Sustainable Implementation of Robotic Process Automation Based on a Multi-Objective Mathematical Model

Abstract

:1. Introduction

2. Literature Review

2.1. Sustainability and Robotic Process Automation

2.2. Concepts about Production Planning and Scheduling Problems

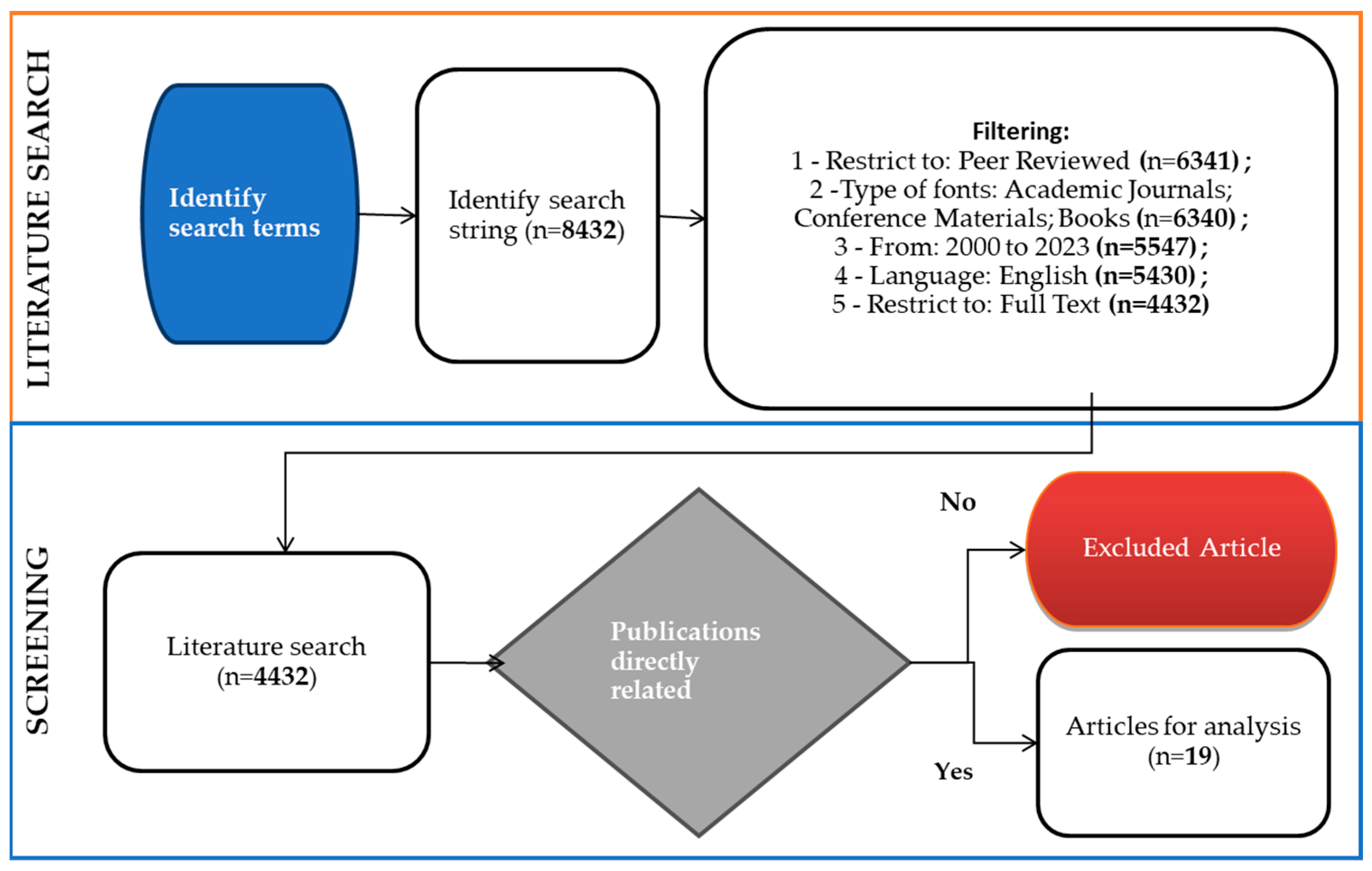

2.3. Identification and Analysis of Relevant Articles

Summary of Review Findings

3. Case Study and Data Collection

3.1. Case Study

3.2. Data Collection

- 1.

- How many RPA activities have been implemented currently?

- A: 44 RPA activities

- 2.

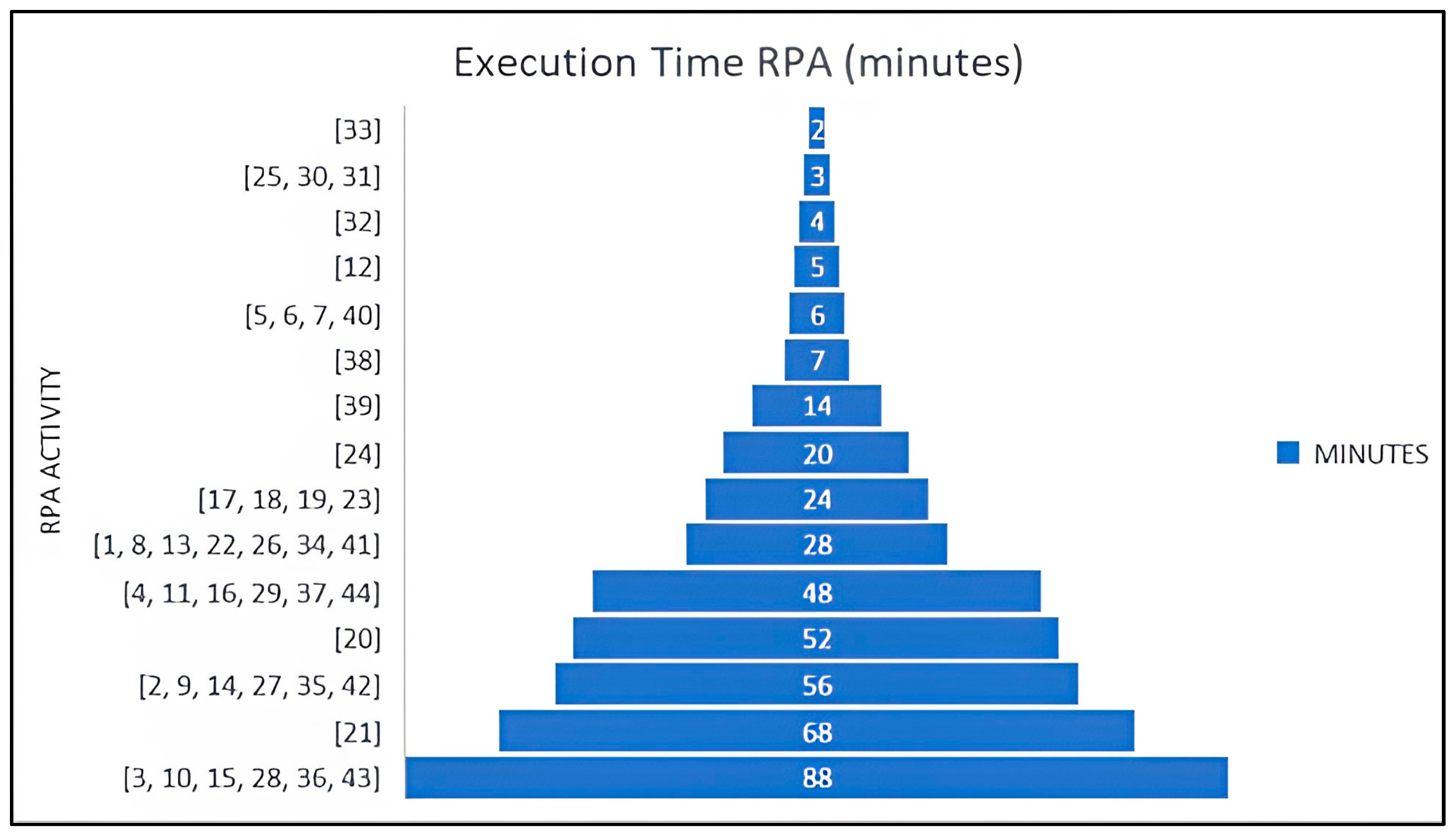

- What is the average execution time for each RPA activity?

- A: The answer to this question is presented through a graph analyzing the times, in minutes, of the company’s 44 RPA activities, in Figure 2.

- 3.

- What is the daily cost spent on total RPA resources?

- A: 3000 monetary units (m. u.)

- 4.

- How many RPA machines have been acquired in the company?

- A: 4 RPA machines

- 5.

- What is the daily available time of each RPA machine and what is the daily cost?

- A: The answer to this question is presented through a Table 5 with the cost and availability of each RPA machine.

- 6.

- Are you part of the company’s RPA team?

- (a)

- Yes (10)

- (b)

- No (20)

- 7.

- Regarding costs, how important is this factor in the implementation of RPA?

- (a)

- Extremely important. (20)

- (b)

- Important. (5)

- (c)

- Neutral. (5)

- (d)

- Less important.

- (e)

- It is not important.

- 8.

- How would you rate the energy efficiency of RPA solutions compared to manual/traditional processes?

- (a)

- RPA solutions are more energy efficient. (22)

- (b)

- RPA solutions are less energy efficient.

- (c)

- RPA solutions are energy efficient similar to manual/traditional processes.

- (d)

- I don’t know enough to answer. (8)

- 9.

- What would be the possible impacts on employees with the implementation of RPA in the current company?

- (a)

- Reduction in the number of employees. (2)

- (b)

- Redirecting employees to more strategic tasks. (10)

- (c)

- Improvement of working conditions. (8)

- (d)

- I don’t know enough to answer. (10)

- 10.

- In what ways do you think RPA automation can help reduce paper consumption in the enterprise?

- (a)

- Eliminating the need for printed documents. (5)

- (b)

- Automating processes to reduce waste.

- (c)

- Minimizing errors that lead to rework and unnecessary use of resources. (5)

- (d)

- All of the above options. (20)

- 11.

- Do you believe that the sustainable implementation of RPA can improve team productivity?

- (a)

- Yes, definitely. (20)

- (b)

- Maybe, depending on the context.

- (c)

- No, I don’t believe there is a direct correlation. (2)

- (d)

- I’m not sure. (8)

- 12.

- How would you rate the current process for allocating RPA projects to machines in terms of effectiveness?

- (a)

- Highly effective.

- (b)

- Moderately effective. (2)

- (c)

- Ineffective. (13)

- (d)

- Not sure. (15)

- 13.

- How do you rate the importance of minimizing the time required to complete automation projects?

- (a)

- Very important to ensure efficiency and agility in operations. (24)

- (b)

- Important, but not the most critical factor. (1)

- (c)

- Neutral, as the project completion time does not significantly affect the results. (2)

- (d)

- Not sure about the importance of completion time. (3)

- 14.

- What is the main objective of implementing RPA in an organization?

- (a)

- Completely replace employees with robots to reduce costs. (3)

- (b)

- Improve operational efficiency by automating repetitive tasks. (23)

- (c)

- Increase the complexity of business processes to achieve more advanced results.

- (d)

- Expand the current workforce by hiring robots. (4)

- Economic pillar: By allocating RPA projects more efficiently, minimizing machine downtime, it is possible to increase productivity and operational efficiency, resulting in a better allocation of the organization’s financial resources.

- Environmental pillar: The efficient allocation of RPA projects to machines can reduce the unnecessary consumption of energy and resources, contributing to the reduction in carbon emissions and the more sustainable use of natural resources.

- Economic Pillar: Minimizing costs in implementing RPA can lead to a more efficient allocation of the organization’s financial resources, freeing up funds for investments in sustainable practices and initiatives in other areas.

- Social pillar: Cost reduction can allow the organization to adopt a more socially responsible approach, such as protecting existing jobs, improving working conditions, and redirecting employees to more strategic tasks.

- Economic pillar: By minimizing the time required to complete automation projects, the organization can improve operational efficiency, reduce costs, and increase productivity, resulting in better financial performance.

- Environmental pillar: By reducing makespan, less resources are used, such as energy and paper, in addition to a decrease in carbon emissions associated with the automation process.

- Social Pillar: By reducing the average workload of employees, the sustainable implementation of RPA can improve work–life balance, promote employee well-being, and contribute to a healthy work environment.

- Economic pillar: Reducing the average workload can increase the productivity and efficiency of the team, resulting in a better allocation of the organization’s financial resources and an increase in profitability.

4. Proposed Multi-Objective Optimization Model

4.1. Mathematical Formulation

4.1.1. Decision Variables

- n—total number of tasks;

- m—total number of machines;

- Ti,j—time of task i on machine j;

- Ci,j – cost of task i on machine j;

- Xi,j—binary variable indicating if task i is scheduled on machine j (1 if the task is scheduled, 0 otherwise);

- Makespan—variable representing the makespan (total completion time of all tasks).

4.1.2. Model (Constraints and Objective Functions)

- 1.

- Each task must be scheduled on exactly one machine:

- 2.

- Each machine can execute only one task at a time:

- 3.

- The variable makespan is defined as the total completion time of tasks:

- 4.

- The cost variable is defined as the sum of costs of all scheduled tasks:

- 5.

- The average workload is defined as

4.2. Scheduling Methods

4.3. Weight Assignment to Objectives and Tested Combinations

5. Implementation and Results to Case Study in an Administrative Department

5.1. Implementation Details

5.2. Results

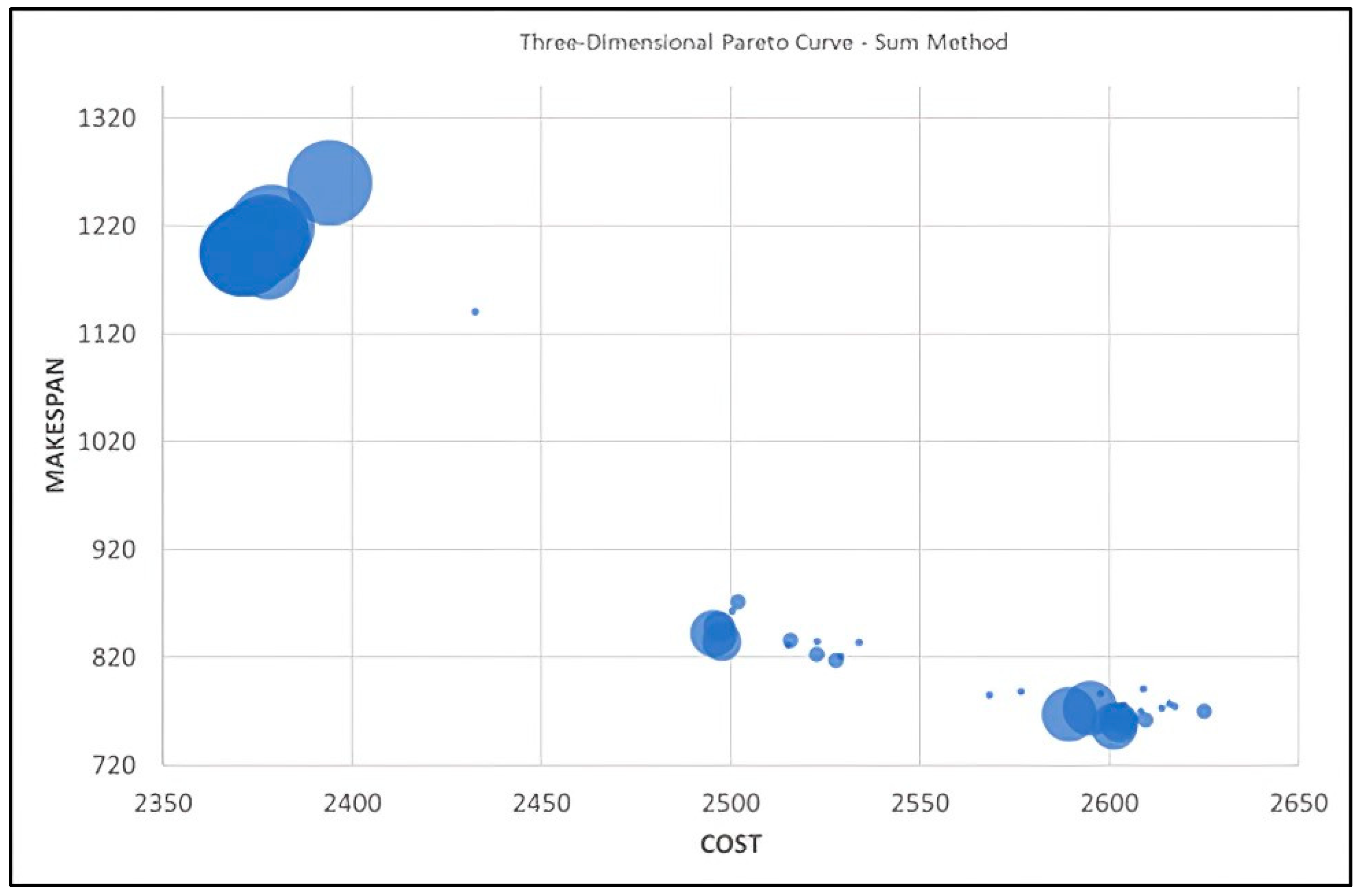

- The cost values range from 2371 to 2394, with Point 8 having the lowest cost.

- The makespan values range from 1195 to 1260, with Point 8 having the lowest makespan.

- The average workload is consistently 11 for all points.

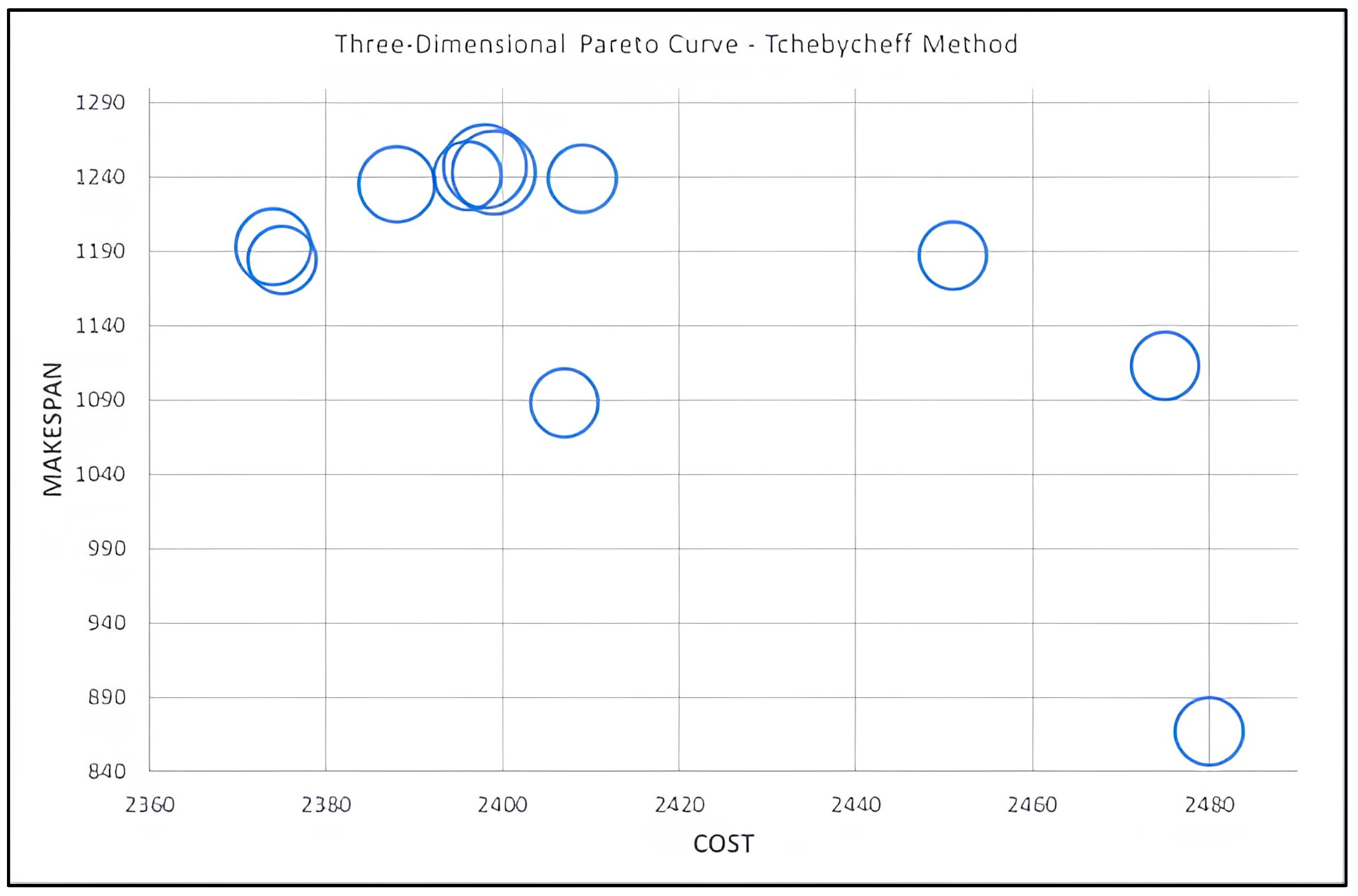

- The cost values range from 2374 to 2480, with Point 11 having the lowest cost.

- The makespan values range from 867 to 1247, with Point 1 having the lowest makespan.

- The average workload is consistently 9 for most points, except for Points 6, 7, and 8, which have a workload of 11, and Points 9 and 11, which have a workload of 10.

6. Discussion

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- World Commission on Environment and Development (WCED). Our Common Future. In The Brundtland Report; Oxford University Press: Oxford, UK, 1987. [Google Scholar]

- Bansal, P. Evolving sustainably: A longitudinal study of corporate sustainable development. Strateg. Manag. J. 2005, 26, 123–136. [Google Scholar] [CrossRef]

- Fernandez, D.; Aman, A. Impacts of Robotic Process Automation on Global Accounting Services. Asian J. Account. Gov. 2018, 9, 123–132. [Google Scholar] [CrossRef]

- Asatiani, A.; Penttinen, E. Turning robotic process automation into commercial success—Case Opus Capita. J. Inf. Technol. Teach. Cases 2016, 6, 67–74. [Google Scholar] [CrossRef]

- Leopold, H.; Van der Aa, H.; Reijers, H.A. Identifying Candidate Tasks for Robotic Process Automation in Textual Process Descriptions. Lect. Notes Bus. Inf. Process. 2018, 318, 67–81. [Google Scholar]

- Gartner. Predicts 2020: RPA Renaissance Driven by Morphing Offerings and Zeal for Operational Excellence. Technical Report. 2020. Available online: https://www.gartner.com/en/documents/3976135 (accessed on 14 July 2023).

- Putnik, G.; Ávila, P. Governance and Sustainability (Special Issue Editorial). Int. J. Ind. Syst. Eng. 2016, 24, 137–143. [Google Scholar]

- Camarinha-Matos, L.M.; Afsarmanesh, H. Collaborative networks: A new scientific discipline. J. Intell. Manuf. 2005, 16, 439–452. [Google Scholar] [CrossRef]

- Demirkan, I.; Deeds, D.; Demirkan, S. Exploring the Role of Network Characteristics, Knowledge Quality, and Inertia on the Evolution of Scientific Networks. J. Manag. 2013, 39, 1462–1489. [Google Scholar] [CrossRef]

- Powell, W.; White, D.; Koput, K.; Owen-Smith, J. Network dynamics and field evolution: The growth of inter-organizational collaboration in the life sciences. Am. J. Sociol. 2005, 110, 1132–1205. [Google Scholar] [CrossRef]

- Camarinha-Matos, L.; Afsarmanesh, H. Redes Colaborativas: Modelagem de Referência; Springer: Berlin/Heidelberg, Germany, 2008; pp. 139–164. ISBN 978-0-387-79426-6. [Google Scholar]

- Ávila, P. Modelo Rigoroso de Seleção de Sistemas de Recursos para o Projeto de Empresas Ágeis/Virtuais para Produtos Complexos. Ph.D. Thesis, Universidade do Minho, Braga, Portugal, 2004. [Google Scholar]

- Ávila, P.; Mota, A.; Bastos, J.; Patrício, L.; Pires, A.; Castro, H.; Cruz-Cunha, M.; Varela, L. Framework for a risk assessment model to apply in Virtual/Collaborative Enterprises. Procedia Comput. Sci. 2020, 181, 612–618. [Google Scholar] [CrossRef]

- Cruz-Cunha, M.M. Organization of a Market of Resources for Agile and Virtual Enterprises Integration. Ph.D. Thesis, Universidade do Minho, Braga, Portugal, 2013. [Google Scholar]

- Cunha, M.M.; Putnik, G.D.; Gunasekaran, A.; Ávila, P. Market of resources as a virtual enterprise integration enabler. In Virtual Enterprise Integration: Technological and Organizational Perspectives; IGI Global: Hershey, PA, USA, 2005. [Google Scholar]

- Lange, D.E.; Busch, T.; Delgado-Ceballos, J. Sustaining Sustainability in Organizations. J. Bus. Ethics 2012, 110, 151–156. [Google Scholar] [CrossRef]

- Brundtland, G.H.; Khalid, M.; Agnelli, S.; Al-Athel, S.; Chidzero, B. Our Common Future; Brundtland Report: New York, NY, USA, 1987; Volume 8. [Google Scholar]

- Kaur, J. Robotic Process Automation in Healthcare Sector. In E3S Web of Conferences; EDP Sciences: Les Ulis, France, 2023; Volume 391. [Google Scholar]

- Gajjar, N.; Rathod, K.; Jani, K. A Systematic Literature Review on Robotic Process Automation Security; Cornell University: Ithaca, NY, USA, 2022. [Google Scholar]

- Kuppan, S. Robotic Process Automation (RPA) to Automate Business Process. BJIB 2023 Information Technology and Communications. 2022. Available online: https://www.researchgate.net/publication/366012844_ROBOTIC_PROCESS_AUTOMATION_RPA_TO_AUTOMATE_BUSINESS_PROCESS (accessed on 1 May 2023).

- Eulerich, M.; Waddoups, N.; Wagener, M.; Wood, D. The Dark Side of Robotic Process Automation (RPA): Understanding Risks and Challenges with RPA. Account. Horiz. 2023, 21, 1–10. [Google Scholar] [CrossRef]

- Chakraborty, A.; Bhattacharyya, S.; De Debashis, M.; Banerjee, J. Intelligent Automation Framework Using AI and RPA: An Introduction. In Confluence of Artificial Intelligence and Robotic Process Automation; Springer Nature: Singapore, 2023; pp. 1–13. [Google Scholar]

- Seshadri, A.; Anand, P.; Parameswari, M.; Sasikala, M. Automated Work Schedule Management with Various Robotics Process Automation (RPA) Tools. In Recent Advances in Materials Technologies; Springer Nature: Singapore, 2022; pp. 337–345. [Google Scholar]

- Chi-Shiuan Lin, P.; Jun-Min Wei, M. Integration of process planning and scheduling for distributed flexible job shops. Comput. Oper. Res. 2020, 124, 1–16. [Google Scholar]

- Chaudhry, I.A.; Khan, A.A. A research survey: Review of flexible job shop scheduling techniques. Int. Trans. Oper. Res. 2016, 23, 551–591. [Google Scholar] [CrossRef]

- Zhou, L.; Liang, Z.; Chou, C.; Chaovalitwongse, W. Airline planning and scheduling: Models and solution methodologies. Front. Eng. Manag. 2020, 7, 1–26. [Google Scholar] [CrossRef]

- Hooker, J. Planning and Scheduling by Logic-Based Benders Decomposition. Oper. Res. 2007, 55, 588–602. [Google Scholar] [CrossRef]

- Ibn Majdoub Hassani, Z.; El Barkany, A.; Moumen, D.; Jabri, A.; Ikram, E. Planning and scheduling problems of production systems: Review. classification and opportunities. Int. J. Product. Qual. Manag. 2019, 28, 372. [Google Scholar] [CrossRef]

- Foumani, M.; Razeghi, A.; Smith-Miles, K. Stochastic optimization of two-machine flow shop robotic cells with controllable inspection times: From theory toward practice. Robot. Comput. Integr. Manuf. 2020, 61, 101822. [Google Scholar] [CrossRef]

- Srivivas, N.; Deb, K. Multiobjective optimization using non dominated sorting in genetic algorithms. Evol. Comput. 1995, 2, 221–248. [Google Scholar] [CrossRef]

- Miettinen, K. Nonlinear multiobjective optimization. In International Series in Operations Research & Management Science, 1st ed.; Springer Science & Business Media: Berlin/Heidelberg, Germany, 1998. [Google Scholar]

- Zitzler, E. Evolutionary Algorithms for Multiobjective Optimization: Methods and Applications. Ph.D. Thesis, Federal Institute of Technology Zurich, Zurich, Switzerland, 1999. [Google Scholar]

- Neves, A.; Godina, R.; Azevedo, S.; Matias, J. A Comprehensive Review of Industrial Symbiosis. J. Clean. Prod. 2020, 247, 119113. [Google Scholar] [CrossRef]

- Silva, A. Robotic Process Automation: A Comparative Analysis of Current Solutions. Master’s Thesis, Open University and Técnico Lisbon, Lisbon, Portugal, 2017. [Google Scholar]

- Pozdnyakov, O. Benefits of Implementing RPA and IPA in the Banking Sector: A Case Study. Master’s Thesis, Lisbon School of Economics & Management, University of Lisbon, Lisbon, Portugal, 2019. [Google Scholar]

- Sobczak, A. Developing a Robotic Process Automation Management Model. Inform. Ekon./Bus. Inform. 2019, 2, 52. [Google Scholar]

- Hofmann, A.; Fischer, M.; Imgrund, F.; Janiesch, C.; Geyer-Klingeberg, J. Process Selection in RPA Projects—Towards a Quantifiable Method of Decision Making. In Proceedings of the 40th International Conference on Information Systems (ICIS), Munich, Germany, 15–18 December 2019. [Google Scholar]

- Kopper, V.; Rodrigues, G.; Zomb, M.; Zuxxolillo, F. Implementing Robotic Process Automation for Internal Process Optimization. Ph.D. Thesis, Worcester Polytechnic Institute (WPA), Worchester, MA, USA, 2020. [Google Scholar]

- Timbadia, D.; Shah, P.; Sudhanvan, S.; Agrawal, S. Robotic Process Automation Through Advance Process Analysis Model. In Proceedings of the International Conference on Inventive Computation Technologies (ICICT), Coimbatore, India, 26–28 February 2020. [Google Scholar]

- Wellmann, C.; Stierle, M.; Dunzer, S.; Matzner, M. A framework to evaluate the viability of robotic process automation for business process activities. In Proceedings of the RPA Forum at the International Conference on Business Process Management (BPM 2020), Seville, Spain, 13–18 September 2020. [Google Scholar]

- Wewerka, J.; Reichert, M. Towards Quantifying the Effects of Robotic Process Automation. In Proceedings of the IEEE 24th International Enterprise Distributed Object Computing Workshop (EDOCW), Eindhoven, The Netherlands, 5–8 October 2020. [Google Scholar]

- Mora, H.; Sánchez, P. Digital Transformation in Higher Education Institutions with Business Process Management: Robotic Process Automation mediation model. In Proceedings of the 15th Iberian Conference on Information Systems and Technologies (CISTI), Seville, Spain, 24–27 June 2020. [Google Scholar]

- Pargana, M. Contributions to the Design of a Robotic Process Automation Implementation Framework in a Financial Institution: Case Study. Bachelor’s Thesis, New University of Lisbon, Lisbon, Portugal, 2020. [Google Scholar]

- Farinha, D. Selecting Processes for Automation. Master’s Thesis, University Institute of Lisbon, Lisbon, Portugal, 2021. [Google Scholar]

- Grande, V. Development of a Decision-Making System for Automating Business Processes Using A fuzzy Inference System. Master’s Thesis, Faculty of Engineering of the Guaratinguetá Campus, Paulista State University, Sao Paulo, Brazil, 2021. [Google Scholar]

- Herm, L.; Janiesch, C.; Helm, A.; Imgrund, F.; Hofmann, A.; Winkelmann, A. A framework for implementing robotic process automation projects. Inf. Syst. e-Bus. Manag. 2022, 21, 1–35. [Google Scholar] [CrossRef]

- E-Fatima, K.; Khandan, R.; Hosseinian-Far, A.; Sarwar, D. The Adoption of Robotic Process Automation Considering Financial Aspects in Beef Supply Chains: An Approach towards Sustainability. Sustainability 2023, 15, 7236. [Google Scholar] [CrossRef]

- Asatiani, A.; Copeland, O.; Penttinen, E. Deciding on the robotic process automation operating model: A checklist for RPA managers. Bus. Horiz. 2023, 66, 109–121. [Google Scholar] [CrossRef]

- Huang, F.; Vasarhelyi, M. Applying robotic process automation (RPA) in auditing: A framework. Int. J. Account. Inf. Syst. 2019, 35, 100433. [Google Scholar] [CrossRef]

- Kim, S.H. Development of Evaluation Criteria for Robotic Process Automation (RPA) Solution Selection. Electronics 2023, 12, 986. [Google Scholar] [CrossRef]

- Beetz, R.; Riedl, Y. Robotic Process Automation: Developing a Multi-Criteria Evaluation Model for the Selection of Automatable Business Processes. AMCIS Proc. 2019, 4, 1–10. [Google Scholar]

- Patrício, L.; Ávila, P.; Varela, L.; Cruz-Cunha, M.; Ferreira, L.; Bastos, J.; Castro, H.; Silva, J. Literature review of decision models for the sustainable implementation of Robotic Process Automation. Procedia Comput. Sci. 2023, 219, 870–878. [Google Scholar] [CrossRef]

- Soltan, E.; Abdelrazek, F.; Talaat, W. Practice of Concept Mapping in Brainstorming and Debriefing Sessions in Relation to Gender among Nursing Students. Trends Nurs. Health Care J. 2022, 5, 36. [Google Scholar]

- Zarei, A.; Feizollahi, K. Concept Mapping and Brainstorming Affecting Writing Anxiety and Accuracy. J. Mod. Res. Engl. Lang. Stud. 2018, 5, 117–144. [Google Scholar]

- Ivanov, A.; Cyr, D. The Concept Plot: A Concept Mapping Visualization Tool for Asynchronous Web-Based Brainstorming Sessions. Inf. Vis. 2006, 5, 185–191. [Google Scholar] [CrossRef]

- Ryzhuk, O.; Gitelman, L.; Kozhevnikov, M.; Bashorina, O.; Boyarinov, A.; Buntov, E.; Kuzmina, A.; Makarova, O.; Pishevskaya, E.; Polyakova, V.; et al. Visual Brainstorming in Concept Project Development in the Power Industry. In Challenges and Solutions in the Russian Energy Sector; Springer: Cham, Switzerland, 2018. [Google Scholar]

- Cieniawski, S.E.; Eheart, J.W.; Ranjithan, S. Using Genetic Algorithms to Solve a Multiobjective Groundwater Monitoring Problem. Water Resour. Res. 1995, 31, 399–409. [Google Scholar] [CrossRef]

- Miettinen, K.M. Nonlinear Multiobjective Optimization; Kluwer Academic Publishers: Boston, MA, USA, 1999. [Google Scholar]

- Hwang, C.L.; Masud, A.S.M. Multiple Objective Decision Making—Methods and Applications: A State-of-the-Art Survey. In Lecture Notes in Economics and Mathematical Systems; Springer Science & Business Media: Berlin/Heidelberg, Germany, 1979; Volume 164. [Google Scholar]

- Ercan, M.; Malmodin, J.; Bergmark, P.; Kimfalk, E.; Nilsson, E. Life Cycle Assessment of a Smartphone. In ICT for Sustainability; Atlantis Press: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Steuer, R.E.; Choo, E. An interactive weighted Tchebycheff procedure for multiple objective programming. Math. Program. 1983, 26, 326–344. [Google Scholar] [CrossRef]

- Dächert, K.; Gorski, J.; Klamroth, K. An augmented weighted Tchebycheff method with adaptively chosen parameters for discrete bicriteria optimization problems. Comput. Oper. Res. 2012, 39, 2929–2943. [Google Scholar] [CrossRef]

| Group 1 | Group 2 | Group 3 |

|---|---|---|

| “RPA” Or “Robotic Process Automation” Or “Intelligent Process Automation” Or “Tools Process Automation” Or “Artificial Intelligence In Business Process” Or “Machine Learning In Business Process” Or “Cognitive Process Automation” | “Model” Or “Model Evaluation” Or “Tool” Or “Tool Evaluation” Or “Evaluation” Or “Framework” Or “Structure” Or “Multi-objective” or “Planning and scheduling” | “Sustainability” Or “Sustainable” Or “Social Sustainability” Or “Environment” Or “Environmental Sustainability” Or “Economic Sustainability” Or “Sustainable Development” |

| Title | OR | Keywords (KW) | OR | Abstract (AB) | ||

|---|---|---|---|---|---|---|

| Set 1 | (Group 1 AND Group 2 and Group 3) n = 0 | OR | (Group 1 AND Group 2 AND Group 3) n = 1 | OR | (Group 1 AND Group 2 AND Group 3) n = 170 | n = 171 |

| Set 2 | (Group 1 AND Group 2) n = 380 | OR | (Group 1 AND Group 2) n = 114 | OR | (Group 1 AND Group 2) n = 7626 | n = 8120 |

| Set 3 | (Group 1 AND Group 3) n = 11 | OR | (Group 1 AND Group 3) n = 17 | OR | (Group 1 AND Group 3) n = 635 | n = 663 |

| Set 1 | Set 2 | Set 3 | |

|---|---|---|---|

| Initial result: | n = (0; 1; 170) | n = (380; 114; 7626) | n = (11; 17; 635) |

| 1—Restrict to Peer-Reviewed | n = (0; 1; 125) | n = (237; 77; 5533) | n = (9; 12; 347) |

| 2—Type of fonts: Academic Journals; Conference Materials; Books | n = (0; 1; 125) | n = (237; 77; 5533) | n = (9; 12; 346) |

| 3—From 2000 to 2023 | n = (0; 1; 123) | n = (197; 69; 4799) | n = (9; 12; 337) |

| 4—Language: English | n = (0; 1; 120) | n = (191; 69; 4704) | n = (9; 12; 324) |

| 5—Restrict to Full Text | n = (0; 0; 107) | n = (164; 58; 3797) | n = (9; 11; 286) |

| Decision Support Model for Implementing RPA | Decision Support Template for Selecting RPA Tool | RPA Financing Return Assessment Model | RPA Monitoring Assessment Model | |

|---|---|---|---|---|

| [34] | X | |||

| [35] | X | |||

| [36] | X | |||

| [37] | X | |||

| [38] | X | |||

| [39] | X | |||

| [40] | X | |||

| [41] | X | |||

| [42] | X | |||

| [43] | X | |||

| [44] | X | |||

| [45] | X | |||

| [46] | X | |||

| [47] | X | |||

| [48] | X | |||

| [49] | X | |||

| [50] | X | |||

| [51] | X | |||

| [52] | X | |||

| [This work] | X | X | X | X |

| RPA Machines Cost per Day (Monetary Units) | Availability RPA Machines per Day (Min) | |

|---|---|---|

| Machine 1 | 0.7 | 480 |

| Machine 2 | 1.4 | 600 |

| Machine 3 | 2.1 | 960 |

| Machine 4 | 2.8 | 1440 |

| Weight Objective 1 | Weight Objective 2 | Weight Objective 3 |

|---|---|---|

| 0 | 0 | 1 |

| 0.1 | 0 | 0.9 |

| 0.2 | 0 | 0.8 |

| 0.3 | 0 | 0.7 |

| 0.4 | 0 | 0.6 |

| … | … | … |

| 1 | 0 | 0 |

| 0.9 | 0.1 | 0 |

| 0.8 | 0.2 | 0 |

| … | … | … |

| 0 | 1 | 0 |

| 0.1 | 0.9 | 0 |

| 0.2 | 0.8 | 0 |

| … | … | … |

| Weighted Sum | ||

|---|---|---|

| Cost | Makespan | |

| Point 1 | 2394 | 1260 |

| Point 2 | 2379 | 1218 |

| Point 3 | 2377 | 1210 |

| Point 4 | 2376 | 1205 |

| Point 5 | 2374 | 1201 |

| Point 6 | 2374 | 1199 |

| Point 7 | 2372 | 1199 |

| Point 8 | 2371 | 1195 |

| Tchebycheff | |||

|---|---|---|---|

| Cost | Makespan | Average Workload | |

| Point 1 | 2480 | 867 | 9 |

| Point 2 | 2475 | 1113 | 9 |

| Point 3 | 2451 | 1187 | 9 |

| Point 4 | 2409 | 1239 | 9 |

| Point 5 | 2407 | 1088 | 9 |

| Point 6 | 2399 | 1243 | 11 |

| Point 7 | 2398 | 1247 | 11 |

| Point 8 | 2396 | 1241 | 9 |

| Point 9 | 2388 | 1235 | 10 |

| Point 10 | 2375 | 1184 | 9 |

| Point 11 | 2374 | 1193 | 10 |

| Weighted Sum | |||||

|---|---|---|---|---|---|

| Metric | Mean | Standard Deviation | Median | Maximum | Minimum |

| Cost | 2520.3 | 95.3 | 2531.6 | 2682.4 | 2371 |

| Makespan | 904.6 | 180.7 | 822.2 | 1260.0 | 756.0 |

| Average workload | 3.8 | 4.2 | 1.0 | 11.0 | 0.0 |

| Tchebycheff | |||||

|---|---|---|---|---|---|

| Metric | Mean | Standard Deviation | Median | Maximum | Minimum |

| Cost | 2516.4 | 92.9 | 2506.4 | 2891.7 | 2374 |

| Makespan | 934.9 | 154.4 | 867.4 | 1247.4 | 758.8 |

| Average workload | 5.7 | 2.9 | 6.0 | 11.0 | 0.0 |

| Weighted Sum | |||

|---|---|---|---|

| Weight Cost | Weight Makespan | Weight Average Workload | |

| Solution 1 | 0.70 | 0.00 | 0.30 |

| Solution 2 | 0.80 | 0.10 | 0.10 |

| Solution 3 | 0.70 | 0.20 | 0.10 |

| Solution 1 | |||

|---|---|---|---|

| Activity | Total Activity | Occupancy (%) | |

| Machine 1 | (2, 4, 6, 12, 15, 17, 18, 24, 25, 26, 30, 35, 38, 40, 42, 44) | 16 | 100% |

| Machine 2 | (3, 7, 9, 10, 16, 21, 23, 28, 33, 39, 41, 43) | 12 | 100% |

| Machine 3 | (5, 11, 13, 14, 20, 22, 27, 29, 31, 34, 37) | 11 | 42% |

| Machine 4 | (1, 8, 19, 32, 36) | 5 | 12% |

| Solution 2 | |||

|---|---|---|---|

| Activity | Total Activity | Occupancy (%) | |

| Machine 1 | (1, 2, 5, 6, 7, 8, 12, 15, 17, 18, 19, 21, 22, 25, 26, 30, 32, 33, 34, 38, 39) | 21 | 100% |

| Machine 2 | (3, 4, 9, 10, 13, 16, 20, 28, 29, 35) | 10 | 100% |

| Machine 3 | (11, 14, 23, 24, 27, 31, 36, 37, 40, 41, 42, 43, 44) | 13 | 60% |

| Machine 4 | - | 0 | 0% |

| Solution 3 | |||

|---|---|---|---|

| Activity | Total Activity | Occupancy (%) | |

| Machine 1 | (2, 5, 6, 7, 8, 15, 17, 18, 19, 21, 22, 23, 25, 26, 30, 31, 32, 33, 34, 38, 39, 40) | 22 | 100% |

| Machine 2 | (1, 3, 4, 9, 11, 13, 14, 16, 24, 29, 35, 41, 44) | 13 | 100% |

| Machine 3 | (10, 12, 20, 27, 28, 36, 37, 42, 43) | 9 | 60% |

| Machine 4 | 0 | 0% | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Patrício, L.; Costa, L.; Varela, L.; Ávila, P. Sustainable Implementation of Robotic Process Automation Based on a Multi-Objective Mathematical Model. Sustainability 2023, 15, 15045. https://doi.org/10.3390/su152015045

Patrício L, Costa L, Varela L, Ávila P. Sustainable Implementation of Robotic Process Automation Based on a Multi-Objective Mathematical Model. Sustainability. 2023; 15(20):15045. https://doi.org/10.3390/su152015045

Chicago/Turabian StylePatrício, Leonel, Lino Costa, Leonilde Varela, and Paulo Ávila. 2023. "Sustainable Implementation of Robotic Process Automation Based on a Multi-Objective Mathematical Model" Sustainability 15, no. 20: 15045. https://doi.org/10.3390/su152015045

APA StylePatrício, L., Costa, L., Varela, L., & Ávila, P. (2023). Sustainable Implementation of Robotic Process Automation Based on a Multi-Objective Mathematical Model. Sustainability, 15(20), 15045. https://doi.org/10.3390/su152015045

_Li.png)