The Use and Recycling of Agricultural Plastic Mulch in China: A Review

Abstract

:1. Introduction

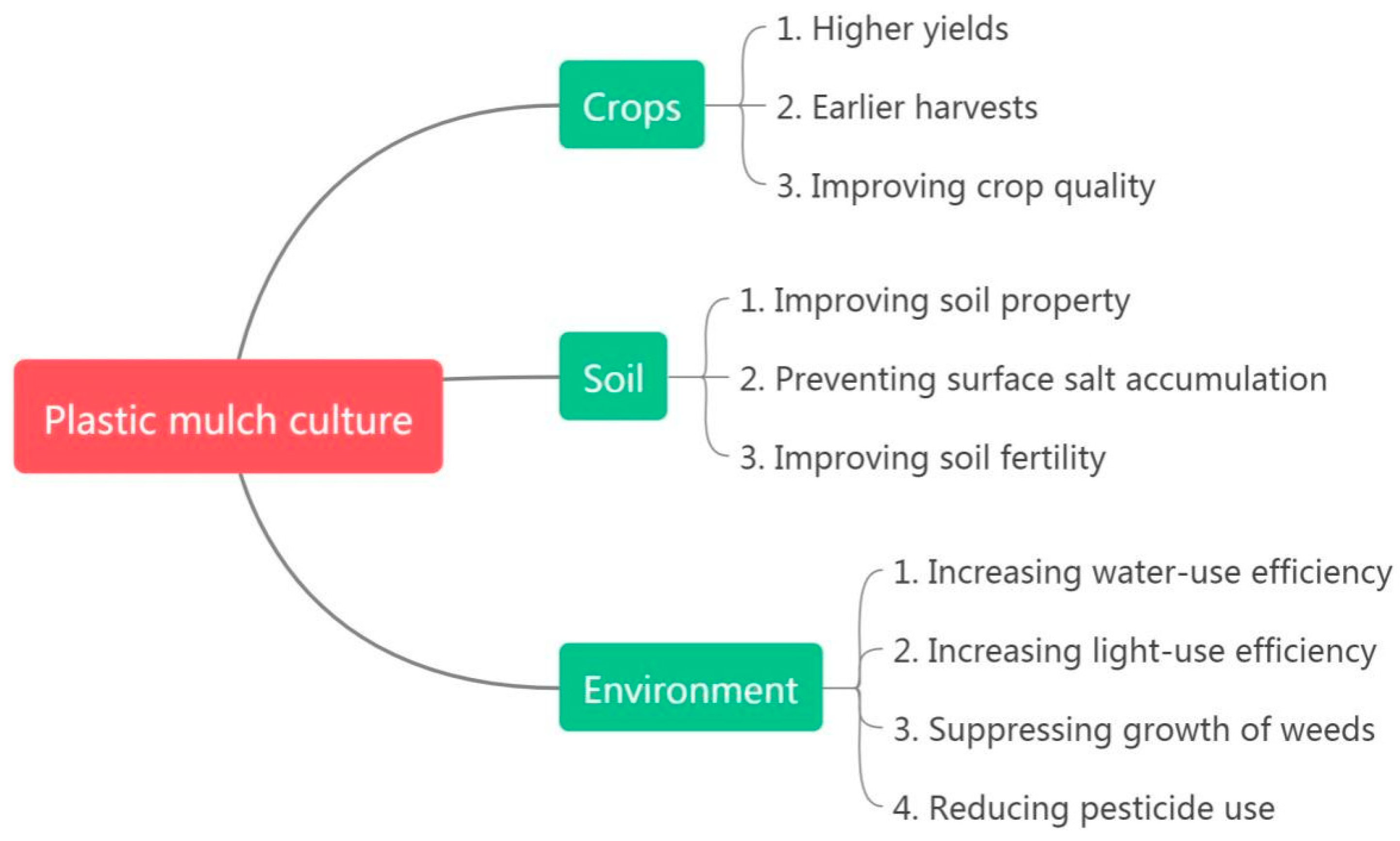

2. The Advantages and Classification of Agricultural Plastic Mulch

3. The Current Situation Regarding the Use of Agricultural Plastic Mulch in China

3.1. The Area Covered by Plastic Mulch

3.2. The Consumption of Agricultural Plastic Mulch

4. The Practice of Agricultural Mulch Film Recycling and Reuse in China

4.1. Early Practice of Recycling and Reuse of Agricultural Plastic Mulch

- Preliminary study on the residual amount of plastic mulch in farmland and its impact on soil and crops

- Attempts to manually remove residual plastic mulch from farmland

- Development of a plastic mulch lifter

- Exploration and research on degradable agricultural film mulch film

- Research and formulation of relevant standards for agricultural plastic mulch

4.2. Current Practice of Recycling and Reuse of Agricultural Plastic Mulch

- Determination of the residual quantity of plastic mulch in China

- Further improvement of laws, regulations, and standards related to plastic mulch

- Vigorous promotion of mechanized recycling of plastic mulch

- Strengthen the research and promotion of biodegradable plastic mulch

- New breakthrough in recycling and utilizing waste farmland plastic mulch

5. Discussion

- Strictly supervise and manage the production, sales, and use of high-strength plastic mulch

- Comprehensively promote the mechanized recycling of farmland waste plastic mulch

- Explore new strategies and future directions for the reuse of waste plastic mulch

- Continuously promote the research and application of biodegradable mulching film

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Smith, E.; Bilec, M.M.; Khanna, V. Evaluating the Global Plastic Waste Management System with Markov Chain Material Flow Analysis. ACS Sustain. Chem. Eng. 2023, 11, 2055–2065. [Google Scholar] [CrossRef] [PubMed]

- Almadhi, A.; Abdelhadi, A.; Alyamani, R. Moving from Linear to Circular Economy in Saudi Arabia: Life-Cycle Assessment on Plastic Waste Management. Sustainability 2023, 15, 10450. [Google Scholar]

- Abrha, H.; Cabrera, J.; Dai, Y.; Irfan, M.; Toma, A.; Jiao, S.; Liu, X. Bio-Based Plastics Production, Impact and End of Life: A Literature Review and Content Analysis. Sustainability 2022, 14, 4855. [Google Scholar]

- Tulatz, F.; Gabrielsen, G.W.; Bourgeon, S.; Herzke, D.; Krapp, R.; Langset, M.; Neumann, S.; Lippold, A.; Collard, F. Implications of regurgitative feeding on plastic loads in northern fulmars (Fulmarus glacialis): A study from svalbard. Environ. Sci. Technol. 2023, 57, 3562–3570. [Google Scholar]

- Thiemann, T. Microplastic in the marine environment of the indian ocean. J. Environ. Prot. 2023, 14, 297–359. [Google Scholar]

- Zhu, X.; Rochman, C. Emissions inventories of plastic pollution: A critical foundation of an international agreement to inform targets and quantify progress. Environ. Sci. Technol. 2022, 56, 3309–3312. [Google Scholar] [CrossRef]

- Ding, F.; Jones, D.L.; Chadwick, D.R.; Kim, P.J.; Jiang, R.; Flury, M. Environmental impacts of agricultural plastic film mulch: Fate, consequences, and solutions. Sci. Total Environ. 2022, 836, 155668. [Google Scholar]

- Kasirajan, S.; Ngouajio, M. Polyethylene and biodegradable mulches for agricultural applications: A review. Agron. Sustain. Dev. 2012, 32, 501–529. [Google Scholar]

- Braunack, M.V.; Johnston, D.B.; Price, J.; Gauthier, E. Soil temperature and soil water potential under thin oxodegradable plastic film impact on cotton crop establishment and yield. Field Crops Res. 2015, 184, 91–103. [Google Scholar]

- Ding, D.; Wang, N.; Zhang, X.; Zou, Y.; Zhao, Y.; Xu, Z.; Chu, X.; Liu, J.; Bai, Y.; Feng, S.; et al. Quantifying the interaction of water and radiation use efficiency under plastic film mulch in winter wheat. Sci. Total Environ. 2021, 794, 148704. [Google Scholar]

- Snyder, K.; Grant, A.; Murray, C.; Wolff, B. The effects of plastic mulch systems on soil temperature and moisture in central ontario. Horttechnology 2015, 25, 162–170. [Google Scholar] [CrossRef]

- Bhatta, M.; Shrestha, B.; Devkota, A.R.; Joshi, K.R.; Dhakal, U. Effect of plastic mulches on growth and yield of potato (Solanum tuberosum L.) in dadeldhura, nepal. J. Agric. Nat. Resour. 2020, 3, 2661–6289. [Google Scholar] [CrossRef]

- Zhang, R.; Lei, T.; Wang, Y.; Xu, J.; Zhang, P.; Han, Y.; Hu, C.; Yang, X.; Sadras, V.; Zhang, S. Responses of yield and water use efficiency to the interaction between water supply and plastic film mulch in winter wheat-summer fallow system. Agric. Water Manag. 2022, 266, 107545. [Google Scholar]

- Madrid, B.; Wortman, S.; Hayes, D.G.; DeBruyn, J.M.; Miles, C.; Flury, M.; Marsh, T.L.; Galinato, S.P.; Englund, K.; Agehara, S.; et al. End-of-Life Management Options for Agricultural Mulch Films in the United States—A Review. Front. Sustain. Food Syst. 2022, 6, 921496. [Google Scholar]

- Clarkson, V.A. Effect of Black Polyethylene Mulch on Soil and Microclimate Temperature and Nitrate Level. Agron. J. 1960, 52, 307. [Google Scholar] [CrossRef]

- Free, G.R.; Bay, C. Effects of Plastic Mulch on the Growth, Maturity, and Yields of Corn. Soil Sci. Soc. Am. J. 1965, 29, 461–464. [Google Scholar] [CrossRef]

- Bennett, O.L.; Ashley, D.A.; Doss, B.D. Cotton responses to black plastic mulch and irrigation. Agron. J. 1966, 58, 57–60. [Google Scholar] [CrossRef]

- Noguchi, K.; Akimoto, Y.; Yamanaka, H.; Kitamura, T. Studies on Cover-Culture of Tobacco: 5. Effects of plastic film mulch on tobacco in the early stages of growth. Jpn. J. Crop Sci. 1968, 37, 359–365. [Google Scholar]

- Ingman, M.; Santelmann, M.V.; Tilt, B. Agricultural water conservation in china: Plastic mulch and traditional irrigation. Ecosyst. Health Sustain. 2015, 1, 12. [Google Scholar]

- Zhang, M.; Song, D.; Pu, X.; Dang, P.; Qin, X.; Siddique, K.H.M. Effect of different straw returning measures on resource use efficiency and spring maize yield under a plastic film mulch system. Eur. J. Agron. 2022, 134, 126461. [Google Scholar]

- Santosh, D.T.; Tiwari, K.N.; Sagar, M. Influence of different levels of irrigation and black plastic mulch on the performance of banana under drip irrigation. Crop Res. 2022, 57, 202–210. [Google Scholar]

- Pathak, S.V.; Rangbhal, A.V.; Shahare, P.U.; Bagde, C.S.; More, S.S. Performance evaluation of manually operated mulch laying machine on different soil conditions. NASS J. Agric. Sci. 2023, 5, 11. [Google Scholar] [CrossRef]

- Boyle, S.M.; Alford, A.M.; McIntyre, K.C.; Weber, D.C.; Kuhar, T.P. Effect of Plastic Mulch Colors on Anasa tristis (Hemiptera: Coreidae) Population Dynamics in Summer Squash, Cucurbita pepo (Cucurbitales: Cucurbitaceae). J. Econ. Entomol. 2022, 115, 808–813. [Google Scholar] [CrossRef] [PubMed]

- DeVetter, L.W.; Goldberger, J.R.; Miles, C.; Gomez, J. Grower acceptance of new end-of-life management strategies for plastic mulch in strawberry systems. Acta Hortic. 2021, 1309, 659–662. [Google Scholar] [CrossRef]

- Lee, J.G.; Chae, H.G.; Hwang, H.Y.; Kim, P.J.; Cho, S.R. Effect of plastic film mulching on maize productivity and nitrogen use efficiency under organic farming in south korea. Sci. Total Environ. 2021, 787, 147503. [Google Scholar]

- Adhikari, R.; Bristow, K.L.; Casey, P.S.; Freischmidt, G.; Hornbuckle, J.W.; Adhikari, B. Preformed and sprayable polymeric mulch film to improve agricultural water use efficiency. Agric. Water Manag. 2016, 169, 1–13. [Google Scholar]

- Touchaleaume, F.; Martin-Closas, L.; Angellier-Coussy, H.; Chevillard, A.; Cesar, G.; Gontard, N.; Gastaldi, E. Performance and environmental impact of biodegradable polymers as agricultural mulching films. Chemosphere 2016, 144, 433–439. [Google Scholar]

- Anikwe, M.A.N.; Mbah, C.N.; Ezeaku, P.I.; Onyia, V.N. Tillage and plastic mulch effects on soil properties and growth and yield of cocoyam (Colocasia esculenta) on an ultisol in southeastern nigeria. Soil Tillage Res. 2007, 93, 264–272. [Google Scholar] [CrossRef]

- Tarricone, L.; Gentilesco, G.; Di Gennaro, D.; Amendolagine, A.M.; Vox, G.; Mugnozza, G.S.; Schettini, E.; de Palma, L. Radiometric properties, vine physiology and yield parameters of irrigated ‘sublima’ table grape under different plastic films in south italy. Acta Hortic. 2017, 1170, 365–372. [Google Scholar] [CrossRef]

- Wees, D.; Seguin, P.; Josée, B. Sweet potato production in a short-season area utilizing black plastic mulch: Effects of cultivar, in-row plant spacing, and harvest date on yield parameters. Can. J. Plant Sci. 2016, 96, 139–147. [Google Scholar]

- Muoz, K.; Sren, T.B.; Kenngott, K.G.J.; Meyer, M.; Diehl, D.; Steinmetz, Z.; Schaumann, G.E. Effects of Plastic versus Straw Mulching Systems on Soil Microbial Community Structure and Enzymes in Strawberry Cultivation. Soil Syst. 2022, 6, 21. [Google Scholar]

- Hu, Q.; Li, X.Y.; Shi, H.B.; Chen, N.; Zhang, Y.H. Residual plastic film exerts dual effects of blocking and preferential flow on soil water movement. Soil Tillage Res. 2023, 227, 105628. [Google Scholar]

- Steinmetz, Z.; Wollmann, C.; Schaefer, M.; Buchmann, C.; David, J.; Tröger, J.; Muñoz, K.; Frör, O.; Schaumann, G.E. Plastic Mulching in Agriculture. Trading Short-Term Agronomic Benefits for Long-Term Soil Degradation? Sci. Total Environ. 2016, 550, 690–705. [Google Scholar] [PubMed]

- Van Schothorst, B.; Beriot, N.; Huerta Lwanga, E.; Geissen, V. Sources of Light Density Microplastic Related to Two Agricultural Practices: The Use of Compost and Plastic Mulch. Environments 2021, 8, 36. [Google Scholar]

- Büks, F.; Kaupenjohann, M. Global concentrations of microplastics in soils: A review. Soil 2020, 6, 649–662. [Google Scholar]

- Uzamurera, A.G.; Wang, P.Y.; Zhao, Z.Y.; Tao, X.P.; Zhou, R.; Wang, W.Y.; Xiong, X.B.; Wang, S.; Wesly, K.; Tao, H.Y.; et al. Thickness-dependent release of microplastics and phthalic acid esters from polythene and biodegradable residual films in agricultural soils and its related productivity effects. J. Hazard. Mater. 2023, 448, 130897. [Google Scholar]

- Thomas, D.; Schütze, B.; Heinze, W.M.; Steinmetz, Z. Sample Preparation Techniques for the Analysis of Microplastics in Soil—A Review. Sustainability 2020, 12, 9074. [Google Scholar]

- Cao, J.H.; Gao, X.D.; Cheng, Z.; Song, X.L.; Cai, Y.H.; Siddique, K.H.M.; Zhao, X.N.; Li, C.J. The harm of residual plastic film and its accumulation driving factors in northwest China. Environ. Pollut. 2023, 318, 120910. [Google Scholar]

- Sun, Q.; Zhang, X.X.; Liu, C.R.; Nier, A.; Ying, S.; Zhang, J.X.; Zhao, Y.J.; Zhang, Y.T.; Wang, Z.H.; Shi, M. The content of PAEs in field soils caused by the residual film has a periodical peak. Sci. Total Environ. 2023, 864, 161078. [Google Scholar] [CrossRef]

- Reimonn, G.; Lu, T.; Gandhi, N.; Chen, W.T. Review of microplastic pollution in the environment and emerging recycling solutions. J. Renew. Mater. 2019, 7, 18. [Google Scholar] [CrossRef]

- Sharma, S.; Sharma, B.; Sadhu, S.D. Microplastic profusion in food and drinking water: Are microplastics becoming a macroproblem? Environ. Sci. Process. Impacts 2022, 24, 992–1009. [Google Scholar] [PubMed]

- Grause, G.; Kuniyasu, Y.; Chien, M.F.; Inoue, C. Separation of microplastic from soil by centrifugation and its application to agricultural soil. Chemosphere 2022, 288, 132654. [Google Scholar] [CrossRef] [PubMed]

- Mbachu, O.; Jenkins, G.; Kaparaju, P.; Pratt, C. The rise of artificial soil carbon inputs: Reviewing microplastic pollution effects in the soil environment. Sci. Total Environ. 2021, 780, 146569. [Google Scholar]

- Steinmetz, Z.; Kintzi, A.; Muoz, K.; Schaumann, G.E. A Simple Method for the Selective Quantification of Polyethylene, Polypropylene, and Polystyrene Plastic Debris in Soil by Pyrolysis-Gas Chromatogra-phy/Mass Spectrometry. J. Anal. Appl. Pyrolysis 2020, 147, 104803. [Google Scholar] [CrossRef]

- Cowger, W.; Steinmetz, Z.; Gray, A.; Munno, K.; Herodotou, O. Microplastic spectral classification needs an open source community: Open specy to the rescue! Anal. Chem. 2021, 93, 7543–7548. [Google Scholar]

- Steinmetz, Z.; Schröder, H. Plastic debris in plastic-mulched soil—A screening study from western Germany. PeerJ 2022, 10, 13781. [Google Scholar]

- Li, S.T.; Ding, F.; Flury, M.; Wang, Z.; Xu, L.; Li, S.Y.; Jones, D.; Wang, J.K. Macro- and microplastic accumulation in soil after 32 years of plastic film mulching. Environ. Pollut. 2022, 300, 118945. [Google Scholar]

- Krishnaswamy, R.K.; Lamborn, M.J. Tensile properties of linear low density polyethylene (lldpe) blown films. Polym. Eng. Sci. 2010, 40, 2385–2396. [Google Scholar] [CrossRef]

- Al-Salem, S.M.; Al-Dousari, N.M.; Joseph Abraham, G.; D’Souza, M.A.; Al-Qabandi, O.A.; Al-Zakri, W. Effect of Die Head Temperature at Compounding Stage on the Degradation of Linear Low Density Polyethylene/Plastic Film Waste Blends after Accelerated Weathering. Int. J. Polym. Sci. 2016, 2016, 5147209. [Google Scholar] [CrossRef]

- Guo, K.; Cao, M.; Gu, F.; Wu, F.; Yang, H.; Xu, H.; Hu, Z. Mechanical Properties of Metallocene Linear Low-Density Polyethylene Mulch Films Correlate with Ultraviolet Irradiation and Film Thickness. Sustainability 2023, 15, 6713. [Google Scholar]

- Isaac, W.A.P.; Brathwaite, R.A.I.; Cohen, J.E.; Bekele, I. Effects of alternative weed management strategies on Commelina diffusa burm. infestations in fairtrade banana (Musa spp.) in st. vincent and the grenadines. Crop Prot. 2007, 26, 1219–1225. [Google Scholar] [CrossRef]

- Group, P.N. Improvement of plastic technology for soil solarization. Plast. News 2006, 11, 98. [Google Scholar]

- Mashingaidze, A.B.; Chivinge, O.A.; Zishiri, C. The effects of clear and black plastic mulch on soil temperature, weed seed viability and seedling emergence, growth and yield of tomatoes. J. Appl. Sci. S. Afr. 1996, 2, 6–14. [Google Scholar] [CrossRef]

- Rahmani, Z.; Faqiri, S.M.; Muradi, A.J. Weed control in tomato through mulching approaches. Asian J. Agric. Hortic. Res. 2021, 8, 1–6. [Google Scholar] [CrossRef]

- Islam, F.; Quamruzzaman, A.; Mallick, S.R. Effect of different mulch paper on growth and yield of different high value vegetables in bangladesh. J. Integr. Agric. 2021, 3, 237–246. [Google Scholar] [CrossRef]

- Khoirunnisa, F.A.; Fuskhah, E. Growth and production of cucumber (Cucumis sativus L.) that cultivaed using various types of mulch and different doses of goat manure. J. Pertan. Trop. 2019, 6, 383–393. [Google Scholar] [CrossRef]

- Lasmini, S.A.; Wahyudi, I.; Rosmini, R.; Nasir, B.; Edy, N. Combined application of mulches and organic fertilizers enhance shallot production in dryland. Agron. Res. 2019, 17, 165–175. [Google Scholar]

- Wang, Q.W.; Jiang, H.X.; Liu, X.L.; Cao, Q.; Cai, X.K. Effects of Different Color Mulching Films on Growth and Development of Spring Potato. Chin. Potato J. 2021, 35, 538–543. [Google Scholar]

- Elyazied, A.; Mady, M.A. Plastic mulch color and potassium foliar application affect growth and productivity of strawberry (Fragaria x ananassa duch). J. Appl. Sci. Res. 2012, 8, 1227–1239. [Google Scholar]

- Bhutia, T.L.; Singh, S.H.; Reddy, K.C.S. Effect of mulching and nitrogen on growth, yield and economics of okra (Abelmoschus esculentus). Ecol. Environ. Conserv. 2017, 23, 2017–2826. [Google Scholar]

- Keshavarz Afshar, R.; Chen, C.; Eckhoff, J.; Flynn, C. Impact of a living mulch cover crop on sugarbeet establishment, root yield and sucrose purity. Field Crops Res. 2018, 223, 150–154. [Google Scholar] [CrossRef]

- Lyu, B.; Lu, X.R.; Gao, D.G.; Wu, H.Y.; Ma, J.Z. Construction and evaluation of environment-friendly POSS multi-crosslinked mulch film based on bone gelatin. Int. J. Biol. Macromol. 2023, 247, 125829. [Google Scholar] [CrossRef] [PubMed]

- Guo, W.S.; Hu, C.; He, X.W.; Wang, L.; Hou, S.L.; Wang, X.F. Construction of virtual mulch film model based on discrete element method and simulation of its physical mechanical properties. Int. J. Agric. Biol. Eng. 2020, 13, 211–218. [Google Scholar] [CrossRef]

- Liu, C.A.; Jin, S.L.; Zhou, L.M.; Jia, Y.; Li, F.M.; Xiong, Y.C.; Li, X.G. Effects of plastic film mulch and tillage on maize productivity and soil parameters. Eur. J. Agron. 2009, 31, 241–249. [Google Scholar] [CrossRef]

- Zhu, W.; Qiao, R.; Jiang, R. Modelling of Water and Nitrogen Flow in a Rain-Fed Ridge-Furrow Maize System with Plastic Mulch. Land 2022, 11, 1514. [Google Scholar] [CrossRef]

- Yin, T.; Yao, Z.P.; Yan, C.R.; Liu, Q.; Ding, X.D.; He, W.Q. Maize yield reduction is more strongly related to soil moisture fluctuation than soil temperature change under biodegradable film vs plastic film mulching in a semi-arid region of northern China. Agric. Water Manag. 2023, 287, 108351. [Google Scholar] [CrossRef]

- Fu, W.; Fan, J.; Hao, M.d.; Hu, J.S.; Wang, H. Evaluating the effects of plastic film mulching patterns on cultivation of winter wheat in a dryland cropping system on the Loess Plateau, China. Agric. Water Manag. 2021, 244, 106550. [Google Scholar] [CrossRef]

- Fu, Y.F.; Si, L.Y.; Jin, Y.; Xia, Z.Q.; Wang, Q.; Lu, H.D. Efficacy of black plastic film mulching as a cultivation strategy to cope with leaf senescence and increase yield of rainfed spring maize (Zea mays L.). Soil Use Manag. 2020, 38, 1044–1053. [Google Scholar] [CrossRef]

- Zhao, Y.; Chen, X.g.; Wen, H.j.; Zheng, X.; Niu, Q.; Kang, J.m. Research status and prospect of control technology for residual plastic film pollution in farmland. Trans. Chin. Soc. Agric. Mach. 2017, 48, 1–14. [Google Scholar]

- Hu, C.; Wang, X.F.; Chen, X.G.; Tang, X.Y.; Zhao, Y.; Yan, C.R. Current situation and control strategies of residual film pollution in Xinjiang. Trans. Chin. Soc. Agric. Eng. 2019, 35, 223–234. [Google Scholar]

- Chen, J.; Huang, B.S.; Ji, H.Y.; Cui, L.M. A tentative report on the study of the impact on agricultural environment due to the remainder plastic sheet covered the soils. J. Agro-Environ. Sci. 1989, 2, 16–19. [Google Scholar]

- Wen, Q.k.; Liu, Y.L.; Yang, G.B.; Lai, Z.S.; Zhao, N.A.; Liu, X.W.; Shi, S.B. A Study on the influences of accumulative residual plastics on soil properties and following crop. J. Arid Land Resour. Environ. 1992, 4, 71–78. [Google Scholar]

- Huang, X.J.; Chen, Z.Q.; Liu, X.C. Effect of residual plastic film in soil on growth and development of groundnut. Chin. J. Oil Crop Sci. 1993, 3, 47–50. [Google Scholar]

- Jiang, Y.J.; Zheng, D.M.; Zhu, Z.Y. Effects of remnant plastic film in soil on growth and yield of cotton. Agro-Environ. Prot. 2001, 20, 177–179. [Google Scholar]

- Liu, J.G.; Li, Y.B.; Zhang, W.; Sun, Y.Y. The distributing of the residual film and influence on cotton growth under continuous cropping in oasis of Xinjiang. J. Agro-Environ. Sci. 2010, 29, 246–250. [Google Scholar]

- Hou, S.L.; Hu, S.Y.; Kong, J.M.; Zhang, H.Y.; Na, M.J.; Dong, X. Present situation of research on plastic film residue collector in China. Trans. Chin. Soc. Agric. Eng. 2002, 3, 186–190. [Google Scholar]

- Yang, S.S.; Shen, M.R.; Jiang, H.; Hou, S.L. Study on row mulch plastic film collector. J. Northeast Agric. Coll. 1990, 3, 255–260. [Google Scholar]

- Zhang, D.X. Research and design on collector of used plastic film on farm field. J. China Agric. Univ. 1999, 4, 41–43. [Google Scholar]

- Lou, X.H.; Zhang, D.X.; Gen, D.Y.; Ji, Y.F. Research and Design on Loosening Shovel of Polythene Film Collector. Trans. Chin. Soc. Agric. Eng. 2002, 6, 88–90. [Google Scholar]

- Li, B.; Wang, J.K.; Hu, K.; Jiang, B. Analysis and test of forward film removing mechanism for polythene film collector. Trans. Chin. Soc. Agric. Eng. 2012, 21, 23–28. [Google Scholar]

- Yang, S.S. A study on the working parts of the spring-tooth type mulching plastic film collector. Trans. Chin. Soc. Agric. Eng. 1988, 2, 17–25. [Google Scholar]

- Hou, S.L.; Mao, Z.H.; Kong, J.M.; Na, M.J.; Zhang, H.Y.; Dong, X. Development of used plastic film collector machine in idler wheel enwind. J. China Agric. Univ. 2002, 7, 26–28. [Google Scholar]

- Ma, S.H.; Zhang, X.J.; Ren, W.T. Theoretical design and experiments on used plastic film collector with vibration sieve. J. Agric. Mech. Res. 2008, 1, 132–133, 137. [Google Scholar]

- Han, C.T. Present situation in production and application of plastic film used in agricultural in China. Trans. Chin. Soc. Agric. Eng. 1990, 2, 32–37. [Google Scholar]

- Zhao, A.Q.; Li, Z.Z.; Gong, Y.S. Effects of biodegradable mulch film on corn growth and its degradation in field. J. China Agric. Univ. 2005, 2, 74–78. [Google Scholar]

- Liu, Q.; Mu, X.M.; Yuan, Z.C.; Gao, H.; Zhang, R. Degradation of biodegradable mulch film and its effects on growth and yield of maize. Bull. Soil Water Conserv. 2011, 31, 126–129. [Google Scholar]

- GB 13735-1992; Polyethylene Blown Mulch Film for Agricultural Uses. Standards Press of China: Beijing, China, 1992.

- GB 13735-2017; Polyethylene Blown Mulch Film for Agricultural Uses. Standards Press of China: Beijing, China, 2017.

- GB/T 25412-2010; Mulch Film Residue Collector. Standards Press of China: Beijing, China, 2011.

- GB/T 25412-2021; Mulch Film Residue Collector. Standards Press of China: Beijing, China, 2021.

- GB/T 25413-2010; Limit and Test Method for Residual Quantity of Agricultural Mulch Film. Standards Press of China: Beijing, China, 2011.

- GB/T 25414-2010; Thickness Limit and Test Method of Mulch Film for Cotton Planting. Standards Press of China: Beijing, China, 2011.

- Ma, S.H.; Yang, Y. Investigation of residual plastic film pollution and treatment technologies in Xinjiang farmland. J. Anhui Agric. Sci. 2013, 41, 13678–13681. [Google Scholar]

- Dong, A.Q.; Liu, H.; Yu, Y.; Yang, T.; Chen, Y.H.; Wu, H.L.; Xu, C.X.; Xie, J. Study on residual condition of farmland plastic film in Jiangxi province based on survey data of typical plots. Acta Agric. Jiangxi 2022, 34, 128–135. [Google Scholar]

- Li, L.L.; Dai, L.Y.; Gao, W.C.; Zhang, S.Y.; Liu, T.Z. The occurrence characteristics and influencing factors of residual mulching film of typical farmland with plastic film in Guizhou province. Ecol. Environ. Sci. 2022, 31, 2189–2197. [Google Scholar]

- Wang, J.L.; Wu, Y.; Liu, H.J.; Liu, H.; Guo, X.Y.; Chun, L.; Liu, J.P.; Sun, D.H.; Liu, B. Study on residual status and characteristics of plastic film in farmland in Inner Mongolia Autonomous Region. Mod. Agric. Sci. Technol. 2022, 12, 108–112. [Google Scholar]

- Xu, Y.; Jiang, L.H.; Shi, J.; Tan, D.S.; Li, Z.E.; Lin, H.T.; Song, X.Z.; Liu, Z.H.; Gao, X.H. Analysis of film residues status of typical mulching crops in Shandong province. Shandong Agric. Sci. 2018, 50, 91–95, 99. [Google Scholar]

- Zhou, X.G.; Rao, Z.S.; Yang, Y.; Yi, M.; Huang, H.L.; Wang, G.H. Analysis on membrane residue and influence factors in Yibin Tobacco area in Sichuan. J. Anhui Agric. Sci. 2018, 46, 70–71, 99. [Google Scholar]

- Guo, Z.L.; Zhang, X.; Kou, C.L.; Yang, Z.P.; Zhang, X.N.; Li, T.K. Status and influencing factors of residual mulching film of typical crops mulched with plastic film in Henan province. J. Henan Agric. Sci. 2016, 45, 58–61, 71. [Google Scholar]

- Zhang, D.; Hu, W.L.; Liu, H.B.; Du, L.F.; Xu, Y.; Cheng, Z.H.; Sun, S.Y.; Wang, H.Y. Characteristics of residual mulching film and residual coefficient of typical crops in North China. Trans. Chin. Soc. Agric. Eng. 2016, 32, 1–5. [Google Scholar]

- Zeng, Z.B.; Yao, J.W.; Li, M.J.; Tan, Y.Q.; Wang, R.H.; Luo, Y.J.; Yu, D.N. The status quo of mulching film residues in representative regions of Guangdong province. Chin. Agric. Sci. Bull. 2014, 30, 189–193. [Google Scholar]

- Hu, H.J.; Zhang, X.Z.; Li, Q.; Gao, W.; He, Y.; Peng, C.; Zhu, P. Mulch plastic film residue investigation of the main crops in Jilin province, China. J. Agric. Resour. Environ. 2013, 6, 50–52. [Google Scholar]

- Gu, X.B.; Li, Y.N.; Du, Y.D. Biodegradable film mulching improves soil temperature, moisture and seed yield of winter oilseed rape (Brassica napus L.). Soil Tillage Res. 2017, 171, 42–50. [Google Scholar] [CrossRef]

- Yin, M.; Li, Y.; Fang, H.; Chen, P. Biodegradable mulching film with an optimum degradation rate improves soil environment and enhances maize growth. Agric. Water Manag. 2019, 216, 127–137. [Google Scholar] [CrossRef]

- Tang, H.; Xu, C.S.; Xu, W.L.; Xu, Y.N.; Xiang, Y.S.; Wang, J.W. Method of straw ditch buried returning, development of supporting machine and analysis of influencing factor. Front. Plant Sci. 2022, 13, 967838. [Google Scholar] [CrossRef]

- Huang, F.; Wang, B.; Li, Z.; Liu, Z.; Wu, P.; Wang, J.; Ye, X.; Zhang, P.; Jia, Z. Continuous years of biodegradable film mulching enhances the soil environment and maize yield sustainability in the dry land of northwest china. Field Crops Res. 2022, 288, 108698. [Google Scholar] [CrossRef]

- GB/T 35795-2017; Biodegradable Mulching Film for Agricultural Uses. Standards Press of China: Beijing, China, 2017.

- GB/T 41010-2021; Degradability and Identification Requirements of Biodegradable Plastics and Products. Standards Press of China: Beijing, China, 2021.

- Gao, H.; Yan, C.; Liu, Q.; Ding, W.; Chen, B.; Li, Z. Effects of plastic mulching and plastic residue on agricultural production: A meta-analysis. Sci. Total Environ. 2018, 651, 484–492. [Google Scholar] [CrossRef] [PubMed]

- Zhao, J.J.; Tang, J.R.; Li, C.X.; Liu, W.; Zhou, T.; Hu, Y.J. Research on five methods of promoting recycling and comprehensive utilization of waste plastic film in Gansu province. J. Hebei Agric. Sci. 2018, 22, 89–91. [Google Scholar]

- Liang, J.Y.; Long, W.; Wang, Y.b. Effects of Farmers’ Cognition and Policy Environment on Recycling of Plastic Film Residues. J. Agric. 2023, 13, 88–95. [Google Scholar]

- Li, C.Q.; Zhao, M.J.; Shi, Y.X. Farmers’ preferences for diversifying compensation policy for mulch film pollution control: A discrete choice experiment in Northwest China. J. Clean. Prod. 2023, 461, 137962. [Google Scholar] [CrossRef]

- Chen, J.; Chen, X.; Guo, J.; Zhu, R.; Liu, M.; Kuang, X.; He, W.; Lu, Y. Agricultural, Ecological, and Social Insights: Residual Mulch Film Management Capacity and Policy Recommendations Based on Evidence in Yunnan Province, China. Sustainability 2021, 13, 1603. [Google Scholar] [CrossRef]

- Xu, J.Z.; Zhang, M.L.; Chen, Y.Y.; Cui, J.X.; He, W.Q. Mulch film consumption, residual film recovery, and treatment for different agricultural business entities. J. Agric. Resour. Environ. 2023, 40, 229–237. [Google Scholar]

- Xu, J.Z.; Zhang, M.L.; Xu, Y.N.; He, W.Q.; Chen, Y.Y.; Cui, J.X. Influencing factors of farmers’ plastic film recycling behavior based on binary logistic-ISM modeling—A case study in Xinjiang, China. Chin. J. Agric. Resour. Reg. Plan. 2022, 43, 57–65. [Google Scholar]

- Long, W.; Guo, H.J.; Lu, Y. SEM empirical study based on 900 questionnaires about farmers’ Willingness to recover film residue in Yunnan Province. J. China Agric. Univ. 2022, 27, 246–257. [Google Scholar]

- Lv, J.; Feng, H.; Li, S.t.; Cai, J.l.; He, W.Q. Analysis of factors affecting cotton farmers’ recovery behavior of residual film in Xinjiang-based on the Logistic empirical analysis and priority study. China Cotton 2021, 48, 6–11, 16. [Google Scholar]

- Yang, W.; Qi, J.L.; Arif, M.; Liu, M.R.; Lu, Y. Impact of information acquisition on farmers’ willingness to recycle plastic mulch film residues in China. J. Clean. Prod. 2021, 297, 126656. [Google Scholar] [CrossRef]

- Sun, D.B.; Li, H.G.; Wang, E.L.; He, W.Q.; Hao, W.P.; Yan, C.R.; Li, Y.Z.; Mei, X.R.; Zhang, Y.Q.; Sun, Z.X.; et al. An overview of the use of plastic-film mulching in China to increase crop yield and water-use efficiency. Natl. Sci. Rev. 2020, 7, 1523–1526. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Wang, B.; Li, Z.; Huang, F.; Zhao, C.; Zhang, P.; Jia, Z. Plastic film mulch combined with adding biochar improved soil carbon budget, carbon footprint, and maize yield in a rainfed region. Field Crops Res. 2022, 284, 108574. [Google Scholar] [CrossRef]

- Zhang, W.; Dong, A.; Liu, F.; Niu, W.; Siddique, K.H.M. Effect of film mulching on crop yield and water use efficiency in drip irrigation systems: A meta-analysis. Soil Tillage Res. 2022, 221, 105392. [Google Scholar] [CrossRef]

- Chen, L.; Yang, X.; Zhai, D.; Song, N.; Yang, M.; Hou, J. Effects of mulching with Caragana powder and plastic film on soil water and maize yield. Trans. Chin. Soc. Agric. Eng. 2015, 31, 108–116. [Google Scholar]

- Ding, F.; Yan, C.R.; Wang, J.K. An overlooked issue in black soil protection: Plastic film accumulation and pollution. Chin. J. Soil Sci. 2022, 53, 234–240. [Google Scholar]

- Díaz-Pérez, J.C. Plant growth and fruit yield of watermelon as influenced by colored plastic film mulch. Int. J. Veg. Sci. 2023, 29, 84–92. [Google Scholar] [CrossRef]

- Rao, S.A.; Singh, P.; Gonsalves, T. Black plastic mulch affects soil temperature and yield of sweet potato under short season temperate climates. Int. J. Veg. Sci. 2023, 29, 72–83. [Google Scholar] [CrossRef]

- Gyeong, H.C.; Ji, H.S.; Islam, S.M.B.; Joo, K.P.; Gu, L.J. Unexpected high suppression of ammonia volatilization loss by plastic film mulching in Korean maize cropping system. Agric. Ecosyst. Environ. 2022, 335, 108022. [Google Scholar]

- Mayanti, B.; Helo, P. Closed-loop supply chain potential of agricultural plastic waste: Economic and environmental assessment of bale wrap waste recycling in finland. Int. J. Prod. Econ. 2022, 244, 108347. [Google Scholar] [CrossRef]

- Kholil, A.; Budiaman, B.; Mirtawati; Jumhur, A.A. Implementation plastic crushing machine to increase profit in mutiara waste banks. J. Manuf. Technol. Res. 2019, 8, 622–625. [Google Scholar]

- Odusote, J.K. Design and fabrication of polyethylene/nylon wastes recycling machine. Acta Tech. Corvininesis-Bull. Eng. 2015, 8, 153–156. [Google Scholar]

- Sonkhaskar, Y.M.; Sahu, A.; Choubey, A.; Singhal, R.; Singh, A. Design and development of a plastic bottle crusher. Int. J. Eng. Res. Technol. 2014, 3, 297–300. [Google Scholar]

- Kalali, E.N.; Lotfian, S.; Shabestari, M.E. A critical review of the current progress of plastic waste recycling technology in structural materials. Curr. Opin. Green Sustain. Chem. 2023, 40, 100763. [Google Scholar] [CrossRef]

- Smith, R.L.; Takkellapati, S.; Riegerix, R.C. Recycling of plastics in the United States: Plastic material flows and polyethylene terephthalate (pet) recycling processes. ACS Sustain. Chem. Eng. 2022, 10, 2084–2096. [Google Scholar] [CrossRef] [PubMed]

- Liang, R.Q.; Chen, X.G.; Zhang, B.C.; Meng, H.W.; Jiang, P.; Peng, X.B.; Kan, Z.; Li, W.M. Problems and countermeasures of recycling methods and resource reuse of residual film in cotton fields of Xinjiang. Trans. Chin. Soc. Agric. Eng. 2019, 35, 1–13. [Google Scholar]

- Hou, J.Y. Analysis Report on current status of PE mulch film application in China. Sino-Ger. Proj. Upgrad. Plast. Manag. Agric. 2022, 12, 32. [Google Scholar]

- Li, J.H.; Luo, X.; Hu, B.; Wang, M.; Yao, Q.Q. Research and experiment of the water-separating device for residual film mixture. J. Agric. Mech. Res. 2019, 41, 152–156. [Google Scholar]

- He, H.M.; Hu, B.; Pan, F.; Luo, X.; Guo, M.Y.; Xie, Y.Y.; Chen, X.G. Effects and experiment on settlement and aggregation behavior of plastic film and cotton stalk under the action of disturbing water by the impeller. Trans. Chin. Soc. Agric. Eng. 2021, 37, 86–95. [Google Scholar]

- Tang, H.; Xu, C.S.; Zhao, J.L.; Wang, J.W. Stripping mechanism and loss characteristics of a stripping-prior-to-cutting header for rice harvesting based on CFD-DEM simulations and bench experiments. Biosyst. Eng. 2023, 229, 116–136. [Google Scholar] [CrossRef]

- Tang, H.; Xu, C.S.; Zhao, J.L.; Wang, J.W. Formation and steady state characteristics of flow field effect in the header of a stripping prior to cutting combine harvester with CFD. Comput. Electron. Agric. 2023, 211, 107959. [Google Scholar] [CrossRef]

- Guo, K.; Cao, M.; Yang, H.; Luo, W.; Qin, M.; Wu, F.; Gu, F.; Hu, Z. A Preliminary Determination of Mechanical and Suspension Properties of Waste Mulch Film and Cotton Stalk. Agriculture 2023, 13, 1572. [Google Scholar] [CrossRef]

- Qian, R.; Guo, R.; Liu, Y.; Naseer, M.A.; Hussain, S.; Liu, D.; Zhang, P.; Chen, X.; Ren, X. Biodegradable film mulching combined with straw incorporation can significantly reduce global warming potential with higher spring maize yield. Agric. Ecosyst. Environ. 2022, 340, 108181. [Google Scholar] [CrossRef]

- Harada, J.; Souza, A.G.D.; Macedo, J.R.N.D.; Rosa, D.S. Soil culture: Influence of different natural fillers incorporated in biodegradable mulching film. J. Mol. Liq. 2019, 273, 33–36. [Google Scholar] [CrossRef]

- Cheruiyot, W.K.; Wang, W.; Zhu, S.G.; Kavagi, L.; Zhang, X.C.; Mburu, D.M.; Ma, M.S.; Munyasya, A.N.; Koskei, K.; Indoshi, S.N.; et al. Environmental and economic impacts of biodegradable plastic film mulching on rainfed maize: Evaluations on sustainability and productivity. ACS Agric. Sci. Technol. 2022, 2, 908–918. [Google Scholar] [CrossRef]

- Passaretti, M.G.; Ninago, M.D.; Villar, M.A.; López, O.V. Thermoplastic starch and mica clay composites as biodegradable mulching films. J. Polym. Environ. 2022, 30, 4394–4405. [Google Scholar] [CrossRef]

- Liu, L.Y.; Zou, G.Y.; Zuo, Q.; Li, S.J.; Bao, Z.; Jin, T.; Liu, D.S.; Du, L.F. It is still too early to promote biodegradable mulch film on a large scale: A bibliometric analysis. Environ. Technol. Innov. 2022, 27, 102487. [Google Scholar] [CrossRef]

- Mola, I.D.; Ventorino, V.; Cozzolino, E.; Ottaiano, L.; Mori, M. Biodegradable mulching vs. traditional polyethylene film for sustainable solarization: Chemical properties and microbial community response to soil management. Appl. Soil Ecol. 2021, 163, 103921. [Google Scholar] [CrossRef]

- Lu, L.; Han, Y.; Wang, J.Y.; Xu, J.; Li, Y.S.; Sun, M.T.; Zhao, F.J.; He, C.X.; Sun, Y.J.; Wang, Y.J.; et al. PBAT/PLA humic acid biodegradable film applied on solar greenhouse tomato plants increased lycopene and decreased total acid contents. Sci. Total Environ. 2023, 871, 162077. [Google Scholar] [CrossRef]

- Ding, F.; Flury, M.; Schaeffer, S.M.; Xu, Y.; Wang, J. Does long-term use of biodegradable plastic mulch affect soil carbon stock? Resour. Conserv. Recycl. 2021, 175, 105895. [Google Scholar] [CrossRef]

- Yan, C.; Liu, Q.; He, W.; Li, Z.; Qi, R. Comparison of Traditional Mulch Film and Biodegradable Mulch Film in China; 2022 Series Report of Sino-European Sustainable Transition towards Circular Economy; Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ) GmbH: Beijing, China, 2022; p. 4. [Google Scholar]

| Types | Pictures | Characteristics |

|---|---|---|

| Clear |  | This is currently the most commonly used plastic mulch in agricultural production. Its material is mainly polyethylene, suitable for planting crops in early spring and winter. The advantage is low cost and the ability to quickly increase soil temperature. But the disadvantage is that the ability to suppress weeds is weak, and herbicides usually need to be sprayed once before covering with plastic film [51,52]. |

| Black |  | This type of plastic mulch is made by adding carbon black to polyethylene. It has low transparency and poor warming effect. But the effect is significant in reducing soil moisture evaporation and inhibiting weed growth [53,54]. |

| Silver-black |   | The front and back of this type of plastic film are black and silver. Generally, when used, the black color is facing downwards and the silver color is facing upwards. It not only has the effect of controlling grass with the black mulch, but also has the effect of repelling insects and preventing toxins with the silver surface [55,56,57]. |

| Composite |  | This type of plastic mulch is distributed in clear and black intervals. It has both the warming effect of clear plastic mulch and the light-blocking and weed-controlling effect of black plastic mulch. Normally, the clear part covers crops [58]. |

| Red, Blue, Green |    | This type of plastic mulch can further promote crop growth and is often used for economically valuable crops [59,60,61]. Red plastic mulch can meet the needs of rice, sugar beets, and other plants for red light. It can promote the vigorous growth of rice seedlings and increase the sugar content of sugar beets. Blue plastic mulch can promote the growth of muskmelon. Green plastic mulch can reduce the visible light transmittance of plants during photosynthesis and has the effect of inhibiting weed growth. |

| Standard Name | Standard Number | Main Content | Current State |

|---|---|---|---|

| Polyethylene blown mulch film for agricultural uses | GB 13735-1992 | This standard mainly specifies the product classification and technical requirements of polyethylene blown mulch film for agricultural uses. Among them, the minimum thickness of the plastic mulch is specified as 0.008 mm [87]. | Replaced by GB 13735-2017 [88] |

| Mulch film residue collector | GB/T 25412-2010 | This standard specifies the product requirements, operational performance indicators, and test methods of residual plastic mulch recycling machines [89]. | Replaced by GB/T 25412-2021 [90] |

| Limit and test method for residual quantity of agricultural mulch film | GB/T 25413-2010 | This standard specifies the limits and determination methods for the residual amount of plastic mulch in farmland soil. Among them, it is stipulated that the residual quantity of plastic mulch in the cultivation layer of the farmland to be sown should not exceed 75.0 kg/hm2 [91]. | Currently effective |

| Thickness limit and test method of mulch film for cotton planting | GB/T 25414-2010 | This standard specifies the limit values and measurement methods for the thickness of plastic mulch used for cotton cultivation. Among them, it is stipulated that the thickness limit of plastic mulch for cotton planting should not be less than 0.008 mm [92]. | Currently effective |

| Regions | Main Crops Covered by Plastic Mulch | Residual Quantity of Plastic Mulch in Farmland (kg/hm2) | References |

|---|---|---|---|

| Xinjiang | Cotton | The range is 143.3 to 378.9, with an average of 261.1. | [93] |

| Jiangxi | Vegetables, fruits, flue-cured tobacco, oilseeds, mushrooms | The average value is 11.54. | [94] |

| Guizhou | Vegetables, flue-cured tobacco, pepper | The range is 8.18 to 235.39, with an average of 70.84. | [95] |

| Inner Mongolia | Corn, potato (Solanum tuberosum L.), sunflower (Helianthus annuus L.) | The average value is 101.7. | [96] |

| Shandong | Cotton, peanut | The range is 5.33 to 46.99, with an average of 23.91. | [97] |

| Yibin, Sichuan | Flue-cured tobacco | The average value is 6.88. | [98] |

| Henan | Peanut, cotton | The range is 6.8 to 37.3, with an average of 20.4. | [99] |

| North China | Peanut, cotton | The range is 0.2 to 82.2, with an average of 26.8. | [100] |

| Guangdong | Winter melon, peanut | The average value is 45.0. | [101] |

| Jilin | Melons, vegetables, corn, peanut | The average value is 27.7. | [102] |

| Standard Name | Standard Number | Main Content | Current State |

|---|---|---|---|

| Polyethylene blown mulch film for agricultural uses | GB 13735-2017 | Compared with the original standard, this standard simplifies the original four types of plastic mulch products into two categories. The lower limit of film thickness was increased from 0.008 mm to 0.01 mm [88]. | Currently effective |

| Farm waste film pick-up machines | GB/T 25412-2021 | This standard revised the product requirements, operational performance indicators, and test methods of residual plastic mulch recycling machines [90]. | Currently effective |

| Standard Name | Standard Number | Main Content | Current State |

|---|---|---|---|

| Biodegradable mulching film for agricultural uses | GB/T 35795-2017 | This standard specifies the requirements, test methods, and inspection rules for biodegradable mulching film for agricultural uses [107]. | Currently effective |

| Degradability and identification requirements of biodegradable plastics and products | GB/T 41010-2021 | This standard specifies the degradability and identification requirements for biodegradable plastics and products [108]. | Currently effective |

| Items | Indexes | ||

|---|---|---|---|

| d < 0.010 mm | 0.010 ≤ d < 0.015 | d ≥ 0.015 | |

| Tensile load (longitudinal and transverse)/N | ≥1.50 | ≥2.00 | ≥2.20 |

| Nominal strain at fracture (longitudinal)/% | ≥150 | ≥150 | ≥200 |

| Nominal strain at fracture (transverse)/% | ≥250 | ≥250 | ≥280 |

| Right angle tear load (longitudinal and transverse)/N | ≥0.50 | ≥0.80 | ≥1.20 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, H.; Hu, Z.; Wu, F.; Guo, K.; Gu, F.; Cao, M. The Use and Recycling of Agricultural Plastic Mulch in China: A Review. Sustainability 2023, 15, 15096. https://doi.org/10.3390/su152015096

Yang H, Hu Z, Wu F, Guo K, Gu F, Cao M. The Use and Recycling of Agricultural Plastic Mulch in China: A Review. Sustainability. 2023; 15(20):15096. https://doi.org/10.3390/su152015096

Chicago/Turabian StyleYang, Hongguang, Zhichao Hu, Feng Wu, Kai Guo, Fengwei Gu, and Mingzhu Cao. 2023. "The Use and Recycling of Agricultural Plastic Mulch in China: A Review" Sustainability 15, no. 20: 15096. https://doi.org/10.3390/su152015096

APA StyleYang, H., Hu, Z., Wu, F., Guo, K., Gu, F., & Cao, M. (2023). The Use and Recycling of Agricultural Plastic Mulch in China: A Review. Sustainability, 15(20), 15096. https://doi.org/10.3390/su152015096