1. Introduction

Since the first industrial revolution, established manufacturers have wished to satisfy the increasing customer demand without compromising the fast-depleting natural resources [

1]. However, over the years, the world has moved from mass production to customized production and is currently in the era of personalized production [

2]. As a result, manufacturers must respond quickly and with greater flexibility. The modular design satisfies the changing customer requirements and cost constraints [

3]. Moreover, modular and reconfigurable products can enhance the flexibility and acceptability of Industry 4.0 [

4]. The core idea of Industry 4.0 is to use emerging technologies in a way that business and engineering processes are deeply integrated, making production operate in a flexible, efficient, and sustainable way with consistently high quality and low cost [

5].

The term “Industry 4.0” was coined in Germany in 2011 and used for the next industrial revolution aiming for the digitalization of the manufacturing industry. This digitalization was brought by Industry 4.0 strategies by creating automation with software and connecting all the processes in the manufacturing setup. With this strategy, businesses will establish global networks using their machinery, production facilities, and warehousing systems in the cyber-physical systems (CPS). These CPS in the manufacturing environment include smart machines, storage systems, and production facilities capable of autonomously exchanging information and controlling one another. This leads to significant benefits in the manufacturing, supply chain, material utilization, and product life cycle management processes [

6]. It is worth noting that sustainability is a major global issue, and ignoring it might lead to financial losses [

7]. Therefore, digitization has been the key enabler for sustainability and sustainable development and is the building block of Industry 4.0 [

8].

Modular product architectures enable mass customization by allowing a large range of goods to be built and assembled. Hence, modularity can be employed in goods (product architectural designs), manufacturing processes, and logistics (supply chain configuration) [

9,

10]. Product architectures that use standardized interfaces in both hardware and software allow for the effective implementation of mass customization and related manufacturing strategies [

11]. It is worth noting that product architecture refers to how a product’s functional parts are organized into physical units and how they interact. A module is a physical or conceptual grouping of components, and modularity is the concept of breaking down a system into independent portions or modules that can be regarded as logical entities in both hardware and software [

12].

Modularity is also a business approach aiming for a flexible product architecture that allows companies to quickly develop, produce, and market new products to mass customization and personalization [

13]. Furthermore, a module is a specification entity containing a specific function and related interface information, any module variant carries relevant information in the value chain, such as in sales, engineering, supply chain, and production [

14]. Following this approach, modularity creates system information on different business levels to support Industry 4.0 or smart manufacturing in a reliable way. Software modularity is the decomposition of a program into smaller programs with standardized interfaces and it has the same definitions as hardware modularity [

12]. Software modules are based on different functions required by customers with standardized interfaces, i.e., to allocate different functions to software modules and then implement them in software code. In addition, the choice of product architecture has broader implications in design and manufacturing [

15].

The process of converting system-level specifications into component-level specifications is known as system architecting [

16]. The breaking down of complex products, assemblies or large engineering systems into smaller subsystems can be managed easily by system-wide decomposition. Therefore, system architecture is used to identify parts and subassemblies to construct modular product architecture in this study [

16].

Table 1 shows the previous research by various authors related to the key technologies and enablers of Industry 4.0 and smart manufacturing. This table also represents the state of the art in Industry 4.0-related topics and current research. Various authors have worked on different aspects of smart manufacturing, including improved quality of production systems, inventory control, supply chains, and cost reduction [

17,

18,

19,

20,

21]. Further work includes modeling of flexible manufacturing systems, applying mass customization strategies, effects of performance and variable production rates, and how to improve production systems for Industry 4.0 [

22,

23,

24,

25,

26].

According to Ngjeqari [

44], the 4th Industrial Revolution is an enabler of sustainable development, but the convergence of digital transformation and sustainability remains underdeveloped. Furthermore, previous research related to Industry 4.0 technologies and approaches has not adequately addressed the issues of short product life cycles, volatile user demands and interchangeable and sustainable modules. Therefore, to address the issue of short product life cycles, companies can offer differentiated products by sharing modules in the product families by applying product platforms. In addition, they can upgrade and redesign products for the next generation. In the product platforms, the standard and differentiated entities are balanced in the modular structure. Simply focusing on the Internet of Things, automation of manufacturing processes, or the cost and efficiency of production operations is no longer enough to compete in the global marketplace. Therefore, in this study, a method is proposed applying a system architecture approach to develop modular product architecture that supports identifying the product and manufacturing relationships at the early design phase, customization, and sustainable flexible manufacturing system for an Industry 4.0 environment. The study includes how the proposed method was used in case studies of 3D printers and electric toothbrushes and validated it by applying it to the development of product architecture.

The study also illustrates the hierarchical decomposition of the system in terms of its functional and structural levels and the use of the Module Indication Matrix (MIM) to identify the modules. The architecture of the products was developed based on the analysis by assembling the nine modules and the various interfaces in the product structure. In addition, product platforms were developed from the product architecture. Then, the product-to-process relationships that support sustainable manufacturing planning were illustrated, and a framework based on the proposed information and decision-making method for Industry 4.0 solutions were represented. In addition, the study discusses the significance of modular product architectures and managerial implications in the context of the 4th industrial revolution.

2. Proposed Method

Modular product architecture not only improves sustainability performance from a technological point of view but also improves its creative and social dimensions. Initially, the modular product was used primarily for design engineering at the product level, but with respect to time, the frameworks and methodologies of the modular product are used for designing process and system levels. In this study, system architecting is used to define systems, subsystems and their interfaces via hierarchical system decomposition. It is crucial because the product’s general functions, significant subfunctions, and their relationships are identified in the conceptual design phase [

45,

46].

Modularization approaches such as Modular Product Development (MPD), Design Structure Matrix (DSM), and Modular Function Deployment (MFD) are widely used in academia and industry. These methods have a variety of applications, from product design to organizational domains [

47,

48]. However, they differ in terms of the aim of modularization. These methods are also useful for system decomposition, module identification, and modeling of interactions between elements, but they neither assist in modeling of interfaces from function to form at various levels nor do they identify the product and process relationships. Therefore, a method is required that supports modeling of interactions from function to form at multiple hierarchical levels, identifies product and process relationships, and supports customized products in a flexible manufacturing system for Industry 4.0 environments as an enabler of sustainable development.

2.1. Method to Develop Product Architecture

This study investigates the Fused Deposition Modeling (FDM) type (direct extrusion) 3D printer system and electric toothbrush. First, both products were examined from product manuals and then the data collected was used to analyze and synthesize the products. These products were analyzed using quality function deployment, system decomposition and module indication matrix. The analysis identifies the requirements and facilitates the physical realization of the system in the form of modules and their interfaces. Then, a synthesis of the systems was conducted to develop the product architecture and product platforms [

49,

50]. Finally, the outcomes represent the manufacturing requirements and framework model.

2.2. Steps in the Proposed Method

The proposed methodology is based on an iterative design with the following steps:

Initially, quality function deployment (QFD), which is the key approach of the proposed method, was employed and divided into four processes. First, the voice of the customer (VOC), which consists of customer feedback, was recognized in order to improve the product and process for a significant change. Second, the importance of the customer requirements was identified, as this information is essential to properly weight users’ needs in the QFD. Third, it was determined which product characteristics have an impact on users’ needs. Fourth, mapping of the user needs to product attributes was performed in the QFD.

Then customer needs were converted into system-level specifications (i.e., abstract descriptions for product modeling). In the system decomposition, the major functions were broken down into subfunctions until no more functions could be obtained. The system model is created by putting the functions into physical form. In system architecting, the product’s main functions, subfunctions and components were identified.

Finally, in the analysis step, each technical solution identified from product decomposition was analyzed against the module drivers to form potential modules. This analysis was performed in a module interaction matrix (MIM). Technical solutions identified in the system were essential in supporting the development of modules by using module drivers [

51]. In addition, the division of modules from the perspective of sustainability and reliability was discussed.

During synthesis, the modules were assembled to build the product architecture. In the product architecture, modules and their interfaces were developed. Product platforms were then developed from the product architecture. Synthesis is based on the analysis in the previous step; however, product architecture and platforms may change due to market or technology requirements.

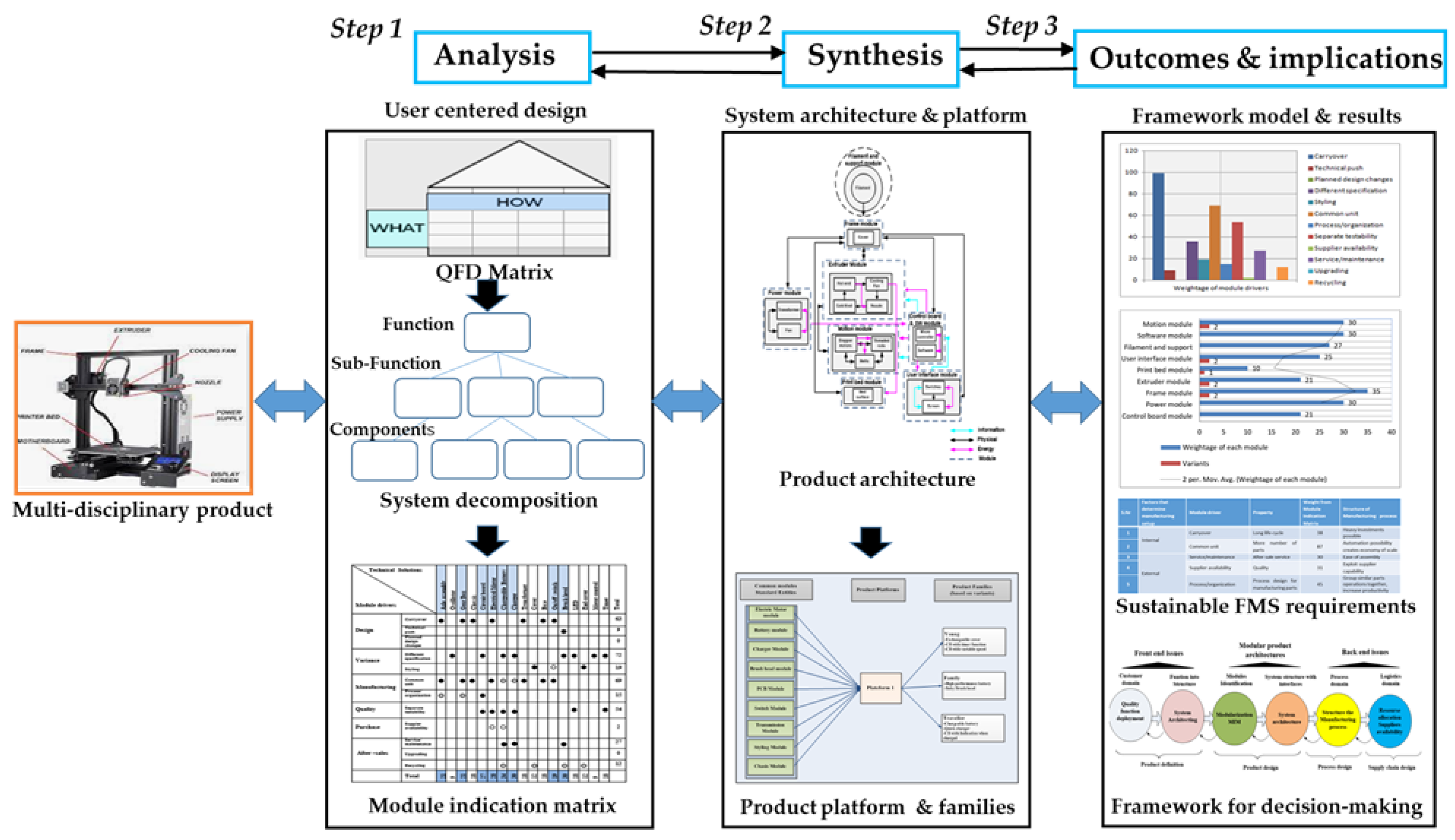

Finally, based on the analysis and synthesis, outcomes and implications, i.e., customization, interface management, and the flexible manufacturing systems were built as shown in

Figure 1. Furthermore, a framework model for decision-making at different levels was developed to implement a sustainable flexible manufacturing system in Industry 4.0.

The flexibility and functionality of modular products make them more conducive to sustainability. From the analysis and synthesis, companies can offer distinct products by sharing modules across product families by using product platforms. This approach enables them to upgrade and redesign products for future generations. This will lower the cost of the product and increase production flexibility and sustainability.

Since it is an iterative process, any change or addition in modules due to new technology or from the market will change the synthesis and analysis part, as shown in

Figure 1.

The overall approach comprises three steps, i.e., analysis, synthesis and outcomes, as given in

Figure 1. The analysis represents the QFD, system decomposition and MIM. Synthesis includes product architecture and platform, while the product implications and results were displayed in the outcomes.

3. Application of the Proposed Method

3.1. Case Study 1: 3D Printer

3D printing is one of the latest manufacturing technologies. Different types of methods and technologies are employed for 3D printing. This case study is about Fused Deposition Modeling (FDM), where the raw material (plastic filament) is melted and layers are added to the 3D model. The main parts of FDM printer include an extruder, control panel, threaded rods, frame, and print bed. The manufacturing of 3D printers has increased as a result of rising demand. Currently, 3D printers are largely used for research; however, in developed nations, they are also utilized for manufacturing purposes. As a result, 3D printers are mostly utilized for three fundamental tasks, including research, manufacturing, and education, or demonstration.

From the user’s perspective, requirements include the following:

Functional performance (reliable, long-life time, less printing time, etc.);

Physical requirements (e.g., size, weight, shape);

Low price;

Type of material that can be printed;

Exchangeable parts (e.g., nozzle, rods, heaters, etc.);

Easy maintenance;

Ease of assembly and upgradation.

3.1.1. Analyze Requirements and Product Attributes by Applying Quality Function Deployment Matrix (QFD)

Initially, the product properties are derived from the customer’s requirements. Once the company-specific needs and market demands have been identified, the next step is the use of the quality function deployment (QFD) matrix to analyze the customer requirements and the product attributes. This analysis helps to determine what essential product properties can be used to fulfill the respective customer needs.

To know what customers, want in a 3D printer, it is necessary to first determine the significance of each customer’s request. In this study, 3D printer data was collected through a survey form. Based on the survey results, the customer requirements, along with the weights, are enumerated in

Table 2. There were a total of 11 customer demands for a 3D printer, and 20 observations from various 3D printer users were acquired, as mentioned in

Table A1 in

Appendix A.

It is also important to find measurable product attributes that can be derived from customer demands. Product attributes can be size, weight, shape, speed, range of material, as well as assembly and modularization etc.

Relationship between Demands and Attributes:

For successful product design, it is important to transform the customer voice into the essential technical requirement of the product. A careful analysis by participants from the engineering, product development, manufacturing, and marketing departments is often necessary to identify all related product attributes that affect customer demands. Data about product attributes of 3D printers were collected from design and production engineers. In this study, 3D printer data was collected through a survey form. The product attributes for the 3D printers are modularization, motion control, level of control, power, build area, weight, frame size, material, printing (parameters), and quality.

Next, the QFD was created, i.e., the relationship chart between customers’ demands and product attributes, as shown in

Table 3. The table is filled with three standard values: 9, 3, and 1, where 9 denotes a strong correlation, 3 is a medium correlation, and 1 a weak correlation between needs and product attributes. In the QFD table, the points in a vertical column represent that these demands are more important to consider with high weightage. The large weights in the horizontal line, on the other hand, show that the product’s qualities can generally meet 3D printer requirements. For instance, the surface finish of the 3D part can be relevant to product properties, i.e., printing parameters, material and quality. A need like printing (parameters) gets a higher score as it is associated with things like surface finish and material type. A similar higher weighting is given to modularization, which is associated with low cost, a variety of materials, and simple maintenance (due to standardized modules).

3.1.2. Hierarchical Decomposition Using System Architecting to Identify Functions and Select Technical Solutions

Once the market requirements and product attributes are identified, the next step is to perform hierarchical product decomposition using system architecture as defined by Ulrich [

52]. The decomposition of the 3D printer is represented in function-system-component domains, as shown in

Figure 2. Initially, the functional decomposition reveals that the main functions of a 3D Printer are: (a) to control, (b) to move, (c) to print (direct extrusion), (d) to supply power, and (e) to support.

These functions are then linked to core systems (e.g., motion control system, user interface system, extruder system, power supply system and support system). These core systems provide information about the technical solutions in the form of modules. For instance, in the extruder system, threaded rods, hot end, cold end, belts and nozzle components are identified as technical solutions. These technical solutions are then analyzed against the module drivers to form potential modules, as discussed in the next sections.

3.1.3. Module Identification and Their Reasons to form Modules Using Module Indication Matrix (MIM)

After decomposition, each technical solution derived from the product decomposition is assessed against the module drivers. As shown in

Table 4, this analysis is carried out in a module interaction matrix (MIM) where the product technical solutions are assessed against the module drivers to generate possible modules. In the MIM, module drivers are the driving forces the firm could generate modules. There are 12 different module drivers, which together define the whole product lifecycle. The 12 module drivers are technology evolution, planned design changes, different specifications, styling, service/maintenance, upgrading, carry over, common unit, process/organization, separate testing, supplier availability, and recycling.

In the module interaction matrix, each technical solution is assessed with respective module drivers on a scale (9, 3, and 1) according to the importance of its reasons for becoming a module. According to this method, highly weighted and many and unique module drivers points toward the technical solution under consideration are likely to form a module. For example, the technical solution ‘stepper motor’ has higher scores in carryover, common unit, and separate testability due to its strong relationship with them. This is because the motor is carried from one generation to another and is a part of every printer as a common unit. In addition, the motor can be separately tested or outsourced to supplies. Due to its higher weight and unique module drivers, it might be a strong candidate for a separate module named as motion module.

The technical solution ‘frame’ is scoring higher with planned design changes, process organization, and different specifications due to its close association with them. This is because frame design can be changed in different printers and is available in various sizes, such as small and large ones. Further, its manufacturing process is the same for various versions. Due to its higher weight and unique module drivers, it might be a strong candidate for a separate module named as frame module. In this way rest of the modules are identified, as shown in

Figure 3 and

Figure 4. In the module indication matrix (MIM) of the 3D printer, the module drivers, such as common unit, process/organization, carryover, and supplier availability, have big totals. This indicates a well-developed product (or subassemblies) with a variety of options (

Figure 3). A high carryover score indicates the need for more technical solutions in future products. Customer demands are represented by styling and different specification scores. Technology evolution and upgrading receive lower scores.

Five modules, along with weightage and variants in the 3D printer case, are shown in

Figure 4. These variants include a motion module, extruder, print bed, frame and user interface.

In the MIM (

Table 4), seven of the most weighted technical solutions, along with the print bed and power module, were chosen to develop nine modules in the 3D printer. This way, both hardware and software modules were identified in the 3D printer.

3.1.4. Division of Modules from the Perspective of Sustainability and Reliability

The recyclability, flexibility and functionality of modular products make them more conducive to sustainability. By creating products that can be modified to fit new environments and meet changing needs, manufacturers offer customized products to markets. Moreover, these products are more quickly built, reducing the amount of resource use. In this study, the MIM analysis is used to reconstruct the architecture of a commercial product into a modular architecture. The sustainable modular drivers, specifically interface complexity, upgrading, recycling, and manufacturing process similarity, are utilized to drive sustainable modular design.

Table 5 shows the 3D printer modules, the strongest drivers for each module and sustainability in modules.

3.1.5. Product Architecture: 3D Printer with Modules and Interface Design

Product architecture refers to how a product’s functional parts are organized into physical units and how they interact [

53]. The architecture of the 3D printer is developed based on the analysis (using system architecting and module indication matrix) by assembling the nine modules, as shown in

Figure 5. The modular product structure assumes that the design changes and a number of variants should not be spread within the whole system but be confined to just a few modules. In this product, variants are introduced only in the nozzle, threaded rods, end stops, frame, build area, and user interface modules.

The interfaces between the components are shown with arrows. Various interfaces, such as geometrical connections, energy flows and information flows, can be identified between the modules.

3.1.6. Product Platforms and Product Families

Modules and their interfaces in the product can be used to develop product platforms [

53]. From the 3D printer analysis and synthesis in the preceding section, it is feasible to construct product platforms and families. Companies can offer distinct products by sharing modules across product families using product platforms. This will lower the cost of the product and increase production flexibility and sustainability. Companies can also upgrade and redesign products for future generations.

In the 3D printer example, nine software and hardware modules are identified in the module identification matrix. With software modularity, it is possible to move the software solution from one hardware to another and enable hardware portability and scalability. One platform is developed that comprises common entities used in all four variants of the 3D printer, as shown in

Figure 6.

This platform is also extended to product families such as 3D printers for research, education, personal use, and manufacturing, where derivative products can be created from the platform based on

For research purposes, smaller frames and multi-nozzles can be one of the possibilities; however, other frame sizes can also be used for full-scale printing.

For personal use, a high-performance battery and simple user interface can be used.

For industrial use in manufacturing setup, a large print bed area with instant layer cooling can be used.

For educational demonstration, a small size with a single nozzle and multi-parameter control board can be used.

3.2. Case Study 2: Electric Toothbrush

To develop modular architecture, Electric Brush is used as an illustrative example. Electric toothbrushes, a new form of a battery-powered toothbrush with an oscillating brush head, are becoming more popular. The main parts of the device are the battery pack, electrical motor, drive shaft, brush head, control card and charging unit.

A global “small appliance” manufacturer has decided to introduce a new global toothbrush platform, focusing on three key end-user segments: Young, Family and Traveler. According to a market survey, the top customer demands and functionality for each segment are as follows:

Functional performance (high impact resistance, long lifetime, long battery life, quick charging, variable speed, timer function, etc.);

Physical requirements (e.g., size, weight, and shape);

Low price;

Exchangeable cover;

Easy maintenance, ease of assembly, and upgradation.

It is also important to find product attributes that are measurable and derive from customer demands. Product attributes can be size, weight, shape, speed, range of material, as well as assembly and modularization etc.

3.2.1. Analyze Requirements and Product Attributes by Applying Quality Function Deployment Matrix (QFD)

Initially, the product attributes are derived from the customer’s requirements. Once the company-specific needs and market demands have been identified, the next step is the use of the quality function deployment (QFD) matrix to analyze the customer requirements and the product attributes. This analysis helps determine what essential product properties can be used to fulfill the respective customer needs.

To know what customers want in an electric toothbrush, it is necessary to first determine the significance of each customer’s request. Therefore, electric toothbrush data was collected through a survey form. The customer requirements and the weights were identified based on the survey results. There were a total of 12 customer demands for an electric toothbrush, and 20 observations from various electric toothbrush users were acquired, as mentioned in

Table A2 in

Appendix A. Referring to

Table 6, requirements like degree of variation in use (variety) have a higher score and is an indication of future trends. Similarly, another higher weight-age is for modularization, which is related to flexibility in use, upgradation and easy maintenance (due to standardized modules). Furthermore, the material is relevant to long life and reliability concerns.

3.2.2. Hierarchical Decomposition Using System Architecture to Identify Functions and Select Technical Solutions

Once the market requirements and product attributes are identified, in the next step, the hierarchical product decomposition is performed using system architecting tasks to develop product architectures in the way defined by Ulrich [

54]. The toothbrush is decomposed into function, system, and component domains, as shown in

Figure 7. The major functions of an Electric Brush are (a) to control, (b) to rotate, (c) to give power, and (d) to support, according to the functional decomposition.

Following that, these functions are linked to core systems (e.g., motion control system, power conversion system, power supply system and support system). These basic systems provide information about technical solutions in the form of modules. For example, technical solutions in the control system include motor control, circuit board, LED, timer, and oscillator components. These technical solutions are then analyzed against the module drivers to build possible modules, as described in the following sections.

3.2.3. Module Identification and Their Reasons to Form Modules Using Module Indication Matrix (MIM)

Each technical solution derived from the product decomposition is assessed against the module drivers. As indicated in

Table 7, this analysis is carried out in a module interaction matrix (MIM) where the product technical solutions are assessed to generate possible modules. In the MIM, each technical solution is rated on a scale of (9, 3, and 1) and assessed with respective module drivers for the importance of its reasons for becoming a module. According to this approach, highly weighted, many and unique module drivers indicate that the technical solution under consideration is likely to constitute a module.

In the module indication matrix (MIM) of an electric toothbrush, there are large totals for the module drivers, such as common unit, carryover, various specifications, and separate testability. This indicates a mature product with variants availability and acceptable quality as a result of separate testability. A high carryover score indicates more technical solutions for next-generation products. Score by different specifications and styling represents external factors related to the user’s requirements. Lower scores for recycling and service/maintenance indicate the need for after-sales support. However, there are no scores for product upgrades and planned design changes, as demonstrated in

Figure 8.

Figure 9 depicts the weighting of each module as well as the variants. In the MIM matrix, four modules with variants are identified to address the three market sectors. These variants are in the charger, battery, brush head and PCB modules.

In the MIM, seven of the most weighted technical solutions, along with chassis and styling, were chosen to develop nine modules for the electric toothbrush.

3.2.4. Product Architecture: Electric Toothbrush with Modules and Interface Design

The architecture of the electric toothbrush is developed based on the analysis (using system architecting and module indication matrix) by assembling the nine modules. The modular product structure assumes that the design changes and a number of variants should not be spread within the whole system but be confined to just a few modules. In this product, variants are introduced only in the battery, charger, brush head and PCB modules.

The interfaces between the components are shown in

Figure 10 with arrows. Various interfaces can be identified between the modules, including:

Physical or geometrical connections.

Energy flows (e.g., mechanical rotary, electrical, thermal, etc.).

Information flows (e.g., sensor signals, actuator commands, and control commands)

Designers and engineers have the crucial role of finding, creating, and optimizing modules and their interactions in the early stages of systems design by examining the system architecture of existing products.

3.2.5. Product Platforms and Product Families

From the toothbrush analysis and synthesis in the preceding section, it is feasible to construct product platforms and families. Companies can offer distinct products by sharing modules across product families by using product platforms. This will lower the cost of the product and increase production flexibility. Companies can also upgrade and redesign products for future generations.

The standard entities and differentiated entities are balanced in the modular structure of product platforms. For instance, nine modules are identified in the module identification matrix in the case of the electric toothbrush. The electric toothbrush is designed on a single platform with common entities utilized in all three variations, as indicated in

Figure 11. This platform has been expanded to include product families such as young travelers, and families. From this platform, the variants can be developed as

For young, an exchangeable cover and a circuit board with a timer can used;

For families, high-performance batteries and separate baby brush heads can be used;

For travelers, a chargeable battery with quick charging can be used.

4. Sustainable Flexible Manufacturing System—Product-to-Process Relationships

The product’s architecture supports the product and manufacturing process relationships. These relationships can be developed concurrently, thus enabling product features to be linked to the manufacturing setup. Thus, when a modular architecture is developed, the factory can be reorganized accordingly, or reconfiguration is possible.

In the 3D printer case (

Table 8), the manufacturing setup is based on internal and external factors derived from the module drivers. From the analysis of the 3D printer, the main drivers for internal setup, i.e., production, are related to carryover and common units because they have higher weightage in the MIM. Similarly, the main drivers for the external factors are more related to supplier availability, process/organization, and service maintenance.

For instance, parts such as the fan and stepper motor are identified as carryover (specific functions can carry over to different products, and no technology changes are expected). Similarly, in the process/manufacturing domain, more parts such as the extruder, support system, and power supply are identified in the common unit (involves parts that are identical in all products and used in several versions). Therefore, product and process relationships can be identified for a sustainable flexible manufacturing system by applying modularity approaches at the system design level.

In the case of the electric toothbrush, as given in

Table 9, the manufacturing setup is based on internal and external factors derived from the module drivers. From the analysis of the toothbrush, the main drivers for internal setup, i.e., production related to carry-over and common units, as they have higher weightage in the MIM. Similarly, the main drivers for the external factors are more related to variance, supplier availability, and service maintenance. This way, manufacturing requirements at the system level can be identified for each module. By modularization, companies can structure their manufacturing setups and concurrently undertake their development activities.

The comparative analysis of the two manufacturing products indicates that both have higher scores for carry-over, common unit, service and maintenance. A higher score for common unit indicates that automation is possible for those modules to achieve economies of scale. Both products have ease of assembly due to higher scores for service & maintenance. A module driver, i.e., supplier availability in both products, indicates the availability of suppliers to improve quality. However, a higher score for module driver-process/organization in 3D printer means that process design of manufacturing parts is possible, i.e., grouping similar parts with the same manufacturing process to increase productivity. While in the case of the electric toothbrush, a flexible material handling system is required to manufacture the three variants of young, traveler, and family.

5. Framework for Information and Decision-Making for Industry 4.0 Solutions

Based on the information and the decision models using product architectures, companies can make strategies in their business models to handle the challenges of shorter time to market, complexity issues, and product life cycle issues to implement Industry 4.0 strategies effectively.

Modular approaches can be used to develop a basic skeleton of decision-making model at various business levels. This study develops a method that supports the modeling of relationships from function to form at multiple levels and enables customization for sustainable flexible manufacturing system in Industry 4.0. Furthermore, from the analysis of the case studies, a decision-making model is developed (

Figure 12) as a guideline for new business models that can be used in Industry 4.0 scenarios.

As shown in

Figure 12, front-end issues are more related to customer requirements, market segmentations, and how to translate requirements into technical specifications using quality function deployment and system architecture approaches. From this framework, the industry can have solutions to apply to certain customer requirements coming from the Internet of Service and have an edge in defining company strategy and the way to implement it while pursuing Industry 4.0 solutions.

The back-end issues are associated with the process domain and logistics domain, as shown in

Figure 12. While the system architecture supports the structuring of the manufacturing process and allocation of resources with suppliers’ availability, as given in

Table 8. The supplier availability, service and maintenance are related to the organizational effects of modularization. As illustrated in

Table 8, service and maintenance are related to after-sale service, supplier availability is related to quality, and process organization refers to the fact that parts of the product that require the same production process can be combined into a module that might improve the efficiency of the production process. Furthermore, the modular design enables the postponement of parts production to later stages of supply chain management, making it possible to assemble parts as per the customer’s requirements in different geographical locations. This will facilitate the industry to make a strategy for production planning and supply chain management, as shown in the back end of the framework in

Figure 12.

The proposed framework can be used by applying Industry 4.0 technologies to support advanced manufacturing. For example, digital twins (DT) technology offers a way to test products using models in a virtual environment rather than physically. DT can enable the flow of information from the front end (product information) and from the back end (process and supply chain design) to optimize the concept of the Modular Product Architecture Framework in product design.

The core of a digital twin is the virtual models to reproduce the geometry, physical properties and behaviors. The information at the front end (see

Figure 12) is the customer requirements, and product specifications can be utilized for the digital twin product at the system design level. Then modeling and simulations of the product are performed for system behavior analysis. After the system design, component or module design can be initiated in DT. The information from the module indication matrix (MIM) in the framework can be utilized in the digital twins to initiate module design prototypes. Next, the information from the front end and modular product architecture can be used to develop the digital twin production. In addition, the information in the process design, such as structuring the manufacturing, can be used to develop digital twin production. The production DT is critical to implementing factory automation and advanced manufacturing technologies. The Quality Function Deployment Matrix of the proposed framework can be improved by using the performance digital twin utilizing customer feedback through the Industrial Internet of Things (IIoT). Each digital twin builds on and provides feedback to the other digital twin. The digital twin reduces the time and cost of developing and manufacturing products by enabling more robust designs and reducing product costs. Further, the design improvements enable efficient manufacturing processes and technologies.

Software modules are based on different functions required by customers with standardized interfaces—that is, to allocate different functions to software modules and then implement them in software code. It is possible to move the software solution from one hardware to another, called hardware portability. If the software is not flexible that does not scale well with the hardware. However, with the software modules in place, it is possible to enable hardware portability and scalability.

Greater flexibility through the combination of pre-configured units via standardized interfaces is possible through modular product architectures. This supports a flexible material handling system that would pave the way for decentralized control based on cyberphysical systems. These systems can facilitate that assembling is not controlled centrally, but self-organized and decentralized. A CPS can control both highly automated and manual processes.

6. Discussion and Implications

In the Industry 4.0 scenario, machines, products, and operators in a factory are all connected to the Internet of Things (IoT). The Cyber-Physical Systems (CPS) in each factory can create and test virtual prototypes of a product, allowing for quick feasibility, drafting, and quoting following customer-specific requests. Companies are linked to their customers and each other in an ecosystem via the Internet of Services (IoS), which simplifies business processes for customers and provides an infrastructure for a shared value chain. These actions would benefit from modular architectures, allowing companies to quickly develop, produce, and market new products. These approaches create standardized interfaces that carry and advance company-specific strategies.

In order to make quick changes in the manufacturing setup, such as easily upgradable and reconfigurable machines, cells or plants, this framework supports the development of modular manufacturing architectures. The architecture of the manufacturing system must be based on exchangeable mechatronic modules. With the combination of electromechanical and embedded systems and vertical and horizontal integration of the whole system, including manufacturing, the system could be adopted according to the variable requirements, even with a lot size one.

The proposed method supports how to develop product architecture for a flexible manufacturing system. These architectures allow flexibility to adapt to changing requirements that will efficiently support Industry 4.0 solutions. Modular products lead to product platforms and families that facilitate customization and are sustainable. Product platforms are sets of common components, modules, or parts from which derivative products can be developed. For example, Volvo’s production strategy aims to ensure commonalities across assembly plants. This new method of vehicle design makes it possible to build several car models from a common ‘platform.’ The purpose was to achieve such advantages as shortened lead times, higher production efficiency, and flexibility in model changes.

One of the modern-day challenges to manufacturers is the responsiveness required by the markets. This issue is handled through reconfigurable manufacturing systems (RMS), as modularity is one of its characteristics [

55]. RMS is a responsive manufacturing system whose production capacity can be adjusted to changes in market demands, and its functionality is adaptable to new products [

11]. Part of the family identified in the modular architectures is mapped to the machining functions. Machine tool parts are identified based on the machining functions required for these parts. These tool parts are grouped into machine modules for machining a particular part of the family. In this way, reconfigurable machine tools (RMT) can be designed to give quick responses to the varying demands of the markets.

Modular designs enable companies to outsource modules to suppliers that improve the overall quality and management in the development process, as the suppliers are specialists in their respective domains. For example, Dell computers offer customized solutions with processors supplied by the Intel Company. Soon, companies may outsource product assembly to customers. Thus, customers could assemble and upgrade the products of their choice based on technological advancements and changing requirements.

Modular innovation strategies will complement the latest technologies, such as the Internet of Things (IoT), 3D printing, and virtual inventories envisioned by Industry 4.0. Modular design will enable the postponement of parts production to later stages of supply chain management, making it possible to manufacture products using 3D printers resulting in lower inventories and costs. This has been observed during the COVID-19 pandemic as some companies adopted additive manufacturing.

Managerial Implications

Industries are facing challenges to achieving sustainability on the basis of technological development. However, the improvement is not possible without huge investment and capital. With mass customization strategies, managers can focus on providing distinct functionality in the products that can be offered to the customers. As a result, managers may concentrate on improving their core technical competencies and R&D emphasis to promote product innovation for sustainable development with minimum cost.

Adopting a modular design approach has several benefits. The modular design enables easier administration. More resources can be allocated at the beginning of product development. This method allows for concurrent product development. Firms can also employ modular architecture and platforms to structure their manufacturing processes. The assembly process and required manufacturing resources can be recognized early in the design stage by determining the architecture and required interactions between the modules. Automation is a viable option for common unit parts to achieve economies of scale. It is evident from the analysis that the necessary resources can be identified earlier in the design stage.

7. Conclusions

Innovation, technology development, and R&D are a way towards sustainability. Product and process level re-engineering to improve sustainability performance from further integration of modular product architecture concepts and methods. This study contributes to the development of a sustainable flexible manufacturing system for the Industry 4.0 environment, where a method is proposed to develop modular product architecture. This architecture identifies the product modules and their interfaces, as that knowledge is being used to identify the product and manufacturing relationships. These relationships can be developed concurrently enabling product features to be linked to the manufacturing setup. Thus, when a modular architecture is developed, the factory has to be reorganized accordingly. By identifying the architecture and required interfaces between the modules, the assembly process and the necessary manufacturing resources can be identified early in the design stage. For instance, a standard module that is common in all versions of the product family can be used to structure the manufacturing process, i.e., utilizing automation in a factory to achieve economies of scale. Thus, from the above aspects, the overall cost can be reduced for a sustainable manufacturing system.

This study proposes a method using analysis and synthesis to develop product architecture, platforms and a decision-making model. First, the customer requirements are translated into system-level specifications, i.e., the main functions are decomposed into subfunctions that are mapped on subsystems. Then, these subsystems are mapped into the components to identify technical solutions. Afterward, the technical solutions are evaluated against the module drivers in the module interaction matrix to identify modules. The modules are combined to develop the modular architecture of the product along with the interfaces. Additionally, the decomposition process identified commonality instances in the product architecture, which can be utilized for the development of product platforms and product families. Finally, modular architecture has been used to identify the product and process relationships that aid in designing a flexible manufacturing system.

Modular architectures allow companies to quickly develop, produce, and market new products. This approach creates standardized interfaces that carry and advance company-specific strategies. In the 3D printer case study, nine modules were identified in the module identification matrix. With these modules, one platform was developed that comprises common entities used in all four variants of the 3D printer. This platform is further extended to product families. Variants were identified mainly in terms of physical components such as in the nozzle, bed area, frame and user interface.

In the Module Indication Matrix of the electric toothbrush, seven of the most weighted technical solutions, along with chassis and styling, were chosen to develop nine modules. In the MIM of the electric toothbrush, there are big totals for the module drivers such as common unit, carryover, various specifications and separate testability. This indicates a mature product with variants availability and acceptable quality as a result of separate testability. A high carryover score indicates more technical solutions for next-generation products. Score by different specifications and styling represents external factors related to the user’s requirements. The electric toothbrush is designed on a single platform that has common entities utilized in all three variations. This platform has been expanded to include product families such as young, traveler, and family.

Using this method, the designers can identify a maximum number of standard components required and develop product families with minimal changes in architecture. The product architecture in the case studies can be altered by redesigning and using new technology in modules to develop product platforms and product families. Customization can be used to generate more variants in the product using product platforms. In this way, companies can make derivative products for the markets and generate more innovations.

This research also addresses the aspect of sustainable design and manufacturing. The sustainable modular product architecture contributes to enhancing product recovery processes by recycling and reusing modules without full disassembly at the component or material levels. It results in less environmental harm from landfills and reduced usage of natural resources. In this study, the MIM analysis is used to reconstruct the architecture of a commercial product into a modular architecture. The sustainable modular drivers, specifically interface complexity, upgrading, recycling, and manufacturing process similarity, are utilized to drive sustainable modular design.