Industry 4.0 in “Major Emerging Markets”: A Systematic Literature Review of Benefits, Use, Challenges, and Mitigation Strategies in Supply Chain Management

Abstract

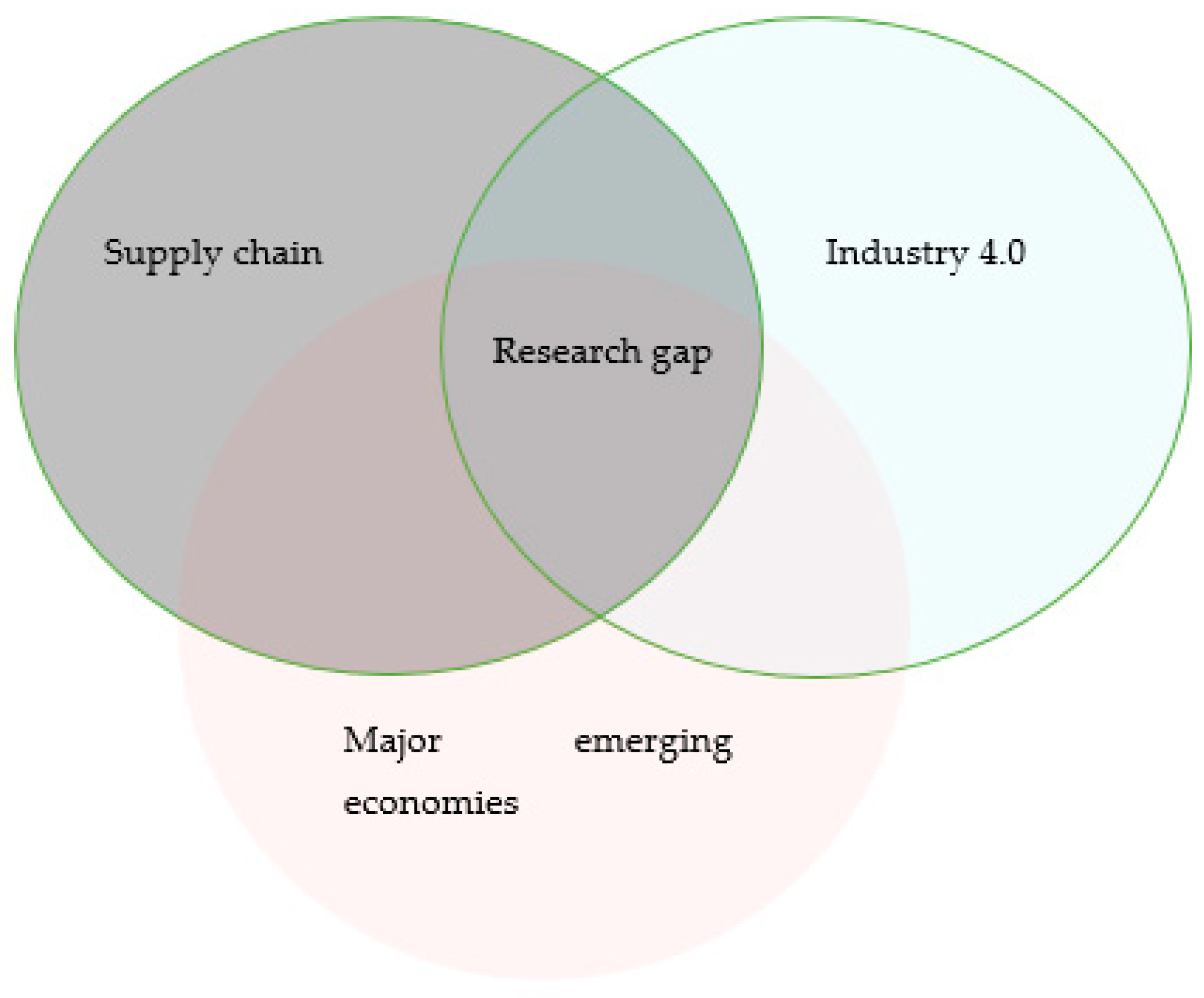

:1. Introduction

- RQ1. How are Industry 4.0 technologies being used to support supply chains in a novel way in “major emerging markets”?

- RQ2. What are the benefits of using Industry 4.0 in supply chains in “major emerging markets”?

- RQ3. What challenges do “major emerging markets” face in using Industry 4.0 in supply chains?

- RQ4. How can “major emerging markets” mitigate challenges faced in using Industry 4.0 in supply chains?

Definition of Terms

2. Theoretical Background

2.1. Industry 4.0

2.2. Supply Chain

2.3. Emerging Markets

3. Methodology

3.1. Protocol

3.2. Search

3.3. Selection of Studies

3.4. Quality Assessment

- (a)

- The inclusion/exclusion criteria are clearly and adequately described.

- (b)

- The literature search strategy provided all relevant papers.

- (c)

- The SLR is peer-reviewed.

- (d)

- The SLR adequately describes the use of Industry 4.0 on supply chains in emerging economies.

3.5. Synthesis

3.6. Analysis

4. Results and Discussion

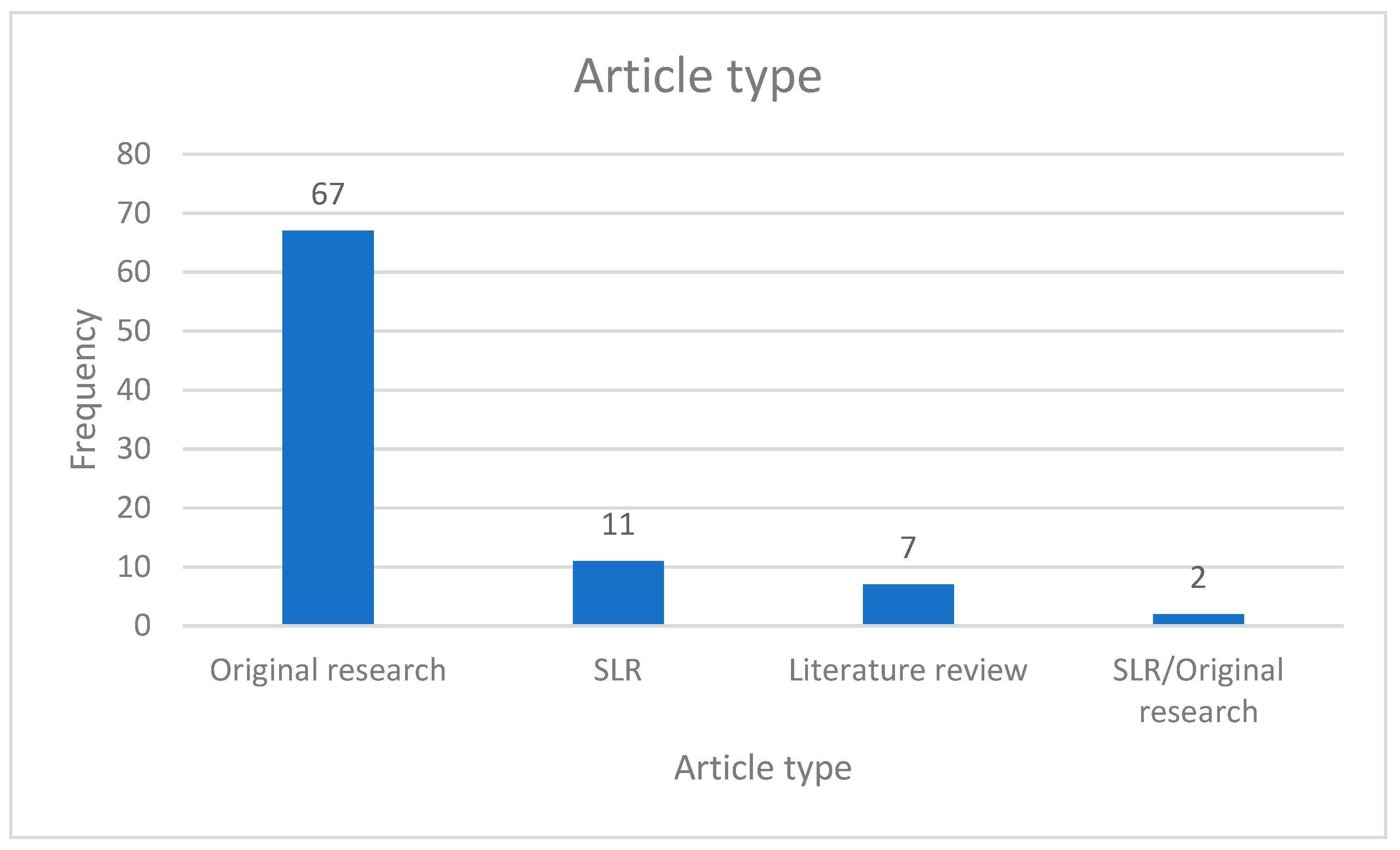

4.1. Quantitative Results

4.2. Qualitative Results

4.2.1. Industry 4.0 Technologies Being Used to Support Supply Chains in Emerging Markets

IoT

Big Data and Artificial Intelligence

Blockchain

Cloud

Robots and Virtualization

Digital Twin

3D Printing/Additive Manufacturing

4.2.2. Challenges in the Use of Industry 4.0 in Supply Chains in Emerging Markets

The Need for Investment in Industry 4.0

Business Risks

Skills Shortage

Data Integration and Cyber-Security

Weak Policy and Legislation

Weak Infrastructure

Organization Culture

Lack of Management Support

4.2.3. Mitigation Measures

Conducive Policy and Legislation

Executive Management Support

Training

Investment and Infrastructure Development

Data Security

Supply Chain Agility

Third-Party Audits

4.3. Benefits of Using Industry 4.0 in Supply Chains

4.4. Discussion

Summary of Main Results

5. Conclusions, Implications, and Limitations

5.1. Implications for Practice

5.2. Implications for Research

5.3. Limitations

5.4. Conclusions

Funding

Acknowledgments

Conflicts of Interest

References

- Frank, A.G.; Dalenogare, L.S.; Ayala, N.F. Industry 4.0 Technologies: Implementation Patterns in Manufacturing Companies. Int. J. Prod. Econ. 2019, 210, 15–26. [Google Scholar] [CrossRef]

- Bai, C.; Dallasega, P.; Orzes, G.; Sarkis, J. Industry 4.0 Technologies Assessment: A Sustainability Perspective. Int. J. Prod. Econ. 2020, 229, 107776. [Google Scholar] [CrossRef]

- Vaidya, S.; Ambad, P.; Bhosle, S. Industry 4.0—A Glimpse. Procedia Manuf. 2018, 20, 233–238. [Google Scholar] [CrossRef]

- Weerabahu, S.; Samaranayake, P.; Nakandala, D.; Hurriyet, H. Digital Supply Chain Research Trends: A Systematic Review and a Maturity Model for Adoption. Benchmarking Int. J. 2022. [Google Scholar] [CrossRef]

- Khan, M.D.; Schaefer, D.; Milisavljevic-Syed, J. Supply Chain Management 4.0: Looking Backward, Looking Forward. Procedia CIRP 2022, 107, 9–14. [Google Scholar] [CrossRef]

- Farooq, M.U.; Hussain, A.; Masood, T.; Habib, M.S. Supply Chain Operations Management in Pandemics: A State-of-the-Art Review Inspired by COVID-19. Sustainability 2021, 13, 2504. [Google Scholar] [CrossRef]

- Prause, G.; Atari, S. On Sustainable Production Networks for Industry 4.0. Entrep. Sustain. Issues 2017, 4, 421. [Google Scholar] [CrossRef]

- Rad, F.F.; Oghazi, P.; Palmié, M.; Chirumalla, K.; Pashkevich, N.; Patel, P.C.; Sattari, S. Industry 4.0 and Supply Chain Performance: A Systematic Literature Review of the Benefits, Challenges, and Critical Success Factors of 11 Core Technologies. Ind. Mark. Manag. 2022, 105, 268–293. [Google Scholar] [CrossRef]

- Chauhan, C.; Singh, A. A Review of Industry 4.0 in Supply Chain Management Studies. J. Manuf. Technol. Manag. 2020, 31, 863–886. [Google Scholar] [CrossRef]

- Abdirad, M.; Krishnan, K. Industry 4.0 in Logistics and Supply Chain Management: A Systematic Literature Review. Eng. Manag. J. 2021, 33, 187–201. [Google Scholar] [CrossRef]

- Naseem, M.H.; Yang, J. Role of Industry 4.0 in Supply Chains Sustainability: A Systematic Literature Review. Sustainability 2021, 13, 9544. [Google Scholar] [CrossRef]

- Yadav, V.S.; Singh, A.R.; Raut, R.D.; Mangla, S.K.; Luthra, S.; Kumar, A. Exploring the Application of Industry 4.0 Technologies in the Agricultural Food Supply Chain: A Systematic Literature Review. Comput. Ind. Eng. 2022, 169, 108304. [Google Scholar] [CrossRef]

- Srhir, S.; Jaegler, A.; Montoya-Torres, J.R. Uncovering Industry 4.0 Technology Attributes in Sustainable Supply Chain 4.0: A Systematic Literature Review. Bus. Strategy Environ. 2023; in print. [Google Scholar] [CrossRef]

- Taddei, E.; Sassanelli, C.; Rosa, P.; Terzi, S. Circular Supply Chains in the Era of Industry 4.0: A Systematic Literature Review. Comput. Ind. Eng. 2022, 170, 108268. [Google Scholar] [CrossRef]

- Spieske, A.; Birkel, H. Improving Supply Chain Resilience through Industry 4.0: A Systematic Literature Review under the Impressions of the COVID-19 Pandemic. Comput. Ind. Eng. 2021, 158, 107452. [Google Scholar] [CrossRef]

- Sayem, A.; Biswas, P.K.; Khan, M.M.A.; Romoli, L.; Dalle Mura, M. Critical Barriers to Industry 4.0 Adoption in Manufacturing Organizations and Their Mitigation Strategies. J. Manuf. Mater. Process. 2022, 6, 136. [Google Scholar] [CrossRef]

- Tamvada, J.P.; Narula, S.; Audretsch, D.; Puppala, H.; Kumar, A. Adopting New Technology Is a Distant Dream? The Risks of Implementing Industry 4.0 in Emerging Economy SMEs. Technol. Forecast. Soc. Chang. 2022, 185, 122088. [Google Scholar] [CrossRef]

- Michele, D.; Carlo, P.; Elisa, C.; Alejandro, L. Are Emerging Economies already Engaging with Industry 4.0 Technologies? Development Matters. Available online: https://oecd-development-matters.org/2022/07/28/are-emerging-economies-engaging-with-industry-4-0-technologies/ (accessed on 9 August 2023).

- Shamika, S. What Is “Industry 4.0” and What Will It Mean for Developing Countries?|UNCTAD. UNCTAD. Available online: https://unctad.org/news/blog-what-industry-40-and-what-will-it-mean-developing-countries (accessed on 5 May 2023).

- Oracle. What Is the Internet of Things (IoT)? Available online: https://www.oracle.com/ke/internet-of-things/what-is-iot/ (accessed on 9 August 2023).

- Microsoft Azure. What Is Big Data Analytics?|Microsoft Azure. Available online: https://azure.microsoft.com/en-us/resources/cloud-computing-dictionary/what-is-big-data-analytics (accessed on 9 August 2023).

- Steve, R. What Is Cloud Computing? Everything You Need to Know about the Cloud Explained. ZDNET. Available online: https://www.zdnet.com/article/what-is-cloud-computing-everything-you-need-to-know-about-the-cloud/ (accessed on 9 August 2023).

- Copeland, B. Artificial Intelligence (AI)|Definition, Examples, Types, Applications, Companies, & Facts|Britannica. Available online: https://www.britannica.com/technology/artificial-intelligence (accessed on 13 August 2023).

- Jia, X.; Feng, Q.; Fan, T.; Lei, Q. RFID Technology and Its Applications in Internet of Things (IoT). In Proceedings of the 2012 2nd International Conference on Consumer Electronics, Communications and Networks (CECNet), Yichang, China, 21–23 April 2012; pp. 1282–1285. [Google Scholar] [CrossRef]

- AWS. What Is Blockchain Technology?—Blockchaining Explained—AWS. Amazon Web Services, Inc. Available online: https://aws.amazon.com/what-is/blockchain/ (accessed on 13 August 2023).

- McKinsey. What Is Digital-Twin Technology?|McKinsey. Available online: https://www.mckinsey.com/featured-insights/mckinsey-explainers/what-is-digital-twin-technology (accessed on 10 August 2023).

- General Electric. What Is Additive Manufacturing|GE Additive. Available online: https://www.ge.com/additive/additive-manufacturing (accessed on 10 August 2023).

- Kaspersky. What Is Cyber Security? Available online: https://www.kaspersky.com/resource-center/definitions/what-is-cyber-security (accessed on 11 August 2023).

- Ghobakhloo, M. Industry 4.0, Digitization, and Opportunities for Sustainability. J. Clean. Prod. 2020, 252, 119869. [Google Scholar] [CrossRef]

- Guo, D.; Li, M.; Lyu, Z.; Kang, K.; Wu, W.; Zhong, R.Y.; Huang, G.Q. Synchroperation in Industry 4.0 Manufacturing. Int. J. Prod. Econ. 2021, 238, 108171. [Google Scholar] [CrossRef]

- Raj, A.; Dwivedi, G.; Sharma, A.; de Sousa Jabbour, A.B.L.; Rajak, S. Barriers to the Adoption of Industry 4.0 Technologies in the Manufacturing Sector: An Inter-Country Comparative Perspective. Int. J. Prod. Econ. 2020, 224, 107546. [Google Scholar] [CrossRef]

- Ojubanire, O.A.; Sebti, H.; Berbain, S. Towards Developing a National Framework for Industry 4.0 in African Emerging Economies. Afr. J. Sci. Technol. Innov. Dev. 2022, 15, 496–513. [Google Scholar] [CrossRef]

- Maisiri, W.; Van, D.L. Industry 4.0 Readiness Assessment for South African Industries. S. Afr. J. Ind. Eng. 2019, 30, 134–148. [Google Scholar] [CrossRef]

- Yerpude, S.; Singhal, T.K. Value Enablement of Collaborative Supply Chain Environment Embedded with the Internet of Things: Empirical Evidence from the Automotive Industry in India. Int. J. Intell. Inf. Technol. IJIIT 2020, 16, 19–51. [Google Scholar] [CrossRef]

- Adebanjo, D.; Laosirihongthong, T.; Samaranayake, P.; Teh, P.-L. Key Enablers of Industry 4.0 Development at Firm Level: Findings from an Emerging Economy. IEEE Trans. Eng. Manag. 2021, 70, 400–416. [Google Scholar] [CrossRef]

- Pasi, B.N.; Mahajan, S.K.; Rane, S.B. Smart Supply Chain Management: A Perspective of Industry 4.0. Supply Chain Manag. 2020, 29, 3016–3030. [Google Scholar]

- Hofmann, E.; Sternberg, H.; Chen, H.; Pflaum, A.; Prockl, G. Supply Chain Management and Industry 4.0: Conducting Research in the Digital Age. Int. J. Phys. Distrib. Logist. Manag. 2019, 49, 945–955. [Google Scholar] [CrossRef]

- Dalmarco, G.; Barros, A.C. Adoption of Industry 4.0 Technologies in Supply Chains. In Innovation and Supply Chain Management: Relationship, Collaboration and Strategies; Moreira, A.C., Ferreira, L.M.D.F., Zimmermann, R.A., Eds.; Contributions to Management Science; Springer International Publishing: Cham, Switzerland, 2018; pp. 303–319. [Google Scholar] [CrossRef]

- Hahn, G.J. Industry 4.0: A Supply Chain Innovation Perspective. Int. J. Prod. Res. 2020, 58, 1425–1441. [Google Scholar] [CrossRef]

- International Monetary Fund. Fiscal Monitor (April 2023). imf.org. Available online: https://www.imf.org/external/datamapper/datasets/FM (accessed on 9 August 2023).

- Sankaran, A.; Krishna, A.; Vadivel, A. How Does Manufacturing Output Affect Export Behaviors in Emerging Market Economies? Evidence from a Dynamic Panel ARDL for Ten Biggest Emerging Market Economies. Future Bus. J. 2021, 7, 26. [Google Scholar] [CrossRef]

- Duttagupta, R.; Pazarbasioglu, C. Miles to Go: The Future of Emerging Markets—IMF F&D. International Monetary Fund. Available online: https://www.imf.org/external/pubs/ft/fandd/2021/06/the-future-of-emerging-markets-duttagupta-and-pazarbasioglu.htm (accessed on 5 May 2023).

- Huidrom, R.; Kose, M.A.; Ohnsorge, F.L. How Important Are Spillovers from Major Emerging Markets? Int. Financ. 2020, 23, 47–63. [Google Scholar] [CrossRef]

- Verma, P.; Kumar, V.; Bhatt, P.C.; kumar Drave, V.A.; Hsu, S.-C.; Lai, K.K.; Pal, V. Industry 4.0 in Emerging Economies: Technological and Societal Challenges for Sustainability. In Applications and Challenges of Maintenance and Safety Engineering in Industry 4.0; IGI Global: Hershey, PA, USA, 2020; pp. 31–48. [Google Scholar] [CrossRef]

- Mengist, W.; Soromessa, T.; Legese, G. Method for Conducting Systematic Literature Review and Meta-Analysis for Environmental Science Research. MethodsX 2020, 7, 100777. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 Statement: An Updated Guideline for Reporting Systematic Reviews. Syst. Rev. 2021, 10, 89. [Google Scholar] [CrossRef]

- Page, M.J.; Moher, D.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. PRISMA 2020 Explanation and Elaboration: Updated Guidance and Exemplars for Reporting Systematic Reviews. BMJ 2021, 372, n160. [Google Scholar] [CrossRef]

- Lochmiller, C. Conducting Thematic Analysis with Qualitative Data. Qual. Rep. 2021, 26, 2029–2044. [Google Scholar] [CrossRef]

- Soares, M.C.; Ferreira, C.V.; Murari, T.B. Supply Chain Resilience and Industry 4.0: A Evaluation of the Brazilian Northeast Automotive OEM Scenario Post COVID-19. AI Perspect. 2021, 3, 1–12. [Google Scholar] [CrossRef]

- Sharma, A.; Jain, D.K. Development of Industry 4.0. In A Roadmap to Industry 4.0: Smart Production, Sharp Business and Sustainable Development; Springer: Berlin/Heidelberg, Germany, 2020; pp. 23–38. [Google Scholar]

- Zhang, A.; Venkatesh, V.G.; Wang, J.X.; Mani, V.; Wan, M.; Qu, T. Drivers of Industry 4.0-Enabled Smart Waste Management in Supply Chain Operations: A Circular Economy Perspective in China. Prod. Plan. Control 2021, 34, 870–886. [Google Scholar] [CrossRef]

- Lu, H.; Zhao, G.; Liu, S. Integrating Circular Economy and Industry 4.0 for Sustainable Supply Chain Management: A Dynamic Capability View. Prod. Plan. Control 2022, 1–17. [Google Scholar] [CrossRef]

- Soni, G.; Kumar, S.; Mahto, R.V.; Mangla, S.K.; Mittal, M.L.; Lim, W.M. A Decision-Making Framework for Industry 4.0 Technology Implementation: The Case of FinTech and Sustainable Supply Chain Finance for SMEs. Technol. Forecast. Soc. Chang. 2022, 180, 121686. [Google Scholar] [CrossRef]

- Gharaibeh, L.; Eriksson, K.M.; Lantz, B.; Matarneh, S.; Elghaish, F. Toward Digital Construction Supply Chain-Based Industry 4.0 Solutions: Scientometric-Thematic Analysis. Smart Sustain. Built Environ. 2022; ahead-of-print. [Google Scholar] [CrossRef]

- Kazancoglu, Y.; Ozkan-Ozen, Y.D.; Sagnak, M.; Kazancoglu, I.; Dora, M. Framework for a Sustainable Supply Chain to Overcome Risks in Transition to a Circular Economy through Industry 4.0. Prod. Plan. Control 2021, 34, 902–917. [Google Scholar] [CrossRef]

- Suharjanto, G.; Soebandrija, K.E.N. Logistics and Supply Chain Engineering: Perspectives on Paperless System for Highway Automatic Tollgate (HAT) through Industry 4.0. in Indonesia. KnE Life Sci. 2020, 2020, 103–109. [Google Scholar] [CrossRef]

- Sutawijaya, A.H.; Nawangsari, L.C. What Is the Impact of Industry 4.0 to Green Supply Chain. J. Environ. Treat. Tech. 2020, 8, 207–213. [Google Scholar]

- Aravindaraj, K.; Chinna, P.R. A Systematic Literature Review of Integration of Industry 4.0 and Warehouse Management to Achieve Sustainable Development Goals (SDGs). Clean. Logist. Supply Chain 2022, 5, 100072. [Google Scholar] [CrossRef]

- Granillo-Macías, R.; Simón-Marmolejo, I.; González-Hernández, I.J.; Zuno-Silva, J. Traceability in Industry 4.0: A Case Study in the Metalmechanical Sector. Acta Logística 2020, 7, 95–101. [Google Scholar] [CrossRef]

- Mahdiraji, H.A.; Yaftiyan, F.; Abbasi-Kamardi, A.; Garza-Reyes, J.A. Investigating Potential Interventions on Disruptive Impacts of Industry 4.0 Technologies in Circular Supply Chains: Evidence from SMEs of an Emerging Economy. Comput. Ind. Eng. 2022, 174, 108753. [Google Scholar] [CrossRef]

- Amani, M.A.; Sarkodie, S.A. Mitigating Spread of Contamination in Meat Supply Chain Management Using Deep Learning. Sci. Rep. 2022, 12, 5037. [Google Scholar] [CrossRef] [PubMed]

- Manavalan, E.; Jayakrishna, K. An Analysis on Sustainable Supply Chain for Circular Economy. Procedia Manuf. 2019, 33, 477–484. [Google Scholar] [CrossRef]

- Kunkel, S.; Matthess, M.; Xue, B.; Beier, G. Industry 4.0 in Sustainable Supply Chain Collaboration: Insights from an Interview Study with International Buying Firms and Chinese Suppliers in the Electronics Industry. Resour. Conserv. Recycl. 2022, 182, 106274. [Google Scholar] [CrossRef]

- Narwane, V.S.; Raut, R.D.; Yadav, V.S.; Singh, A.R. Barriers in Sustainable Industry 4.0: A Case Study of the Footwear Industry. Int. J. Sustain. Eng. 2021, 14, 175–189. [Google Scholar] [CrossRef]

- Kayikci, Y.; Kazancoglu, Y.; Gozacan-Chase, N.; Lafci, C.; Batista, L. Assessing Smart Circular Supply Chain Readiness and Maturity Level of Small and Medium-Sized Enterprises. J. Bus. Res. 2022, 149, 375–392. [Google Scholar] [CrossRef]

- Yu, Y.; Zhang, J.Z.; Cao, Y.; Kazancoglu, Y. Intelligent Transformation of the Manufacturing Industry for Industry 4.0: Seizing Financial Benefits from Supply Chain Relationship Capital through Enterprise Green Management. Technol. Forecast. Soc. Chang. 2021, 172, 120999. [Google Scholar] [CrossRef]

- Prakash, A.; Francis, R.C. A Desk Study on the Impact of Industry 4.0 on the Supply Chain in India. Int. J. Emerg. Trends Eng. Res. 2021, 9, 367–372. [Google Scholar]

- Wamba, S.F.; Queiroz, M.M. Industry 4.0 and the Supply Chain Digitalisation: A Blockchain Diffusion Perspective. Prod. Plan. Control 2022, 33, 193–210. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A. A Digital Supply Chain Twin for Managing the Disruption Risks and Resilience in the Era of Industry 4.0. Prod. Plan. Control 2021, 32, 775–788. [Google Scholar] [CrossRef]

- Caiado, R.G.G.; Scavarda, L.F.; Gavião, L.O.; Ivson, P.; de Mattos Nascimento, D.L.; Garza-Reyes, J.A. A Fuzzy Rule-Based Industry 4.0 Maturity Model for Operations and Supply Chain Management. Int. J. Prod. Econ. 2021, 231, 107883. [Google Scholar] [CrossRef]

- Dash, B.P.; Dixit, V. Disaster Supply Chain with Information and Digital Technology Integrated in Its Institutional Framework. Int. J. Prod. Res. 2022, 1–20. [Google Scholar] [CrossRef]

- Ding, B. Pharma Industry 4.0: Literature Review and Research Opportunities in Sustainable Pharmaceutical Supply Chains. Process Saf. Environ. Prot. 2018, 119, 115–130. [Google Scholar] [CrossRef]

- Caiado, R.G.G.; Scavarda, L.F.; Azevedo, B.D.; de Mattos Nascimento, D.L.; Quelhas, O.L.G. Challenges and Benefits of Sustainable Industry 4.0 for Operations and Supply Chain Management—A Framework Headed toward the 2030 Agenda. Sustainability 2022, 14, 830. [Google Scholar] [CrossRef]

- Luthra, S.; Mangla, S.K. Evaluating Challenges to Industry 4.0 Initiatives for Supply Chain Sustainability in Emerging Economies. Process Saf. Environ. Prot. Trans. Inst. Chem. Eng. Part B 2018, 117, 168–179. [Google Scholar] [CrossRef]

- Kumar, P.; Singh, R.K. Application of Industry 4.0 Technologies for Effective Coordination in Humanitarian Supply Chains: A Strategic Approach. Ann. Oper. Res. 2021, 319, 379–411. [Google Scholar] [CrossRef]

- Perez-Moron, J. Eleven Years of Cyberattacks on Chinese Supply Chains in an Era of Cyber Warfare, a Review and Future Research Agenda. J. ASIA Bus. Stud. 2022, 16, 371–395. [Google Scholar] [CrossRef]

- Sharma, R. Industry 4.0 Technologies in Agri-Food Supply Chains: Key Performance Indicators. In Agri-Food 4.0; Emerald Publishing Limited: Bingley, UK, 2022. [Google Scholar]

- Cezarino, L.O.; Liboni, L.B.; Oliveira Stefanelli, N.; Oliveira, B.G.; Stocco, L.C. Diving into Emerging Economies Bottleneck: Industry 4.0 and Implications for Circular Economy. Manag. Decis. 2021, 59, 1841–1862. [Google Scholar] [CrossRef]

- Kumar, S.; Mallipeddi, R.R. Impact of Cybersecurity on Operations and Supply Chain Management: Emerging Trends and Future Research Directions. Prod. Oper. Manag. 2022, 31, 4488–4500. [Google Scholar] [CrossRef]

- Salam, M.A. Analyzing Manufacturing Strategies and Industry 4.0 Supplier Performance Relationships from a Resource-Based Perspective. Benchmarking Int. J. 2021, 28, 1697–1716. [Google Scholar] [CrossRef]

- Sharma, M.; Raut, R.D.; Sehrawat, R.; Ishizaka, A. Digitalisation of Manufacturing Operations: The Influential Role of Organisational, Social, Environmental, and Technological Impediments. Expert Syst. Appl. 2023, 211, 118501. [Google Scholar] [CrossRef]

- Pourmehdi, M.; Paydar, M.M.; Ghadimi, P.; Azadnia, A.H. Analysis and Evaluation of Challenges in the Integration of Industry 4.0 and Sustainable Steel Reverse Logistics Network. Comput. Ind. Eng. 2022, 163, 107808. [Google Scholar] [CrossRef]

- Tripathi, S.; Gupta, M. Indian Supply Chain Ecosystem Readiness Assessment for Industry 4.0. Int. J. Emerg. Mark. 2021, 18, 1917–1947. [Google Scholar] [CrossRef]

- Agarwal, S.; Tyagi, M.; Garg, R.K. Framework Development and Evaluation of Industry 4.0 Technological Aspects towards Improving the Circular Economy-Based Supply Chain. Ind. Robot Int. J. Robot. Res. Appl. 2022, 49, 555–581. [Google Scholar] [CrossRef]

- Telukdarie, A.; Buhulaiga, E.; Bag, S.; Gupta, S.; Luo, Z. Industry 4.0 Implementation for Multinationals. Process Saf. Environ. Prot. 2018, 118, 316–329. [Google Scholar] [CrossRef]

- Hsu, C.-H.; He, X.; Zhang, T.-Y.; Chang, A.-Y.; Liu, W.-L.; Lin, Z.-Q. Enhancing Supply Chain Agility with Industry 4.0 Enablers to Mitigate Ripple Effects Based on Integrated QFD-MCDM: An Empirical Study of New Energy Materials Manufacturers. Mathemathics 2022, 10, 1635. [Google Scholar] [CrossRef]

- Kumar, A.; Kumar, S. Industry 4.0: Evolution, Opportunities and Challenges. Int. J. Res. Bus. Stud. 2020, 5, 139–148. [Google Scholar]

- Piunko, L.; Tolkacheva, E. Significant Directions of Digitalization of the Khabarovsk Territory Economy in the Implementation of the National Program “Digital Economy”. SHS Web Conf. 2021, 128, 01016. [Google Scholar] [CrossRef]

- Rejikumar, G.; Arunprasad, P.; Persis, J.; Sreeraj, K.M. Industry 4.0: Key Findings and Analysis from the Literature Arena. Benchmarking Int. J. 2019, 26, 2514–2542. [Google Scholar]

- Alamsjah, F.; Yunus, E.N. Achieving Supply Chain 4.0 and the Importance of Agility, Ambidexterity, and Organizational Culture: A Case of Indonesia. J. Open Innov. Technol. Mark. Complex. 2022, 8, 83. [Google Scholar] [CrossRef]

- Sharma, M.; Kamble, S.; Mani, V.; Sehrawat, R.; Belhadi, A.; Sharma, V. Industry 4.0 Adoption for Sustainability in Multi-Tier Manufacturing Supply Chain in Emerging Economies. J. Clean. Prod. 2021, 281, 125013. [Google Scholar] [CrossRef]

- Bag, S.; Pretorius, J.H.C. Relationships between Industry 4.0, Sustainable Manufacturing and Circular Economy: Proposal of a Research Framework. Int. J. Organ. Anal. 2022, 30, 864–898. [Google Scholar] [CrossRef]

- Liboni, L.B.; Cezarino, L.O.; Jabbour, C.J.C.; Oliveira, B.G.; Stefanelli, N.O. Smart Industry and the Pathways to HRM 4.0: Implications for SCM. Supply Chain Manag. Int. J. 2019, 24, 124–146. [Google Scholar] [CrossRef]

- Chaudhary, K.; Singh, M.; Tarar, S.; Chauhan, D.K.; Srivastava, V.M. Machine Learning Based Adaptive Framework for Logistic Planning in Industry 4.0. In Advances in Computing and Data Sciences: Second International Conference, ICACDS 2018, Dehradun, India, 20–21 April 2018, Revised Selected Papers, Part I 2; Springer: Berlin/Heidelberg, Germany, 2018; pp. 431–438. [Google Scholar]

- Luthra, S.; Kumar, A.; Zavadskas, E.K.; Mangla, S.K.; Garza-Reyes, J.A. Industry 4.0 as an Enabler of Sustainability Diffusion in Supply Chain: An Analysis of Influential Strength of Drivers in an Emerging Economy. Int. J. Prod. Res. 2020, 58, 1505–1521. [Google Scholar] [CrossRef]

- Dongfang, W.; Ponce, P.; Yu, Z.; Ponce, K.; Tanveer, M. The Future of Industry 4.0 and the Circular Economy in Chinese Supply Chain: In the Era of Post-COVID-19 Pandemic. Oper. Manag. Res. 2022, 15, 342–356. [Google Scholar] [CrossRef]

- Khan, S.A.R.; Razzaq, A.; Yu, Z.; Miller, S. Industry 4.0 and Circular Economy Practices: A New Era Business Strategies for Environmental Sustainability. Bus. Strategy Environ. 2021, 30, 4001–4014. [Google Scholar] [CrossRef]

- Chau, K.-Y.; Tang, Y.M.; Liu, X.; Ip, Y.-K.; Tao, Y. Investigation of Critical Success Factors for Improving Supply Chain Quality Management in Manufacturing. Enterp. Inf. Syst. 2021, 15, 1418–1437. [Google Scholar] [CrossRef]

- Fernando, Y.; Tseng, M.-L.; Wahyuni-Td, I.S.; de Sousa Jabbour, A.B.L.; Chiappetta Jabbour, C.J.; Foropon, C. Cyber Supply Chain Risk Management and Performance in Industry 4.0 Era: Information System Security Practices in Malaysia. J. Ind. Prod. Eng. 2023, 40, 102–116. [Google Scholar] [CrossRef]

- Saengchai, S.; Jermsittiparsert, K. Coping Strategy to Counter the Challenges towards Implementation of Industry 4.0 in Thailand: Role of Supply Chain Agility and Resilience. Int. J. Supply Chain Manag. 2019, 8, 733–744. [Google Scholar]

- Princes, E. Facing Disruptive Challenges in Supply Chain 4.0. Int. J. Supply Chain Manag. 2020, 9, 52–57. [Google Scholar]

- Daú, G.; Scavarda, A.; Scavarda, L.F.; Portugal, V.J.T. The Healthcare Sustainable Supply Chain 4.0: The Circular Economy Transition Conceptual Framework with the Corporate Social Responsibility Mirror. Sustainability 2019, 11, 3259. [Google Scholar] [CrossRef]

- Ismail, R.F.; Safieddine, F.; Hammad, R.; Kantakji, M.H. Towards Sustainable Production Processes Reengineering: Case Study at INCOM Egypt. Sustainability 2022, 14, 6564. [Google Scholar] [CrossRef]

| Concept | Application |

|---|---|

| Population | Scientific research on the use of Industry 4.0 in the supply chain in the thirteen major emerging economies. |

| Intervention | Use of Industry 4.0 in supply chains. |

| Comparison | Differences in the use of Industry 4.0 in thirteen major emerging economies. |

| Outcome | Knowledge of novel uses of Industry 4.0 in supply chains in emerging economies, challenges faced, benefits of Industry 4.0, and mitigation measures. |

| Context | Trends in the use of Industry 4.0 in supply chains. |

| Database | Search String | Number of Articles | Date Acquired |

|---|---|---|---|

| ProQuest | “industry 4.0” AND “supply chain” AND “emerging markets” | 12 | 9 June 2023 |

| “industry 4.0” AND “supply chain” AND “emerging economies” | 16 | ||

| “industry 4.0” AND “supply chain” AND “China” | 14 | ||

| “industry 4.0” AND “supply chain” AND “Brazil” | 4 | ||

| “industry 4.0” AND “supply chain” AND “India” | 14 | ||

| “industry 4.0” AND “supply chain” AND “Indonesia” | 2 | ||

| “industry 4.0” AND “supply chain” AND “Russia” | 2 | ||

| “industry 4.0” AND “supply chain” AND “Mexico” | 0 | ||

| “industry 4.0” AND “supply chain” AND “Turkey” | 1 | ||

| Web of Science | “industry 4.0” AND “supply chain” AND “emerging markets” | 24 | 9 June 2023 |

| “industry 4.0” AND “supply chain” AND “emerging economies” | 46 | ||

| “industry 4.0” AND “supply chain” AND “China” | 31 | ||

| “industry 4.0” AND “supply chain” AND “Brazil” | 8 | ||

| “industry 4.0” AND “supply chain” AND “India” | 35 | ||

| “industry 4.0” AND “supply chain” AND “Indonesia” | 5 | ||

| “industry 4.0” AND “supply chain” AND “Russia” | 2 | ||

| “industry 4.0” AND “supply chain” AND “Mexico” | 0 | ||

| “industry 4.0” AND “supply chain” AND “Turkey” | 7 | ||

| EBSCOhost | “industry 4.0” AND “supply chain” AND “emerging markets” | 9 June 2023 | |

| “industry 4.0” AND “supply chain” AND “emerging economies” | 2 | ||

| “industry 4.0” AND “supply chain” AND “China” | 2 | ||

| “industry 4.0” AND “supply chain” AND “Brazil” | 0 | ||

| “industry 4.0” AND “supply chain” AND “India” | 0 | ||

| “industry 4.0” AND “supply chain” AND “Indonesia” | 1 | ||

| “industry 4.0” AND “supply chain” AND “Russia” | 0 | ||

| “industry 4.0” AND “supply chain” AND “Mexico” | 0 | ||

| “industry 4.0” AND “supply chain” AND “Turkey” | |||

| Google Scholar | “industry 4.0” AND “supply chain” AND “emerging economies” OR “emerging market” OR “China” OR “India” OR “Brazil” OR “Russia” OR “Turkey” OR “Indonesia” OR “Mexico” | 496 | 9 June 2023 |

| Criteria | Decision |

|---|---|

| Search string is found in the title, abstract, or keywords | Include |

| Paper is published in a peer-reviewed journal | Include |

| Paper is published in English | Include |

| Paper is original research | Include |

| Paper is SLR | Include |

| Paper is cited in SLR | Include |

| Paper is published before 2018 | Exclude |

| Paper is not accessible | Exclude |

| Paper does not focus on any of the thirteen emerging economies | Exclude |

| Criteria | Categories Considered | Justification |

|---|---|---|

| Year of publication | Between 2018 and 2023 | This provides an understanding of the growth of literature over time. |

| Name of journal and publisher | Name of journal and publisher | This facilitates the understanding of the distribution of studies in journals and publishers. |

| Study site | Name of country | This enables cross-country comparison. |

| Industry | This enables cross-industry comparison. | |

| Ways in which Industry 4.0 is used in SCM | To help answer RQ1. | |

| Benefits of Industry 4.0 | To help answer RQ2. | |

| Challenges faced in using Industry 4.0 in SCM | To help answer RQ3. | |

| Mitigation measures | To help answer RQ4. |

| Journal | SJR Impact Factor | Frequency | Percentage |

|---|---|---|---|

| Production Planning & Control | 8.282 | 8 | 9.20 |

| Computers & Industrial Engineering | 1.760 | 5 | 5.75 |

| Benchmarking an International Journal | 5.703 | 4 | 4.60 |

| International Journal of Production Economics | 11.369 | 4 | 4.60 |

| Journal of Cleaner Production | 11.25 | 4 | 4.60 |

| Sustainability | 4.326 | 4 | 4.60 |

| Technological Forecasting and Social Change | 11.733 | 3 | 3.45 |

| Cleaner Logistics and Supply Chain | 1.329 | 2 | 2.30 |

| International Journal of Production Research | 11.301 | 2 | 2.30 |

| International Journal of Supply Chain Management | 11.612 | 2 | 2.30 |

| Procedia Manufacturing | 2 | 2.30 | |

| Process Safety and Environment Protection | 1.338 | 2 | 2.30 |

| Resources, Conservation & Recycling | 13.039 | 2 | 2.30 |

| Transportation Research Part E: Logistics and Transportation Review | 10.564 | 2 | 2.30 |

| Acta Logistica | 1.153 | 1 | 1.15 |

| AI Perspectives | 1 | 1.15 | |

| Asia Pacific Management Review | 4.456 | 1 | 1.15 |

| Brazilian Journal of Operations & Production Management | 1 | 1.15 | |

| Business Strategy and the Environment | 11.382 | 1 | 1.15 |

| Computers in Industry | 12.719 | 1 | 1.15 |

| Enterprise Information Systems | 4.806 | 1 | 1.15 |

| Expert Systems with Applications | 9.766 | 1 | 1.15 |

| Food ScienTech Journal | 1 | 1.15 | |

| IEEE Transactions on Engineering Management | 3.744 | 1 | 1.15 |

| Information Processing and Management | 8.387 | 1 | 1.15 |

| Information Systems Frontiers | 7.169 | 1 | 1.15 |

| International Conference on Logistics and Business Innovation | 1 | 1.15 | |

| International Journal of Advanced Science and Technology | 1 | 1.15 | |

| International Journal of Emerging Markets | 3.565 | 1 | 1.15 |

| International Journal of Emerging Trends in Engineering Research | 1 | 1.15 | |

| International Journal of Information Management Data Insights | 1 | 1.15 | |

| International Journal of Logistics Research and Applications | 6.298 | 1 | 1.15 |

| International Journal of Operations & Production Management | 9.257 | 1 | 1.15 |

| International Journal of Production and Performance Management | 3.997 | 1 | 1.15 |

| Journal of Advanced Manufacturing Systems | 2.195 | 1 | 1.15 |

| Journal of Advances in Management Research | 3.593 | 1 | 1.15 |

| Journal of Asia Business Studies | 4.061 | 1 | 1.15 |

| Journal of Business Administration Research | 1 | 1.15 | |

| Journal of Business Research | 10.9 | 1 | 1.15 |

| Journal of Enterprise Information Management | 6.256 | 1 | 1.15 |

| Journal of Environmental Treatment Techniques | 0.776 | 1 | 1.15 |

| Journal of Global Operations and Strategic Sourcing | 3.017 | 1 | 1.15 |

| Journal of Governance and Integrity | 1 | 1.15 | |

| Journal of Industrial and Production Engineering | 2.547 | 1 | 1.15 |

| Journal of Open Innovation | 4.362 | 1 | 1.15 |

| Machines | 3.537 | 1 | 1.15 |

| Management Decision | 5.617 | 1 | 1.15 |

| Mathematics | 0.446 | 1 | 1.15 |

| Operations Management Research | 6.216 | 1 | 1.15 |

| Renewable and Sustainable Energy Reviews | 18.916 | 1 | 1.15 |

| Scientific Reports | 1 | 1.15 | |

| SHS Web of Conferences | 1 | 1.15 | |

| Smart and Sustainable Built Environment | 0.791 | 1 | 1.15 |

| South Asian Journal of Social Review | 0.135 | 1 | 1.15 |

| TQM Journal | 4.577 | 1 | 1.15 |

| Publisher | Frequency | Percentage |

|---|---|---|

| Elsevier | 31 | 35.63 |

| Emerald | 14 | 16.09 |

| Taylor & Francis | 13 | 14.94 |

| MDPI | 7 | 8.05 |

| Springer | 3 | 3.45 |

| ExcellingTech Pub | 2 | 2.30 |

| EFCE | 2 | 2.30 |

| World Scientific Publishing | 1 | 1.15 |

| Wiley | 1 | 1.15 |

| WARSE | 1 | 1.15 |

| Universitas Sultan Ageng Tirtayasa | 1 | 1.15 |

| UMP Press | 1 | 1.15 |

| SERSC | 1 | 1.15 |

| SAG Publishing | 1 | 1.15 |

| Nature | 1 | 1.15 |

| KNE Publishing | 1 | 1.15 |

| EDP Sciences | 1 | 1.15 |

| 4S go | ||

| IEEE | 1 | 1.15 |

| Dorma Journal Publisher | 1 | 1.15 |

| Bilingual Publishing | 1 | 1.15 |

| ABEPRO | 1 | 1.15 |

| Country | Frequency | Percentage |

|---|---|---|

| India | 34 | 39.08 |

| China | 14 | 16.09 |

| Brazil | 6 | 6.90 |

| Turkey | 5 | 5.75 |

| Indonesia | 4 | 4.60 |

| Malaysia | 4 | 4.60 |

| India/China | 3 | 3.45 |

| Iran | 2 | 2.30 |

| Thailand | 2 | 2.30 |

| Turkey/India | 2 | 2.30 |

| Brazil/China/India/Turkey/South Africa | 1 | 1.15 |

| China/India/Saudi Arabia | 1 | 1.15 |

| China/India/Turkey | 1 | 1.15 |

| China/Iran/India/Russia/Brazil | 1 | 1.15 |

| China/South Africa | 1 | 1.15 |

| Egypt | 1 | 1.15 |

| India/Indonesia | 1 | 1.15 |

| India/Iran/Brazil | 1 | 1.15 |

| Mexico | 1 | 1.15 |

| Russia | 1 | 1.15 |

| South Africa | 1 | 1.15 |

| Industry | Frequency | Percentage |

|---|---|---|

| Manufacturing | 23 | 26.44 |

| Unclear | 14 | 16.09 |

| Automotive | 10 | 11.49 |

| Circular economy | 8 | 9.20 |

| Food processing | 6 | 6.90 |

| Electronics | 3 | 3.45 |

| Health care | 2 | 2.30 |

| Logistics | 2 | 2.30 |

| Pharmaceutical | 2 | 2.30 |

| Service | 2 | 2.30 |

| Agriculture | 1 | 1.15 |

| Automotive/chemical and plastics/electronics/software engineering | 1 | 1.15 |

| Disaster management | 1 | 1.15 |

| Electrical and electronics | 1 | 1.15 |

| Electrical/electronics/forging | 1 | 1.15 |

| Energy | 1 | 1.15 |

| FinTech | 1 | 1.15 |

| FMCG | 1 | 1.15 |

| Food and health | 1 | 1.15 |

| Food/Pharmaceutical | 1 | 1.15 |

| Oil and gas | 1 | 1.15 |

| Transport | 2 | 2.30 |

| Textile | 1 | 1.15 |

| Research Methodology | Frequency | Percentage |

|---|---|---|

| Survey | 20 | 22.99 |

| Modeling | 11 | 12.64 |

| Case study | 10 | 11.49 |

| SLR | 10 | 11.49 |

| Literature review/modeling | 8 | 9.20 |

| Literature review/survey | 6 | 6.90 |

| Literature review | 5 | 5.74 |

| Literature review/case study | 4 | 4.60 |

| Survey/modeling | 4 | 4.60 |

| Literature review/survey/modeling | 2 | 2.30 |

| Qualitative | 3 | 3.44 |

| SLR/survey | 2 | 2.30 |

| Desk study | 1 | 1.15 |

| Survey/observation | 1 | 1.15 |

| Research Question (Theme) | Code | Number of Supporting Articles |

|---|---|---|

| Use of Industry 4.0 | IoT | 13 |

| Big data and artificial intelligence | 9 | |

| Blockchain | 6 | |

| Cloud computing | 3 | |

| Robots and virtualization | 3 | |

| Digital twin | 2 | |

| 3D printing/additive manufacturing | 2 | |

| Challenges | High investment in Industry 4.0 | 11 |

| Business risks | 8 | |

| Skills shortage | 10 | |

| Data integration and cyber-security | 13 | |

| Weak policy and legislation | 8 | |

| Weak infrastructure | 4 | |

| Organization culture | 4 | |

| Lack of management support | 2 | |

| Mitigation measures | Conducive policy and legislation | 12 |

| Executive management support | 9 | |

| Training | 9 | |

| Investment and infrastructure development | 5 | |

| Data security | 4 | |

| Supply chain agility | 2 | |

| Third-party audits | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alshahrani, S.T. Industry 4.0 in “Major Emerging Markets”: A Systematic Literature Review of Benefits, Use, Challenges, and Mitigation Strategies in Supply Chain Management. Sustainability 2023, 15, 14811. https://doi.org/10.3390/su152014811

Alshahrani ST. Industry 4.0 in “Major Emerging Markets”: A Systematic Literature Review of Benefits, Use, Challenges, and Mitigation Strategies in Supply Chain Management. Sustainability. 2023; 15(20):14811. https://doi.org/10.3390/su152014811

Chicago/Turabian StyleAlshahrani, Saeed Turki. 2023. "Industry 4.0 in “Major Emerging Markets”: A Systematic Literature Review of Benefits, Use, Challenges, and Mitigation Strategies in Supply Chain Management" Sustainability 15, no. 20: 14811. https://doi.org/10.3390/su152014811

APA StyleAlshahrani, S. T. (2023). Industry 4.0 in “Major Emerging Markets”: A Systematic Literature Review of Benefits, Use, Challenges, and Mitigation Strategies in Supply Chain Management. Sustainability, 15(20), 14811. https://doi.org/10.3390/su152014811