1. Introduction

Buildings with a high glass-to-wall ratio in facades have high operational heating energy consumption due to low thermal insulation and a high cooling demand because of solar heat gains in the summer. In recent decades, there have been new technologies to solve the problem of high energy consumption in buildings with glazed envelopes that can be divided between passive and dynamic solutions [

1]. Double skins, shading devices, and coatings are considered passive technologies. Dynamic solutions, including, among others, switchable glazing and fluid-filled glazing, adapt their behavior to changing environmental conditions [

2]. Water Flow Glazing (WFG) technology has been previously studied as a dynamic envelope with the ability to absorb heat by changing the mass flow rate of the fluid [

3]. Water Flow Glazing is made up of two or three glass panes. A spacer separates the glasses with a standard water chamber that is 16 mm thick, so the chamber between the glass panes is filled with liquid. The spacer also holds a special fitting that allows the chamber to be connected with a hydraulic circuit. Once the glass panes and the spacers are put together, a structural silicone cord seals the panel around the edges to make the chamber airtight, and the units are ready for assembly using the chosen frame material when complete.

The glass’s high brittleness and low resistance to tension limit its size as a facade element. Therefore, knowing its mechanical behavior under different operating conditions is essential [

4]. The fluid chamber radically alters the structural behavior of the system. One of the most significant differences appears when studying the internal and external loads that a WFG panel must endure, for it is always subjected to the hydrostatic pressure of the water. The UNE EN 1279-1:2019 standard that defines and characterizes insulating glass units cannot be applied to WFG as it does not consider the inner water chamber and all the consequences that this entails on the glass and the sealing cord [

5]. The standard UNE-EN 13022-1:2015, which applies mainly to glass in facades, does not contemplate any similar state of charge for glass or sealant [

6]. The standard ISO 1288-3:2016 studies the effect of permanent loads in building glass and the design’s choice of maximum permissible stresses, which could be applied to Water Flow Glazing [

7,

8]. Finally, UNE EN 15434:2007+A1:2010 defines the structural and ultra-violet resistance characteristics that affect the sealant of all types of glazing [

9]. The fluid in the cavity causes a significant increase in the hydrostatic pressure, which requires thicker and heavier transparent glass panels to avoid a fracture. In addition to the weight, thicker panels raise the price, making the system economically inviable for standard sizes in windows and curtain walls [

10]. Some authors have solved the issue with hydrostatic pressure by imposing the atmospheric pressure at the bottom of the enclosure so that the glass panels work at depression instead of overpressure [

11]. Consequently, to avoid fracture, some authors have introduced spacers between the transparent panels and, thus, reduce the span. Other authors have proposed to set the atmospheric pressure at the midpoint of the panel height [

12]. Therefore, the glass panels are exposed to depression in the upper part and to overpressure at the bottom, reducing the stresses and deflections. Thus, the thickness of the panels can be reduced, and the presence of spacers between the panes is unnecessary. The admissible bending stress for a glass depends on the surface’s treatment, the polymer interlayers between two layers of glass, the panel’s dimension, the environmental conditions, and the duration of the load application [

7]. Laminated and tempered glass can improve strength and durability for specific purposes [

13,

14]. The standard ISO 1288-3 defines the requirements relating to the mechanical strength of the glass in a wide range of cases. It also proposes a model for the treatment of laminated glass. The text provides formulas for calculating deflection and stresses for glass subjected to evenly distributed loads.

Prestressed glass, such as thermally, heat, and chemically toughened glass, has been subjected to strengthening treatments, which generate compressive surface stress in the glass surface, counteracted by tensile stress within the glass body [

15]. Prestressed treatments have a double beneficial effect since they provide extra tensile strength to the glass and a relevant post-tensioning contribution to the cross-section [

16]. Laminated glass is made of two glass panels stuck together by a polyvinyl butyral (PVB) interlayer. The PVB is an elastomer that keeps broken glass fragments in the frame of the glass unit after failure and reduces the harmful consequences. However, the strength calculations at the design stage limit the use of laminated glass [

17]. Pressure-sensitive, plasticity, and failure models are introduced and calibrated to capture the adhesives’ behavior [

18] accurately. The modeling of laminated glasses is challenging due to the complex non-linear behavior of the PVB, which is viscoelastic and temperature-dependent [

19], so its effect has not been considered in this article, as per the recommendation of the standard UNE-EN ISO 12543-1:2022 [

20].

In order to secure a long-life Water Flow Glazing panel, it is crucial to guarantee that the sealing of the water chamber maintains its tightness over the years. The fluid in the chamber plays a vital role in the stresses to which the silicon adhesive fixes both frames of the glasses comprising the glazing [

21]. Therefore, it is desirable to maintain the hydrostatic pressure below the atmospheric pressure level on the maximum possible surface of the glass to reduce the traction loads. However, this can lead to a deflection that brings together the glasses of the glazing, putting them too close or even in contact [

22].

Another critical design condition for WFG panels is the uniformity of the fluid flow inside the fluid chamber. On the one side, it significantly influences the thermal and energetic properties of the WFG. Conversely, it determines the pressure drop in the WFG element and, thus, the required electrical pump power [

23]. Laminar flow models are characterized by the accuracy with which numerical methods quantify their performance and internal flow patterns [

24,

25]. The optimum fluid flow has been analyzed in previous articles. The flow rate can vary from zero to a maximum 2 L/min per m

2 according to the energy management strategy and the weather conditions [

26]. Firstly, the models were selected to accurately describe the behavior of the fluid through the WFG panels [

27]. The experimental conditions were defined and used as a reference for initial simulations. Secondly, the Computer Fluid Dynamics model was validated with the empirical data obtained by full-size prototypes.

The novelty of this article is the development of a mathematical method to assess the structural behavior of Water Flow Glazing to consider the hydrostatic pressure produced by the fluid chamber on the glass to reduce the glass thickness and allow larger glazing sizes. The simulation goals were, firstly, the design of components for homogeneous flow distribution inside the WFG panel; secondly, the reduction in pressure drop in WFG; and, finally, dimensioning the glass panes to guarantee the structural stability of WFG. This article proposes a methodology to assess Water Flow Glazing panels from structural aspects, fluid dynamics, and energy performance.

2. Materials and Methods

This section presents the methodology of geometrical and structural optimization. An initial design of a WFG element for big-scale facades must include the definition of geometrical size, shape, and materials concerning the manufacture and on-site energy production. The simulation model must cover all physical processes, such as heat exchange, fluid flow, and structural behavior, which determine the functionality and performance of the Water Flow Glazing panel.

2.1. Description of the Case Studies

The analyzed Water Flow Glazing panels were made of 2 or 3 transparent glass panes with a cavity between them. Liquid can flow through the cavities in closed-loop interchanging energy with inner and outer environments. The circulation system was composed of a circulation pump and a heat exchanger. The fluid could absorb heat depending on the mass flow rate [

28,

29].

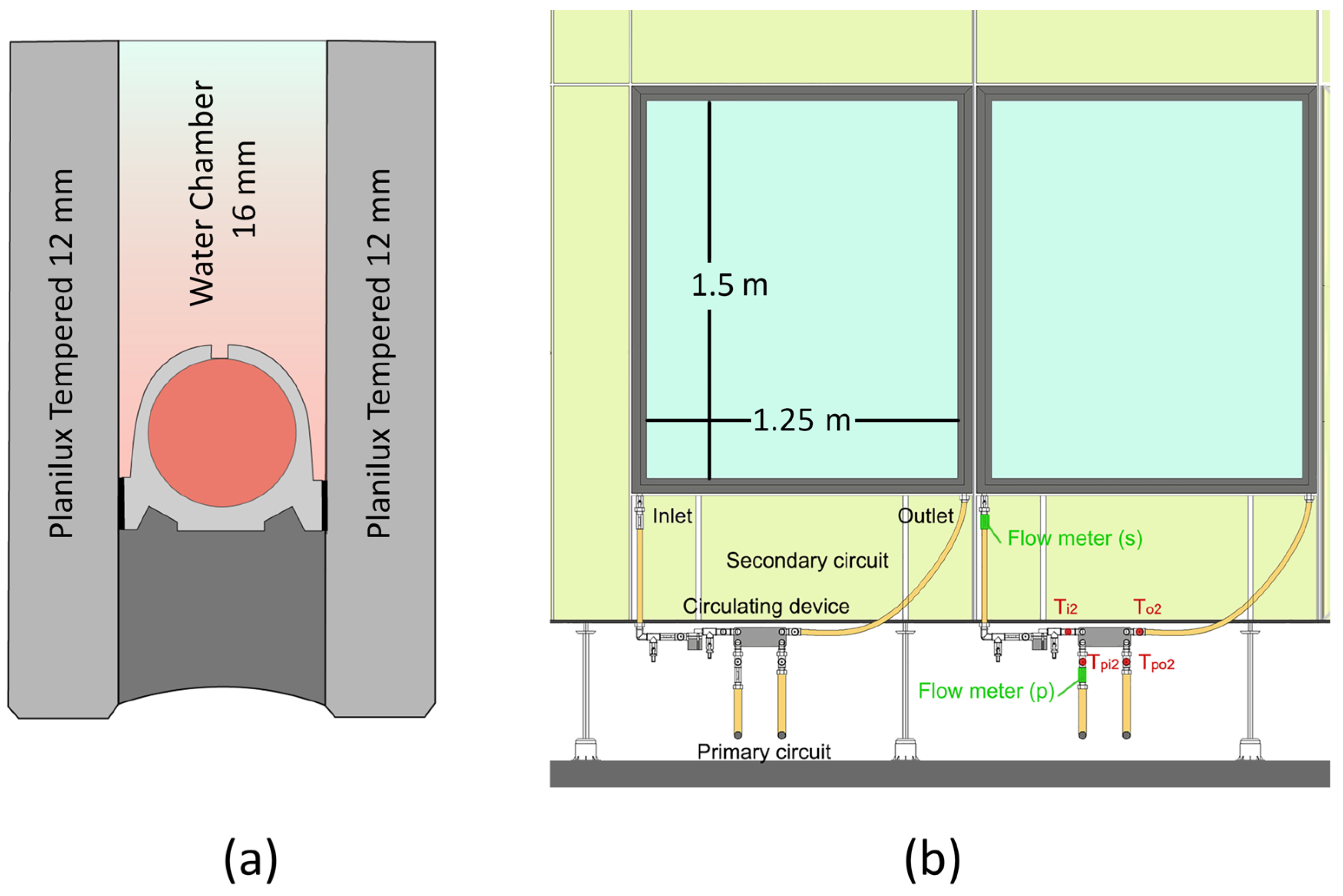

Figure 1 illustrates the geometry of the first case study, an interior partition made of double glazing with a 16 mm water chamber.

Figure 2a shows the WFG module comprising three main components: glazing, circulator, and frame. A correct component selection and assembling process is essential to achieve maximum transparency for full daylight utilization and savings on lighting and thermal energy for nZEB. In addition, optimizing the glass thickness is essential to reduce the cost of the unitized curtain wall system.

Figure 2b illustrates a triple Water Flow Glazing configuration to reject energy. A highly reflective coating Xtreme 60.28 from the manufacturer Cerviglass S.L.U. in Turis, Valencia, Spain, is placed close to the outer glass pane to minimize energy absorption. The strategy behind this glazing was to eliminate internal heat loads by circulating cool water through the water chamber facing indoors. This isothermal envelope allowed for insulating the building from external boundary conditions.

The Water Flow Glazing assembly process follows the same protocol as conventional triple glazing. Once the height and width of the panels are defined, the next step is to select the glass thickness to meet the requirements of maximum stress and deflection according to the standards. The energetic performance of WFG during operation can be controlled using the mass flow rate and inlet temperature [

30].

2.2. Calculation of Stress and Deflection in the Glass

Different loads act on a Water Flow Glazing panel. For example, on the inner face of the glass, there is a hydrostatic pressure distribution due to fluid. This pressure becomes very important if the glass is in a vertical axis since it is linear with height, whereas hydrostatic pressure is uniform in the horizontal axis. On the outside surface of the glazing, the glass is subjected to the action of atmospheric pressure uniformly, regardless of its position. In addition, there is another load due to the weight of the glass sheet that appears if the glass is in a horizontal position or with a tilt.

Figure 3a shows the hydrostatic pressure distribution when the zero-pressure line is placed at the top of the WFG panel. Since stress increases at the same linear rate, compression is above the axis and tension below. The maximum stress on the glass can be reduced by moving the zero-pressure line. Thus, if the zero-pressure axis is precisely at the midpoint of the panel, these stresses will have the same value at the top and bottom of the panel, as shown in

Figure 3b, where h

0 is H/2. The stressed part of the panel is the weakest on the structural front since the glass is fragile and cannot bear tension stress. Another advantage of this system is reducing the maximum stress that affects the sealing of the glass panels.

Figure 3c illustrates the effect of placing the zero-pressure line at the bottom of the WFG panel, where the glass is bearing compression stress.

The panel’s height can make the stress surpass the maximum allowable stress of the material. Consequently, to maximize the panel height and avoid excessive deformations or even fractures, glass manufacturers can introduce spacers between the transparent panels and, thus, reduce the span. Previous articles have studied that the maximum deflection of the glass must be maintained below 1‰ of a characteristic dimension of the panel to prevent optical issues [

31,

32]. In addition, the standards limit the maximum tension and compression stress in glass [

8].

Equation (1) shows the expression to determine the maximum allowable stress,

fg;d for regular or annealed glass, in which the characteristic value of the bending strength obtained in other standards (

fg;k = 45 MPa) is reduced using a series of modification coefficients that affect the characteristics of the load.

where

γM,A is the material partial factor for annealed glass and has different values for the ultimate (

γM,A = 1.8) or serviceability (

γM,A = 1.0) limit state;

ksp is the factor for the glass surface profile with typical values of 1 for float and annealed float glass and 0.75 for patterned glass. The coefficient

kmod is the factor for the load duration [

8]. The standard distinguishes the duration of the loads between short (wind), medium (snow or climatic effect), and permanent (own weight). The

kmod value decreases as the duration of the load increases. It has a maximum value of 1 for loads that last between 20 ms and 1 min, and a minimum value of 0.25. Typical values are 0.75 for wind loads and 0.29 for self-weight. Equation (2) determines the allowable stress of prestressed or tempered glass.

where

fg;k,

γM;A,

kmod, and

ksp are defined in Equation (1);

γM;ν is the material factor for surface prestress that has different values for the ultimate (

γM,ν = 1.2) or serviceability (

γM,ν = 1.0) limit state;

fb;k is the characteristic value of the bending strength of prestressed glass, whose values are found in

Table 1; and

kν is the factor for the strengthening of prestressed glass with typical values of 1 for horizontal and 0.6 for vertical toughening.

For Water Flow Glazing under a permanent load, with an area not exceeding 2 m2, fg;d values are 10 MPa for annealed glass and 45 MPa for tempered glass.

2.3. Hydrostatic Pressure on Vertical Water Flow Glazing

In a vertical position, the pressure on the glass results from the pressure of the water chamber on the inner face and atmospheric pressure on the outer face. Thus, the pressure in the glazing chamber is determined using hydrostatics. Equation (3) shows the expression of the pressure on WFG.

where

P0 represents the pressure at the coordinate

y = 0, g is the acceleration of the gravity,

y is the height of the WFG panel, and

ρ is the density of the fluid. A reference level,

h0, is defined as the height at which the pressure in the chamber is equal to atmospheric pressure,

Pa, as shown in Equation (4).

Equation (5) shows the expression of

Pc by replacing

P0 in Equation (4),

The uniform atmospheric pressure acts on the outer face. Equation (6) shows the resulting pressure acting on the WFG after establishing the balance of forces between the inner and outer faces.

In placement on exterior facades, it is necessary to consider an overpressure factor,

Pad, due to wind action. This term is constant at all the points of the outer face of the glass, so the total pressure distribution is shown in Equation (7).

Hence, for the region , the pressure inside the glazing is less than the atmospheric, and the glasses deflect towards each other.

2.4. Mathematical Model with the Effect of Pillars and Stripes

This section presents a mathematical model for the structural behavior of the glazing and an algorithm with a High-Order Finite Difference Method. Finally, a simulation with an example of the application of the algorithm and model is discussed. The High-Order Structural Simulation has been established over the last decades as one of the most widely used methods [

33]. However, using highly dynamic applications increases computational time and cost. The accuracy of the results from High-Order Structural Simulation methods depends mostly on user expertise [

34]. A wrong choice of inputs can be a source of possible problems, mainly if the element needs to grasp the simulated physics accurately, or it may demand excessively dense meshes, leading to computational inefficiencies. A way to overcome the problems related to the computational burden was through linear approaches that simplify the non-linear models [

35]. Equation (8) shows the domain

that defines the geometry of each glass panel.

where

is the width of the glass,

is its height, and

is its thickness. As the glass panel meets the relational order

, dependence on the magnitudes can be decoupled using the elastic plate theory [

36]. Thus, the transversal deflection and membrane stresses are assumed to stay constant through the thickness, and all the other magnitudes vary linearly with

in each point (

x,

y) of the plane

z = 0. In the case in which the transversal deflection of the plate,

u, is much lesser than its thickness,

t, the resultant model is linear. The differential equation that controls the deformation of the glazing is given by Equations (9) and (10).

where

is the biharmonic operator,

is the stiffness of the plate,

is the Young’s modulus of the glass, and

is the Poisson’s coefficient. The maximum stresses that appear as a consequence of the bending of the glasses are given by Equations (11)–(13).

These stresses appear at the outer and inner surfaces of the glass in opposite directions. For example, if one point is submitted to a traction normal stress, its opposite point is submitted to a compression normal stress.

The effect of the silicon sealing is included as the simply supported boundary conditions shown in Equations (14) and (15).

Whenever geometrical non-linearity is considered, that is, the deflection

is of the same order or greater than the thickness, the effect of the membrane stresses

,

, and

must be taken in account [

37,

38]. In these conditions, Equation (9) must be substituted by Equations (16) and (17).

where

is the Airy stress function and

is a non-linear differential operator which verify, respectively, Equations (18) and (19).

In addition to Equations (14) and (15), boundary conditions to the Airy function must be imposed, as is shown in Equations (20) and (21).

The presence of pillars or stripes is introduced as a zero-displacement condition for the points which are in the inner region of the element. These conditions can be imposed on both pillars’ region

and the stripes region

, substituting the differential equations for the linear or non-linear plate by Equations (22) and (23) in this region:

The next step to solving the differential equations involved was to discretize the domain

in

nodal points. In this manner, the solution is also discretized in a vector

, where

is the number of variables (1 in the linear case; 2 in the non-linear case). Analogously, the derivatives involved in the differential equation were approximated by arbitrary order finite differences. Therefore, the differential operator turns into a difference operator

for

, which satisfies Equation (24).

Furthermore, the boundary conditions merge as a difference operator as well.

, as shown in Equation (25).

Both systems of equations can be agglutinated into a single system

, as shown in Equation (20).

Solving the system of Equation (21) will provide the desired solution. In the case in which the problem is linear, the system is solved by LU decomposition, and when it is non-linear, an iterative method is required, such as Newton’s.

4. Discussion

Previous sections have shown methods to calculate how Water Flow Glazing behaves on the structural front. The

Section 3 showed deformations and stresses considering the panel dimensions (height, width, and thickness). However, when it comes to designing, it is necessary to have criteria to evaluate the results and thus be able to ensure the system’s viability. This section lists the design criteria used in Water Flow Glazing for sizing. These criteria limit the maximum permissible stress in the glass and sealant, the maximum deformation, and the elastic constant. According to scientific articles, there are different approaches to validating structural simulation tools: empirical validation, in which simulated results are compared to measured data from actual buildings or prototypes; cross-validation, in which a validated system is compared to other validated systems; and analytical verification, in which outputs from a new system are compared to the results from a known analytical solution or a generally accepted numerical method. This article utilized the latter to validate the results using the analytical methods from glass standards. Another validation approach is comparing the results from linear and non-linear methods. The linear model was built using simulated test data from mathematical models. The non-linear model considers the influence of other features in the system. This article considers both a linear and non-linear approach to the effect of hydrostatic pressure and the presence of support elements in the water cavity. The similarity in the results from both approaches is another step in validating the accuracy of the presented method [

39].

4.1. Structural Considerations: Stress in the Glass Pane

Enlarging the WFG panel’s size and increasing the water chamber’s thickness led to much higher physical mass, raising new questions according to the structural stability of the façade. Thus, it was necessary to perform new simulations to assess the structural stability of large WFG units. Several parametrical structural analyses showed that additional structural support is needed to ensure an admissible deflection of the two glass planes. Different support configurations, pillars and stripes, inside the water chamber were analyzed, both from a structural and flow distribution point of view. The supports have two different functions. First, they compensate for the additional stress from the hydrostatic pressure loads from the water in the chamber. Second, they reduce deflections between the glass plates. The simulation of four cases illustrated the effect of pillars and stripes on the glazing structural stress. The maximum stress that occurs in the glass is limited to prevent the fracture of the glass. Since glass can break with a bending stress lower than its maximum resistance when a load is applied continuously over time, it is necessary to assess the loads that occur occasionally and permanently and limit each to its corresponding value.

A Water Flow Glazing panel is always full of water and therefore subjected to hydrostatic pressure for a long time. Over the operation time, the zero-pressure line shall be maintained at a fixed level above the bottom. When the zero-pressure line is close to the top of the panel, tension is the main cause of stress and can end up affecting the stability of the silicone over time. On the other hand, when the zero-pressure line is near the bottom of the panel, it minimizes the tension stress on the glass, and compression stress is the main factor. However, its permanent nature can cause static fatigue fractures over time. Using Equations (1) and (2), the serviceability limit state for permanent loads was 10 MPa for annealed glass and 45 MPa for tempered glass. When loads do not occur permanently, static fatigue’s effect is irrelevant, so the breaking limit increases. Loads that occur occasionally can be of internal or external origin. Loads of internal origin are due to decompensations of the hydraulic circuit, which produce deviations in the level of the zero-pressure line. As a deviation value for design, it was considered that the zero-pressure line could vary by 10% above or below the zero-pressure line of WFG’s height [

40,

41,

42]. For example, for a window 3 m high, this deviation is 30 cm. Loads of external origin are mainly due to the action of the wind. These overpressures (all evenly distributed) are superimposed on the hydrostatic load due to the initial filling to calculate the maximum stress in the glass. Using Equations (1) and (2), the serviceability limit state for non-permanent loads was 20 MPa for annealed glass and 60 MPa for tempered glass.

4.2. Deflection Limitations

Permanent loads are used to calculate deflections. The displacement or deflection limitation in WFGs is not due to structural reasons but aesthetic considerations. Glass panes with excessive deflections could generate annoying reflections and distortions. If the glasses are transparent, a magnifying glass effect may appear that ostensibly deforms vision. For these reasons, the deflection of WFG is limited to 1‰ of the height of the glass [

43]. For example, for a glass 1.3 m wide by 3 m high, the maximum allowed deflection would be 3 mm. In the case of non-permanent loads, the displacement is not limited; moreover, excessive deformation indicates that an alteration of the system’s operation is occurring and lead to identifying the problem. The second consideration to limit the maximum deflection was the water chamber thickness. If the deflection of two glass panes makes the chamber too thin at some points, it could cause turbulences in the water flow through the panel, which could end up affecting both the visual properties and the ability to absorb energy. Thus, a limitation of 10% of the water chamber thickness was imposed to select the correct WFG configuration [

44]. Depending on the glass unit’s dimensions and the hydrostatic pressure’s balancing, support stripes can be introduced to control and limit the deflection of the glass adjacent to the water-filled cavity. The maximum allowed deflection was the minimum between 1‰ of the height of the glass and 10% of the water chamber thickness. Every glass unit must be structurally analyzed considering the boundary conditions for the specific application.

4.3. Solutions: Increasing the Glass Thickness and Placing Support Elements in the Water Cavity

Table 2 illustrates the values of stress and deflection of the first case study of an internal WFG partition. Two different glass thicknesses have been analyzed for two different positions of the zero-pressure line. The maximum allowed stress under permanent loads, such as hydrostatic pressure, was set at 10 MPa for annealed glass and 45 MPa for tempered glass, whereas the maximum allowed deflection was the minimum between 1‰ of the height of the glass and 10% of the water chamber thickness. All configurations met the requirements for maximum stress. However, with a water chamber of 16 mm, the maximum deflection was limited to 1.60 mm, so only the 12 mm glass panel with the zero-pressure line at 0.5 H met the imposed conditions. In the event of temporary system failure in which the zero-pressure line rises to 0.7 H, the deflection can increase up to 4.8 mm, which does not affect the structural stability of the glass but might cause fluid flow issues. In conclusion, by selecting a glass thickness of 12 mm, this WFG format does not require a support element inside the water chamber.

Table 3 illustrates the maximum values of each case that have been shown in

Figure 4 for a unitized façade module. In the case in which the water chamber thickness is set to 16 mm, the only possible configuration, if the thickness is not increased or the zero-line pressure is raised, is case d, the two stripes configuration. In other cases, the glasses came too close to each other. If the water chamber thickness is set to 24 mm, case c can be selected because a deflection of 2.66 mm meets both requirements. The same methodology can be applied to different glass thicknesses, zero-pressure lines, and the layout of support elements that restrict the deformation in some areas of the glass surface and help avoid the deflection problem without increasing the thickness of the glass.

The non-linear plate model yielded similar results to those considering the linear case. In particular, for case a, the maximum deflection for a non-linear plate of the same dimensions and hydrostatic pressure distribution led to a maximum deflection of 59.41 mm and maximum bending stresses σxx = 133.93 MPa, σyy = 78.89 MPa, σxy = 90.79 MPa. The membrane stresses obtained are = 0.08 MPa, = 0.15 MPa, = 0.09 MPa, which are negligible compared to the bending stresses. Therefore, the linear plate model can be used to estimate the structural behavior of the Water Flow Glazing.

Figure 10 provides an estimation of whether additional cavity support is required considering the stress on the glass panel.

If the panel height is less than 1.5 m, the stress and deformation constraints can be met using a tempered glass pane up to a thickness of 12 mm. If the height surpasses 1.5 m, the harmful effects of static stress can be lessened using supports inside the water chamber instead of increasing the glass thickness.

5. Conclusions

This article showed linear and non-linear models to predict the structural behavior of Water Flow Glazing panels under permanent and non-permanent loads to provide safety and energy efficiency. The first conclusion was that the linear plate model was accurate enough at a predesign stage to consider the most relevant physical aspects involved in the structural behavior of the glazing. Even though the plate theory conditions are not valid in a region near the structural support, the stresses and deflections predicted by the model are conservative concerning a three-dimensional elastic solid model.

The geometry, particularly the panel’s height and the placement of the zero-pressure line, are significant factors regarding material stress and deflection. According to the ISO standards, the maximum allowed stress under permanent loads, such as hydrostatic pressure, was set at 45 MPa for tempered glass. The maximum allowed deflection was set as the minimum between 1‰ of the glass height and 10% of the water chamber thickness. The latter condition is more stringent than the former one to ensure proper heat absorption by the fluid through the WFG panel.

Several conclusions are extracted from using the linear model to assess the structural behavior of Water Flow Glazing for dimensioning purposes. When the WFG panel’s height (H) is less than 1.5 m and the glass thickness is 12 mm, it does not require a support element inside the water chamber. The maximum bending stress was 8.35 MPa when the zero-pressure line was at 0.5 H and 15.70 MPa when the zero-pressure line was at 0.7 H. Both values are far from the limit of 45 MPa defined by the ISO standard. The deflection with a water chamber of 16 mm was limited to 1.60 mm, so only the 12 mm glass panel with the zero-pressure line at 0.5 H met the conditions. In the case of a 3 m height WFG panel, only a two-stripe supported water chamber of 24 mm met both requirements.

The presence of structural supports inside the water chamber allows for reducing the maximum deflection of each glass to a fixed thickness. Conversely, this will permit reducing the glasses’ thickness given a maximum deflection value.

The most significant limitation of this article was the need for the empirical validation of the simulation results. Nevertheless, the similarity between the results from the two proposed mathematical models, linear and non-linear, was a decisive step in validating the accuracy of the proposed methodology. Future research must include testing actual prototypes and considering other factors that may affect the structural behavior of Water Flow Glazing panels, such as the mechanical properties of the sealant. This article did not show models of the elastic performance of the structural silicone used as a sealant to manufacture the WFG panel. Further studies must delve into these topics that affect the system’s stability and final cost.