Estimating Energy Efficiency and Energy Saving Potential in the Republic of Korea’s Offshore Fisheries

Abstract

:1. Introduction

2. Literature Review

3. Materials and Methods

3.1. Data and Variables

3.2. Energy Distance Function

3.3. Estimating Energy Distance Function through SFA

4. Results

4.1. Energy Distance Function of Offshore Fisheries

4.2. Energy Efficiency and Energy Saving Potential of Offshore Fisheries

5. Discussion and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- 77 Countries, 100+ Cities Commit to Net Zero Carbon Emissions by 2050 at Climate Summit, International Institute for Sustainable Development, Winnipeg, Canada. 2019. Available online: https://sdg.iisd.org/news/77-countries-100-cities-commit-to-net-zero-carbon-emissions-by-2050-at-climate-summit/ (accessed on 3 January 2023).

- 2050 Carbon Neutral Strategy of the Republic of Korea, Daejeon, Republic of Korea. 2020. Available online: http://me.go.kr/home/web/policy_data/read.do?pagerOffset=0&maxPageItems=10&maxIndexPages=10&searchKey=title&searchValue=%ED%83%84%EC%86%8C&menuId=10259&orgCd=&condition.orderSeqId=7633&condition.rnSeq=0&condition.deleteYn=N&seq=7633 (accessed on 2 January 2023).

- Oceans and Fisheries, Beyond Carbon Neutrality to Carbon Negative, Ministry of Oceans and Fisheries. Sejong, Republic of Korea. 2021. Available online: https://www.korea.kr/news/policyNewsView.do?newsId=156486922 (accessed on 3 January 2023).

- Woo, D.S.; Kim, J.H.; Jeong, R.H.; Lim, Y.J.; Hwang, H.K.; Son, K.T.; Bae, B.S.; Ko, J.C.; Kim, K.Y.; Kim, S.T.; et al. Annual Report for Climate Change Trends in Fisheries, 2022; Ministry of Ocean and Fisheries National Institute of Fisheries Science: Busan, Republic of Korea, 2022; pp. 73–75.

- Fisheries Management Survey, Korean Statistical Information Service, Daejeon, Republic of Korea. 2023. Available online: https://kosis.kr/statisticsList/statisticsListIndex.do?parentId=K2.1&vwcd=MT_ZTITLE&menuId=M_01_01#content-group (accessed on 2 January 2023).

- Establishment of ‘Basic Plan for Structural Improvement of Offshore and Coastal Fisheries’ for Sustainable Fisheries, Ministry of Oceans and Fisheries. Sejong, Republic of Korea. 2014. Available online: https://www.korea.kr/briefing/pressReleaseView.do?newsId=156017088#pressRelease (accessed on 26 May 2023).

- The 3rd Fisheries Resources Management Basic Plan, Ministry of Oceans and Fisheries. Sejong, Republic of Korea. 2021. Available online: https://www.mof.go.kr/doc/ko/selectDoc.do?menuSeq=375&bbsSeq=9&docSeq=37965 (accessed on 26 May 2023).

- FAO. The State of World Fisheries and Aquaculture 2020. Sustainability in Action; Food and Agriculture Organization of the United Nations: Rome, Italy, 2020. [Google Scholar]

- Kim, M.J.; Hong, J.B.; Han, I.S.; Lee, J.S.; Kim, D.H. Vulnerability assessment of Korean fisheries to climate change. Mar. Policy 2023, 155, 105735. [Google Scholar] [CrossRef]

- Kristofersson, D.; Gunnlaugsson, S.; Valtysson, H. Factors affecting greenhouse gas emissions in fisheries: Evidence from Iceland’s demersal fisheries. ICES J. Mar. Sci. 2021, 78, 2385–2394. [Google Scholar] [CrossRef]

- Oh, S.C.; Hildreth, A.J. Estimating the Technical Improvement of Energy Efficiency in the Automotive Industry—Stochastic and Deterministic Frontier Benchmarking Approaches. Energies 2014, 7, 6196–6222. [Google Scholar] [CrossRef]

- Shui, H.; Jin, X.; Ni, J. Manufacturing productivity and energy efficiency: A stochastic efficiency frontier analysis. Int. J. Energy Res. 2015, 39, 1649–1663. [Google Scholar] [CrossRef]

- Boyd, A.G.; Lee, J.M. Measuring plant level energy efficiency and technical change in the U.S. metal-based durable manufacturing sector using stochastic frontier analysis. Energy Econ. 2019, 81, 159–174. [Google Scholar] [CrossRef]

- Wang, X.; Wang, H.; Liang, S.; Xu, S. The Influence of Energy Price Distortion on Region Energy Efficiency in China’s Energy-Intensive Industries from the Perspectives of Urban Heterogeneity. Sustainability 2022, 14, 88. [Google Scholar] [CrossRef]

- Haider, S.; Mishra, P.P. Does innovative capability enhance the energy efficiency of Indian Iron and Steel firms? A Bayesian stochastic frontier analysis. Energy Econ. 2021, 95, 105128. [Google Scholar] [CrossRef]

- Haider, S.; Bhat, J.A. Inter-state analysis of energy efficiency- a stochastic frontier approach to the Indian paper industry. Int. J. Energy Sect. Manag. 2018, 12, 547–565. [Google Scholar] [CrossRef]

- Lundgren, T.; Marklund, P.O.; Zhang, S. Industrial energy demand and energy efficiency—Evidence from Sweden. Resour. Energy Econ. 2016, 43, 130–152. [Google Scholar] [CrossRef]

- Macharia, K.K.; Gathiaka, J.K.; Ngui, D. Energy efficiency in the Kenyan manufacturing sector. Energy Policy 2022, 161, 112715. [Google Scholar] [CrossRef]

- Otsuka, A. How do population agglomeration and interregional networks improve energy efficiency? Asia-Pac. J. Reg. Sci. 2020, 4, 1–25. [Google Scholar] [CrossRef]

- Nguyena, L.T.; Ratnasiria, S.; Wagner, L. Industrial energy efficiency and determinants in Vietnam: A stochastic frontier analysis using firm-level data. Appl. Econ. 2023, 1–16. [Google Scholar] [CrossRef]

- Lv, Y.; Chen, W.; Cheng, J. Effects of urbanization on energy efficiency in China: New evidence from short run and long run efficiency models. Energy Policy 2020, 147, 111858. [Google Scholar] [CrossRef]

- Ouyang, X.; Mao, X.; Sun, C.; Du, K. Industrial energy efficiency and driving forces behind efficiency improvement: Evidence from the Pearl River Delta urban agglomeration in China. J. Clean. Prod. 2019, 220, 899–909. [Google Scholar] [CrossRef]

- Du, M.; Wang, B.; Zhang, N. National research funding and energy efficiency: Evidence from the National Science Foundation of China. Energy Policy 2018, 120, 335–346. [Google Scholar] [CrossRef]

- Zhang, H.; Fan, L.W.; Zhou, P. Handling heterogeneity in frontier modeling of city-level energy efficiency: The case of China 2020. Appl. Energy 2020, 279, 115846. [Google Scholar] [CrossRef]

- Zou, G.; Chen, L.; Liu, W.; Hong, X.; Zhang, G.; Zhang, Z. Measurement and evaluation of Chinese regional energy efficiency based on provincial panel data. Math. Comput. Model. 2013, 58, 1000–1009. [Google Scholar] [CrossRef]

- Filippini, M.; Zhang, L. Estimation of the energy efficiency in Chinese provinces. Energy Effic. 2013, 9, 1315–1326. [Google Scholar] [CrossRef]

- Otsuka, A. Determinants of efficiency in residential electricity demand: Stochastic frontier analysis on Japan. Energy Sustain. Soc. 2017, 7, 1–10. [Google Scholar] [CrossRef]

- Honma, S.; Hu, J.L. A panel data parametric frontier technique for measuring total-factor energy efficiency: An application to Japanese regions. Energy 2014, 78, 732–739. [Google Scholar] [CrossRef]

- Filippini, M.; Hunt, L.C. US residential energy demand and energy efficiency: A stochastic demand frontier approach. Energy Econ. 2012, 34, 1484–1491. [Google Scholar] [CrossRef]

- Weyman-Jones, T.; Boucinha, J.M.; Inácios, C.F. Measuring electric energy efficiency in Portuguese households: A tool for energy policy. Manag. Environ. Qual. Int. J. 2015, 26, 407–422. [Google Scholar] [CrossRef]

- Nsangou, J.C.; Kenfack, J.; Nzotcha, U.; Tamo, T.T. Assessment of the potential for electricity savings in households in Cameroon: A stochastic frontier approach. Energy 2020, 211, 118576. [Google Scholar] [CrossRef]

- Filippini, M.; Hunt, L.C. Energy demand and energy efficiency in the OECD countries: A stochastic demand frontier approach. Energy J. 2011, 32, 59–80. [Google Scholar] [CrossRef]

- Zhou, P.; Ang, B.W.; Zhou, D.Q. Measuring economy-wide energy efficiency performance: A parametric frontier approach. Appl. Energy 2012, 90, 196–200. [Google Scholar] [CrossRef]

- Hua, J.L.; Honma, S.A. Comparative study of energy efficiency of OECD countries: An application of the stochastic frontier analysis. Energy Procedia 2014, 61, 2280–2283. [Google Scholar] [CrossRef]

- Filippini, M.; Hunt, L.C.; Zorić, J. Impact of energy policy instruments on the estimated level of underlying energy efficiency in the EU residential sector. Energy Policy 2014, 69, 73–81. [Google Scholar] [CrossRef]

- Marin, G.; Palma, A. Technology invention and adoption in residential energy consumption: A stochastic frontier approach. Energy Econ. 2017, 66, 85–98. [Google Scholar] [CrossRef]

- Hsiao, W.L.; Hu, J.L.; Hsiao, C.; Chang, M.C. Energy Efficiency of the Baltic Sea Countries: An Application of Stochastic Frontier Analysis. Energies 2018, 12, 104. [Google Scholar] [CrossRef]

- Liu, F.; Sim, J.Y.; Edziah, B.K.; Sun, H.; Sarkodie, S.A.; Adom, P.K. Machinery import, R&D spillover, and energy efficiency. J. Environ. Plan. Manag. 2023, 1–22. [Google Scholar] [CrossRef]

- Adom, P.K.; Amakye, K.; Abrokwa, K.K.; Quaidoo, C. Estimate of transient and persistent energy efficiency in Africa: A stochastic frontier approach. Energy Convers. Manag. 2018, 166, 556–568. [Google Scholar] [CrossRef]

- Jin, T.; Kim, J. A comparative study of energy and carbon efficiency for emerging countries using panel stochastic frontier analysis. Sci. Rep. 2019, 9, 6647. [Google Scholar] [CrossRef] [PubMed]

- Lin, B.; Yang, L. The potential estimation and factor analysis of China′s energy conservation on thermal power industry. Energy Policy 2013, 62, 354–362. [Google Scholar] [CrossRef]

- Lin, B.; Wang, X. Exploring energy efficiency in China’s iron and steel industry: A stochastic frontier approach. Energy Policy 2014, 72, 87–96. [Google Scholar] [CrossRef]

- Lin, B.; Long, H. A stochastic frontier analysis of energy efficiency of China’s chemical industry. J. Clean. Prod. 2015, 87, 235–244. [Google Scholar] [CrossRef]

- Xie, C.; Bai, M.; Wang, X. Accessing provincial energy efficiencies in China’s transport sector. Energy Policy 2018, 123, 525–532. [Google Scholar] [CrossRef]

- Xu, M.; Tan, R.; He, X. How does economic agglomeration affect energy efficiency in China?: Evidence from endogenous stochastic frontier approach. Energy Econ. 2022, 108, 105901. [Google Scholar] [CrossRef]

- Lin, B.; Du, K. Measuring energy efficiency under heterogeneous technologies using a latent class stochastic frontier approach: An application to Chinese energy economy. Energy 2014, 76, 884–890. [Google Scholar] [CrossRef]

- Liu, F.; Sim, J.Y.; Sun, H.; Edziah, B.K.; Adom, P.K.; Song, S. Assessing the role of economic globalization on energy efficiency: Evidence from a global perspective. China Econ. Rev. 2023, 77, 101897. [Google Scholar] [CrossRef]

- Liu, J.; Wang, H.; Rahman, S.; Sriboonchitta, S. Energy efficiency, energy conservation and determinants in the agricultural sector in emerging economies. Agriculture 2021, 11, 773. [Google Scholar] [CrossRef]

- Khraiche, M.; Kutlu, L.; Mao, X. Energy efficiencies of European countries. Appl. Econ. 2022, 54, 2694–2706. [Google Scholar] [CrossRef]

- Cheilari, A.; Guillen, J.; Damalas, D.; Barbas, T. Effects of the fuel price crisis on the energy efficiency and the economic performance of the European Union fishing fleets. Mar. Policy 2013, 40, 18–24. [Google Scholar] [CrossRef]

- Jafarzadeh, S.; Ellingsen, H.; Aanondsen, S.A. Energy efficiency of Norwegian fisheries from 2003 to 2012. J. Clean. Prod. 2016, 112, 3616–3630. [Google Scholar] [CrossRef]

- Bastardie, F.; Nielsen, J.R.; Andersen, B.S.; Eigaard, O.R. Effects of fishing effort allocation scenarios on energy efficiency and profitability: An individual-based model applied to Danish fisheries. Fish. Res. 2010, 106, 501–516. [Google Scholar] [CrossRef]

- Bastardie, F.; Nielsen, J.R.; Andersen, B.S.; Eigaard, O.R. Integrating individual trip planning in energy efficiency—Building decision tree models for Danish fisheries. Fish. Res. 2013, 143, 119–130. [Google Scholar] [CrossRef]

- Enforcement Decree of the Fisheries Act, Korean Law Information Center. Sejong, Republic of Korea. 2023. Available online: https://www.law.go.kr/LSW//lsSc.do?section=&menuId=1&subMenuId=15&tabMenuId=81&eventGubun=060101&query=%EC%88%98%EC%82%B0%EC%97%85%EB%B2%95+%EC%8B%9C%ED%96%89%EB%A0%B9#undefined (accessed on 25 May 2023).

- Enforcement Rule of the Fisheries Act, Korean Law Information Center. Sejong, Republic of Korea. 2023. Available online: https://www.law.go.kr/LSW//lsInfoP.do?lsiSeq=252659&ancYd=20230711&ancNo=00614&efYd=20230711&nwJoYnInfo=Y&efGubun=Y&chrClsCd=010202&ancYnChk=0#0000 (accessed on 25 May 2023).

- Nam, J.O.; Park, C.H.; Shin, Y.M.; Kim, B.T.; Lee, H.D.; Seo, H.J.; Jeon, Y.H.; Park, J.H.; Jung, M.K.; Ahn, Y.J. A Study on the Improvement of Annual Cost Estimation Method of Tax-Free Petroluem for Fisheries in 2021; National Federation of Fisheries Cooperatives: Seoul, Republic of Korea, 2021. [Google Scholar]

- Fisheries Producer Price Index, Korean Statistical Information Service, Daejeon, Republic of Korea. 2023. Available online: https://kosis.kr/statisticsList/statisticsListIndex.do?parentId=P2.1&vwcd=MT_ZTITLE&menuId=M_01_01 (accessed on 2 January 2023).

- Enforcement Rule of the Energy Act, Korean Law Information Center. Sejong, Republic of Korea. 2023. Available online: https://www.law.go.kr/%EB%B2%95%EB%A0%B9/%EC%97%90%EB%84%88%EC%A7%80%EB%B2%95%20%EC%8B%9C%ED%96%89%EA%B7%9C%EC%B9%99 (accessed on 5 January 2023).

- Debreu, G. The coefficient of resource utilization. Econometrica 1951, 19, 273–292. [Google Scholar] [CrossRef]

- Farrell, M.J. The measurement of productive efficiency. J. R. Stat. Society. Ser. A 1957, 120, 253–290. [Google Scholar] [CrossRef]

- Fare, R.; Grosskopf, S.; Margaritis, S. Productivity Growth and Convergence in the European Union. J. Product. Anal. 2006, 25, 111–141. [Google Scholar] [CrossRef]

- Du, K.; Lin, B. International comparison of total-factor energy productivity growth: A parametric Malmquist index approach. Energy 2017, 118, 481–488. [Google Scholar] [CrossRef]

- Aigner, D.; Lovell, C.A.K.; Schmidt, P. Formulation and estimation of stochastic frontier production function models. J. Econom. 1977, 6, 21–37. [Google Scholar] [CrossRef]

- Meeusen, W.; van Den Broeck, J. Efficiency Estimation from Cobb-Douglas Production Functions with Composed Error. Int. Econ. Rev. 1977, 18, 435–444. [Google Scholar] [CrossRef]

- Belotti, F.; Daidone, S.; Ilardi, G.; Atella, V. Stochastic frontier analysis using Stata. Stata J. 2013, 13, 719–758. [Google Scholar] [CrossRef]

- Christensen, L.R.; Jorgenson, D.W.; Lau, L.J. Transcendental Logarithmic Production Frontiers. Rev. Econ. Stat. 1973, 55, 28–45. [Google Scholar] [CrossRef]

- Lovell, C.A.K.; Richardson, S.; Travers, P.; Wood, L. Resources and Functionings: A New View of Inequality in Australia. In Models and Measurement of Welfare and Inequality; Springer: Berlin/Heidelberg, Germany, 1994; pp. 787–807. [Google Scholar]

- Battese, G.E.; Coelli, T.J. Frontier Production Functions, Technical Efficiency and Panel Data: With Application to Paddy Farmers in India. J. Product. Anal. 1992, 3, 153–169. [Google Scholar] [CrossRef]

- Battese, G.E.; Coelli, T.J. A Model for Technical Inefficiency Effects in a Stochastic Frontier Production Function for Panel Data. Empir. Econ. 1995, 20, 325–332. [Google Scholar] [CrossRef]

- Wang, H.J.; Schmidt, P. One-Step and Two-Step Estimation of the Effects of Exogenous Variables on Technical Efficiency Levels. J. Product. Anal. 2002, 18, 129–144. [Google Scholar] [CrossRef]

- Jeong, D.S.; Kang, S.M. Analysis of the Cost Efficiency and its Determinants in the Korean Wind Component Industry: Using Stochastic Frontier Model. JIEB 2019, 32, 2273–2293. [Google Scholar] [CrossRef]

- Lee, Y.G.; Jee, H.W.; Yu, J.W.; Kang, D.S.; Kwon, S.Y. Characteristics and improvement plans of the hull form of Korean fishing boats in connection with the performance of hull form resistance. J. Korea Ship Saf. Technol. Auth. 2008, 25, 47–63. [Google Scholar]

- Enforcement Rule of the Act on the Restructuring of and Support for Coastal and Inshore Fisheries, Korean Law Information Center. Sejong, Republic of Korea. 2023. Available online: https://law.go.kr/LSW/lsInfoP.do?lsiSeq=243813&ancYd=20220711&ancNo=00557&efYd=20220712&nwJoYnInfo=Y&efGubun=Y&chrClsCd=010202&ancYnChk=0#J14672969 (accessed on 20 June 2023).

- International Oil Price, Korea National Oil Corporation Petronet. Ulsan, Republic of Korea. 2023. Available online: https://www.petronet.co.kr/main2.jsp (accessed on 26 May 2023).

- Lee, J.H.; Lee, C.W. Low-Carbon trawl design with analysis of a gear drags and calculation of construction costs using numerical methods. J. Kor. Soc. Fish. Tech. 2010, 46, 313–323. [Google Scholar] [CrossRef]

- Lee, K.H.; Lee, C.W.; Yang, Y.S.; Lee, J.H. Development of a low-energy used large midwater trawl using a numerical method. J. Kor. Soc. Fish. Tech. 2012, 48, 195–207. [Google Scholar] [CrossRef]

- Yang, Y.S.; Lee, C.W.; Lee, K.H.; Park, S.B.; Park, S.K.; Kang, M.J.; Lee, J.H. Development of a low energy used anchovy dragnet using a numerical method. J. Kor. Soc. Fish. Tech. 2013, 49, 175–187. [Google Scholar] [CrossRef]

- Kim, J.E.; Lee, J.H.; Park, S.H.; Lee, C.W.; Park, S.B. Performance analysis of a low drag generated midwater trawl using the model experiments and the numerical analysis. J. Kor. Soc. Fish. Tech. 2017, 53, 115–125. [Google Scholar] [CrossRef]

- Catch Fishing Efficiency and Welfare of Fishermen Together with Next Generation Standard Fishing Vessels, Ministry of Oceans and Fisheries. Sejong, Republic of Korea. 2018. Available online: https://www.korea.kr/briefing/pressReleaseView.do?newsId=156247450#pressRelease (accessed on 25 May 2023).

- Kim, D.Y. Trend of Reduction and Direction of Management Response in the Large Purse Seine Fishery. J. Fish. Bus. Adm. 2019, 50, 29–44. [Google Scholar] [CrossRef]

| Author(s) | Object | Main Contents |

|---|---|---|

| Lin and Yang [41] | Thermal power industry (China) | Energy efficiency, Energy saving potential, Energy inefficiency determinants |

| Lin and Wang [42] | Iron and steel industry (China) | |

| Lin and Long [43] | Chemical industry (China) | |

| Xie et al. [44] | Transport industry (China) | |

| Xu et al. [45] | 285 cities (China) | |

| Liu et al. [47] | 141 countries | |

| Liu et al. [48] | Agricultural sector (27 emerging countries) | |

| Lin and Du [46] | 30 provinces (China) | Energy efficiency, Energy saving potential |

| Khraiche et al. [49] | 44 European countries |

| Variable | Observation | Mean | Standard Deviation | Minimum | Maximum |

|---|---|---|---|---|---|

| Fisheries revenue (Thousand KRW) | 126 | 2,098,527 | 2,845,626 | 154,428 | 16,439,039 |

| Crew (Person) | 126 | 17 | 18 | 3 | 76 |

| Vessel HP (Horsepower) | 126 | 1553 | 2010 | 379 | 8478 |

| Vessel Ton (Gross tonnage) | 126 | 154 | 252 | 4 | 1083 |

| Energy (TOE) | 126 | 574 | 825 | 15 | 3548 |

| Vessel age (Year) | 126 | 22 | 9 | 7 | 41 |

| Depreciation cost (Thousand KRW) | 126 | 60,786 | 135,450 | 972 | 765,603 |

| Coefficient | Estimate | Standard Error | z-Statistic |

|---|---|---|---|

| Dependent variable: | |||

| 11.9805 ** | 5.6938 | 2.1000 | |

| 1.4697 | 1.1285 | 1.3000 | |

| 8.6202 *** | 1.2068 | 7.1400 | |

| −6.9171 *** | 1.1980 | −5.7700 | |

| −0.2489 | 0.6291 | −0.4000 | |

| −0.3112 * | 0.1602 | −1.9400 | |

| −0.7760 *** | 0.1235 | −6.2800 | |

| 0.2591 *** | 0.0732 | 3.5400 | |

| −0.3928 *** | 0.1136 | −3.4600 | |

| −0.6749 *** | 0.0744 | −9.0700 | |

| 0.1636 ** | 0.0663 | 2.4700 | |

| 1.2159 *** | 0.1707 | 7.1200 | |

| −0.2289 | 0.2439 | −0.9400 | |

| 1.4154 *** | 0.1421 | 9.9600 | |

| −0.0259 | 0.0404 | −0.6400 | |

| Dependent variable: | |||

| −1.0647 | 0.7301 | −1.4600 | |

| 0.8621 *** | 0.1348 | 6.3900 | |

| 0.2326 * | 0.1301 | 1.7900 | |

| 0.0506 | 0.0587 | 0.8600 | |

| 0.0116 * | 0.0061 | 1.9000 | |

| 3.0700 *** | 0.0259 | 118.5400 | |

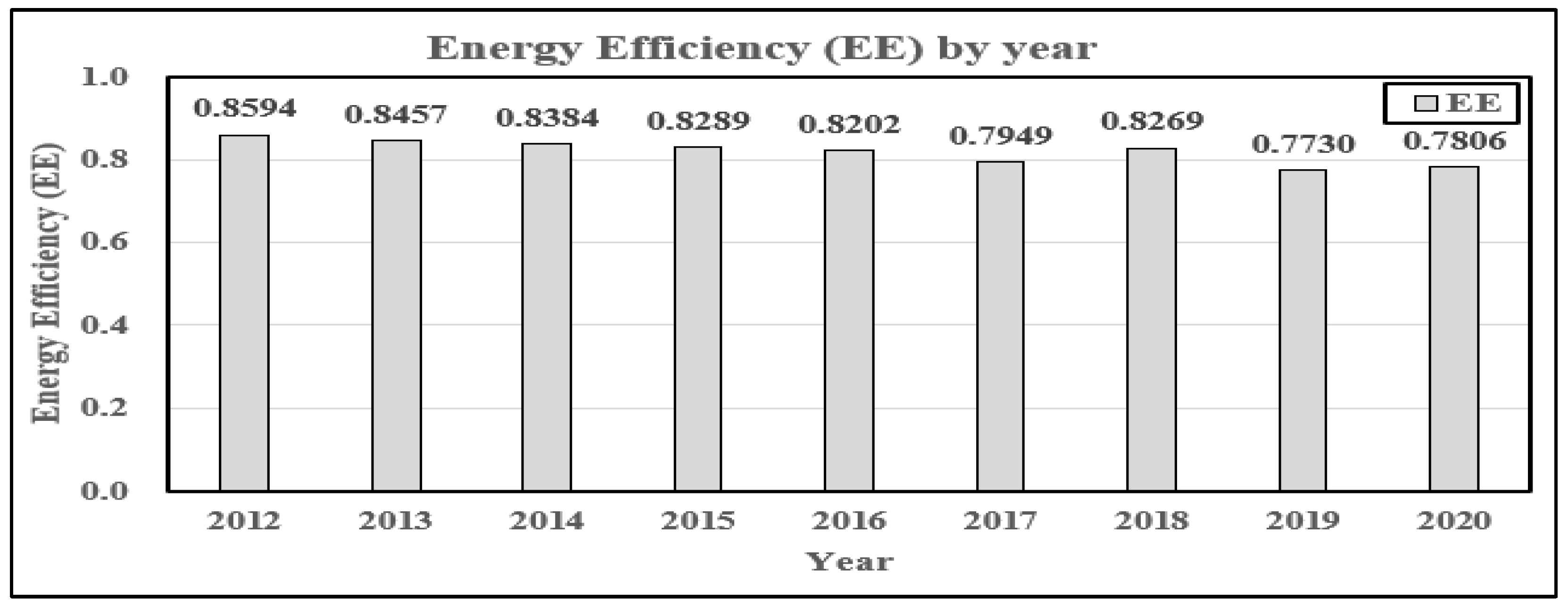

| Year | EE | Ranking |

|---|---|---|

| 2012 | 0.8594 | 1 |

| 2013 | 0.8457 | 2 |

| 2014 | 0.8384 | 3 |

| 2015 | 0.8289 | 4 |

| 2016 | 0.8202 | 6 |

| 2017 | 0.7949 | 7 |

| 2018 | 0.8269 | 5 |

| 2019 | 0.7730 | 9 |

| 2020 | 0.7806 | 8 |

| Average | 0.8187 | - |

| Year | ESP (TOE) | Ranking |

|---|---|---|

| 2012 | 2763.43 | 9 |

| 2013 | 2916.16 | 8 |

| 2014 | 3099.73 | 7 |

| 2015 | 3533.08 | 4 |

| 2016 | 3748.80 | 2 |

| 2017 | 3690.21 | 3 |

| 2018 | 3187.31 | 6 |

| 2019 | 3362.22 | 5 |

| 2020 | 4040.44 | 1 |

| Average | 3371.27 | - |

| Fishing Gear | EE | Ranking |

|---|---|---|

| Offshore stow net (OSN) | 0.9527 | 4 |

| Offshore long line (OLL) | 0.9616 | 2 |

| Offshore gill net (OGN) | 0.9566 | 3 |

| Offshore angling (OA) | 0.9480 | 5 |

| Offshore trap (OT) | 0.9372 | 7 |

| Anchovy drag net (ADN) | 0.4173 | 14 |

| Large purse seine (LPS) | 0.4411 | 13 |

| Large otter trawl (LOT) | 0.8198 | 11 |

| East sea Danish seine (EDS) | 0.9077 | 8 |

| East sea trawl (EST) | 0.9042 | 9 |

| Medium Danish seine (MDS) | 0.9388 | 6 |

| Large pair trawl (LPT) | 0.4522 | 12 |

| Large Danish seine (LDS) | 0.8624 | 10 |

| Diver | 0.9617 | 1 |

| Average | 0.8187 | - |

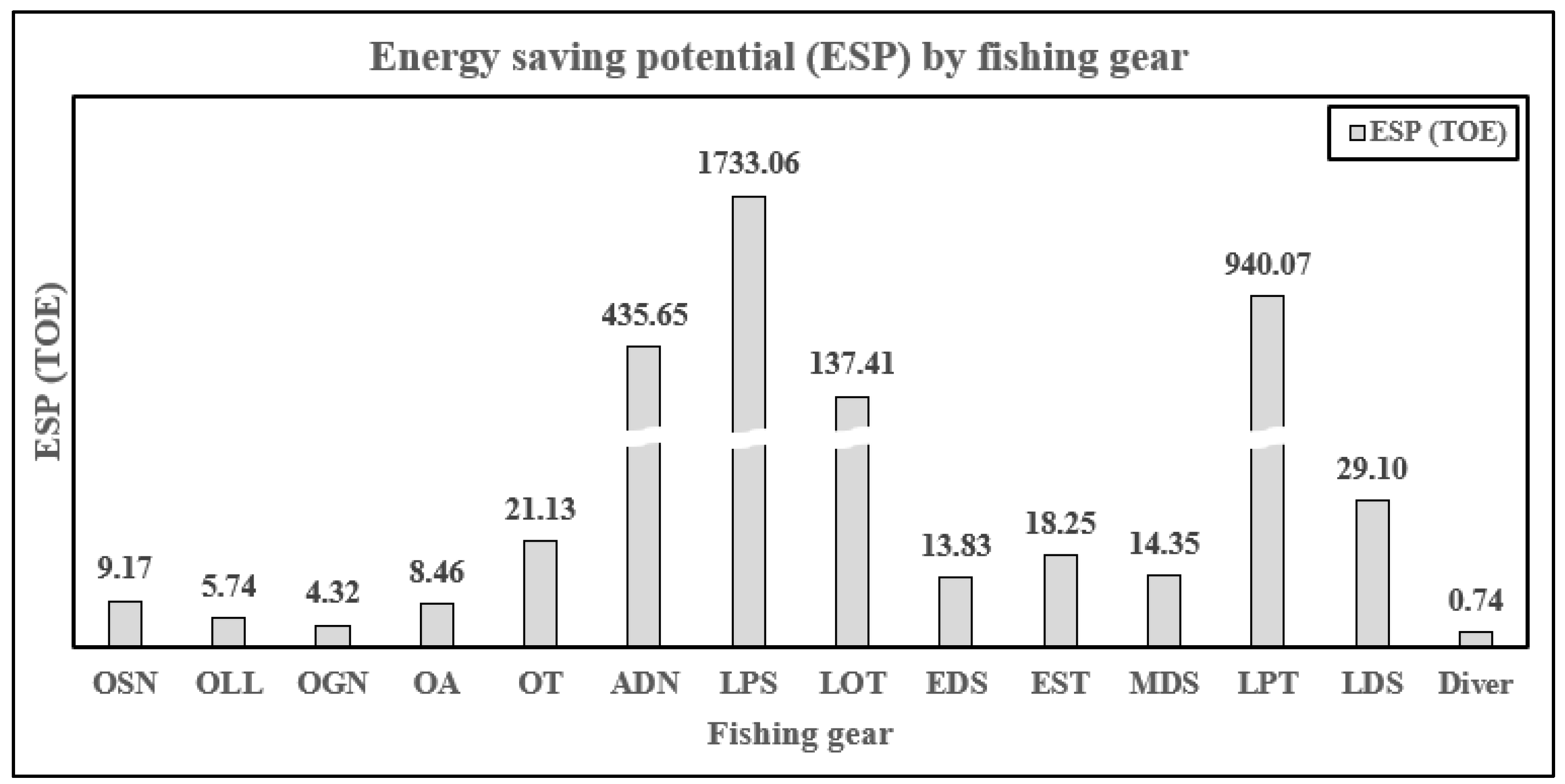

| Fishing Gear | ESP (TOE) | Ranking |

|---|---|---|

| Offshore stow net (OSN) | 9.17 | 10 |

| Offshore long line (OLL) | 5.74 | 12 |

| Offshore gill net (OGN) | 4.32 | 13 |

| Offshore angling (OA) | 8.46 | 11 |

| Offshore trap (OT) | 21.13 | 6 |

| Anchovy Drag net (ADN) | 435.65 | 3 |

| Large purse seine (LPS) | 1733.06 | 1 |

| Large otter trawl (LOT) | 137.41 | 4 |

| East sea Danish seine (EDS) | 13.83 | 9 |

| East sea trawl (EST) | 18.25 | 7 |

| Medium Danish seine (MDS) | 14.35 | 8 |

| Large pair trawl (LPT) | 940.07 | 2 |

| Large Danish seine (LDS) | 29.10 | 5 |

| Diver | 0.74 | 14 |

| Average | 240.80 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jeon, Y.; Nam, J. Estimating Energy Efficiency and Energy Saving Potential in the Republic of Korea’s Offshore Fisheries. Sustainability 2023, 15, 15026. https://doi.org/10.3390/su152015026

Jeon Y, Nam J. Estimating Energy Efficiency and Energy Saving Potential in the Republic of Korea’s Offshore Fisheries. Sustainability. 2023; 15(20):15026. https://doi.org/10.3390/su152015026

Chicago/Turabian StyleJeon, Yonghan, and Jongoh Nam. 2023. "Estimating Energy Efficiency and Energy Saving Potential in the Republic of Korea’s Offshore Fisheries" Sustainability 15, no. 20: 15026. https://doi.org/10.3390/su152015026