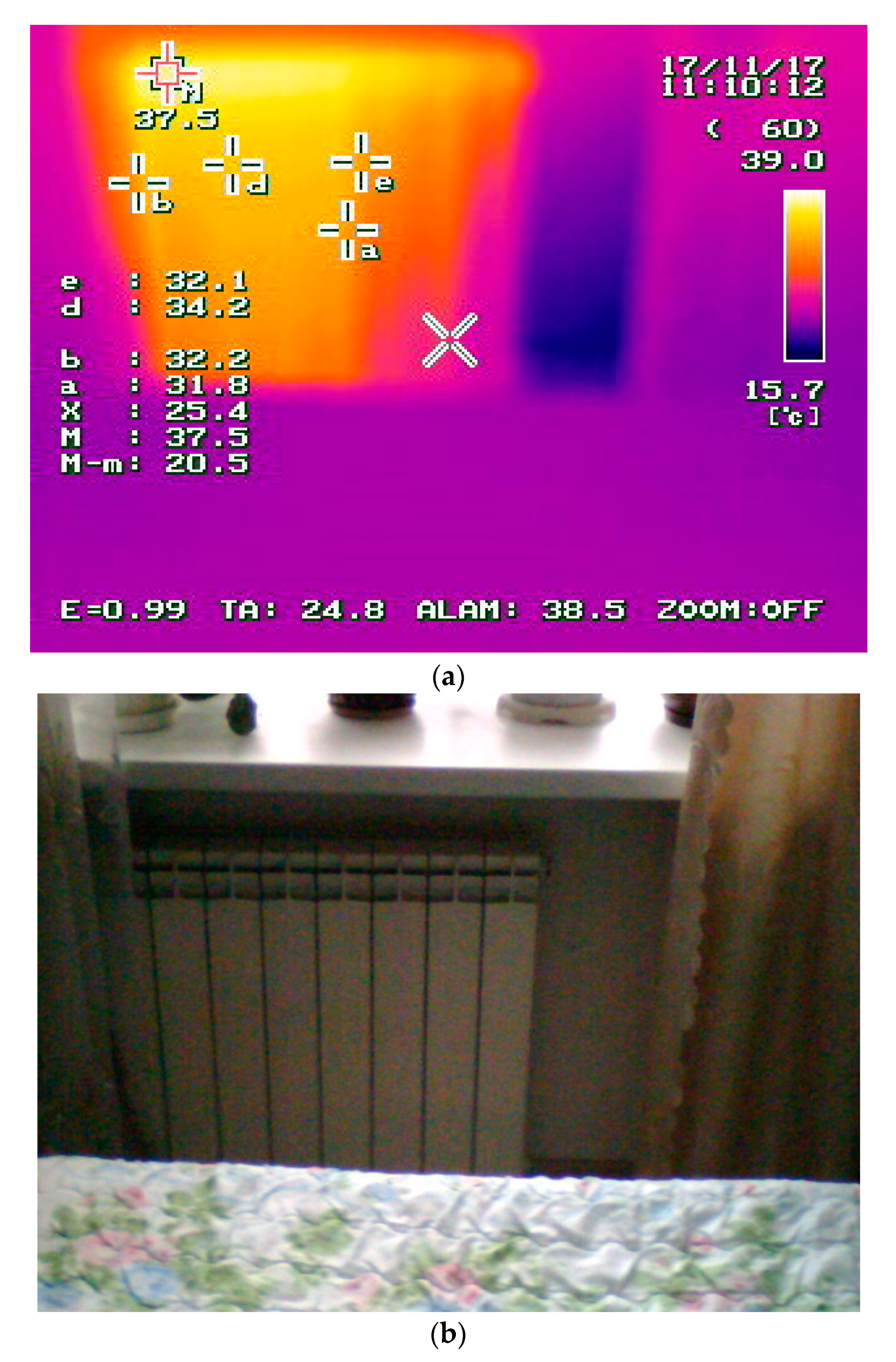

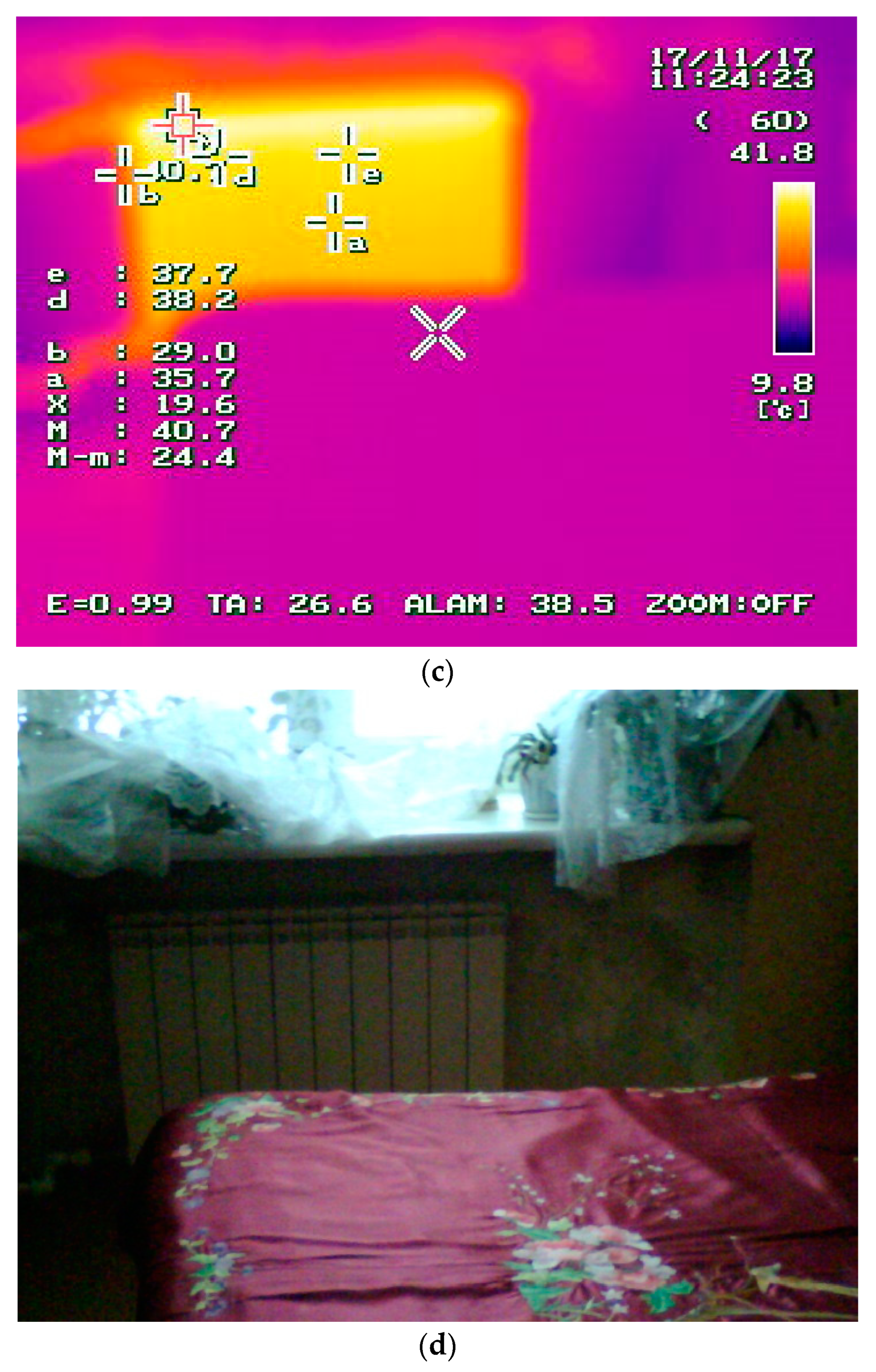

District Heating for Poorly Insulated Residential Buildings—Comparing Results of Visual Study, Thermography, and Modeling

Abstract

:1. Introduction

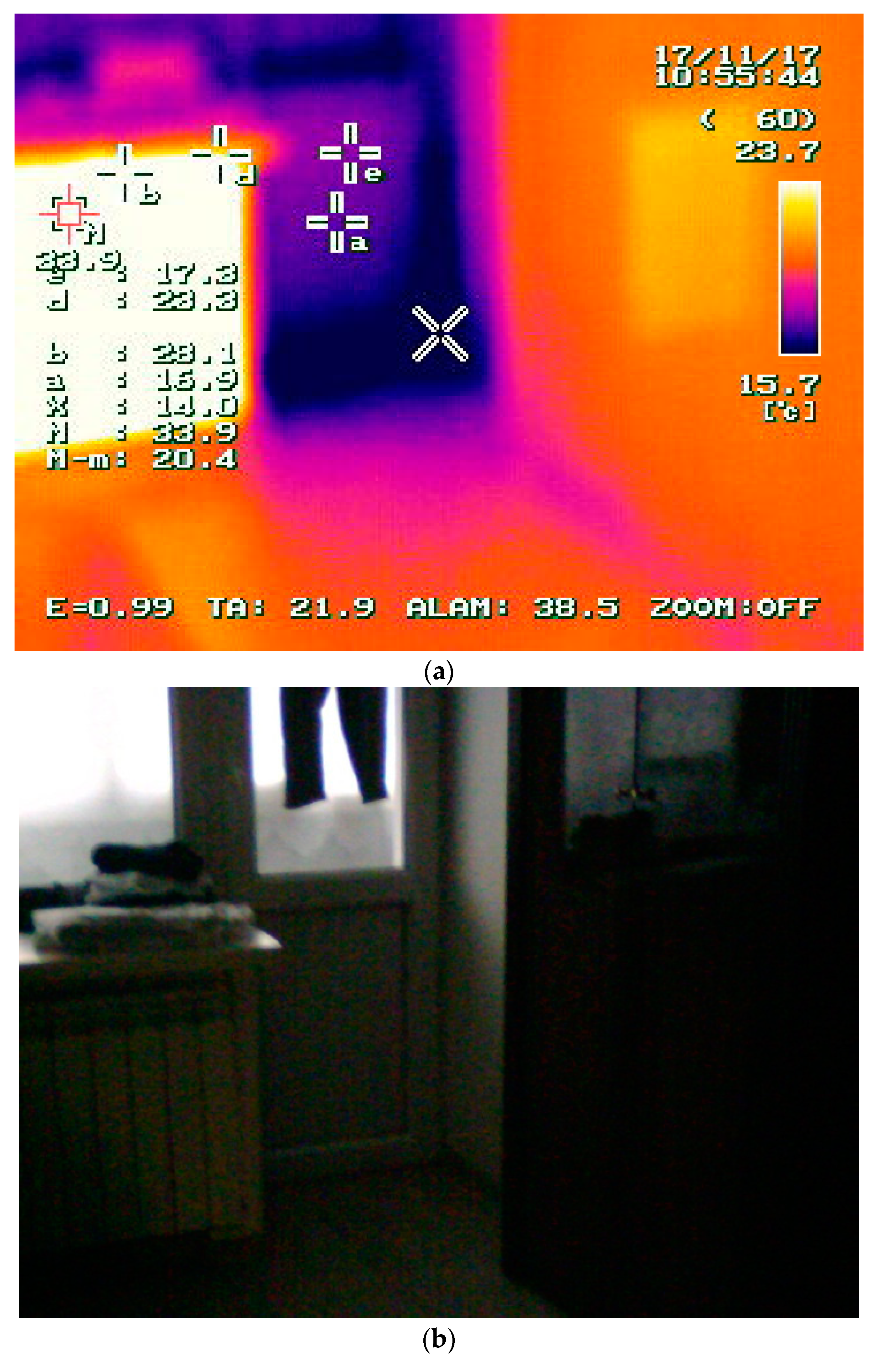

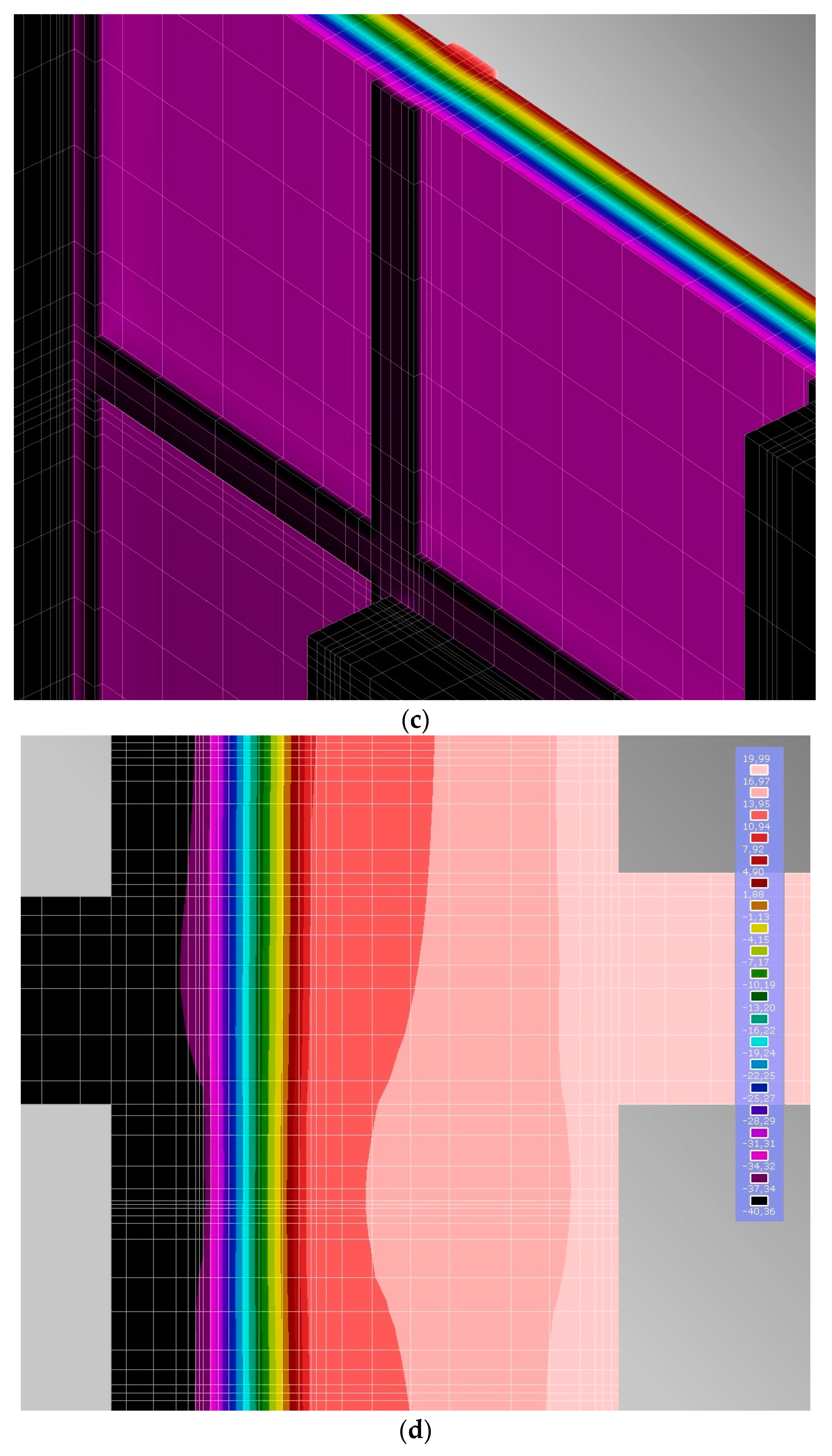

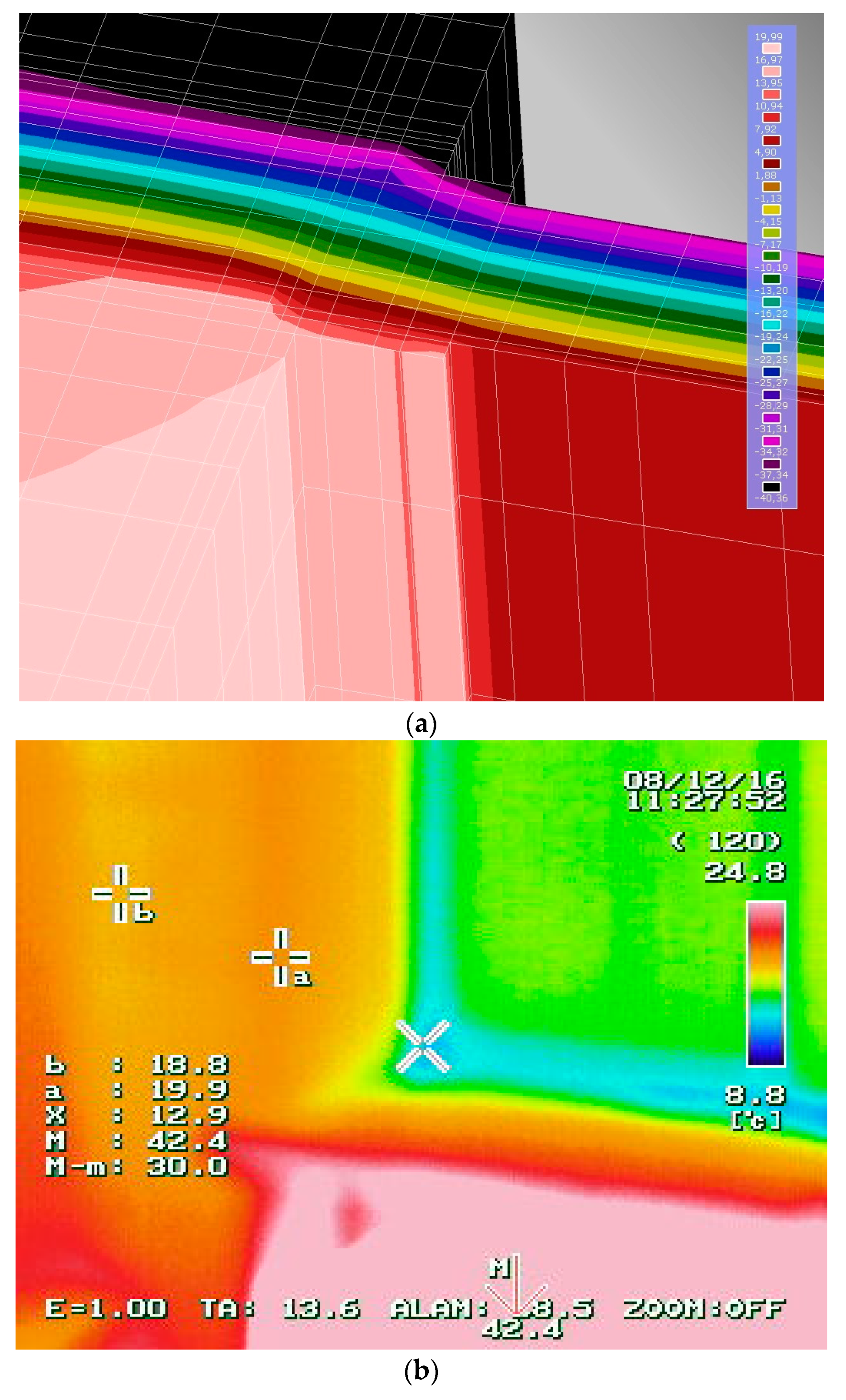

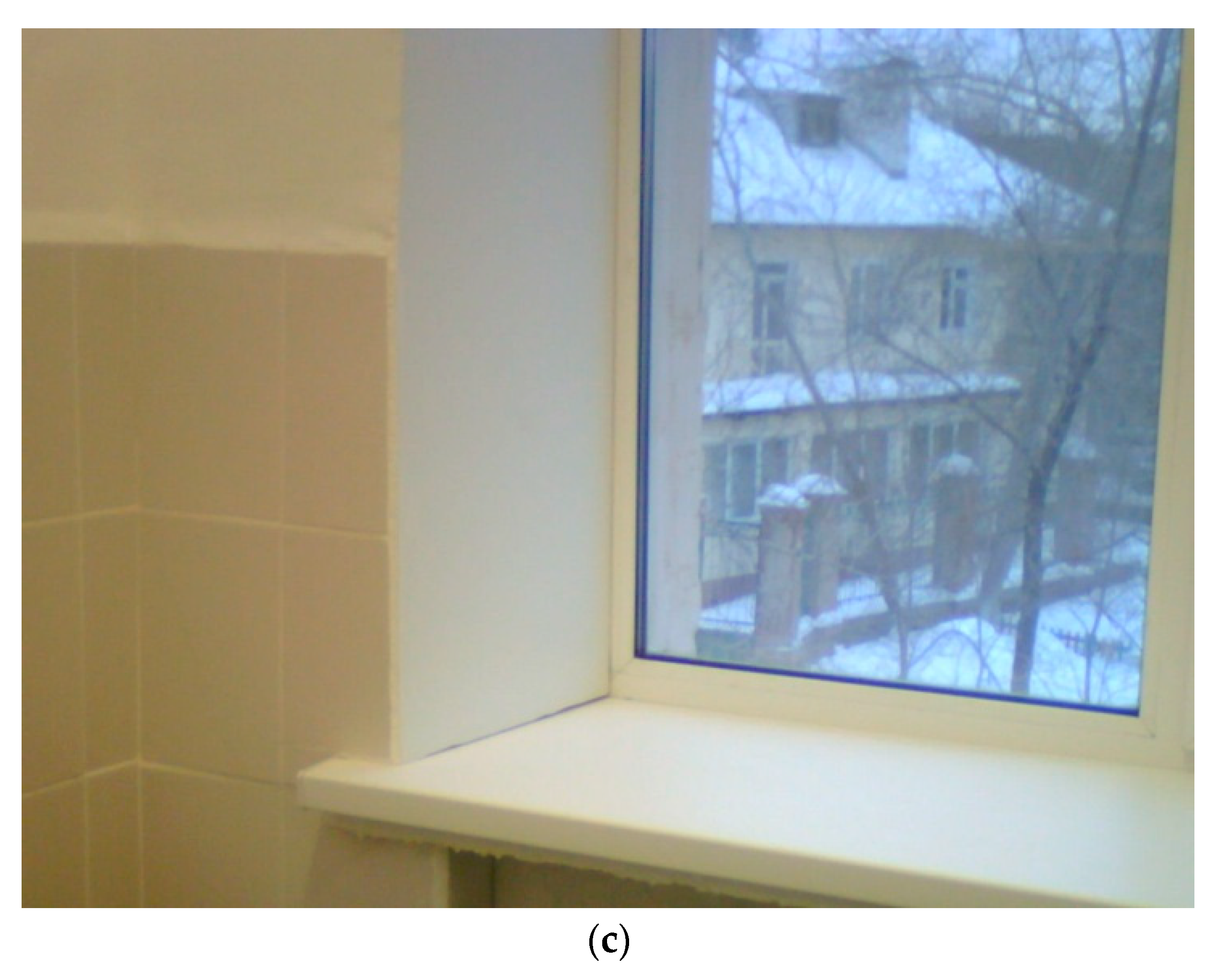

2. Materials and Methods

- 0.7 for triple-glazed doors (both main and emergency) and windows.

- 0.8 for double-glazed doors (both main and emergency) and windows.

- 1 for other doors (both main and emergency) and windows.

- for windows,

- for doors,

- 0.85 for triple doors and two airlocks between and for double doors, if an air door (curtain) is installed 1,

- 0.7 for double doors and one airlock between 1,

- 0.47 for residential buildings and revolving doors, if an air door (curtain) is installed 1,

- 0.16 for four-wing revolving door 1,

- 0.14 for three-wing revolving doors 1,

- 0.07 for a single (incl. balcony) door 1.

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fitó, J.; Hodencq, S.; Ramousse, J.; Wurtz, F.; Stutz, B.; Debray, F.; Vincent, B. Energy- and exergy-based optimal designs of a low-temperature industrial waste heat recovery system in district heating. Energy Convers. Manag. 2020, 211, 112753. [Google Scholar] [CrossRef]

- Guelpa, E. Impact of thermal masses on the peak load in district heating systems. Energy 2021, 214, 118849. [Google Scholar] [CrossRef]

- Turski, M.; Sekret, R. Buildings and a district heating network as thermal energy storages in the district heating system. Energy Build. 2018, 179, 49–56. [Google Scholar] [CrossRef]

- Kristensen, M.H.; Hedegaard, R.E.; Petersen, S. Long-term forecasting of hourly district heating loads in urban areas using hierarchical archetype modeling. Energy 2020, 201, 117687. [Google Scholar] [CrossRef]

- Brandi, S.; Piscitelli, M.S.; Martellacci, M.; Capozzoli, A. Deep reinforcement learning to optimise indoor temperature control and heating energy consumption in buildings. Energy Build. 2020, 224, 110225. [Google Scholar] [CrossRef]

- Aryal, A.; Chaiwiwatworakul, P.; Chirarattananon, S. An experimental study of thermal performance of the radiant ceiling cooling in office building in Thailand. Energy Build. 2023, 283, 112849. [Google Scholar] [CrossRef]

- Vandermeulen, A.; van Oevelen, T.; van der Heijde, B.; Helsen, L. A simulation-based evaluation of substation models for network flexibility characterisation in district heating networks. Energy 2020, 201, 117650. [Google Scholar] [CrossRef]

- Sun, C.; Chen, J.; Cao, S.; Gao, X.; Xia, G.; Qi, C.; Wu, X. A dynamic control strategy of district heating substations based on online prediction and indoor temperature feedback. Energy 2021, 235, 121228. [Google Scholar] [CrossRef]

- Yuan, J.; Huang, K.; Han, Z.; Zhou, Z.; Lu, S. A new feedback predictive model for improving the operation efficiency of heating station based on indoor temperature. Energy 2021, 222, 119961. [Google Scholar] [CrossRef]

- Sleptsov, A.; Crisostomi, E.; Bischi, A. Control schemes for district heating substations considering user-defined building’s indoor temperature. Build. Environ. 2021, 191, 107598. [Google Scholar] [CrossRef]

- Ivanko, D.; Sørensen, Å.L.; Nord, N. Splitting measurements of the total heat demand in a hotel into domestic hot water and space heating heat use. Energy 2021, 219, 119685. [Google Scholar] [CrossRef]

- Chicherin, S.; Zhuikov, A.; Junussova, L. Integrating a heat pump into a 4th generation district heating (4GDH) system—Two-mode configuration inputting operational data. Energy Build. 2022, 275, 112445. [Google Scholar] [CrossRef]

- Saletti, C.; Zimmerman, N.; Morini, M.; Kyprianidis, K.; Gambarotta, A. Enabling smart control by optimally managing the State of Charge of district heating networks. Appl. Energy 2020, 283, 116286. [Google Scholar] [CrossRef]

- Braas, H.; Jordan, U.; Best, I.; Orozaliev, J.; Vajen, K. District heating load profiles for domestic hot water preparation with realistic simultaneity using DHWcalc and TRNSYS. Energy 2020, 201, 117552. [Google Scholar] [CrossRef]

- Aste, N.; Caputo, P.; Del Pero, C.; Ferla, G.; Huerto-Cardenas, H.E.; Leonforte, F.; Miglioli, A. A renewable energy scenario for a new low carbon settlement in northern Italy: Biomass district heating coupled with heat pump and solar photovoltaic system. Energy 2020, 206, 118091. [Google Scholar] [CrossRef]

- Sommer, T.; Sulzer, M.; Wetter, M.; Sotnikov, A.; Mennel, S.; Stettler, C. The reservoir network: A new network topology for district heating and cooling. Energy 2020, 199, 117418. [Google Scholar] [CrossRef]

- Kauko, H.; Kvalsvik, K.H.; Rohde, D.; Nord, N.; Utne, Å. Dynamic modeling of local district heating grids with prosumers: A case study for Norway. Energy 2018, 151, 261–271. [Google Scholar] [CrossRef]

- Hering, D.; Cansev, M.E.; Tamassia, E.; Xhonneux, A.; Müller, D. Temperature control of a low-temperature district heating network with Model Predictive Control and Mixed-Integer Quadratically Constrained Programming. Energy 2021, 224, 120140. [Google Scholar] [CrossRef]

- Brange, L.; Englund, J.; Lauenburg, P. Prosumers in district heating networks—A Swedish case study. Appl. Energy 2016, 164, 492–500. [Google Scholar] [CrossRef]

- Chertkov, M.; Novitsky, N.N. Thermal Transients in District Heating Systems. Energy 2019, 184, 22–33. [Google Scholar] [CrossRef]

- Farouq, S.; Byttner, S.; Bouguelia, M.-R.; Nord, N.; Gadd, H. Large-scale monitoring of operationally diverse district heating substations: A reference-group based approach. Eng. Appl. Artif. Intell. 2020, 90, 103492. [Google Scholar] [CrossRef]

- Chicherin, S.; Starikov, A.; Zhuikov, A. Justifying network reconstruction when switching to low temperature district heating. Energy 2022, 248, 123618. [Google Scholar] [CrossRef]

- Siuta-Olcha, A.; Cholewa, T.; Gomółka, M.; Kołodziej, P.; Østergaard, D.S.; Svendsen, S. On the influence of decommissioning an area thermal substation in a district heating system on heat consumption and costs in buildings—Long term field research. Sustain. Energy Technol. Assess. 2022, 50, 101870. [Google Scholar] [CrossRef]

- Jangsten, M.; Lindholm, T.; Dalenbäck, J.O. Analysis of operational data from a district cooling system and its connected buildings. Energy 2020, 203, 117844. [Google Scholar] [CrossRef]

- Luc, K.M.; Li, R.; Xu, L.; Nielsen, T.R.; Hensen, J.L.M. Energy flexibility potential of a small district connected to a district heating system. Energy Build. 2020, 225, 110074. [Google Scholar] [CrossRef]

- Harney, P.; Gartland, D.; Murphy, F. Determining the optimum low-temperature district heating network design for a secondary network supplying a low-energy-use apartment block in Ireland. Energy 2020, 192, 116595. [Google Scholar] [CrossRef]

- Ren, C.; Cao, S.J. Construction of linear temperature model using non-dimensional heat exchange ratio: Towards fast prediction of indoor temperature and heating, ventilation and air conditioning systems control. Energy Build. 2021, 251, 111351. [Google Scholar] [CrossRef]

- Camci, M.; Karakoyun, Y.; Acikgoz, O.; Dalkilic, A.S. A comparative study on convective heat transfer in indoor applications. Energy Build. 2021, 242, 110985. [Google Scholar] [CrossRef]

- Johra, H.; Heiselberg, P.; Le Dréau, J. Influence of envelope, structural thermal mass and indoor content on the building heating energy flexibility. Energy Build. 2019, 183, 325–339. [Google Scholar] [CrossRef]

- Chicherin, S.; Anvari-Moghaddam, A. Adjusting Heat Demands Using the Operational Data of District Heating Systems. Energy 2021, 235, 121368. [Google Scholar] [CrossRef]

| # | Office (Zone) | Target Indoor Temperature [°C] | Properties of Envelopes | R-Value [m2K/W] | tind − toutd | Design Heat Demand [W] | Corrections | Adjusted Heat Demand [W] | Total Heat Demand [W] | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wall Title (According to the Blueprints) | Orientation | Adjustment Factor β | Adjustment Factor k | Overall Correction (1 + Σβ) | ||||||||

| 1 | Tool shop | 16 | Internal partition #1 | 2.1 | 53 | 2862 | 0 | n/a | 1.0 | 2862 | 6325 | |

| 16 | Internal partition #2 | 4.3 | 53 | 1361 | 0 | n/a | 1.0 | 1361 | ||||

| 16 | Internal partition #3 | 8.6 | 53 | 724 | 0 | n/a | 1.0 | 724 | ||||

| 16 | Internal partition #4 | 14.2 | 53 | 676 | 0 | n/a | 1.0 | 676 | ||||

| 16 | Window | NE | 0.54 | 53 | 424 | 0.1 | 0.8 | 1.1 | 466.6 | |||

| 16 | Door | SW | 0.54 | 53 | 235 | 0 | 1 | 1.0 | 235 | |||

| 2 | Storage room for household chemical goods. garage | 16 | Internal partition #1 | 2.1 | 53 | 3408 | 0 | n/a | 1.0 | 3408 | 7835 | |

| 16 | Internal partition #2 | 4.3 | 53 | 1935 | 0 | n/a | 1.0 | 1935 | ||||

| 16 | Internal partition #3 | 8.6 | 53 | 876 | 0 | n/a | 1.0 | 876 | ||||

| 16 | Internal partition #4 | 14.2 | 53 | 814 | 0 | n/a | 1.0 | 814 | ||||

| 16 | Window | NE | 0.54 | 53 | 494 | 0.1 | 0.8 | 1.1 | 544 | |||

| 16 | Door | NW | 0.54 | 53 | 235 | 0.1 | 1 | 1.1 | 258 | |||

| 13 | Office | 20 | Load-bearing wall | SW | 3.15 | 57 | 235 | 0 | n/a | 1.0 | 235 | 708 |

| 20 | Load-bearing wall | NW | 3.15 | 57 | 430 | 0.1 | n/a | 1.1 | 473 | |||

| 12 | Exhibition hall | 20 | Load-bearing wall | SW | 3.15 | 57 | 860 | 0 | n/a | 1.0 | 860 | 8569 |

| 20 | Window | SW | 0.54 | 57 | 912 | −0.1 | 0.8 | 0.9 | 821 | |||

| 20 | Window | SW | 0.54 | 57 | 912 | −0.1 | 0.8 | 0.9 | 821 | |||

| 20 | Load-bearing wall | SE | 3.15 | 57 | 664 | −0.05 | n/a | 0.95 | 632 | |||

| 20 | Window | SE | 0.54 | 57 | 1158 | −0.05 | 0.8 | 0.95 | 1103 | |||

| 20 | Load-bearing wall | NW | 3.15 | 57 | 704 | 0.1 | n/a | 1.1 | 774 | |||

| 20 | Door | NE | 0.54 | 57 | 456 | 0.1 | 1 | 1.1 | 502 | |||

| 20 | Load-bearing wall | NE | 3.15 | 57 | 521 | 0.1 | n/a | 1.1 | 573 | |||

| 20 | Window | NE | 0.54 | 57 | 336 | 0.1 | 0.8 | 1.1 | 370 | |||

| 20 | Load-bearing wall | NE | 3.15 | 57 | 391 | 0.1 | n/a | 1.1 | 430 | |||

| 20 | Door | NW | 0.54 | 57 | 456 | 0.1 | 1 | 1.1 | 502 | |||

| 20 | Window | SW | 0.54 | 57 | 912 | −0.1 | 0.8 | 0.9 | 821 | |||

| Staircase/ Vestibule | 16 | Load-bearing wall | SW | 3.15 | 53 | 182 | −0.1 | n/a | 0.9 | 164 | 1102 | |

| 16 | Load-bearing wall | NW | 3.15 | 53 | 448 | 0.1 | n/a | 1.1 | 493 | |||

| 16 | Load-bearing wall | NE | 3.15 | 53 | 182 | 0.1 + 0.27 × 3.6 | n/a | 2.072 | 377 | |||

| 16 | Door | NE | 0.54 | 53 | 206 | 0.1 | 1 | 1.1 | 227 | |||

| 2 | Vestibule | 20 | Load-bearing wall | SW | 3.15 | 57 | 278 | 0 | n/a | 1.0 | 278 | 936 |

| 20 | Door | SW | 0.54 | 57 | 329 | −0.1 | 1 | 0.9 | 296 | |||

| 20 | Door | SW | 0.54 | 57 | 329 | −0.1 | 1 | 0.9 | 296 | |||

| 3 | Office | 20 | Window | NE | 0.54 | 57 | 1900 | 0.1 | 0.8 | 1.1 | 2090 | 4720 |

| 20 | Window | SE | 0.54 | 57 | 1900 | −0.05 | 0.8 | 0.95 | 1805 | |||

| 20 | Internal partition #1 | 2.1 | 57 | 543 | 0 | n/a | 1.0 | 543 | ||||

| 20 | Internal partition #2 | 4.3 | 57 | 90 | 0 | n/a | 1.0 | 90 | ||||

| 20 | Internal partition #3 | 8.6 | 57 | 2 | 0 | n/a | 1.0 | 2 | ||||

| Staircase | 16 | Load-bearing wall | NW | 3.15 | 57 | 418 | 0.1 | n/a | 1.1 | 460 | 1334 | |

| 16 | Load-bearing wall | NE | 3.15 | 57 | 300 | 0.1 | n/a | 1.1 | 330 | |||

| 16 | Load-bearing wall | SW | 3.15 | 57 | 300 | 0 | n/a | 1.0 | 300 | |||

| 16 | Door | NW | 0.54 | 57 | 222 | 0.1 | 1 | 1.1 | 244 | |||

| 4 | Exhibition hall | 20 | Load-bearing wall | NW | 3.15 | 57 | 391 | 0.1 | n/a | 1.1 | 430 | 17,294 |

| 20 | Load-bearing wall | SW | 3.15 | 57 | 521 | 0 | n/a | 1.0 | 521 | |||

| 20 | Window | SW | 0.54 | 57 | 897 | 0 | 0.8 | 1.0 | 897 | |||

| 20 | Window | SE | 0.54 | 57 | 7600 | 0.05 | 0.8 | 1.05 | 7980 | |||

| 20 | Load-bearing wall | NE | 3.15 | 57 | 1368 | 0.1 | n/a | 1.1 | 1505 | |||

| 20 | Door | NE | 0.54 | 57 | 329 | 0.1 | 1 | 1.1 | 362 | |||

| 20 | Window | NE | 0.54 | 57 | 1368 | 0.1 | 0.8 | 1.1 | 1505 | |||

| 20 | Load-bearing wall | NW | 3.15 | 57 | 782 | 0.1 | n/a | 1.1 | 860 | |||

| 20 | Window | NW | 0.54 | 57 | 684 | 0.1 | 0.8 | 1.1 | 752 | |||

| 20 | Door | NW | 0.54 | 57 | 456 | 0.1 | 1 | 1.1 | 502 | |||

| 20 | Internal partition #1 | 2.1 | 57 | 1357 | 0 | n/a | 1.0 | 1357 | ||||

| 20 | Internal partition #2 | 4.3 | 57 | 504 | 0 | n/a | 1.0 | 504 | ||||

| 20 | Internal partition #3 | 8.6 | 57 | 119 | 0 | n/a | 1.0 | 119 | ||||

| 12 | Office | 20 | Window | SW | 0.54 | 57 | 8312 | 0 | 0.8 | 1.0 | 8312 | 16,822 |

| 20 | Window | NW | 0.54 | 57 | 3958 | 0.1 | 0.8 | 1.1 | 4354 | |||

| 20 | Window | SE | 0.54 | 57 | 3958 | 0.05 | 0.8 | 1.05 | 4156 | |||

| Staircase | 16 | Load-bearing wall | NE | 3.15 | 53 | 379 | 0.1 | n/a | 1.1 | 417 | 1955 | |

| 16 | Window | NE | 0.54 | 53 | 368 | 0.1 | 0.8 | 1.1 | 405 | |||

| 16 | Load-bearing wall | SW | 3.15 | 53 | 561 | 0.05 | n/a | 1.05 | 589 | |||

| 16 | Load-bearing wall | NW | 3.15 | 53 | 126 | 0.1 | n/a | 1.1 | 139 | |||

| 16 | Window | NW | 0.54 | 53 | 368 | 0.1 | 0.8 | 1.1 | 405 | |||

| 6 | Hallway | 20 | Load-bearing wall | NW | 3.15 | 57 | 426 | 0.1 | n/a | 1.1 | 469 | 2001 |

| 20 | Door | NW | 0.54 | 57 | 259 | 0.1 | 1 | 1.1 | 285 | |||

| 20 | Load-bearing wall | NW | 3.15 | 57 | 122 | 0.1 | n/a | 1.1 | 134 | |||

| 20 | Load-bearing wall | NW | 3.15 | 57 | 122 | 0.1 | n/a | 1.1 | 134 | |||

| 20 | Load-bearing wall | NE | 3.15 | 57 | 277 | 0.1 | n/a | 1.1 | 305 | |||

| 20 | Window | NE | 0.54 | 57 | 285 | 0.1 | 0.8 | 1.1 | 314 | |||

| 20 | Load-bearing wall | SE | 3.15 | 57 | 144 | 0.05 | n/a | 1.05 | 151 | |||

| 20 | Window | NW | 0.54 | 57 | 190 | 0.1 | 0.8 | 1.1 | 209 | |||

| 11 | Office | 20 | Window | SW | 0.54 | 57 | 2375 | 0 | 0.8 | 1.0 | 2375 | 2375 |

| 19 | Office | 20 | Load-bearing wall | NE | 3.15 | 57 | 271 | 0.1 | n/a | 1.1 | 298 | 1164 |

| 20 | Window | NE | 0.54 | 57 | 190 | 0.1 | 0.8 | 1.1 | 209 | |||

| 20 | Load-bearing wall | NW | 3.15 | 57 | 407 | 0.1 | n/a | 1.1 | 448 | |||

| 20 | Window | NW | 0.54 | 57 | 190 | 0.1 | 0.8 | 1.1 | 209 | |||

| 1 | Office | 20 | Load-bearing wall | NW | 3.15 | 57 | 407 | 0.1 | n/a | 1.1 | 448 | 657 |

| 20 | Window | NW | 0.54 | 57 | 190 | 0.1 | 0.8 | 1.1 | 209 | |||

| 2.3 | Office | 20 | Load-bearing wall | NE | 3.15 | 57 | 814 | 0.1 | n/a | 1.1 | 895 | 1731 |

| 20 | Window | NE | 0.54 | 57 | 760 | 0.1 | 0.8 | 1.1 | 836 | |||

| 4 | Office | 20 | Load-bearing wall | NE | 3.15 | 57 | 339 | 0.1 | n/a | 1.1 | 373 | 2224 |

| 20 | Load-bearing wall | NE | 3.15 | 57 | 611 | 0.1 | n/a | 1.1 | 672 | |||

| 20 | Load-bearing wall | SE | 3.15 | 57 | 407 | 0.05 | n/a | 1.05 | 427 | |||

| 20 | Window | NE | 0.54 | 57 | 684 | 0.1 | 0.8 | 1.1 | 752 | |||

| 5 | Office | 20 | Window | SE | 0.54 | 57 | 2375 | 0.05 | 0.8 | 1.05 | 2494 | 2494 |

| 10 | Office | 20 | Window | SE | 0.54 | 57 | 4750 | 0.05 | 0.8 | 1.05 | 4988 | 8155 |

| 20 | Window | SW | 0.54 | 57 | 3167 | 0 | 0.8 | 1.0 | 3167 | |||

| 14 | Office | 20 | Load-bearing wall | NW | 3.15 | 57 | 407 | 0.1 | n/a | 1.1 | 448 | 646 |

| 20 | Window | NW | 0.54 | 57 | 180 | 0.1 | 0.8 | 1.1 | 198 | |||

| 20 | Office | 20 | Load-bearing wall | NW | 3.15 | 57 | 407 | 0.1 | n/a | 1.1 | 448 | 3976 |

| 20 | Load-bearing wall | SW | 3.15 | 57 | 204 | 0 | n/a | 1.0 | 204 | |||

| 20 | Window | NW | 0.54 | 57 | 1583 | 0.1 | 0.8 | 1.1 | 1741 | |||

| 20 | Window | SW | 0.54 | 57 | 1583 | 0 | 0.8 | 1.0 | 1583 | |||

| 14 | Office | 20 | Window | NW | 0.54 | 57 | 3132 | 0.1 | 0.8 | 1.1 | 3445 | 12,754 |

| 20 | Window | SW | 0.54 | 57 | 3132 | 0 | 0.8 | 1.0 | 3132 | |||

| 20 | Window | SE | 0.54 | 57 | 3569 | 0.05 | 0.8 | 1.05 | 3748 | |||

| 20 | Window | NE | 0.54 | 57 | 1821 | 0.1 | 0.8 | 1.1 | 2003 | |||

| 20 | Internal partition | 4.18 | 57 | 426 | 0 | n/a | 1.0 | 426 | ||||

| 5 | Office | 20 | Window | NE | 0.54 | 57 | 2404 | 0.1 | 0.8 | 1.1 | 2644 | 6341 |

| 20 | Window | NW | 0.54 | 57 | 3205 | 0.1 | 0.8 | 1.1 | 3526 | |||

| 20 | Door | NW | 0.54 | 57 | 155 | 0.1 | 1 | 1.1 | 171 | |||

| 1 | Security room | 20 | Window | NW | 0.54 | 57 | 874 | 0.1 | 0.8 | 1.1 | 961 | 961 |

| 13 | Hallway | 20 | Window | NW | 0.54 | 57 | 947 | 0.1 | 0.8 | 1.1 | 1042 | 1376 |

| 20 | Door | SE | 0.54 | 57 | 222 | 0.05 | 1 | 1.05 | 233 | |||

| 20 | Window | SW | 0.54 | 57 | 101 | 0 | 0.8 | 1.0 | 101 | |||

| 9 | Lounge | 20 | Window | SE | 0.54 | 57 | 3350 | 0.05 | 0.8 | 1.05 | 3518 | 4975 |

| 20 | Window | SW | 0.54 | 57 | 1457 | 0 | 0.8 | 1.0 | 1457 | |||

| 6 | Exhibition hall | 20 | Window | NE | 0.54 | 57 | 4443 | 0.1 | 0.8 | 1.1 | 4887 | 6990 |

| 20 | Window | SE | 0.54 | 57 | 2003 | 0.05 | 0.8 | 1.05 | 2103 | |||

| Vestibule | 20 | Window | SW | 0.54 | 57 | 2185 | 0 | 0.8 | 1.0 | 2185 | 2185 | |

| 7 | Vestibule | 18 | Window | SE | 0.54 | 55 | 422 | 0 | 0.8 | 1.0 | 422 | 422 |

| 3 | Vestibule | 18 | Window | NW | 0.54 | 55 | 351 | 0.1 | 0.8 | 1.1 | 386 | 386 |

| 15 | Vestibule | 18 | Window | SW | 0.54 | 55 | 351 | 0 | 0.8 | 1.0 | 351 | 351 |

| 2 | Principal’s office | 20 | Window | SW | 0.54 | 57 | 1710 | 0 | 0.8 | 1.0 | 1710 | 4569 |

| 20 | Internal partition | 4.18 | 57 | 246 | 0 | n/a | 1.0 | 246 | ||||

| 20 | Window | NW | 0.54 | 57 | 2375 | 0.1 | 0.8 | 1.1 | 2613 | |||

| 1 | Reception | 20 | Internal partition | 4.18 | 57 | 246 | 0 | n/a | 1.0 | 246 | 4565 | |

| 20 | Window | NE | 0.54 | 57 | 1786 | 0.1 | 0.8 | 1.1 | 1965 | |||

| 20 | Window | ЮB | 0.54 | 57 | 2242 | 0.05 | 0.8 | 1.05 | 2354 | |||

| 4 | Bathroom | 20 | Window | NE | 0.54 | 57 | 456 | 0.1 | 0.8 | 1.1 | 502 | 502 |

| 3 | Lounge area | 20 | Window | NE | 0.54 | 57 | 1425 | 0.1 | 0.8 | 1.1 | 1568 | 2509 |

| 20 | Window | NW | 0.54 | 57 | 855 | 0.1 | 0.8 | 1.1 | 941 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chicherin, S.; Zhuikov, A.; Junussova, L. District Heating for Poorly Insulated Residential Buildings—Comparing Results of Visual Study, Thermography, and Modeling. Sustainability 2023, 15, 14908. https://doi.org/10.3390/su152014908

Chicherin S, Zhuikov A, Junussova L. District Heating for Poorly Insulated Residential Buildings—Comparing Results of Visual Study, Thermography, and Modeling. Sustainability. 2023; 15(20):14908. https://doi.org/10.3390/su152014908

Chicago/Turabian StyleChicherin, Stanislav, Andrey Zhuikov, and Lyazzat Junussova. 2023. "District Heating for Poorly Insulated Residential Buildings—Comparing Results of Visual Study, Thermography, and Modeling" Sustainability 15, no. 20: 14908. https://doi.org/10.3390/su152014908