4.1. Measure of HCM Carbon Emissions in the Digital Process

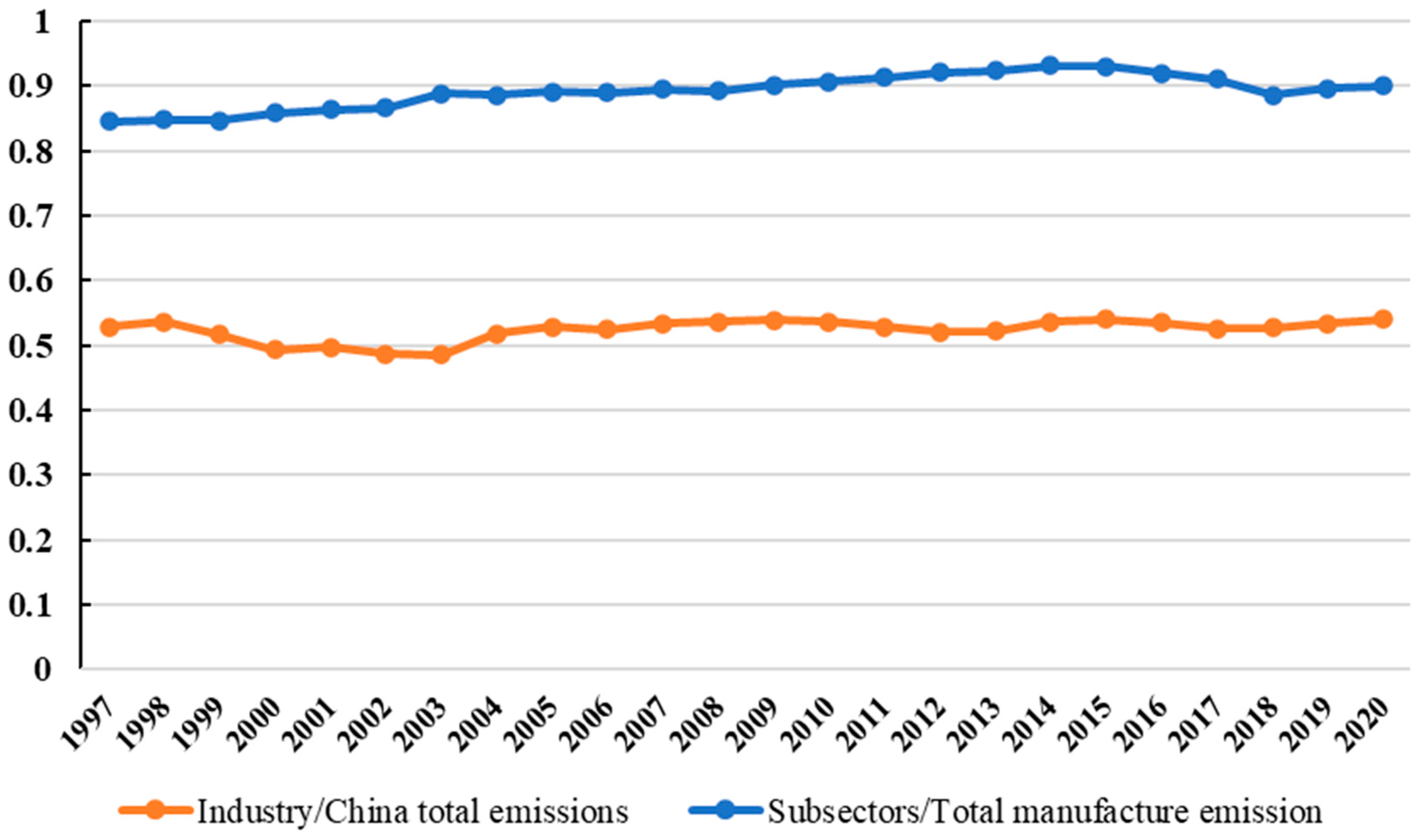

According to Alcántara and Padilla [

47] and Butnar and Llop [

48], a subsystem analysis (SA) approach is applied to calculate the carbon emissions produced by HCM subsectors and uncover their interactions with digital subsectors, that is, the carbon emissions generated in the digital process of HCM; the formula is as follows.

According to the classification of sectors in

Section 3.3, the basic Leontief model can be expressed as

According to Formula (4), it can be rewritten as

Formula (8) can be rewritten as

The three equations in Formula (9) give us the production of the HCM, Digital, and Other subsectors. The first equation, showing the total production of the HCM subsectors, can be divided into three parts. The summand shows the production that is needed to cover the intermediate and final demand of the HCM subsectors themselves. The term shows the production required to cover the final demand of the digital sectors. The term shows the production required to cover the final demand of other sectors. The second and third equations are interpreted similarly.

By using vectors

, which contain the CO2 emission coefficients (measured by CO2 emissions per unit sectoral output) of the HCM, Digital, and Other subsectors, respectively, we transform Formula (9) into an emission model. Thus, the carbon emissions embodied in all sectors’ production to cover the final demand of the digital process in the HCM sectors are as follows:

The term shows the emissions embodied in the production of digital sectors required to cover the final demand of HCM sectors; we can define it as external-embodied carbon emissions from the digital demand of the HCM sectors (ExC). The term shows the emissions embodied in the production of the HCM sectors required to cover the final demand of the HCM sectors that involve digital sectors and can be defined as internal-embodied carbon emissions from the digital demand of the HCM sectors (InC). These two components (ExC + InC) make up the embodied carbon emissions generated by the demand for digitization in the HCM sectors.

Figure 4 shows the embodied carbon emissions from the digital process of HCM at the national level. From 2002 to 2020, the ratio of emissions from the digitization of HCM in the total embodied emissions was very small (less than 1%); thus, the digital process of HCM generated fewer emissions compared with the whole production. And the

InC was higher than the

ExC; the mathematical reason for this is that the direct carbon emissions generated by the HCM sectors were much higher than the digital sectors, making

fG higher than

fD. The economic explanation is that the emissions generated from the direct demand of the digital sectors caused by the digitization of HCM were smaller than those caused by the carbon-intensive intermediate inputs that the digital sectors required from the HCM sectors due to the HCM digital demand. Similarly,

Table 3 and

Table 4 show that, at the provincial level, the emissions were also much lower than the total emissions.

Then, after estimating the carbon emissions generated in the digital process of HCM, we return to the issue addressed in the introduction: at this stage, does the digital process of HCM increase or reduce carbon emissions? To answer this question, we also need to know the mechanism and quantity of carbon emissions reduction during the process. However, at present, China does not officially count and report the specific reduction in emissions after digitization at enterprise, industry, or even national levels. In this regard, the White Paper on Digital Carbon Neutrality released by the China Academy of Information and Communications Technology (CAICT) points out the following: After analyzing and quantifying the carbon emission structure of each link of industry, digital technology mainly empowers HCM energy conservation and emission reduction through two main mechanisms: first, the digital technology application of HCM can optimize product design and process flow, e.g., for Chemical-related Manufacturing (H2); based on digital technology, the chemical reaction process can be simulated online, greatly reducing the offline experiment process and accelerating the development of low-carbon products and processes. Second, the digital technology application of HCM can reduce the energy consumption of production and improve the comprehensive management of energy in the full process, e.g., for the Iron and steel industry (H4), based on digital technology, the main processes such as ironmaking, steelmaking, and steel rolling can realize intelligent closed-loop control, thereby reducing the excess energy consumption caused by unreasonable production operations, and enterprises can establish a system including the real-time docking of production and sales to achieve cross-process scheduling optimization, equipment safe operation, and whole-process energy forecasting and scheduling, so as to improve energy utilization efficiency, thus reducing carbon emissions. It can be seen that the emissions reduced by the digital technology application of HCM are mainly in scope 1 (direct carbon emissions), and the two parts account for approximately 70% of the carbon emission reduction from HCM digitization. Meanwhile, according to appendix II of the White Paper on Digital Carbon Neutrality, the carbon reduction ratio of digital technology enabling HCM is roughly 13–22% [

49]. Therefore, based on

Section 3.1, we can estimate the emission reduction in the digital process of HCM and then answer the question.

Table 5 shows that, at the national level, the digital process of HCM has resulted in a far greater reduction in carbon emissions than it has generated.

Table 6 shows the provincial results that are consistent with the national conclusion except for Beijing. Therefore, the digital process of HCM can indeed help to reduce carbon emissions at this stage. However, it is worth noting that in 16 provinces, the amount of emission reductions showed a trend of first increasing (2002–2012) and then decreasing (2012–2017). This shows that considering the carbon emissions generated by the final demand for HCM products from the intermediate inputs of other sectors between provinces, the digitization of equipment and systems at the initial stage of digital transformation can effectively reduce the direct carbon emissions of HCM. But in the future, with the development of digitization, the increase in carbon emissions from the direct demand for the digital sectors and the corresponding demand for carbon-intensive intermediate inputs generated by the digital sectors has the potential to offset the emission reductions in HCM from the application of digital technologies. Therefore, we still need to be vigilant about the carbon emissions generated by the digital process of HCM.

4.2. Analysis of HCM Carbon Emissions in Digital Process

Since 2000, the digitization progress of HCM has undergone two stages, and the carbon emissions generated in this process have also shown significant temporal changes (

Figure 4). In the first stage (2002–2012), the emergence of digital technology in business stimulated the exploration of its application in all industries, including HCM, in a short period of time (2002–2005), leading to an increase in HCM’s demand for digital sector products, which led to a transient increase in emissions. However, in this stage, digital sectors were still in development, and corresponding digital technology and digital products were not mature, which made it difficult to support the development of HCM; therefore, HCM reduced the product demand for digital sectors (2005–2012), the emissions of HCM in the digital process were also reduced, and the progress of HCM digitization slowed down. In the second stage (2012–2020), after 10 years of development, the corresponding technologies and products of the digital sectors were mature and could be well embedded in the production and sales process of HCM. Meanwhile, in 2015, the Chinese government raised digital development to a national strategy, proposed the Made in China 2025 strategy, and put forward a clear development direction and goals for HCM digitization. Under the dual stimulation of the advantage of digital technology on HCM production and government orientation, the digital progress in HCM was accelerated, the demand of HCM for the digital sectors increased significantly [

50], and the carbon emissions generated by this process also increased. Similarly, due to the influence of the digital sector development and government policy, the emissions of HCM’s digital process in provinces showed a two-stage temporal change (

Table 4); the emissions in the second stage (2012–2017) were obviously larger than first stage (2002–2012), and with the development of HCM’s digital process, they showed an increasing trend.

According to the previous paragraph, the development of digital sectors and their technical products determines the HCM industry’s digitization progress and its emissions. And the development of digital sectors and their technical products are closely related to the level of regional economic growth [

51]; therefore, we evaluated the emissions of four main districts to study the regional differences (

Table 7), according to the regional classification criteria for socioeconomic development produced by the NBSC. Before 2015, the emissions in the east were much higher than in other districts because of its relative developed economy and advanced digital technology, and the number of emissions along the east→northeast→central→west decreased. After 2015, due to the Made in China 2025 strategy and government support in regions with relatively low economic development, some provinces in the west (Guizhou and Chongqing) and northeast (Heilongjiang and Liaoning) districts realized the rapid development of digitalization progress, to accelerate the digital transformation of HCM, causing more emissions than the east and central districts in 2017 [

52]. Furthermore, the geographical resource endowment and the industrial scale and structure are also important factors that caused the emissions difference in the HCM digitization process in provinces (

Table 4). HCM is a resource-dependent industry, and the provinces with rich resource endowments often have a greater scale of HCM, e.g., Hebei is rich in ferrous metal resources and is the largest steel production province in China, and the scale of H4 is large. When it started digitization, it needed more products from the digital sectors, causing more emissions. Similarly, Guizhou is rich in coal and mercury; therefore, the scales of H2 and H4 were large. On the contrary, Hubei’s resource endowment is relatively unremarkable so the scale of the HCM industry was not large. Also, due to the slow development of the economy and population, the scale of HCM in Qinghai was not large.

Further, we observed the supply chains and crucial paths of carbon emissions generated by the digital process of HCM. To reveal the mechanism of how carbon emissions are transferred along supply chains that are from digital sectors to HCM sectors, a structural path analysis (SPA) approach was used. Using the Taylor series approximation to expand the Leontief inverse [

53], the embodied carbon emissions of sectors in Equation (6) can be rewritten as a summand of different emission layers:

where

represents the contribution of CO

2 emissions from the

t th sectoral production tier. For instance, assuming the case where

is the final demand of the Processing of Petroleum, Coal, and Other Fuels (H1),

is the direct CO

2 emissions generated by the H1 enterprises (e.g., from fossil fuel combustion) in the process of gasoline, tar, coke, and other products for consumption in other industries (Tier 0). To produce these products, enterprises need to purchase crude oil, raw coal, etc., (

) from their upstream suppliers, and these suppliers emit

CO

2 in the processes of obtaining the raw materials (Tier 1). In turn, the Mining and Washing of Coal and the Extraction of Petroleum and Natural Gas (O2, O3) suppliers also need to purchase machines to dig these materials (

), e.g., excavators, well drills, and trunks, and thus,

CO

2 emissions are released in the production of the machines (Tier 2), and so on and so forth; hence, the process continues similarly for all production tiers. Similarly, the CO

2 emissions are generated from primary suppliers (digital sectors) and accumulated through intermediate supply chain tiers (all sectors) due to the final demand of HCM; therefore, the total emissions from digital sectors to HCM equal the following:

Further, the nodes (sectors) in successive production tiers constitute a complete supply chain or carbon transfer path [

54,

55]. For example,

is a third-tier path, which denotes the emission path

. In general, there are

n paths in the zeroth tier,

paths in the first tier, and

paths in the second tier, and the number of paths increases exponentially with each tier. Therefore, crucial emission paths can be identified by calculating the carbon emissions associated with each supply chain. According to this, the carbon emissions of the supply chain tiers and transfer paths generated from the digital sectors to fill the demand of HCM can be calculated. The specific calculation process is as follows: first, we calculate the emissions of each supply chain (Tier 1 to Tier 5

), based on Formula (12); second, in each supply chain, we calculate the emissions of each transfer path, e.g., for Tier 1, there only exists one carbon transfer path

; for Tier 2, there exist thirty-eight carbon transfer paths

due to

n = 38 in this paper; third, after calculating the emissions of all paths, we choose the path with the top five emissions as the crucial path.

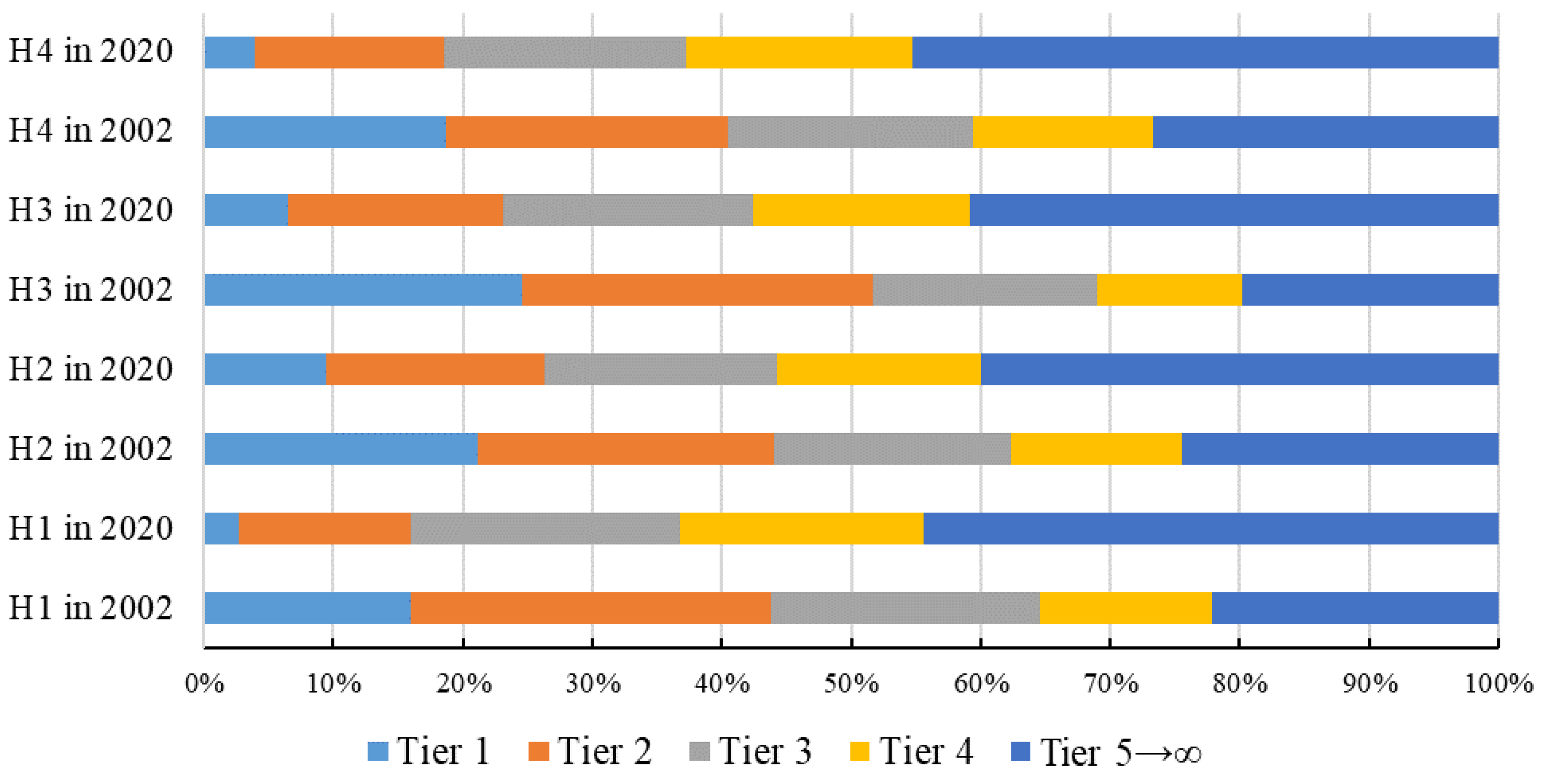

Table 8 shows the change in the embodied carbon emissions in supply chains from 2002 to 2020. The emissions in high supply chain tiers (Tier 3, 4, 5

) increased in all HCM sectors, and the fastest growth was in Tier 5

, while the emissions in Tier 1 declined. For the emissions of Tier 2, except for the Manufacture of Nonmetallic Mineral Products (H3), other HCM sectors increased. Specific to HCM subsectors, the emissions generated in the digital process of Chemical-related Manufacturing (H2) were much higher than those of the other three sectors in 2002 and 2020. In addition, the emissions generated in the digital process of Processing of Petroleum, Coal, and Other Fuels (H1) in all tiers ranked last, but the change rates were the highest. For the emission changes in the tiers, the emissions generated in the digital sectors caused by the direct demand of HCM digitization gradually decreased, which was inseparable from the efforts made by the digital sectors (especially D2) to reduce their own carbon emissions. And the emissions generated through the high supply-chain tiers from the digital sectors to HCM digitization increased, a result consistent with Zhou et al. [

35]. This reveals that, when only considering the direct connection between the HCM and digital sectors, the emissions generated in the digital process of HCM gradually decreased, but considering the high supply chain tiers, emissions increased. The emissions difference of the HCM subsectors showed that the digital demand and development scale of H2 was much larger than the other three subsectors, and the digital process of H1 has the potential for rapid emission growth.

Figure 5 shows the distribution features of the carbon transfer paths by the digital supply chain tiers of HCM. As

Figure 5 depicts, in the digital process of HCM sectors, the proportion of emissions generated by Tiers 1 and 2 decreased, and the decrease rate of Tier 1 was more than 10%. The proportion of emissions generated by Tiers 4 and 5

increased, the increase rate of Tier 5

was about 20%, and the proportion of Tier 3 did not change much. At the same time, for H2 and H4, the proportion of emissions generated by Tier 5

was the highest; while for H1 and H3, the highest proportion of the emissions changed from Tier 2 in 2002 to Tier 5

in 2020. The above findings indicate that with the development of HCM digitization, its emissions were gradually transferred from a direct connection between the HCM and digital sectors to the high supply-chain tiers. In addition, considering the influence of the Made in China 2025 strategy in promoting HCM digitalization in 2015, we also estimate the data for 2015 (see

Appendix A), which further strengthens the conclusion of this trend. Further, we observe the crucial carbon emission transfer paths of China’s HCM digitization to identify the key related sectors.

The digital process of HCM involves two digital sectors, digital infrastructure (hardware equipment manufacturing, D1) and digital system (information technology software system construction, D2); therefore, the critical carbon emission transfer path runs from these two digital sectors to the four HCM sectors, and it can be divided into eight subpaths. These paths start from the digital production process, then proceed to the intermediate consumption of inputs, and eventually to cover the final demand of HCM. We focus primarily on the first four tier supply chains (from Tier 0 to Tier 4), and

Table 8 lists the top five ranking transfer paths in 2002 and 2020.

As can be seen in

Table 9, from 2002 to 2020, while the change in the total contribution of the top five crucial paths to the digital process of HCM showed a clear downward trend, the two digital sectors showed the opposite trend in terms of the quantitative change in emissions. The emissions of the top five crucial paths from the D1 to HCM subsectors showed an increasing trend, while the emissions from the D2 to HCM subsectors showed a decreasing trend. The explanation for this result is that for equipment digitization, enterprises’ improvement of digital construction and the updating of digital machinery increase the demand for D1, thus requiring the overall replacement of equipment or the installation of new devices, which leads to continuous production throughout the supply chain, thereby increasing emissions. For software system digitization, one needs to install electronic equipment to embed the software system during the initial installation, and then there is only the need for a software system-based update or maintenance, which generally does not generate extra production; therefore, emissions decrease to a certain range that only includes data transfer and storage, system operation, and updates.

Specifically, for the Processing of Petroleum, Coal, and Other Fuels (H1), the existing paths are Digital→Extraction of Petroleum and Natural Gas (O3)→H1, D1→Manufacture of Measuring Instruments and Machinery (O15)→O3→H1, D2→O23→O3→H1, and D2→Transport, Storage, and Post (O21)→H1. It is worth noting that in the field of equipment digitization, H1 strengthens the direct connection with O12 and O15 over time, which are also the key support sectors for intelligent manufacturing. In the field of system digitization, O21 and O23 are the key related sectors. For Chemical-related Manufacturing (H2), its crucial paths do not change significantly over time. The existing paths are Digital→H2→H2, D1→D1→H2, D1→Leasing and Commercial Services (O25)→H2, and D2→O23→H2. For the Manufacture of Nonmetallic Mineral Products (H3), the existing paths are D1→D1→H3, D1→O25→H3, D2→O23→H3, and D2→H3→H3. It is worth noting that in the field of equipment digitization, H3 also strengthens the direct connection with O12, and in the field of system digitization, the transfer path has changed from the Mining and Processing of Nonmetal and Other Ores (O5) and Wholesale and Retail Trades, Hotels, and Catering Services (O22) to O21. For the Smelting and Pressing of Metals (H4), the existing paths are D1→D1→H4, D1→O12→H4 and D2→O23→H4. It is worth noting that in the field of equipment digitization, the transfer path has changed from O22 to Other Manufacture (O16), and in the field of system digitization, the transfer path has changed from O22 to the Mining and Processing of Metal Ores (O4), the Production and Supply of Electric Power and Heat Power (O17), and O21. In summary, the crucial path that has always existed is Digital→HCM, and the emissions are mainly transferred within the digital sectors and HCM subsectors. From HCM equipment digitization, the existing path is D1→D1→HCM, and another crucial emission transfer path is through O12 due to the fact that the product of O12 is necessary in the digital process, and emissions in this path increase over time. From software system digitization, the existing path is D2→Finance and Insurance (O23)→HCM; the explanation for this path is that the initial development of digital sectors needs the support of O23, and the software system as the core of HCM digitization is an important property for HCM; therefore, it is necessary to ensure. In addition, another crucial emission transfer path is through O21 due to the data storage demand of HCM digitization, and emissions in this path are increasing over time. Also, considering that only observing the crucial transfer path changes of 2002 and 2020 may not fully reflect this trend, we supplemented the intermediate representative year (the government officially implemented Made in China 2025 in 2015) to verify the results (see

Appendix A). The results showed that the crucial transfer path changes in the key sector began in 2015 (O12 in equipment digitization and O21 in software system digitization), and the emissions from both paths increased over time.

As relatively independent regions in China, the digital process of HCM in each province presents differences due to differences in geographical resource endowment, regional policies, industrial scale and structure, and digital technology development, which further leads to differences in the carbon emissions generated in the process (

Table 4 and

Table 7). Therefore, we intend to explore whether the emissions difference caused by these factors are represented in the supply chain tiers and transfer paths, so as to select the three provinces (Guizhou, Shandong, and Guangxi) that ranked first, fifteenth, and thirtieth among the carbon emissions of provincial HCM digitization in 2017 to explore the regional heterogeneity.

Table 10 shows the provincial emissions in different production tier of HCM digitization. For the same tier, the ranking of emissions in three provinces is the same (

). But the maximum and minimum emissions are in different tiers for three provinces: for Shandong, the maximum emissions are in Tier 5

and the minimum emissions are in Tier 1. For Guangxi, the maximum emissions are in Tier 1 and the minimum emissions are in Tier 4. For Guizhou, the minimum emissions are in Tier 4, the maximum emissions of H1 and H2 are in Tier 1, and H3 and H4 are in Tier 2. In H1, there is a 10-fold emissions difference in each tier between Guizhou and Guangxi, and Shandong and Guangxi; in H2, there is a 10-fold emissions difference in each tier between Guizhou and Shandong, and Shandong and Guangxi; in H3, the emission difference between Guizhou and Guangxi and Shandong and Guangxi are increasing gradually from Tier 1 to Tier 5

, and the minimum emission difference is between Shandong and Guangxi, while the increasing rate of emission difference is maximum; in H4, the proportion of Shandong emissions in Tier 5

is close to 50%, while the proportion of Guangxi and Guizhou emissions in Tiers 1 and 2 all exceed 50%, and the proportion of emissions in Tier 1 and Tier 2 are different between Guangxi and Guizhou. In summary, the emissions of Shandong are increasing gradually from the low supply tier to the high supply tier, but those in Guangxi and Guizhou are decreasing. The explanation for this is that the digital process of HCM cannot be separated from the development of the digital sectors. According to the White Paper on Development and Employment of China’s Digital Economy, in 2017, Shandong ranked third in the total digital economy of Chinese provinces. The development of digital sectors and industrial digitization in Shandong have a higher degree than the other two provinces (CAICT, 2018). When the degree of industrial digitization is low, the emissions generated by digitalization are concentrated in Tier 1; then, with the development of digitization, more emissions are transferred to Tier 5

, which is consistent with the result in

Table 7. In addition, the subsectors with the maximum emissions from the HCM digitization of Guizhou are H2 and H4, Shandong is H2, and Guangxi is H4. The provincial differences in emissions in the subsectors are mainly caused by the differences in mineral resources within the regions.

After understanding that the emissions generated from HCM digitization in different provinces varied significantly in different supply chain tiers, we observed the crucial paths of HCM subsectors in different provinces.

Table 11 shows the top five ranking carbon emission paths of H1 digitization in three provinces. From D1 to H1, the same path is D1→O21→H1; in this path, the emissions of Shandong were maximum, the contribution was minimum, and the emissions and contribution of Guizhou were the opposite of Shandong. The differences in the provincial emission transfer paths were that Guizhou transferred through the Mining and Washing of Coal (O2), Shandong transferred through the Manufacture of Measuring Instruments and Machinery (O15), and Guangxi the Extraction of Petroleum and Natural Gas (O3) and the Production and Supply of Gas (O18). From D2 to H1, the same paths were D2→H1 (ranked first) and D2→H1→H1; for D2→H1, the emissions of Guangxi were minimal, but the contribution was maximal. The differences in the provincial emission transfer paths were that Guizhou transferred through O2, Shandong through the Extraction of Petroleum and Natural Gas (O3), and Guangxi through the Mining and Processing of Nonmetal and Other Ores (O5). The possible reason for this result is that Guizhou, known as the “Jiangnan Coal Sea”, is the province with the most abundant coal resources in southern China. Relative to Guizhou and Shandong, Guangxi is a coastal province, near the South China Sea, which is rich in undersea oil and gas. Shandong is rich in oil resources, and the relevant sectors were established earlier; so, when H1 started the digital process, it needed to replace or improve old equipment.

Table 12 shows the top five ranking carbon emission paths of H2 digitization in three provinces; from D1 to H2, the same paths were D1→H2 (ranked first), D1→D1→H2, and D1→H2→H2 (ranked fifth). In addition, Guizhou and Guangxi had the same unique path (D1→O21→H2), and Guizhou and Shandong had the same unique path (D1→H2→H2→H2). The difference in the provincial emission transfer path was that Guangxi transferred through O18. For D1→H2, the emissions of Shandong were at a maximum, but the contribution was minimal. From D2 to H2, the paths of Shandong and Guangxi were exactly the same, while the first four paths of Guizhou were the same as those of the two provinces, and there was a unique path (D2→O5→H2). For D2→H2, the emissions of Guangxi were minimal, but the contribution was maximal. In H2, there was little difference in the crucial emission transfer paths in the digital process of the three provinces, mainly between the digital sectors and H2, but there were still provincial differences in emissions generated in the same path.

Table 13 shows the top five ranking carbon emission paths of H3 digitization in three provinces; from D1 to H3, the same path was D1→H3. In addition, Guizhou and Guangxi had the same unique path (D1→O21→H3, D1→O5→H3, D1→O18→H3). The differences of provincial emission transfer path were that Guizhou transferred through O2, and the other four paths in Shandong were all related to O12. From D2 to H3, the same paths were D2→H3, D2→D2→H3, and D2→H3→H3 and Guizhou and Guangxi had the same unique path (D2→O5→H3); the differences in the provincial emission transfer path were that Guizhou transferred through O2, and Guangxi through H2. For D2→H3, the emissions of Guangxi were minimal, but the contribution was at a maximum. In H3, the path difference between Guangxi and Guizhou was small, while the path difference in Shandong was mainly in the digital process of hardware equipment (From D1 to H3).

Table 14 shows the top five ranking carbon emission paths of H4 digitization in three provinces; from D1 to H4, the three provinces did not have the same path, while Guizhou and Guangxi had the same unique path (D1→H4, D1→O16→H4, and D1→O18→H4), and Shandong and Guangxi had the same unique path (D1→O4→H4). The differences in the provincial emission transfer path were that Guizhou transferred through O2 and O21, and the path in Shandong was all related to O4. From D2 to H4, the same paths were D2→H4 and D2→H4→H4, Guizhou and Guangxi had the same unique path (D2→O4→H4), and Shandong and Guangxi had the same unique path (D2→D2→H4). The difference in the provincial emission transfer path was that Guizhou transferred through O18. For D2→H4, the emissions of Guangxi were minimal, but the contribution was maximal. In H4, in terms of the top five ranking crucial paths, Guangxi (80%) and Guizhou (90%) were mainly in Tier 1 and 2, with Shandong in Tier 3 (60%).

To sum up, the differences between the three provinces in industrial structure, mineral endowment, level of digital development, and policies has led to differences in supply chain tiers and crucial paths of emissions generated by HCM digitization. Specifically, when the degree of industrial digitization is low (Guangxi and Guizhou), the emissions generated by digitalization are concentrated in Tier 1, and with strengthening industrial digitization (Shandong), more emissions are transferred to Tier 5. Meanwhile, the provincial differences are also reflected in the different subsectors with the most emissions from digital process. Guizhou is H2 and H4, Shandong is H2, and Guangxi is H4. The main reason is the differences in mineral resources, sectoral development scale, and policy orientation in different provinces. For example, Guizhou is rich in coal, leading to the crucial transfer path of emissions mainly through O2; Shandong is rich in oil and developing industrial digitization well, leading to the crucial transfer path of emissions mainly through O3 and O12; and Guangxi is rich in submarine natural gas, leading to the crucial transfer path of emission mainly through O18. In addition, it is worth noting that at least one-third of the crucial paths are between the HCM and digital sectors, especially in H2; and, because H3 and H4 are extremely dependent on the upstream-related material mining industries, the three provinces in the crucial transfer path of these two sectors also have O5 and O4, respectively.