Abstract

This study investigates the impact of various pre-drying treatments and drying methods on the physicochemical, phytochemical, and sensorial quality of dried bananas. To achieve this goal, four pretreatment solutions were used before drying to enhance the quality characteristics of banana slices: citric acid 1% and ascorbic acid 1%, sucrose 10%, sodium bisulphate 0.5%, and lemon juice 5% and acetic acid 0.5%. Two drying methods were applied, sun drying (SD) and tunnel drying (TD). The dried slices were evaluated for moisture, total acidity, water activity (aw), browning index, rehydration ratio (RR), reducing sugar, ascorbic acid, total phenol, and DPPH %, as well as sensory attributes (color, odor, taste, texture, and overall acceptability). The results showed that the retention of acid content, ascorbic acid, total phenolics, and DPPH in slice samples dried in TD was higher than that in SD. The browning index values in the TD samples were lower than those in the SD samples. Moreover, the TD samples showed a higher RR than the SD samples. It is noted that the pretreatment solutions used have an important role in improving the final quality characteristics of dried banana slices. The results of the sensory evaluation revealed a significant difference in the degrees of color and texture for the slices pretreated with sodium bisulphate. Meanwhile, the rates of taste and odor were significantly higher for the sucrose-pretreated slices. TD can improve the drying kinetics, shorten the drying time, and maintain the quality of the dried slices.

1. Introduction

Bananas are one of the most popular fruits worldwide due to their great sensory acceptance. These seasonal fruits have a short shelf-life and high water activity. The moisture content in ripe bananas is 80%, which is very susceptible to deterioration; this causes significant losses after harvesting. The processing of bananas aims to produce other products and minimize waste [1]. Drying is a strategy process to reduce post-harvest losses [2]. The drying process decreases a food’s moisture level to a level that permits safe storage over an extended time while also preventing microbe growth and minimizing damage [3]. The dehydration method improves the sustainability of food products’ nutritious components, increases shelf life, lowers packing, storage, handling, and transportation costs, and may even make certain foods available outside of the growing season [4,5]. Additionally, fruit that has been rejected by the market can be turned into dried goods, decreasing food waste and providing a well-liked fruit-derived product [6].

Consuming dried fruits in place of unhealthy snacks that are heavy in sugar, salt, and fats may be a realistic alternative to achieving the WHO’s daily fruit intake requirements and encouraging the adoption of a sustainable diet [6]. Although dried fruits have several advantages that satisfy the growing consumer desire for wholesome and practical products [7,8], their consumption is still considerably lower than the daily suggested serving (30 g) [9]. Consumption of dried fruit is lower than that of harmful foods, particularly among young individuals [6].

Many studies have found that consumers prefer dried fruits and attempt to comprehend the elements that influence this decision [10,11,12]. For instance, Jesionkowska and colleagues [13] highlighted that health factors are key factors in the selection of dried fruits as perceived as rich in beneficial components, while Sabe et al. [14] demonstrated that product familiarity is the most significant determinant of purchase intention. Similarly, a study by Sun and Liang [10] that divided consumers into age groups based on their preference for dried fruits discovered that younger people consider health-related factors to be the most significant variable in the decision-making process, while older consumers prefer the convenience features.

By contrast, Sijtsema et al. [15] noted that dried fruits are preferred over their fresh counterparts not because of their health benefits, but rather because of their convenience. Alphonce and colleagues, on the other hand, showed in their study [16] that consumers are most influenced by the flavor of dried fruits and their credibility attributes, such as organic and fair trade, for which consumers are willing to pay a higher price. The researchers have discussed various drying techniques typically employed in drying fruits [17,18,19,20].

Sun drying (SD) is a well-known process for drying agricultural commodities in tropical and subtropical areas. However, it has several drawbacks, including a lengthy drying period, nutritional loss, and contamination from dirt, dust, sand particles, and insects [9,21]. As a result, the quality of sun-dried items may suffer, failing to fulfill local and international requirements [22]. To solve these issues, other drying procedures must be used. As a result, using hot air in controlled cabinet drying by convective air is significantly more efficient and offers consistency and sanitation for commercial food drying procedures.

The new drying procedures should offer benefits including less energy consumption, high quality at a reasonable cost, and low CO2 emissions with improved environmental footprint. The choice of drying methods depends on several factors, such as the food being dried, quality, energy consumption, and drying time. These drying methods attempt to produce food products with superior qualities. Although many drying machines have been designed and tested in the food industry [23], industrial drying is a costly and energy-intensive process. Therefore, solar drying appears to be the best substitute approach [24]. The solar drying method does not require electricity and skilled labor. It is effective, sustainable, and economical. Furthermore, it creates jobs in the off-season in rural areas of developing countries. Additionally, it minimizes reliance on fossil fuels and their negative effects on the environment [24,25]. However, drying may result in flavor, color, nutrient, and antioxidant activity losses, as well as a reduction in bulk density and rehydration capacity of the final product [26]. Enzymatic and non-enzymatic processes that may occur during the drying of fresh plant tissues may result in significant changes in phytochemical composition [27]. Therefore, several pretreatments have been applied to lessen negative alterations during drying [26,28,29]. Accordingly, the main objective of this study is to investigate the effect of pretreatments (citric and ascorbic acid, sucrose, sodium bisulphate, lemon juice, and acetic acid) and drying methods (sun and solar-controlled tunnel drying) on the quality of dried bananas.

2. Materials and Methods

2.1. Materials

High-purity solvents and chemicals were purchased from El-Gomhoria Company for Chemicals and Drugs, Cairo, Egypt.

The Grand Nain variety bananas were purchased from the local fruit and vegetable market in Cairo, Egypt, in September 2021. Banana fruits were chosen for their uniform color and size, lack of pests, and physical damage. The samples were brought to the Laboratory of Food Science and Technology, Faculty of Agriculture, Al-Azhar University, Cairo, Egypt, for processing before sun and tunnel drying.

2.2. Drying Methods

Sun drying (SD) and solar-controlled tunnel drying (TD) were the two drying techniques employed in this study. In sun drying, the treated banana slices were laid out on drying trays in a thin layer and exposed to the sun to dry the banana samples. The trays were put on an elevated platform to dry in the sun. The high platform allows for ample airflow around the fruit, which was dried at an average temperature of 34 °C. The other method used solar-controlled tunnel drying.

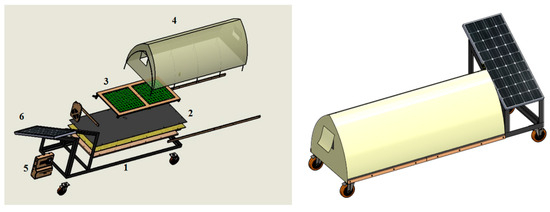

Figure 1 depicts the solar tunnel dryer assembly drawing. The solar tunnel setup had dimensions of 150 × 60 × 50 cm (latitude 30°02′30″ N, longitude 31°14′07″ E, and mean altitude above sea level 18 m) and was used to ascertain the behavior of sliced bananas under solar drying. To maximize the impact of sun radiation on the tunnel method, it was oriented towards an east–west axis orientation. A 200-micron-thick plastic sheet made of polyethylene that is transparent was used to cover the tunnel. Banana slice halves were set on a single wire mesh tray that was 1.20 × 0.50 m in size and utilized for thin-layer solar drying. Sensors were used to measure the interior’s temperature and relative humidity in the tunnel and outside. These sensors were installed in the tunnel dryer inlet, middle, and outlet points to continuously track the relative humidity and temperature for drying air. An appropriate Arduino device linked to a computer continuously recorded the relative humidity and temperature in the solar tunnel dryer throughout the tests at 10-min intervals.

Figure 1.

Assembly drawing of the solar tunnel dryer. Where: (1)—steel structure, (2)—tunnel floor, (3)—drying tray, (4)—reticular structure and plastic cover, (5)—control box, and (6)—solar panel.

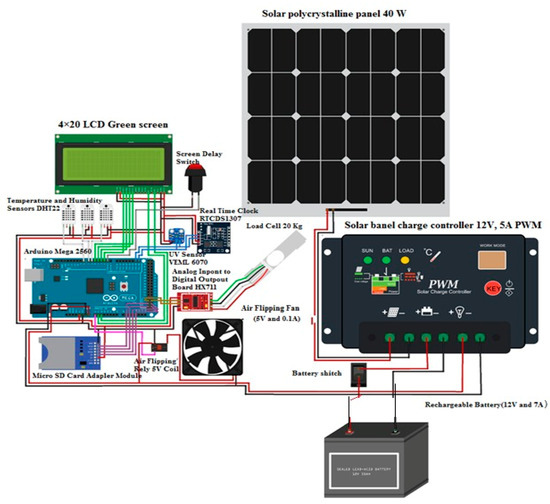

The solar tunnel drying is provided with a system for measuring, recording, and maintaining temperature and humidity as shown in Figure 2 on the right. A polycrystalline solar panel produces the required voltage in the morning when it is exposed to sunlight, producing a power of 40 watts with an average voltage of 18 V, which is then used to charge an acid battery at a rate of 12 V and 7 A. The code that is tied to the processor memory instructs the processor to read the data output from the sensors, store them, and then send them to the screen for display at certain periods for each sensor. This is how the Arduino Mega 2560 (Monza, Italy) board functions. The Tiny RTC DS1307 (Real Time Clock, Shanghai, China) board keeps the time and date to ensure that the values and readings are recorded together for accuracy, and restarting the Arduino board will reset the time and date. Three temperature and humidity sensors DHT22 collect humidity and temperature distributed inside and outside the tunnel to see the extent of the impact of insulation of the plastic tunnel and the amount of heat transferred, which are high-accuracy sensors. The VEML 6070 UV (Munich, Germany) light sensor works to measure the level of ultraviolet rays, specifically from the sun’s total radiation, because it increases damage to the product to be dried. The reading is displayed on the screen at an update and permutation rate of 0.25 s. The load cell sensor installed in the center of the tunnel floor measures the weight of the drying tray (known as “2350 g”) in addition to the product’s weight spread within the tray every 10 min. The air-agitating fan inside the tunnel works to expel the moisture-laden air and replace it with fresh air, so as not to damage the product to be dried by relay, for only one minute to prevent all heat from leaking out. Every 10 min, with a micro SD card adapter, the current reading is taken from all sensors and recorded on the memory card with the time and date, which facilitates the process of follow-up.

Figure 2.

Various parts of embedded systems and their connection methods.

The weather was mainly sunny and dry throughout the drying experiments. The times of each experiment were 7:30 and 17:00. In all drying experiments, banana slices were placed in a single layer on a metal mesh tray within the tunnel for drying. Weight measurements were taken every 10 min. Afterward, dried slices were stored in low-density polyethene pouches until the start of the analysis. For the sun drying method, samples of banana slices were placed on a tray near the dryer and dried concurrently under the same weather conditions to compare tunnel drying effectiveness with sun drying.

2.3. Preparation and Pretreatment of Bananas before Drying

The banana fruits were peeled, weighed, and then cut into slices using a stainless-steel knife to a thickness of about 4 mm. The slices were pretreated before drying using four different pretreatments: citric acid 1% and ascorbic acid 1%; sucrose 10%; sodium bisulphate 0.5%; lemon juice 5% and acetic acid 0.5%; one sample was untreated and served as the control. The citric acid 1% and ascorbic acid 1% treatment was prepared using 20 g of citric acid and 20 g of ascorbic acid dissolved in 2000 mL of distilled water. To prepare a sucrose 10% treatment, 200 g of sucrose was dissolved in 2000 mL of distilled water. To prepare the sodium bisulphate 0.5% treatment, 10 g of sodium bisulphate was dissolved in 2000 mL of distilled water. Finally, lemon juice 5% and acetic acid 0.5% treatment was prepared using 10 g of acetic acid dissolved in 1900 mL distilled water, and then 100 mL of lemon juice was added.

About 1000 g of banana slices were weighed for pretreatment for 10 min; after pretreatment, they were subjected to drying. An untreated sample was used to compare differences between all pretreatments. Then, each treatment was divided into two parts, the first into the open sun dryer (SD) and the second into the tunnel dryer (TD).

2.4. Estimation of Thermo-Physical Parameters

2.4.1. Initial Moisture Content

The oven was set at 105 °C to measure the initial moisture content till a consistent weight was obtained [30], and the equation that follows was employed:

where Mid is moisture content on a dry basis (%), Wm is moisture content in the sample (g), and Wd is dry material content (g).

2.4.2. Moisture (Mt)

Every 30 min, the moisture percentage and wet basis (w.b.) percentage were calculated as follows [31].

where Wt is sample weight (g) at any time, Wo is the fresh sample weight (g), and mo is initial moisture percent (w.b.%).

2.4.3. Moisture Ratio

Moisture ratio (MR) can be measured utilizing the dried samples’ moisture percent at time t [32]:

where Mi is initial moisture content (w.b.%), Mt is moisture percent at any time during drying (w.b.%), and Me is equilibrium moisture (w.b.%).

2.4.4. Drying Rate

The drying rate was calculated as follows:

where Mt−dt and Mt are the moisture contents at dt and t times, respectively, and dt is the drying period (hour).

2.5. Analytical Methods

2.5.1. pH Value

The pH value was assessed by a pH meter (a Jenway 3505, Keison Products, Chelmsford, UK) as described in reference [30].

2.5.2. Total Acidity

Acidity content was determined according to the titration method [33]. A total of 50 mL of distilled water was added to 2 g of the dried slices sample. The mixture was stirred for 20 min, then three drops of phenolphthalein were added, and the titration was carried out by using NaOH solution 0.1 N, up to an endpoint of pH 8.1. The results were given as a percentage of malic acid (g per 100 g).

2.5.3. Water Activity

Water activity (aw) of dried banana slices depended on pouring about 3 g of water into a sample cup. The aw was measured in an Aqualab Model CX-2 m (Decagon Devices Inc., Pullman, WA, USA) at 25 °C [34,35].

2.5.4. Browning Index (Optical Density (OD) Measurement)

The browning index was assessed as absorbance density value using a UV–visible spectrophotometer as described in reference [36], where 2 g of dried slices were soaked in 20 mL of 60% ethanol and kept overnight, then filtered measuring absorbance (OD) at 440 nm by a UV–visible spectrophotometer (Thermo Electron Company, Beverly, MA, USA).

2.5.5. Rehydration Ratio

The rehydration ratio (RR) tests were performed after immersing five grams of dried banana slices in 300 mL of distilled water at ambient temperature; then, the slices were drained and weighed. Based on the following equation, the amount of water rehydration was quantified as RR [37].

where M is the sample weight (g).

RR = M after soaking/M before soaking

2.5.6. Reducing Sugar

Reducing sugar content was determined by resolving 60 mg of dried slices in a 20 mL H2SO4 solution (1.5 M). The solution was heated at 100 °C for 20 min in the water bath. Afterward, it was cooled, neutralized using 12 mL of 10% NaOH, filtered, and diluted to 60 mL with distilled water. Utilizing a UV–visible spectrophotometer (Thermo Electron Company, Beverly, MA, USA), reducing sugars were quantified at 540 nm [38].

2.5.7. Extraction and Determination of Total Phenol and DPPH

Five grams of dried banana slices were suspended in 40 mL of methanol (80%) for 12 h, with centrifugation at 10,000× g for 20 min. The supernatant was collected, then filtrated using Whatman paper, and used as crude extract [39]. For total phenolic (TPC) determination, 600 µL of crude extract and 600 µL of Folin–Ciocalteu reagent were combined with 4.80 mL of water and put in the dark for 90 min as described by Yu et al. [40]. The absorbance was read at 760 nm using a UV–visible spectrophotometer (Thermo Electron Company, Beverly, MA, USA), and the TPC is given in mg GA/kg. To determine the DPPH radical scavenging activity, 100 µL of the crude extract was added to 100 µL of the DPPH solution (0.2 mM). The combination was maintained at room temperature for one hour [41]. At 517 nm, the absorbance was recorded by a UV–visible spectrophotometer (Thermo Electron Company, Beverly, MA, USA), and the DPPH was calculated as a percentage.

2.6. Sensory Evaluation

The dried banana slice samples were served to a sensory panel, which consisted of ten staff members of the Department of Food Sciences and Technology, Faculty of Agriculture, Al-Azhar University, and ten staff members of the Agriculture Constructer Engineering and Environmental Control Department, Faculty of Agriculture Engineering, Al-Azhar University. The samples were assessed for sensory attributes of color, odor, taste, texture, and overall acceptability. The evaluation used a ten-point hedonic test scale, as reference [42] explained.

2.7. Cost Analysis

The results were calculated using the following formula: dryer hourly expenses based on the fixed and variable costs of the dryer [43].

where C = dryer hourly cost, L.E./h, P = price of dryer, L.E. (800 L.E.), h = yearly working hours (which were assumed in the present work to be 300 day/year × 1 period/day × 8 h/period = 2400 h/year), a = life expectancy of machine (about 10 years), i = interest rate/year (the bank interest in Egypt, which was about 14%), t = taxes and overhead ratio (which is assumed in the present work to be 20%), r = repair and maintenance ratio (which is assumed in the present work to be 10%), W = power of dryer (kW), e = hourly cost/kW. h (0.0 L.E./kW. h), m = the monthly average wage, L.E. (2400 L.E), calculating that there are 20 dryers (120 L.E./man. dryer, month), 200 = the monthly average working hours.

2.8. Statistical Analysis

The mean values and standard error were used to express the results. Every analysis assay was completed in triplicate. The mean values were subjected to evaluation using a two-way analysis of variance (ANOVA) to check for significant differences (p < 0.05) by SPSS (version 22).

3. Results

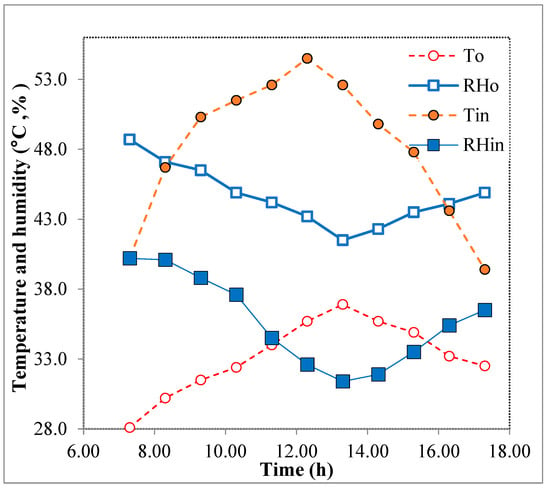

Variations in the tunnel dryer’s outside and inside air temperature and relative humidity during the experiments are shown in Figure 3. During the drying experiment, the daily mean values in and out of the tunnel of air temperature and relative humidity variations are from 39.4 to 54.5 °C, 28.1 to 36.9 °C, and 31.6 to 40.2%, 41.5 to 48.7%, respectively. The ambient air temperature in and out of the TD reached the maximum between 11:00 and 14:00. This was when the relative humidity was at its lowest levels. It was found that the drying temperature in TD was higher than the outside temperature. In contrast, the TD relative humidity was lower than the outside relative humidity. There were significant differences between the values of the temperature and relative humidity. During the experimental time, these values were about 11.3 to 17.6 °C and 8.5 to 9.9%. This indicates that the rate of drying in TD will be higher than SD.

Figure 3.

Changes in ambient temperature (°C) and relative humidity (%) with the drying hours for a typical day in September 2021.

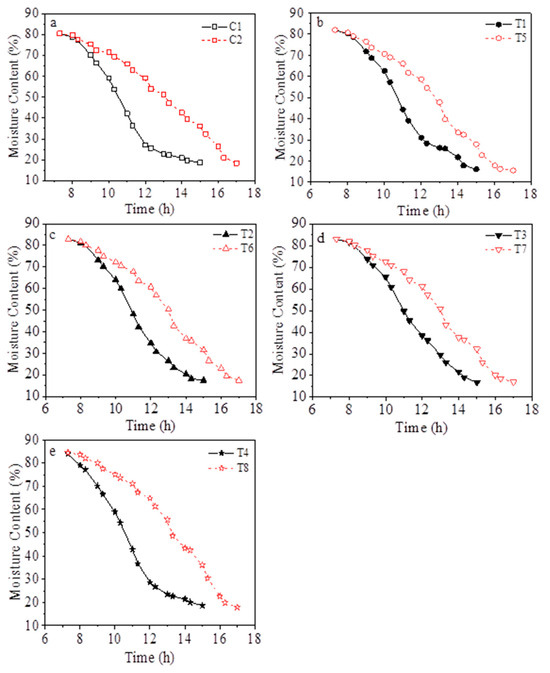

The results of moisture content for dried banana slices by SD were compared with those obtained by TD under different pretreatment solutions, which are presented in Figure 4. There was a finding that the slices had moisture of 80.4%. This value decreases exponentially with the increasing duration in drying time. TD had more of an effect on the moisture content of the banana slices than SD.

Figure 4.

Variations in moisture % over time during a typical experimental run during the solar drying of banana slices. (a) C1: control tunnel and C2: control sun, (b) T1: sucrose tunnel and T5: sucrose sun, (c) T2: sodium bisulphate tunnel and T6: sodium bisulphate sun, (d) T3: ascorbic + citric tunnel and T7: ascorbic + citric sun, (e) T4: lemon juice + acetic tunnel and T8: lemon juice + acetic sun.

The moisture content in the control tunnel (C1) reached 18.6% (w.b.) in 8 h of drying, though it needs 10 h of drying to reduce the moisture content to 18.3% (w.b.) in the control sun (C2). The lower drying time of banana slices inside the TD system may be because slices in the dryer received a collector’s energy and incidental sun radiation. Meanwhile, the sample under SD received the energy from the incident radiation only and lost energy that is significant for the environment. The slices treated with sucrose dried in TD had the lowest moisture percent (15.5%), which might be related to plasma and some moisture loss in the sample. The product is a consequence of the immersion process in these solutions, which shortened the time spent in the drying processes in TD.

Also, Figure 4 displays the relationship between moisture content and drying rate for banana slices in TD and SD. These curves do not have a constant rate drying phase, and all of the drying operations in the drying of the samples took place during the falling-rate drying phase. The drying rate is reduced with increased drying time and decreased moisture percent. These outcomes concurred with the findings of [44] for prickly pear peel and [20] for grape, carrot, and okra.

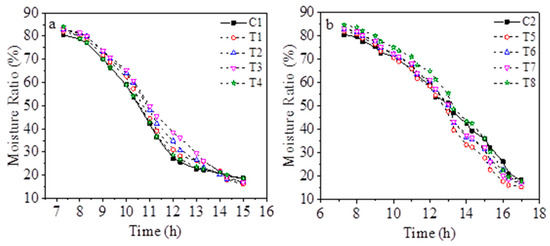

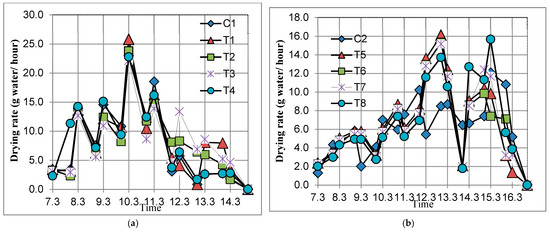

According to the results, the best moisture ratio is TD from SD (Figure 5). For example, after drying for 6 h’s time, the moisture ratios are TD (C1) 0.2438 and SD (C2) 0.62079; the minimum value of the MR is equal to 0.1965, which corresponds to (C1).

Figure 5.

Moisture ratio vs. time (h) curves. (a) C1: control tunnel, T1: sucrose tunnel, T2: sodium bisulphate tunnel, T3: ascorbic and citric tunnel, T4: lemon juice and acetic tunnel, (b) C2: control sun, T5: sucrose sun, and T6: sodium bisulphate sun, and T7: ascorbic and citric sun, and T8: lemon juice and acetic sun.

The drying rate versus drying time shows the presence of a falling drying rate period, which is enormously influenced by the drying air temperature. A higher drying air temperature produces a higher moisture loss and a consequently weak drying time. This is mainly due to the acceleration of the water migration inside the tunnel due to increased heat air supply to the product (Figure 6).

Figure 6.

Drying rate (g water/h) over time (h) curves. (a) C1: control tunnel, T1: sucrose tunnel, T2: sodium bisulphate tunnel, T3: ascorbic and citric tunnel, T4: lemon juice and acetic tunnel, (b) C2: control sun, T5: sucrose sun, and T6: sodium bisulphate sun, and T7: ascorbic and citric sun, and T8: lemon juice and acetic sun.

The results of the effects of pretreatments and drying methods on the physicochemical properties of dried slices are presented in Table 1. No significant differences between the two drying methods (sun and tunnel) were observed in pH values. As opposed to that, no notable variations between pretreatments were observed except for those samples treated with citric and ascorbic acids. The pH value for fresh bananas was 5.86, which decreased after drying for all slice samples. The samples treated with citric and ascorbic acids had the lowest significant pH values (4.59 for TD and 4.66 for SD). In contrast, other samples were close to each other, varying from 5.33 to 5.78 with no significant differences. These findings align with those discussed in the references [45,46].

Table 1.

Effect of some pretreatments and drying methods on physicochemical properties of dried banana slices.

The acidity content of fresh bananas was 0.47%, which increased in the dried slices (Table 1). The highest acidity contents were found in dried slices treated with citric and ascorbic acid (1.08 and 0.99%), followed by the sample treated with lemon and acetic acid (0.98 and 0.96%), with non-significant differences between them (p < 0.05). For other samples, total acidity contents were close, with no statistically significant difference between these samples. As opposed to that, significant differences were found between these samples and samples treated with citric and ascorbic acid and lemon and acetic acid. These findings show that utilizing citric and ascorbic, lemon and acetic acid before the treatments raised the acidity number, agreeing with references [45,46,47].

High quantities of moisture are present (80.4%); they corroborate the high water activity (aw) of the fresh banana (0.972). Dried bananas’ water activity ranged from 0.652 to 0.695 (Table 1). It was observed that the highest water activity (0.695) was found for the control sample on the tunnel dryer. The decrease in aw minimizes degradation reactions and microbial growth, which helps preserve and lengthen the fruit’s shelf-life [48].

The browning index for fresh banana was 0.25, and it increased in dried banana slices and reached 0.60, 0.81, 0.56, and 0.69 for treatments with citric and ascorbic acids, sucrose, sodium bisulphate, and lemon and acetic acids, respectively, with the SD method. The same treatments in TD reached 0.61, 0.66, 0.50, and 0.65 compared to control, which showed the highest browning, 0.85 for SD and 0.79 for TD, with a significant difference between treatments. These results show that the banana slices are excellent in retaining a white color after drying by treating the slices with sodium bisulphate and citric and ascorbic acids, respectively. Anti-browning and antioxidant activities of bisulphate and ascorbic and citric acids might be the reason. Sulfate is widely used as a food preservative to inhibit oxidation either by oxygen or enzymes. These observations agree with the results reported in reference [49].

The rehydration ratio (RR) is one of the important indicators for the quality of dried fruits and vegetables. The higher rehydration ratio values indicate these crops’ quality [50]. A noticeable difference was found in the rehydration ratio from pretreatment impact, where citric and ascorbic acids, lemon and acetic acid had the highest values compared to other treatments (Table 1). In addition, a noteworthy difference was observed in the dried samples’ rehydration ratio by SD and TD, and TD had the highest rehydration ratio. It was revealed that the rehydration ratio ranged from 2.34 to 3.12. The highest rehydration ratio (3.12) was noticed for samples treated with citric and ascorbic acids under TD, while the lowest ratio was 2.34 recorded for control samples under SD. Rehydration ratio changed from 2.34 to 2.94 for SD and from 2.43 to 3.12 for TD, respectively. An increased rehydration ratio in TD banana slices can be used to explain why fewer physical and chemical changes that happened by TD are faster and more uniform. However, various irreversible physical and chemical changes occur as a result of drying, and the solutes that leak from damaged cells move to the surface and form a crust, resulting in a relatively closed surface structure [51]. Additionally, it can be noted that samples dried by TD rather than SD had higher rehydration capacities due to their porous structures.

Finally, there was no significant difference between drying methods for pH, acidity, water activity, browning index, and rehydration ratio, except for the sample treated with sodium bisulphate, which showed a meaningful difference between drying methods for rehydration ratio. From the results in Table 2, the highest reducing sugar content was found in dried banana slices with sucrose (21.25 for TD and 21.22 for SD on a dry weight basis). As opposed to that, the lowest reducing sugar content was recorded for citric and ascorbic acid treatments (19.72 for SD and 19.75% in TD). The dried banana slices showed a reduction in sugar concentration similar to that observed by Takougnadi et al. [52]. These compositional variations are mostly caused by the fruit’s maturity level at the time of drying, and too much reducing sugar might cause non-enzymatic browning [53]. There was no significant difference between SD and TD on reducing sugar of the dried banana slices, and the effect was similar, but a significant difference was observed in pretreatments where sucrose treatments had the highest values (21.22 for SD and 21.25 for TD). Also, the losses of the reducing sugar content in SD and TD banana slices might be attributed to the drying time of this method (10 and 8 h), which may result in the browning reaction, which creates distinctive brown pigments when certain components react with one another [54]. Furthermore, the Millard reaction may have occurred in dried banana slices produced by SD, which involves the binding of reducing sugars with amino acids, eventually leading to a loss in the total sugars, especially the reducing sugars [55].

Table 2.

Effect of pretreatments and drying methods on reducing sugar, total phenolic content, ascorbic acid, and antioxidant activity.

The phenolic compounds content in fruits and vegetables depends on the cultivar, growing condition, storage and transport conditions, and processing technology [56,57,58]. The total phenolic content (TPC) as affected by drying techniques and pretreatment solutions is presented in Table 2. TPC in fresh bananas was 96.91 mg/kg, while it ranged from 99.09 to 115.90 mg/kg for dried slices. From Table 2, the impact of drying methods on TPC was statistically significant (p < 0.05). The sample pretreated with citric and ascorbic acids had the highest TPC (p< 0.05), while the control samples had the lowest TPC. The TPC was higher in TD samples than in slices dried under SD. These results might be attributed to increased enzymatic degradation by polyphenol oxidase, because direct and mixed mode dryers dried materials more slowly than TD, with more enzymatic reactions.

A significant difference between treatments was observed in ascorbic acid content (Table 2). The highest ascorbic acid content was detected with sodium bisulphate treatments, while the lowest content was observed for the control treatments. The treatments with sodium bisulphate, as well as citric and ascorbic acids, were the highest for preserving ascorbic acid from heat breakage, while the rest of the dried treatments were close to each other in both treatments. In addition, using a tunnel for drying prevented ascorbic acid from breaking down and minimized its loss throughout the drying process, which is a benefit of using a tunnel for drying. These findings align with Alam et al. reports [46]. Also, from the table, the TD samples showed a higher ascorbic acid content than the SD samples, and this might be because of the fast drying process in TD. The greater loss of ascorbic acid in SD samples might be related to the time of the drying process [59]. Where the ascorbic acid was destroyed, during the process of dehydration, it was oxidized to dehydroascorbic acid. Reactions that followed, like decarboxylation and cyclization, 3-hydroxy-2-pyrone and 2-furoic acid, were finally produced.

Furthermore, all dried banana slices showed a high content of antioxidants (83.03 to 86.61%) compared to fresh bananas (60.22%). The increased antioxidant activity that was seen in dried bananas might correspond to the much higher phenolic and ascorbic acid contents. Additionally, the antioxidant capacity of SD bananas was not as high as that of TD bananas, and this may be related to the greater decline in ascorbic acid and the overall amount of phenolic content in the banana slices drying in the open sun. For the TD bananas, the retention of the antioxidant ranged from 83.28 to 86.61%, compared to 83.03 to 85.57% for SD. Also, all pretreatments resulted in a higher antioxidant (p< 0.05) activity (from 84.11 to 86.61%) as compared to control (83.03 and 83.28%). This is explained by the increase in total phenolic content and ascorbic acid upon drying. These results are roughly in accordance, since antioxidant activity completely depends on pigments like carotenoid and anthocyanin, ascorbic acid, and overall phenolic content in the product [60,61].

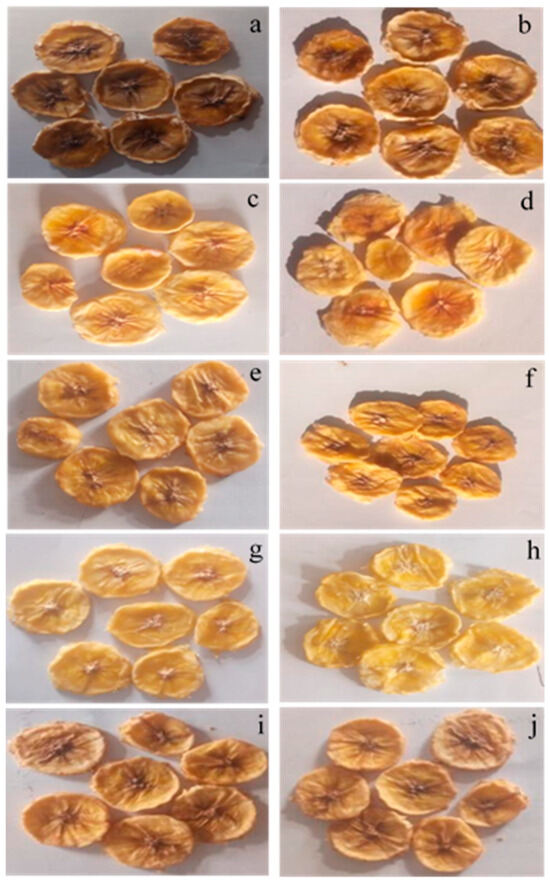

The color, taste, odor, texture, and overall acceptability scores for dried banana slices were evaluated and are presented in Table 3. These might suggest that the results of the sensory attributes show that bananas dried in TD have a higher likability score for the most tested organoleptic characteristics compared to SD slices. The results showed that the highest (p < 0.05) color score was observed for dried slices treated with sodium bisulphate (9.0 for SD and 9.50 for TD), while the lowest (p < 0.05) was recorded for control (5.00 for SD and 6.00 for TD), whereas other dried slices ranged from 7.0 to 8.5 with significant differences between them.

Table 3.

Effect of pretreatments and drying methods on organoleptic properties of dried banana slices.

The variation in pretreatment techniques and drying conditions could all be contributing factors to the observed color variation in dried bananas in this study. Boudhrioua et al. [62] found that blanching and sodium pyrophosphate pretreatments can help avoid the browning of raw and ripe bananas dried at 60 °C air temperature. In a different investigation, Ranken et al. [63] employed a 1:1 ascorbic-citric acid solution as a chemical treatment to stop dry bananas cooked to temperatures between 40 and 70 °C from turning discolored.

TD presented fewer color changes than the SD process. This also corresponds to the results of Elicin and Sacilik [64]. This darker color throughout the SD process resulted from the fruit surfaces being exposed to solar radiation for longer. This might be because enzymatic browning is limited when drying at high temperatures in the beginning. However, high energy input may also lead to non-enzymatic browning after drying, which is why sample TD is superior to sun drying in terms of quality. At the beginning of drying, low temperatures keep the product’s surface moist longer than high temperatures, which encourages the enzymatic browning of the product. This is consistent with the findings of Pekke et al. [65].

On the other hand, the judging scores of taste properties were recorded (5.25 to 8.0 for SD and 5.50–8.0 for TD slices). The highest (p < 0.05) taste score was recorded for slices treated with sucrose (8.0), while the lowest (p < 0.05) was recorded for lemon and acetic acid treatments (5.25 for SD and 5.50 for TD). These results are supported by Soomro et al. [26].

For odor, the highest (p < 0.05) score was found in slices treated with sucrose (7.50 and 8.0), while the lowest (p < 0.05) was recorded for control samples (5.0 for SD and 5.80 for TD). The texture score was the highest, significantly, in slices treated with sodium bisulphate (8.0 for SD and 9.0 for TD) even if the lowest score was noted for control samples (5.0). The slices rated by sulfate and sucrose had overall acceptability more than other treatments.

The taste rating is similarly lower, which may be related to the same effect of hardening and moisture loss. Banana slice sensory scores across the board may have decreased, which has led to a decline in the overall acceptability of SD banana slices. Additionally, because of the lengthy drying duration necessity, SD degrades the nutritional value, texture, color, and taste of food. The most popular method for drying food is sun exposure. However, due to the prolonged drying time and temperature irregularities, this method causes serious harm, such as deteriorating the flavor, color, and nutritional value of the dry product, decreasing density and water absorption capacity, and shifting solutes from the internal part of the drying material to the surface. The ability of water to rehydrate itself as well as the mobility of the drying material have further negative impacts. Finally, the slices dried by TD were superior in terms of all the characteristics, especially in color and texture properties, so they outperformed the slices dried by SD due to increasing the drying time (10 h) as compared with the drying time taken by tunnel drying (8 h) as shown in Figure 7. A significant difference was observed in color, odor, and texture at the probability p < 0.05 level between treatments and drying methods.

Figure 7.

Effect of pretreatments and some drying methods on color values of dried banana slices: (a) control (sun), (b) control (tunnel), (c) citric 1% + ascorbic 1% (sun), (d) citric 1% + ascorbic 1% (tunnel), (e) sucrose 10% (sun), (f) sucrose 10% (tunnel), (g) sodium bisulphate 0.5% (sun), (h) sodium bisulphate 0.5% (tunnel), (i) lemon 5% + acetic 0.5% (sun), (j) lemon 5% + acetic 0.5% (tunnel).

Costs Analysis

The operating cost (LE/h) for the convection dryer and the costs per kilogram of the dried product of banana slices is calculated by Equations (6) and (7). The expenses were calculated using drying settings, resulting in a shorter drying time. The operating cost of TD was 0.7551 LE/h, and the cost per kilogram of the dried product was 11.4 LE/kg, while the operating cost of SD was 0.6 LE/h, and the cost per kilogram of the dried product was 11.3 LE/kg.

4. Conclusions

Effects of pretreatment solutions (citric and ascorbic acids, sucrose, sodium bisulphate, lemon juice and acetic acids, as well as drying techniques (sun drying (SD) and tunnel drying (TD)) on the properties of dried banana slices are assessed. The outcomes showed that TD is more closely matched to the drying curves than the SD method. It is concluded from the present study that the application of pretreatment methods plays a significant role in the quality of dried banana slices. It is shown that the effect of pre-treatment methods on moisture, rehydration ratio, aw, pH, total acidity, browning index, reducing sugar, ascorbic acid, polyphenols, and DPPH % was significant, while non-significant (p > 0.05) for water activity. The banana slices pretreated with sodium bisulphate and sucrose observed good characteristics for most of the sensory evaluation parameters. However, most of the physicochemical characteristics were higher in ascorbic and citric acids and sucrose solution-pretreated slices, but their color, flavor, taste, texture, and overall acceptability could not obtain higher scores. Consequently, based on these results, the final product of banana slices may have a great potential application on a commercial scale as a raw product or as an ingredient that can be used in baby foods. Applying pretreatment techniques already has a significant role in saving dried banana slices’ final qualitative attributes and has enormous potential for use in the food industry. In addition, TD is a substitute drying method for obtaining products with a huge market potential and relatively high quality.

Author Contributions

Conceptualization, I.M.T. and G.G.A.E.-W.; Methodology, A.Z., A.N. (Ali Nasr), I.M.T., G.G.A.E.-W. and A.N. (Ashraf Nagib); Validation, M.A.A.; Formal Analysis, A.N. (Ali Nasr) and A.N. (Ashraf Nagib); Software, G.G.A.E.-W.; Investigation, M.A.A., M.H. and A.Z.; Resources, A.N. (Ashraf Nagib), A.N. (Ali Nasr) and M.B.; Data Curation, Y.M.R. and A.M.A.-E.; Writing—Original Draft Preparation, A.Z., A.N. (Ali Nasr), A.N. (Ashraf Nagib) and I.M.T.; Writing—Review and Editing, M.A.A., H.A.A.S., I.M.T., A.Z. and G.G.A.E.-W.; Funding Acquisition, A.M.A.-E.; Supervision, I.M.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research is supported by The Researchers Supporting Project number (RSPD2023R676), King Saud University, Riyadh, Saudi Arabia.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors extend their appreciation to The Researchers Supporting Project number (RSPD2023R676), King Saud University, Riyadh, Saudi Arabia.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Amini Khoozani, A.; Birch, J.; Bekhit, A.E.D.A. Production, application and health effects of banana pulp and peel flour in the food industry. J. Food Sci. Technol. 2019, 56, 548–559. [Google Scholar] [CrossRef] [PubMed]

- Abe-Inge, V.; Agbenorhevi, J.K.; Kpodo, F.M.; Adzinyo, O.A. Effect of different drying techniques on quality characteristics of African Palmyra palm (Borassus aethiopum) Fruit Flour. Food Res. 2018, 2, 331–339. [Google Scholar] [CrossRef] [PubMed]

- Doymaz, İ. Drying of green bean and okra under solar energy. Chem. Ind. Chem. Eng. Q. CICEQ 2011, 17, 199–205. [Google Scholar] [CrossRef]

- Zielinska, M.; Markowski, M. The influence of microwave-assisted drying techniques on the rehydration behavior of blueberries (Vaccinium corymbosum L.). Food Chem. 2016, 196, 1188–1196. [Google Scholar] [CrossRef] [PubMed]

- Amit, S.K.; Uddin, M.M.; Rahman, R.; Islam, S.M.; Khan, M.S. A review on mechanisms and commercial aspects of food preservation and processing. Agric. Food Secur. 2017, 6, 51. [Google Scholar] [CrossRef]

- Testa, R.; Rizzo, G.; Schifani, G.; Tinebra, I.; Farina, V.; Vella, F.; Migliore, G. Can dried fruits replace unhealthy snacking among millennials? an empirical study on dried fruit consumption in Italy. Sustainability 2023, 15, 7083. [Google Scholar] [CrossRef]

- Testa, R.; Schifani, G.; Migliore, G. Understanding consumers’ convenience orientation: An exploratory study of fresh-cut fruit in Italy. Sustainability 2021, 13, 1027. [Google Scholar] [CrossRef]

- Asioli, D.; Rocha, C.; Wongprawmas, R.; Popa, M.; Gogus, F.; Almli, V.L. Microwave-dried or air-dried? Consumers’ stated preferences and attitudes for organic dried strawberries. A multi-country investigation in Europe. Food Res. Int. 2019, 120, 763–775. [Google Scholar] [CrossRef]

- Sadler, M.J.; Gibson, S.; Whelan, K.; Ha, M.A.; Lovegrove, J.; Higgs, J. Dried fruit and public health—What does the evidence tell us? Int. J. Food Sci. Nutr. 2019, 70, 675–687. [Google Scholar] [CrossRef]

- Sun, Y.; Liang, C. Effects of determinants of dried fruit purchase intention and the related consumer segmentation on ecommerce in China. Br. Food J. 2021, 123, 1133–1154. [Google Scholar] [CrossRef]

- Sun, Y.; Liang, C. Factors determining consumers’ purchase intentions towards dried fruits. Int. J. Fruit Sci. 2020, 20 (Suppl. S2), S1072–S1096. [Google Scholar] [CrossRef]

- Cinar, G. Consumer perspective regarding dried tropical fruits in Turkey. Ital. J. Food Sci. 2018, 30, 809–827. [Google Scholar]

- Jesionkowska, K.; Sijtsema, S.J.; Konopacka, D.; Symoneaux, R. Dried fruit and its functional properties from a consumer’s point of view. J. Hortic. Sci. Biotechnol. 2009, 84, 85–88. [Google Scholar] [CrossRef]

- Sabbe, S.; Verbeke, W.; Van Damme, P. Familiarity and purchasing intention of Belgian consumers for fresh and processed tropical fruit products. Br. Food J. 2008, 110, 805–818. [Google Scholar] [CrossRef]

- Sijtsema, S.J.; Jesionkowska, K.; Symoneaux, R.; Konopacka, D.; Snoek, H. Perceptions of the health and convenience characteristics of fresh and dried fruits. LWT Food Sci. Technol. 2012, 49, 275–281. [Google Scholar] [CrossRef]

- Alphonce, R.; Temu, A.; Almli, V.L. European consumer preference for African dried fruits. Br. Food J. 2015, 117, 1886–1902. [Google Scholar] [CrossRef]

- Sehrawat, R.; Nema, P.K.; Kaur, B.P. Quality evaluation and drying characteristics of mango cubes dried using low-pressure superheated steam, vacuum and hot air drying methods. LWT 2018, 92, 548–555. [Google Scholar] [CrossRef]

- Izli, N.; Izli, G.; Taskin, O. Impact of different drying methods on the drying kinetics, color, total phenolic content and antioxidant capacity of pineapple. CyTA J. Food 2018, 16, 213–221. [Google Scholar] [CrossRef]

- Link, J.V.; Tribuzi, G.; Laurindo, J.B. Conductive multi-flash drying of mango slices: Vacuum pulse conditions on drying rate and product properties. J. Food Process. Preserv. 2018, 42, e13440. [Google Scholar] [CrossRef]

- Abul-Fadl, M.M.; Ghanem, T.H.; EL-Badry, N.; Nasr, A. Effect of puff drying on seedless grape fruits quality criteria compared to convective air drying. Al-Azhar J. Agric. Res. 2020, 45, 75–91. [Google Scholar] [CrossRef]

- Folaranmi, J. Design, construction and testing of simple solar maize dryer. Leonardo Electron. J. Pract. Technol. 2008, 1, 122–130. [Google Scholar]

- Ivanova, D.; Andonov, K. Analytical and experimental study of combined fruit and vegetable dryer. Energy Convers. Manag. 2001, 42, 975–983. [Google Scholar] [CrossRef]

- Nemzer, B.; Vargas, L.; Xia, X.; Sintara, M.; Feng, H. Phytochemical and Physical properties of blueberries, tart cherries, strawberries, and cranberries as affected by different drying methods. Food Chem. 2018, 262, 242–250. [Google Scholar] [CrossRef]

- Nabnean, S.; Janjai, S.; Thepa, S.; Sudaprasert, K.; Songprakorp, R.; Bala, B.K. Experimental performance of a new design of solar dryer for drying osmotically dehydrated cherry tomatoes. Renew. Energy 2016, 94, 147–156. [Google Scholar] [CrossRef]

- Varalakshmi, K. Role of conventional energy in rural development in India: Feasibility analysis of solar drying technology. Int. J. Energy Environ. Eng. 2016, 7, 321–327. [Google Scholar] [CrossRef]

- Soomro, A.H.; Miano, T.F.; Marri, A.; Kumar, D.; Khaskheli, G.S.; Arain, U.F.; Baloch, A.B. Application of pretreatments on banana slices for improving drying characteristics. Food Sci. Qual. Manag. 2020, 103, 35–41. [Google Scholar]

- Capecka, E.; Mareczek, A.; Leja, M. Antioxidant activity of fresh and dry herbs of some lamiaceae species. Food Chem. 2005, 93, 223–226. [Google Scholar] [CrossRef]

- Abano, E.E.; Sam-Amoah, L.K.; Owusu, J.; Engmann, F.N. Effects of ascorbic acid, salt, lemon juice, and honey on drying kinetics and sensory characteristic of dried mango. Croat. J. Food Sci. Technol. 2013, 5, 1–10. [Google Scholar]

- Deori, G.D.; Langthasa, S.; Hazarika, D.N.; Goswami, R.K.; Kalita, M.K. Effect of pretreatment on quality of minimally processed culinary banana cv. kachkal (ABB Group). J. Pharmacogn. Phytochem. 2020, 9, 2256–2262. [Google Scholar] [CrossRef]

- AOAC International. Official Methods of Analysis of the Association of Official Analytical Chemists International, 20th ed.; AOAC International: Rockville, MD, USA, 2016. [Google Scholar]

- Usub, T.; Lertsatitthanakorn, C.; Poomsa-ad, N.; Wiset, L.; Yang, L.; Siriamornpun, S. Experimental performance of a solar tunnel dryer for drying silkworm pupae. Biosyst. Eng. 2008, 101, 209–216. [Google Scholar] [CrossRef]

- Karthikeyan, A.K.; Murugavelh, S. Thin layer drying kinetics and exergy analysis of turmeric (Curcuma longa) in a mixed mode forced convection solar tunnel dryer. Renew. Energy 2018, 128, 305–312. [Google Scholar] [CrossRef]

- Araújo, C.d.S.; Macedo, L.L.; Vimercati, W.C.; Ferreira, A.; Prezotti, L.C.; Saraiva, S.H. Determination of pH and acidity in green coffee using near-infrared spectroscopy and multivariate regression. J. Sci. Food Agric. 2020, 100, 2488–2493. [Google Scholar] [CrossRef] [PubMed]

- Lewicki, P.P.; Lukaszuk, A. Changes of rheological properties of apple tissue undergoing convective drying. Dry. Technol. 2000, 18, 707–722. [Google Scholar] [CrossRef]

- Gabas, A.L.; Menegalli, F.C.; Ferrari, F.; Telis-Romero, J. Influence of drying conditions on the rheological properties of prunes. Dry. Technol. 2002, 20, 1485–1502. [Google Scholar] [CrossRef]

- Siddiqui, S.; Gehlot, R.; Arora, S.; Ahmed, N. Effects of Anti-browning pretreatments on browning of banana pulp. Int. J. Curr. Microbiol. Appl. Sci. 2018, 7, 242–249. [Google Scholar] [CrossRef]

- Dehghannya, J.; Kadkhodaei, S.; Heshmati, M.K.; Ghanbarzadeh, B. Ultrasound-assisted intensification of a hybrid intermittent microwave—Hot air drying process of potato: Quality aspects and energy consumption. Ultrasonics 2019, 96, 104–122. [Google Scholar] [CrossRef] [PubMed]

- Anjos, O.; Paula, V.; Delgado, T.; Estevinho, L. Influence of the storage conditions on the quality of bee pollen. Zemdirbyste 2019, 106, 87–94. [Google Scholar] [CrossRef]

- Alshallash, K.S.; Abolaban, G.; Elhamamsy, S.M.; Zaghlool, A.; Nasr, A.; Nagib, A.; El-Hakim, A.F.A.; Zahra, A.A.; Hamdy, A.E.; Taha, I.M. Bee pollen as a functional product—Chemical constituents and nutritional properties. J. Ecol. Eng. 2023, 24, 173–183. [Google Scholar] [CrossRef]

- Yu, G.; Bei, J.; Zhao, J.; Li, Q.; Cheng, C. Modification of carrot (Daucus carota Linn. var. Sativa Hoffm.) pomace insoluble dietary fiber with complex enzyme method, ultrafine comminution, and high hydrostatic pressure. Food Chem. 2018, 257, 333–340. [Google Scholar] [CrossRef]

- Akan, E.; Yerlikaya, O.; Akpinar, A.; Karagozlu, C.; Kinik, O.; Uysal, H.R. The effect of various herbs and packaging material on antioxidant activity and colour parameters of whey (lor) cheese. Int. J. Dairy Technol. 2021, 74, 554–563. [Google Scholar] [CrossRef]

- Gallali, Y.M.; Abujnah, Y.S.; Bannani, F.K. Preservation of fruits and vegetables using solar drier: A comparative study of natural and solar drying, III; chemical analysis and sensory evaluation data of the dried samples (grapes, figs, tomatoes and onions). Renew. Energy 2000, 19, 203–212. [Google Scholar] [CrossRef]

- Awady, M.N.; Yehia, I.; Ebaid, M.T.; Arif, E.M. Development and theory of rice cleaner for reduced impurities and losses. Misr J. Agric. Eng. 2003, 4, 53–68. [Google Scholar]

- Lahsasni, S.; Kouhila, M.; Mahrouz, M.; Idlimam, A.; Jamali, A. Thin layer convective solar drying and mathematical modeling of prickly pear peel (Opuntia ficus indica). Energy 2004, 29, 211–224. [Google Scholar] [CrossRef]

- Ferreira, T.H.B.; Freitas, M.L.F. Production, physical, chemical and sensory evaluation of dried banana (Musa cavendish). Emirates J. Food Agric. 2019, 31, 102–108. [Google Scholar] [CrossRef]

- Alam, M.; Afzal, M.; Ku Leuven, H.; Sarkar, A.; Hossain, M.A. Effect of edible coating on functional properties and nutritional compounds retention of air dried green banana (Musa sapientum L.). IOSR J. Environ. Sci. Toxicol. Food Technol. 2020, 14, 51–58. [Google Scholar] [CrossRef]

- Cobzaru, C.; Olteanu, A.; Marinoiu, A.; Cernătescu, C.; Asachi, G. Natural and artificial dehydratation of apples and bananas. Comparative studies. Niversitatea Tehnică Gheorghe Asachi din Iaşi 2019, 65, 40–49. [Google Scholar]

- Batista, D.D.V.S.; Cardoso, R.L.; de Godoy, R.C.B.; Evangelista-Barreto, N.S. Stability physical-chemical and microbiological of organic dehydrated banana/Estabilidade fisico-quimica e microbiologica de banana passa organica. Cienc. Rural. 2014, 44, 1886–1893. [Google Scholar] [CrossRef]

- Isaac, A.; Davis, J.; Livingstone, C.; Wain, A.J.; Compton, R.G. Electroanalytical methods for the determination of sulfite in food and beverages. TrAC Trends Anal. Chem. 2006, 25, 589–598. [Google Scholar] [CrossRef]

- Kaveh, M.; Abbaspour-Gilandeh, Y.; Fatemi, H.; Chen, G. Impact of different drying methods on the drying time, energy, and quality of green peas. J. Food Process. Preserv. 2021, 45, e15503. [Google Scholar] [CrossRef]

- Cui, Z.W.; Xu, S.Y.; Sun, D.W. Dehydration of garlic slices by combined microwave-vacuum and air drying. Dry. Technol. 2003, 21, 1173–1184. [Google Scholar] [CrossRef]

- Takougnadi, E.; Boroze, T.E.T.; Azouma, O.Y. Effects of drying conditions on energy consumption and the nutritional and organoleptic quality of dried bananas. J. Food Eng. 2020, 268, 109747. [Google Scholar] [CrossRef]

- Travaglini, D.A.; Neto, P.M.; Bleinroth, E.W.; Leitao, M.F.F. Banana-Passa Princıpios de Secagem—Manual Tecnico; ITAL/Rede de Nucleos de Informacao Tecnologica: Campinas, Brazil, 1993; No. 12. [Google Scholar]

- Wellner, A.; Huettl, C.; Henle, T. Formation of Maillard reaction products during heat treatment of carrots. J. Agric. Food Chem. 2011, 59, 7992–7998. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Xia, B.; Hu, L.T.; Ni, Z.J.; Thakur, K.; Wei, Z.J. Maillard conjugates and their potential in food and nutritional industries: A Review. Food Front. 2020, 1, 382–397. [Google Scholar] [CrossRef]

- Bennett, L.E.; Jegasothy, H.; Konczak, I.; Frank, D.; Sudharmarajan, S.; Clingeleffer, P.R. Total polyphenolics and antioxidant properties of selected dried fruits and relationships to drying conditions. J. Funct. Foods 2011, 3, 115–124. [Google Scholar] [CrossRef]

- Hafez, M.; Popov, A.I.; Rashad, M. A Novel Environmental Additives to Decrease Nitrate Level in Agriculture Wastewater and Enhancement Nutrient Status under greenhouse plant growth in calcareous soil. Plant Arch. 2020, 20, 3165–3172. [Google Scholar]

- Abdelraouf, R.E.; Abdou, S.M.M.; Abbas, M.M.; Hafez, M.; Popov, A.I.; Hamed, L.M.M. Influence of N-Fertigation Stress and Agro-Organic Wastes (Biochar) io Improve Yield and Water Productivity of Sweet Pepper Under Sandy Soils Conditions. Plant Arch. 2020, 20, 3165–3172. [Google Scholar]

- Dufera, L.T.; Hofacker, W.; Esper, A.; Hensel, O. Physicochemical quality of twin layer solar tunnel dried tomato slices. Heliyon 2021, 7, e07127. [Google Scholar] [CrossRef]

- Kapasakalidis, P.G.; Rastall, R.A.; Gordon, M.H. Extraction of polyphenols from processed black currant (Ribes nigrum L.) residues. J. Agric. Food Chem. 2006, 54, 4016–4021. [Google Scholar] [CrossRef]

- Oszmiański, J.; Wojdyło, A. Effects of blackcurrant and apple mash blending on the phenolics contents, antioxidant capacity, and colour of juices. Czech J. Food Sci. 2009, 27, 338–351. [Google Scholar] [CrossRef]

- Boudhrioua, N.; Michon, C.; Carelier, G.; Borazz, C. Influence of ripeness and temperature on changes in banana texture during drying. J. Food Eng. 2002, 55, 115–127. [Google Scholar] [CrossRef]

- Ranken, M.D.; Blackie, G.; Dandamrongrak, R.; Young, G.; Mason, R. Evaluation of various pretreatments for the dehydration of banana and selection of suitable drying models. J. Food Eng. 2002, 55, 139–146. [Google Scholar]

- Elicin, A.K.; Sacilik, K. An experimental study for solar tunnel drying of apple. Tarim Bilim. Derg. 2005, 11, 207–211. [Google Scholar]

- Pekke, M.A.; Pan, Z.; Atungulu, G.G.; Smith, G.; Thompson, J.F. Drying characteristics and quality of bananas under infrared radiation heating. Int. J. Agric. Biol. Eng. 2013, 6, 58–70. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).