Verification of Performance Standards for Construction Equipment in Terms of CO2 Emissions

Abstract

:1. Introduction

- model cost structure according to DIN 276,

- standard for dynamically created descriptions of works—STLB-Bau—Dynamische BauDaten,

- standard technical specifications defining the transfer to the contractor of the necessary information about construction products, local conditions for the execution of works, or rules of pre-timing/timing and billing—VOB (C),

- standard formats for data exchange between participants in the construction process—GAEB.

- Use of normative documents that provide guidance and recommendations on the labour intensity of a construction work. For example, in Ukraine, there are the regulations of the State Construction Standards, which contain information on productivity standards for different types of work.

- Analysis of completed construction projects in which similar types of work were performed. An assessment is made of the time required to perform a certain amount of work, and performance standards are formulated on this basis.

- Use of expert evaluation. Experts can estimate the performance of different types of works based on their experience and knowledge.

2. Materials and Methods

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zou, G.; Li, Z.; He, C. A New Product Configuration Model for Low Product Cost and Carbon-Neutral Expenditure. Sustainability 2023, 15, 10358. [Google Scholar] [CrossRef]

- Romero Quidel, G.; Soto Acuña, M.J.; Rojas Herrera, C.J.; Rodríguez Neira, K.; Cárdenas-Ramírez, J.P. Assessment of Modular Construction System Made with Low Environmental Impact Construction Materials for Achieving Sustainable Housing Projects. Sustainability 2023, 15, 8386. [Google Scholar] [CrossRef]

- Fan, H. A Critical Review and Analysis of Construction Equipment Emission Factors. Procedia Eng. 2017, 196, 351–358. [Google Scholar] [CrossRef]

- Barati, K.; Shen, X. Operational Level Emissions Modelling of On-Road Construction Equipment through Field Data Analysis. Autom. Constr. 2016, 72, 338–346. [Google Scholar] [CrossRef]

- Barati, K.; Shen, X. Optimal Driving Pattern of On-Road Construction Equipment for Emissions Reduction. Procedia Eng. 2017, 180, 1221–1228. [Google Scholar] [CrossRef]

- Rogalska, M.; Hejducki, Z. Prognozowanie Emisyjności CO2 Koparek Gąsiennicowych i Samochodów Samowyładowczych Metodami Regresji Wielorakiej i Sieci Neuronowych. Arch. Inst. Inżynierii Lądowej 2012, 13, 293–298. [Google Scholar]

- Runkiewicz, L. Realizacja Obiektów Budowlanych Zgodnie z Zasadami Zrównoważonego Rozwoju. Przegląd Bud. 2010, 81, 17–23. [Google Scholar]

- Sarte, S.B. Sustainable Infrastructure: The Guide to Green Engineering and Design; John Wiley & Sons: Hoboken, NJ, USA, 2010; ISBN 0-470-45361-3. [Google Scholar]

- Wieczorek, D.; Zima, K. Analysis of the Selection of Materials for Road Construction Taking into Account the Carbon Footprint and Construction Costs. Arch. Civ. Eng. 2022, 68, 199–219. [Google Scholar]

- Golański, M. Wybór Materiałów Budowlanych w Kontekście Efektywności Energetycznej i Wpływu Środowiskowego. Bud. I Inżynieria Sr. 2012, 3, 39–53. [Google Scholar]

- Rogalska, M.; Hejducki, Z. Analiza Doboru Materiałów Budowlanych w Aspekcie Zrównoważonego Rozwoju. Przegląd Bud. 2007, 78, 36–40. [Google Scholar]

- Shiers, D. The Green Guide to Specification: An Environmental Profiling System for Building Materials and Components; Wiley: Hoboken, NJ, USA, 2002; ISBN 1-281-31858-2. [Google Scholar]

- Berge, B. Ecology of Building Materials; Routledge: London, UK, 2007; ISBN 0-08-050498-1. [Google Scholar]

- Ashfaq, M.; Lal, M.H.; Moghal, A.A.B.; Murthy, V.R. Carbon Footprint Analysis of Coal Gangue in Geotechnical Engineering Applications. Indian Geotech. J. 2020, 50, 646–654. [Google Scholar] [CrossRef]

- Kowalski, J.; Połoński, M.; Lendo-Siwicka, M.; Trach, R.; Wrzesiński, G. Method of Assessing the Risk of Implementing Railway Investments in Terms of the Cost of Their Implementation. Sustainability 2021, 13, 13085. [Google Scholar] [CrossRef]

- Trach, R.; Lendo-Siwicka, M.; Pawluk, K.; Bilous, N. Assessment of the Effect of Integration Realisation in Construction Projects. Teh. Glas. 2019, 13, 254–259. [Google Scholar] [CrossRef]

- Zima, K. Integrated Analysis of Costs and Amount of Greenhouse Gases Emissions during the Building Lifecycle. Arch. Civ. Eng. 2021, 67, 413–423. [Google Scholar]

- Tomczewski, A.; Kasprzyk, L.; Nadolny, Z. Reduction of Power Production Costs in a Wind Power Plant–Flywheel Energy Storage System Arrangement. Energies 2019, 12, 1942. [Google Scholar] [CrossRef]

- Rogoda, B. Polskie Regulacje Prawne Dotyczące Cen w Perspektywie Przystąpienia Do Unii Europejskiej. Zesz. Nauk. Akad. Ekon. W Krakowie 2002, 609, 123–141. [Google Scholar]

- Sekunda, R.; Więcław-Bator, L. Koszty Robót Budowlanych. Ustalanie Wartości i Rozliczanie Zamówień Publicznych; Wolters Kluwer: Alphen aan den Rijn, The Netherlands, 2022; ISBN 83-8286-795-2. [Google Scholar]

- Paris, V.; Ruscica, G.; Olivieri, C.; Mirabella Roberti, G. A Systemic Approach to Simulate the Construction Process of Self-Supporting Masonry Structures. Sustainability 2023, 15, 9596. [Google Scholar] [CrossRef]

- Xu, J.; Jia, R.; Wang, B.; Xu, A.; Zhu, X. The Optimal Emission Reduction and Recycling Strategies in Construction Material Supply Chain under Carbon Cap–Trade Mechanism. Sustainability 2023, 15, 9181. [Google Scholar] [CrossRef]

- Kulejewski, J. Ogólne Zasady Kalkulacji Kosztorysowej w Krajach UE. Mater. Bud. 2004, 4, 112–116. [Google Scholar]

- Trach, R.; Pawluk, K.; Lendo-Siwicka, M. Causes of Rework in Construction Projects in Ukraine. Arch. Civ. Eng. 2019, 65, 61–74. [Google Scholar] [CrossRef]

- Budowlanych, S.K. Zasady i Standardy Kosztorysowania Robót Budowlanych Dla Zamawiających, Inwestorów i Wykonawców: Konferencja Stowarzyszenia Kosztorysantów Budowlanych w Dniach 23–24 Marca 2017 r; Stowarzyszenie Kosztorysantów Budowlanych: Warszawa, Poland, 2017; ISBN 83-944002-1-3. [Google Scholar]

- CO2 Emisji Litrze Paliwa: Benzyna, Olej Napędowy i LPG. Available online: https://pl.econologie.com/Emisje-co2-litra-paliwa%2C-benzyna-lub-diesel-gpl/ (accessed on 2 August 2023).

- Jassim, H.; Lu, W.; Olofsson, T. Predicting Energy Consumption and CO2 Emissions of Excavators in Earthwork Operations: An Artificial Neural Network Model. Sustainability 2017, 9, 1257. [Google Scholar] [CrossRef]

- Chłopek, Z. Propozycja Charakterystyk Emisji Zanieczyszczeń z Silników Spalinowych Pracujących w Warunkach Dynamicznych. Arch. Motoryz. 2009, 2, 111–134. [Google Scholar]

- Kryzia, D.; Kopacz, M.; Orzechowska, M. Szacowanie Emisji Ditlenku Węgla i Zużycia Oleju Napędowego w Samochodach Osobowych. Zesz. Nauk. Inst. Gospod. Surowcami Miner. I Energią PAN 2015, 90, 79–92. [Google Scholar]

- Shahnavaz, F.; Akhavian, R. Automated Estimation of Construction Equipment Emission Using Inertial Sensors and Machine Learning Models. Sustainability 2022, 14, 2750. [Google Scholar] [CrossRef]

- Lee, D.I.; Park, J.; Shin, M.; Lee, J.; Park, S. Characteristics of Real-World Gaseous Emissions from Construction Machinery. Energies 2022, 15, 9543. [Google Scholar] [CrossRef]

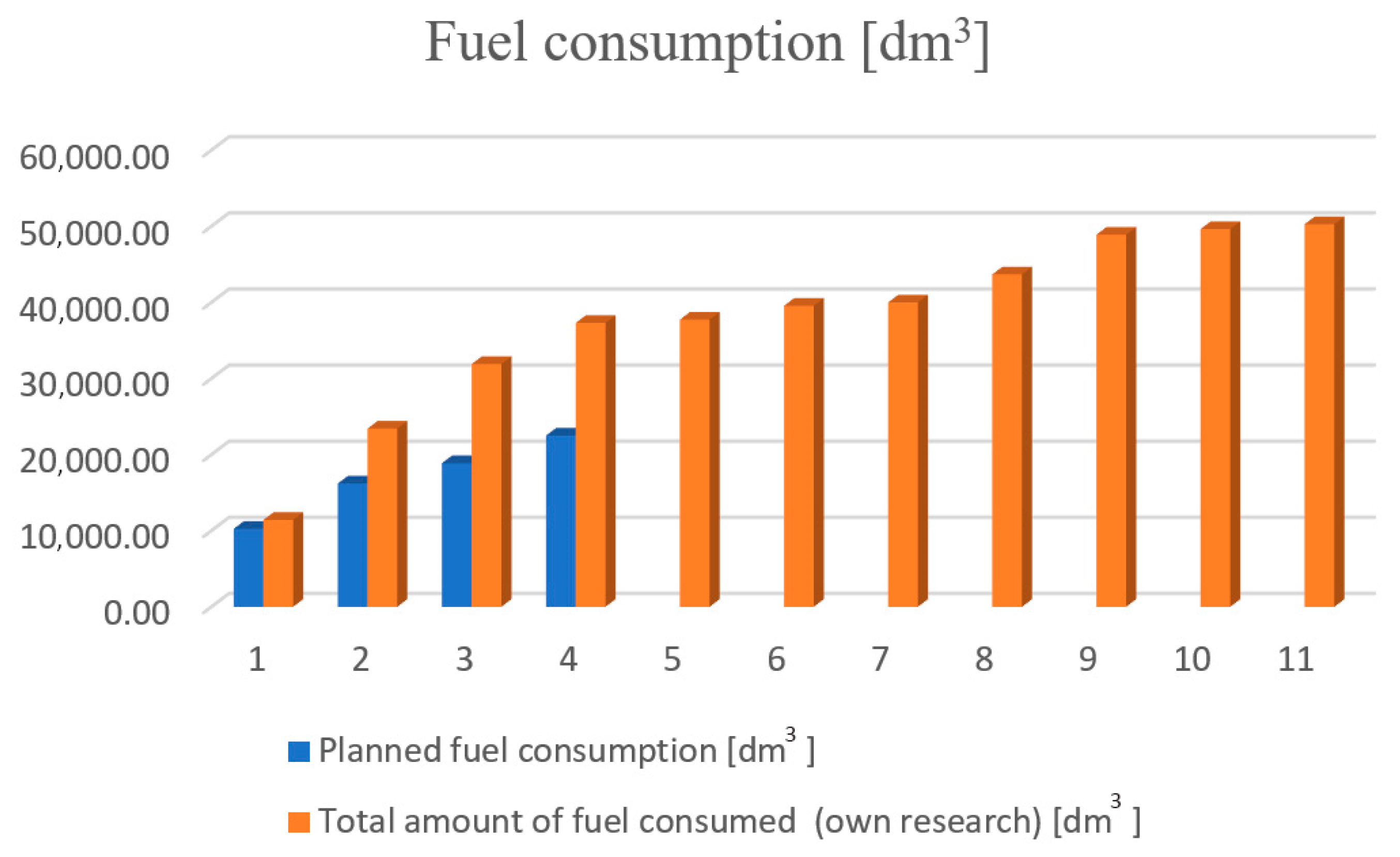

| No. | Type of Equipment | Excavator Model | Number of Moto Hours [m-h] | Amount of Fuel Consumed [dm3] | Average Diesel Consumption [dm3/m-h] |

|---|---|---|---|---|---|

| 1 | Wheeled excavator (CAT 318F) | CAT 318F | 1876.00 | 11,425.00 | 6.09 |

| 2 | Wheeled excavator (Doosan 190W-5, No. 2) | Doosan 190W-5 (1) | 1824.00 | 11,998.00 | 6.58 |

| 3 | Tracked excavator (CASE CX210 B) | CASE CX210 B | 939.00 | 8479.00 | 9.03 |

| 4 | Wheeled excavator (CASE WX185) | CASE WX185 | 511.00 | 5412.00 | 10.59 |

| 5 | Backhoe loader (CASE 695) | CASE 695 | 89.00 | 550.00 | 6.18 |

| 6 | Wheeled excavator (Doosan 160 W-5, no 3) | Doosan 160 W-5 | 289.00 | 1815.00 | 6.28 |

| 7 | Wheeled excavator (Doosan 190W-5, No. 1) | Doosan 190W-5 (2) | 138.00 | 620.00 | 4.49 |

| 8 | Wheeled excavator (Doosan DX 210W-5 Dx 210W-5) | Doosan DX 210W-5 Dx 210W-5 | 575.00 | 3679.00 | 6.40 |

| 9 | Wheeled excavator (Komatsu PW200) | Komatsu PW200 | 515.00 | 5216.00 | 10.13 |

| 10 | Wheeled excavator (Doosan Dx190W-5 DX-190 W-5, No. 4) | Doosan Dx190W-5 (3) | 60.00 | 640.00 | 10.67 |

| 11 | Tracked excavator (Doosan DX85R-3) | Doosan DX85R-3 | 206.00 | 1483.20 | 7.20 |

| Total | 7022.0 | 51,317.2 | - | ||

| No. | Type of Equipment | Number of Moto Hours [m-h] | Assumption of Fuel Consumption [dm3/h] | Assumed Amount of Fuel Consumed [dm3] |

|---|---|---|---|---|

| 1 | Wheeled excavator 0.60 dm3 | 1683.02 | 6.09 | 10,249.61 |

| 2 | Crawler dozers | 559.22 | 10.67 | 5966.88 |

| 3 | Mobile crane 4 t | 404.82 | 6.58 | 2663.73 |

| 4 | Manual winch 3–5 t | 808.20 | 4.49 | 3628.94 |

| Total | 3455.29 | - | 22,509.15 | |

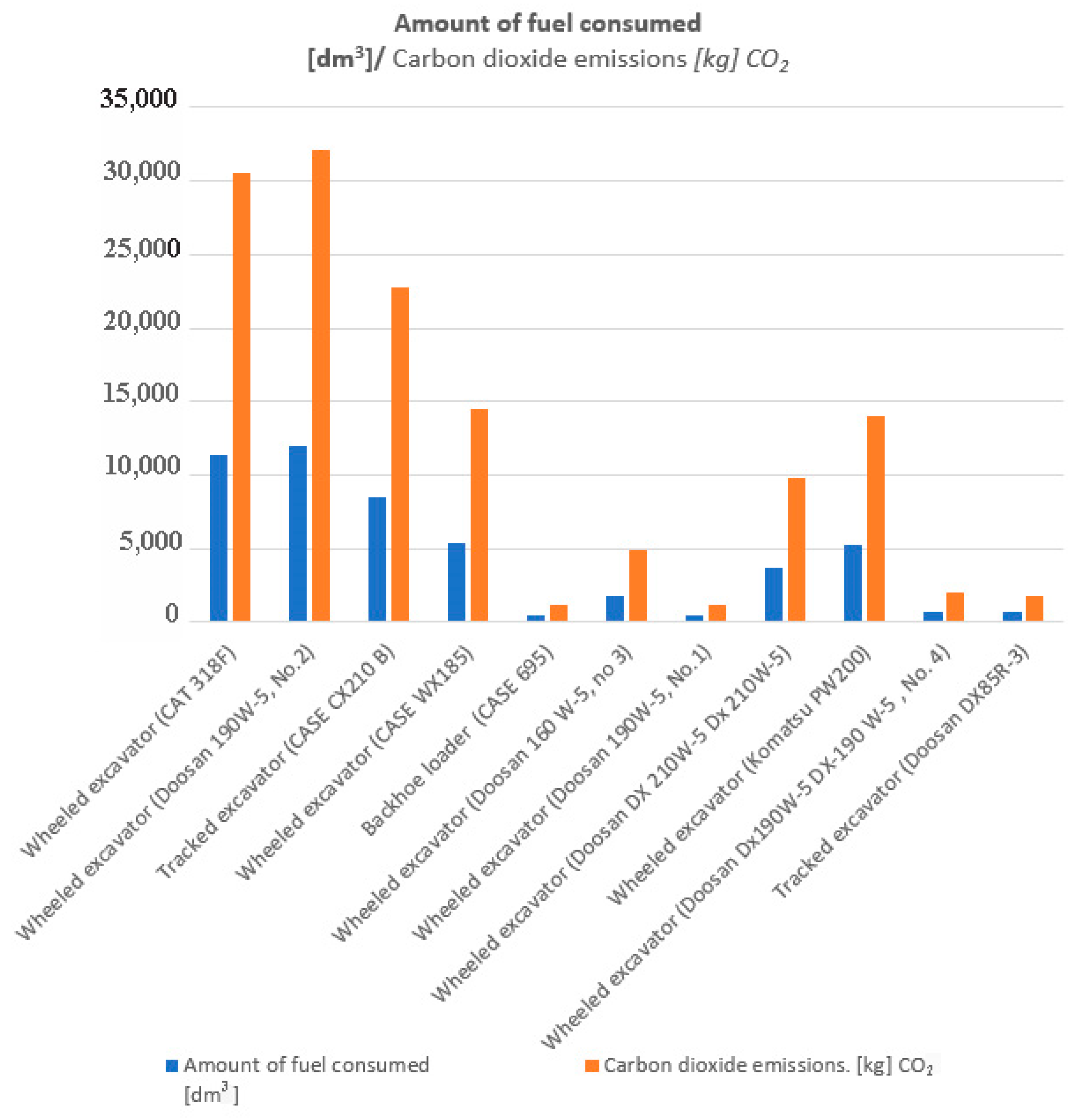

| No. | Type of Equipment | Total Amount of Fuel Consumed [dm3] | Assumption CO2 Emission from Burning 1 dm3 Diesel Fuel | CO2 Emissions [kg] CO2 |

|---|---|---|---|---|

| 1 | Wheeled excavator (CAT 318F) | 11,425.00 | 2.67 | 30,619.00 |

| 2 | Wheeled excavator (Doosan 190W-5, No. 2) | 11,998.00 | 2.67 | 32,154.64 |

| 3 | Tracked excavator (CASE CX210 B) | 8479.00 | 2.67 | 22,723.72 |

| 4 | Wheeled excavator (CASE WX185) | 5412.00 | 2.67 | 14,504.16 |

| 5 | Backhoe loader (CASE 695) | 428.00 | 2.67 | 1147.04 |

| 6 | Wheeled excavator (Doosan 160 W-5, no 3) | 1815.00 | 2.67 | 4864.05 |

| 7 | Wheeled excavator (Doosan 190W-5, No. 1) | 442.00 | 2.67 | 1184.56 |

| 8 | Wheeled excavator (Doosan DX 210W-5 Dx 210W-5) | 3679.00 | 2.67 | 9859.72 |

| 9 | Wheeled excavator (Komatsu PW200) | 5216.00 | 2.67 | 13,978.88 |

| 10 | Wheeled excavator (Doosan Dx190W-5 DX-190 W-5, No. 4) | 743.00 | 2.67 | 1991.24 |

| 11 | Tracked excavator (Doosan DX85R-3) | 641.00 | 2.67 | 1717.88 |

| Total | 134,744.89 |

| No. | Type of Equipment | Assumption of Amount of Fuel Consumed | Assumption of CO2 Emission from Burning 1 dm3 Diesel Fuel [kg] | CO2 Emissions [kg] |

|---|---|---|---|---|

| 1 | Wheeled excavator 0.60 dm3 | 10,249.61 | 2.67 | 27,366.45 |

| 2 | Crawler dozers | 5966.88 | 2.67 | 15,931.56 |

| 3 | Mobile crane 4 t | 2663.73 | 2.67 | 7112.17 |

| 4 | Manual winch 3–5 t | 3628.94 | 2.67 | 9689.26 |

| Total | 60,099.44 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kowalski, J.; Lendo-Siwicka, M.; Wrzesiński, G.; Trach, R. Verification of Performance Standards for Construction Equipment in Terms of CO2 Emissions. Sustainability 2023, 15, 15188. https://doi.org/10.3390/su152115188

Kowalski J, Lendo-Siwicka M, Wrzesiński G, Trach R. Verification of Performance Standards for Construction Equipment in Terms of CO2 Emissions. Sustainability. 2023; 15(21):15188. https://doi.org/10.3390/su152115188

Chicago/Turabian StyleKowalski, Jan, Marzena Lendo-Siwicka, Grzegorz Wrzesiński, and Roman Trach. 2023. "Verification of Performance Standards for Construction Equipment in Terms of CO2 Emissions" Sustainability 15, no. 21: 15188. https://doi.org/10.3390/su152115188

APA StyleKowalski, J., Lendo-Siwicka, M., Wrzesiński, G., & Trach, R. (2023). Verification of Performance Standards for Construction Equipment in Terms of CO2 Emissions. Sustainability, 15(21), 15188. https://doi.org/10.3390/su152115188