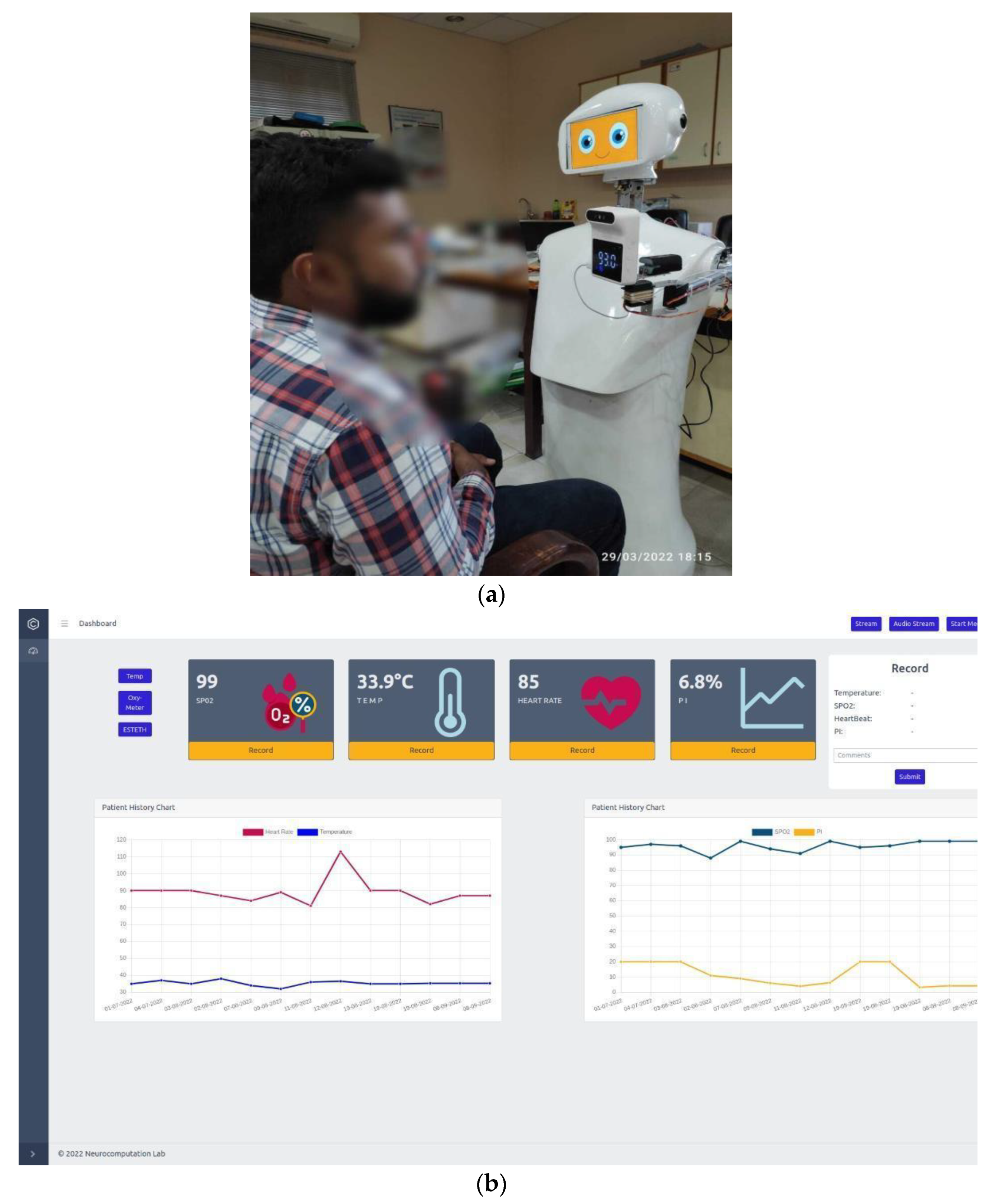

9. Vital Experiment Results

9.1. Stethoscope Haptic Feedback

9.2. Wireless Temperature

9.3. Pulse Oximeter

10. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bertelsen, A.; Melo, J.; Sánchez, E.; Borro, D. A review of surgical robots for spinal interventions. Int. J. Med. Robot. Comput. Assist. Surg. 2012, 9, 407–422. [Google Scholar] [CrossRef] [PubMed]

- Sarker, S.; Jamal, L.; Ahmed, S.F.; Irtisam, N. Robotics and artificial intelligence in healthcare during COVID-19 pandemic: A systematic review. Robot. Auton. Syst. 2021, 146, 103902. [Google Scholar] [CrossRef] [PubMed]

- der Loos, V.; Machiel, H.F.; Reinkensmeyer, D.J.; Guglielmelli, E. Rehabilitation and health care robotics. In Springer Handbook of Robotics; Springer: Berlin/Heidelberg, Germany, 2016; pp. 1685–1728. [Google Scholar]

- Micera, S.; Carrozza, M.C.; Beccai, L.; Vecchi, F.; Dario, P. Hybrid Bionic Systems for the Replacement of Hand Function. Proc. IEEE 2006, 94, 1752–1762. [Google Scholar] [CrossRef]

- Matarić, M.J.; Scassellati, B. Socially assistive robotics. IEEE Robot. Autom. Mag. 2016, 18, 1973–1994. [Google Scholar]

- Scassellati, B.; Boccanfuso, L.; Huang, C.-M.; Mademtzi, M.; Qin, M.; Salomons, N.; Ventola, P.; Shic, F. Improving social skills in children with ASD using a long-term, in-home social robot. Sci. Robot. 2018, 3, eaat7544. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Leo, M.; Del Coco, M.; Carcagni, P.; Distante, C.; Bernava, M.; Pioggia, G.; Palestra, G. Automatic emotion recognition in robot-children interaction for ASD treatment. In Proceedings of the IEEE International Conference on Computer Vision Workshops, Santiago, Chile, 7–13 December 2015. [Google Scholar]

- Joseph, A.; Christian, B.; Abiodun, A.A.; Oyawale, F. A review on humanoid robotics in healthcare. MATEC Web Conf. 2018, 153, 02004. [Google Scholar] [CrossRef]

- King, C.-H.; Chen, T.L.; Jain, A.; Kemp, C.C. Towards an assistive robot that autonomously performs bed baths for patient hygiene. In Proceedings of the IEEE/RSJ 2010 International Conference on Intelligent Robots and Systems, Taipei, Taiwan, 18–22 October 2010. [Google Scholar]

- Hu, J.; Edsinger, A.; Lim, Y.-J.; Donaldson, N.; Solano, M.; Solochek, A.; Marchessault, R. An advanced medical robotic system augmenting healthcare capabilities—robotic nursing assistant. In Proceedings of the 2011 IEEE International Conference on Robotics and Automation, Shanghai, China, 9–13 May 2011. [Google Scholar]

- Hirose, T.; Fujioka, S.; Mizuno, O.; Nakamura, T. Development of Hair-washing Robot Equipped with Scrubbing Fingers. In Proceedings of the 2012 IEEE International Conference on Robotics and Automation, Saint Paul, MN, USA, 14–18 May 2012. [Google Scholar]

- Miseikis, J.; Caroni, P.; Duchamp, P.; Gasser, A.; Marko, R.; Miseikiene, N.; Zwilling, F.; de Castelbajac, C.; Eicher, L.; Fruh, M.; et al. Lio-A Personal Robot Assistant for Human-Robot Interaction and Care Applications. IEEE Robot. Autom. Lett. 2020, 5, 5339–5346. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Vaish, A.; Vaishya, R.; Iyengar, K.P. Robotics Applications in COVID-19: A Review. J. Ind. Integr. Manag. 2020, 5, 441–451. [Google Scholar] [CrossRef]

- Shen, Y.; Guo, D.; Long, F.; Mateos, L.A.; Ding, H.; Xiu, Z.; Hellman, R.B.; King, A.; Chen, S.; Zhang, C.; et al. Robots Under COVID-19 Pandemic: A Comprehensive Survey. IEEE Access 2020, 9, 1590–1615. [Google Scholar] [CrossRef]

- Erico Guizzo, R.K. How-Robots-Became-Essential-Workers-in-the-Covid19-Response. 30 September 2020. Available online: https://spectrum.ieee.org/how-robots-became-essential-workers-in-the-covid19-response (accessed on 18 November 2022).

- Ackerman, E. Autonomous robots are helping kill coronavirus in hospitals. IEEE Spectr. 2020, 11, 1–5. [Google Scholar]

- Ackerman, E. How-Diligents-Robots-Are-Making-a-Difference-in-Texas-Hospitals. 2020. Available online: https://spectrum.ieee.org/how-diligents-robots-are-making-a-difference-in-texas-hospitals (accessed on 18 November 2022).

- Ramalingam, B.; Yin, J.; Elara, M.R.; Tamilselvam, Y.K.; Rayguru, M.M.M.; Muthugala, M.A.V.J.; Gómez, B.F. A Human Support Robot for the Cleaning and Maintenance of Door Handles Using a Deep-Learning Framework. Sensors 2020, 20, 3543. [Google Scholar] [CrossRef] [PubMed]

- Raje, S.; Reddy, N.; Jerbi, H.; Randhawa, P.; Tsaramirsis, G.; Shrivas, N.V.; Pavlopoulou, A.; Stojmenović, M.; Piromalis, D. Applications of Healthcare Robots in Combating the COVID-19 Pandemic. Appl. Bionics Biomech. 2021, 2021, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Kursumovic, E.; Lennane, S.; Cook, T. Deaths in healthcare workers due to COVID-19: The need for robust data and analysis. Anaesthesia 2020, 75, 989–992. [Google Scholar] [CrossRef] [PubMed]

- Zhan, M.; Qin, Y.; Xue, X.; Zhu, S. Death from Covid-19 of 23 Health Care Workers in China. N. Engl. J. Med. 2020, 382, 2267–2268. [Google Scholar] [CrossRef] [PubMed]

- Gouda, D.; Singh, P.M.; Gouda, P.; Goudra, B. An Overview of Health Care Worker Reported Deaths During the COVID-19 Pandemic. J. Am. Board Fam. Med. 2021, 34, S244–S246. [Google Scholar] [CrossRef] [PubMed]

- Heyer, C. Human-robot interaction and future industrial robotics applications. In Proceedings of the 2010 IEEE/RSJ International Conference on Intelligent Robots and Systems, Taipei, Taiwan, 18 October 2010. [Google Scholar]

- Asfour, T.K.; Berns, K.; Dillmann, R. The humanoid robot ARMAR: Design and control. In Proceedings of the 1st IEEE-RAS International Conference on Humanoid Robots (Humanoids 2000), Cambridge, MA, USA, 7 September 2000. [Google Scholar]

- Berns, K.; Vogt, H.; Asfour, T.; Dillmann, R. Design and control architecture of an anthropomorphic robot arm. In Proceedings of the 3rd International Conference on Advanced Mechatronics ICAM, Okayama, Japan, 3–6 August 1998. [Google Scholar]

- Borst, C.; Ott, C.; Wimbock, T.; Brunner, B.; Zacharias, F.; Bäuml, B.; Hillenbrand, U.; Haddadin, S.; Albu-Schäffer, A.; Hirzinger, G. A humanoid upper body system for two-handed manipulation (Video). In Proceedings of the 2007 IEEE International Conference on Robotics and Automation, Rome, Italy, 10–14 April 2007. [Google Scholar]

- Hirzinger, G.; Sporer, N.; Albu-Schaffer, A.; Hahnle, M.; Krenn, R.; Pascucci, A.; Schedl, M. DLR’s torque-controlled light weight robot III-are we reaching the technological limits now? In Proceedings of the 2002 IEEE International Conference on Robotics and Automation (Cat. No. 02CH37292), Washington, DC, USA, 11–15 May 2002. [Google Scholar]

- Ott, C.; Eiberger, O.; Friedl, W.; Bauml, B.; Hillenbrand, U.; Borst, C.; Albu-Schaffer, A.; Brunner, B.; Hirschmuller, H.; Kielhofer, S.; et al. A humanoid two-arm system for dexterous manipulation. In Proceedings of the 2006 6th IEEE-RAS International Conference on Humanoid Robots, Genova, Italy, 4–6 December 2006. [Google Scholar]

- Yu, Z.; Huang, Q.; Ma, G.; Chen, X.; Zhang, W.; Li, J.; Gao, J. Design and Development of the Humanoid Robot BHR-5. Adv. Mech. Eng. 2014, 6, 852937. [Google Scholar] [CrossRef]

- Buschmann, T.; Lohmeier, S.; Ulbrich, H. Humanoid robot Lola: Design and walking control. J. Physiol. 2009, 103, 141–148. [Google Scholar] [CrossRef] [PubMed]

- Lohmeier, S.; Buschmann, T.; Ulbrich, H. Humanoid robot LOLA. In Proceedings of the 2009 IEEE International Conference on Robotics and Automation, Kobe, Japan, 12–17 May 2009. [Google Scholar]

- Favot, V.; Buschmann, T.; Schwienbacher, M.; Ewald, A.; Ulbrich, H. The sensor-controller network of the humanoid robot LOLA. In Proceedings of the 2012 12th IEEE-RAS International Conference on Humanoid Robots (Humanoids 2012), Osaka, Japan, 29 November–1 December 2012. [Google Scholar]

- Lohmeier, S.; Buschmann, T.; Ulbrich, H.; Pfeiffer, F. Modular joint design for performance enhanced humanoid robot LOLA. In Proceedings of the 2006 IEEE International Conference on Robotics and Automation (ICRA), Orlando, FL, USA, 15–19 May 2006. [Google Scholar]

- Mohamed, Z.; Capi, G. Development of a New Mobile Humanoid Robot for Assisting Elderly People. Procedia Eng. 2012, 41, 345–351. [Google Scholar] [CrossRef] [Green Version]

- Ñope-Giraldo, R.M.; Illapuma-Ccallo, L.A.; Cornejo, J.; Palacios, P.; Napán, J.L.; Cruz, F.; Palomares, R.; Cornejo-Aguilar, J.A.; Vargas, M. Mechatronic Systems Design of ROHNI-1: Hybrid Cyber-Human Medical Robot for COVID-19 Health Surveillance at Wholesale-Supermarket Entrances. In Proceedings of the 2021 Global Medical Engineering Physics Exchanges/Pan American Health Care Exchanges (GMEPE/PAHCE), Sevilla, Spain, 15–20 March 2021. [Google Scholar]

- Available online: https://www.alibaba.com/showroom/humanoid-robot-price.html (accessed on 18 November 2022).

- Albers, A.; Brudniok, S.; Ottnad, J.; Sauter, C.; Sedchaicharn, K. Armar iii design of the upper body. In Proceedings of the 2nd International Workshop on Human Centered Robotic Systems, Technische Universität München, Munich, Germany, 6–7 October 2006. [Google Scholar]

- Gouaillier, D.; Blazevic, P. A mechatronic platform, the Aldebaran robotics humanoid robot. In Proceedings of the IECON 2006-32nd Annual Conference on IEEE Industrial Electronics, Paris, France, 6–10 November 2006. [Google Scholar]

- Gao, B.; Xu, J.; Zhao, J.; Xi, N.; Shen, Y.; Yang, R. A Humanoid Neck System Featuring Low Motion-Noise. J. Intell. Robot. Syst. 2011, 67, 101–116. [Google Scholar] [CrossRef]

- Tadesse, Y.; Subbarao, K.; Priya, S. Realizing a Humanoid Neck with Serial Chain Four-bar Mechanism. J. Intell. Mater. Syst. Struct. 2010, 21, 1169–1191. [Google Scholar] [CrossRef]

- Daraz. eSteth Lite-Digital Stethoscope. Available online: https://www.daraz.pk/products/esteth-lite-digital-stethoscope-i221392610.html (accessed on 18 November 2022).

- Store, S.O. Bluetooth Finger Pulse Oximeter. 3 August 2020. Available online: shorturl.at/mzAIR (accessed on 18 November 2022).

- Store, C.H. Bluetooth Smart Forehead Temperature Sensor with Fever Alarm. 24 July 2022. Available online: shorturl.at/mDN57 (accessed on 18 November 2022).

- Hannaford, B.; Okamura, A.M. Haptics. In Springer Handbook of Robotics; Springer: Berlin/Heidelberg, Germany, 2016; pp. 1063–1084. [Google Scholar]

- BasheeruddinAsdaq, S.M.; Naveen, N.R.; Gunturu, L.N.; Pamayyagari, K.; Abdullah, I.; Sreeharsha, N.; Imran, M.; Alsalman, A.J.; Al Hawaj, M.A.; Al Mohaini, M.; et al. Wireless Networking-Driven Healthcare Approaches in Combating COVID-19. BioMed Res. Int. 2021, 2021, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Saeed, U.; Shah, S.Y.; Ahmad, J.; Imran, M.A.; Abbasi, Q.H. Machine learning empowered COVID-19 patient monitoring using non-contact sensing: An extensive review. J. Pharm. Anal. 2022, 12, 193–204. [Google Scholar] [CrossRef] [PubMed]

- Uddin, R.; Ryu, J. Predictive control approaches for bilateral teleoperation. Annu. Rev. Control 2016, 42, 82–99. [Google Scholar] [CrossRef]

- Uddin, R.; Park, S.; Ryu, J. A predictive energy-bounding approach for Haptic teleoperation. Mechatronics 2016, 35, 148–161. [Google Scholar] [CrossRef]

- Su, H.; Qi, W.; Schmirander, Y.; Ovur, S.E.; Cai, S.; Xiong, X. A human activity-aware shared control solution for medical human–robot interaction. Assem. Autom. 2022, 42, 388–394. [Google Scholar] [CrossRef]

- Qi, W.; Su, H. A Cybertwin Based Multimodal Network for ECG Patterns Monitoring Using Deep Learning. IEEE Trans. Ind. Informatics 2022, 18, 6663–6670. [Google Scholar] [CrossRef]

| S. NO | Robotic Platforms | Mechanical Design | Electrical Design | Ai | Haptics | Desktop Interface | Data Logging | Tele Operated | Soft Robotics | References | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dof | End Effector | Rover | Motor | Sensor | Controller | |||||||||||

| Neck | Arm | Torso | ||||||||||||||

| 1 | ROHNI-1 | 2 | 4 | × | Dispenser valve, pulse oximeter | ✓ | Servo, dc motor | HC-SR04, MLX90614, Ardu Cam PTZ, Quadrature Encoder Motor | Raspberry Pi 3B+, PIC 18F4550 | ✓ | × | × | × | ✓ | ✓ | [35] |

| 2 | LIO | × | 6 | × | Gripper | ✓ | LiDARs, Distance sensor, Infrared floor sensors, Intel RealSense D435 Depth Camera, FSR | 4 embedded computing units: Intel NUC, Nvidia Jetson AGX Xavier, Raspberry Pi and an embedded PC with Atom processor | ✓ | ✓ | × | × | × | ✓ | [12] | |

| 3 | ARMAR | 3 | 7 | 4 | Gripper | ✓ | dc motors | ultrasonic sensors, a planar laser-scanner, angle encoders, artificial skin, stereo camera system, stain gauges, gyroscopes and acceleration sensors, FasTrak (pos sensor), joint encoders, Artificial skin (tactile sensor) | PC, C-167 micro-controllers, position joint controllers, 80C167 (microcontroller for motor), pc | × | ✓ | ✓ | × | × | × | [24,25] |

| 4 | JUSTIN | 2 | 7 | 3 | 4 fingers | × | Torque sensor, (joints), 6-dof force/torque sensor at finger tips. Joint torque sensors, laser-range scanner, laser-stripe profiler, stereo camera sensor | Torque and impedance controllers, local signal processor (embedded PC running linux), | ✓ | - | ✓ | × | × | × | [26,26,27,28] | |

| 5 | ARMAR III | 4 | 7 | 3 | 5 fingers | × | Servo | Encoder, Tactile sensor, strain gauge, load cells, optical sensor, quasi absolute angular sensor | two PC-104s, four Universal Controller Modules (UCoM), A/D converter, DC/DC converters and force-moment controllers | × | ✓ | ✓ | × | × | × | [37] |

| 6 | BHR-5 | 2 | 7 | 2 | tennis | × | brushless DC motors | Cameras, gyroscopes, accelerometers, six-axis force/torque sensors, encoder | Inertial sensor processor, motor controllers | ✓ | × | ✓ | × | ✓ | × | [29] |

| 7 | MOBILE HUMANOID ROBOT | 2 | 6 | 0 | gripper(2dof) | × | 6 dc motors, 8 servos | Webcams(1.4 MP), Microphone laser range finder(URG-04LX-UG01), Potentiometers are used as the angle encoder for each joint with a resolution of 0.1 degrees | PC | ✓ | × | ✓ | × | × | × | [34] |

| 8 | ALDEBARAN HUMANOID ROBOT | 2 | 5 | 1 | 3 Fingers | × | DC motors | USB camera, microphones, speakers, proprioceptive sensors. (locomotion sensors), accelerometer, gyroscopic sensor, resistance strain gauge (fsr) | MOTHER BOARD: Korebot board, SERVO BOARD: Micro controller for PID control and I2C communication | × | × | × | × | × | × | [38] |

| 9 | HUMANOID ROBOT LOLA | 3 | 3 | 2 | × | PMSMs | Angular sensor, camera, incremental rotary encoder, limit switch, fiber-optic gyroscopes, MEMS accelerometers, two six-axis force/torque sensors, strain gauges, temperature sensor, light-barrier, altitude sensor | PC, central control unit (CCU- Core 2Duo Mobile, 2.33 GHz, running the QNX Neutrino real-time operating system) 3elmos controllers over CAN, inertial measuring unit {IMU iMAR iVRU-FC-C167 | ✓ | × | ✓ | - | ✓ | × | [30,31,32,33] | |

| Components | Amps/Volts | Specifications | |

|---|---|---|---|

| Sensors | HC-SR04 (Ultra-Sonic sensor) | 15 mA, 5 V DC | Measuring Range: 2–400 cm, accuracy: 3 mm |

| Micro Limit switch | 5 V | Three pins: normally open (NO), normally closed (NC), neutral | |

| Force Sensitive Resistor (FSR) | <1 mA, 5 V | Diameter: 12.5 mm, Force Range: (0 to 100 Newtons), Resistance Range: 100 KΩ (light pressure) to 200 Ω (max pressure) | |

| Actuators | DHV840 Servo motor | 6–7.4 V | Torque: 34 kg-cm/6.0 V; 38 kg-cm/7.4 V, Speed: 0.21 s/60°/6.0 V; 0.18 s/60°/7.4 V |

| HP300 Servo Motor | 12–24 V | Maximum torque: 300 kg/500 kg·cm (24 V), Operating Speed: 24 V 0.5 s/60° at no-load | |

| RDS5160 Servo Motor | 6–8.4 V | Torque: 58 kg·cm.at (6 v) 65 kg·cm.at (7.4 v) 70 kg·cm.at (8.4 v) Speed: 0.17 s/60 degree at (6 v) 0.15 s/60 degree at (7.4 v) 0.13 s/60 degree at (8.4 v) | |

| XD-60GA775 DC, 5/50 RPM | 3 A, 12–24 V | Speed: 5/50 rpm Power: 35 W | |

| Micro linear actuator | 12 V | 100 mm Stroke | |

| Motor Driver | L2986N | 2 A, 12 V | |

| Controller | Arduino Atmega 2560 | 2 A. 5 V | Dimensions and weight: 101.52 × 53.3 mm, 37 g |

| Raspberry Pi 4 | 3 A, 5 V | Power via USB Type-C, 4 GB RAM | |

| Power Supply | Lead Acid Battery | 12 Ah, 12 V | 3.9 kg |

| LM2596 (Buck Converter) | 4.75 V–35 V | Output voltage:1.25–26 V(Adjustable) Output current: Rated current is 2 A, maximum 3 A (Additional heat sink is required) |

| S. No. | Component | Safety & Precautions |

|---|---|---|

| 1 | Arms motor | Mercury limit switches to limit the arm movement in order to avoid wire twisting/stretching and collision with the camera stand |

| 2 | Camera Zoom motor & Tilt Motor | Use of 270-degree servo instead of continuous servo to avoid over rotation of the zoom lenses. Use of lever limit switches to limit the camera tilt. |

| 3 | Main PCB circuit | Fuses for overcurrent protection, free-wheeling diode to suppress regenerative breaking, C3 Ac input cord for reverse polarity protection, use of crimp-seal connectors, screw terminals, lugs, heat shrink tubes to avoid loose connections. Replaceable modules and drivers. Thick tracks are used in PCBs are used to sustain any major current influx. Major connectors, connecting peripherals, are placed on one side of the PCB to avoid mishandling. Moreover, proper PCB labelling is ensured to mitigate any unforeseen safety hurdle. Proper labelling also ensures engineers/designers to place components properly. A blueprint (schematic) was created before designing the PCBs, and was thoroughly reviewed before production process. |

| 4 | Neck movement | Use of lever limit switches to limit the Head-Up and Head-Down movements. |

| 5 | Collision Avoidance | HC-SR04 Ultrasonic Proximity Sensor |

| 6 | Linear Actuator | Built-in micro limit switches to avoid over linear extension. The actuators used have limit switches on its either side. |

| 7 | Wiring channel | Use of wire sleeve conduits to through the wire along and provide flexible/safe movement while moving arm, with rubber bush endings. Major sections of wiring are kept isolated from each other in order to avoid any sparks. Proper heat sleaves adhere to maximum safety precautions. |

| 8 | Battery Over-discharge protection | Use of cut-off circuit with the battery which will cut the robot’s supply if voltage drops below 10.5 V to protect it from over discharge. |

| 9 | Battery Over-Charge protection | Use of a standard battery charger which has built-in charging cut-off circuit when the battery is fully charged. |

| 10 | Low Battery Alarm Indicator | A LED push button with built-in LED has been used which will light up as an alarm when the cut-off circuit cut the robot supply in case the battery is low. |

| 11 | On charging operation | The charging system is designed in such a way that we can also operate the robot even if it is charging. We do not need to wait for battery to get charged first. |

| S. No. | Resistance | Comfort Level of the Patient | Quality of Heartbeat Sound | Stage | Xbox Vibration Feedback |

|---|---|---|---|---|---|

| 1 | >20 KΩ | x | No Heartbeat sound or pure noise | When stethoscope does not touch the body | No Vibration |

| 2 | 20 KΩ to 8 KΩ | Easily bearable for patient | Noisy Unclear heartbeat sound wi | When stethoscope has just touched the body | Pulsating vibration with more delay |

| 3 | 8 KΩ to 1.5 KΩ | Bearable for patient but not for long period of time | Audible heartbeat sound but the intensity is low | When Stethoscope slightly presses on the body | Pulsating vibration with less delay |

| 4 | <1.5 KΩ | Unbearable for patient after few seconds | Clear heartbeat sound | When Stethoscope presses hardly on the body | Continuously vibrating |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, H.R.; Haura, I.; Uddin, R. RoboDoc: Smart Robot Design Dealing with Contagious Patients for Essential Vitals Amid COVID-19 Pandemic. Sustainability 2023, 15, 1647. https://doi.org/10.3390/su15021647

Khan HR, Haura I, Uddin R. RoboDoc: Smart Robot Design Dealing with Contagious Patients for Essential Vitals Amid COVID-19 Pandemic. Sustainability. 2023; 15(2):1647. https://doi.org/10.3390/su15021647

Chicago/Turabian StyleKhan, Hashim Raza, Insia Haura, and Riaz Uddin. 2023. "RoboDoc: Smart Robot Design Dealing with Contagious Patients for Essential Vitals Amid COVID-19 Pandemic" Sustainability 15, no. 2: 1647. https://doi.org/10.3390/su15021647

APA StyleKhan, H. R., Haura, I., & Uddin, R. (2023). RoboDoc: Smart Robot Design Dealing with Contagious Patients for Essential Vitals Amid COVID-19 Pandemic. Sustainability, 15(2), 1647. https://doi.org/10.3390/su15021647