Study on the Effect of Multi-span Pit Excavation on Supporting Structures Based on the Cutter Soil Mixing Method

Abstract

:1. Introduction

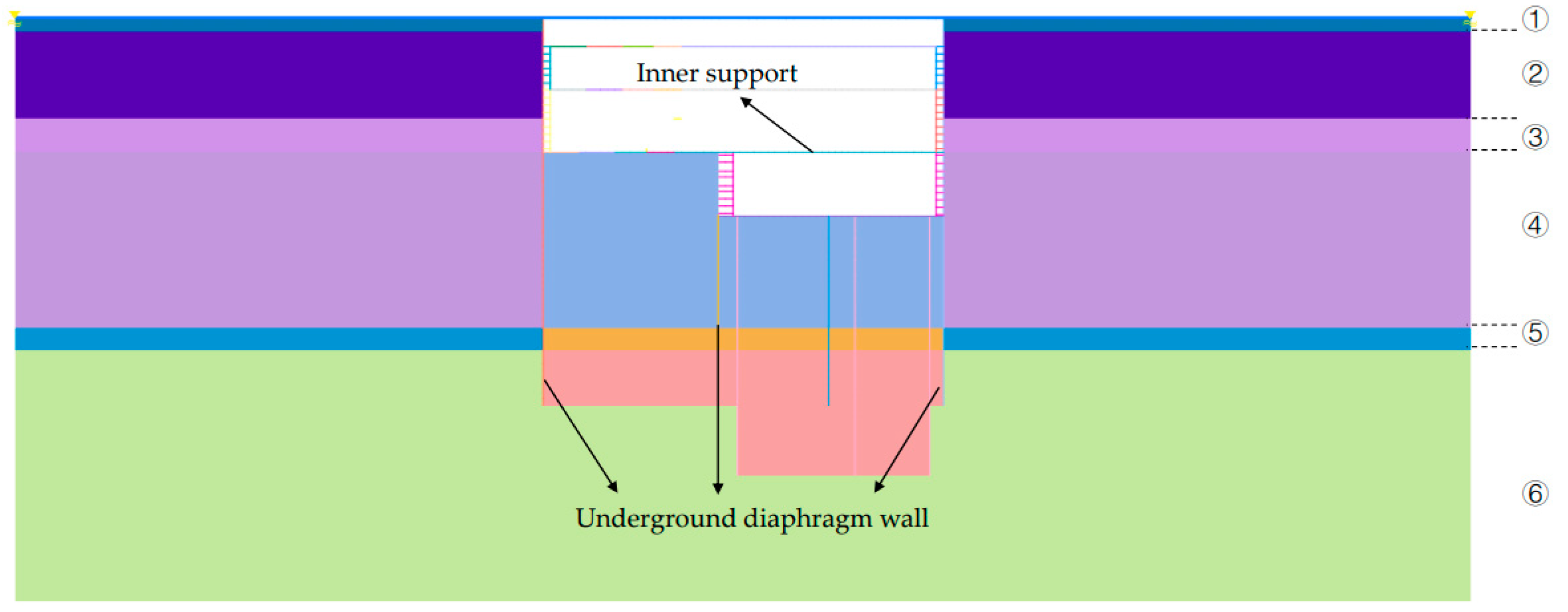

2. Project Overview

2.1. General Situation of Foundation Pit Retaining Structure

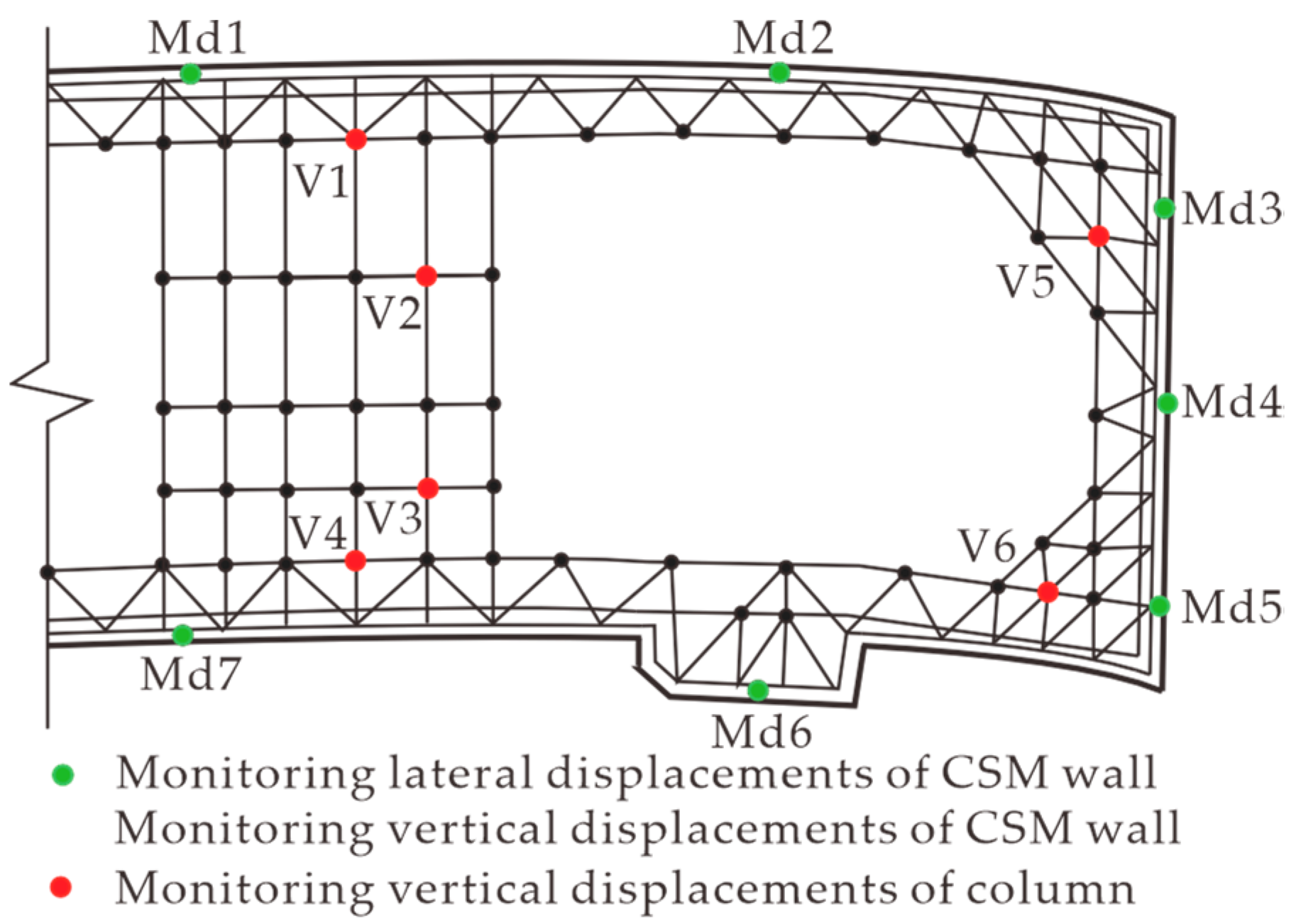

2.2. Monitoring Program

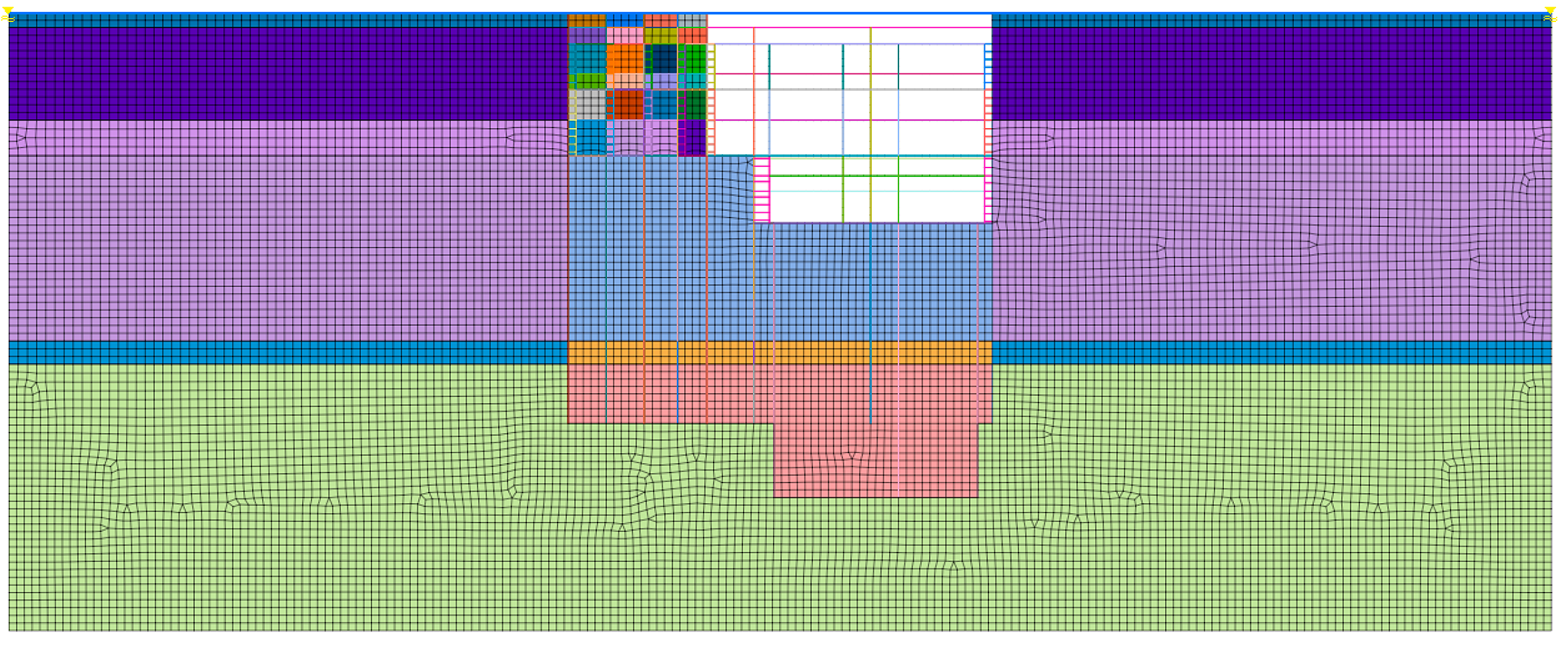

3. Model Building

3.1. Basic Assumptions

- It is assumed that the soil within the influence range of the foundation pit behaves as an elastic-plastic body, meaning that it is uniformly distributed, continuous, and isotropic. To model the constitutive behavior of the soil, the Modified Mohr–Coulomb constitutive model was adopted. The ground wall, uplift pile, and internal support system are all equivalent to a beam system, whereas the pressure bar between walls is equivalent to a truss system. A linear elastic beam or truss model was utilized for all of these structural components.

- The calculation of the initial ground stress only considers the gravity stress of soil in each layer while neglecting the influence of tectonic stress and other stresses between the rock and soil bodies.

- Good foundation pit drainage is maintained during construction, regardless of any deformation in the retaining structure due to groundwater or soil consolidation.

- The time effect of the soil deformation and the effect of the construction of the support structure on the soil are not considered. All the support is timely and only considers the deformation of the foundation pit retaining structure due to the spatial effect of soil excavation.

3.2. Model Overview

3.2.1. Constitutive Model

3.2.2. GTS NX Models

3.2.3. Boundary Constraints

3.3. Process Simulation

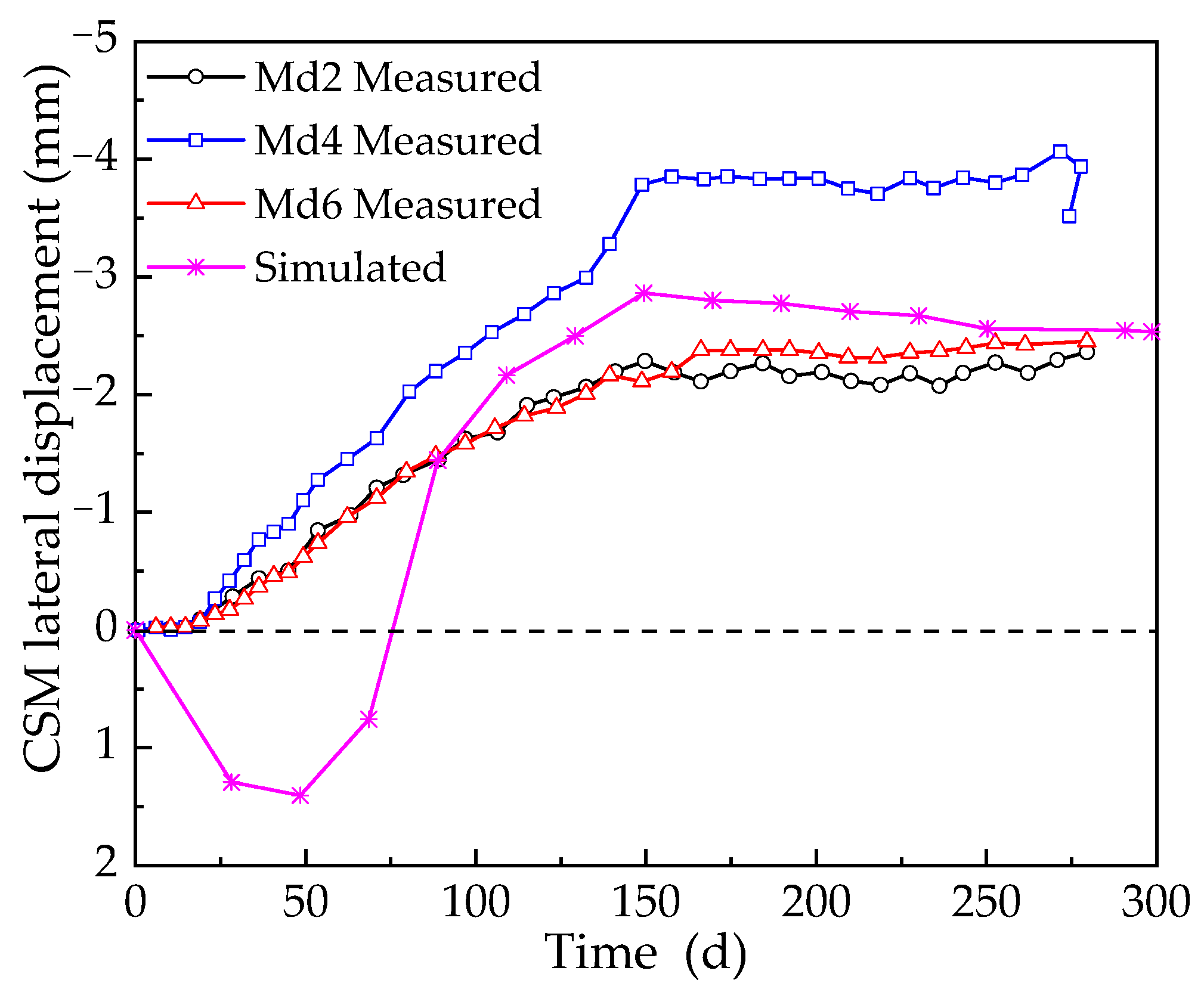

3.4. Validation of Model Results

4. Analysis of Calculation Results

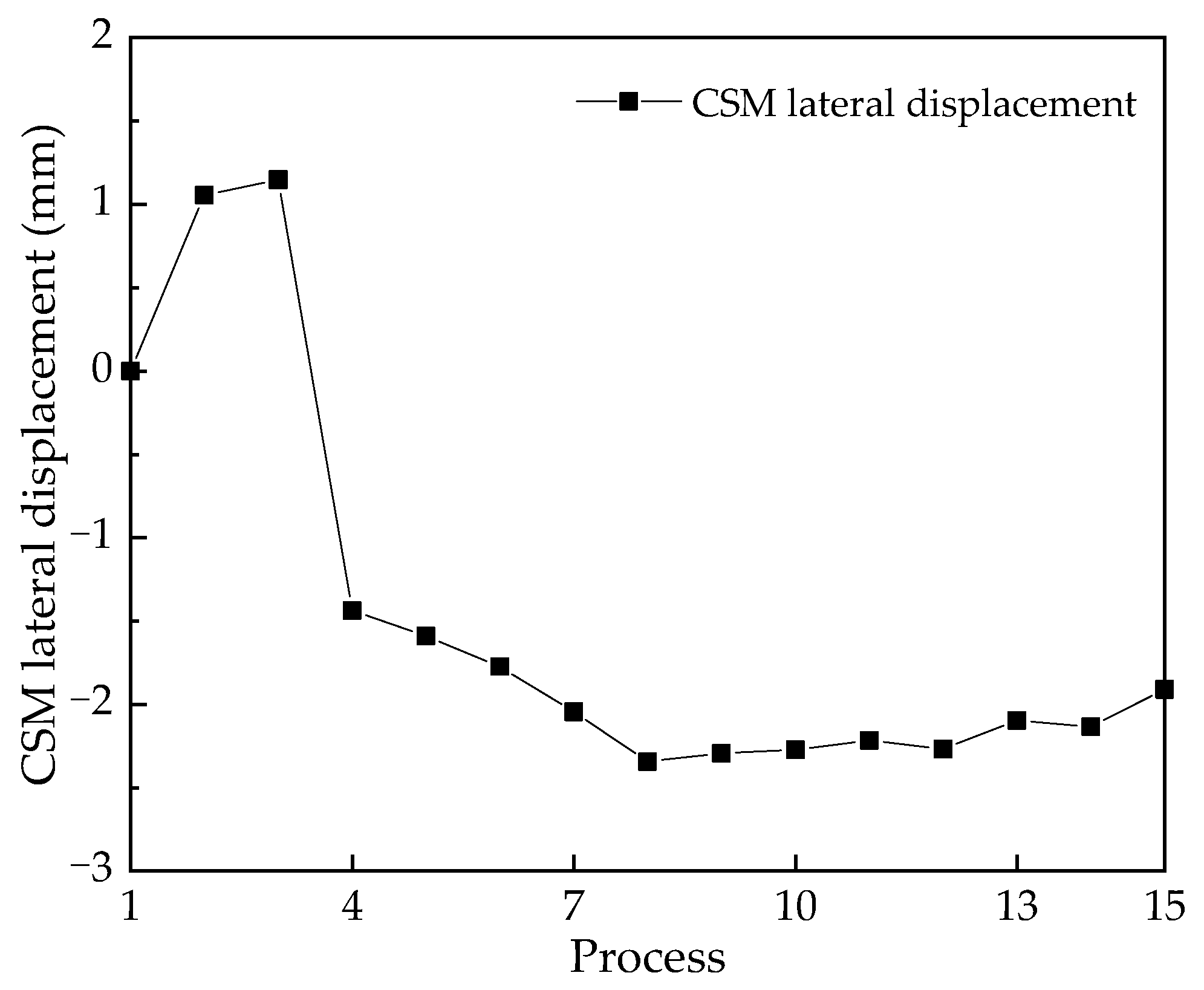

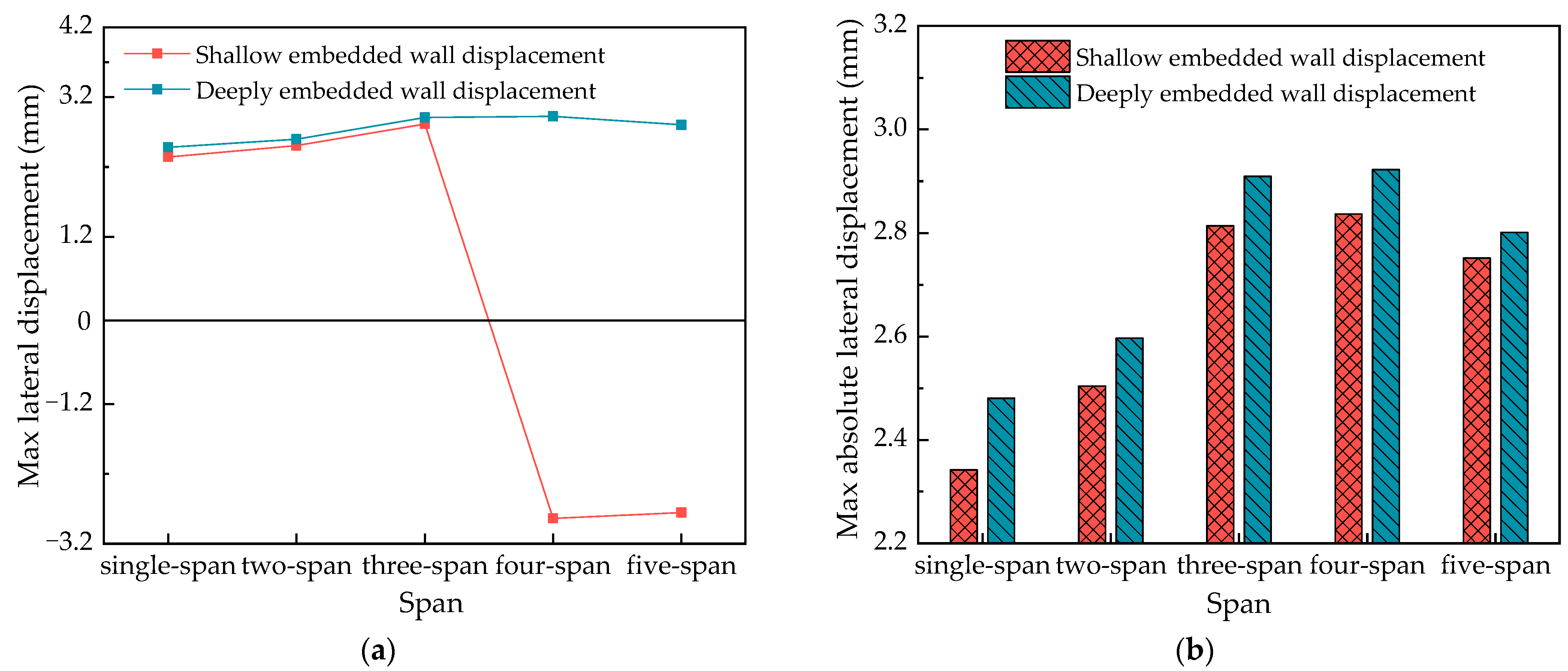

4.1. CSM Wall Lateral Displacement

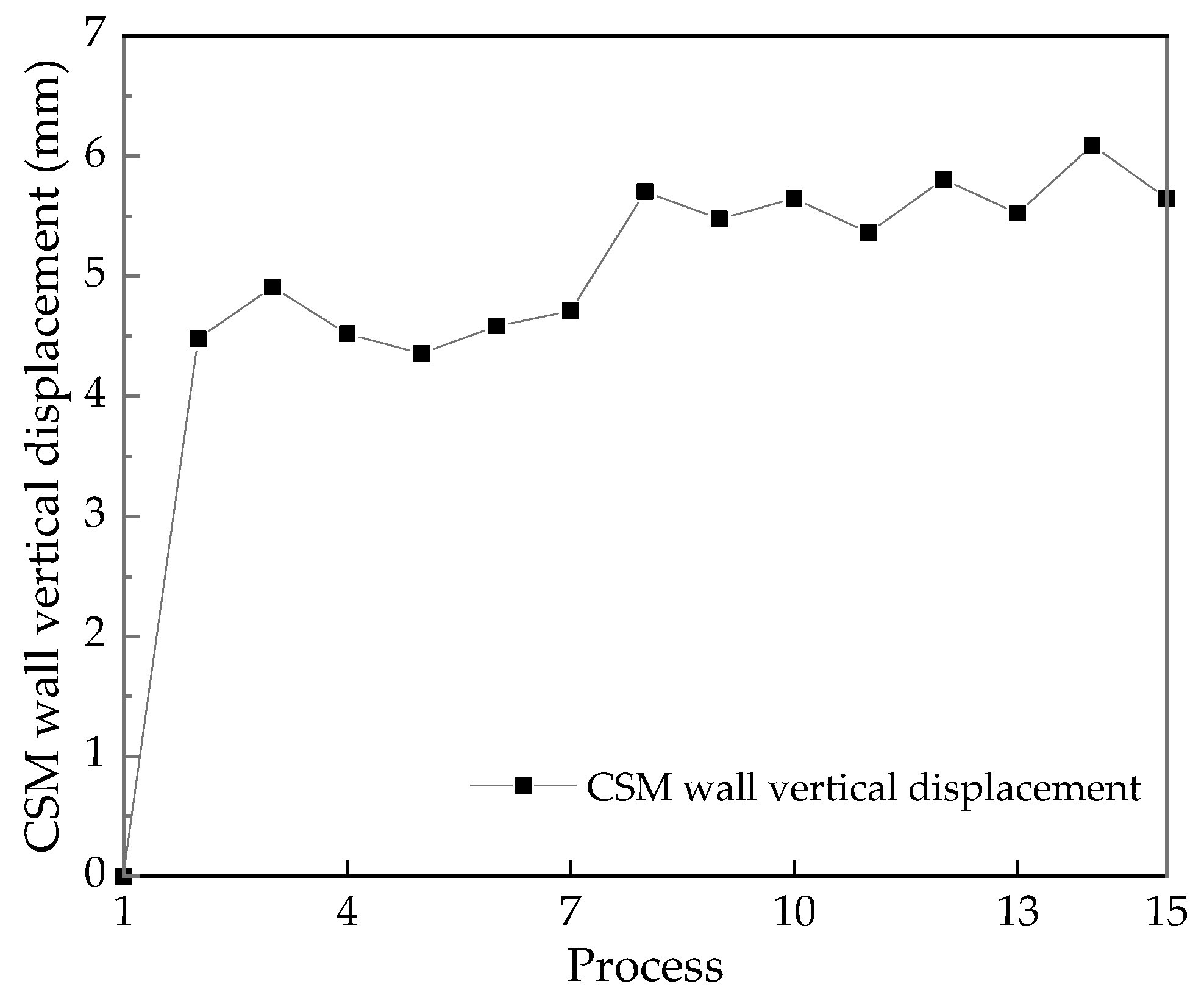

4.2. CSM Wall Vertical Displacement

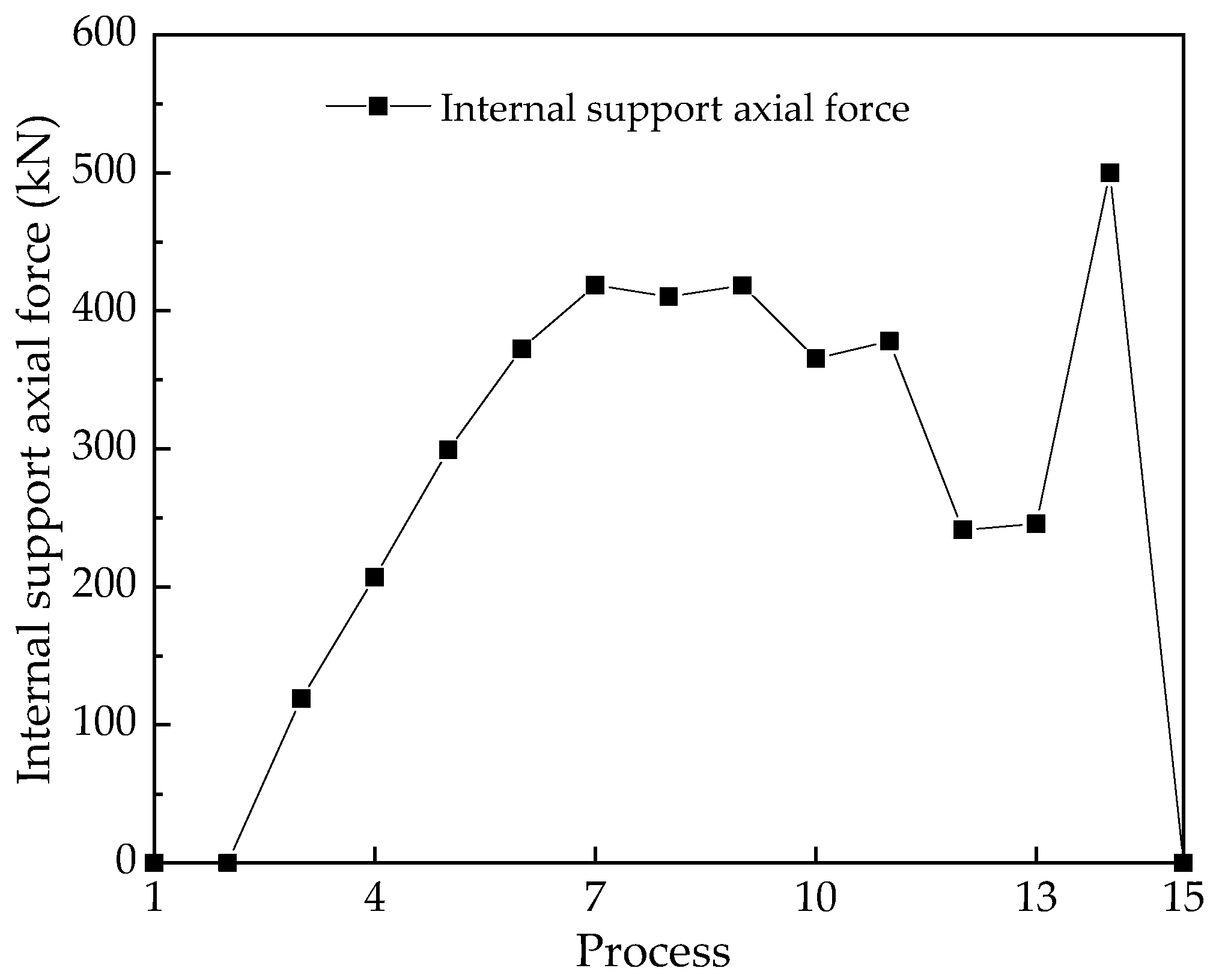

4.3. Internal Support Shaft Force

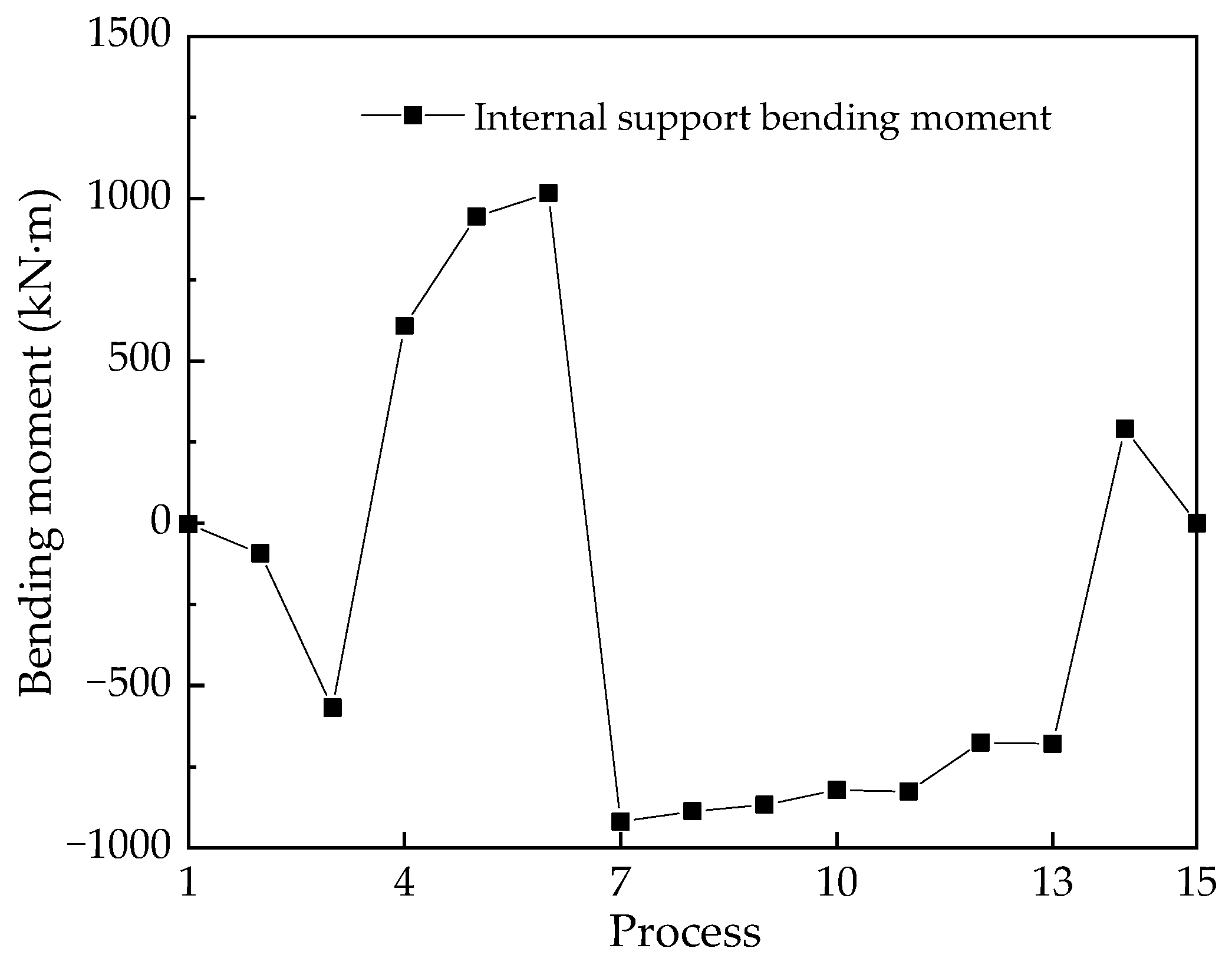

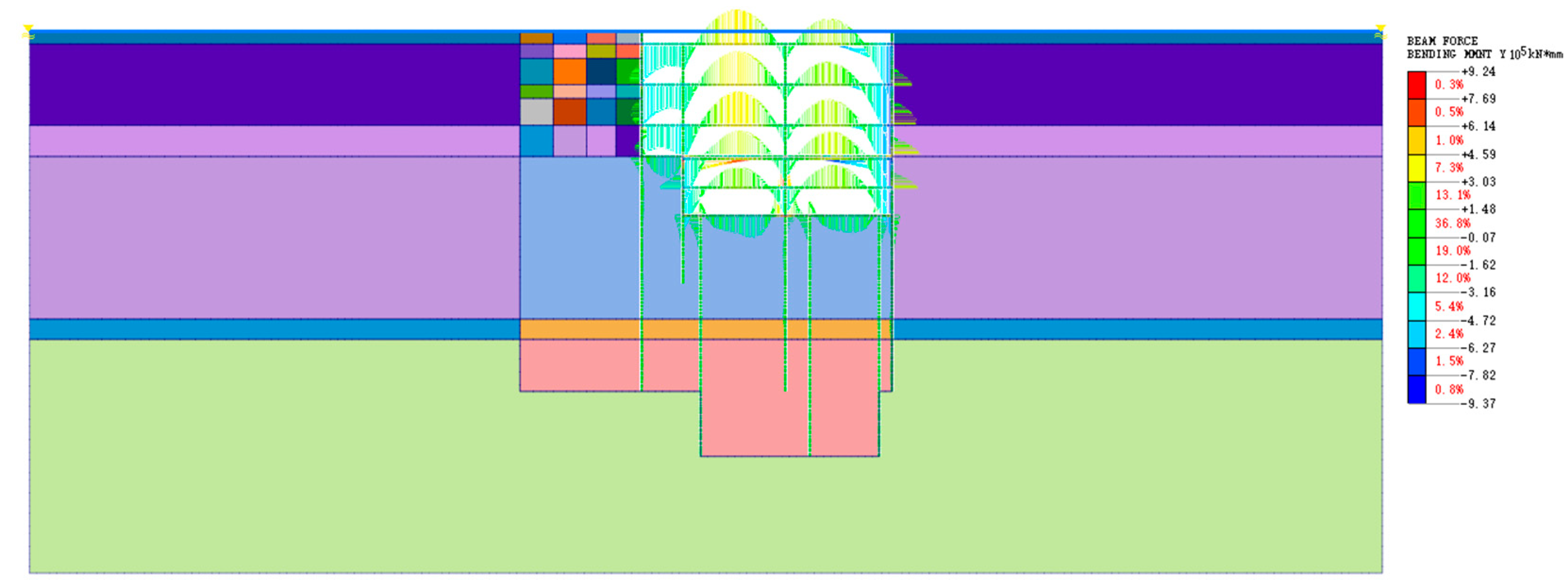

4.4. Bending Moment of Internal Support

5. Conclusions

- Measured field data indicate that the maximum lateral displacement of the side wall of the foundation pit increases gradually with the excavation of the foundation pit, and the lateral displacement tends to be stable gradually at the later stage of excavation. The apex of the CSM wall exhibits a maximum lateral displacement toward the ground of merely 4.06 mm, which is less than the lower limit of allowable displacement. This outcome substantiates the efficacy of this technology in delivering robust foundation pit support. Moreover, the simulation results underscore their precision and reliability, as evidenced by the commendable concurrence between on-site measurements and the numerical data.

- Once embedment depth was reached, further increases in embedment depth may be helpful in improving cavity containment, but their effectiveness is limited. As the embedment depth increases, the internal support moment and lateral displacement of the wall increase slightly. To achieve optimal design and ensure safety, the depth of the CSM wall embedment should be fully considered during the design stage of the foundation pit.

- As the span of the excavation increases, the pressure of the soil on the CSM wall increases, the axial force of the steel column increases continuously, and the values of the lateral displacement of the CSM wall, the vertical displacement, and the bending moments of the steel column first increase and then decrease. The most unfavorable value is in this area of the pit span, so it should be fully considered in the pit design.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cano-Hurtado, J.J.; Canto-Perello, J. Sustainable development of urban underground space for utilities. Tunn. Undergr. Space Technol. 1999, 14, 335–340. [Google Scholar] [CrossRef]

- Yu, P.; Liu, H.H.; Wang, Z.S.; Fu, J.N.; Zhang, H.; Wang, J.; Yang, Q. Development of urban underground space in coastal cities in China: A review. Deep Undergr. Sci. Eng. 2023, 2, 148–172. [Google Scholar] [CrossRef]

- Zeng, F.Y.; Li, M.G.; Chen, J.J.; Wang, J.H. Development and application of a system for dynamic and synchronous analysis of both monitor data and construction information in foundation Pit groups. J. Shanghai Jiao Tong Univ. 2017, 51, 269–276. (In Chinese) [Google Scholar] [CrossRef]

- Li, J.P.; Chen, H.H.; Li, L.; Ma, J.S. Observation on depth and spatial effects of deep excavation in soft clay. China J. Highw. Transp. 2018, 31, 208–218. (In Chinese) [Google Scholar] [CrossRef]

- Bobylev, N.; Sterling, R. Urban underground space: A growing imperative. Perspectives and current research in planning and design for underground space use. Tunn. Undergr. Space Technol. Inc. Trenchless Technol. Res. 2016, 55, 1–4. [Google Scholar] [CrossRef]

- Hunt, D.V.L.; Makana, L.O.; Jefferson, I.; Rogers, C.D.F. Liveable cities and urban underground space. Tunn. Undergr. Space Technol. 2016, 55, 8–20. [Google Scholar] [CrossRef]

- Gerressen, F.W.; Vohs, T. CSM-Cutter Soil Mixing-Worldwide Experiences of a young soil mixing method. Grouting Deep Mix. 2012, 2012, 281–290. [Google Scholar] [CrossRef]

- Bellato, D.; Marzano, I.P.; Simonini, P. Microstructural Analyses of a Stabilized Sand by a Deep-Mixing Method. J. Geotech. Geoenvironmental Eng. 2020, 146, 04020032. [Google Scholar] [CrossRef]

- Cheng, H.Z.; Li, W.T.; Chen, R.P.; Yi, Y.L. Workability study of sand-bentonite-cement mixtures for construction of two-phase cut-off wall. Constr. Build. Mater. 2022, 345, 128058. [Google Scholar] [CrossRef]

- Nishanthan, R.; Liyanapathirana, D.S.; Leo, C.J. Deep cement mixed walls with steel Inclusions for excavation support. Geotech. Geol. Eng. 2018, 36, 3375–3389. [Google Scholar] [CrossRef]

- Gomes, C.A.; Tinoco, J.; Pinto, A.; Tomásio, R. An anchored retaining wall in CSM. In Proceedings of the 18th International Conference On Soil Mechanics And Geotechnical Engineering, Paris, France, 2–6 September 2013; pp. 1–4. Available online: https://www.researchgate.net/publication/256445919 (accessed on 15 July 2023).

- Leach, C.; Gerressen, F.W. First known application of Cutter Soil Mixing for support of a Heritage Building. IFCEE 2015, 2015, 554–568. [Google Scholar] [CrossRef]

- Lindquist, D.; Upsall, B.; Horvitz, G. Cutter Soil Mixing excavation and shoring in Seattle’s pioneer square district. In Proceedings of the Earth Retention Conference 3, Washington, DC, USA, 1–4 August 2010; pp. 303–310. [Google Scholar]

- Arnold, M.; Beckhaus, K.; Wiedenmann, U. Cut-off wall construction using cutter soil mixing: A case study. Geotechnik 2015, 34, 11–21. [Google Scholar] [CrossRef]

- Capelo, A.; Correia, A.G.; Ramos, L.F.; Pinto, A.; Rui, T. Modeling and monitoring of an excavation support using CSM. Int. Conf. Grouting Deep Mix. 2012, 2012, 243–250. [Google Scholar] [CrossRef]

- Pinto, A.; Tomásio, R.; Pita, X.; Pereira, A.; Peixoto, A. Cutter Soil Mixing solutions in portugal. Grouting Deep Mix. 2012, 2012, 316–325. [Google Scholar] [CrossRef]

- Liao, S.M.; Wei, S.F.; Tan, Y.; Liu, J.X. Measured analysis of deformation behavior of large-scale deep foundation pit in Suzhou area. Chin. J. Geotech. Eng. 2015, 37, 458–469. (In Chinese) [Google Scholar] [CrossRef]

- Wang, Z.; Guo, B.L.; Wei, G.; Hu, C.B.; Zhang, L.S. Simplified deformation analyses of a single pile subjected to different deformation modes of the pit enclosure structure. Int. J. Geomech. 2023, 23, 04023014. [Google Scholar] [CrossRef]

- Han, M.; Li, Z.; Mei, G.X.; Bao, X.H.; Jia, J.Q.; Liu, L.L.; Li, Y.Y. Characteristics of subway excavation in soft soil and protective effects of partition wall on the historical building and pile foundation building. Bull. Eng. Geol. Environ. 2022, 81, 307. [Google Scholar] [CrossRef]

- Li, Y.J.; Feng, Z.J.; Zhu, Y.P. Monitoring and numerical simulation analysis of support structures of deep foundation pit in special red sandstone stratum in Lanzhou. Chin. J. Geotech. Eng. 2022, 44, 236–240. (In Chinese) [Google Scholar] [CrossRef]

- Li, X.J.; Zeng, K.H.; Bai, D.Z.; Chen, F.L.; Ju, H.Y.; Xu, M.Q. Application of CSM waterproof curtain in foundation pit engineering of deep saturated sand layer. IOP Conf. Ser. Earth Environ. Sci. 2020, 455, 012048. [Google Scholar] [CrossRef]

- Rabbani, P.; Lajevardi, S.H.; Tolooiyan, A.; Daghigh, Y.; Falah, M. Effect of Cutter Soil Mixing (CSM) method and curing pressures on the tensile strength of a treated soft clay. Heliyon 2019, 5, e02186. [Google Scholar] [CrossRef]

- Russell, A.R.; Chapman, M.; Teh, S.H.; Wiedmann, T. Cost and embodied carbon reductions in cutter soil mix walls through fibre reinforcement. Geosynth. Int. 2017, 24, 280–292. [Google Scholar] [CrossRef]

- Cao, S.Y.; Song, S.; Qi, X.L. Research on deep foundation pit excavation based on numerical simulation. J. Phys. Conf. Ser. 2021, 1885, 022051. [Google Scholar] [CrossRef]

- Wang, J.F.; Xiang, H.W.; Yan, J.G. Numerical simulation of steel sheet pile support structures in foundation pit excavation. Int. J. Geomech. 2019, 19, 05019002. [Google Scholar] [CrossRef]

- Castaldo, P.; Jalayer, F.; Palazzo, B. Probabilistic assessment of groundwater leakage in diaphragm wall joints for deep excavations. Tunn. Undergr. Space Technol. 2018, 71, 531–543. [Google Scholar] [CrossRef]

- Ye, S.H.; Ding, S.H.; Gong, X.N.; Gao, S.; Chen, C.L. Monitoring and numerical simulation of deep foundation pit of a subway station in Lanzhou. Chin. J. Geotech. Eng. 2018, 40, 177–182. (In Chinese) [Google Scholar]

- Ye, S.H.; Zhao, Z.; Wang, D. Deformation analysis and safety assessment of existing metro tunnels affected by excavation of a foundation pit. Undergr. Space 2021, 6, 421–431. [Google Scholar] [CrossRef]

- Ramm, H.; Reul, O.; Ruiken, A.; Kissel, W.; Toker, E. Hochhaus omniturm–Baugrube und Gründung unter komplexen innerstädtischen Randbedingungen. Bautechnik 2020, 97, 656–663. [Google Scholar] [CrossRef]

- Zhang, C. Control force characteristics of different control strategies for the wind-excited 76-story benchmark building structure. Adv. Struct. Eng. 2016, 15, 423–434. [Google Scholar] [CrossRef]

- Lin, P.; Liu, P.; Ankit, G.; Singh, Y.J. Deformation monitoring analysis and numerical simulation in a deep foundation pit. Soil Mech. Found. Eng. 2021, 58, 56–62. [Google Scholar] [CrossRef]

- Qian, Q.H.; Lin, P. Safety risk management of underground engineering in China: Progress, challenges and strategies. J. Rock Mech. Geotech. Eng. 2016, 8, 423–442. [Google Scholar] [CrossRef]

- Theunissen, W.; Fraser, O.D. Three-dimensional numerical modeling of a propped cutter soil mix retention system in sand. Int. J. Geoengin. Case Hist. 2021, 6, 115–151. [Google Scholar] [CrossRef]

- Parmantier, D.M.; Stow, R.F.; Byrne, R.J. Case study: Cement-bentonite pre-trenching and cutter soil mixing (CSM) for temporary shoring and groundwater cutoff. In Contemporary Topics in Ground Modification, Problem Soils, and Geo-Support; ASCE Library: Reston, VA, USA, 2009; pp. 153–160. [Google Scholar]

- Bose, S.K.; Som, N.N. Parametric study of a braced cut by finite element method. Comput. Geotech. 1998, 22, 91–107. [Google Scholar] [CrossRef]

- Borja, R.I.; Amies, A.P. Multiaxial cyclic plasticity model for clays. J. Geotech. Eng. 1994, 120, 1051–1070. [Google Scholar] [CrossRef]

- Feng, Z.Y.; Xu, Q.; Xu, X.Y.; Tang, Q.; Li, X.D.; Liao, X. Deformation characteristics of soil layers and diaphragm walls during deep foundation pit excavation: Simulation verification and parameter analysis. Symmetry 2022, 14, 254. [Google Scholar] [CrossRef]

- Ezzat, M.; Zaghloul, Y.; Sorour, T.; Hefny, A.; Eid, M. Numerical simulation of axially loaded to failure large diameter bored pile. Int. J. Geotech. Geol. Eng. 2019, 13, 283–297. [Google Scholar]

- Zhang, C.G.; Shan, Y.P.; Gao, B.X. A new mathematical fitting formulation of earth pressure considering the displacement of retaining walls. Chin. J. Rock Mech. Eng. 2021, 40, 2124–2135. (In Chinese) [Google Scholar] [CrossRef]

- Ni, P.P.; Mangalathu, S.; Song, L.H.; Mei, G.X.; Zhao, Y.L. Displacement-dependent lateral earth pressure models. J. Eng. Mech. 2018, 144, 04018032. [Google Scholar] [CrossRef]

- JGJ 120-2012; Technical Specification for Retaining and Protection of Building Foundation Excavations. China Architecture Publishing & Medi Co., Ltd.: Beijing, China, 2012.

- QJ/STEC 001-2015; Construction Regulations for Steel Bracing System for Pit Works. Shanghai Tunnel Engineering Co., Ltd.: Shanghai, China, 2015.

| Number | Stratum | Initial Void Ratio e0 | Poisson’s Ratio v | Volumetric Weight γ (kN∙m−3) | Elasticity Modulus E (MPa) | Internal Friction Angle φ (°) | Cohesion c (kPa) | Secant Modulus (Mpa) | Tangent Modulus (Mpa) | Unloading Elastic Modulus (Mpa) |

|---|---|---|---|---|---|---|---|---|---|---|

| ① | Miscellaneous fill | 0.7 | 0.4 | 18.4 | 21.00 | 8.0 | 10.0 | 2500 | 2500 | 7500 |

| ② | Clay 1 | 0.9 | 0.3 | 18.9 | 24.70 | 18.0 | 14.0 | 3100 | 3100 | 9300 |

| ③ | Clay 2 | 0.6 | 0.3 | 20.2 | 23.44 | 20.8 | 13.0 | 3100 | 3100 | 9300 |

| ④ | Clay 3 | 0.7 | 0.3 | 20.0 | 28.50 | 22.6 | 14.6 | 3100 | 3100 | 9300 |

| ⑤ | Sandy silt | 0.6 | 0.3 | 20.2 | 22.68 | 32.4 | 6.6 | 3700 | 3700 | 11,100 |

| ⑥ | Clay 4 | 0.8 | 0.3 | 20.1 | 25.82 | 18.9 | 24.0 | 3100 | 3100 | 9300 |

| Structure Name | Meshing Type | Material | Elasticity Modulus (GPa) | Sectional Dimension (m) |

|---|---|---|---|---|

| Ground wall | 1D beam element | C35 concrete | 32.5 | B = 1.0 H = 1.0 |

| Inner support | 1D beam element | Steel | 206 | B = 0.9 H = 1.2 |

| Uplift pile | 1D beam element | C35 concrete | 32.5 | D = 1.2 |

| Support replacement | 1D beam element | Steel | 206 | B = 1.0 H = 0.8 |

| Intermediate temporary column | 1D beam element | Steel | 206 | D = 0.4 |

| Side wall | 1D beam element | C35 concrete | 32.5 | B = 1.0 H = 0.8 |

| Press bar between walls | 1D truss element | Steel | 206 | B = 1.0 H = 1.0 |

| Process | Working Process |

|---|---|

| 1 | Preparation for construction, site leveling, initial stress field analysis, and initial displacement return to zero. |

| 2 | Construct pile foundation, ground wall structure, supporting structure, and column pile. |

| 3 | For the first earthwork excavation, the foundation pit was excavated at 4.0 m, and the first steel support was constructed at the same time. |

| 4 | The second earthwork excavation, foundation pit excavation of 10.0 m, at the same time construction of the second steel support. |

| 5 | The third earthwork excavation, the foundation pit excavation of 14.0 m, and, at the same time, the construction of the third steel support. |

| 6 | The fourth earthwork excavation, foundation pit excavation of 18.5 m, at the same time construction of the fourth steel support. |

| 7 | The fifth earthwork excavation, foundation pit excavation of 23.0 m, at the same time construction of the fifth steel support. |

| 8 | For the sixth earthwork excavation, the foundation pit was excavated 27.0 m to the bottom of the pit, and the bottom plate and the bottom anti-pulling pile were constructed at the same time. |

| 9 | Remove the fifth steel support. |

| 10 | Construct new negative three floors and remove the fourth steel support. |

| 11 | Remove the third steel support. |

| 12 | Construction of new negative first floor, construction of center slab and negative first floor columns, side walls, etc. |

| 13 | Remove the second steel support. |

| 14 | Construct a new negative floor and remove the first steel support. |

| 15 | Remove the remaining temporary structures. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, J.; Shan, Y.-P.; Liu, D.-J.; Su, Y.-L.; Wang, H.-X.; Cai, G.-Q. Study on the Effect of Multi-span Pit Excavation on Supporting Structures Based on the Cutter Soil Mixing Method. Sustainability 2023, 15, 14745. https://doi.org/10.3390/su152014745

Wu J, Shan Y-P, Liu D-J, Su Y-L, Wang H-X, Cai G-Q. Study on the Effect of Multi-span Pit Excavation on Supporting Structures Based on the Cutter Soil Mixing Method. Sustainability. 2023; 15(20):14745. https://doi.org/10.3390/su152014745

Chicago/Turabian StyleWu, Jian, Ye-Peng Shan, De-Jun Liu, Yan-Lin Su, Hua-Xiong Wang, and Guo-Qing Cai. 2023. "Study on the Effect of Multi-span Pit Excavation on Supporting Structures Based on the Cutter Soil Mixing Method" Sustainability 15, no. 20: 14745. https://doi.org/10.3390/su152014745

APA StyleWu, J., Shan, Y.-P., Liu, D.-J., Su, Y.-L., Wang, H.-X., & Cai, G.-Q. (2023). Study on the Effect of Multi-span Pit Excavation on Supporting Structures Based on the Cutter Soil Mixing Method. Sustainability, 15(20), 14745. https://doi.org/10.3390/su152014745