The Design and Experimental Study of a Double-Column Scrambler Wind–Sand Separator for Sustainable Soil Wind Erosion Monitoring

Abstract

:1. Introduction

2. Materials and Methods

2.1. Structural Design and Speed Reduction Principle

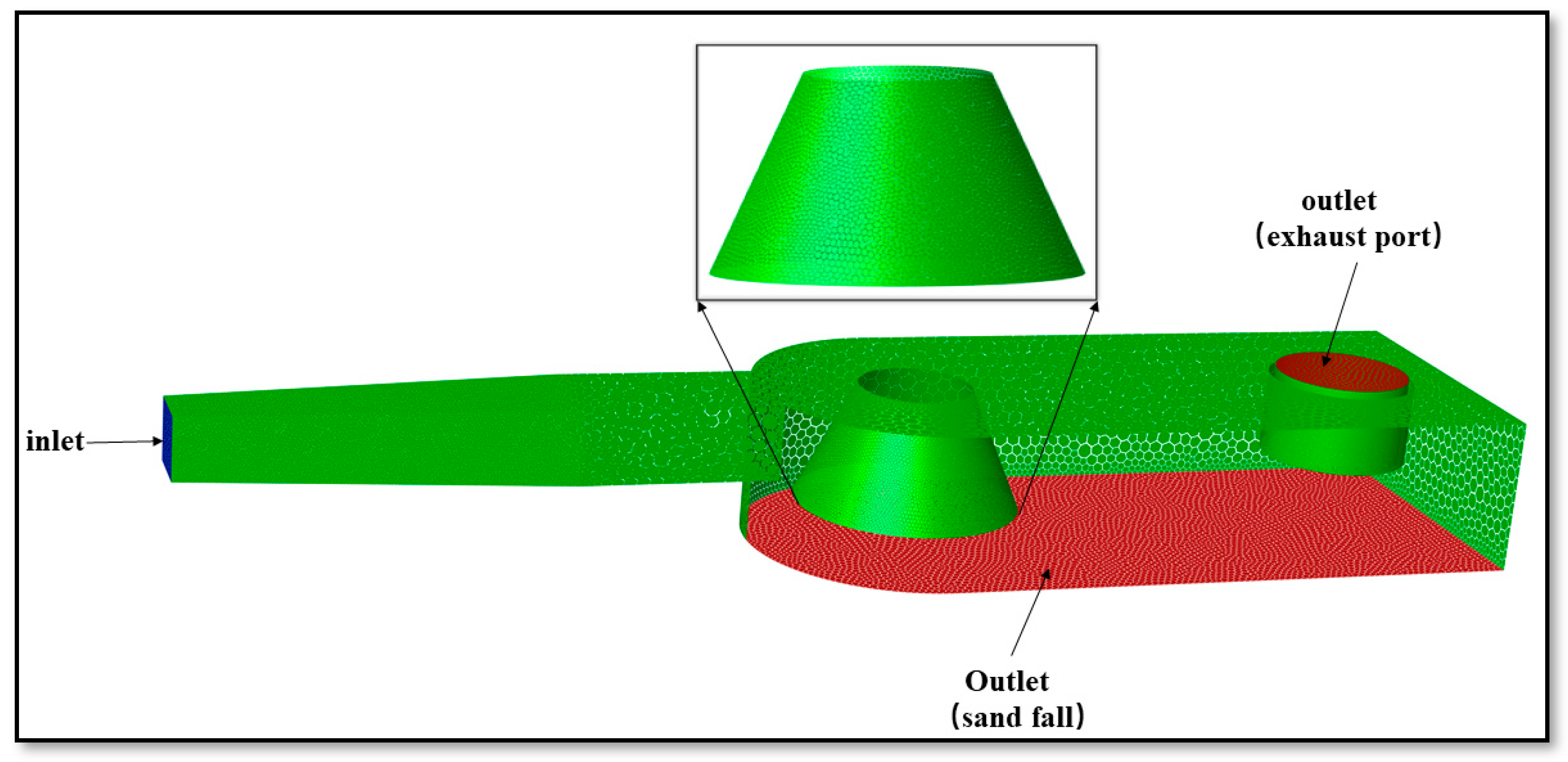

2.2. Computational Fluid Dynamics (CFD) Simulation

2.3. TCSS Separator Testing

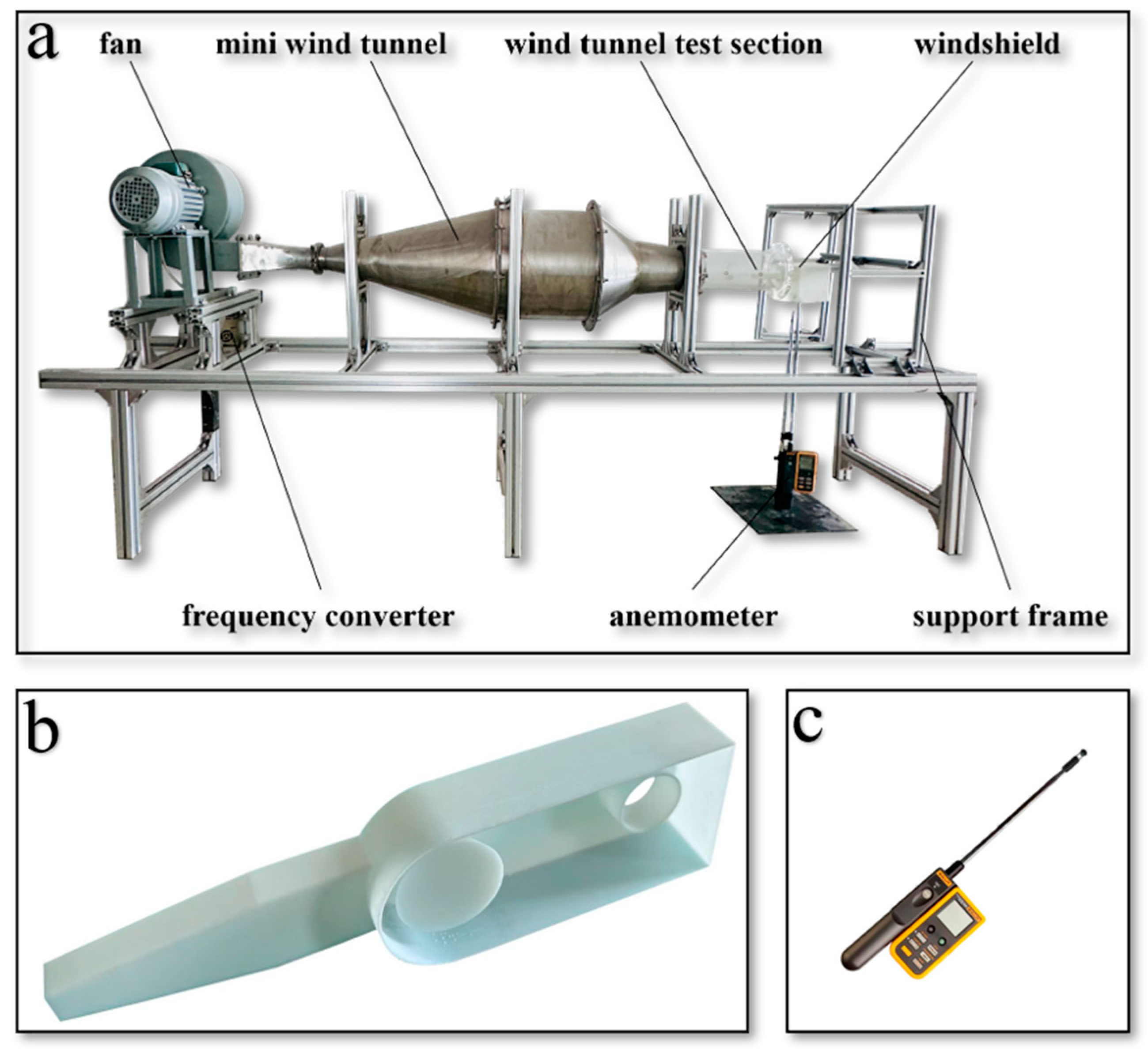

2.3.1. Experimental Test Equipment

2.3.2. Speed Reduction Performance Test

2.3.3. Wind–Sand Separation Efficiency Test

3. Results

3.1. Determination of Key Parameters for Wind–Sand Separators

- (1)

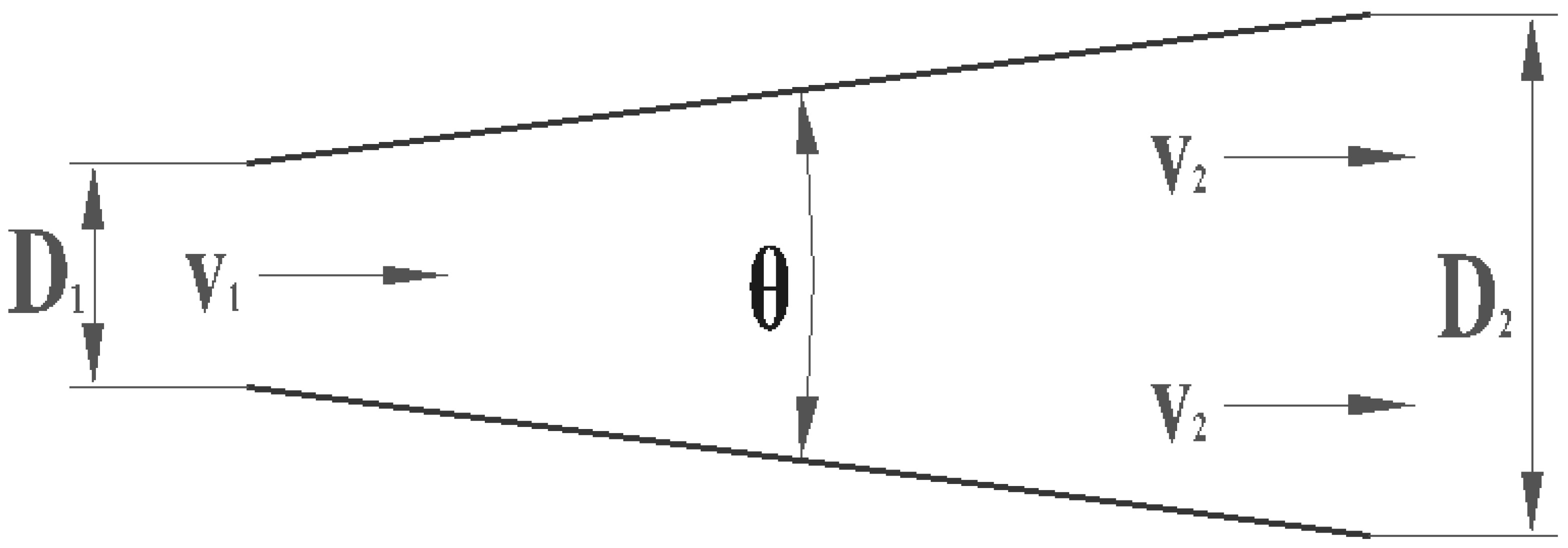

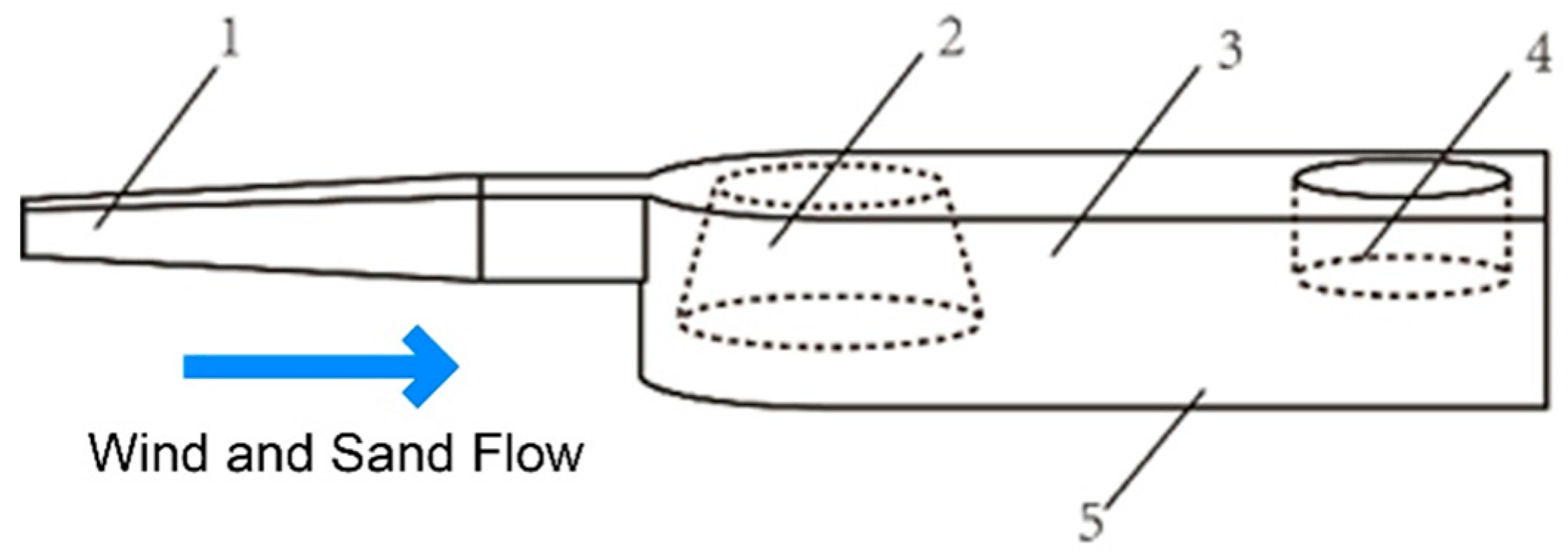

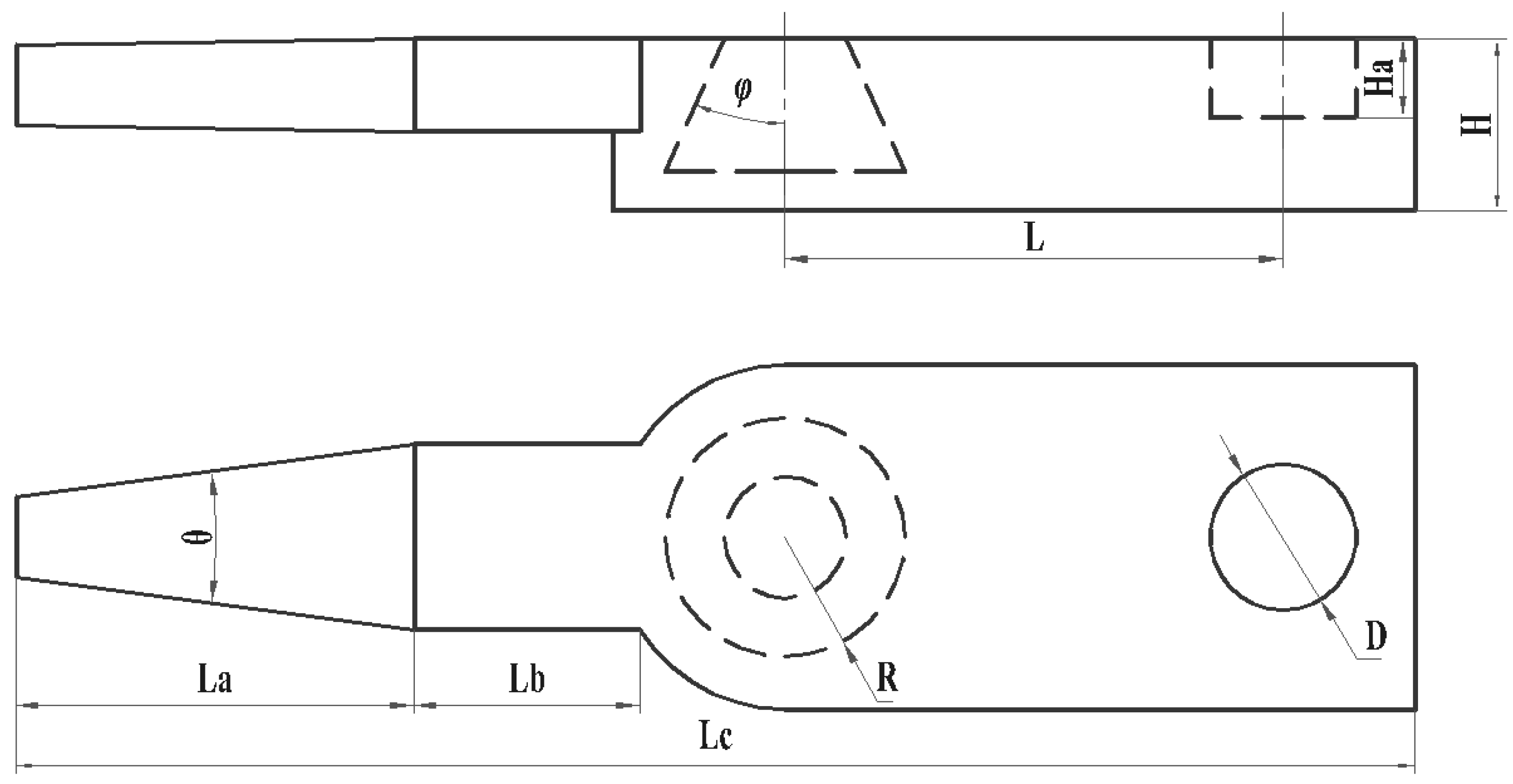

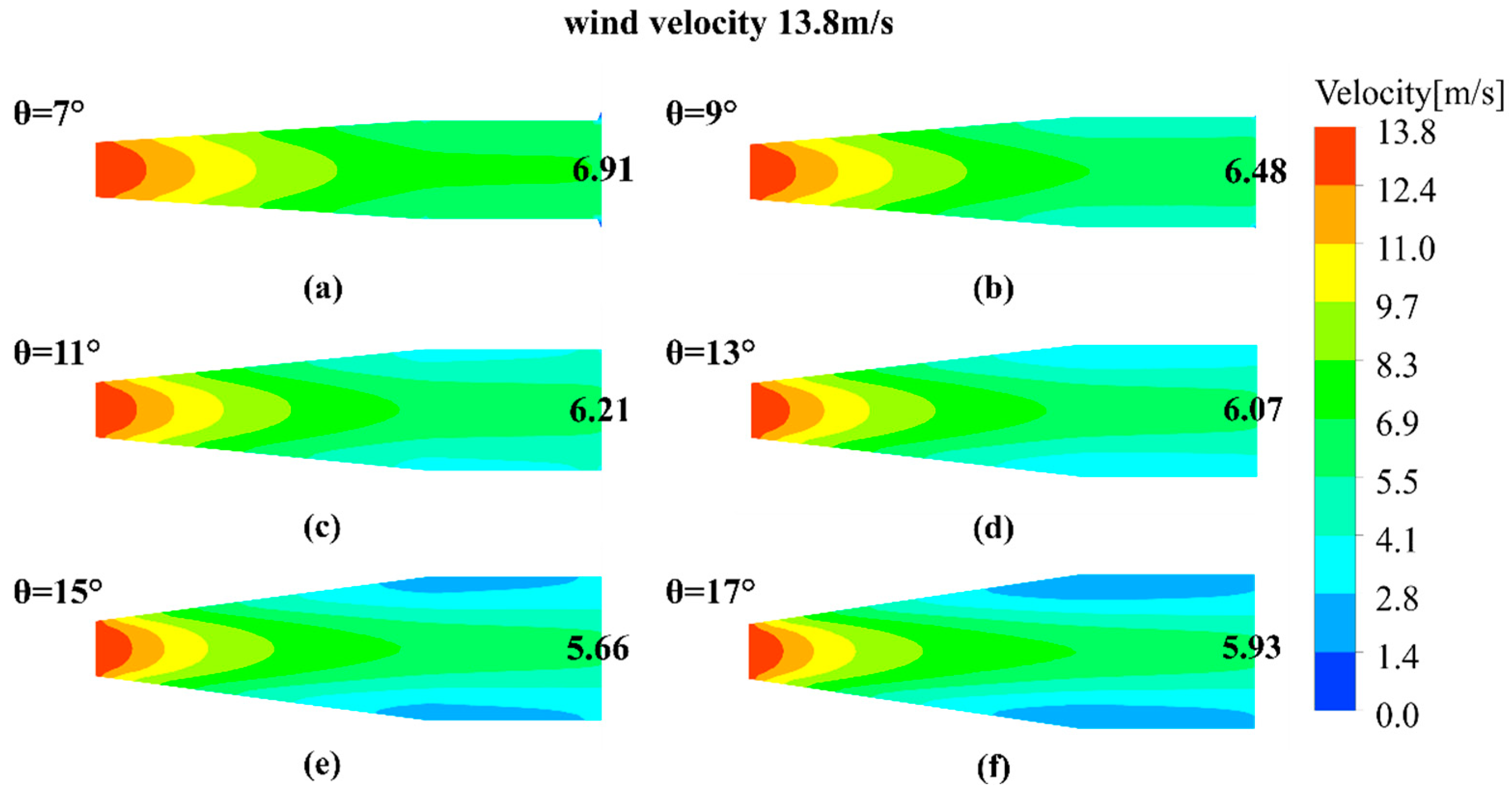

- Setting the inlet pipe’s expansion angle (θ) at 15° (Figure 8) increased the boundary layer thickness, significantly reducing the mainstream airflow velocity (from 13.8 m s−1 to 5.66 m s−1). The expansion section’s length (La) was established at 60 mm, and the horizontal channel’s length (Lb) was fixed at 35 mm (Figure 9). These measures were taken to prevent the blockage of the inlet airflow by the sand collector’s shell and to ensure isodynamic requirements.

- (2)

- Setting the cone angle (φ) and its bottom radius (R) at φ = 25° and R = 18 mm (Figure 10) effectively slowed down the airflow’s speed and reduced the impact on the bottom caused by the slanting column’s end.

- (3)

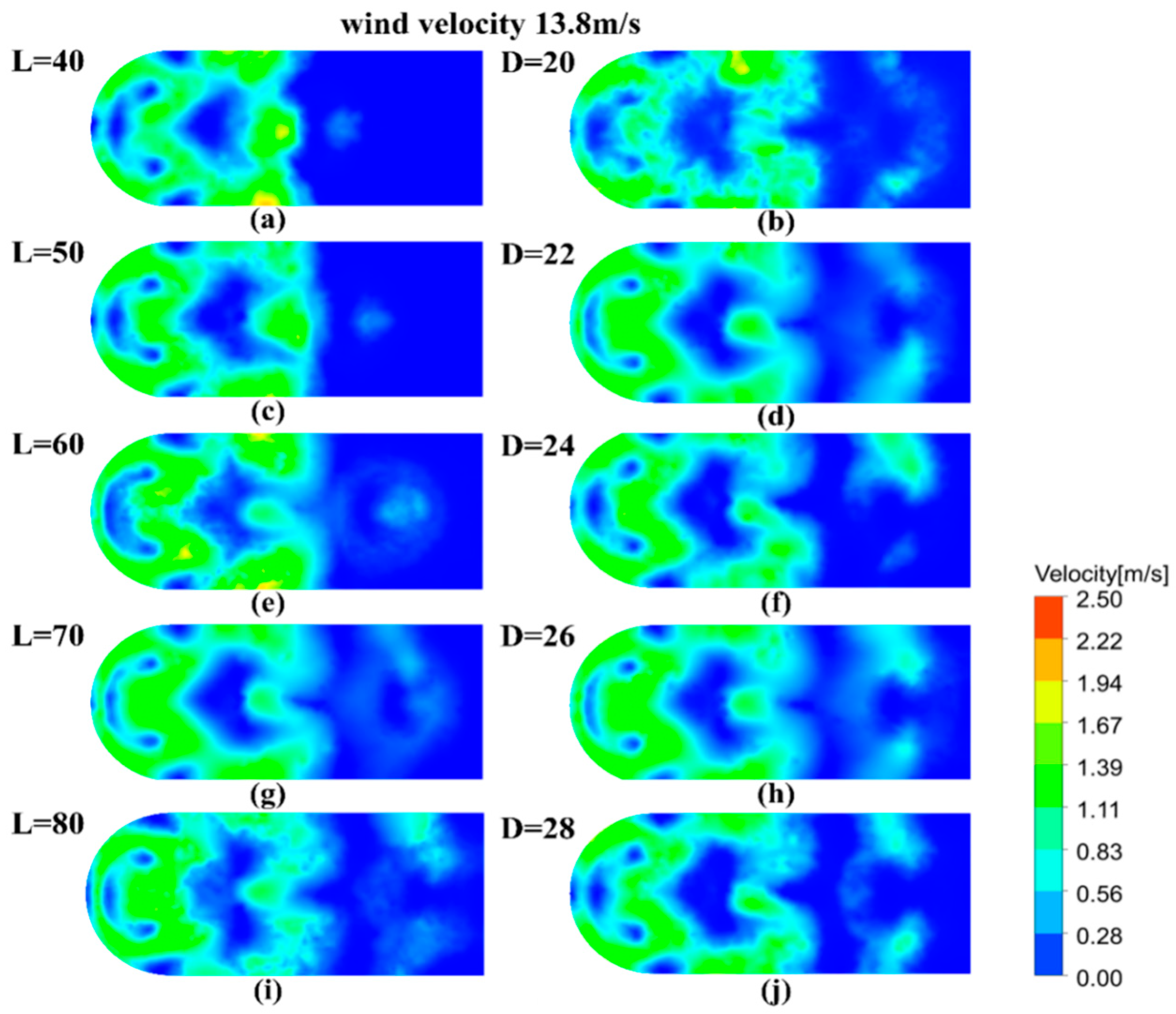

- Finalizing the values of double-column spacing (L) and exhaust pipe diameter (D) at L = 75 mm and D = 22 mm (Figure 11) ensured a smoother airflow inside the separator and prevented the formation of Carmen vortex steps on the column’s surface.

3.2. CFD Simulation Analysis of Wind–Sand Separator

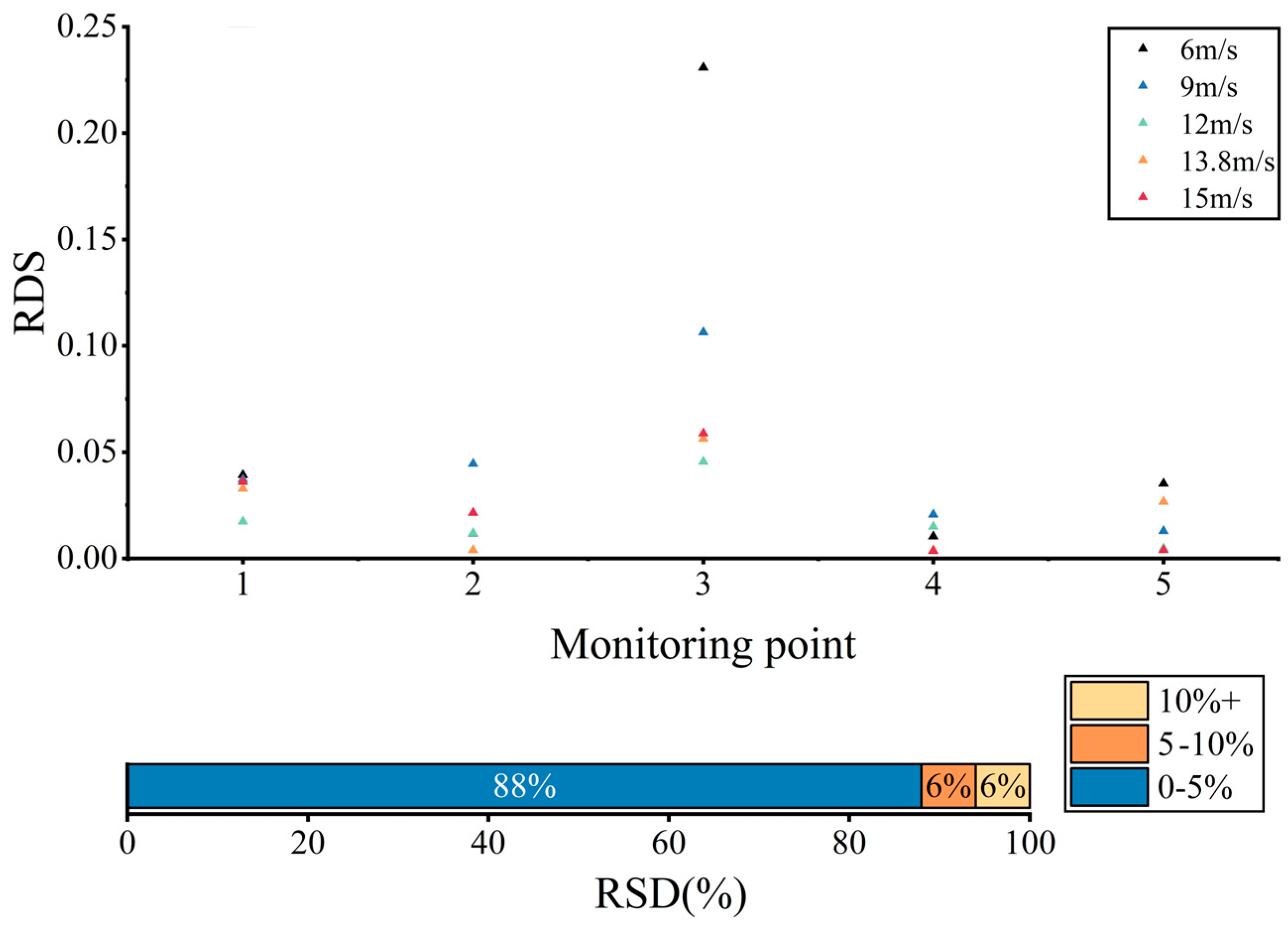

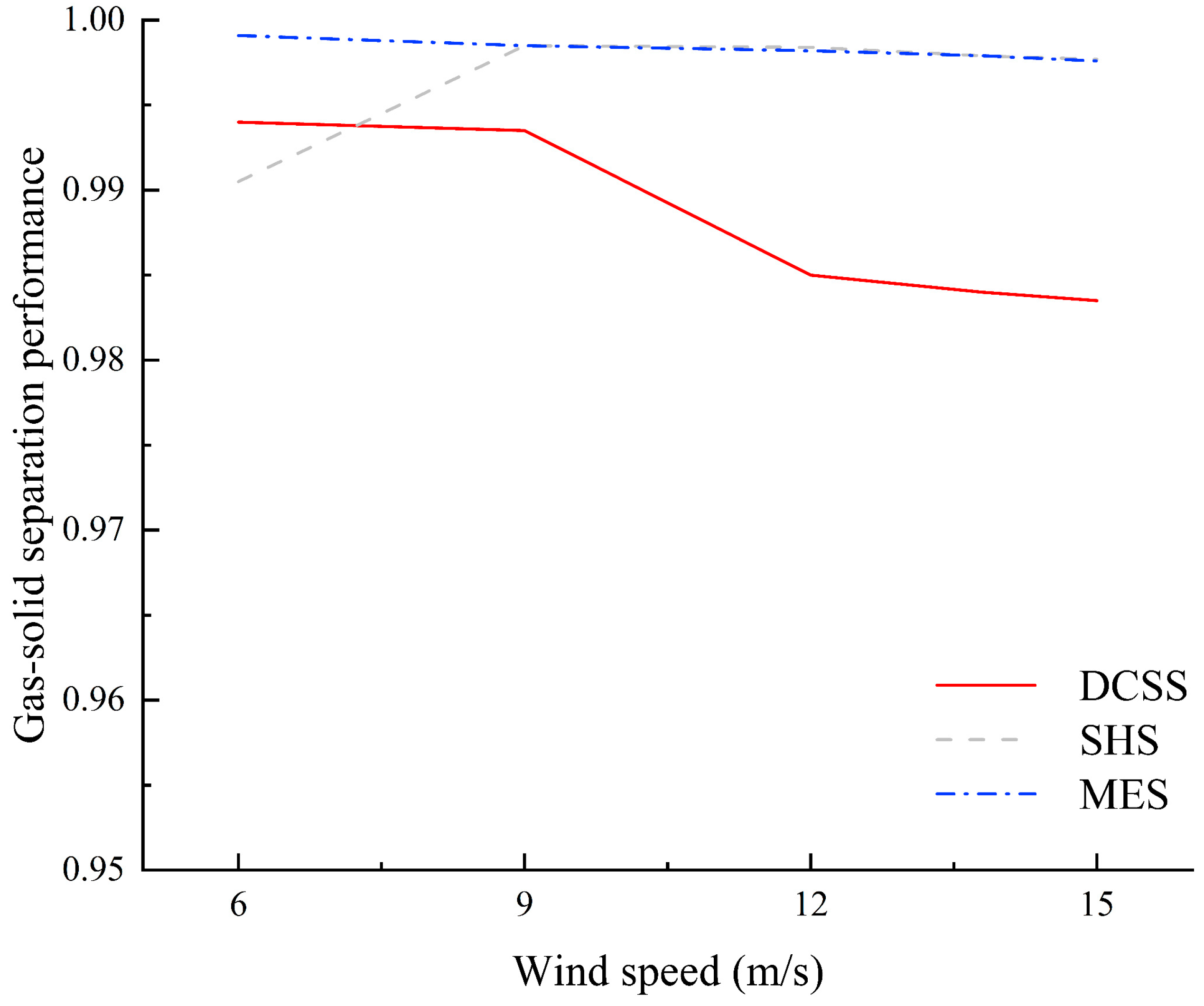

3.3. TCSS Separator Test

3.3.1. Separator Exhaust and Sandfall Wind Velocity

3.3.2. Separator Exhaust and Sandfall Wind Velocity

4. Discussion

- (1)

- Influence of Intake Duct Structural Parameters (θ, La, and Lb)

- (2)

- Influence of the structural parameters of the truncated cone (φ and R)

- (3)

- Influence of exhaust pipe structural parameters (L and D)

5. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bullard, J.E.; Zhou, Z.; Davis, S.; Fowler, S. Technology. Breakdown and modification of microplastic beads by aeolian abrasion. Environ. Sci. Technol. 2022, 57, 76–84. [Google Scholar] [PubMed]

- Giambastiani, Y.; Giusti, R.; Gardin, L.; Cecchi, S.; Iannuccilli, M.; Romanelli, S.; Bottai, L.; Ortolani, A.; Gozzini, B. Assessing Soil Erosion by Monitoring Hilly Lakes Silting. Sustainability 2022, 14, 5649. [Google Scholar]

- Zhi, C.; Shuoshi, M.; Yonglai, Z.; Yuechao, S.; Hongmei, C. Characteristics of drifting sand flux over conservation tillage fiel. Trans. Chin. Soc. Agric. Eng. 2010, 26, 118–122. [Google Scholar]

- Goossens, D.; Offer, Z.; London, G. Wind tunnel and field calibration of five aeolian sand traps. Geomorphology 2000, 35, 233–252. [Google Scholar]

- An, M.; Li, S.; Liu, Z.; Yan, B.; Li, L.; Chen, Z. Galloping vibration of stay cable installed with a rectangular lamp: Field observations and wind tunnel tests. J. Wind. Eng. Ind. Aerodyn. 2021, 215, 104685. [Google Scholar]

- Shannak, B.; Corsmeier, U.; Kottmeier, C.; Al-Azab, T. Wind tunnel study of twelve dust samples by large particle size. Atmos. Environ. 2014, 98, 442–453. [Google Scholar] [CrossRef]

- Mendez, M.J.; Funk, R.; Buschiazzo, D.E. Field wind erosion measurements with big spring number eight (BSNE) and modified wilson and cook (MWAC) samplers. Geomorphology 2011, 129, 43–48. [Google Scholar]

- Fryrear, D.W. A field dust sampler. J. Soil Water Conserv. 1986, 41, 117–120. [Google Scholar]

- Dong, M.; Zhao, S.; Fan, G.; Zhao, M.; Tu, Y. Experimental study on the performance of the whirling separation sand sampler. J. Agric. Mech. Res. 2012, 6, 139–140,222. [Google Scholar]

- Sherman, D.; Swann, C.; Barron, J. A high-efficiency, low-cost aeolian sand trap. Aeolian Res. 2014, 13, 31–34. [Google Scholar] [CrossRef]

- Liu, X.; Kang, Y.; Chen, H.; Lu, H. Application of a High-Precision Aeolian Sand Collector in Field Wind and Sand Surveys. Int. J. Environ. Res. Public Health 2021, 18, 7393. [Google Scholar] [CrossRef] [PubMed]

- Song, T.; Chen, Z.; Ma, Q.; Si, Z.; Liu, H.; Xuan, C. Design and Performance Experiment of Shunt-hedging Sand Sampler. Trans. Chin. Soc. Agric. Eng. 2015, 46, 173–177. [Google Scholar]

- Mingde, S.; Qinjun, K. Large eddy simulation of the turbulent flow around a circular cylinder at subcritical Reynolds number. Chin. J. Theor. Appl. Mech. 1999, 31, 100–105. [Google Scholar]

- Baoling, F.; Tinghui, Z.; Junliu, Y. Numerical simulation of flow over two tandem cylinders. J. Southwest Minzu Univ. 2007, 33, 376–380. [Google Scholar]

- Wu, Y.; Ken, H.; Xia, J. Port & Waterway Engineering. Port Waterw. Eng. 2017, 2, 19–26+56. [Google Scholar]

- Chen, W.; Ji, C.; Alam, M.M.; Yan, Y. Three-dimensional flow past two stationary side-by-side circular cylinders. Ocean Eng. 2022, 244, 110379. [Google Scholar] [CrossRef]

- Masataka, S.; Masahiro, S.; Shoichi, W. Structure of Karman vortex shedding from a yawed cylinder in a uniform flow. Trans. Jpn. Soc. Mech. Eng. Ser. B 1986, 52, 3152–3158. [Google Scholar]

- Cheeseman, I.C. Fluid-Dynamic Drag: Practical Information on Aerodynamic Drag and Hydrodynamic Resistance. SF Hoerner. Hoerner Fluid Dynamics, Brick Town, New Jersey. 1965. 455 pp. Illustrated. $24.20. Aeronaut. J. 1976, 80, 371. [Google Scholar] [CrossRef]

- Urbanowicz, K. Fast and accurate modelling of frictional transient pipe flow. ZAMM-J. Appl. Math. Mech. Z. Für Angew. Math. Und Mech. 2018, 98, 802–823. [Google Scholar] [CrossRef]

- Ziganshin, A.; Logachev, K.; Batrova, K. Environment. Reducing the drag of midpoint lateral orifices of exhaust air ducts by shaping them along vortex zone outlines. J. Affect. Disord. 2021, 188, 107491. [Google Scholar]

- Dou, Y.; He, X. Calculation method for hydraulic resistance of pipe. J. Hydraul. Eng. 1995, 7, 28–31+22. [Google Scholar]

- Choudhury, D. Introduction to the Renormalization Group Method and Turbulence Modeling. In Technical Memorandum TM-107; Fluent Inc.: Lebanon, NH, USA, 1993. [Google Scholar]

- Zhan, X.; He, Y.; Sun, Z.; Shen, B.; Li, X. Technology. Mixing Characteristics of High-Viscosity Fluids under Forced Vertical Vibration. Chem. Eng. Technol. 2020, 43, 1327–1335. [Google Scholar] [CrossRef]

- Guo, Z.; Yang, X.; Wu, X.; Zou, X.; Zhang, C.; Fang, H.; Xiang, H.J.A.; Meteorology, F. Optimal design for vegetative windbreaks using 3D numerical simulations. Agric. For. Meteorol. 2021, 298, 108290. [Google Scholar] [CrossRef]

- Qiang, L.; Jue, D.; Weng, P. Aerodynamic and Structural Design of Low-Velocity and Low-Turbulence Wind Tunnel. J. Shanghai Univ. Nat. Sci. Ed. 2007, 13, 203–207. [Google Scholar]

- Haiyang, L.; Lili, K.; Zhi, C.; Chuanzhong, X.; Tao, S.; Zhimin, S. Design and Experiment of Portable Mini Low—Speed Wind Tunnel. J. Agric. Mech. Res. 2016, 38, 244–249. [Google Scholar]

- Viana, J.R.; Macêdo, A.A.M.; Santos, A.O.d.; Façanha Filho, P.d.F.; Graça, M.P.F.; Silva, C.C.d. Análise comparativa da síntese de hidroxiapatita via estado sólido. Matéria 2020, 25, e-12588. [Google Scholar] [CrossRef]

- Hao, B.; Tong, X.; Chen, Z.; Liu, H. Calibration of simulation parameters for wind erosion gas-solid two-phase flow in arid and semiarid soils. Rev. Bras. Eng. Agrícola E Ambient. 2022, 26, 564–570. [Google Scholar] [CrossRef]

| Items | Turbulence Model | Discretization Method | Under-Relaxation Factor | Solution Algorithm | Residual Convergence Value |

|---|---|---|---|---|---|

| Calculation setup | First-Order Upwind | default | SIMPLE | 0.0001 |

| No. | Double-Column Area Face Grid Size (mm) | Import and Export Face Grid Size (mm) | Geometry Mesh Size (mm) | Average Rate | Number of Grids |

|---|---|---|---|---|---|

| Group 1 | 0.5 | 0.8 | 2 | 1.2 | 1.3 × 106 |

| Group 2 | 0.8 | 1.2 | 2 | 1.2 | 7.55 × 105 |

| Group 3 | 1.2 | 1.8 | 2 | 1.2 | 3.89 × 105 |

kg m−3 | m s−1 | m | Dynamic Viscosity (μ) | ||

|---|---|---|---|---|---|

| 1.205 | 13.8 | 5.43% |

| Soil Particle Size (mm) | Soil Percentage (%) |

|---|---|

| <0.25 | 52.96 |

| 0.25~0.5 | 18.56 |

| 0.5~1 | 8.53 |

| 1~2 | 2.83 |

| >2 | 16.93 |

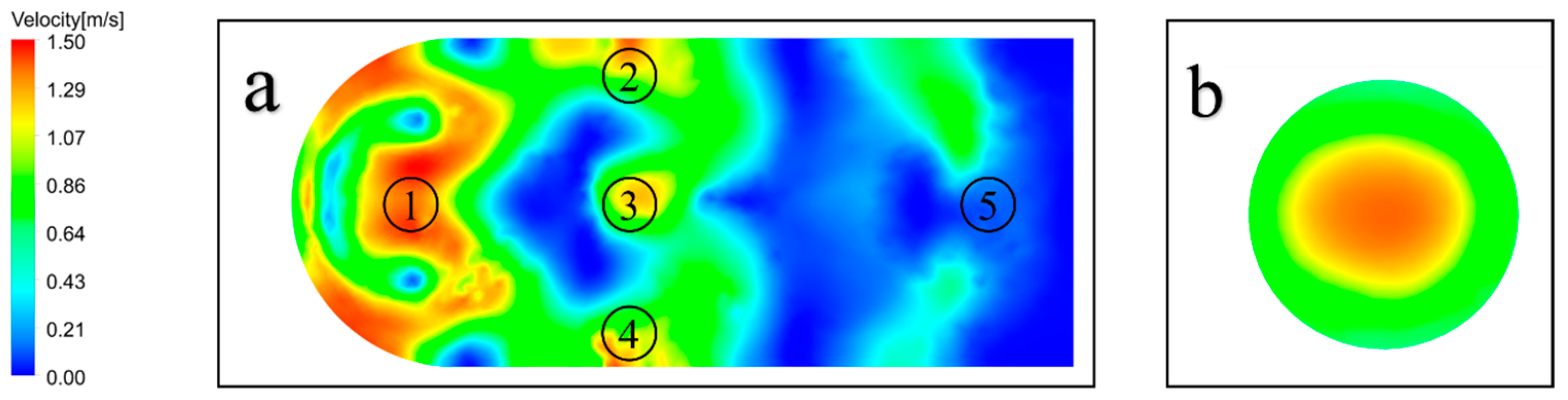

| Items | Area 1 | Area 2 | Area 3 | Area 4 | Area 5 |

|---|---|---|---|---|---|

| Mean wind speed (m s−1) | 1.18 | 1.15 | 0.47 | 1.29 | 1.28 |

| Item | Test Wind Speed (m s−1) | Maximum Air Outlet Wind Speed (m s−1) | Mean Air Outlet Wind Speed (m s−1) | Maximum Sand Outlet Wind Speed (m s−1) | Mean Sand Outlet Wind Speed (m s−1) |

|---|---|---|---|---|---|

| Wind–sand separator | 6 | 0.36 | 0.22 | 0.63 | 0.43 |

| 9 | 0.7 | 0.44 | 0.97 | 0.31 | |

| 12 | 0.76 | 0.54 | 1.26 | 0.48 | |

| 13.8 | 1.03 | 0.66 | 1.34 | 0.59 | |

| 15 | 1.09 | 0.71 | 1.59 | 0.71 |

| Item | Test Number | Test Wind Speed (m s−1) | |||

|---|---|---|---|---|---|

| 6 | 9 | 12 | 15 | ||

| Wind–sand separator | 1 | 19.88 | 19.9 | 19.7 | 19.68 |

| 2 | 19.86 | 19.85 | 19.72 | 19.63 | |

| 3 | 19.89 | 19.87 | 19.69 | 19.7 | |

| Mean | 19.88 | 19.87 | 19.7 | 19.67 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cai, X.; Hao, B.; Liu, H.; Tong, X.; Guo, M.; Hou, Z. The Design and Experimental Study of a Double-Column Scrambler Wind–Sand Separator for Sustainable Soil Wind Erosion Monitoring. Sustainability 2023, 15, 15090. https://doi.org/10.3390/su152015090

Cai X, Hao B, Liu H, Tong X, Guo M, Hou Z. The Design and Experimental Study of a Double-Column Scrambler Wind–Sand Separator for Sustainable Soil Wind Erosion Monitoring. Sustainability. 2023; 15(20):15090. https://doi.org/10.3390/su152015090

Chicago/Turabian StyleCai, Xuyang, Baoer Hao, Haiyang Liu, Xin Tong, Mengjun Guo, and Zhanfeng Hou. 2023. "The Design and Experimental Study of a Double-Column Scrambler Wind–Sand Separator for Sustainable Soil Wind Erosion Monitoring" Sustainability 15, no. 20: 15090. https://doi.org/10.3390/su152015090

APA StyleCai, X., Hao, B., Liu, H., Tong, X., Guo, M., & Hou, Z. (2023). The Design and Experimental Study of a Double-Column Scrambler Wind–Sand Separator for Sustainable Soil Wind Erosion Monitoring. Sustainability, 15(20), 15090. https://doi.org/10.3390/su152015090