Experimental Study on the Dilatancy Characteristics and Permeability Evolution of Sandstone under Different Confining Pressures

Abstract

:1. Introduction

2. Seepage Experiment

2.1. Experimental Device

2.2. Experimental Specimen

2.3. Experimental Scheme

- (1)

- The axial force and confining pressure were loaded at a rate of 0.05 MPa/s to the hydrostatic pressure of σ1 = σ3 = 5 MPa, and the next step was performed after the pressure and displacement sensor readings were stabilized.

- (2)

- A CO2 of 2 MPa was injected into the sandstone specimen, and the next step was performed after the flowmeter indicator at the outlet was stable.

- (3)

- The confining pressure of σ3 = 5 MPa was kept unchanged, and the axial loading was switched to displacement-controlled mode. The specimens were loaded to failure at a rate of 0.1 mm/min.

- (4)

- The test was ceased when the axial load became stable after the peak stress.

- (5)

- According to confining pressure conditions set in Table 1, the seepage tests of sandstone under σ3 = 10, 15, and 20 MPa were performed. Note: The simulated depth was calculated according to σh = 0.0245 H. σh was the minimum horizontal major stress, equivalent to the confining pressure σ3.

3. Mechanical Properties of Sandstone

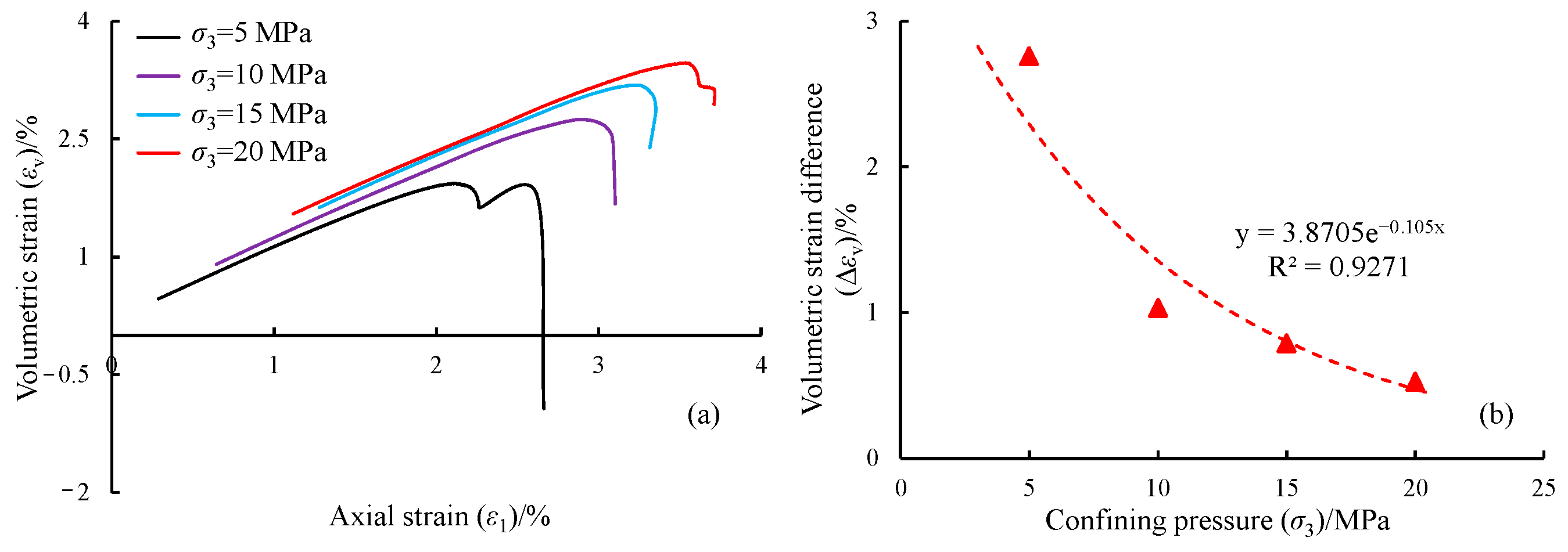

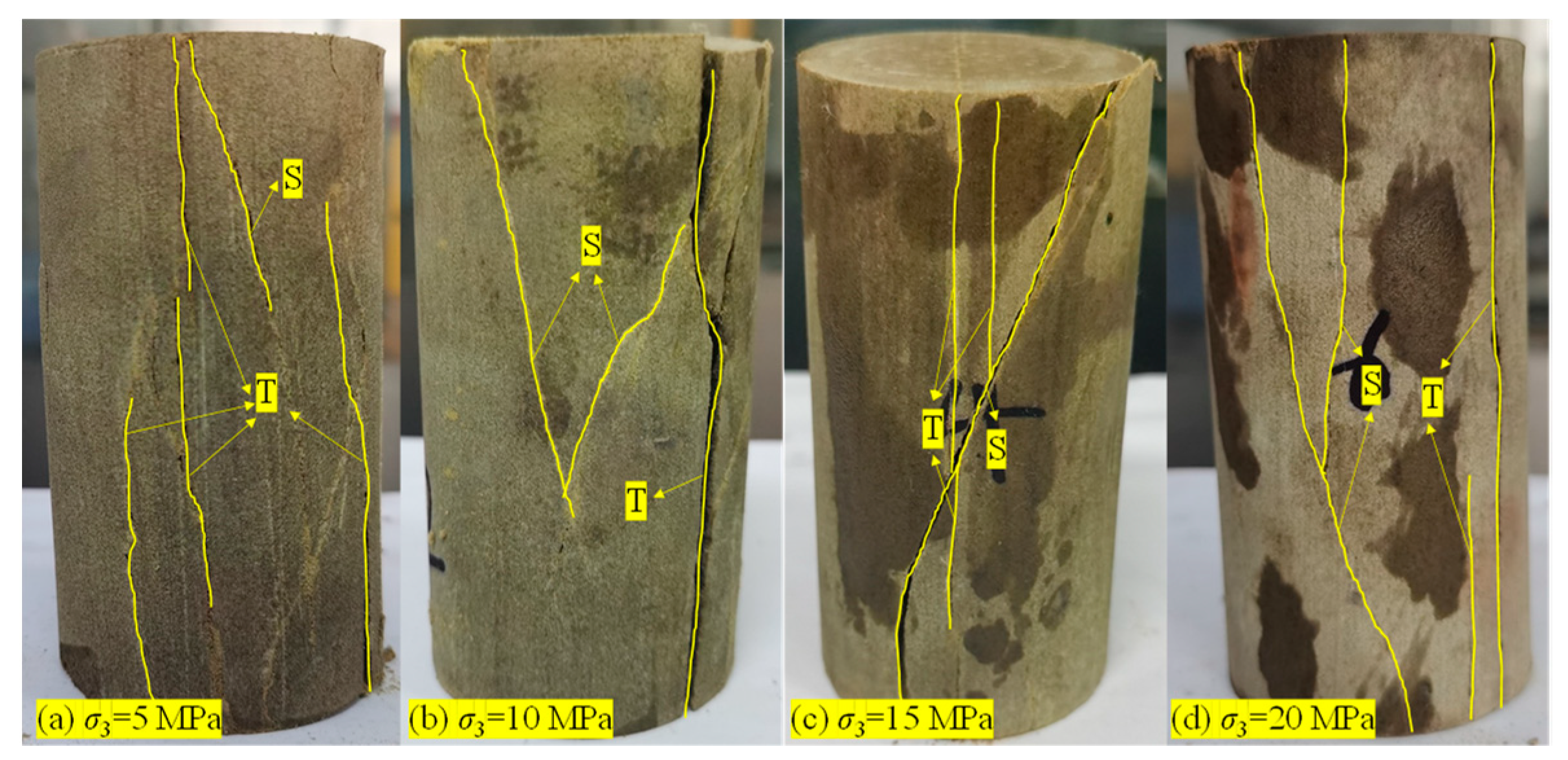

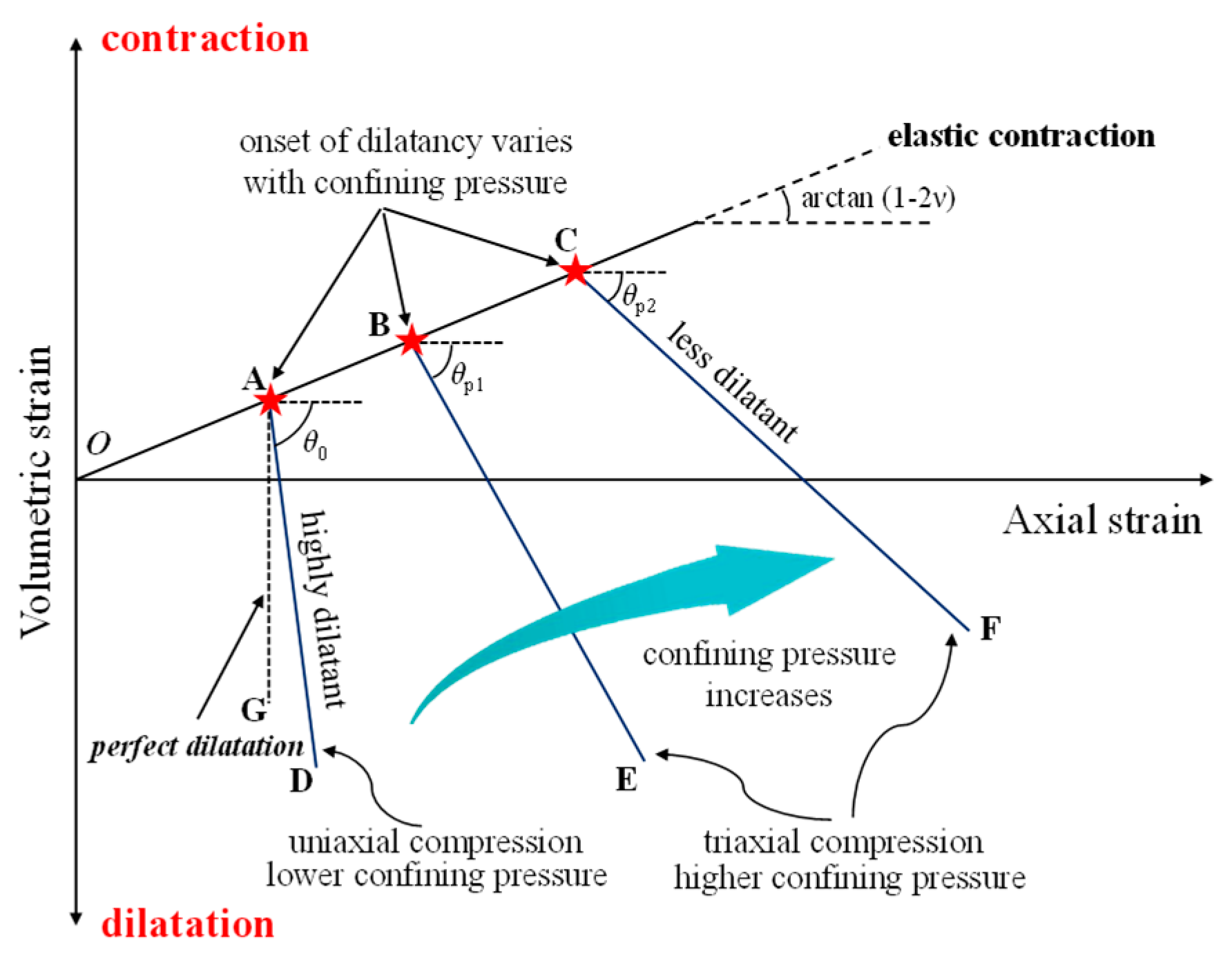

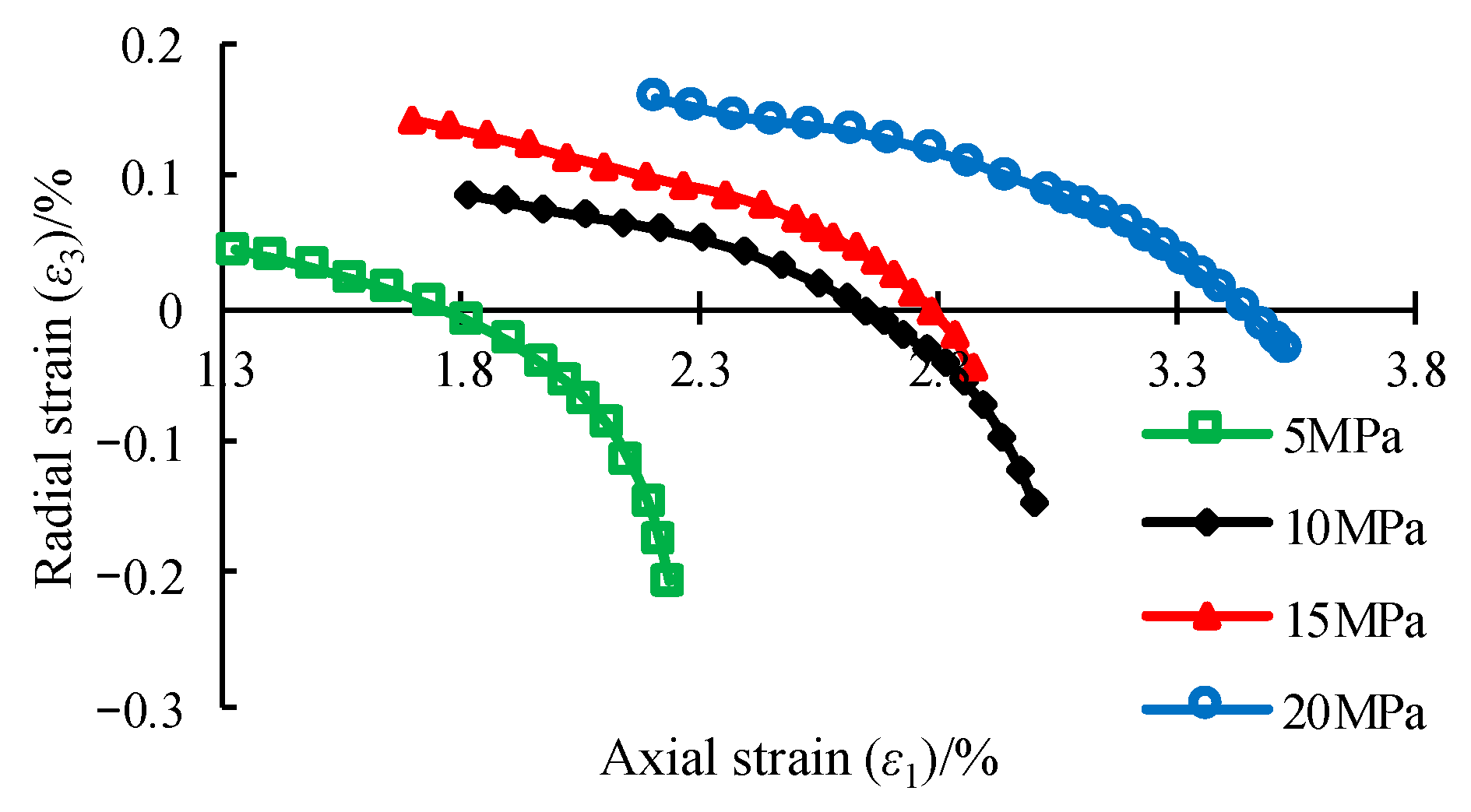

3.1. Deformation and Failure of Sandstone

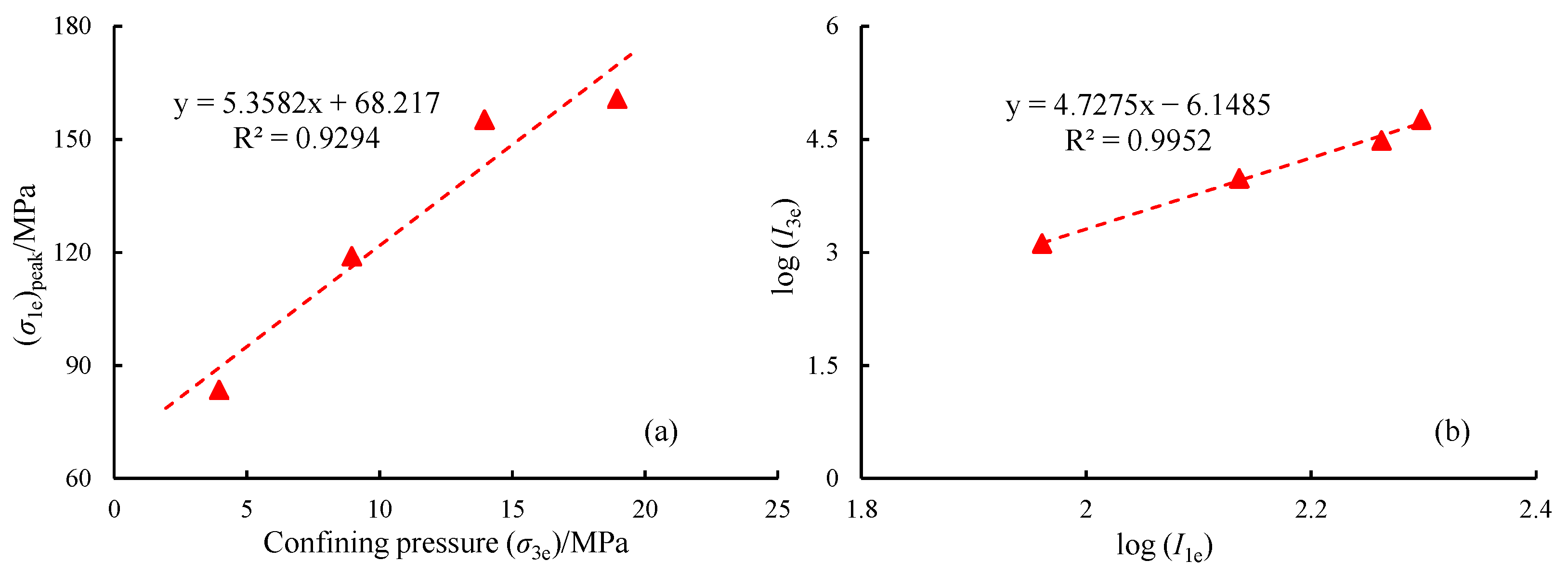

3.2. Sandstone Strength

4. Sandstone Permeability Evolution

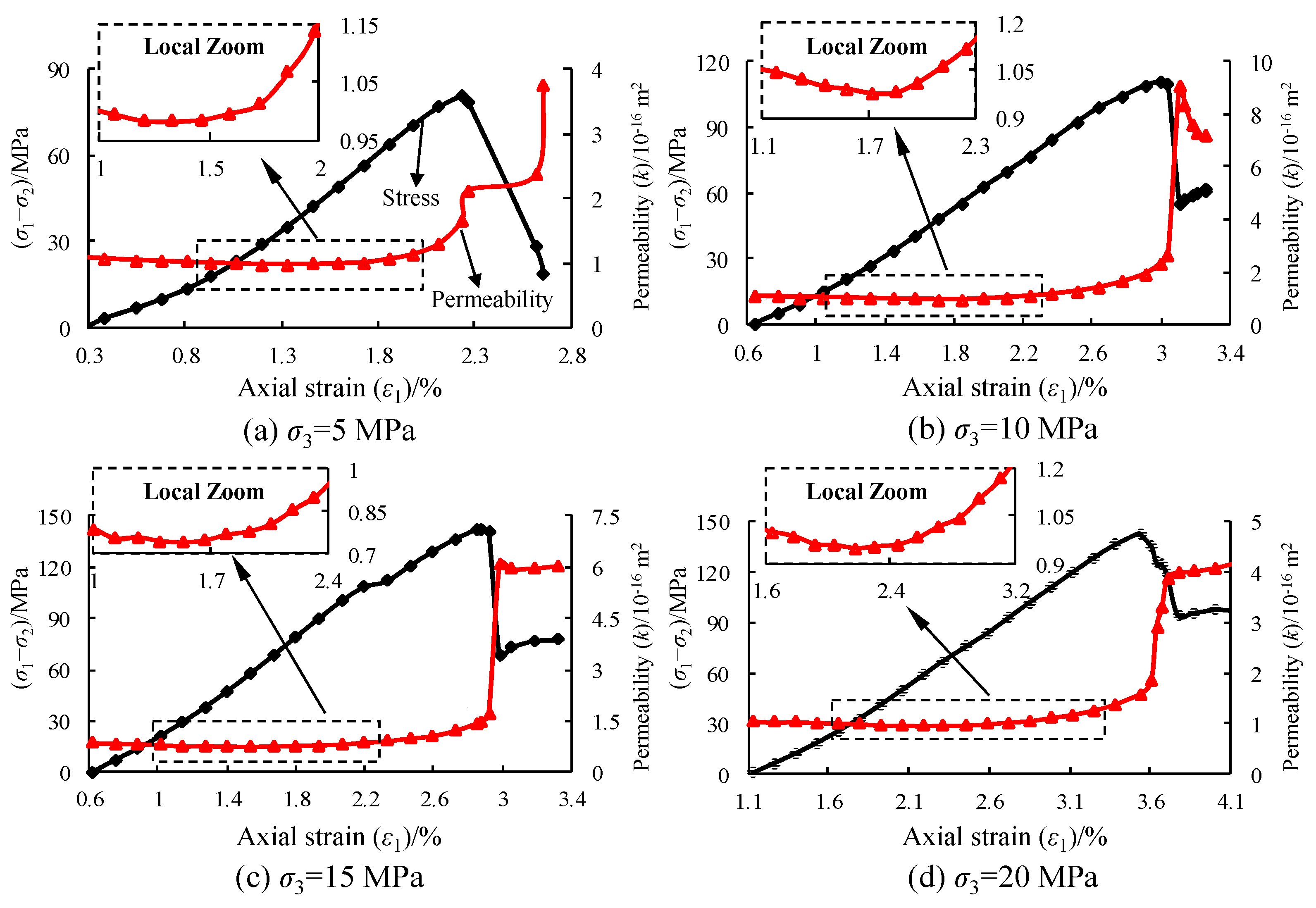

4.1. Measured Sandstone Permeability

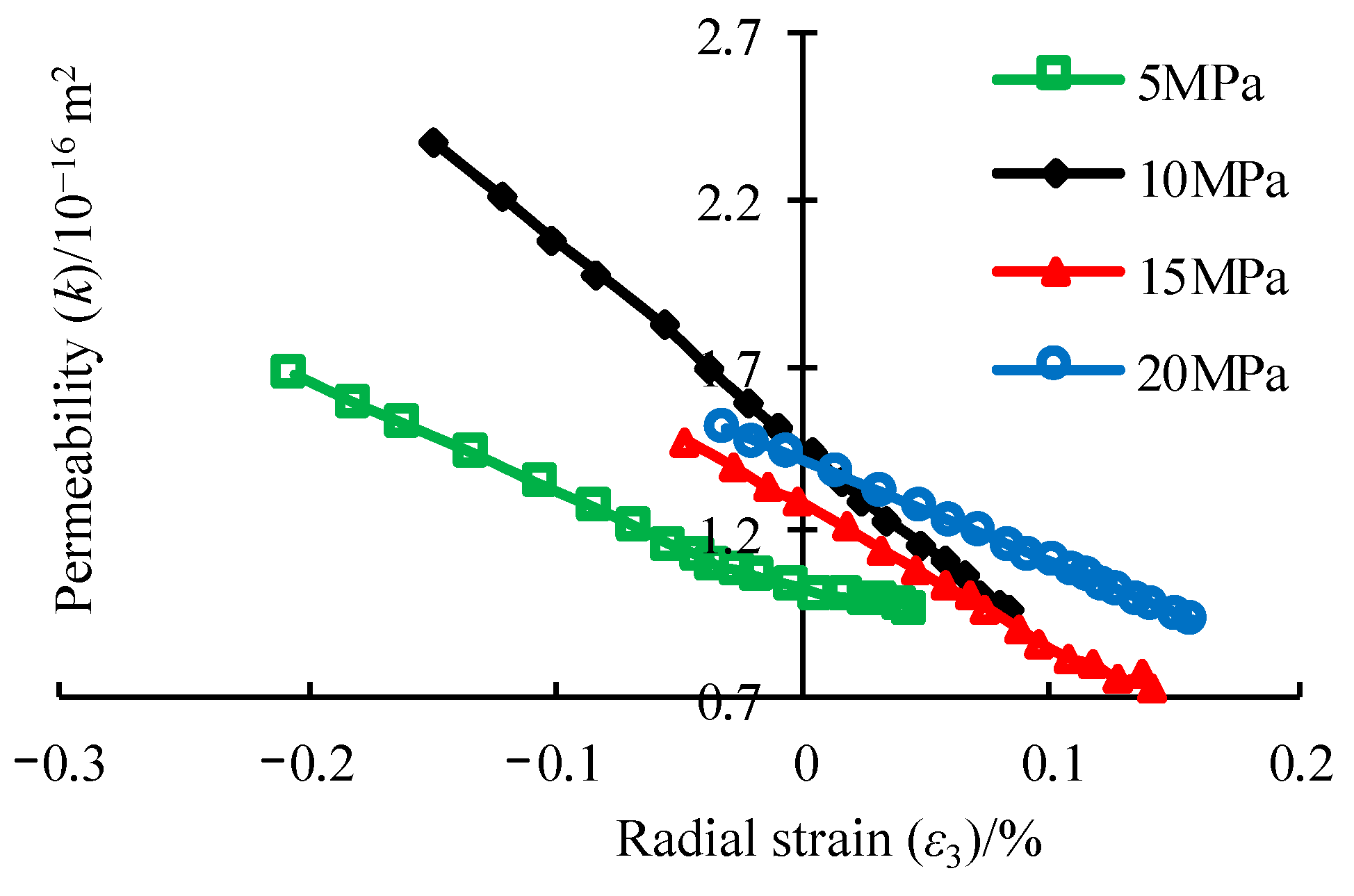

4.2. Permeability Model

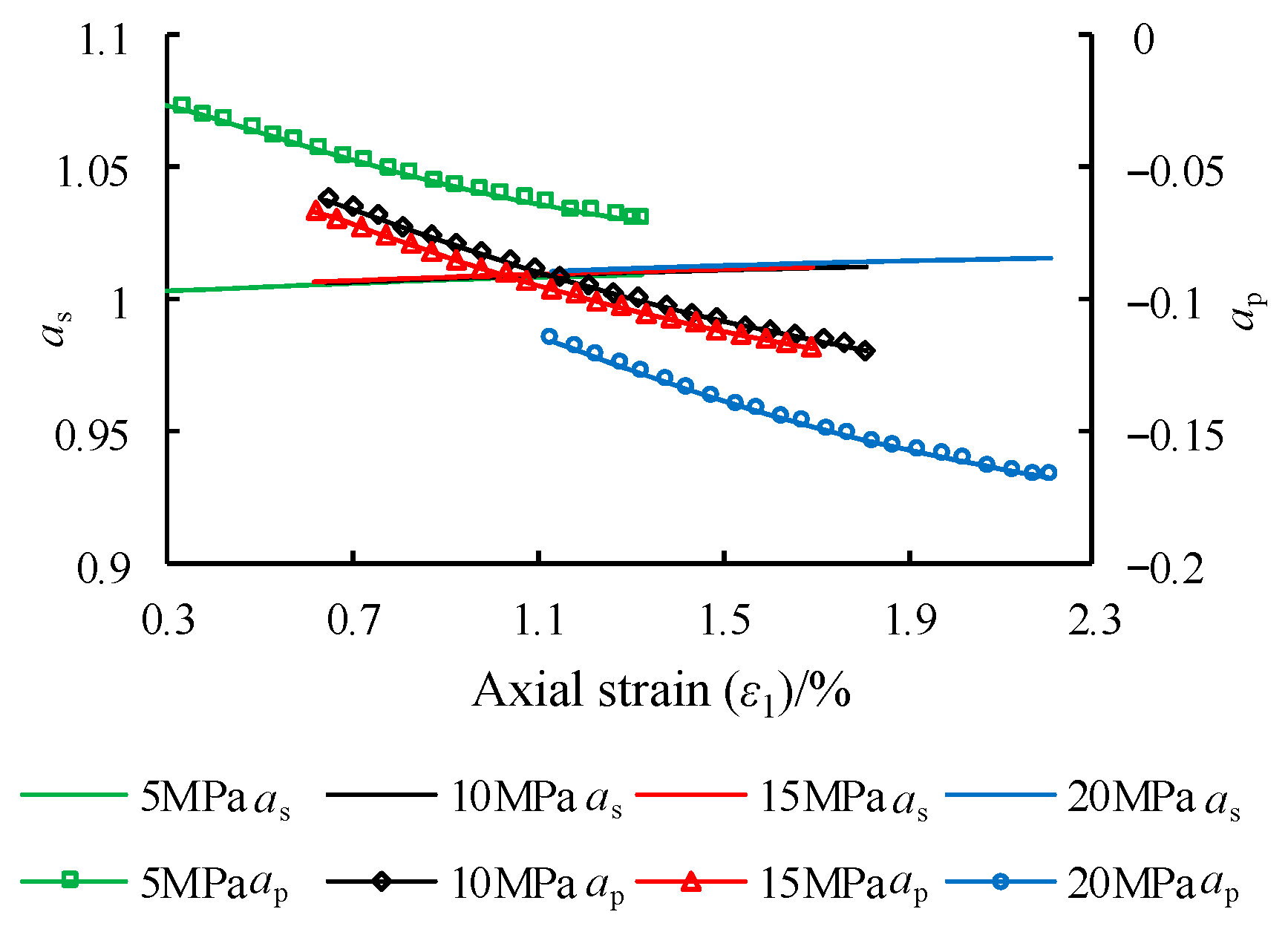

4.2.1. Permeability Decline

4.2.2. Permeability Recovery

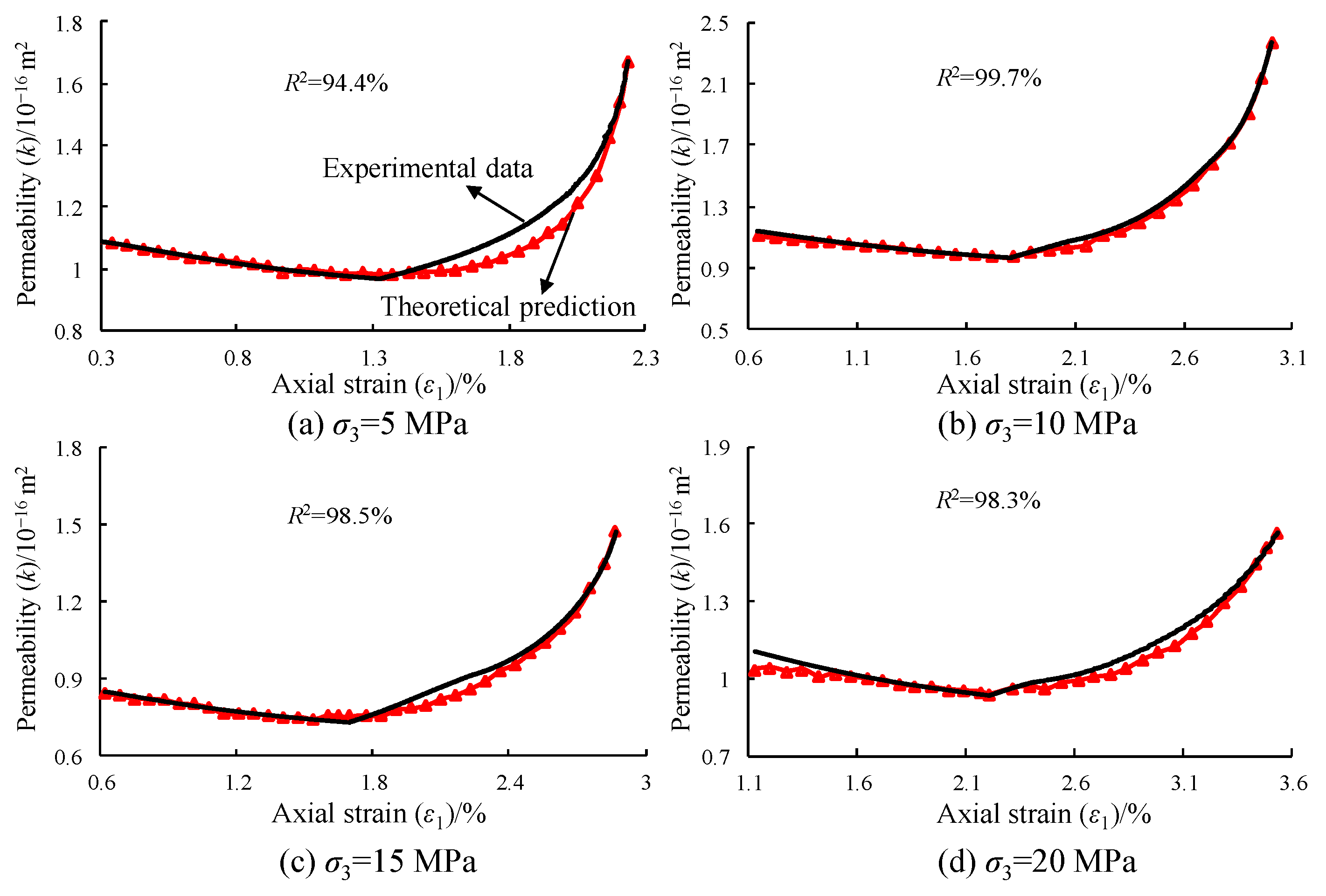

4.3. Permeability Model Verification

4.4. Factors Affecting Permeability

5. Conclusions

- (1)

- The gas-bearing sandstones showed evident brittle properties, and the failure mode was characterized by tensile–shear compounding. The bi-logarithmic model can better characterize the confining pressure dependence of sandstone strength.

- (2)

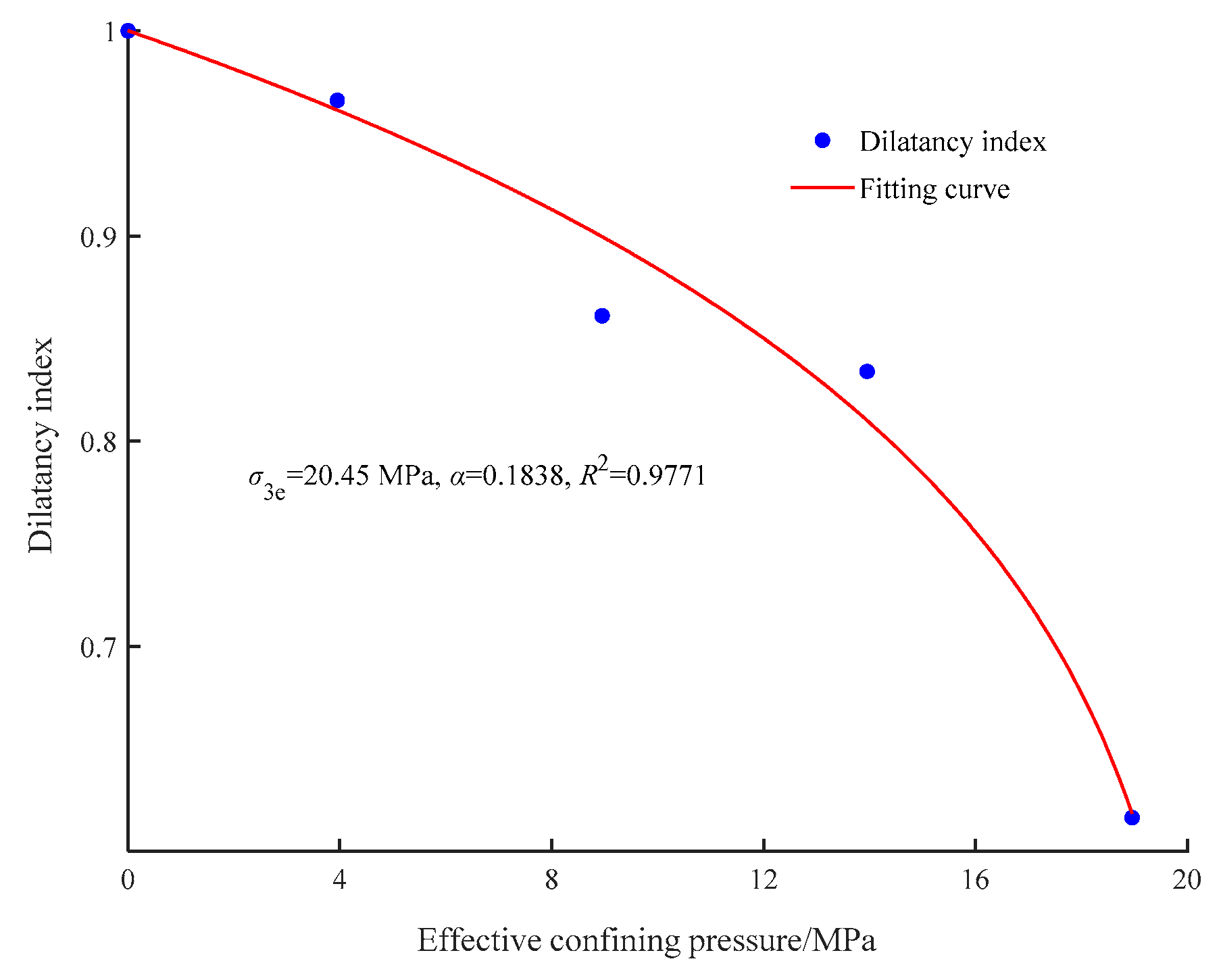

- In the fluid–solid coupling environment, the dilatancy capacity of sandstone at the moment of stress drop decreases exponentially with the increasing confining pressure, and the dilatancy index Id decreases as a power function.

- (3)

- Under different confining pressures, the sandstone permeability decreases, induced by the elastic deformation of solid mineral particles, and the closure of pores is less than that of the dilatancy-induced permeability recovery.

- (4)

- A simple permeability model with volumetric strain and radial strain as independent variables was established in the decreasing and rising stages of permeability, respectively. This model showed the important role of pore compaction and crack propagation on permeability and could better reflect the whole-process evolution of permeability.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gehne, S.; Benson, P.M. Permeability and permeability anisotropy in crab orchard sandstone: Experimental insights into spatio-temporal effects. Tectonophysics 2017, 712–713, 589–599. [Google Scholar] [CrossRef]

- Zhong, X.; Zhu, Y.; Liu, L.; Yang, H.; Li, Y.; Xie, Y.; Liu, L. The characteristics and influencing factors of permeability stress sensitivity of tight sandstone reservoirs. J. Pet. Sci. Eng. 2020, 191, 107221. [Google Scholar] [CrossRef]

- Wang, Y.; Jeannin, L.; Agostini, F.; Dormieux, L.; Skoczylas, F.; Portier, E. Experimental study and micromechanical interpretation of the poroelastic behaviour and permeability of a tight sandstone. Int. J. Rock Mech. Min. Sci. 2018, 103, 89–95. [Google Scholar] [CrossRef]

- Li, Q.; Han, Y.; Liu, X.; Ansari, U.; Cheng, Y.; Yan, C. Hydrate as a by-product in CO2 leakage during the long-term sub-seabed sequestration and its role in preventing further leakage. Environ. Sci. Pollut. Res. 2022, 29, 77737–77754. [Google Scholar] [CrossRef]

- Li, Q.; Wang, F.; Wang, Y.; Forson, K.; Cao, L.; Zhang, C.; Zhou, C.; Zhao, B.; Chen, J. Experimental investigation on the high-pressure sand suspension and adsorption capacity of guar gum fracturing fluid in low-permeability shale reservoirs: Factor analysis and mechanism disclosure. Environ. Sci. Pollut. Res. 2022, 29, 53050–53062. [Google Scholar] [CrossRef]

- Wang, F.; Xiao, Z.; Liu, X.; Ren, J.; Xing, T.; Li, Z.; Li, X.; Chen, Y. Strategic design of cellulose nanofibers@zeolitic imidazolate frameworks derived mesoporous carbon-supported nanoscale CoFe2O4/CoFe hybrid composition as trifunctional electrocatalyst for Zn-air battery and self-powered overall water-splitting. J. Power Source 2022, 521, 230925. [Google Scholar] [CrossRef]

- Yan, W.; Sun, J.; Dong, H.; Cui, L. Investigating NMR-based absolute and relative permeability models of sandstone using digital rock techniques. J. Pet. Sci. Eng. 2021, 207, 109105. [Google Scholar] [CrossRef]

- Zhang, R.; Ning, Z.; Yang, F.; Zhao, H.; Wang, Q. A laboratory study of the porosity-permeability relationships of shale and sandstone under effective stress. Int. J. Rock Mech. Min. Sci. 2016, 81, 19–27. [Google Scholar] [CrossRef]

- Nguyen, V.H.; Gland, N.; Dautriat, J.; David, C.; Wassermann, J.; Guélard, J. Compaction, permeability evolution and stress path effects in unconsolidated sand and weakly consolidated sandstone. Int. J. Rock Mech. Min. Sci. 2014, 67, 226–239. [Google Scholar] [CrossRef]

- Wang, F.; Yang, K.; You, J.; Lei, X. Analysis of pore size distribution and fractal dimension in tight sandstone with mercury intrusion porosimetry. Results Phys. 2019, 13, 102283. [Google Scholar] [CrossRef]

- Lu, J.; Yin, G.; Li, X.; Li, M.; Zhang, D.; Zhang, W.; Kang, Q. Deformation and CO2 gas permeability response of sandstone to mean and deviatoric stress variations under true triaxial stress conditions. Tunn. Undergr. Space Technol. 2019, 84, 259–272. [Google Scholar] [CrossRef]

- Yu, J.; Yao, W.; Duan, K.; Liu, X.; Zhu, Y. Experimental study and discrete element method modeling of compression and permeability behaviors of weakly anisotropic sandstones. Int. J. Rock Mech. Min. Sci. 2020, 134, 104437. [Google Scholar] [CrossRef]

- Hu, D.W.; Zhou, H.; Zhang, F.; Shao, J.F. Evolution of poroelastic properties and permeability in damaged sandstone. Int. J. Rock Mech. Min. Sci. 2010, 47, 962–973. [Google Scholar] [CrossRef]

- Al-Dughaimi, S.; Muqtadir, A.; Alzaki, T.; Dvorkin, J. Stress dependence of elastic and transport properties in tight gas sandstones. J. Pet. Sci. Eng. 2021, 196, 108001. [Google Scholar] [CrossRef]

- Sulem, J.; Ouffroukh, H. Shear-banding in drained and undrained triaxial tests on a saturated sandstone: Porosity and permeability evolution. Int. J. Rock Mech. Min. Sci. 2006, 43, 292–310. [Google Scholar] [CrossRef]

- Zisser, N.; Nover, G. Anisotropy of permeability and complex resistivity of tight sandstones subjected to hydrostatic pressure. J. Appl. Geophys. 2009, 68, 356–370. [Google Scholar] [CrossRef]

- Dong, J.; Hsu, J.; Wu, W.; Shimamoto, T.; Hung, J.; Yeh, E.; Wu, Y.; Sone, H. Stress-dependence of the permeability and porosity of sandstone and shale from TCDP Hole-A. Int. J. Rock Mech. Min. Sci. 2010, 47, 1141–1157. [Google Scholar] [CrossRef]

- Hu, C.; Jia, Y.; Duan, Z. Pore and permeability properties of reservoir sandstone under a uniaxial compression CT test. J. Nat. Gas Sci. Eng. 2022, 104, 104666. [Google Scholar] [CrossRef]

- Li, X.; Duan, K.; Zhang, Q.; Li, J.; Zhang, R.; Wang, L. Investigation of the permeability anisotropy of porous sandstone induced by complex stress conditions. Comput. Geotech. 2023, 157, 105309. [Google Scholar] [CrossRef]

- Wang, F.; Cheng, H. Effect of tortuosity on the stress-dependent permeability of tight sandstones: Analytical modelling and experimentation. Mar. Pet. Geol. 2020, 120, 104524. [Google Scholar] [CrossRef]

- Chen, D.; Pan, Z.; Ye, Z.; Hou, B.; Wang, D.; Yuan, L. A unified permeability and effective stress relationship for porous and fractured reservoir rocks. J. Nat. Gas Sci. Eng. 2016, 29, 401–412. [Google Scholar] [CrossRef]

- Moss, W.C.; Gupta, Y.M. A constitutive model describing dilatancy and cracking in brittle rocks. J. Geophys. Res. 1982, 87, 2985–2998. [Google Scholar] [CrossRef]

- Yuan, S.C.; Harrison, J.P. An empirical dilatancy index for the dilatant deformation of rock. Int. J. Rock Mech. Min. Sci. 2004, 41, 679–686. [Google Scholar] [CrossRef]

- Bésuelle, P.; Desrues, J.; Raynaud, S. Experimental characterisation of the localisation phenomenon inside a Vosges sandstone in a triaxial cell. Int. J. Rock Mech. Min. Sci. 2000, 37, 1223–1237. [Google Scholar] [CrossRef]

- Mahmutoglu, Y.; Vardar, M. Effects of inelastic volume increase on fractured rock behaviour. Bull. Eng. Geol. Environ. 2003, 62, 117–121. [Google Scholar] [CrossRef]

- David, E.C.; Brantut, N.; Schubnel, A.; Zimmerman, R.W. Sliding crack model for nonlinearity and hysteresis in the uniaxial stress–strain curve of rock. Int. J. Rock Mech. Min. Sci. 2012, 52, 9–17. [Google Scholar] [CrossRef]

- Lu, J.; Xie, H.; Li, M.; Li, C.; Gao, M.; Shang, D.; Li, J. Effect of microwave radiation on mechanical behaviors of tight fine sandstone subjected to true triaxial stress. Int. J. Rock Mech. Min. Sci. 2022, 152, 105063. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, Z. On the physical significance of the third invariant of stress deviator J3 and the third invariant of stress tensor I3 and their geometric significance in the space of principal stresses. J. Harbin Inst. Technol. 1982, 2, 110–115. [Google Scholar]

- Zhang, W.; Wang, Q. Permeability anisotropy and gas slippage of shales from the Sichuan Basin in South China. Int. J. Coal Geol. 2018, 194, 22–32. [Google Scholar] [CrossRef]

- Wu, W.; Reece, J.S.; Gensterblum, Y.; Zoback, M.D. Permeability evolution of slowly slipping faults in shale reservoirs. Geophys. Res. Lett. 2017, 44, 11368–11375. [Google Scholar] [CrossRef]

- Hu, D.; Zhou, H.; Pan, P.; Zhang, K.; Shao, J.; Feng, X. Study of permeability of sandstone in triaxial cyclic stress tests. Rock Soil Mech. 2010, 31, 2749–2754. [Google Scholar]

- Cao, W.; Zhao, H.; Zhang, L.; Zhang, Y. Damage statistical softening constitutive model for rock considering effect of damage threshold and its parameters determination method. Chin. J. Rock Mech. Eng. 2008, 27, 1148–1154. [Google Scholar]

- Menezes, F.F. Anisotropy of volume change and permeability evolution of hard sandstones under triaxial stress conditions. J. Pet. Sci. Eng. 2019, 174, 921–939. [Google Scholar] [CrossRef]

- Wang, Y.; Agostini, F.; Skoczylas, F.; Jeannin, L.; Portier, É. Experimental study of the gas permeability and bulk modulus of tight sandstone and changes in its pore structure. Int. J. Rock Mech. Min. Sci. 2017, 91, 203–209. [Google Scholar] [CrossRef]

- Shanley, K.W.; Cluff, R.M.; Robinson, J.W. Factors controlling prolific gas production from low-permeability sandstone reservoirs: Implications for resource assessment, prospect development, and risk analysis. AAPG Bull. 2004, 88, 1083–1121. [Google Scholar] [CrossRef]

- Patrick, B.; Wong, T.F.; Zhu, W. Effects of porosity and crack density on the compressive strength of rocks. Int. J. Rock Mech. Min. Sci. 2014, 67, 202–211. [Google Scholar]

- Doyen, P.M. Permeability, conductivity, and pore geometry of sandstone. J. Geophys. Res. Solid Earth 1988, 93, 7729–7740. [Google Scholar] [CrossRef]

- David, C.; Wong, T.F.; Zhu, W.; Zhang, J. Laboratory measurement of compaction-induced permeability change in porous rocks: Implications for the generation and maintenance of pore pressure excess in the crust. Pure Appl. Geophys. 1994, 143, 425–456. [Google Scholar] [CrossRef]

- Bernabé, Y.; Mok, U.; Evans, B. Permeability-porosity relationships in rocks subjected to various evolution processes. Pure Appl. Geophys. 2003, 160, 937–960. [Google Scholar] [CrossRef]

- Shao, J.F.; Chiarelli, A.S.; Hoteit, N. Modeling of coupled elastoplastic damage in rock materials. Int. J. Rock Mech. Min. Sci. 1998, 35, 444. [Google Scholar] [CrossRef]

- Gao, C.; Xie, L.Z.; Xie, H.P.; He, B.; Li, C.B.; Wang, J.; Luo, Y. Coupling between the statistical damage model and permeability variation in reservoir sandstone: Theoretical analysis and verification. J. Nat. Gas Sci. Eng. 2017, 37, 375–385. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, D.; Guo, M.; Li, B. Study of rock damage characteristics based on acoustic emission tests under triaxial compression. Chin. J. Rock Mech. Eng. 2014, 33, 98–104. [Google Scholar]

| Specimen Number | Diameter (mm) | Height (mm) | CO2 Pressure (MPa) | Confining Pressure (MPa) | Simulated Depth (m) |

|---|---|---|---|---|---|

| 1# | 48.80 | 101.44 | 2 | 5 | −200 m |

| 2# | 48.74 | 100.40 | 2 | 10 | −400 m |

| 3# | 48.70 | 101.16 | 2 | 15 | −600 m |

| 4# | 48.76 | 100.82 | 2 | 20 | −800 m |

| σ3/MPa | a | b | R2 |

|---|---|---|---|

| 5 | 0.8853 | 0.2304 | 0.999 |

| 10 | 0.8854 | 0.3633 | 0.999 |

| 15 | 0.8638 | 0.5509 | 0.999 |

| 20 | 0.856 | 0.6219 | 0.999 |

| Article |

| Effective Confining Pressure, σ3e/MPa | 0 | 3.95 | 8.95 | 13.95 | 18.95 |

|---|---|---|---|---|---|

| Δεvp/Δε1p | 3.547 | 3.03 | 2.045 | 1.875 | 1.027 |

| Apparent dilation angle, degree | 74.256 | 71.736 | 63.942 | 61.925 | 45.771 |

| Dilatancy index, Id | 1 | 0.966 | 0.861 | 0.834 | 0.616 |

| Confining Pressure (MPa) | Initial Permeability (10−16 m2) | Minimum Permeability (10−16 m2) | Maximum Permeability (10−16 m2) |

|---|---|---|---|

| 5 | 1.09 | 0.98 | 1.67 |

| 10 | 1.11 | 0.97 | 2.37 |

| 15 | 0.84 | 0.75 | 1.47 |

| 20 | 1.04 | 0.94 | 1.57 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, C.; Liu, Y.; Xie, Z.; Yu, B. Experimental Study on the Dilatancy Characteristics and Permeability Evolution of Sandstone under Different Confining Pressures. Sustainability 2023, 15, 14795. https://doi.org/10.3390/su152014795

Liu C, Liu Y, Xie Z, Yu B. Experimental Study on the Dilatancy Characteristics and Permeability Evolution of Sandstone under Different Confining Pressures. Sustainability. 2023; 15(20):14795. https://doi.org/10.3390/su152014795

Chicago/Turabian StyleLiu, Chao, Yixin Liu, Zhicheng Xie, and Beichen Yu. 2023. "Experimental Study on the Dilatancy Characteristics and Permeability Evolution of Sandstone under Different Confining Pressures" Sustainability 15, no. 20: 14795. https://doi.org/10.3390/su152014795